Scraping-resistant PE film packing material and preparing method thereof

A film packaging, scratch-resistant technology, applied in the field of packaging materials, which can solve the problems of human health impact, poor performance of high transparency and scratch resistance, and decreased mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

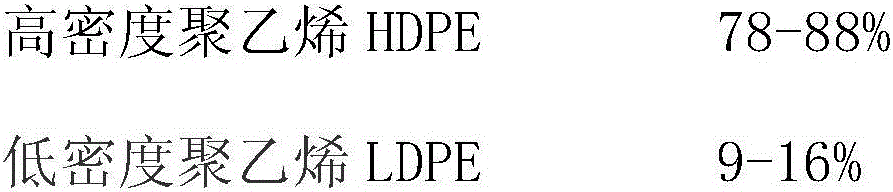

[0014] The scratch-resistant PE film packaging material is calculated by mass percentage, and the composition and content of its raw materials are as follows:

[0015]

Embodiment 2

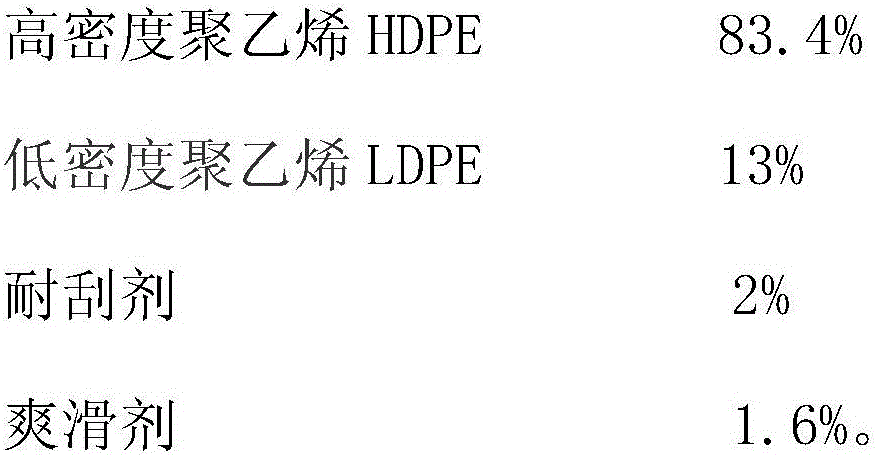

[0017] The scratch-resistant PE film packaging material is calculated by mass percentage, and the composition and content of its raw materials are as follows:

[0018]

Embodiment 3

[0020] The scratch-resistant PE film packaging material is calculated by mass percentage, and the composition and content of its raw materials are as follows:

[0021]

PUM

| Property | Measurement | Unit |

|---|---|---|

| haze | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com