Aqueous environment-friendly touch-sense printing ink and preparation method of same

A water-based, environmentally friendly technology, applied in ink, household utensils, applications, etc., can solve environmental pollution, unfavorable environmental protection, unfavorable health of operators and other problems, and achieve good environmental performance, fast drying speed, and good elasticity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

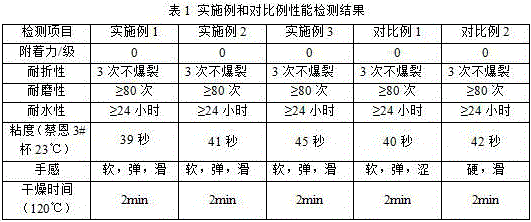

Examples

Embodiment 1

[0041] S1. Stir and mix 60 kg of water-based resin, 20 kg of water-based wax slurry, 1 kg of water-based silicone defoamer, 0.5 kg of water-based silicone leveling agent, 0.25 kg of water-based dry film antifungal agent, and 0.25 kg of water-based preservative in the tank Evenly, the stirring speed is 500 rpm, stirring for 20 minutes;

[0042] S2. Increase the rotating speed to 900 rpm, add 8 kg of water-based polyurethane elastic powder, and stir for 30 minutes until the fineness reaches the standard;

[0043] S3. Reduce the rotation speed to 500 rpm, add 5 kg of absolute ethanol and 5 kg of deionized water and stir for 10 minutes until the mixture is evenly stirred, then filter and pack with an 80-mesh filter.

Embodiment 2

[0045] S1. Stir and mix 70 kg of water-based resin, 15 kg of water-based wax slurry, 0.3 kg of water-based silicone defoamer, 1 kg of water-based silicone leveling agent, 0.5 kg of water-based dry film antifungal agent, and 0.5 kg of water-based tank preservative Evenly, the stirring speed is 600 rpm, stirring for 15 minutes;

[0046] S2. Increase the rotating speed to 1000 rpm again, add 8.7 kg of water-based polyurethane elastic powder, and stir for 25 minutes until the fineness reaches the standard;

[0047] S3. Reduce the rotation speed to 600 rpm, add 2 kg of absolute ethanol and 2 kg of deionized water and stir for 8 minutes until the mixture is evenly mixed, then filter and pack with an 80-mesh filter.

Embodiment 3

[0049] S1. Stir and mix 65 kg of water-based resin, 15.5 kg of water-based wax slurry, 0.5 kg of water-based silicone defoamer, 1.5 kg of water-based silicone leveling agent, 0.75 kg of water-based dry film antifungal agent, and 0.75 kg of water-based preservative in the tank Evenly, the stirring speed is 700 rpm, stirring for 10 minutes;

[0050] S2. Increase the speed to 1100 rpm, add 12 kg of water-based polyurethane elastic powder, and stir for 10 minutes until the fineness reaches the standard;

[0051] S3. Reduce the rotating speed to 700 rpm, add 2 kg of absolute ethanol and 2 kg of deionized water and stir for 5 minutes until the mixture is evenly mixed, then filter and pack with an 80-mesh filter.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com