Chilli sauce packaging composite film and preparation method thereof

A composite film and chili sauce technology, applied in packaging, wrapping paper, household packaging, etc., can solve the problems of packaging contents eroding the glue layer, delamination of the glue layer, affecting the packaging and shelf life of the contents, and achieving good resistance to media. Effect, low cost, make up for the effect of poor processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

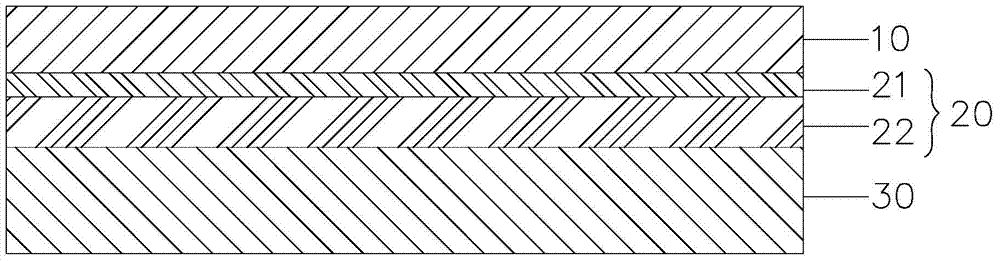

[0048] See figure 1 , the small package roll film in the present invention is the composite structure of PET / extruded PE / PE, wherein PET is the thickness of PET film layer 10 is 12 μm, extruded PE is the thickness of functional polyethylene film layer 20 is 15 μm, and PE is PE film Layer 30 has a thickness of 60 μm.

[0049] The formula of PE film layer 30 is as follows:

[0050] Corona layer: 50Kg Yangtze 7042+50Kg2420-H;

[0051] Middle layer: 25Kg1820+25Kg100AC+25kgHTA108;

[0052] Heat seal layer: 50Kg100AC+25KgPL1881G+1.5Kg10090-K+1.0KgAB-20LD+0.2Kg10091-K.

[0053] The thicknesses of the three layers of the corona layer, the intermediate layer and the heat-sealing layer are 20 μm, 20 μm and 20 μm, respectively.

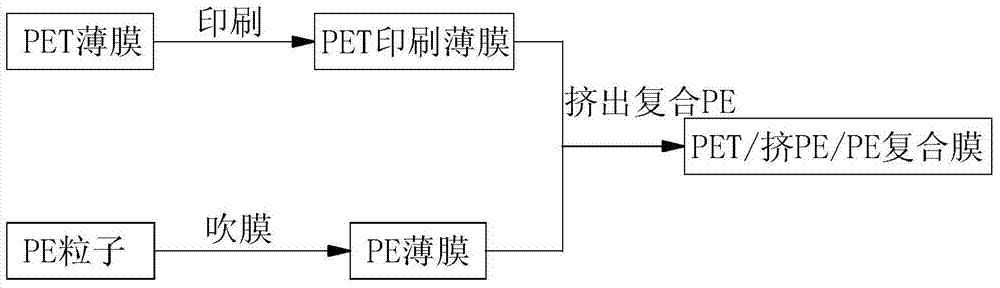

[0054] See figure 2 , the preparation method of the small package roll film in the present invention specifically comprises the following steps:

[0055] 1) Printing process: the PET film is printed by color and multi-color gravure printing through the grav...

Embodiment 2

[0064] See figure 1 , the small packaging film in the present invention is a composite structure of PET / extruded PE / PE, wherein PET is the thickness of the PET film layer 10 is 12 μm, extruded PE is the thickness of the functional polyethylene film layer 20 is 20 μm, and PE is the PE film Layer 30 has a thickness of 80 μm.

[0065] The formula of PE film layer 30 is as follows:

[0066] Corona layer: 50Kg Yangtze 7042+50Kg2420-H;

[0067] Middle layer: 25Kg1820+25Kg100AC+50kgHTA108;

[0068] Heat seal layer: 50Kg100AC+25KgPL1881G+1.5Kg10090-K+1.0KgAB-20LD+0.2Kg10091-K.

[0069] The thicknesses of the three layers of the corona layer, the intermediate layer and the heat-sealing layer are 20 μm, 40 μm and 20 μm, respectively.

[0070] See figure 2 , the preparation method of the small package roll film in the present invention specifically comprises the following steps:

[0071] 1) Printing process: the PET film is printed by color and multi-color gravure printing through...

Embodiment 3

[0080] See figure 1 , the small package roll film in the present invention is the composite structure of PET / extruded PE / PE, and wherein PET is the thickness of PET film layer 10 is 12 μ m, extruded PE is the thickness of functional polyethylene film layer 20 is 18 μ m, and PE is PE film Layer 30 has a thickness of 70 μm.

[0081] The formula of PE film layer 30 is as follows:

[0082] Corona layer: 50Kg Yangtze 7042+50Kg2420-H;

[0083] Middle layer: 25Kg1820+25Kg100AC+75kgHTA108;

[0084] Heat seal layer: 50Kg100AC+25KgPL1881G+1.5Kg10090-K+1.0KgAB-20LD+0.2Kg10091-K.

[0085] The thicknesses of the three layers of the corona layer, the intermediate layer and the heat-sealing layer are 20 μm, 30 μm, and 40 μm, respectively.

[0086] See figure 2 , the preparation method of the small package roll film in the present invention specifically comprises the following steps:

[0087] 1) Printing process: the PET film is printed by color and multi-color gravure printing through...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com