Method for recycling magnesium alloy scraps

A technology for magnesium alloys and crushed materials, which is applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of structural performance discount of magnesium alloy materials, difficult to remove impurities in secondary casting, and limited application fields, etc. Cost-effective, high blocking strength, stable blocking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] The present invention comprises the following steps:

[0016] Step 1. Collect magnesium alloy scraps with magnesium content ≥ 85%. These magnesium alloy scraps mainly come from scraps produced in magnesium alloy processing, including but not limited to blocky scraps, flake scraps, and fibrous scraps and particulate waste;

[0017] Step 2. The magnesium alloy waste collected above is crushed by a metal pulverizer, and it is required to be crushed into pellets and flakes with a particle size ranging from 1 to 100 mesh;

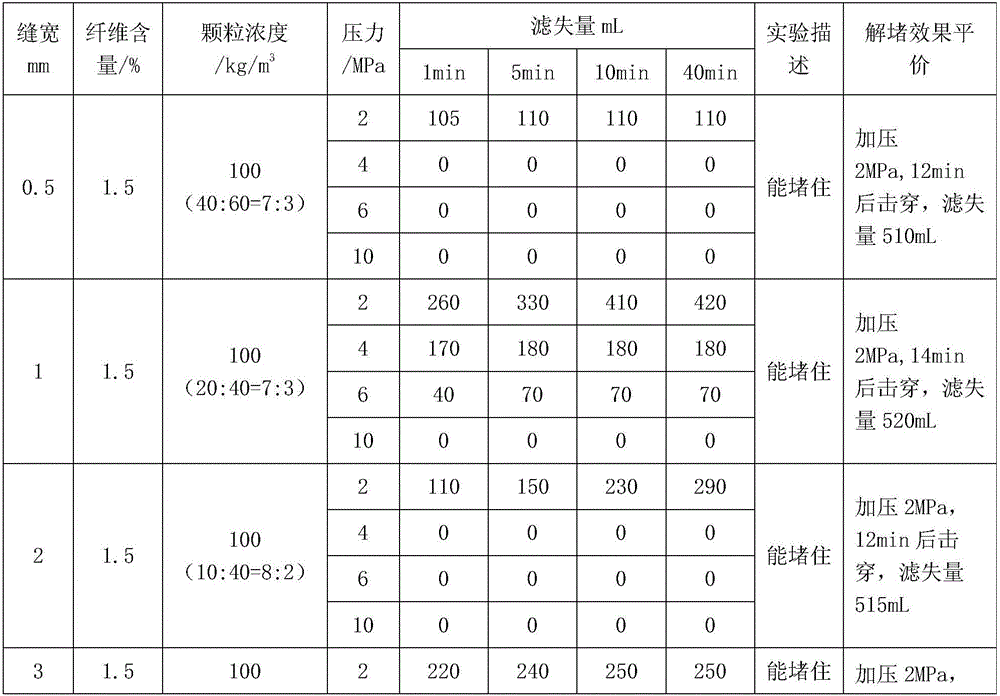

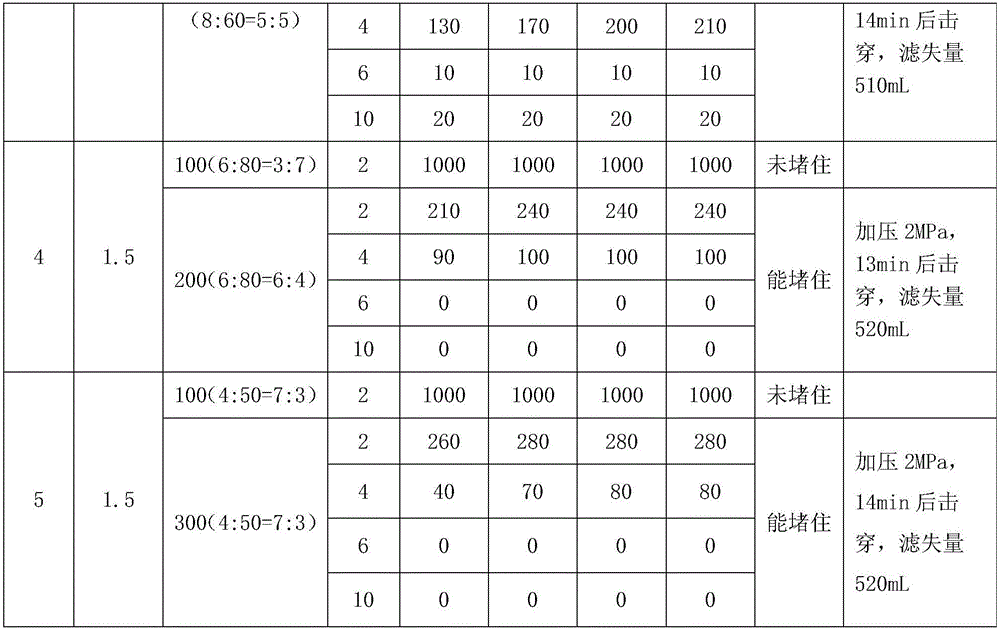

[0018] Step 3. Use a vibrating sieve machine to screen the crushed fragments, wherein 70g of large mesh fragments with a particle size of 40 mesh (about 0.43mm) are selected, and small mesh particles with a particle diameter of 60 mesh (about 0.25mm) are selected. Crushing material 30g, they are mixed together, and in this mixed crushing material, the mass ratio of large mesh crushed material and small mesh crushed material is 7:3;

[0019] Step 4. in t...

Embodiment 2

[0026] The present invention comprises the following steps:

[0027] Step 1. Collect magnesium alloy scraps with magnesium content ≥ 85%. These magnesium alloy scraps mainly come from scraps produced in magnesium alloy processing, including but not limited to blocky scraps, flake scraps, and fibrous scraps and particulate waste;

[0028] Step 2. The magnesium alloy waste collected above is crushed by a metal pulverizer, and it is required to be crushed into pellets and flakes with a particle size ranging from 1 to 100 mesh;

[0029] Step 3. Use a vibrating sieve machine to screen the crushed fragments, wherein 70g of large mesh fragments with a particle size of 20 mesh (about 0.85mm) are selected, and small mesh particles with a particle diameter of 40 mesh (about 0.43mm) are selected. Crushing material 30g, they are mixed together, and in this mixed crushing material, the mass ratio of large mesh crushed material and small mesh crushed material is 7:3;

[0030] Step 4. in t...

Embodiment 3

[0034] The present invention comprises the following steps:

[0035] Step 1. Collect magnesium alloy scraps with magnesium content ≥ 85%. These magnesium alloy scraps mainly come from scraps produced in magnesium alloy processing, including but not limited to blocky scraps, flake scraps, and fibrous scraps and particulate waste;

[0036] Step 2. The magnesium alloy waste collected above is crushed by a metal pulverizer, and it is required to be crushed into pellets and flakes with a particle size ranging from 1 to 100 mesh;

[0037] Step 3. Use a vibrating sieve machine to screen the pulverized fragments, wherein 160g of large mesh fragments with a particle size of 10 mesh (about 2.00mm) are selected, and small mesh particles with a particle diameter of 40 mesh (about 0.43mm) are selected. Crushing 40g, they are mixed together, and in this mixed crushing, the mass ratio of large mesh crushing and small mesh crushing is 8:2;

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com