Low-odor polyurethane open white primer and preparation method thereof

A polyurethane and low-odor technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve problems such as large residual odor, and achieve good environmental performance, cost reduction, and good hiding power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

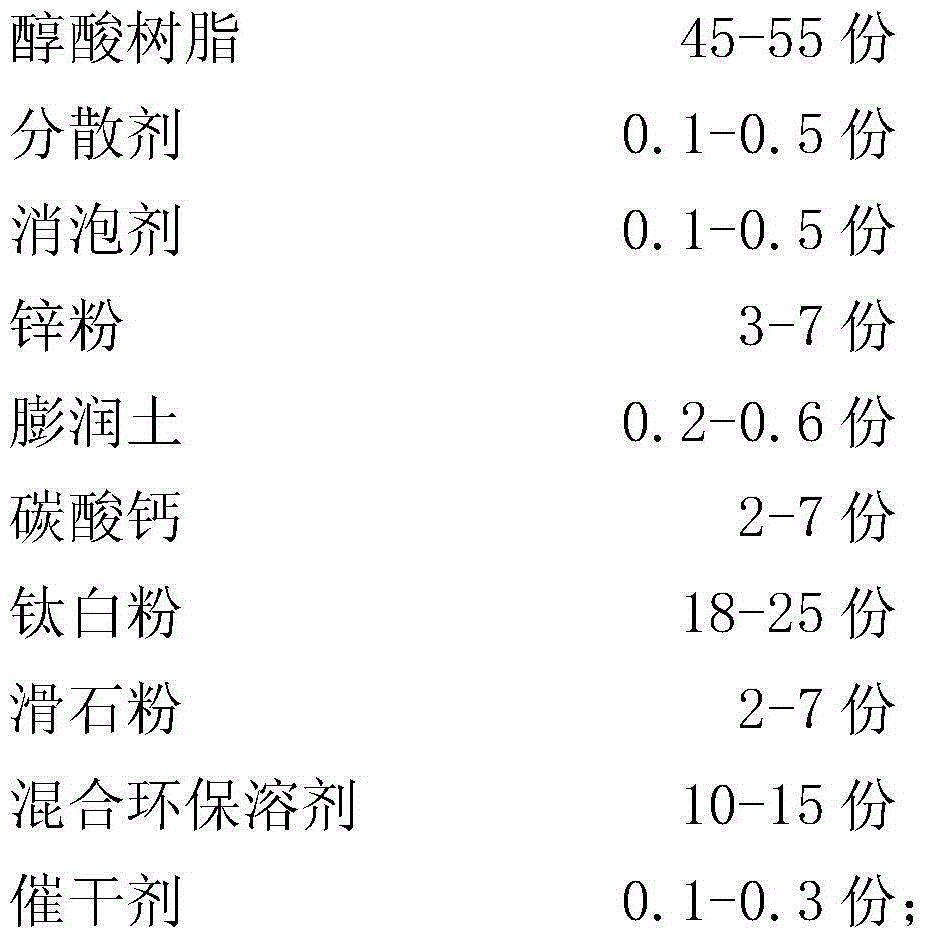

[0043] A low-odor polyurethane open white primer, which is formed by mixing a main agent, a curing agent and a thinner in a mass ratio of 1-1.4:0.5-0.7:0.6-1, wherein the main agent, curing agent and thinner are respectively composed of the following Components and parts by weight ratio are formulated:

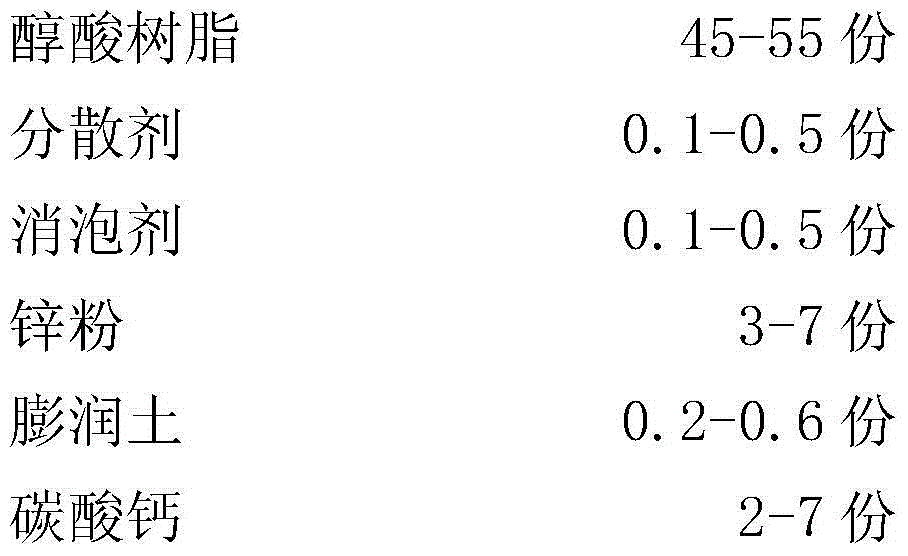

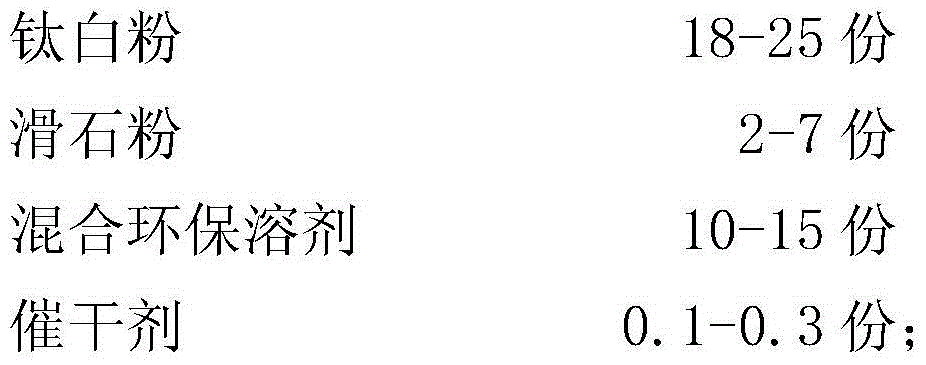

[0044] Wherein the composition and parts by weight ratio of main agent are as follows:

[0045]

[0046] The mixed environment-friendly solvent is formulated according to the following components and parts by weight: 3-8 parts of butyl acetate, 1-5 parts of xylene, and 2-8 parts of ethyl acetate;

[0047] Wherein the component of curing agent and the ratio of parts by weight are as follows:

[0048] Aromatic isocyanate 75-85 parts

[0049] 15-25 parts of dehydrated butyl ester;

[0050] Wherein the component of diluent and the ratio of parts by weight are as follows:

[0051] Xylene 25-35 parts

[0052] Butyl acetate 50-60 parts

[0053] 10-20 parts of propylene glyco...

Embodiment 1

[0064] Embodiment 1: A kind of low-odor polyurethane open white primer is formed by mixing the main agent, curing agent and diluent in a mass ratio of 1:0.5:0.6, wherein the main agent, curing agent and diluent are respectively composed of the following components Formulated with the ratio of parts by weight:

[0065] Wherein the composition and parts by weight ratio of main agent are as follows:

[0066]

[0067]

[0068] The mixed environment-friendly solvent is formulated according to the following components and parts by weight: 3 parts of butyl acetate, 5 parts of xylene, and 8 parts of ethyl acetate;

[0069] Wherein the component of curing agent and the ratio of parts by weight are as follows:

[0070] Aromatic isocyanate 85 parts

[0071] 15 parts of dehydrated butyl ester;

[0072] Wherein the component of diluent and the ratio of parts by weight are as follows:

[0073] Xylene 35 parts

[0074] Butyl acetate 50 parts

[0075] 20 parts of propylene glycol ...

Embodiment 2

[0085] Embodiment 2: A kind of low-odor polyurethane open white primer is formed by mixing the main agent, curing agent and thinner in a mass ratio of 1.4:0.7:1, wherein the main agent, curing agent and thinner are composed of the following components respectively Formulated with the ratio of parts by weight:

[0086] Wherein the composition and parts by weight ratio of main agent are as follows:

[0087]

[0088] The mixed environment-friendly solvent is formulated according to the following components and parts by weight ratio: 6 parts of butyl acetate, 3 parts of xylene, and 6 parts of ethyl acetate;

[0089] Wherein the component of curing agent and the ratio of parts by weight are as follows:

[0090] Aromatic isocyanate 75 parts

[0091] 25 parts of dehydrated butyl ester;

[0092] Wherein the component of diluent and the ratio of parts by weight are as follows:

[0093] Xylene 35 parts

[0094] Butyl acetate 60 parts

[0095] 10 parts of propylene glycol methyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com