Organosilicon coating levelling agent

A technology of silicone coating and leveling agent, which is applied in the direction of coating, etc., can solve the problems of uncommon use, no gloss enhancement, and slip enhancement effect, so as to improve gloss, smoothness and scratch resistance, and improve leveling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Synthesis of Silicone Oil Containing Hydrogen in Part of Methyl

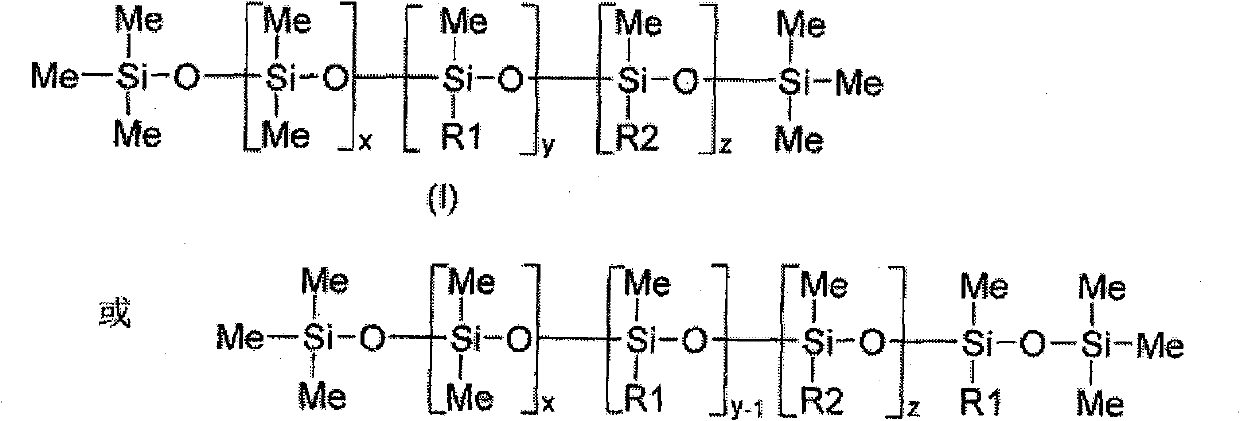

[0041] In a 1000ml four-necked glass reaction flask equipped with an electric stirrer, a loop condenser and a thermometer, add 431.4g D4 (octamethylcyclomethicone), 56.8g D4 H (1,3,5,7-Tetrahydrotetramethylcyclotetrasiloxane), 11.8gMM and 25g acid clay, heat up to 50-75°C, and react at this temperature for 8h, then cool down to 29SiNMR analysis, its structural formula is

[0042]

Embodiment 2

[0044] Synthesis of Silicone Oil Containing Hydrogen in Part of Methyl

[0045] Replace the acid clay with sulfuric acid, and the reaction device, reactant, charging amount and operation method are the same as in Example 1. Also after reacting at 50-75°C for 8 hours, control the temperature of the reactant at 60°C, and slowly add 30g Na 2 CO 3 , to PH=7, filtered to remove white solid Na 2 SO 4 , also changed to a distillation device, and distilled off low boilers at 100°C and 1.3 MPa to obtain a colorless transparent methyl part hydrogen-containing silicone oil with the same structure as formula (II).

Embodiment 3

[0047] Synthesis of organomodified silicone oil

[0048] Equipped with electric stirrer, reflux condenser, thermometer, drip balance tube, guide N 2 In the 1000mL four-necked glass reaction flask with the trachea and the electric heating mantle, add 300g of methyl part hydrogen-containing silicone oil of formula (II), 173g of polyglycol allyl methyl ether, CH 3 COOK15g (1% mass fraction of isopropanol solution), toluene 200g, pass through dry N 2 Gas, start the electric stirrer, and heat, when the temperature reaches 65 ℃, add the toluene solution 1g of platinum-divinyltetramethyldisiloxane chelate (platinum addition is 15 * 10 of the total mass of reactant -6 ), when the system temperature reaches 90°C, the heating is suspended, and the reactant changes from cloudy to transparent. At this time, 79.2 g of 1-dodecene and 6 g of allyl glycidyl ether were added dropwise from the drop material balance tube, and the system changed from slightly turbid to transparent again. The d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com