Spinning machine drafting component capable of improving yarn quality

A spinning machine and quality technology, which is applied in the field of textile machinery components and spinning machine drafting components, can solve problems such as large influence on the consistency of yarn quality, influence on apron operation stability, and influence on yarn quality, etc., to achieve Reduced distribution range, stable transmission, and reduced neps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

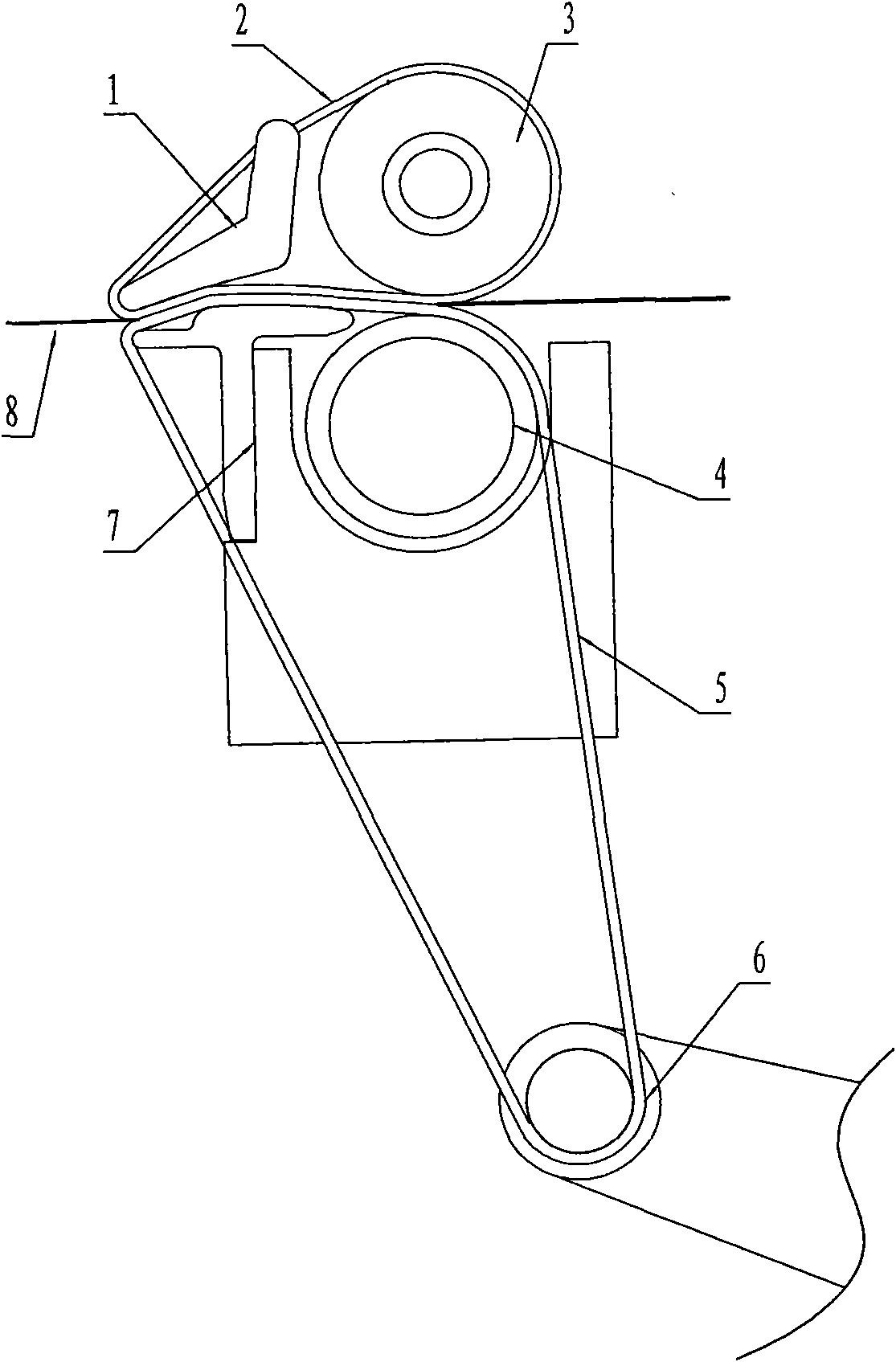

[0015] see figure 1 , the drafting assembly of the present invention is made up of upper pin 1, middle upper roller 3, upper apron 2, middle lower roller 4, lower pin 7, tension frame 6 and lower apron 5, wherein the upper apron surrounds upper pin and The upper and middle rollers, the lower aprons surround the lower and middle rollers, the lower pins, and the tension frame, and the drawn strands 8 are between the upper and lower aprons. In the drafting process, the operating range of the strands is in the middle of the apron, and the two sides of the apron are supported and driven, so the improved idea of the present invention is: fully exert the functions of the transmission parts on both sides of the apron and the rollers, and at the same time Minimize the friction of the apron on the upper and lower pin jaws.

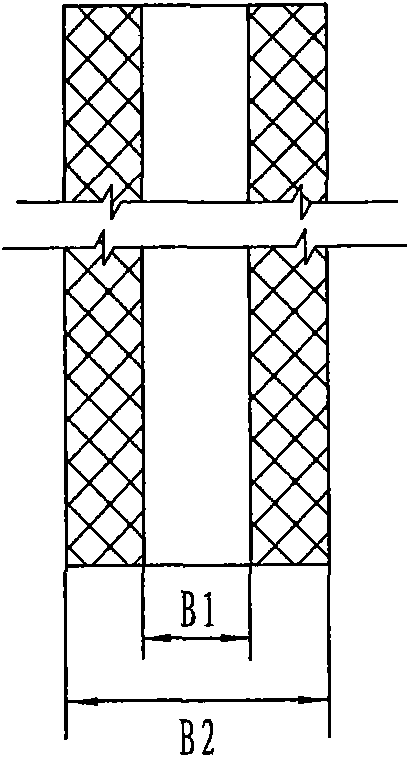

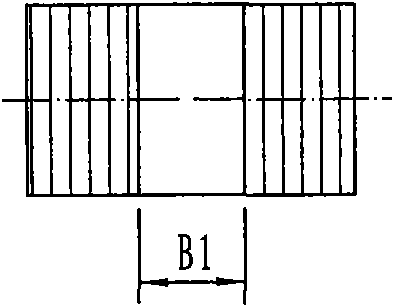

[0016] see Figure 2-6 According to the present invention, the middle part of the inner surface of the upper apron 2 and the lower apron 5 is a flat surface, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com