Method for preparing high-smoothness-level talcum powder

A talcum powder and slippery technology, applied in the direction of magnesium silicate, silicate, etc., can solve the problems of talc powder lamellar crystal shape, gloss, and slippery protection, and achieve uniform particle size , improve skin feel, broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

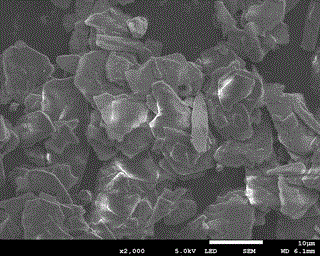

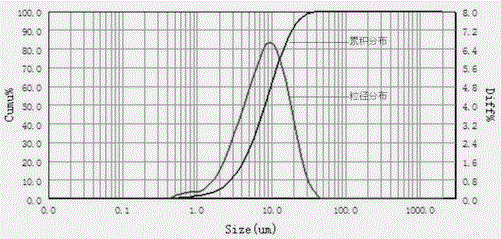

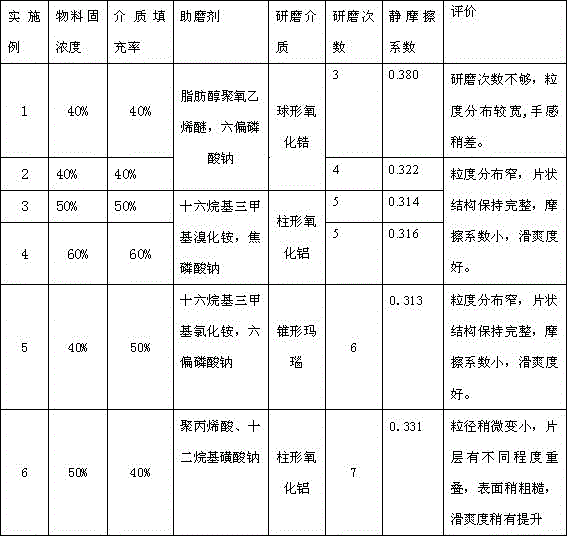

[0023] In order to further illustrate the present invention, implement according to the following steps, the data in the table are the experimental parameters and evaluation instructions of six embodiments.

[0024] (1) Weigh 1 kg of talc ore for crushing treatment, and then crush it into 325-mesh fine powder with a continuous pulverizer.

[0025] (2) Mix deionized water and grinding aid to make a dispersion.

[0026] (3) Add the 325-mesh fine powder material into water and grinding aid, the solid concentration of the material is 30%-50%, and stir evenly.

[0027] (4) Add specific strength grinding media into the sand mill, and the media filling rate is 40%-60% (volume percentage).

[0028] (5) The slurry is circularly ground for 4-5 times by a vertical grinding and peeling machine. After the slurry is adjusted, classified, pressed, dried, crushed and sieved, the high-slippery talc powder can be obtained.

[0029] Table 1 Experimental parameters and evaluation table of each ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com