PE film for powder packaging, and preparation method thereof

A packaging and film technology, applied in the field of PE film, can solve the problems of retained welding sealing parts, affecting the welding sealing effect, low welding sealing strength, etc., achieving the effect of high welding sealing strength, flat appearance and improving welding sealing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

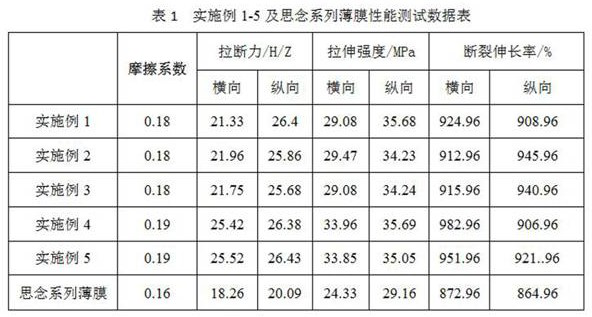

Examples

Embodiment 1

[0027] A PE film for powder packaging, which is made by melting and co-extruding an inner layer, a middle layer, and an outer layer, and the inner layer is composed of the following raw materials in parts by weight: 40 parts of metallocene polyethylene, 35 parts of low-density polyethylene, high 20 parts of density polyethylene, 1.0 parts of anticaking agent masterbatch (silicon dioxide masterbatch), 3.0 parts of antistatic agent masterbatch (monoglyceride), 1.0 parts of erucamide, antibacterial agent (PE antibacterial agent sold by Kepuyin KP-J151) 1.0 copies;

[0028] The middle layer is composed of the following raw materials in parts by weight: 25 parts of low-density polyethylene, 25 parts of linear low-density polyethylene, 49.5 parts of metallocene polyethylene, and 0.5 parts of fluoropolymer (PPA);

[0029] The outer layer is composed of the following raw materials in parts by weight: 33 parts of low-density polyethylene, 33 parts of linear low-density polyethylene, 31...

Embodiment 2

[0038] A PE film for powder packaging, which is made by melting and co-extruding an inner layer, a middle layer, and an outer layer, and the inner layer is composed of the following raw materials in parts by weight: 39 parts of metallocene polyethylene, 37 parts of low-density polyethylene, high 18 parts of density polyethylene, 1.2 parts of anticaking agent masterbatch (silicon dioxide masterbatch), 3.1 parts of antistatic agent masterbatch (monoglyceride), 0.9 parts of erucamide, antibacterial agent (PE antibacterial agent sold by Kepuyin KP-J151) 0.8 parts;

[0039] The middle layer is composed of the following raw materials in parts by weight: 24 parts of low-density polyethylene, 24 parts of linear low-density polyethylene, 50.4 parts of metallocene polyethylene, and 0.6 parts of fluoropolymer (PPA);

[0040] The outer layer is composed of the following raw materials in parts by weight: 35 parts of low-density polyethylene, 32 parts of linear low-density polyethylene, 31....

Embodiment 3

[0049] A PE film for powder packaging, which is made by melting and co-extruding an inner layer, a middle layer, and an outer layer, and the inner layer is composed of the following raw materials in parts by weight: 40 parts of metallocene polyethylene, 34 parts of low-density polyethylene, high 21 parts of density polyethylene, 1.1 parts of anti-caking agent masterbatch (silica masterbatch), 2.8 parts of antistatic agent masterbatch (monoglyceride), 0.8 parts of erucamide, antibacterial agent (PE antibacterial agent sold by Kepuyin) KP-J151) 1.0 copies;

[0050]The middle layer is composed of the following raw materials in parts by weight: 26 parts of low-density polyethylene, 27 parts of linear low-density polyethylene, 46.6 parts of metallocene polyethylene, and 0.4 parts of fluoropolymer (PPA);

[0051] The outer layer is composed of the following raw materials in parts by weight: 33 parts of low-density polyethylene, 35 parts of linear low-density polyethylene, 30.4 parts...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com