Steel pipe hydraulic expansion type external casing packer

A packer and expansion technology, applied in the directions of sealing/packing, wellbore/well components, earth-moving drilling, etc. To solve problems such as short time interval, to achieve the effect of providing formation isolation capability, improving isolation effect, and long isolation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

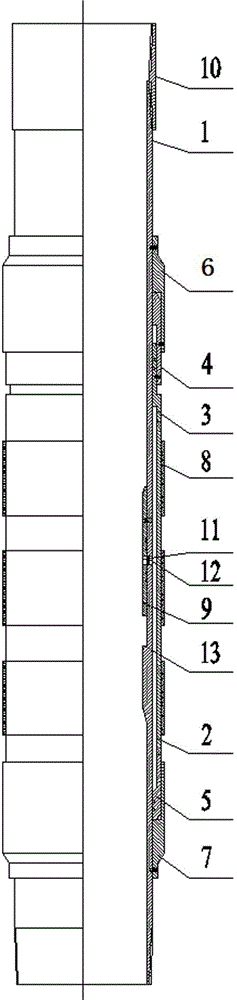

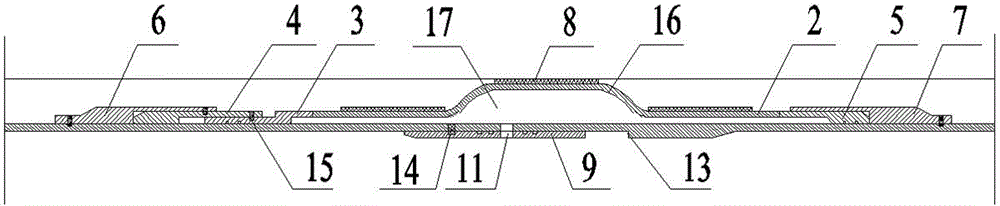

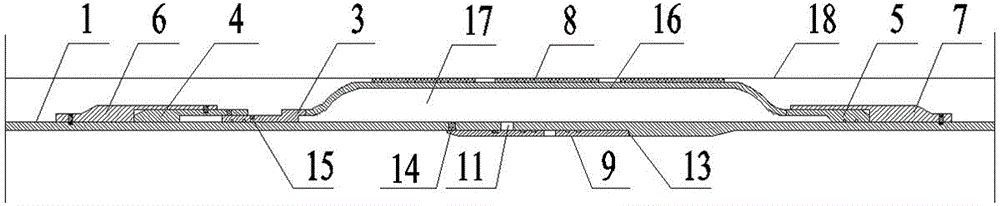

[0026] Now in conjunction with the accompanying drawings of the description, the present invention will be further described.

[0027] like figure 1 As shown in ~4, a steel pipe hydraulically expandable external packer, including a base pipe 1, an expansion pipe 2, a sliding nipple 3, an upper connecting piece 4, a lower connecting piece 5, an upper fixing piece 6, and a lower fixing piece 7 , sealing rubber 8, sliding sleeve 9 and connecting joint 10 and other components. Among them: the base pipe 1 is processed with a liquid inlet hole 11, a sliding sleeve 9 is installed inside, and a connecting joint 10 is processed on the top; the expansion tube 2 is located on the outside of the base pipe 1, and its upper end is connected with the sliding joint 3, and the sliding joint 3 passes through in turn The upper connecting piece 4 and the upper fixing piece 6 are fixed on the outside of the base pipe 1, the lower end of the expansion pipe 2 is fixed on the outside of the base pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com