Patents

Literature

110results about How to "Good opening performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Environment-friendly stemming and preparation method thereof

The invention provides an environment-friendly stemming and a preparation method thereof. The environment-friendly stemming is prepared from, by mass, 15-40% of aluminum containing aggregates, 2-15% of coke, 1-5% of graphite, 10-25% of silicon carbide, 5-20% of ferro-silicon nitride, 5-20% of aluminum containing fine powder, 5-15% of clay, 2-8 parts of sericite, 2-6% of high-temperature pitch, 2-15% of an expanding agent and a binding agent accounting for the total mass of the other materials by 15-30%, wherein thermoplastic phenolic resin serves as the binding agent. The environment-friendly stemming and the preparation method thereof have advantages that toxic gases are avoided, a furnace front operation environment is improved, environmental friendliness, low raw material consumption, high hardening speed and short sintering time are realized, opening performance and slag iron erosion resistance of the anhydrous stemming are improved, resistance of the anhydrous stemming to flushing and abrasion of high-temperature molten iron is enhanced, and quality stability of the anhydrous stemming is improved.

Owner:ZHENGZHOU SAIWO TECH CO LTD

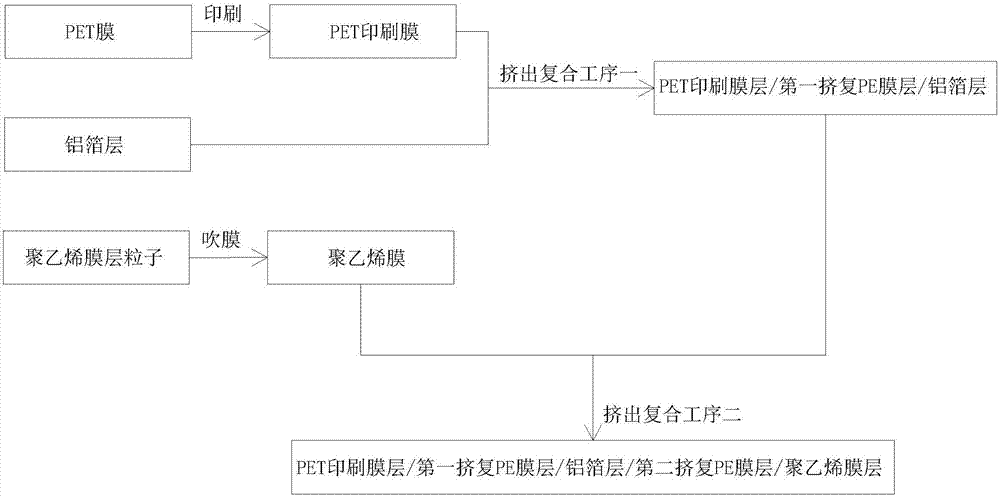

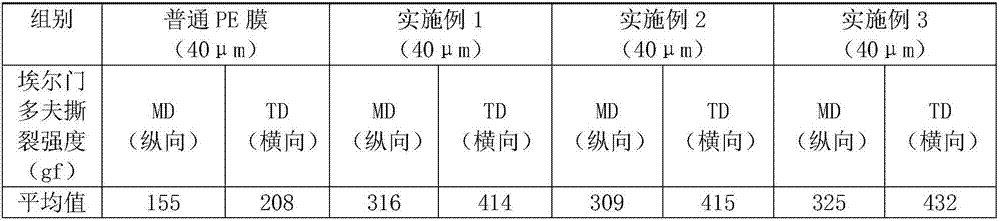

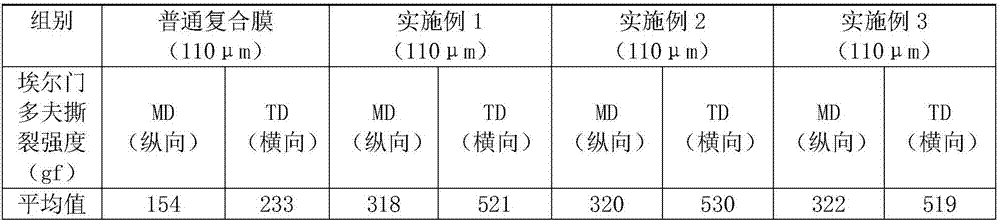

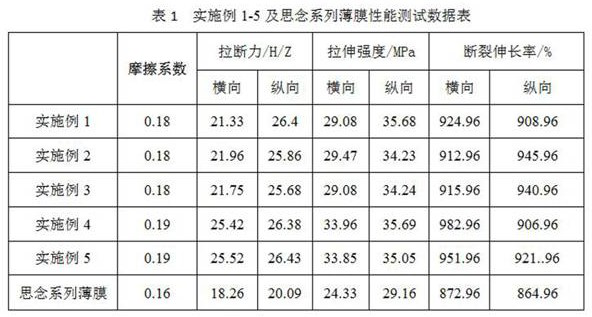

Tear-resistant polyethylene film, composite membrane and preparation method thereof

ActiveCN107323053AHigh peel strengthHigh heat sealing strengthFlexible coversWrappersTear resistanceAluminum foil

The invention relates to a tear-resistant polyethylene film, a composite membrane and a preparation method thereof. The polyethylene film comprises a corona layer, a middle layer and a heat sealing layer, wherein the corona layer and the middle layer are each composed of first metallocene PE, octa-carbon LLDPE and processing aids, and the heat sealing layer is composed of the first metallocene PE, second metallocene PE, silicone, a slipping agent and an opening agent. The composite membrane is formed by a PET printing membrane layer, a first extruded PE membrane layer, an aluminum foil layer, a second extruded PE membrane layer and a polyethylene membrane layer which are sequentially fitted in the membrane layer thickness direction; the extruded PE membrane layer comprises a first adhesive layer in fit with the aluminum foil layer and a second adhesive layer in fit with the PET printing membrane layer or the polyethylene membrane layer, wherein the first adhesive layer is composed of third metallocene PE and adhesive resin, and the second adhesive layer is composed of the third metallocene PE and color master batch. The polyethylene film and the composite membrane disclosed by the invention have higher tear resistance strength. In addition, the composite membrane has excellent humidity resistance property.

Owner:HUANGSHAN NOVEL

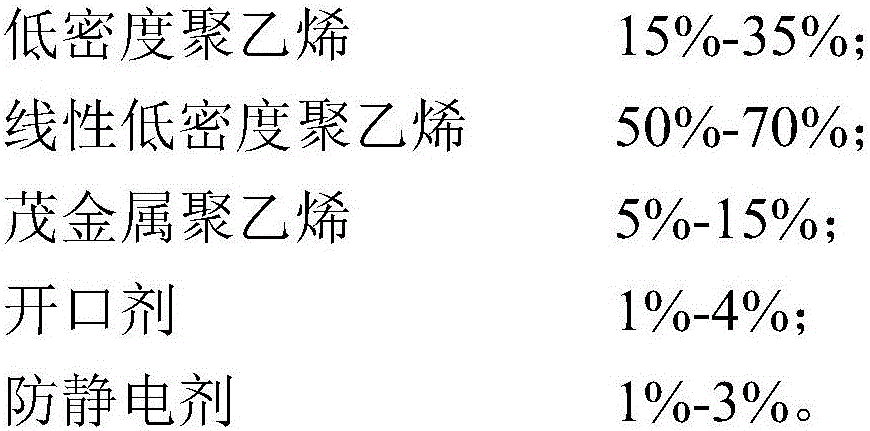

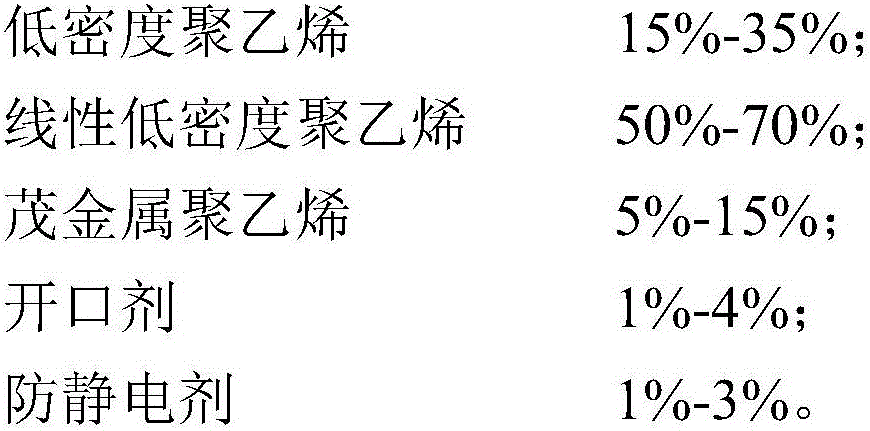

High-strength antistatic polyethylene film as well as preparation method and application thereof

InactiveCN106432888AImprove mechanical propertiesEasy to stretchBag making operationsPaper-makingLow-density polyethyleneBlow molding

The invention discloses a high-strength antistatic polyethylene film. The polyethylene film contains the following components in percentage by weight: 15-35% of low-density polyethylene, 50-70% of linear low-density polyethylene, 5-15% of metallocene polyethylene, 1-4% of an anti-blocking agent, and 1-3% of an antistatic agent. Besides, the invention also discloses a preparation method and application of the high-strength antistatic polyethylene film. The high-strength antistatic polyethylene film provided by the invention is prepared by the steps of taking the low-density polyethylene (LDPE) as a base material, adding the linear low-density polyethylene (LLDPE) and the metallocene polyethylene (MLLPE) and performing blending extrusion, granulation and blow molding, so that the polyethylene film has relatively good tensile strength and antistatic property; and a packaging bag prepared from the high-strength antistatic polyethylene film has the characteristics of good economical efficiency and mechanical property, lasting antistatic property and convenience in use.

Owner:东莞市中为包装制品有限公司

Composition containing PBAT (poly(butylene adipate-co-terephthalate)), preparation method thereof and PBAT full biodegradable mulching film

ActiveCN103709687AMaintain elongation at breakHigh tensile strengthPlant protective coveringsPolymer scienceAntioxidant

The invention discloses a composition containing PBAT (poly(butylene adipate-co-terephthalate)), a preparation method thereof and a PBAT full biodegradable mulching film. The composition contains the following components in percentage by weight: 55-90wt% of PBAT, 5-40wt% of modified talcum powder, 0.1-1wt% of antioxidant, 0.1-1wt% of ultraviolet absorption agent, 0.05-1wt% of light stabilizer, 0.1-1wt% of anti-sticking agent, 0.1-1wt% of lubricant and 0.05-1wt% of dispersing agent. According to the invention, the modified high-transmittancy talcum powder and silicon dioxide and / or SR100 from Ciba Company are added in the PBAT, so that the antiblocking property of the PBAT mulching film prepared from the PBAT composition is enhanced.

Owner:ANHUI JUMEI BIOLOGICAL TECH

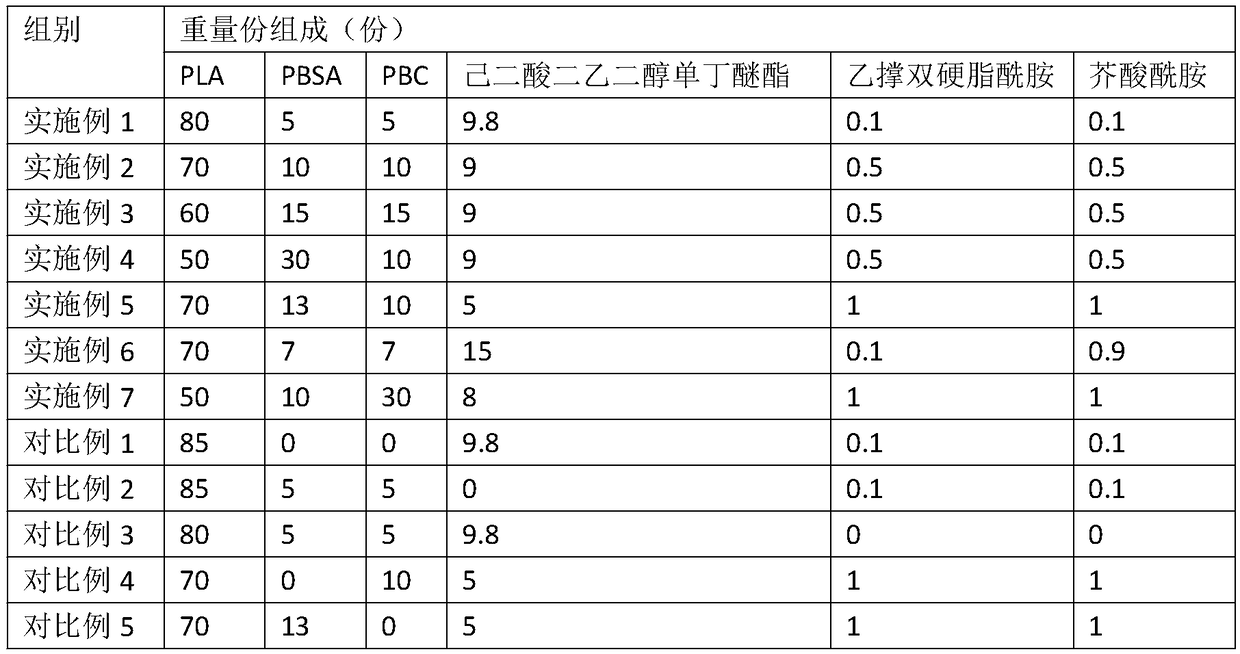

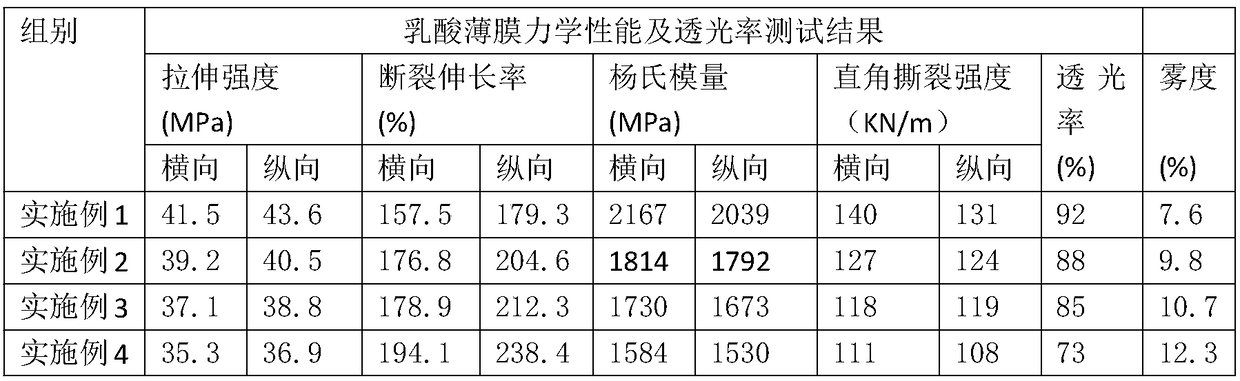

Completely-biodegradable polylactic acid-based blow molding thin film and preparation method thereof

The invention belongs to the field of polymer materials, and particularly relates to a PLA (polylactic acid) biodegradable thin film and a preparation method thereof. The PLA biodegradable thin film is prepared from the following components of PLA, PBSA (poly(butylene succinate-co-adipate)), PBC (polypropylene carbonate), a plasticizer, a lubricant and a pore forming agent. The preparation methodcomprises the following steps of mechanically mixing the PLA, the PBSA, the PBC, the lubricant and the pore forming agent; adding the mixed raw materials into a material hopper of a double-screw extruder; metering the plasticizer by a metering pump, adding via a liquid adding port of the extruder, starting the solid charge and liquid charge, smelting, extruding and granulating, so as to obtain thePLA resin material; performing blow molding and film forming on the PLA resin material, so as to obtain the PLA-based thin film. The PLA-based thin film has the advantages that the mechanical property is better, and the transparency is good; the complete biodegradable effect is realized; the PLA-based thin film can be used for replacing PE (polyethylene), PP (polypropylene), PVC (polyvinyl chloride) and the like to prepare thin films and sheets.

Owner:HEILONGJIANG XINDA ENTERPRISE GRP +1

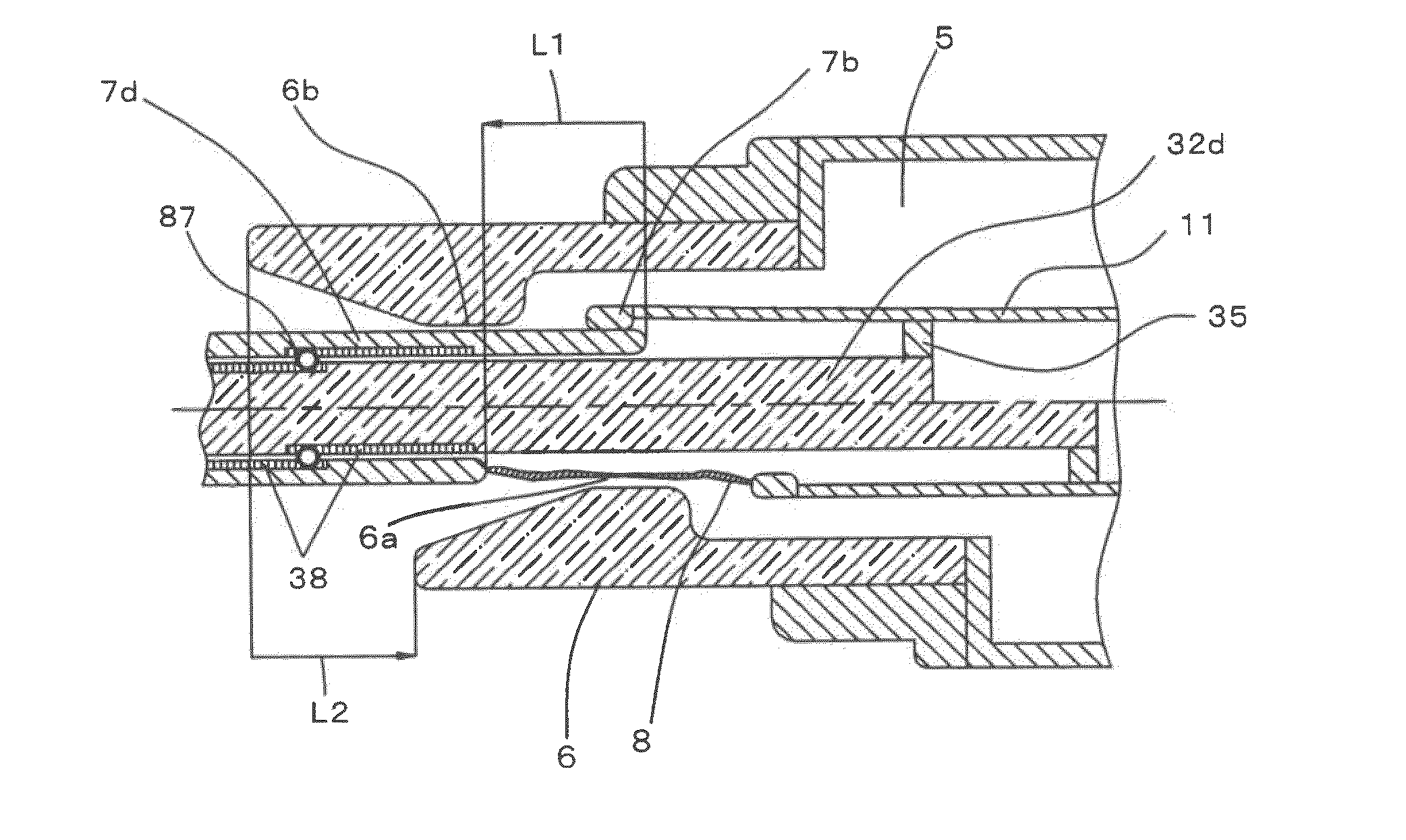

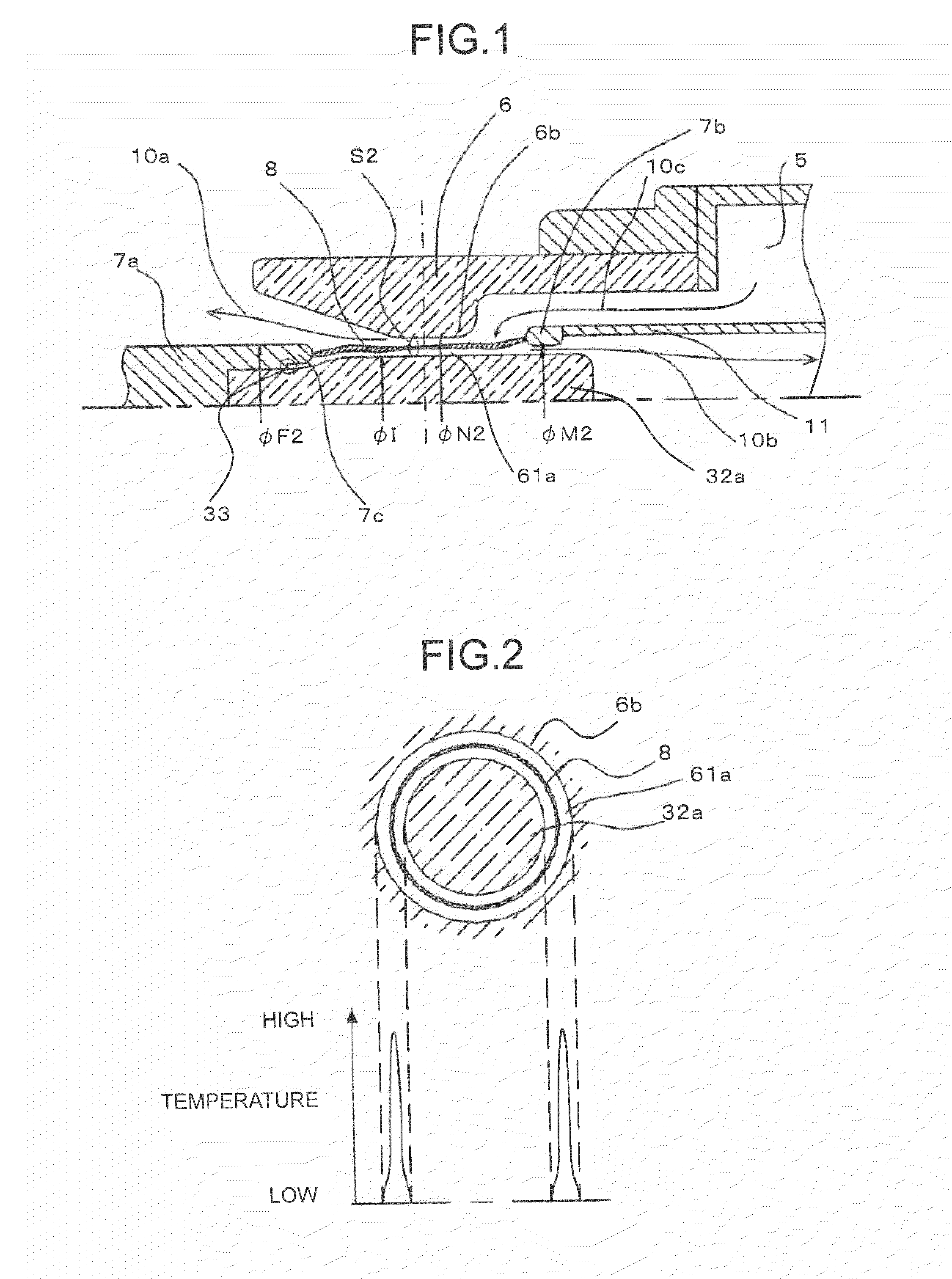

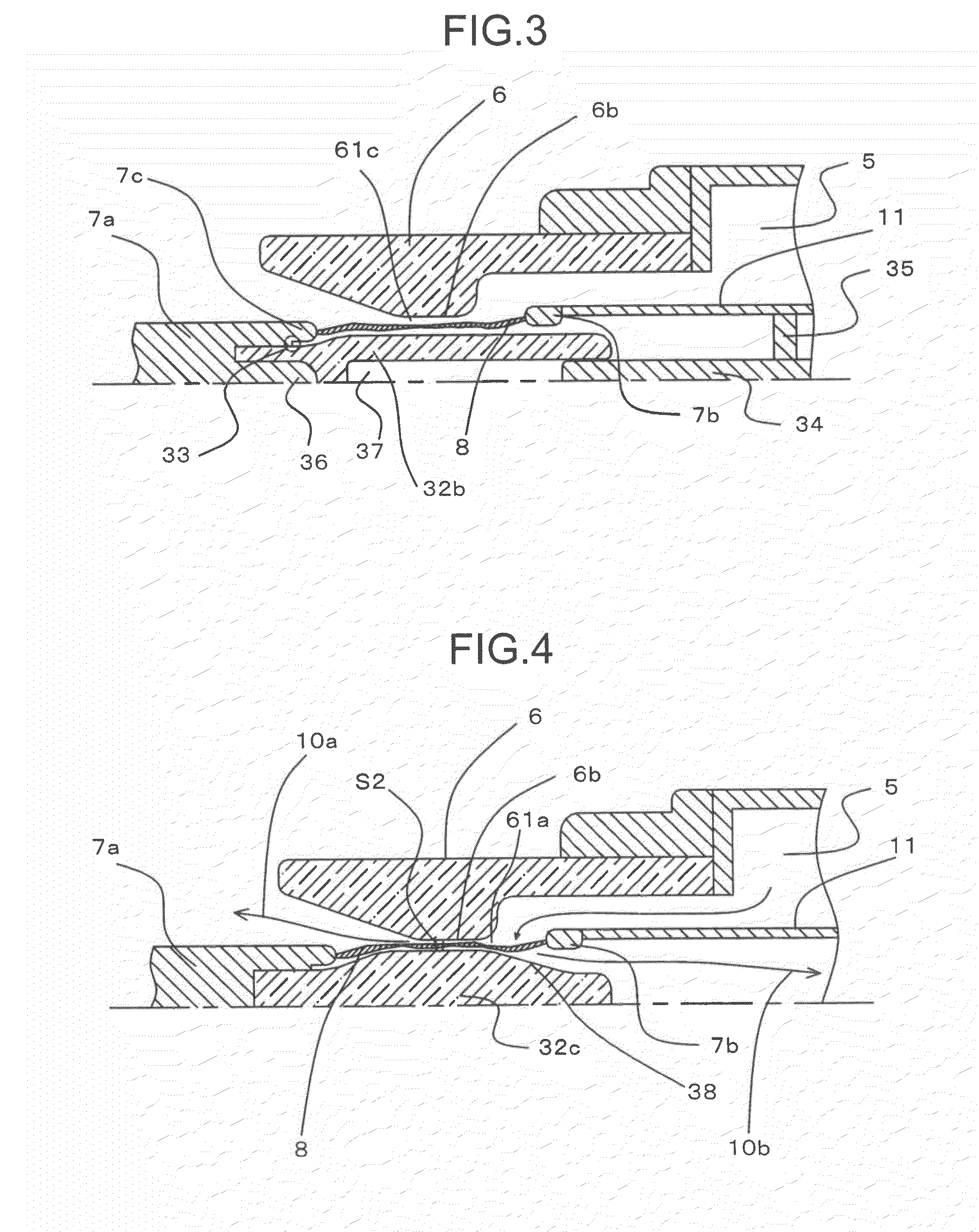

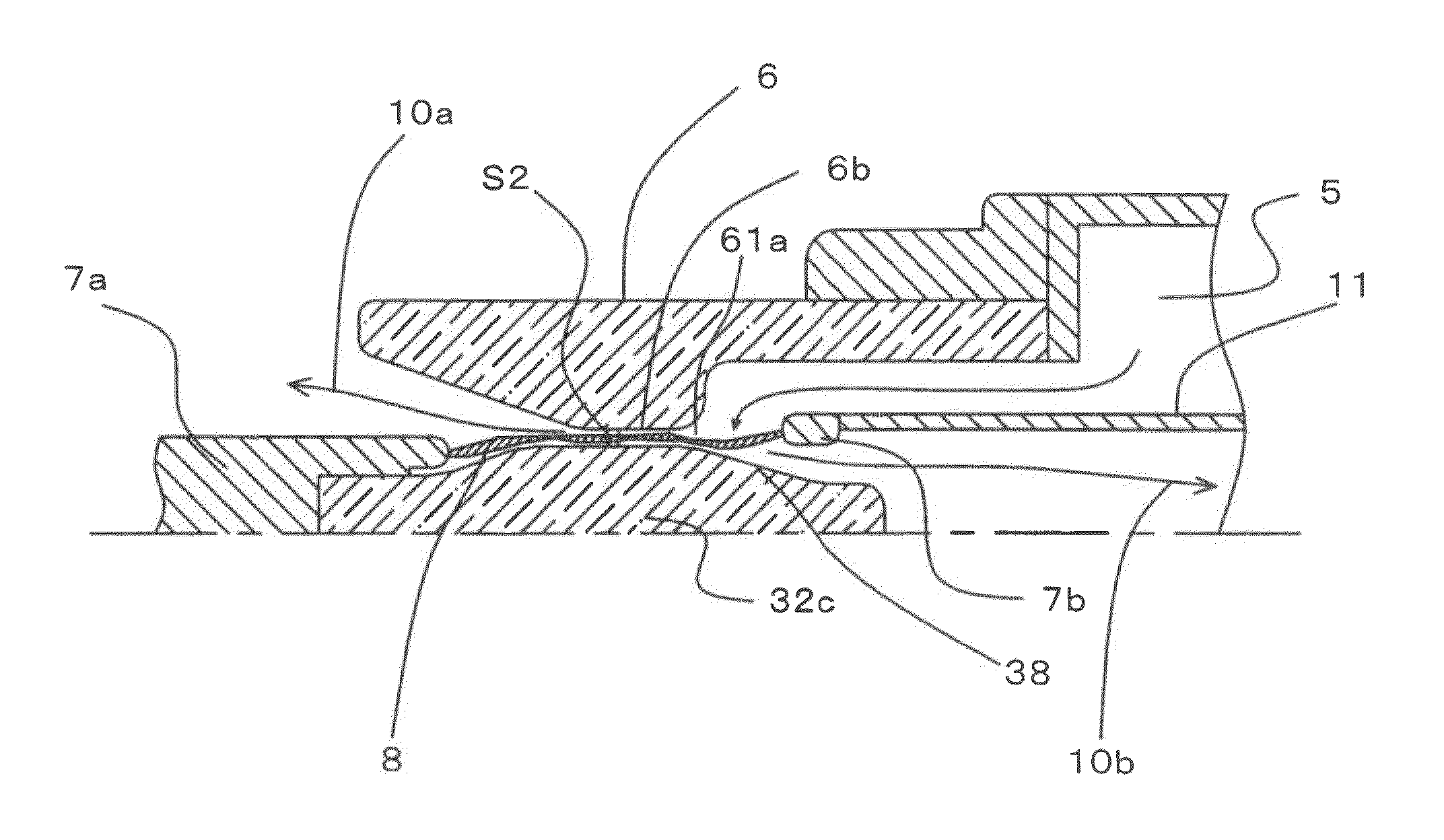

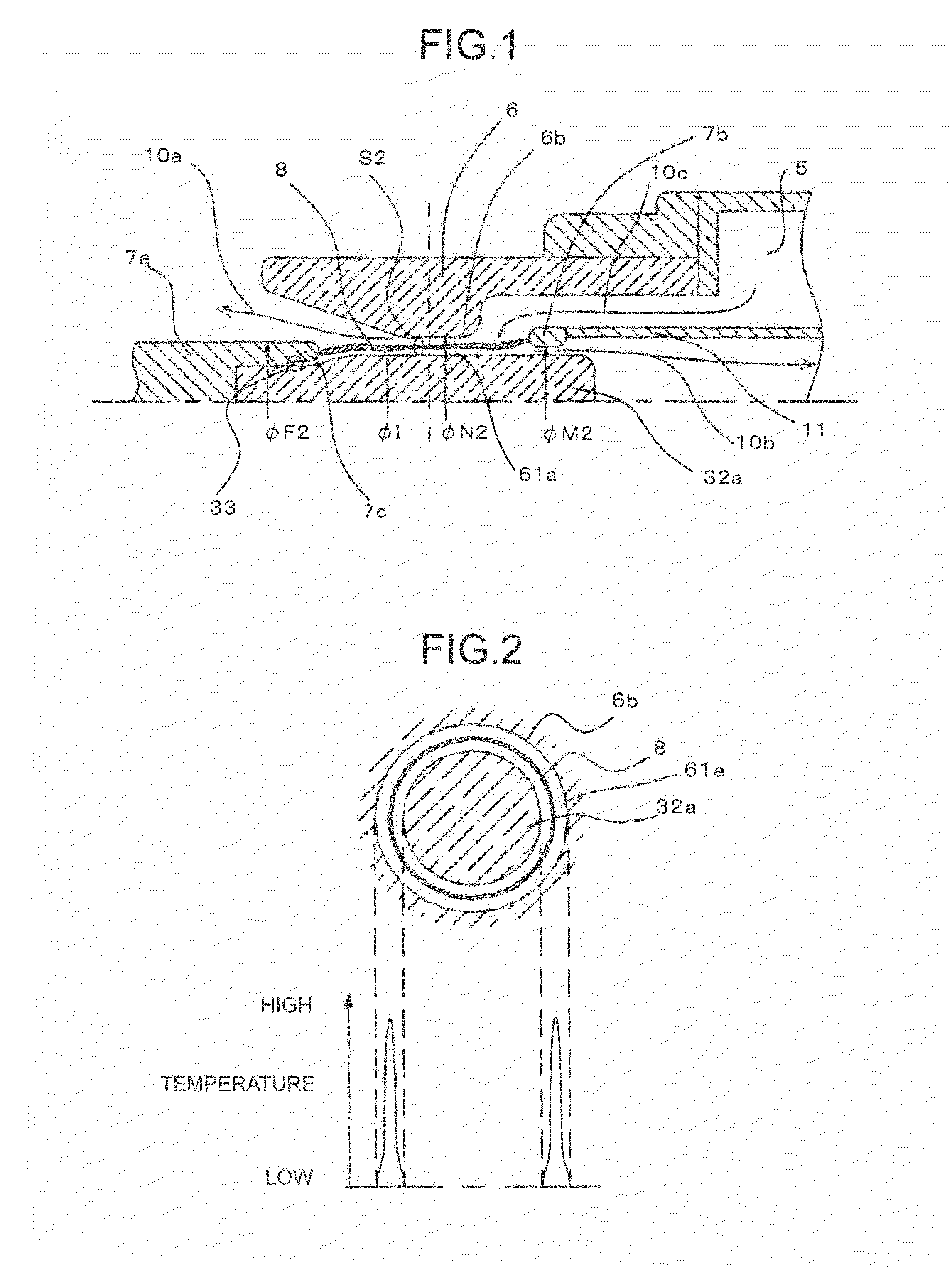

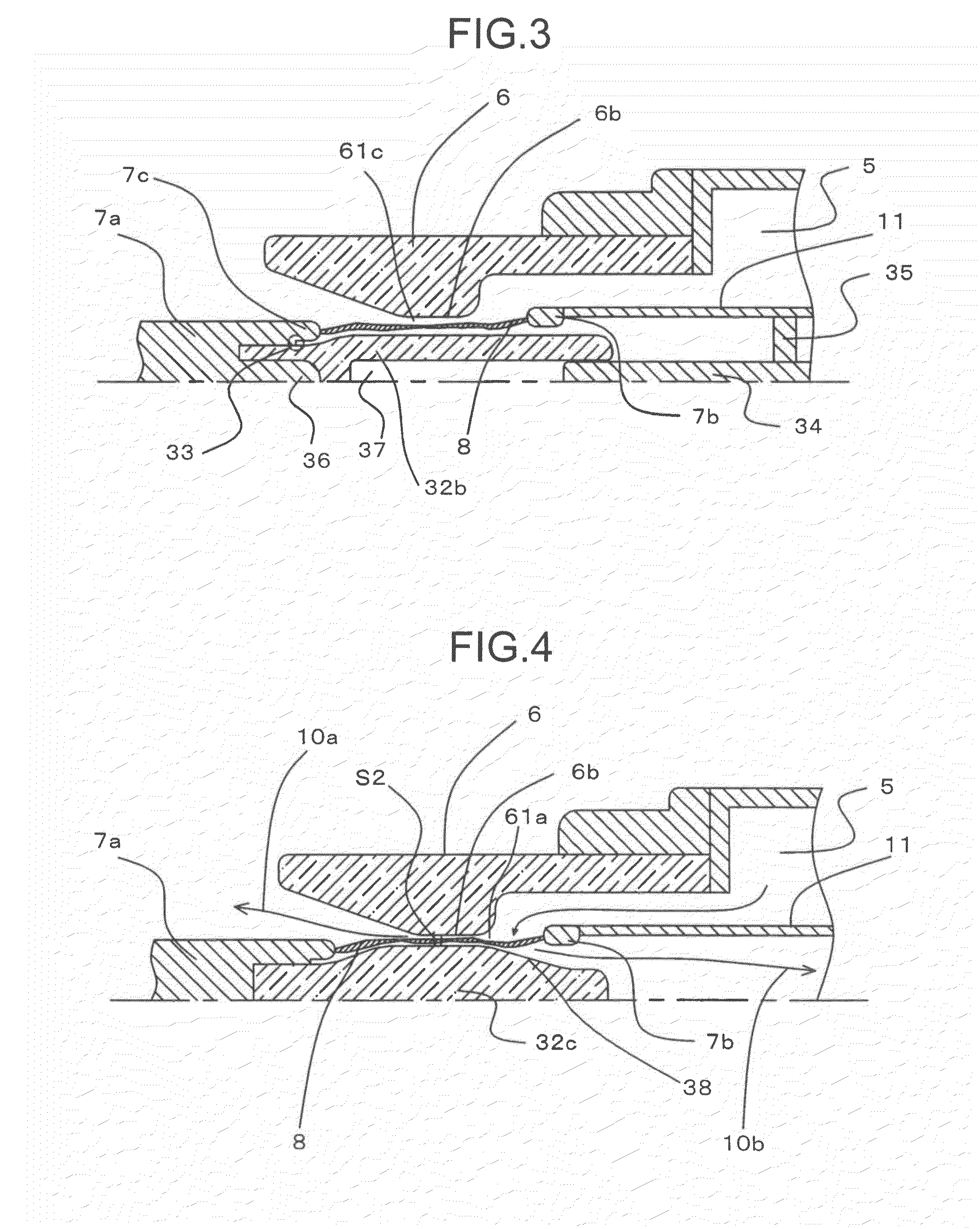

Gas-insulated circuit breaker

InactiveUS20100224594A1Reduce impactProlong lifeHigh-tension/heavy-dress switchesAir-break switchesCircuit breakerGas insulation

A gas-insulated circuit breaker has a sealed container filled with gas; a pair of contacts so constructed as to be connected and separated each other in the sealed container; gas flow generation means for blasting the gas on an arc generated when the contacts are separated, the gas flow generation means including: an accumulation space, pressure increasing means for increasing the pressure of the pressure accumulation space, a gas passage connecting the pressure accumulation space to the arc, and an insulating nozzle that controls the flow of the gas from the pressure accumulation space to the arc; an inside-nozzle insulating member disposed co-axially with the insulating nozzle. The arc is generated in a space between an inner wall section of the insulating nozzle and an outer wall section of the inside-nozzle insulating member, and the gas flows in the space.

Owner:KK TOSHIBA

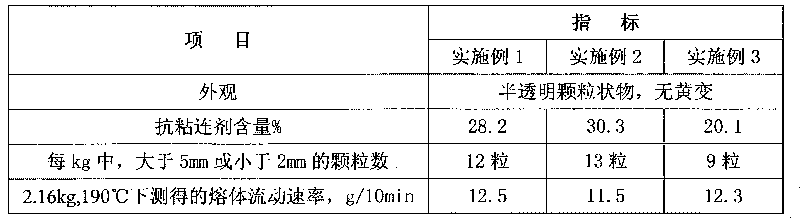

Special compound additive for polyethylene film with high tranparency and low density

ActiveCN101717538ATransparent highHigh transparency, good physiological safetyLow-density polyethyleneLinear low-density polyethylene

The invention relates to a special compound additive for a polyethylene film with high tranparency and low density, which is a particle prepared by the following steps of: stirring and mixing 25-30 percent of silicon dioxide anti-block agent, 5-15 percent of organic silicon glidant, 2-8 percent of organic silicon active crosslinking agent, 1-10 percent of organic silicon antioxidant and the balance of high pressure polyethylene resin by taking high-pressure polyethylene as a carrier; carrying out treatments including preheating, ball milling and dispersing at the temperature of 75-85 DEG C; and finally, extruding pelletization through a twin-screw granulator at the temperature of 140-170 DEG C. The low density polyethylene film prepared by adding the compound additive is tasteless, has high transparency, favorable physiological safety, high anti-blocking property, favorable smoothness and favorable transference resistance and can be particularly used for fields including food covering films, drug covering films, business card covering films, identification card covering films, advertisement packaging and the like which have the requirements of high transparency, high safety and high anti-blocking property.

Owner:南京淳达科技发展有限公司

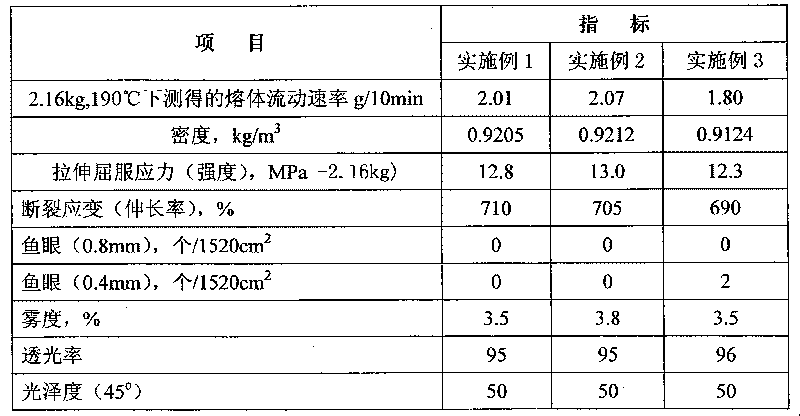

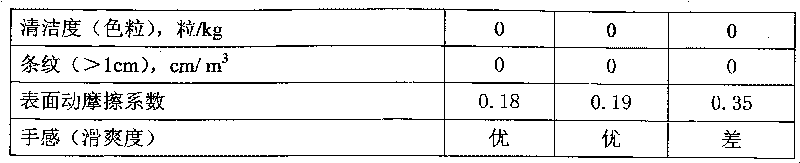

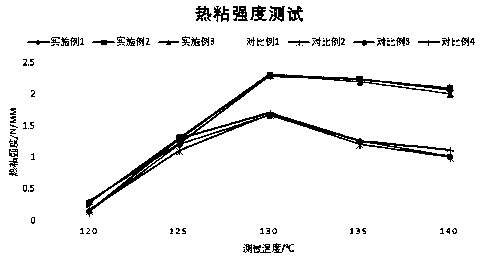

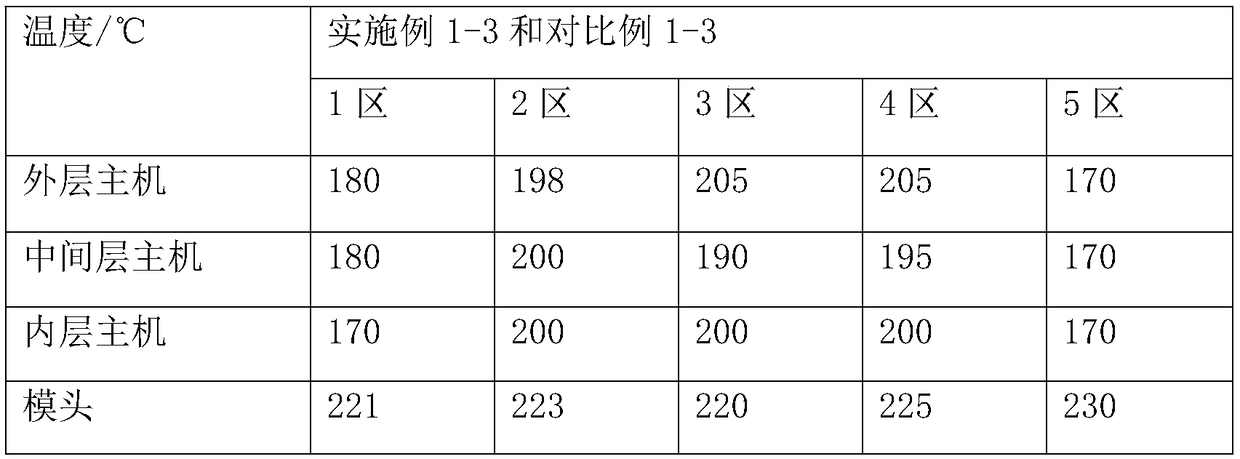

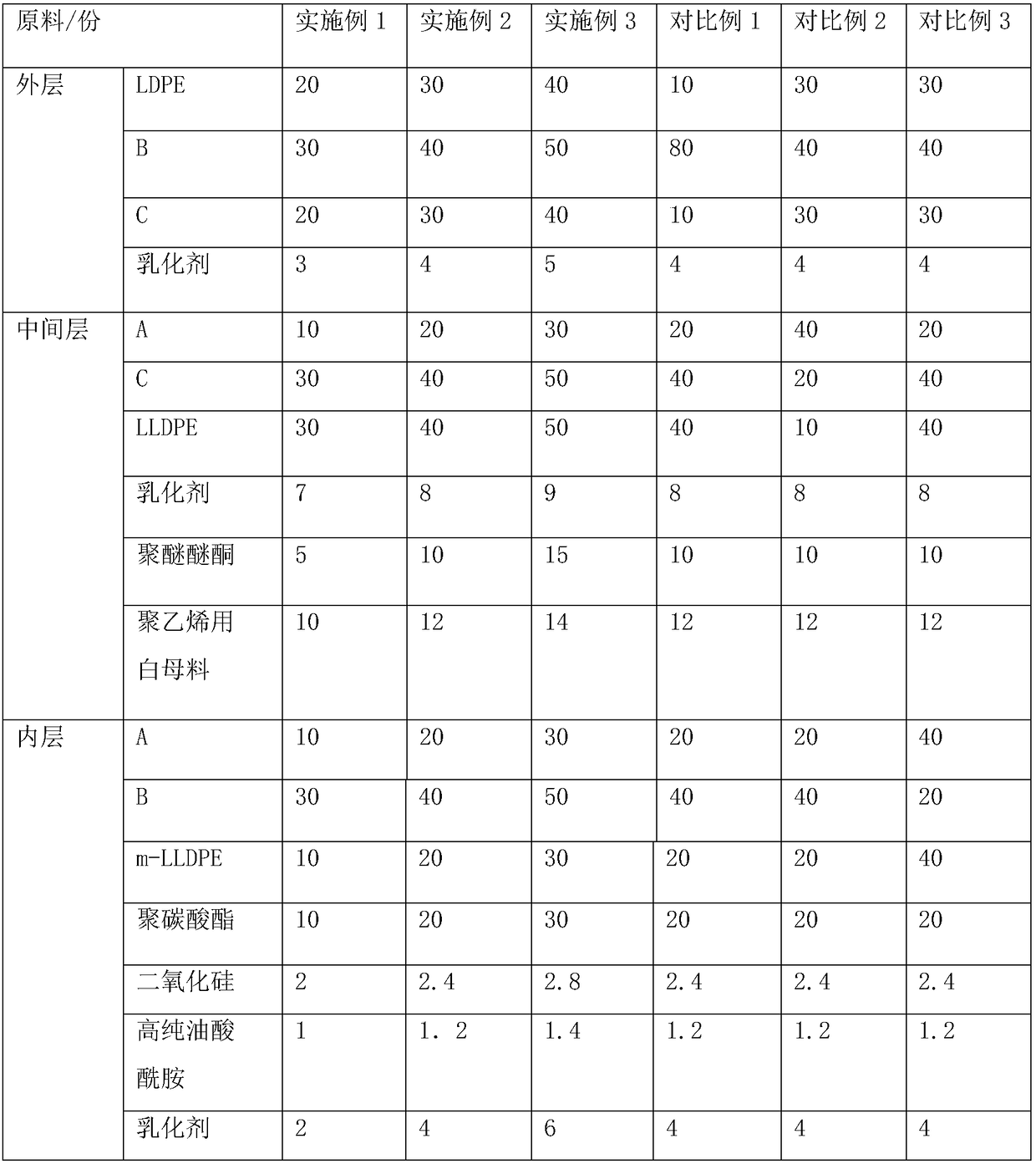

Polyethylene film for automatic packaging and preparation method thereof

ActiveCN108773137AAnti-pollutionComposite strongSynthetic resin layered productsLow-density polyethyleneLinear low-density polyethylene

The invention discloses a polyethylene film for automatic packaging. The polyethylene film comprises an outer layer, an intermediate layer and an inner layer which are sequentially laminated. The outer layer is prepared from the following substances in parts by weight: 20-40 parts of low density polyethylene (LDPE), 30-50 parts of linear low density polyethylene (LLDPE), and 20-40 parts of LLDPE with melt index of 1.1 g / 10 min and density of 0.920 g / cm<3>. The intermediate layer is prepared from the following substances in parts by weight: 10-30 parts of LDPE, 30-50 parts of LLDPE with melt index of 1.1 g / 10 min and density of 0.920 g / cm<3>, and 30-50 parts of LLDPE with melt index of 2.4 g / 10 min and density of 0.921 g / cm<3>. The inner layer is prepared from the following substances in parts by weight: 10-30 parts of LDPE, 30-50 parts of LLDPE, and 10-30 parts of LLDPE. The invention solves the problem that the polyethylene film has lower thermal viscosity and higher bag breaking rate.

Owner:青岛东海包装产业有限公司

Gas-insulated circuit breaker

InactiveUS8115133B2Reduce impactProlong lifeHigh-tension/heavy-dress switchesAir-break switchesCircuit breakerElectric arc

A gas-insulated circuit breaker has a sealed container filled with gas; a pair of contacts so constructed as to be connected and separated each other in the sealed container; gas flow generation means for blasting the gas on an arc generated when the contacts are separated, the gas flow generation means including: an accumulation space, pressure increasing means for increasing the pressure of the pressure accumulation space, a gas passage connecting the pressure accumulation space to the arc, and an insulating nozzle that controls the flow of the gas from the pressure accumulation space to the arc; an inside-nozzle insulating member disposed co-axially with the insulating nozzle. The arc is generated in a space between an inner wall section of the insulating nozzle and an outer wall section of the inside-nozzle insulating member, and the gas flows in the space.

Owner:KK TOSHIBA

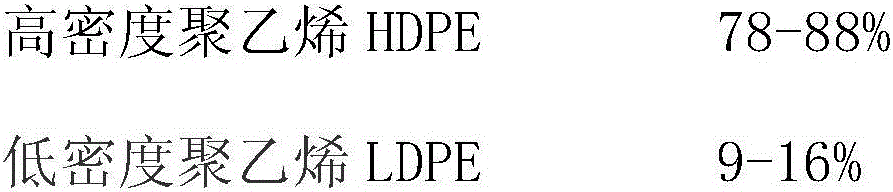

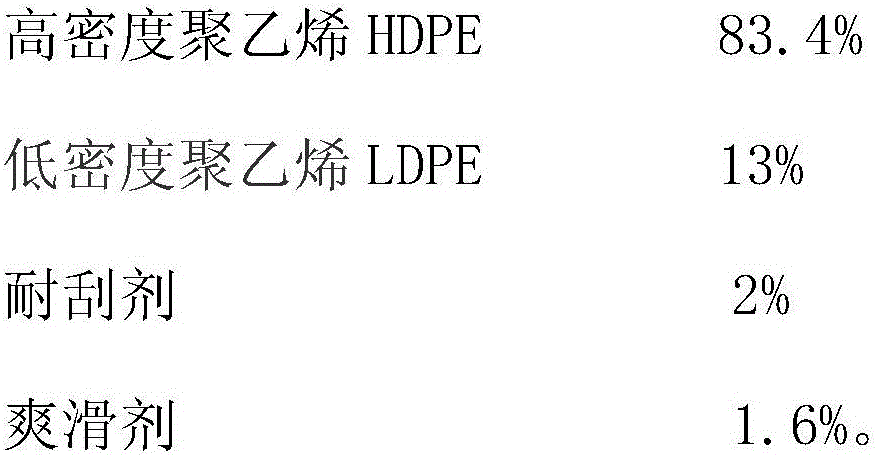

Scraping-resistant PE film packing material and preparing method thereof

The invention relates to a scraping-resistant PE film packing material.The scraping-resistant PE film packing material comprises, by mass, 78%-88% of high density polyethylene (HDPE), 9%-16% of low density polyethylene (LDPE), 1%-3% of scraping-resistant agent and 1.2%-3% of slipping agent.A preparing method of the scraping-resistant PE film packing material includes the following steps that the high density polyethylene (HDPE), the low density polyethylene (LDPE), the scraping-resistant agent and the slipping agent are mixed on a mixing machine according to the mass percent, added into a film blowing unit and heated and extruded through a film-blowing extruding machine, quick cooling is carried out in an air cooling mode during extruding, the product is subjected to the blowing rising process, the drawing process and the rolling process, and the scraping-resistant PE film packing material is obtained.Compared with the prior art, as the specific raw materials are adopted, the transparency of the raw materials is high, the high transparency effect and the scraping-resistant effect of the film can be achieved, and the HAZE can be 10 or below.

Owner:SHANGHAI FUKUSUKE IND

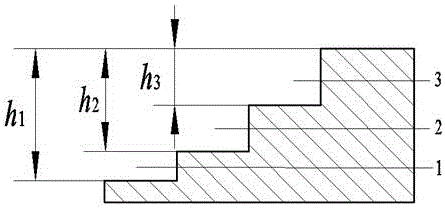

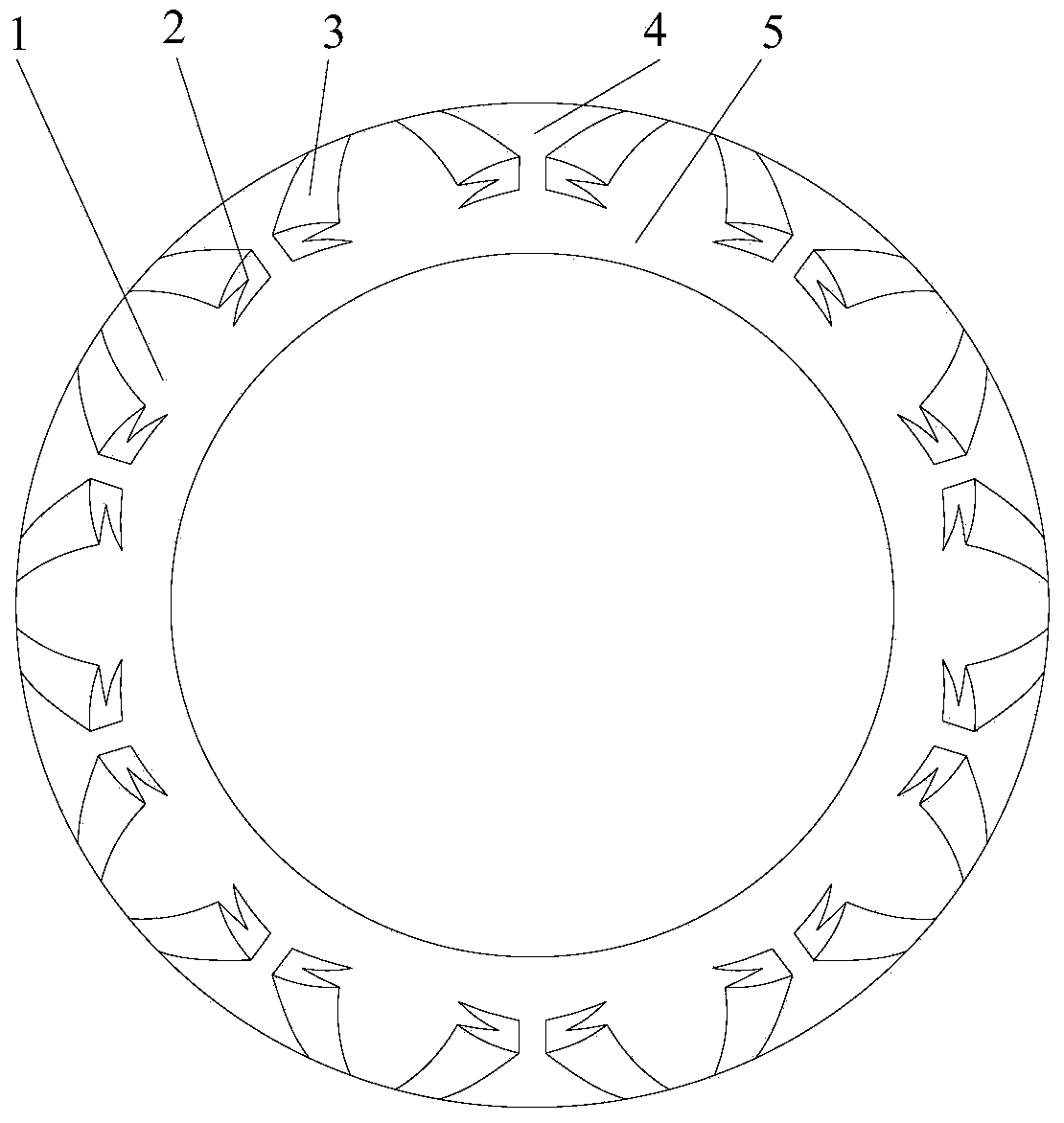

Upstream pumping machinery sealing ring with multiple stages of helical grooves

ActiveCN106763778AAids in compression boostContribute to local pressurizationEngine sealsEngineeringHigh pressure

The invention relates to an upstream pumping machinery sealing ring with multiple stages of helical grooves. The multiple stages of helical grooves uniformly distributed along the circumference of the end surface are formed in the end surface; openings of the multiple stages of helical grooves are formed in the low pressure side of the end surface; the circumferential width and the depth of each stage of helical groove are gradually decreased from the low pressure side to the high pressure side, thus overall forming convergent gaps and greatly enhancing the hydrodynamic pressure effect of the end surface; and therefore, the friction resistance of a machinery seal in an operation process is reduced, and the service life is greatly prolonged.

Owner:云南流体规划研究院有限公司

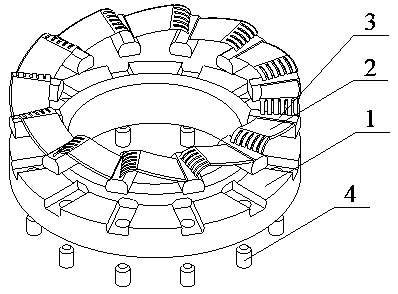

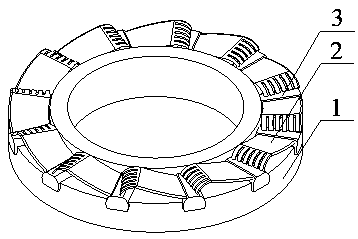

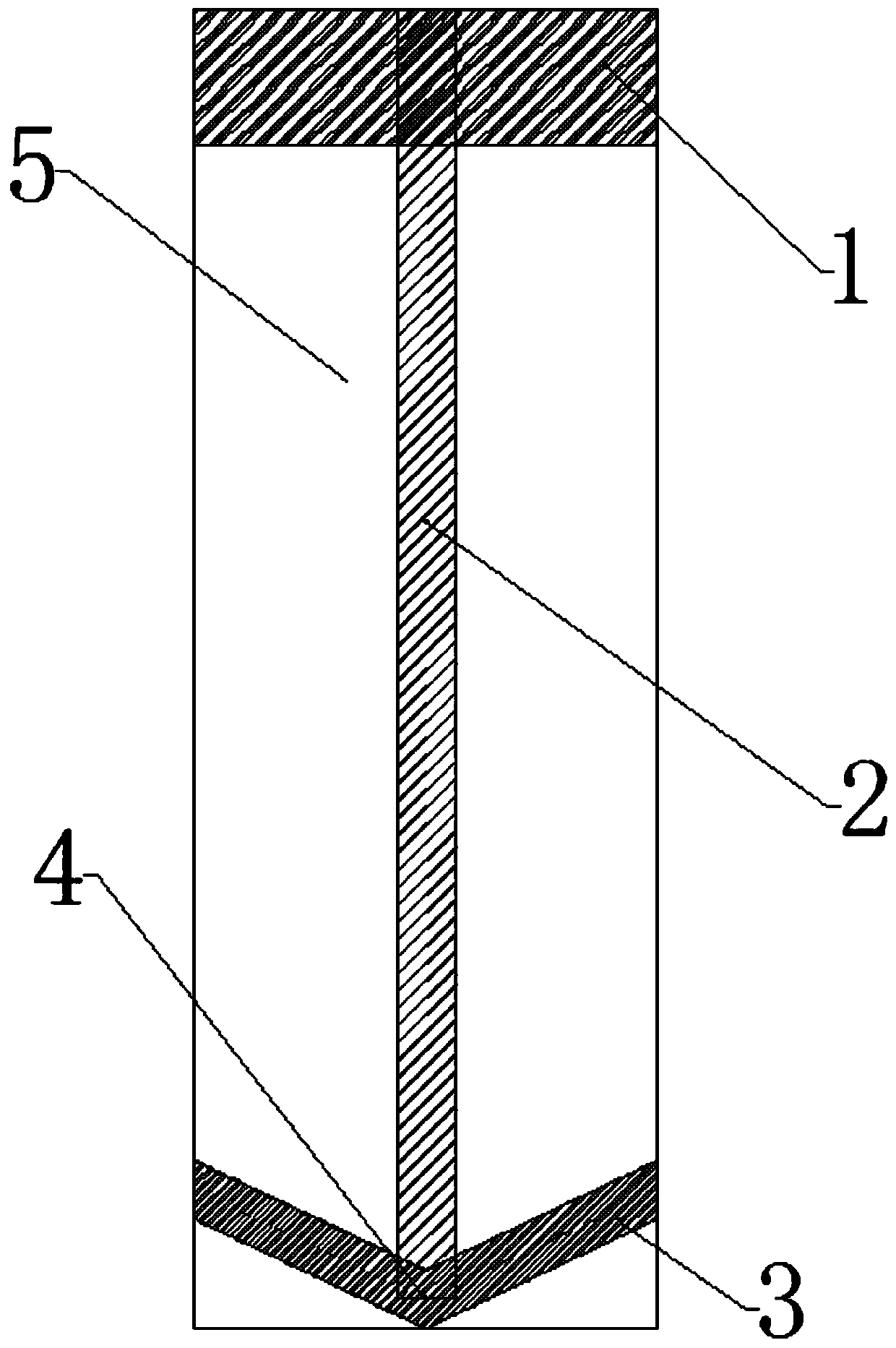

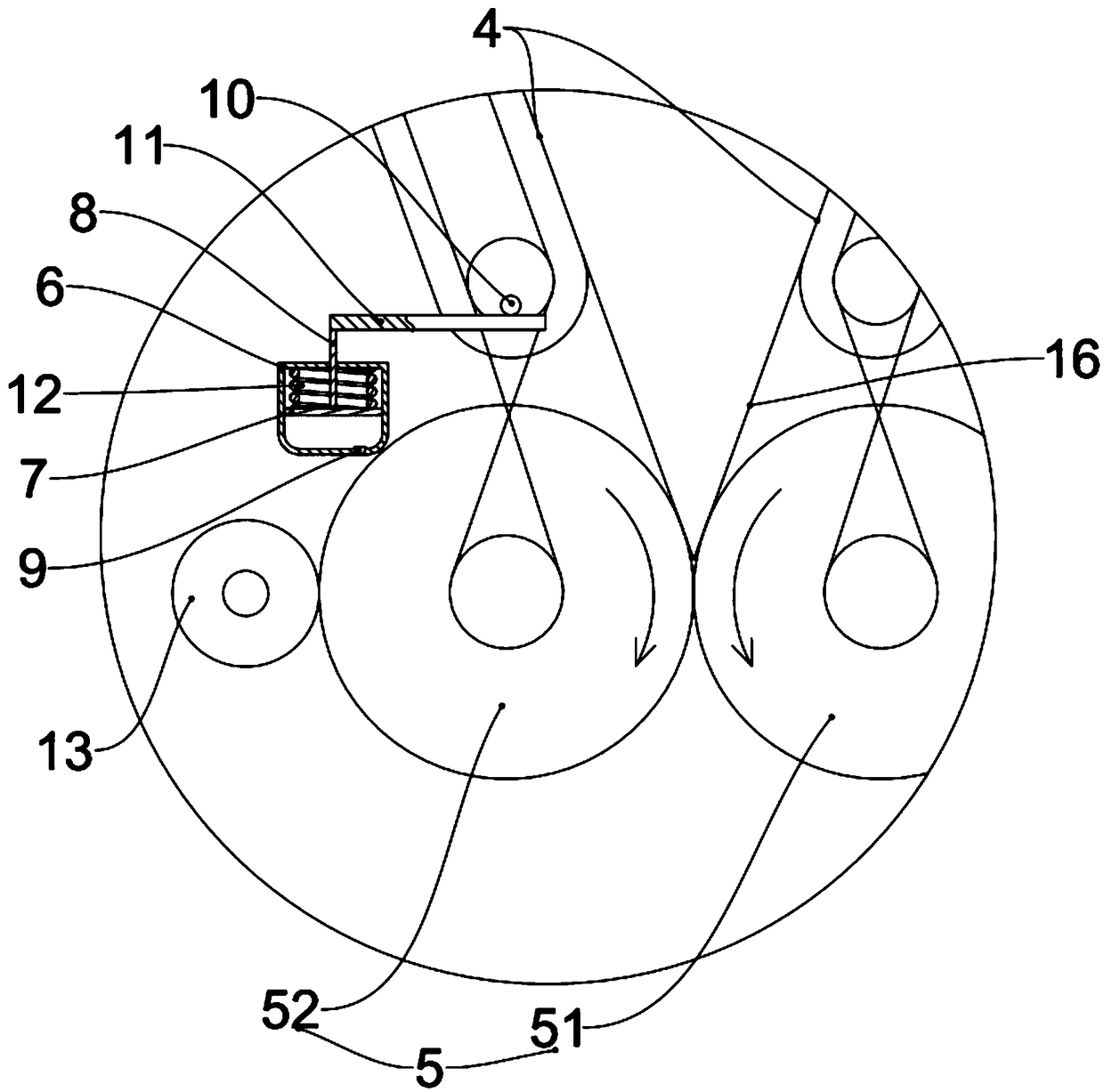

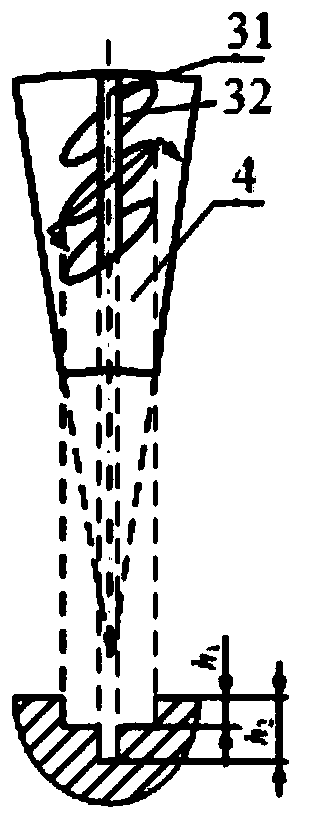

Foil end face gas film sealing structure with enhanced radial flow-induced opening

ActiveCN109237040AReduce resistanceGood opening performanceEngine sealsEngineeringMechanical engineering

The invention discloses a foil end face gas film sealing structure with enhanced radial flow-induced opening. The structure comprises a moving ring and a static ring which are sealed by a gas film, atleast one sealing ring of the moving ring or the static ring is a floating ring supported by a spring, and the sealing end of the floating ring is a foil end face; the foil end face comprises a ring-shaped ring body, a foil, a foil fixing seat and a fastening screw; a plurality of positioning grooves are uniformly formed in the circumferential direction of the ring body; part of the foil is bentto form a bent foil, the other part of the foil is flat and straight to form a straight foil, the bent foil is cut into small pieces in the radial direction, and the cross section of the straight foilin any radial direction is a wing-shaped cross section; the foil fixing seat is inserted into a positioning groove through clearance fit to be fixed through the fastening screw; the end, away from the foil, of the straight foil is welded to the foil fixing seat; the circumferential direction of the part from the flat and straight end to the bent end of the foil is conformed to the circumferentialdirection of air flow.

Owner:CHINA JILIANG UNIV

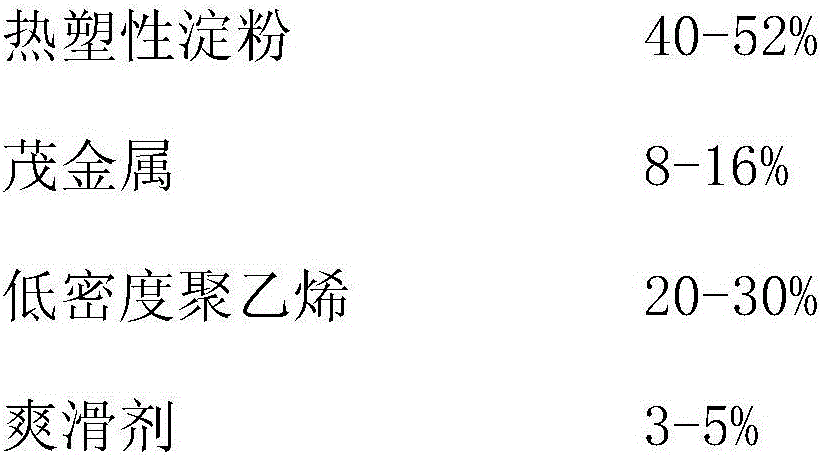

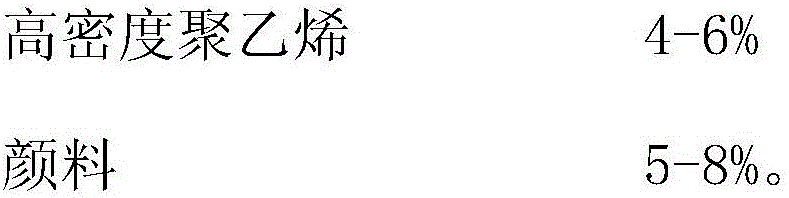

Biodegradable thermoplastic starch resin film and preparation method thereof

The invention relates to a biodegradable thermoplastic starch resin film. The composition and content of raw materials are as follows: thermoplastic starch 40-52%, metallocene 8-16%, low-density polyethylene 20-30%, smooth 3-5% of agent, 4-6% of high-density polyethylene, 5-8% of pigment; the preparation method of the biodegradable thermoplastic starch resin film comprises the following steps: mixing thermoplastic starch, metallocene, low-density polyethylene, smooth Agents, high-density polyethylene, and pigments are mixed by the mixer according to the above mass percentages, added to the film blowing unit, and plasticized, extruded, blown, drawn, and rolled by the blown film extruder, and then blown. Biodegradable thermoplastic starch resin film; Compared with the prior art, the present invention adopts special raw materials, such raw materials are green and environment-friendly bio-polyethylene, etc., so that the film produced can be biodegradable, bio-environmental, and reduce carbon dioxide emissions.

Owner:SHANGHAI FUKUSUKE IND

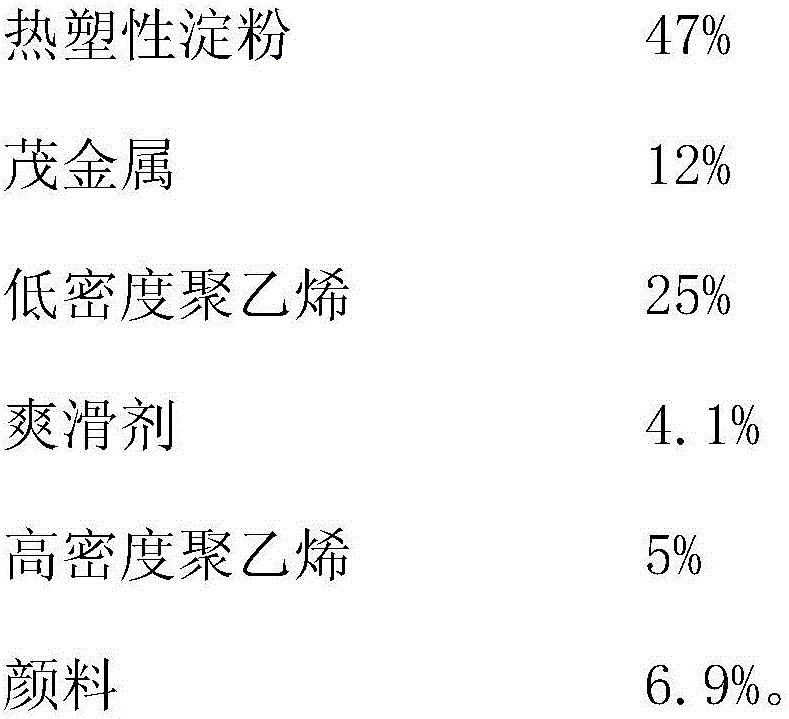

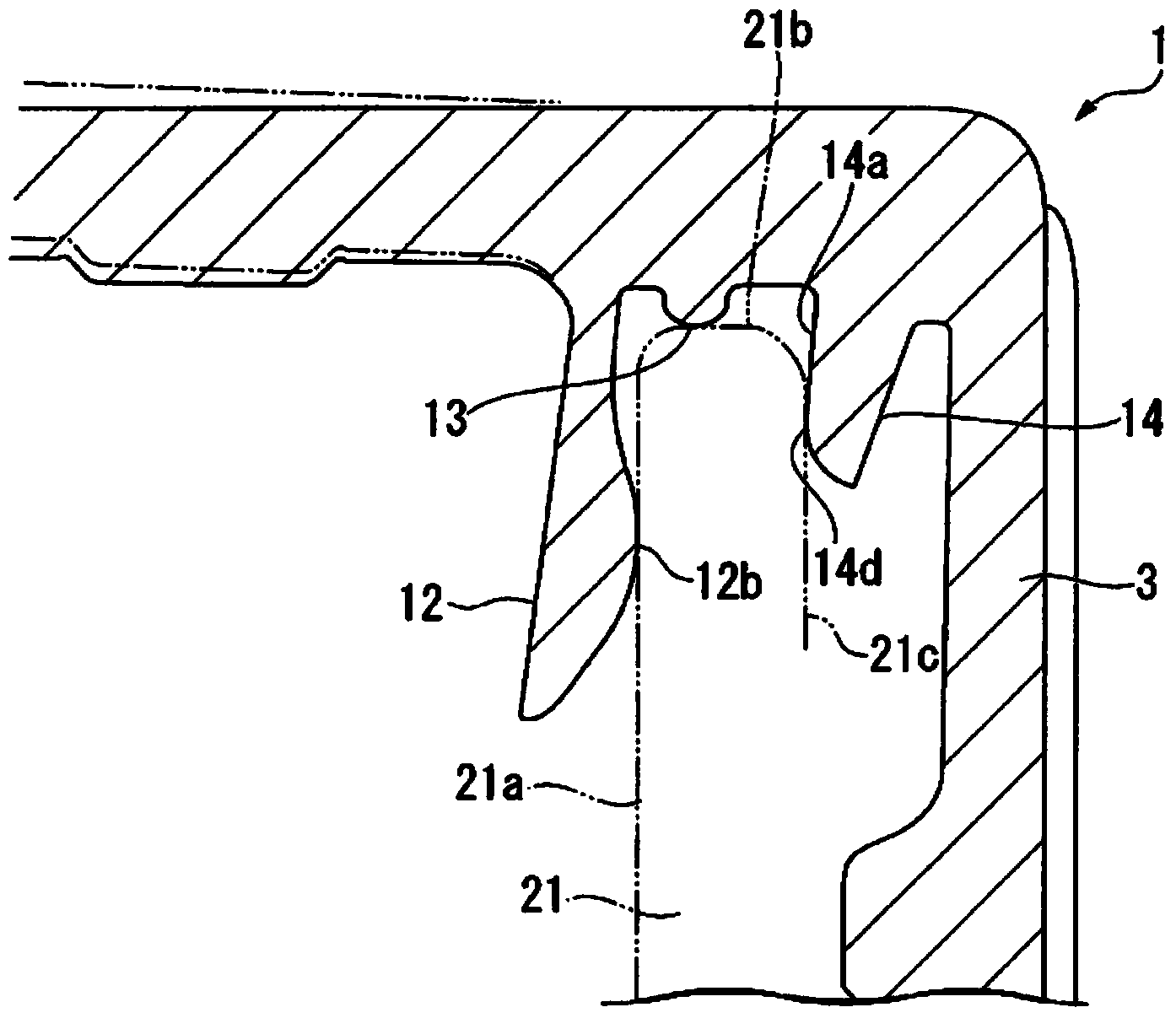

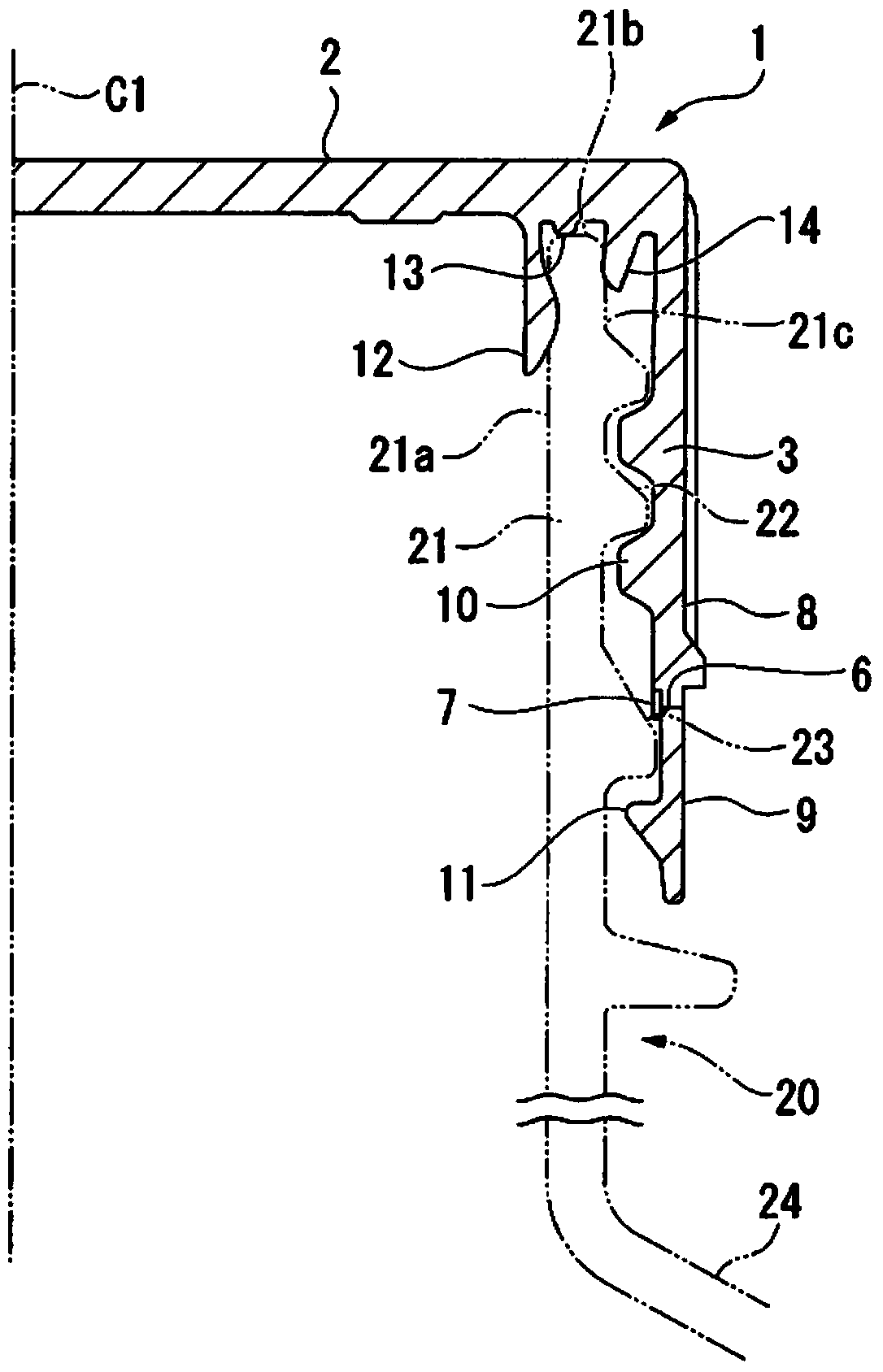

Synthetic resin cap for carbonated beverage-filled container, closure device, and beverage-filled closure device

InactiveCN103987629AAvoid the loss of sealing performancePrevent internal deformationCapsClosure capsEngineeringMechanical engineering

The present invention provides a synthetic resin cap fitted on the mouth section of a container filled with a carbonated beverage. The cap is provided with a top plate and a cylindrical section extending down from the rim thereof. On the inner surface of the top plate, a ring-shaped inner seal projection that is fitted inside the mouth section and an outer seal projection that abuts the outer surface of the mouth section are formed. On the outer surface of the inner seal projection, a ring-shaped contacting protrusion that contacts the inner surface of the mouth section is formed. The outer seal projection has an inner surface, the internal diameter of which decreases towards the leading edge, and the smallest internal diameter section, which is the lower end of the inner surface, contacts the outer surface of the mouth section at a position that is towards the container body side and is at a distance from the open end.

Owner:希赛瓶盖系统日本有限公司

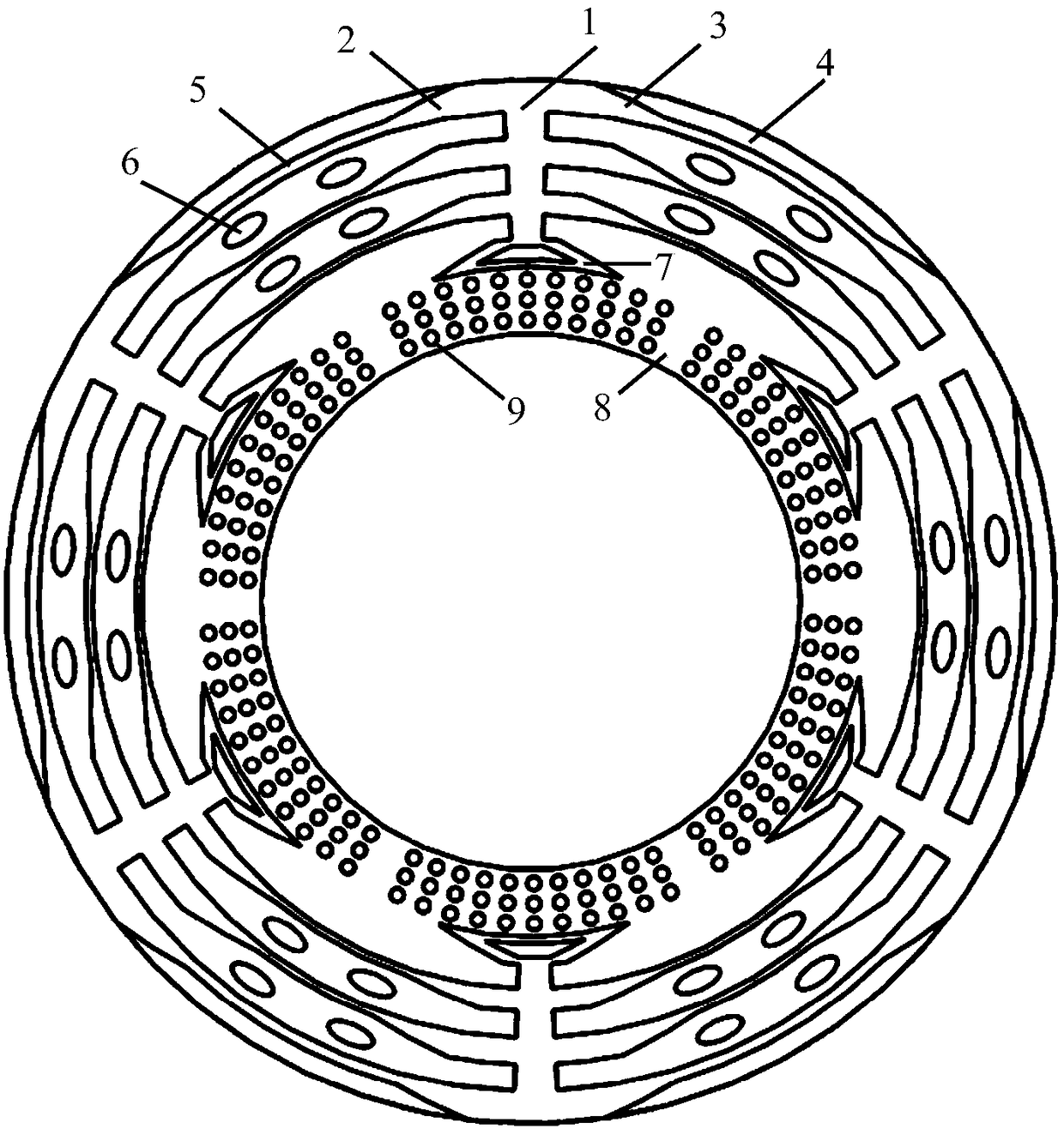

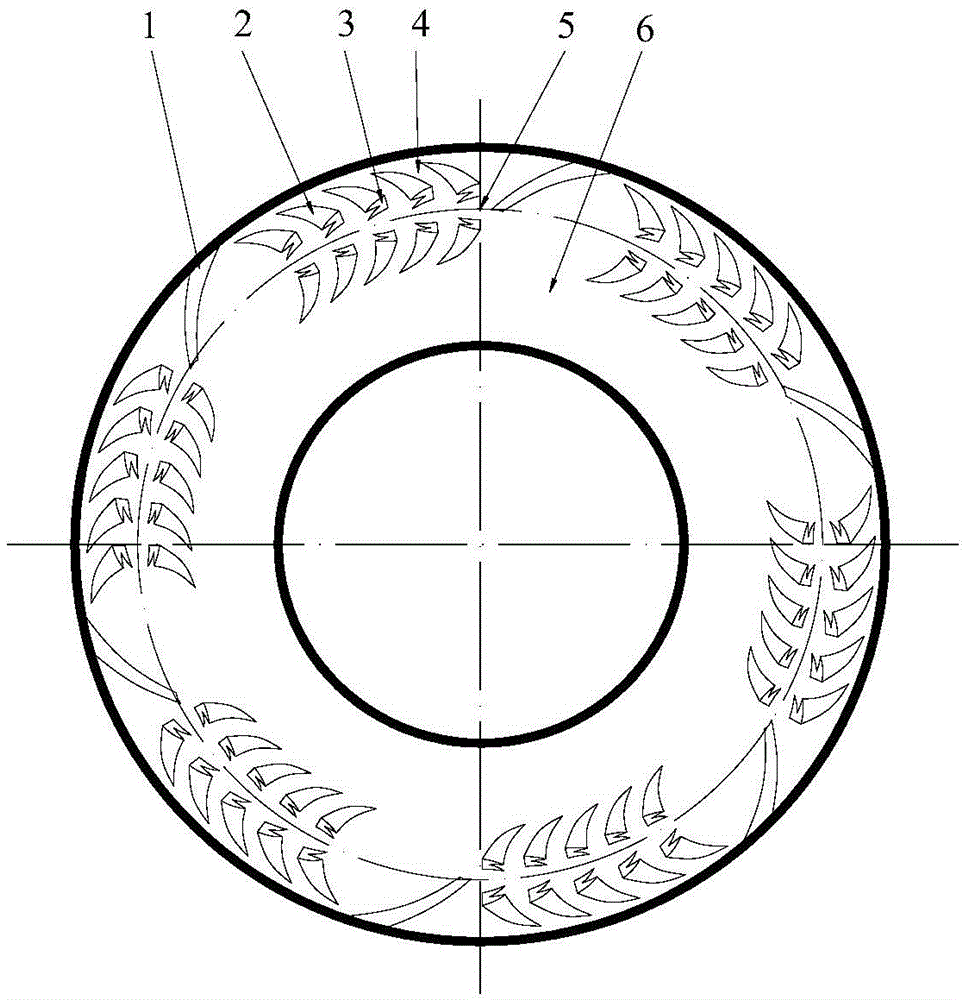

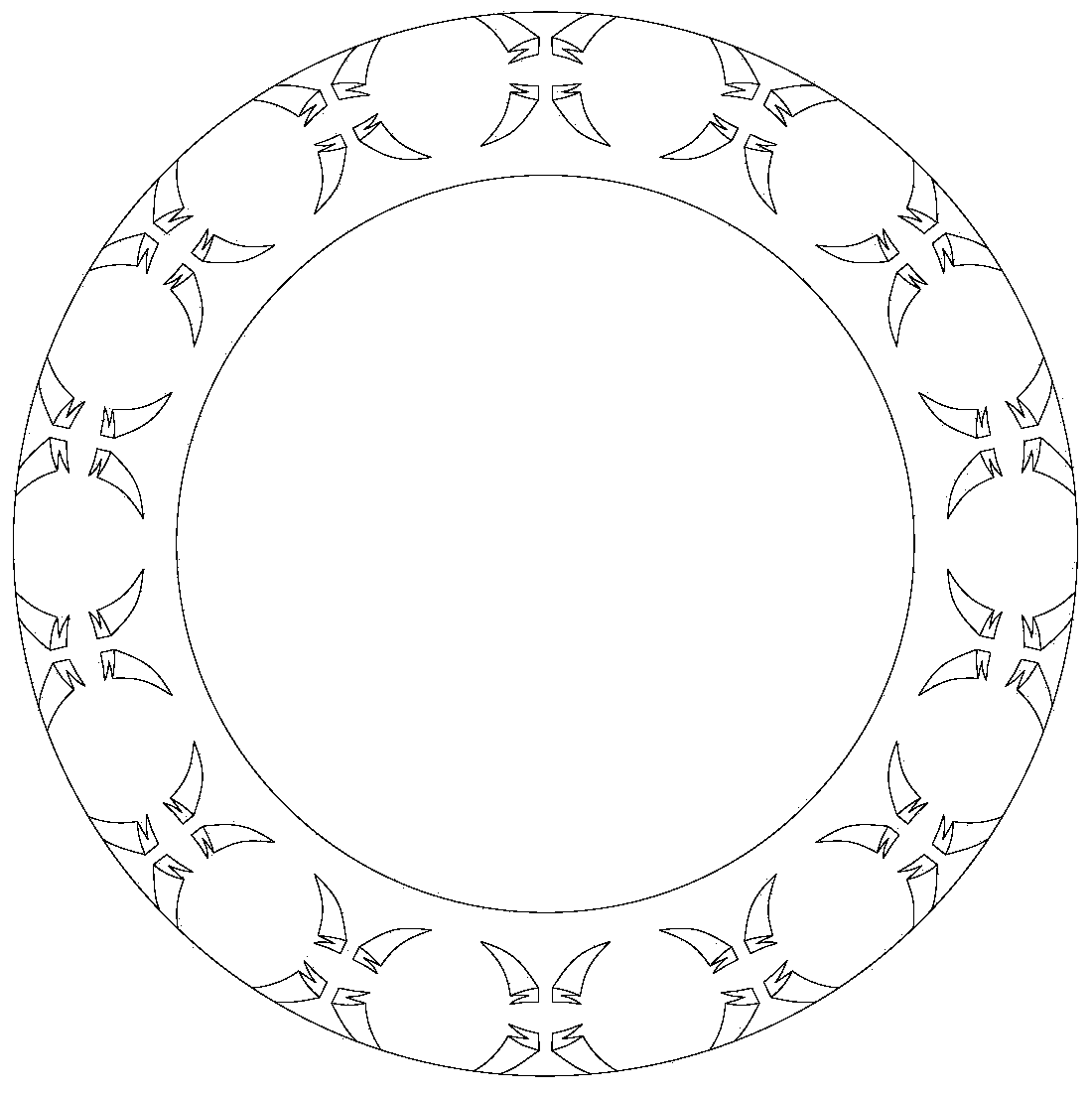

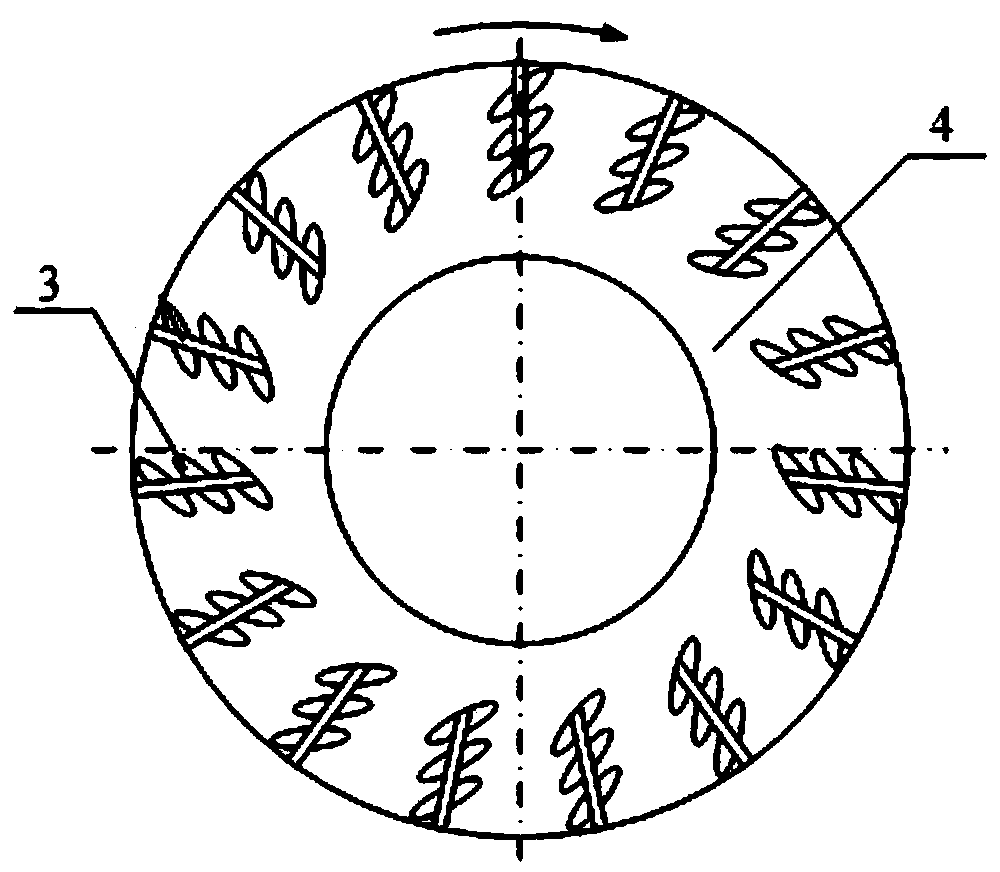

Fishbone simulation type dry gas seal structure

ActiveCN108506494AEnhance the dynamic pressure effectImprove lubrication statusEngine sealsDry gas sealHigh pressure

The invention discloses a fishbone simulation type dry gas seal structure. The fishbone simulation type dry gas seal structure comprises a moving ring and a static ring, wherein a seal inlet is formedin the outer diameter side, namely the high-pressure side, of the moving ring, a seal inlet is formed in the outer diameter side, namely the high-pressure side, of the static ring, a seal outlet is formed in the inner diameter side, namely the low-pressure side, of the moving ring, and a seal outlet is formed in the inner diameter side, namely the low-pressure side, of the static ring. A plurality of fishbone simulation type grooves are evenly distributed on the high-pressure side of at least one end face of the moving ring in the circumferential direction, and a plurality of fishbone simulation type grooves are evenly distributed on the high-pressure side of at least one end face of the static ring in the circumferential direction. A non-hole area between every two adjacent fishbone simulation type grooves in the circumferential direction is a sealing weir 4. Annular sealing dams 8 are arranged below the fishbone simulation type grooves. The fishbone simulation type dry gas seal structure has the remarkable advantages of being high in opening capacity, high in stability, low in leakage quantity, less in sealing end face deformation and capable of carrying out two-way rotation, and the like, and thereby having broad market prospect.

Owner:XI AN JIAOTONG UNIV

PE film for powder packaging, and preparation method thereof

PendingCN112009058AHigh sealing strengthNot easy to break the bagSynthetic resin layered productsDomestic containersLow-density polyethyleneHigh density

The invention discloses a PE film for powder packaging, and belongs to the technical field of PE films. The PE film is prepared from an inner layer, a middle layer and an outer layer through melt co-extrusion. The invention further discloses raw materials of the inner layer, the middle layer and the outer layer, and also provides a preparation method of the PE film. The PE film is high in weldingsealing strength, not prone to bag breaking and material leakage, easy to open, easy to weld and seal, antibacterial and particularly suitable for packaging of various powder materials, and the production cost is reduced; low-density polyethylene, linear low-density polyethylene, metallocene polyethylene and a fluorine-containing polymer in the middle layer are combined, so that the stiffness of the film can be improved, the appearance of the film is flatter, and the strength of the film can also be improved; and the inner layer is used as a solder sealing layer, the strength and solder sealing performance of the film are improved by adding metallocene polyethylene, the strength of the film is also improved by adding high-density polyethylene, the freshness retaining performance of the film is improved by adding an antibacterial agent, the opening performance of the film in use is improved by adding an anti-caking agent, and contents adsorbed by the film due to static electricity are reduced by adding an antistatic agent.

Owner:郑州新生印务有限公司

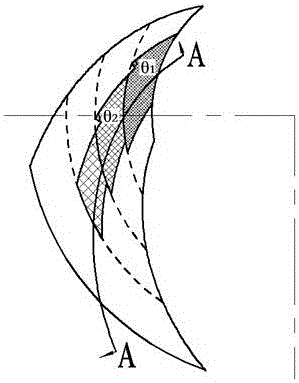

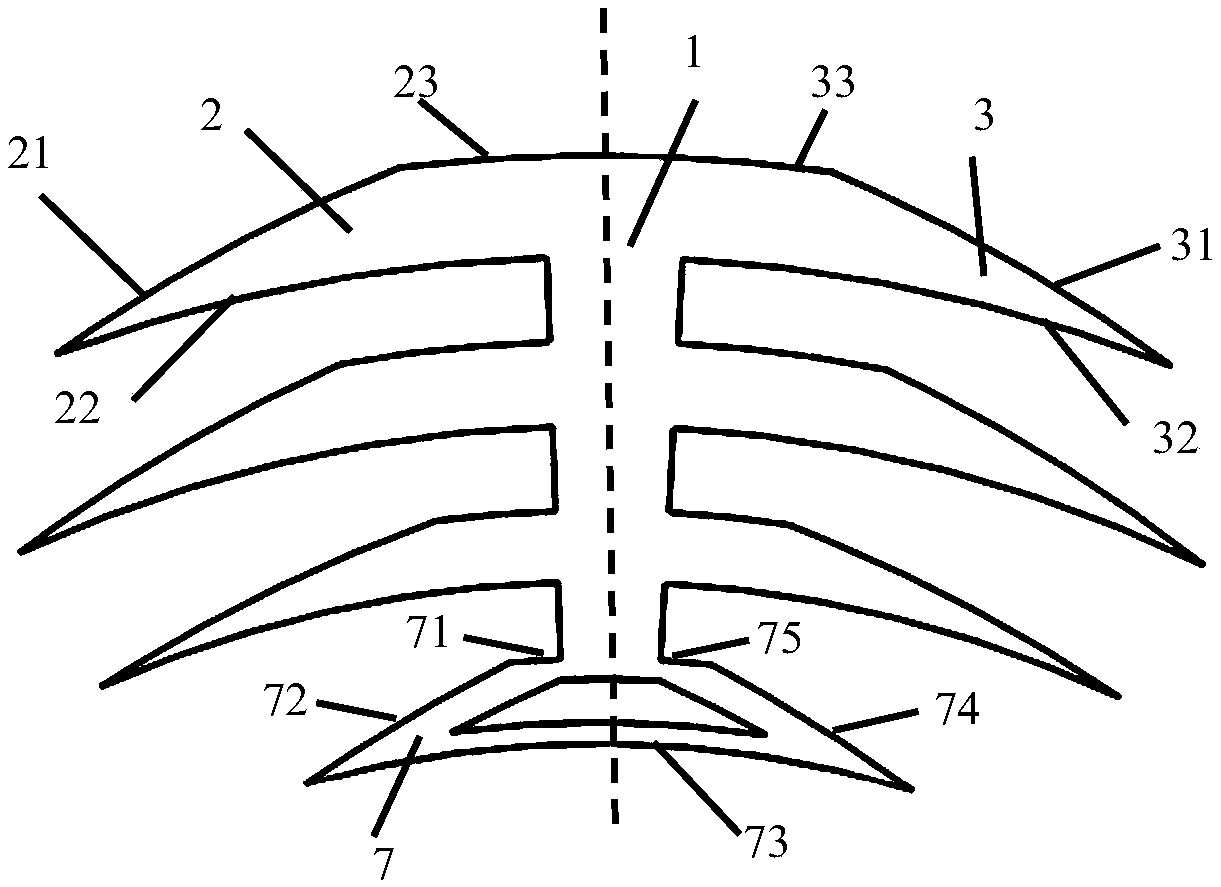

Gas-lubricated bird-wing-shaped groove end face seal structure

ActiveCN104265906BEnhance the dynamic pressure effectGood opening performanceEngine sealsGas lubricationMicrometer scale

A gas lubrication bird-wing-shape-imitation v groove end face sealing structure comprises two sealing rings with sealed end faces; the two sealing rings comprise a movable ring and a static ring; the end face of at least one of the movable ring and the static ring is provided with a plurality of bird-wing-shape-imitation v grooves; each bird-wing-shape-imitation v groove is composed of a tail-feather-shape-imitation v groove body and a flight-feather-shape-imitation v groove body; the tail-feather-shape-imitation v groove bodies are provided with swallow-tail-shaped furcal tails; the flight-feather-shape-imitation v groove bodies are roughly in a bull horn shape with the thick ends and the tail tip ends; the tail-feather-shape-imitation v groove bodies are transversely arranged at the thick ends of the flight-feather-shape-imitation v groove bodies; the thick segments of the flight-feather-shape-imitation v groove bodies and the thick ends of the tail-feather-shape-imitation v groove bodies are toward airflow; the bird-wing-shape-imitation v grooves are arranged to be bird-wing-shape-imitation v groove annular belts; secondary annular sealing dams are arranged between the bird-wing-shape-imitation v groove annular belts; annular main sealing dams are arranged on the low-pressure sides of the end faces; drainage grooves are arranged on the high-pressure sides of the end faces; the drainage grooves and the bird-wing-shape-imitation v grooves are shallow grooves of the micrometer scale; the depths of the flight-feather-shape-imitation v groove bodies are gradually decreased in the airflow direction. The sealing structure has the advantages of being good in stability and long in service life, and resisting abrasion.

Owner:ZHEJIANG UNIV OF TECH

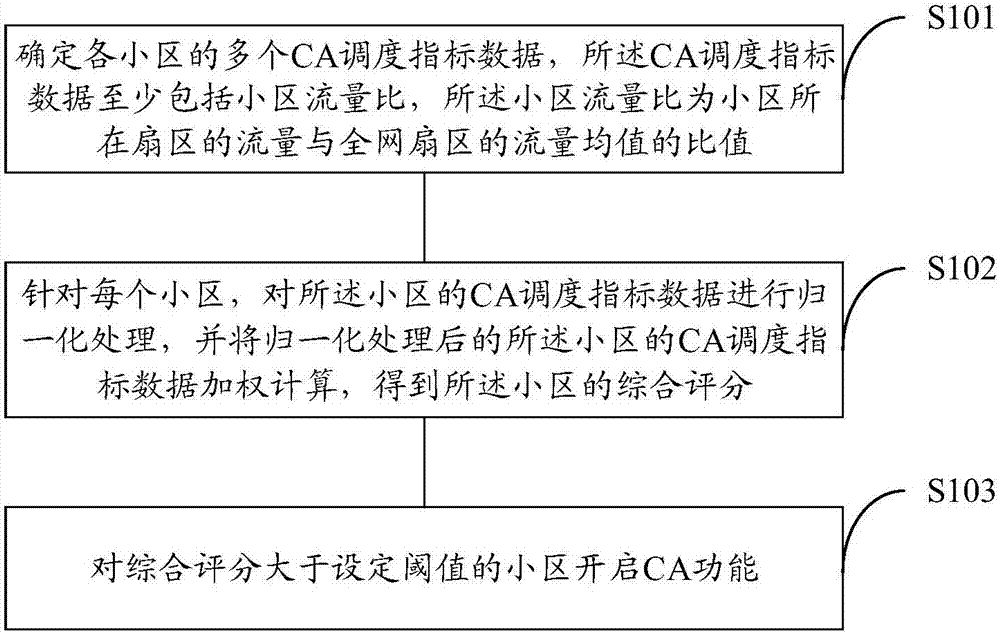

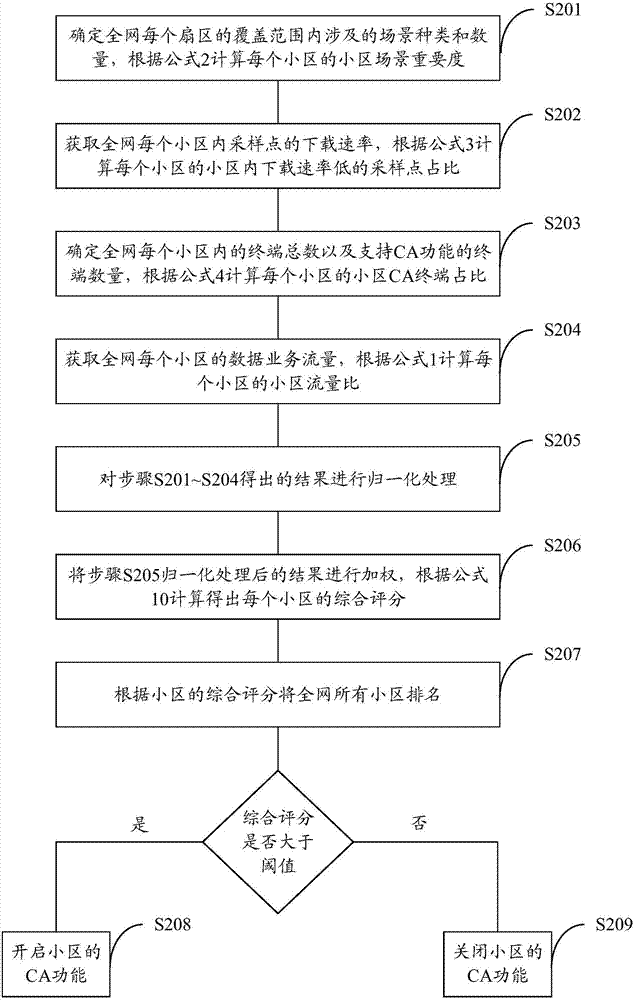

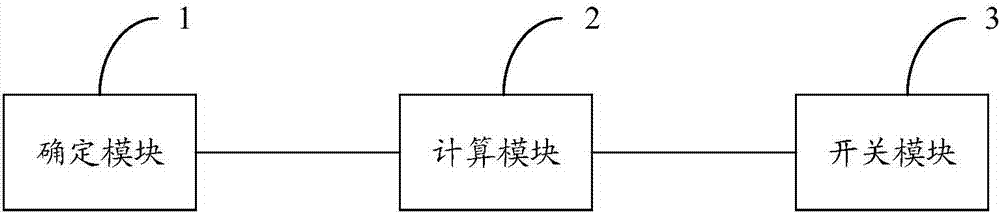

Scheduling method and apparatus for cell carrier aggregation

ActiveCN107294672AGood opening performancePriority allocationPayload allocationWireless communicationCarrier signalCell carrier

The invention, which relates to the technical field of communication, discloses a scheduling method and apparatus for cell carrier aggregation. The method comprises: a plurality of carrier aggregation (CA) scheduling index data of all cells are determined, wherein the CA scheduling index data at least include cell flow ratios that are ratio values of flows of sectors where the cells are located to an average flow value of sectors of the whole network; for each cell, normalization processing is carried out on the CA scheduling index data of the cell and weighted calculation is carried out on the CA scheduling index data after normalization processing to obtain an integrated score of the cell; and CA functions of the cells with the integrated scores larger than a set threshold value are started. Therefore, a problem that the cells for CA function starting are determined only based on flows and thus resources can not be distributed to all cells with large CA needs in priority can be solved.

Owner:CHINA MOBILE GROUP SHAIHAI

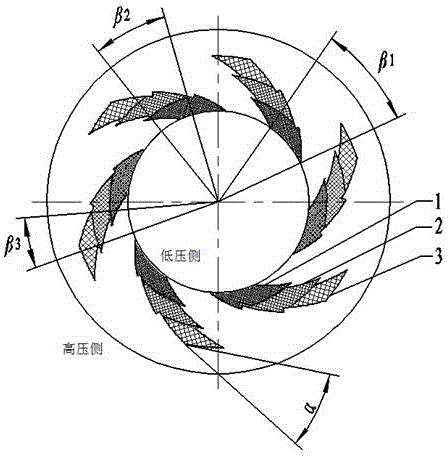

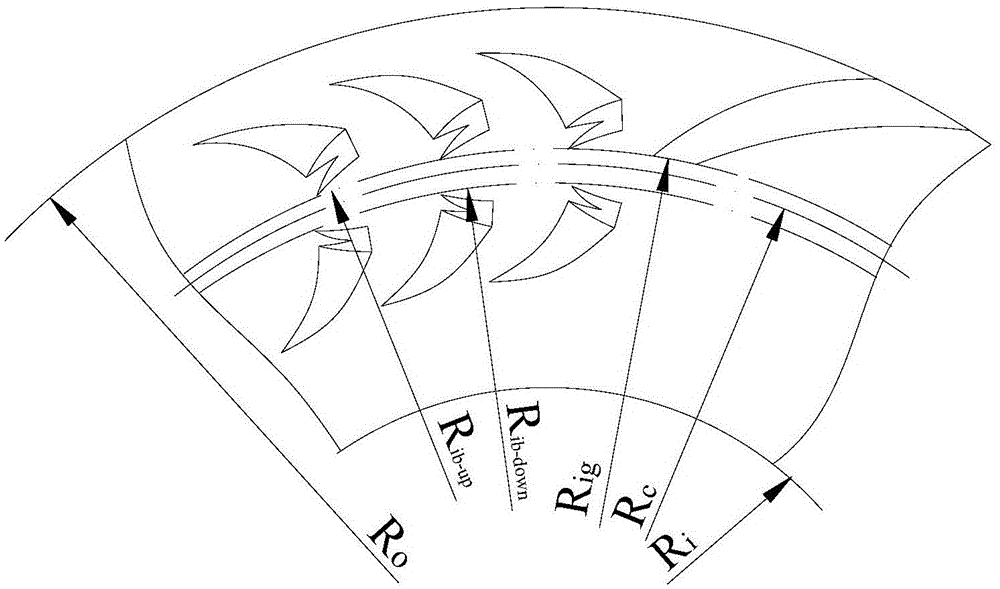

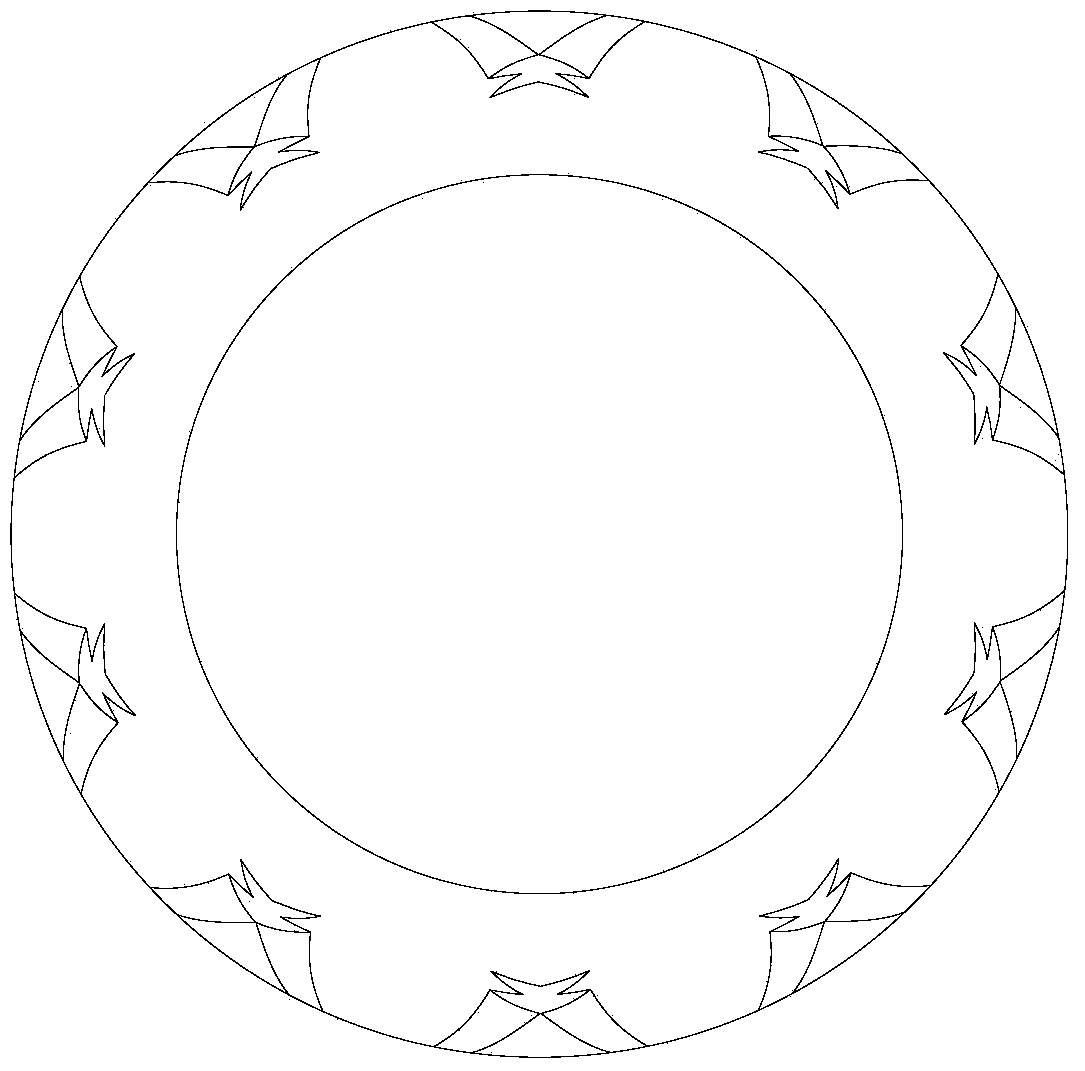

Two-way rotating gas dynamic/static pressure mechanical seal type bird wing-shaped groove structure

ActiveCN104265900AEnhance the dynamic pressure effectStable on and runningEngine sealsMicrometer scaleStructure of the Earth

The invention discloses a two-way rotating gas dynamic / static pressure mechanical seal type bird wing-shaped groove structure. The structure comprises two mechanically sealed sealing rings-a dynamic ring and a static ring. The structure is characterized in that a plurality of bird wing-shaped grooves are formed in the end surface of at least one sealing ring of the dynamic ring and the static ring; the bird wing-shaped grooves are shallow grooves in micrometer scale, and consist of tail feather-shaped grooves and flight feather-shaped grooves; the tail feather-shaped grooves have swallow tail-shaped furcal tails; the flight feather-shaped grooves substantially take the shape of ox horns with thick ends and tail tip ends; the tail feather-shaped grooves are transversely arranged at the thick ends of the flight feather-shaped grooves; every two bird wing-shaped grooves form groove pairs in a splayed shape; multiple groove pairs are evenly arranged peripherally to form a bird wing-shaped groove ring belt; the bird wing-shaped groove ring belt is arranged at the high-pressure side of the end surface; and the depths of the flight feather-shaped grooves are gradually decreased in the airflow direction. The structure has the characteristics of two-way rotation, excellent opening character, good stability, wear resistance and long service life.

Owner:ZHEJIANG UNIV OF TECH

Modified polyketone resin and preparation method thereof, and nylon composite film and preparation method and application thereof

ActiveCN111875947AGood opening performanceImprove wear resistanceSynthetic resin layered productsPhotovoltaic energy generationPolymer sciencePolyketone

The invention belongs to the technical field of nylon films, and particularly relates to modified polyketone resin and a preparation method thereof, a nylon composite film and a preparation method andapplication thereof. The invention provides modified polyketone resin. The modified polyketone resin is prepared from the following raw materials: 96.0 to 99.6 percent of polyketone copolymer, 0.2 to2.0 percent of anti-aging agent and 0.2 to 2.0 percent of rare earth compound. A polyketone copolymer is modified by an anti-aging agent and a rare earth compound, so that the thermal stability of the modified polyketone resin is improved. According to the invention, a nylon composite film is prepared by compounding the modified polyketone resin and the nylon resin, so that the gas barrier property of the nylon composite film is improved, and even the nylon composite film still has relatively high gas barrier property under a relatively high temperature condition; meanwhile, under the combined action of the modified polyketone resin and a waterproof agent, the water absorption performance of the nylon composite film is reduced, and the size stability of the nylon composite film is improved.

Owner:HUNAN UNIV OF TECH

Easy-to-tear packaging composite film and extrusion type liquid packaging bag

InactiveCN111204095AReduce the difficulty of recyclingAchieve recyclabilitySynthetic resin layered productsBagsComposite filmLayer thickness

The invention discloses an easy-to-tear packaging composite film. The easy-to-tear packaging composite film comprises an outer protective layer, a middle barrier layer and an inner heat sealing layer,the thickness of the outer protective layer is 12-30 [mu]m, the thickness of the middle barrier layer is 7-30 [mu]m, and the thickness of the inner heat sealing layer is 30-100 [mu]m; and the outer protective layer, the middle barrier layer and the inner heat sealing layer are compounded by adopting a dry compounding process or an extrusion compounding process. An extrusion-type strip-shaped liquid packaging bag prepared from the easy-to-tear composite film has extrusion weak points, so that contents are convenient to extrude.

Owner:JIANGYIN BAOBO PACKING

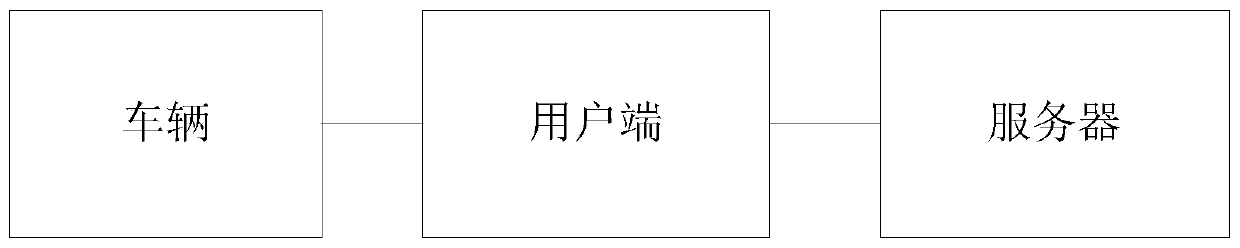

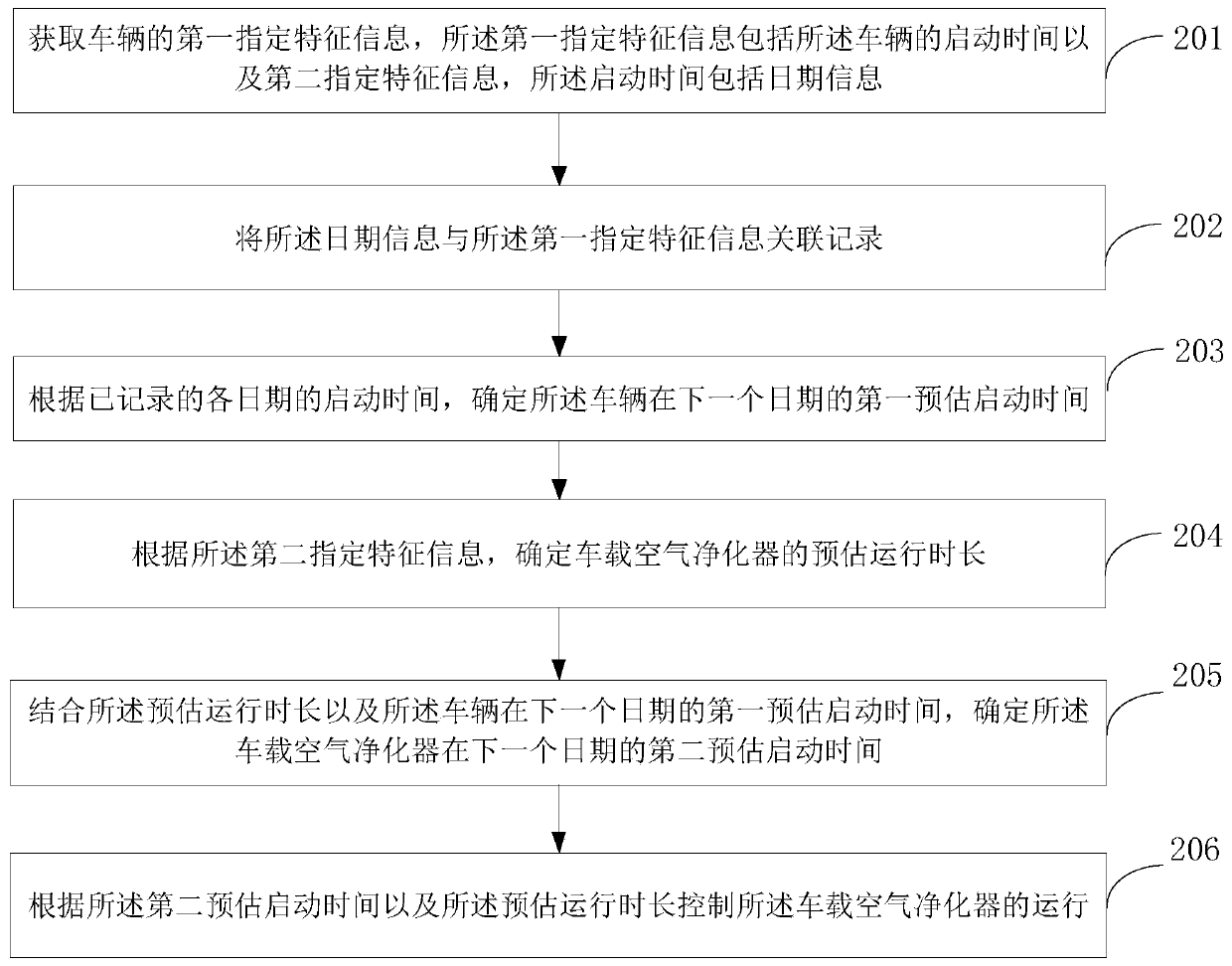

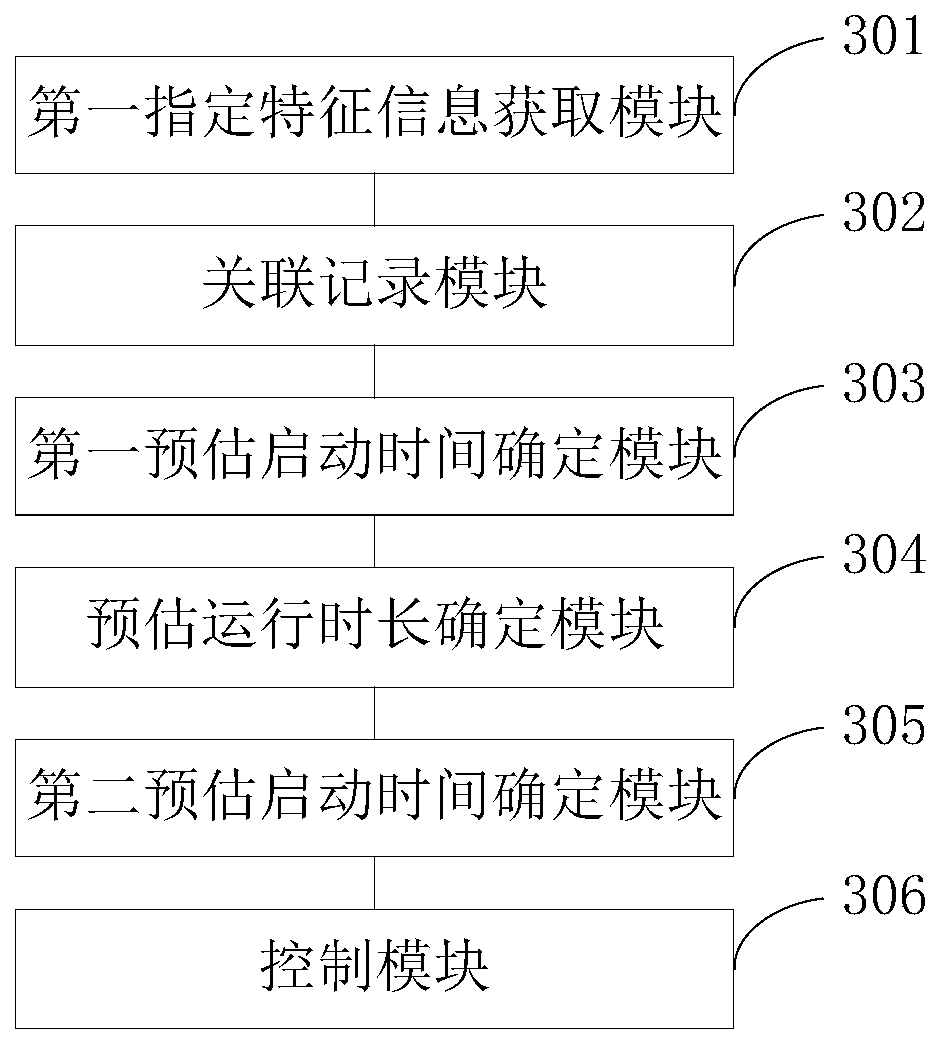

Method and device for controlling starting of vehicle-mounted air purifier

PendingCN111251838AImprove air purification effectGood opening performanceAir-treating devicesVehicle heating/cooling devicesStart timeAir purifiers

The invention relates to a method and device for controlling starting of a vehicle-mounted air purifier, and the method and device are applied to a vehicle. The method comprises the steps of: acquiring first specified feature information reported by the vehicle, wherein the first specified feature information comprises starting time of the vehicle and second specified feature information, and thestarting time comprises date information; associating and recording the date information and the first specified feature information; determining first estimated starting time of the vehicle on a nextdate according to the recorded starting time of each date; according to the second specified feature information, determining an estimated running duration of the vehicle-mounted air purifier; combining the estimated running duration and the first estimated starting time of the vehicle on a next date, determining a second estimated starting time of the vehicle-mounted air purifier on the next date, and controlling the operation of the air purifier according to the second estimated starting time and the estimated running n duration, thus being conducive to improving the starting effect of theair purifier.

Owner:广东中鑫智能网络科技有限公司

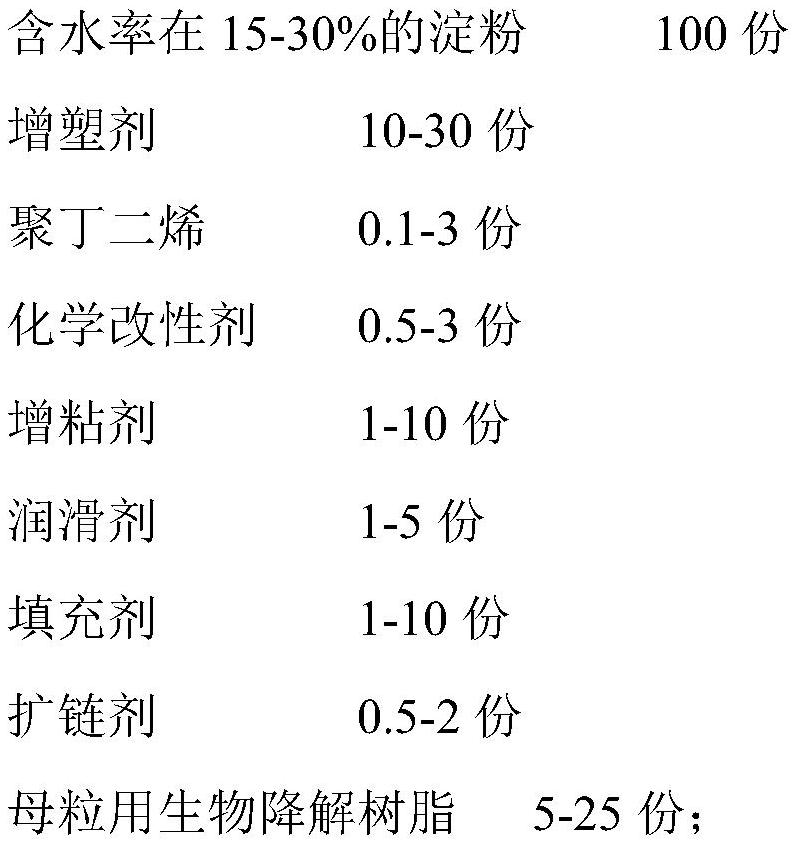

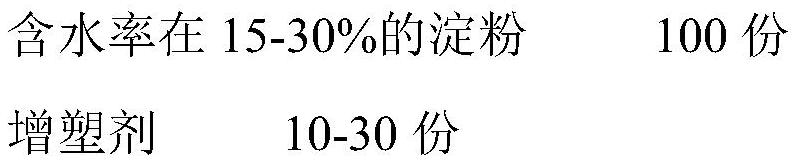

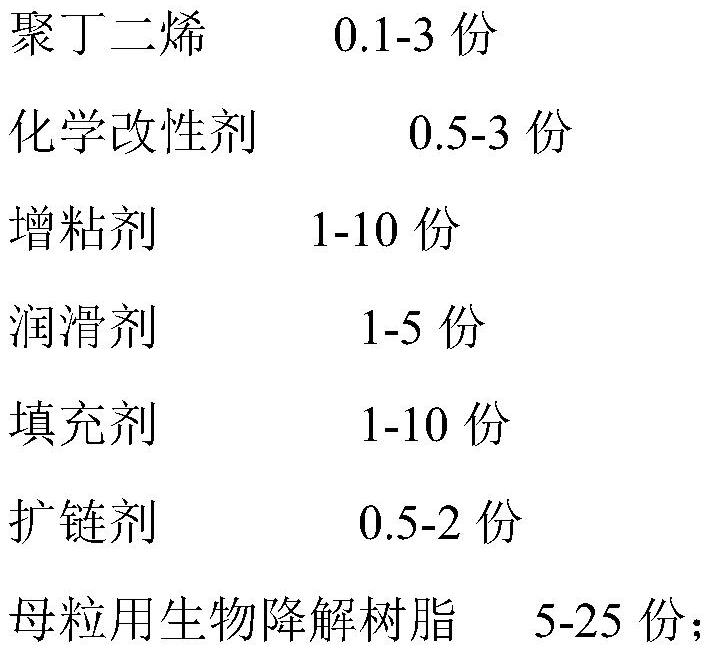

Multi-stage modified thermoplastic starch master batch and application thereof in preparation of starch-based biodegradable film

The invention discloses multi-stage modified thermoplastic starch master batch. According to the invention, starch is subjected to four-stage graded modification treatment. The graded modification treatment comprises the following steps: weighing 100 parts of starch with a water content of 15-30%, and stirring the starch in a high-speed mixer for the first time at a room temperature at a high speed; carrying out heating to 50-70 DEG C, adding polybutadiene, a plasticizer and a chemical modifier, and carrying out high-speed stirring for the second time; carrying out heating to 75-95 DEG C, adding a tackifier, a lubricant, a filler and a chain extender, and carrying out stirring at a high speed for the third time; adding biodegradable resin at the temperature, and carrying out stirring at a high speed for the fourth time; and stopping stirring, keeping the temperature for a period of time, and then adding a formed mixture into a double-screw extruder for melt extrusion. The invention also discloses a preparation method and application of the multi-stage modified thermoplastic starch master batch. The thermoplastic starch master batch disclosed by the invention can effectively improve the compatibility of starch and other biodegradable materials; and meanwhile, the content of starch in a biodegradable film is improved, and relatively good mechanical properties, film surface smoothness and certain transparency are kept.

Owner:NANJING WURUI BIODEGRADABLE NEW MATERIAL RES INST CO LTD

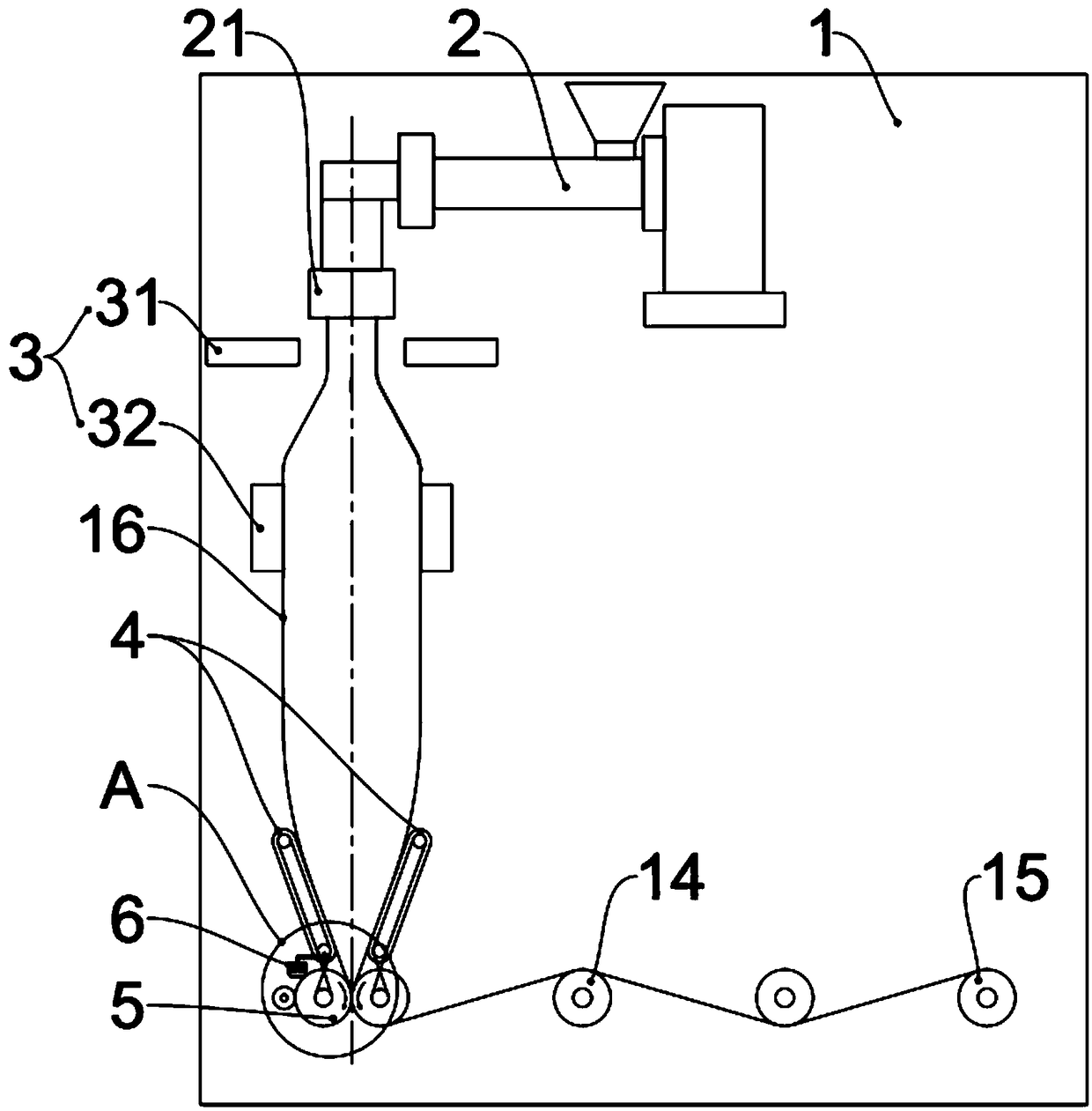

Blow molding processing method of CPP film

The invention relates to the field of high polymer materials, in particular to a blow molding processing method of a CPP film. The blow molding processing method of the CPP film comprises the following steps that 1, a thin-wall tube is extruded, specifically, PP raw materials are added to a barrel of an extruder, the materials are rotated, extruded, stirred and pushed by a screw, and finally the materials are extruded into the thin-wall tube by a right-angle machine head, wherein the screw compression ratio is 2.8-4.0, extrusion temperature of the right angle machine head is 200-215 DEG C; 2,the thin-walled tube is blown into a thin-film tube, specifically, compressed air blows the thin-walled tube into the thin-film tube; 3, the thin-film tube is cooled and shaped, specifically, the thin-film tube is cooled by air cooling first and then water cooling; (4) the film-tube clamp is flattened, specifically, the thin-film tube is flattened through two rotating belt wires in an inverted V shape; and 5, the thin-film tube is pulled and winded, specifically, the flattened thin-film tube is compressed by a pulling roller and then enters a winding device by a guiding roller. The blow molding processing method of the CPP film is used for solving the problems in the prior art that the thin-film tube is unstable in traction and prone to being broken in the process of CPP film blow moldingprocessing.

Owner:CHONGQING RUITING PLASTIC

Dedicated material for full-biodegradation mulching film special for peanuts and preparation method thereof

The invention discloses a dedicated material for a full-biodegradation mulching film special for peanuts. The dedicated material is characterized by being prepared from the following ingredients in parts by weight: 100 parts of PLA, 70 to 90 parts of PBAT, 0.5 to 1.0 part of nucleating agent, 5 to 10 parts of compound anti-hydrolysis agent, 0.5 to 1.5 parts of compound anti-ultraviolet agent, 3 to6 parts of molecular weight modifier and 20 to 30 parts of flexibility modifier. The mulching film prepared from the dedicated material disclosed by the invention has the advantages of excellent anti-hydrolysis performance, excellent light aging resistance, good flexibility performance, good mulching film anti-blocking property (saving mulching film laying time) and high light transmittance. Under the composting condition, the dedicated material can be completely and biologically degraded into carbon dioxide and water; thus, pollution to soil and environment is avoided, and the dedicated material is suitable for being utilized as peanut mulching films.

Owner:山东天野生物降解新材料科技有限公司

PE blown film for liquid packaging and preparation method thereof

ActiveCN114015143AHigh tensile strengthIncreased dart impact strengthSynthetic resin layered productsLinear low-density polyethyleneLow-density polyethylene

The invention discloses a PE blown film for liquid packaging. The PE blown film is mainly prepared from the following raw materials in parts by weight: 50-80 parts of metallocene polyethylene, 10-25 parts of linear low-density polyethylene and 10-25 parts of low-density polyethylene. The density of the metallocene polyethylene is 0.900-0.918 g / cm < 3 >, the density of the linear low-density polyethylene is 0.915-0.921 g / cm < 3 >, and the density of the low-density polyethylene is 0.920-0.925 g / cm < 3 >. According to the PE blown film for liquid packaging provided by the invention, the metallocene polyethylene, the linear low-density polyethylene and the low-density polyethylene are mixed in proportion, so that the advantages of the metallocene polyethylene, the linear low-density polyethylene and the low-density polyethylene can be integrated, the rigidity and the toughness of the PE blown film are improved, and the stress strength and the rubbing performance of the PE blown film can be ensured even in a long-distance liquid transportation process; and meanwhile, through a multi-layer co-extrusion blow molding processing mode, the PE blow molding film has good tensile strength, right-angle tear strength, falling dart impact strength, heat sealing strength and rubbing performance, and the comprehensive performance of the film is improved.

Owner:QINGDAO HENGXIN PLASTIC RUBBER CO LTD

Polyolefin complete transparent master batch and preparation thereof

InactiveCN100592979CGood value for moneyLow costLinear low-density polyethyleneLow-density polyethylene

The invention discloses a polyolefine full transparent master batch and a preparation method thereof; wherein, the weight percentage of the components of the polyolefine full transparent master batchis as follows: 70 to 80 percent of glauber salt, 4 to 15 percent of linear low density polyethylene, 4 to 10 percent of ethylene vinyl acetate copolymer, 2 to 3 percent of polyethylene wax, 1 to 2 percent of soap salt, 0.5 to 1 percent of fatty acid and 1 to 2 percent of a coupling agent. The preparation method of the master batch of the invention includes the following steps: after being added into a highly mixing machine, stirred with high speed and heated to 110 DEG C, the glauber salt is added with the coupling agent for three times for coating; then the polyethylene wax, soap salt and thefatty acid are sequentially added; then the linear low density polyethylene and the ethylene vinyl acetate copolymer are added, mixed uniformly and discharged; the components are transferred into a crusher to be cooled and crushed; finally, the premixed materials are extruded into granular master batches in a co-rotating twin screw extruder with the length-diameter ratio of 36 to 48. The polyolefine full transparent master batch has lower density, good dispersion, opening property and color, excellent optical property and very high economy and is widely used in blow-molded, extrusion and injection-molded products.

Owner:山东中艺橡塑有限公司

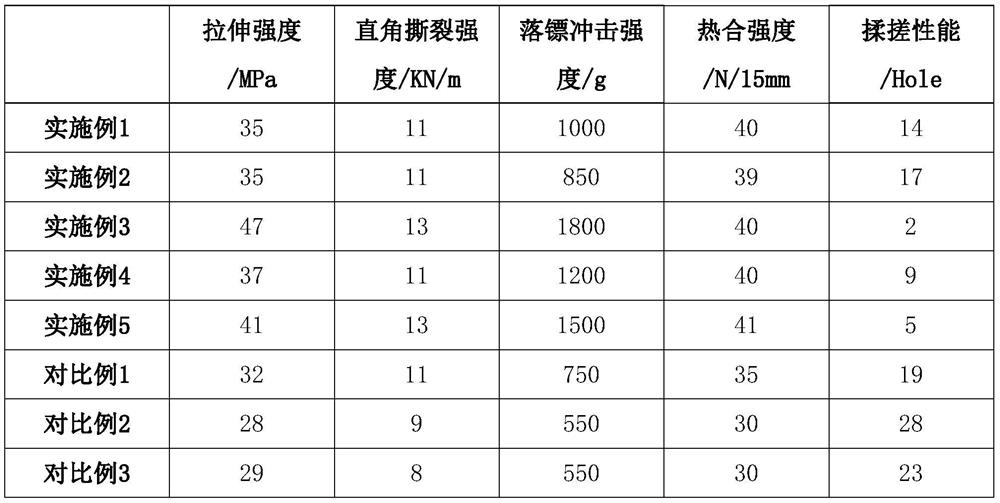

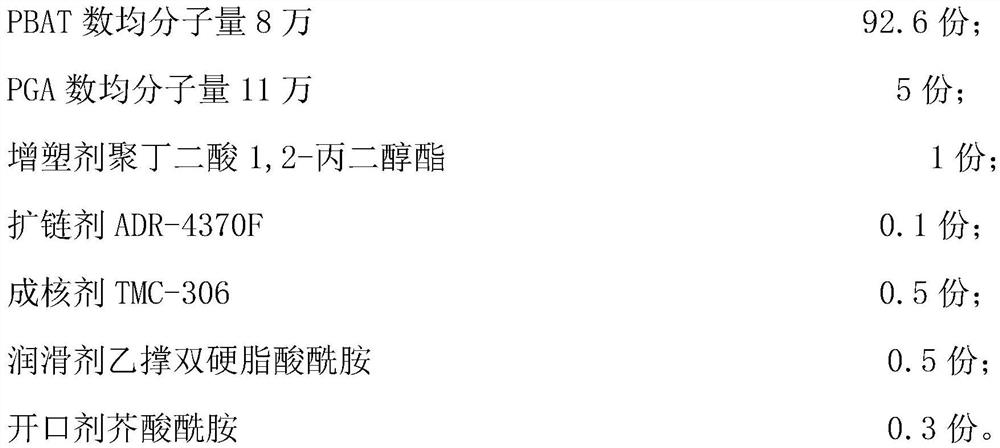

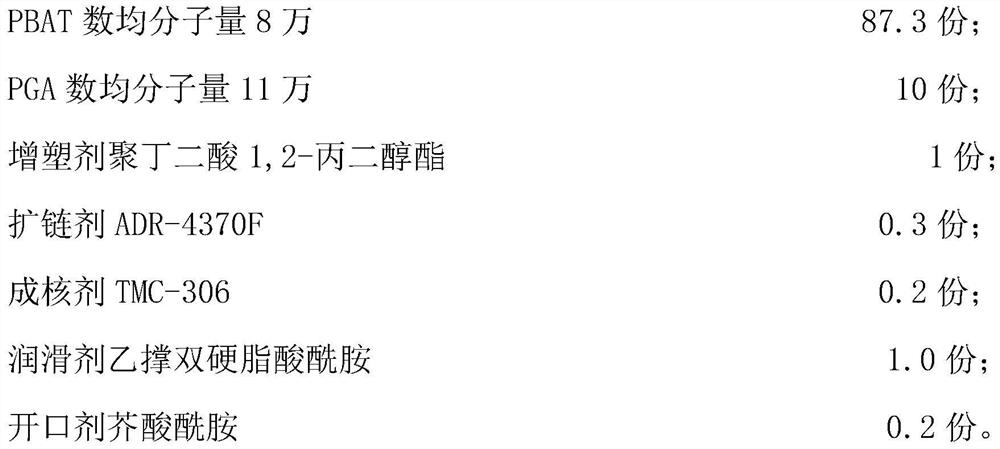

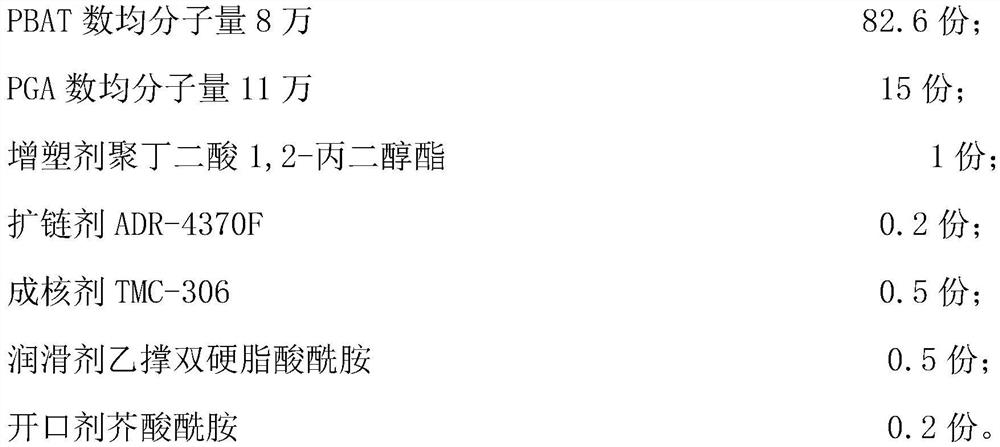

Completely biodegradable film and preparation method thereof

PendingCN113956630AImprove biodegradabilityIncreased tensile elongation at break and tear strengthPlasticizerStearic acid

The invention discloses a completely biodegradable film and a preparation method thereof. The completely biodegradable film is prepared from poly(butylene adipate-co-terephthalate), polyglycolic acid, a chain extender styrene-acrylic acid-glycidyl methacrylate copolymer, a plasticizer poly(succinic acid-1, 2, 4-trimethyl-1, 3-pentanedionate), a plasticizer poly (butylene adipate-co-butylene terephthalate), a plasticizer polysuccinic acid-1, 2-propylene glycol ester, a nucleating agent, a lubricant ethylene bisstearamide and an anti-blocking agent erucyl amide. The preparation method comprises the following steps: weighing the components according to the formula, mechanically mixing to form a premix, metering and adding the plasticizer polysuccinic acid-1, 2-propylene glycol ester from a liquid feeding port of a twin-screw extruder, carrying out melt extrusion, water cooling, pelletizing and drying to obtain special resin for film blowing, and carrying out blow molding film forming through a film blowing machine to obtain the completely biodegradable film. The chain extender, the nucleating agent and the plasticizer can effectively improve the tensile elongation at break and tear strength of the film and obviously improve the rheological behavior of the material, and the film has good mechanical properties and excellent biodegradability and can replace PE, PP, PVC and the like to prepare films and sheets.

Owner:江苏碧升生物新材料有限公司 +1

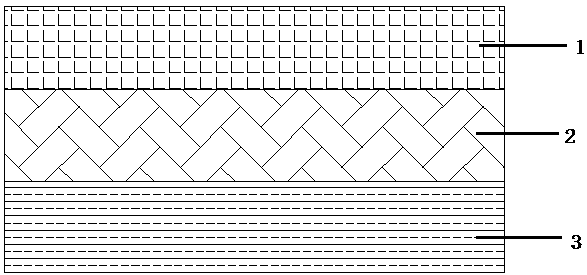

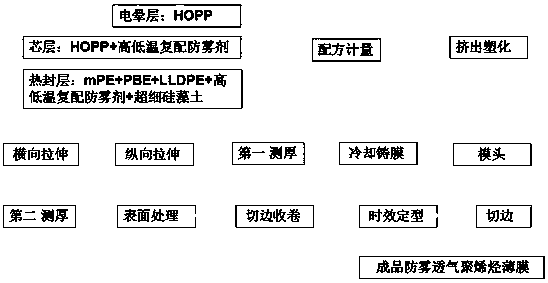

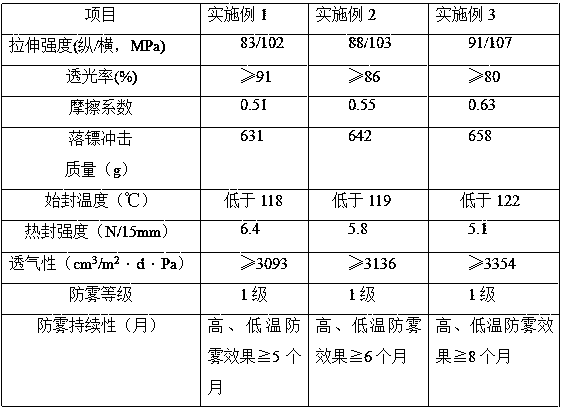

High-low-temperature anti-fog gas-permeable polyolefin heat-sealing film for fruit and vegetable packaging, and preparation method thereof

InactiveCN111300940AReduce precipitationProlong the action timeFlexible coversWrappersPolymer sciencePolyolefin

The invention discloses a high-and-low-temperature anti-fog gas-permeable polyolefin heat-sealing film for fruit and vegetable packaging. The high-and-low-temperature anti-fog gas-permeable polyolefinheat-sealing film comprises a corona layer, a core layer and a heat-sealing layer from top to bottom, wherein a layer ratio structure of three-layer co-extrusion is as follows: the layer ratio structure corona layer / core layer / heat-sealing layer of three-layer co-extrusion is HOPP / (HOPP and high-and-low temperature antifogging agent) / (mPE and LLDPE and PBS and high-and-low temperature antifoggingagent and superfine diatomite). According to the invention, a certain proportion of a high-and-low-temperature compound antifogging agent is added into a heat-sealing layer and a core layer, so thatthe film has high temperature and low temperature antifogging performance at the same time; superfine diatomite is added into the heat-sealing layer, so that the precipitation of the antifogging agentis delayed and the antifogging time of the film is prolonged by using the adsorption function of the superfine diatomite, and the granularity of diatomite can increase the gas permeability and the opening property of the film and increase the strength of the film so as to solve the problem of film strength reducing caused by addition of the antifogging agent and prepare the polyolefin heat-seal film being transparent, high in heat-seal strength and good in antifogging effect.

Owner:FUQING BRANCH OF FUJIAN NORMAL UNIV +1

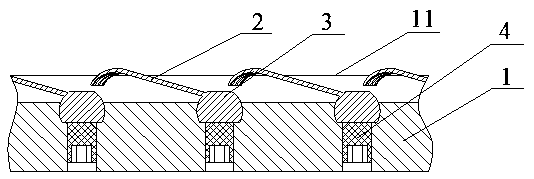

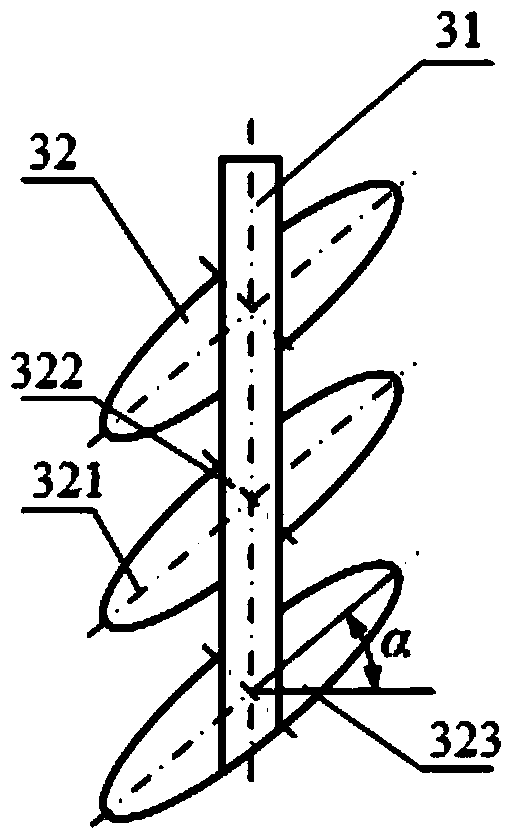

Micro-hole end face mechanical seal structure with air inlet grooves

A micro-hole end face mechanical seal structure with air inlet grooves comprises two end faces for mechanical sealing, namely a moving ring and a stationary ring, wherein one end face is sequentially provided with micro-hole groups and annular sealing dams which are symmetrically distributed relative to the rotation center from the high-pressure side to the low-pressure side. Multiple rows of micro-hole groups are distributed on the high-pressure side of the end face and comprise the linear air inlet grooves and multiple elliptic micro-holes, the centers of the micro-holes are located on the air inlet grooves, included angles formed by long shafts of the micro-holes and the air inlet grooves are identical, and one end of each micro-hole facing air flows is located on the high-pressure side of the end face. A straight line where the air inlet grooves are located is located on the radius of the end face. The low-pressure side of the end face is provided with the annular sealing dams with smooth faces. The micro-hole end face mechanical seal structure has the advantages that the opening performance under the high-pressure frequent start-stop condition is improved; the problem of poor hydrodynamic effect of the end faces caused by the air negative pressure effect is solved; the solid particle preventing capacity and the advantages of the micro-holes are fully played; the hydrodynamic effect and the disturbance-resisting performance are enhanced, the service life is prolonged, and the stability of the end faces is improved.

Owner:ZHEJIANG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com