Quick-drying type acrylic acid and polyurethane environment-friendly water-based wood gloss varnish and preparation method thereof

A technology of acrylic polyurethane and wood varnish, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve problems such as poor paint film performance, improve paint film performance, improve slip and feel, and improve scratch resistance. The effect of grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A quick-drying type acrylic polyurethane environmental protection water-based wood gloss varnish, consisting of the following components in percentage by weight:

[0034] Water-Based Acrylic Emulsion 42%

[0035] Waterborne Polyurethane Emulsion 38%

[0036] Coalescent 7%

[0037] Substrate wetting agent 0.4%

[0038] Defoamer 0.3%

[0039] Thickener 1.0%

[0040] Leveling agent 0.3%

[0041] Anti-slip agent 0.3%

[0042] Water 9.7%

[0043] First, add water, water-based acrylic emulsion and water-based polyurethane emulsion into the dispersion tank and disperse at a medium speed, then add film-forming aids, thickeners, wetting agents, defoamers and other components, and disperse at a medium speed for 20-30 minutes Finally, samples are taken to detect the fineness and viscosity of the finished product, and then filtered, canned, and packaged.

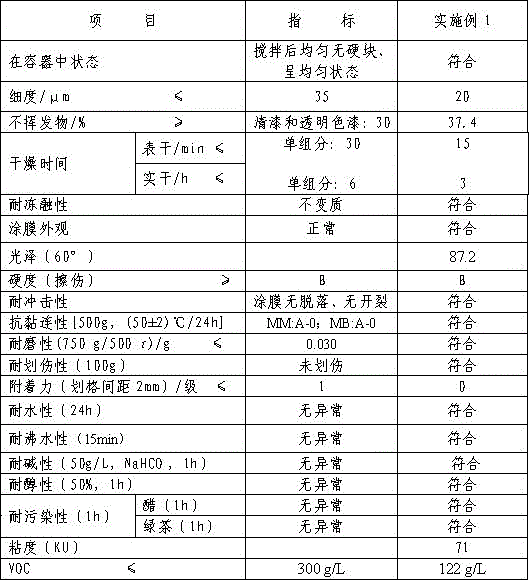

[0044] Embodiment 1 performance testing result

[0045]

Embodiment 2

[0047] A quick-drying type acrylic polyurethane environmental protection water-based wood gloss varnish, consisting of the following components in percentage by weight:

[0048] Water-based acrylic emulsion 30.0%

[0049] Water-based polyurethane emulsion 48.0%

[0050] Coalescing agent 8.0%

[0051] Substrate wetting agent 0.5%

[0052] Defoamer 0.3%

[0053] Thickener 1.2%

[0054] Leveling agent 0.3%

[0055] Anti-slip agent 0.3%

[0056] Water 11.4%

[0057] First, add water, water-based acrylic emulsion and water-based polyurethane emulsion into the dispersion tank and disperse at a medium speed, then add film-forming aids, thickeners, wetting agents, defoamers and other components, and disperse at a medium speed for 20-30 minutes Finally, samples are taken to detect the fineness and viscosity of the finished product, and then filtered, canned, and packaged.

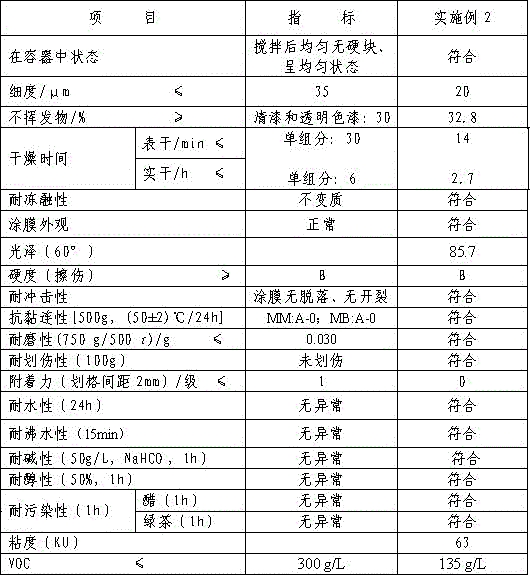

[0058] Embodiment 2 performance testing result

[0059]

PUM

| Property | Measurement | Unit |

|---|---|---|

| luster | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com