Method for preparing black fungus puffed ultramicro powder

A technology of black fungus and superfine powder, which is applied in food preparation, application, food science and other directions, can solve the problems of high cost, reduced volume, low absorption rate, etc., and achieves the effects of low production cost, increased smoothness, and improved absorption rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

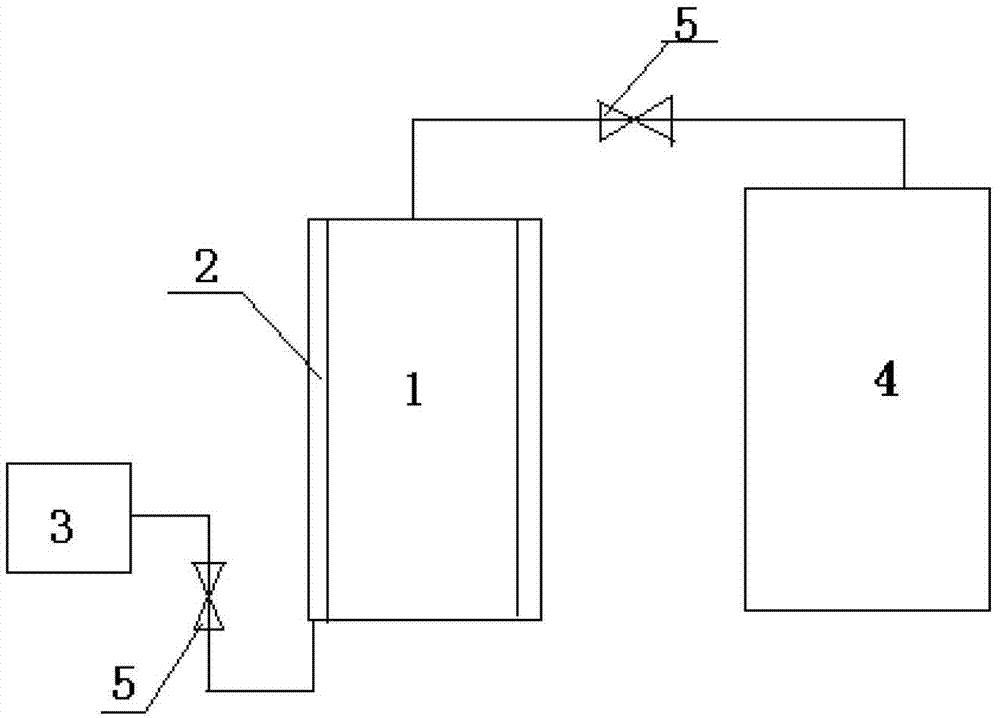

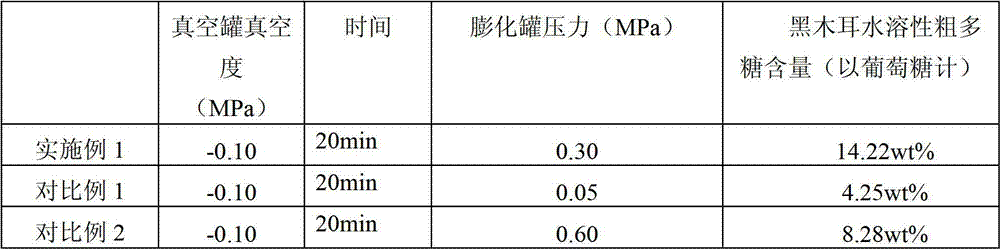

[0037] 1. Select black fungus fruit bodies as raw materials, wash and dry to a water content of 40wt%, put them into an expansion tank, the amount of black fungus put in is 15% of the volume of the expansion tank by volume ratio, and seal the expansion tank;

[0038] 2. Start the electric steam generator, heat and pressurize the black fungus in the expansion tank, so that the temperature in the expansion tank reaches 80°C and the pressure in the tank reaches 0.30 MPa, and keep for 20 minutes;

[0039] 3. Turn on the vacuum pump and evacuate the vacuum tank. The vacuum degree of the vacuum tank is -0.10MPa. Open the valve between the expansion tank and the vacuum tank. The temperature and pressure in the expansion tank will drop instantly. Puffing;

[0040] 4. The temperature inside the puffing tank rises to 80°C, turn on the vacuum pump, and keep the valve between the puffing tank and the vacuum tank always open. At this temperature, vacuum-dry the black fungus in the puffing ...

Embodiment 2

[0044] 1. Select black fungus fruit bodies as raw materials, wash and dry to a water content of 40wt%, put them into an expansion tank, the amount of black fungus put in is 15% of the volume of the expansion tank by volume ratio, and seal the expansion tank;

[0045] 2. Start the electric steam generator, heat and pressurize the black fungus in the expansion tank, make the temperature in the expansion tank reach 80°C and the pressure in the tank reach 0.20MPa, and keep it for 20 minutes;

[0046] 3. Turn on the vacuum pump and evacuate the vacuum tank. The vacuum degree of the vacuum tank is -0.10MPa. Open the valve between the expansion tank and the vacuum tank. The temperature and pressure in the expansion tank will drop instantly. Puffing;

[0047] 4. The temperature inside the puffing tank rises to 70°C, turn on the vacuum pump, and keep the valve between the puffing tank and the vacuum tank always open. At this temperature, vacuum-dry the black fungus in the puffing tank ...

Embodiment 3

[0051] 1. Select black fungus fruit bodies as raw materials, wash and dry to a water content of 40wt%, put them into an expansion tank, the amount of black fungus put in is 15% of the volume of the expansion tank by volume ratio, and seal the expansion tank;

[0052] 2. Start the electric steam generator, heat and pressurize the black fungus in the expansion tank, make the temperature in the expansion tank 80°C and the pressure in the tank reach 0.1MPa, and keep it for 20 minutes;

[0053] 3. Turn on the vacuum pump and vacuumize the vacuum tank. The vacuum degree of the vacuum tank is -0.05MPa. Open the valve between the expansion tank and the vacuum tank. Puffing;

[0054] 4. The temperature inside the puffing tank rises to 90°C, turn on the vacuum pump, and keep the valve between the puffing tank and the vacuum tank open all the time. At this temperature, vacuum-dry the black fungus in the puffing tank for 1 hour, then cool down to 30°C, and restore After reaching normal p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com