Patents

Literature

192results about How to "Short cooldown" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

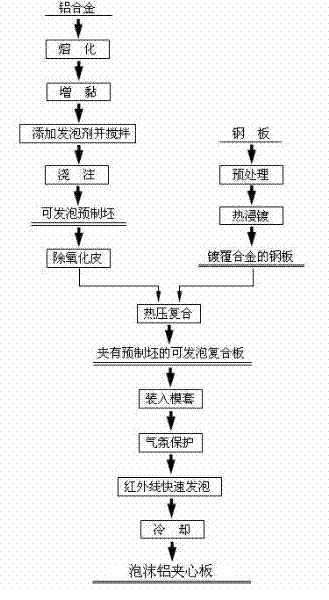

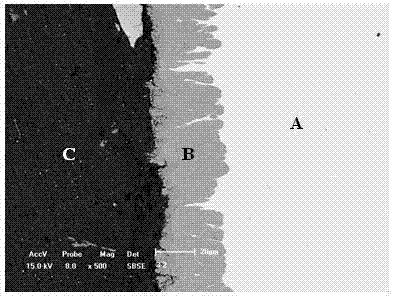

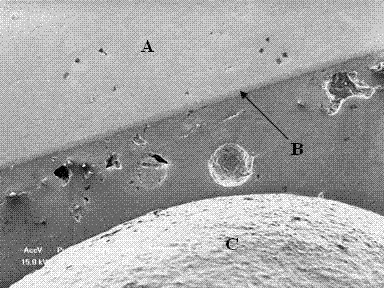

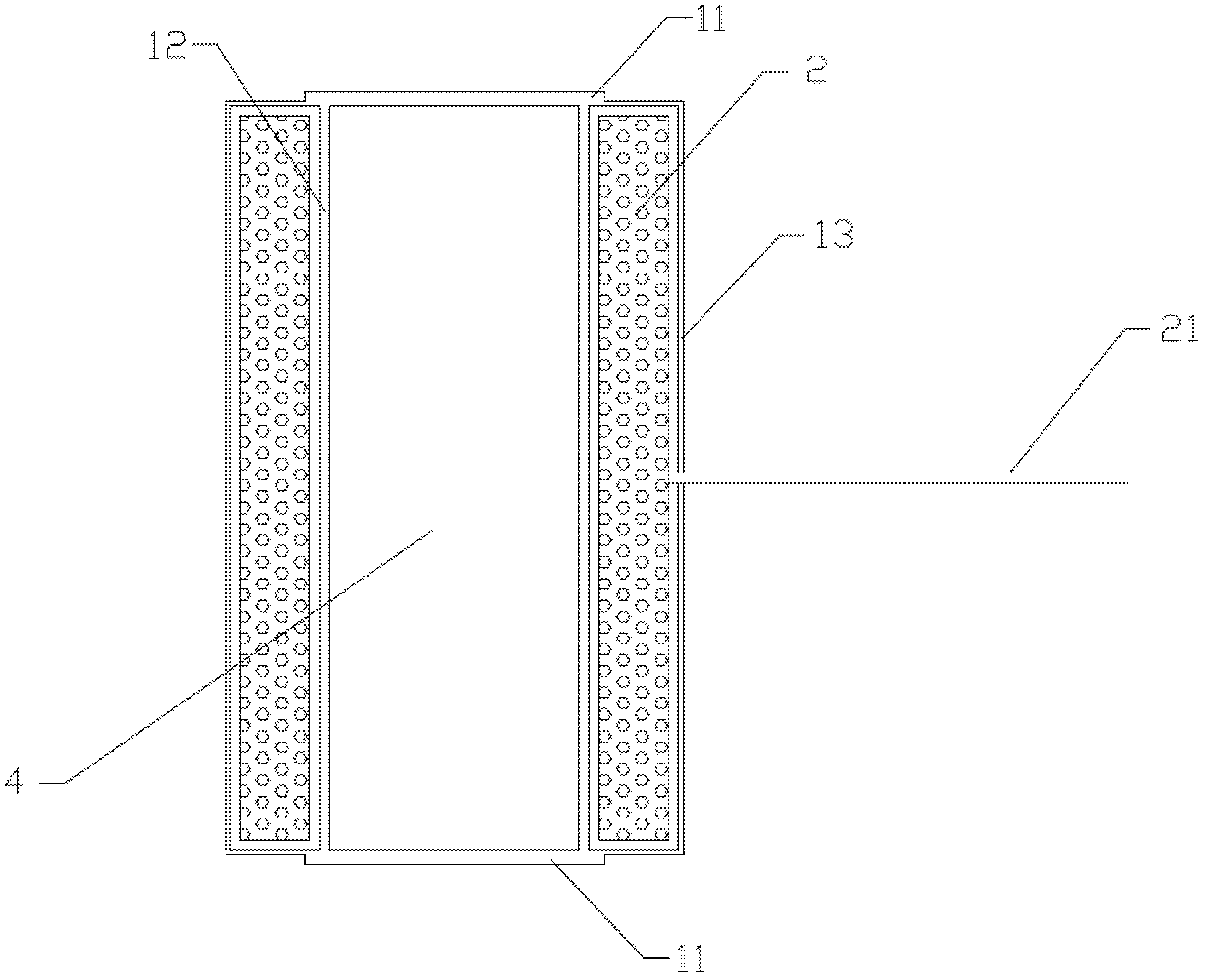

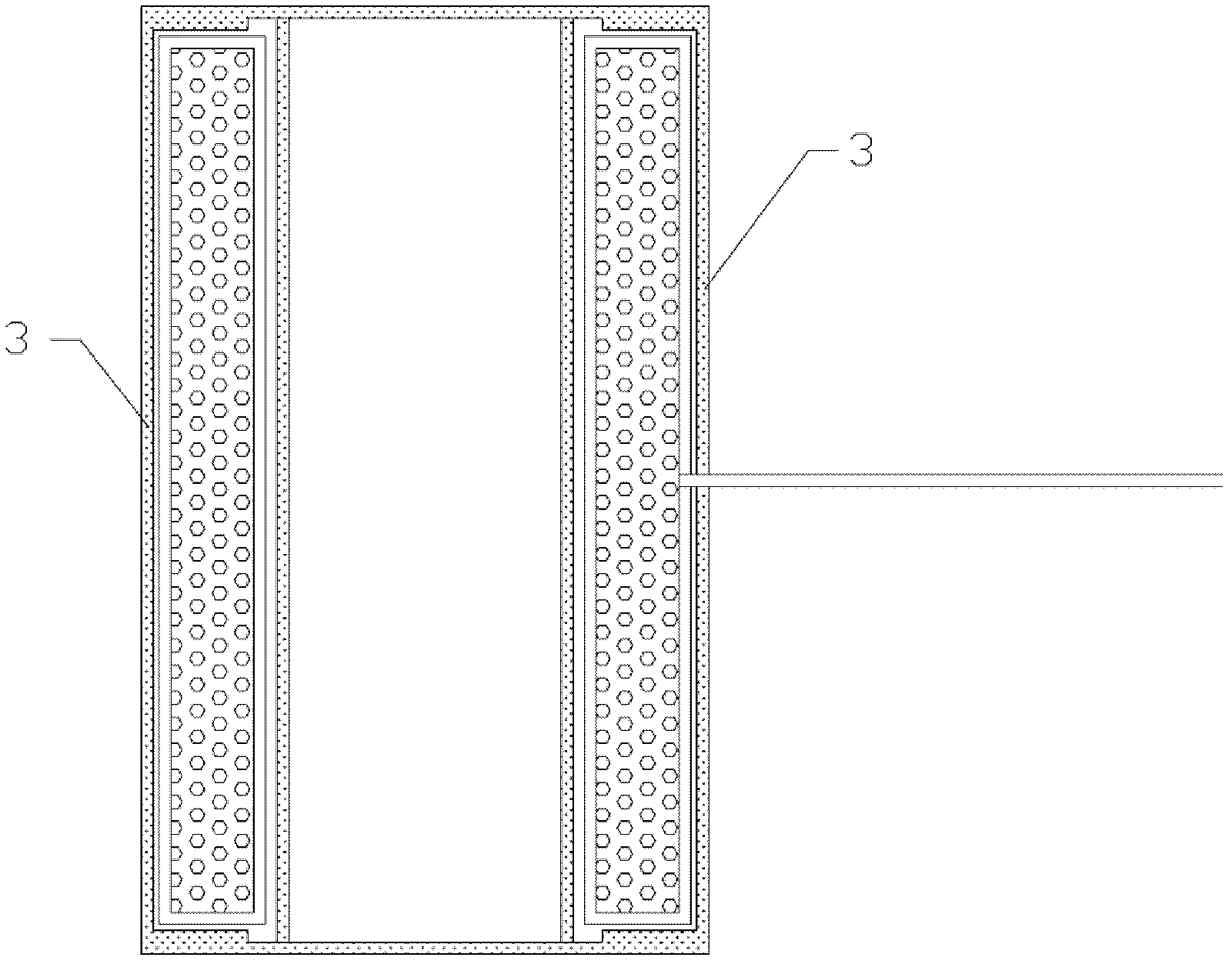

Preparation method of foamed aluminum sandwich plate

ActiveCN102390135AImprove mechanical propertiesAccurate thicknessLaminationLamination apparatusFoaming agentComposite plate

The invention relates to a preparation method of a layered composite material, in particular to a preparation method of a foamed aluminum sandwich plate. The method comprises the following steps of: firstly, uniformly mixing an aluminum alloy, a tackifier and a foaming agent to obtain a platy or blocky foamable precast blank material; then, performing hot-pressing compounding of the precast blankand a steel plate after the surface plating to obtain a foamable composite plate sandwiching the precast blank; placing the foamable composite plate sandwiching the precast blank in a mould sleeve closed around, and delivering into an infrared foaming furnace heating at the upper and lower parts at the same time so as to heat and foam the composite plate sandwiching the precast blank under infrared radiation; and finally, pulling the mould sleeve out of the foaming furnace, and cooling to obtain a foamed aluminum sandwich plate with a fixed thickness. The foamed aluminum sandwich plate prepared by the method provided by the invention has an accurate thickness, a uniform structure and a high yield; and moreover, the preparation processes in the invention can be automatically controlled, thereby being favorable for realizing semi-continuous preparation of the foamed aluminum sandwich plate.

Owner:NORTHEASTERN UNIV

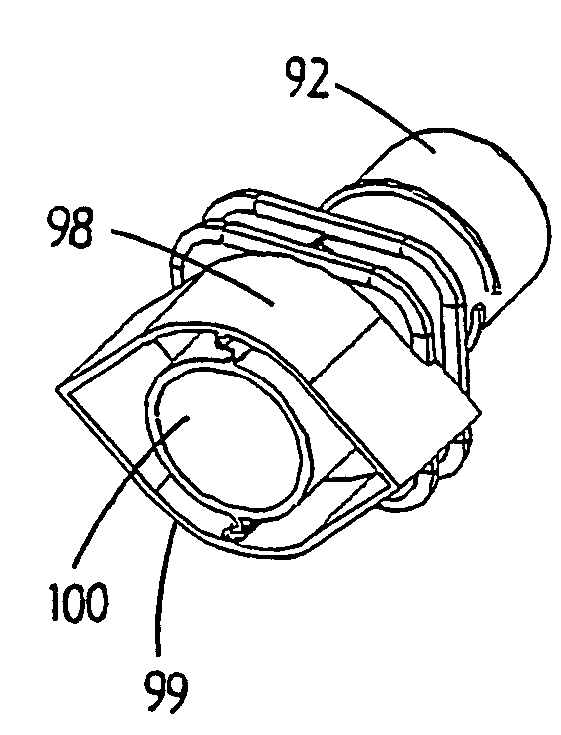

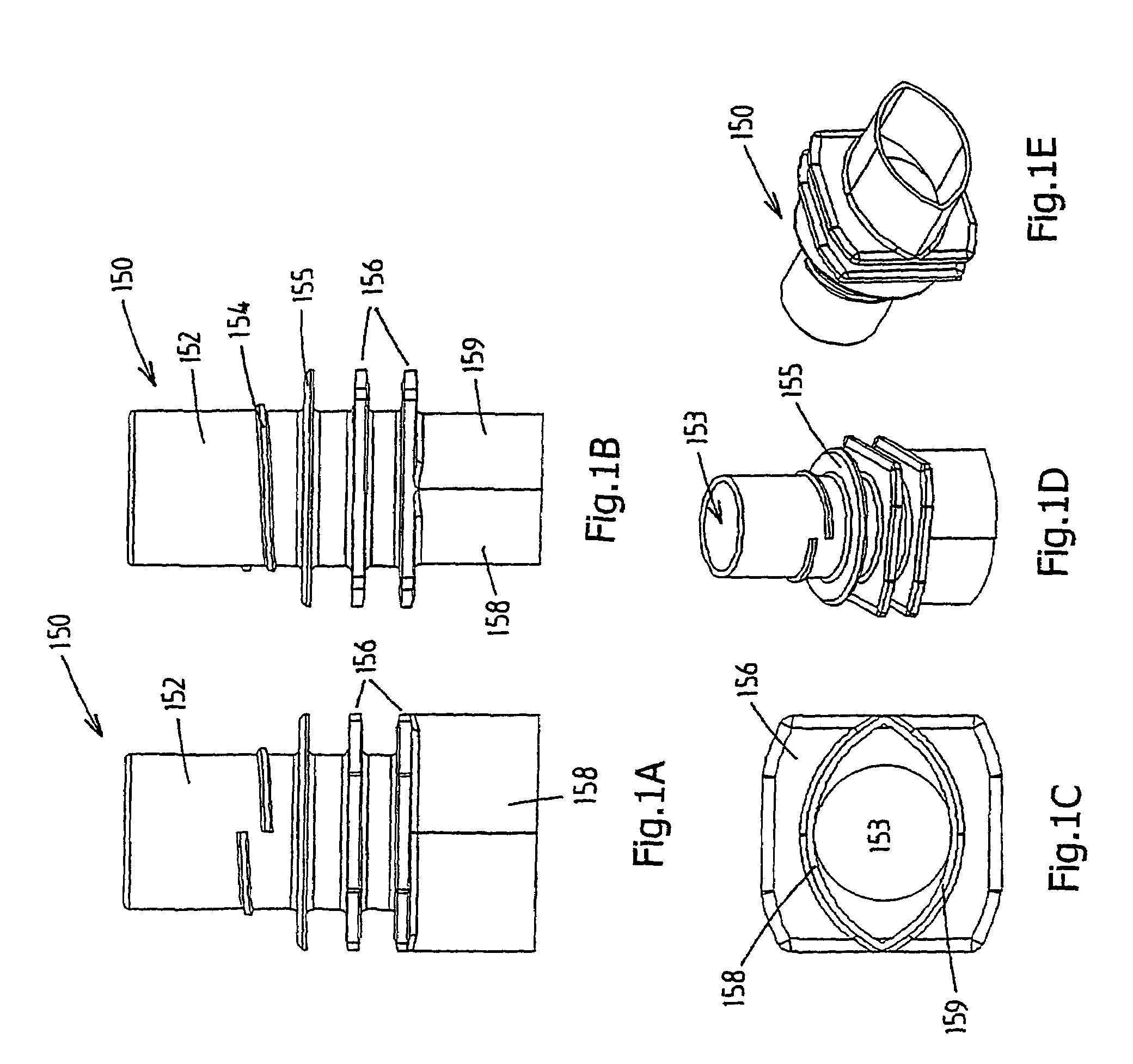

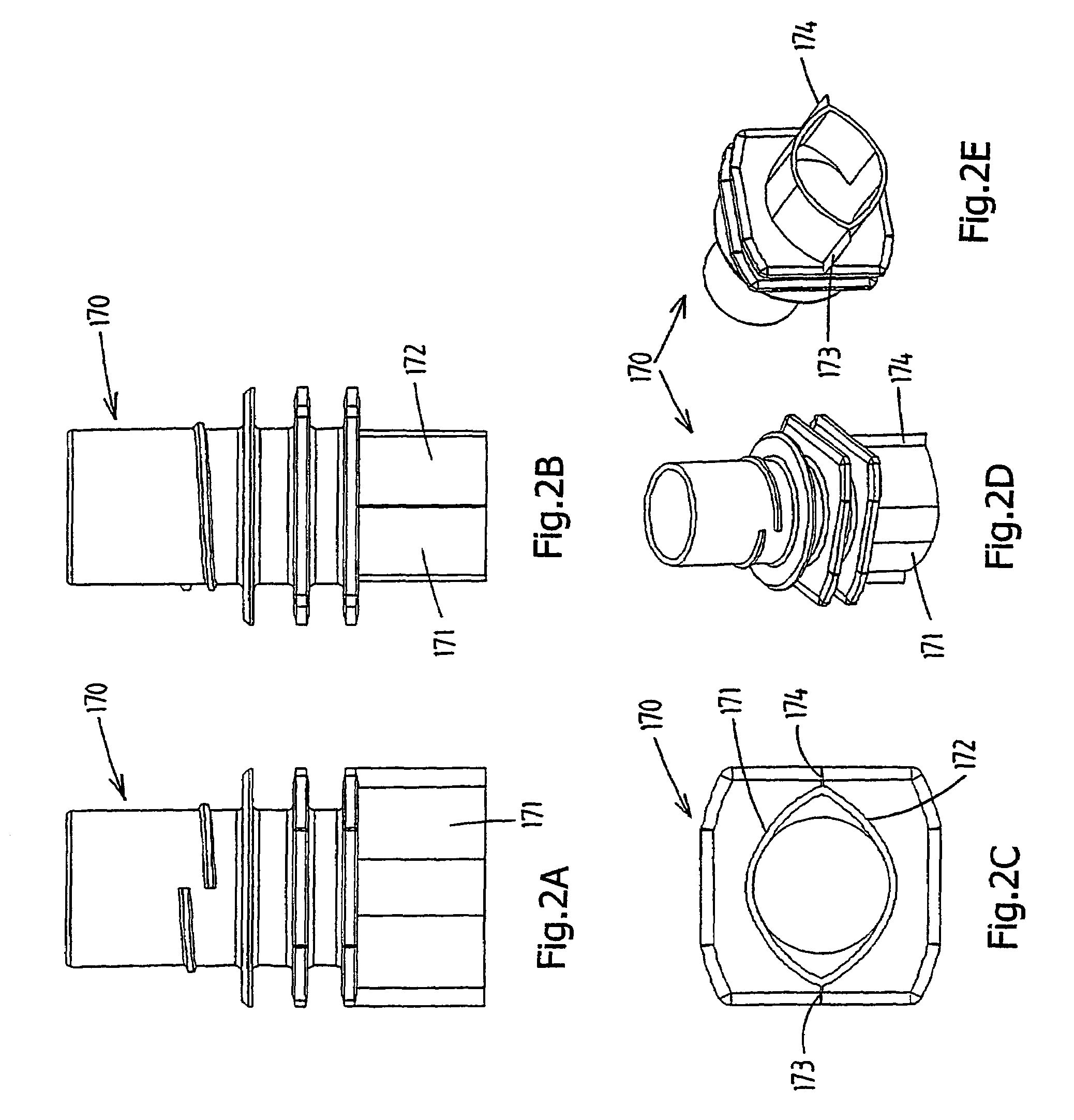

Plastic spout

InactiveUS7232042B2Simple designSimple and efficient coolingOpening closed containersBottle/container closureEngineeringMechanical engineering

Owner:SHOWA MARUTSUTSU CO LTD

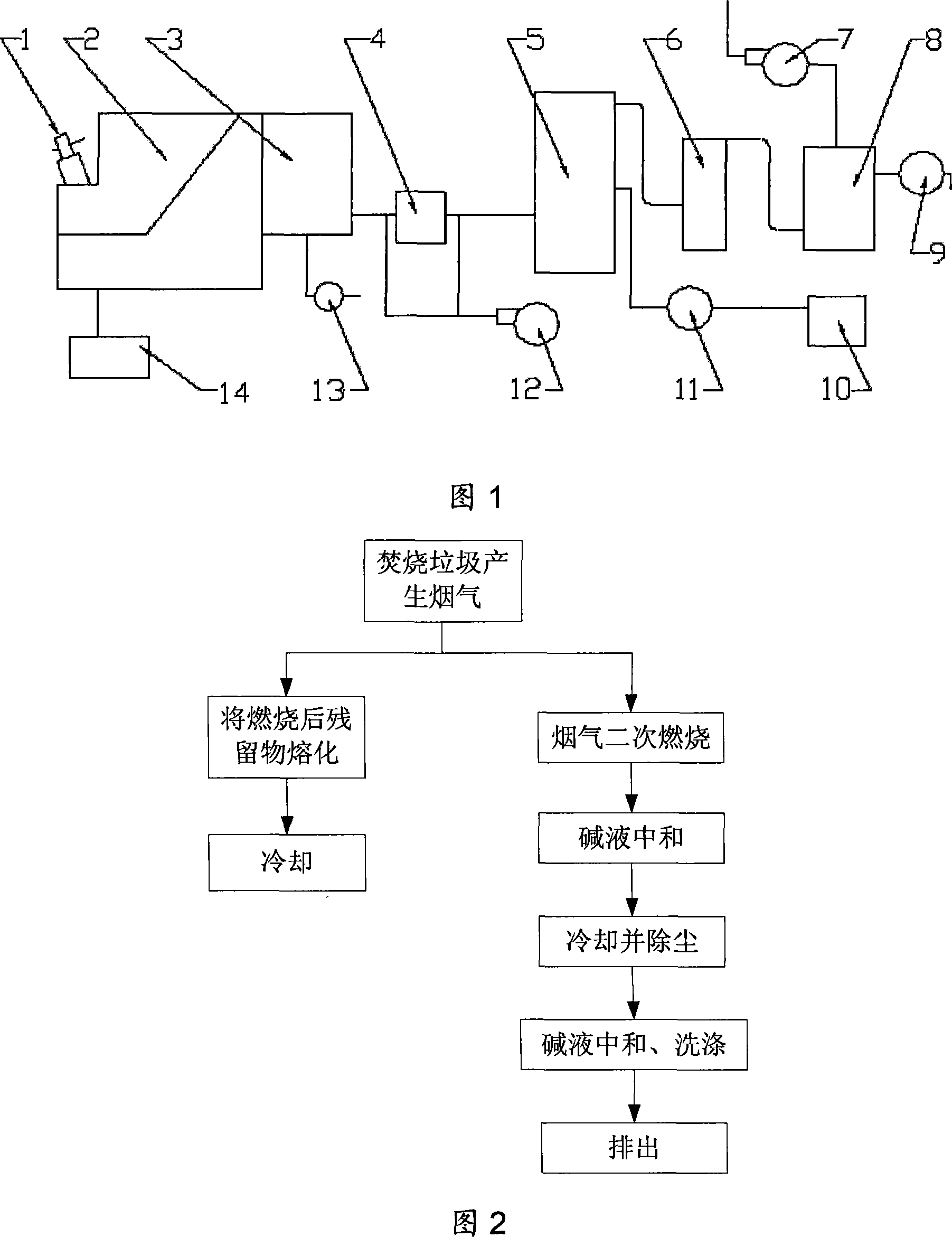

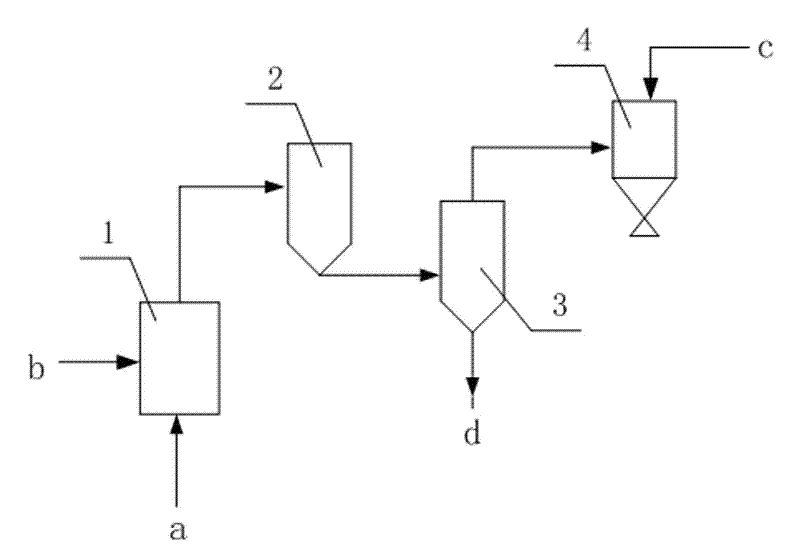

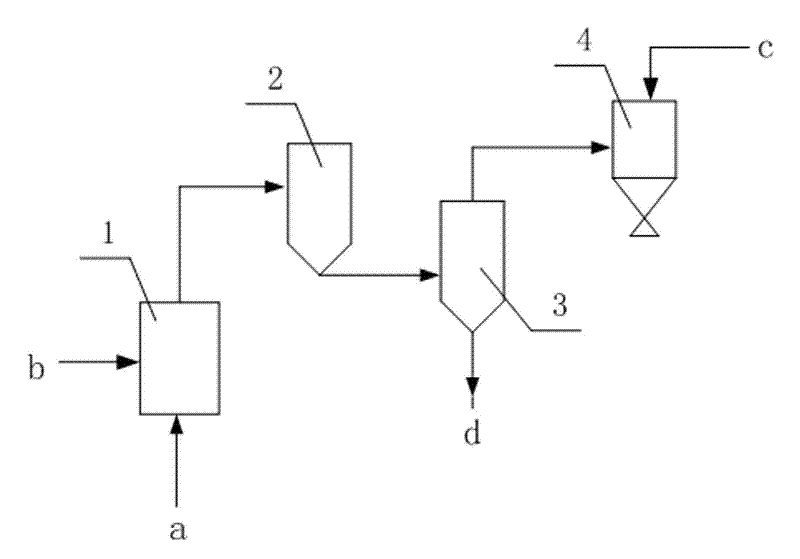

Plasma medical refuse burning methods

ActiveCN101178181ALower manufacturing requirementsProduction controlDispersed particle separationCombustion technology mitigationCombustion chamberMedical waste

The invention relates to a plasma medical waste incineration method, comprising the steps that:(1) the inside temperature of an incinerator is heated to more than 1100 DEG C through plasmas, and the medical wastes are incinerated inside the incinerator; the oxygen content inside the incinerator is controlled to be less than 0.09 percent; and the burned residue is continuously heated till melted inside a melt chamber in the incinerator, and the molten slag flows into a slag separator and are cooled while the smokes generated by burning enter a secondary burning chamber;(2) the generated smokes are burned secondarily at 1150 to 1250 DEG C, and the external oxygen supplied for the secondary burning chamber is controlled so that the oxygen content inside the secondary burning chamber is controlled to be more than 10 percent;(3) the smokes produced by the secondary burning is reacted with the sprayed alkali liquor at an outlet of the secondary burning chamber, so that the part of CL, I and S elements inside the smokes can be fixed in a slat mode;(4) the processed smokes are cooled, so that the temperature of the smokes can be decreased to 155 to 180 DEG C; and the cooled smokes are dedusted to obtain waste gases; (5) the waste gases are sprayed with the alkali liquor and then are discharged after being neutralized and fully washed.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

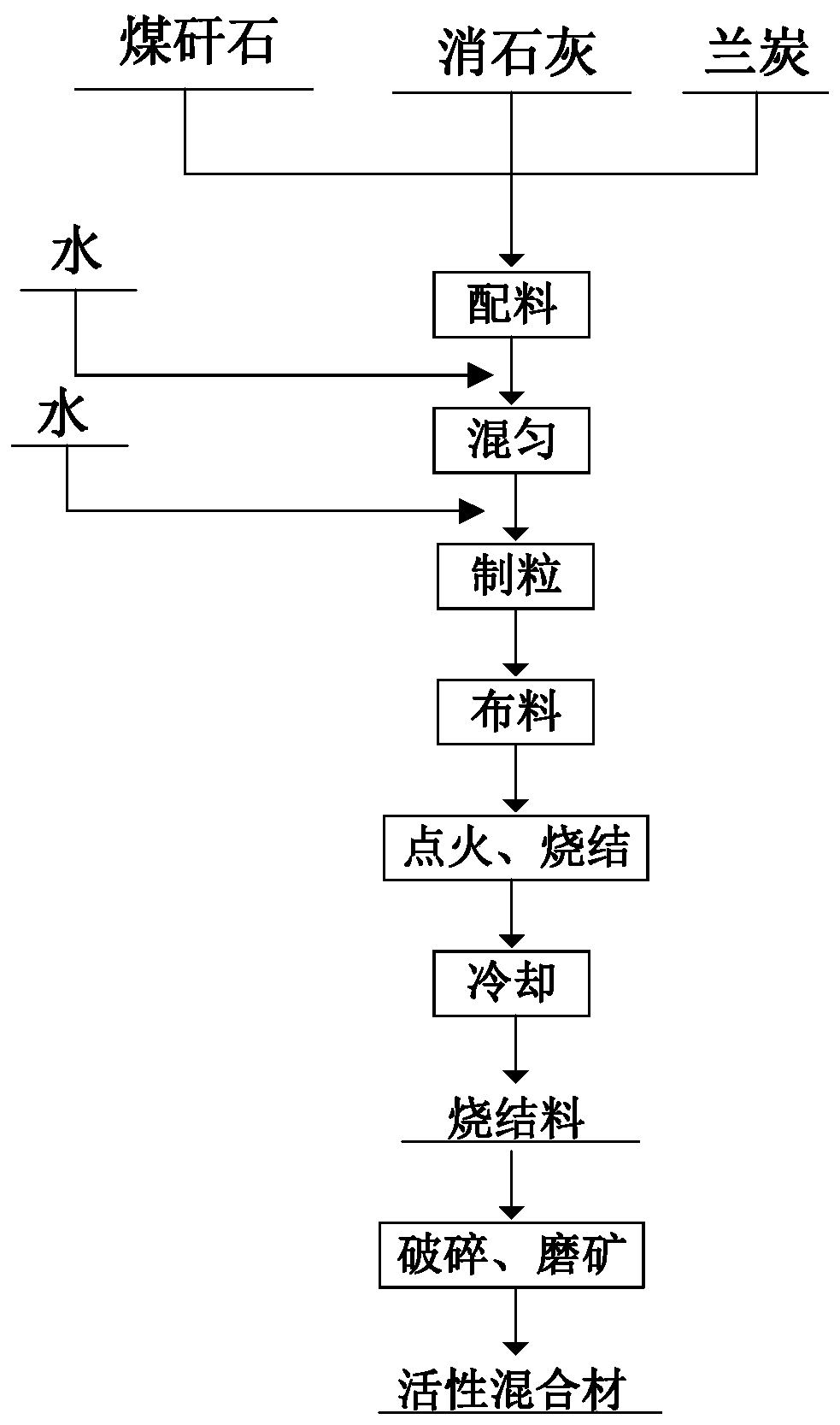

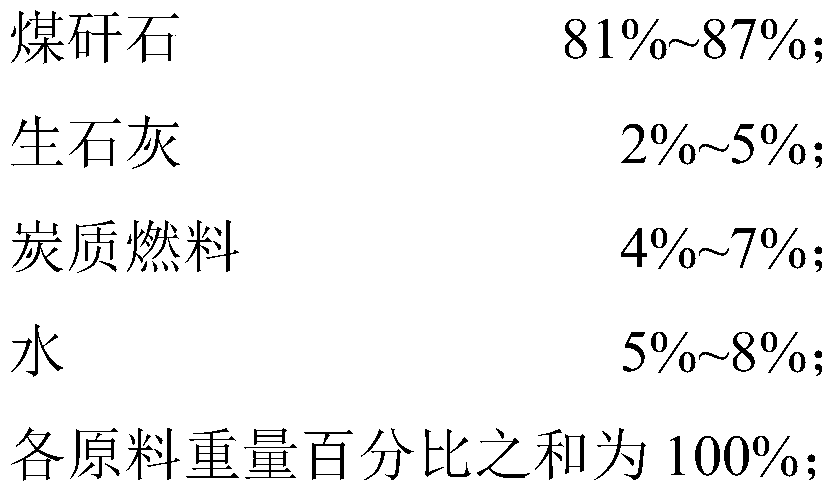

A process for preparing active mixed materials by belt sintering of coal gangue

The invention discloses a process for preparing an activated mixed material through strand sintering of coal gangue. The process comprises the following steps: (1) crushing; (2) preparing materials, and uniformly mixing, namely sufficiently and uniformly mixing crushed coal gangue, quick lime, a carbon fuel and water in a cylinder mixing machine in a set ratio; (3) pelletizing, namely pelletizingthe uniformly mixed minerals into beads of a preset granularity; (4) sintering, namely performing allocation, ignition, air sucking sintering and cooling on the pelletized beads in a strand air sucking sintering machine; (5) crushing and finely grinding, namely crushing the sintered material, and finely grinding till a set specific surface area, thereby obtaining the activated mixed material. Theinvention provides the process for preparing an activated mixed material through strand sintering of coal gangue, by virtue of the properties that a combustion zone is high in temperature and short intime in the sintering process, a vitric phase can be formed, meanwhile, the sintered material mainly contains an oxidation atmosphere, harmful components such as organic matters, residual carbon andsulfur in the coal gangue can be removed at a high temperature, and the cementing property, the freezing resistance and the durability of cement are protected from adverse influence of the harmful components.

Owner:CENT SOUTH UNIV

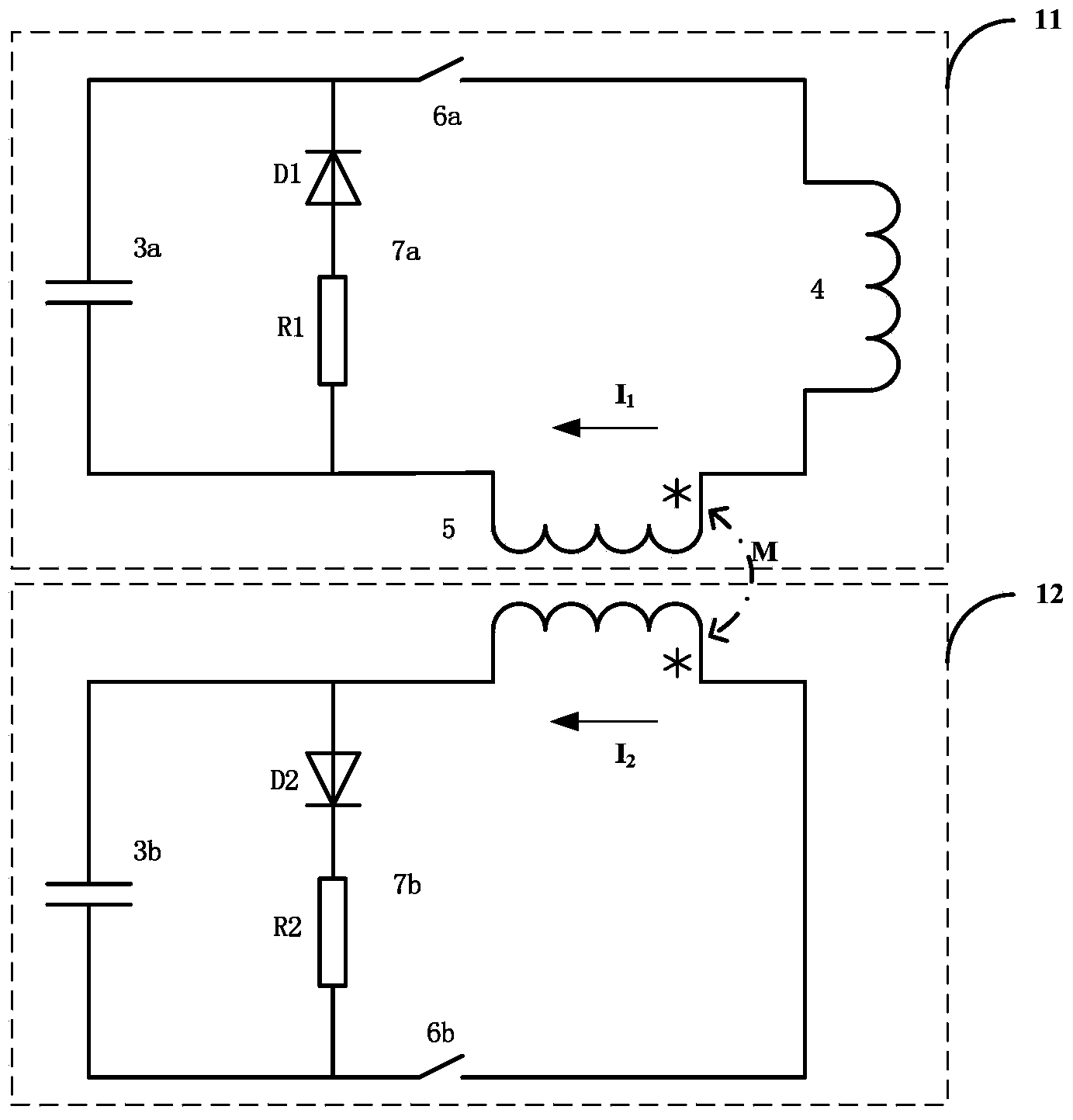

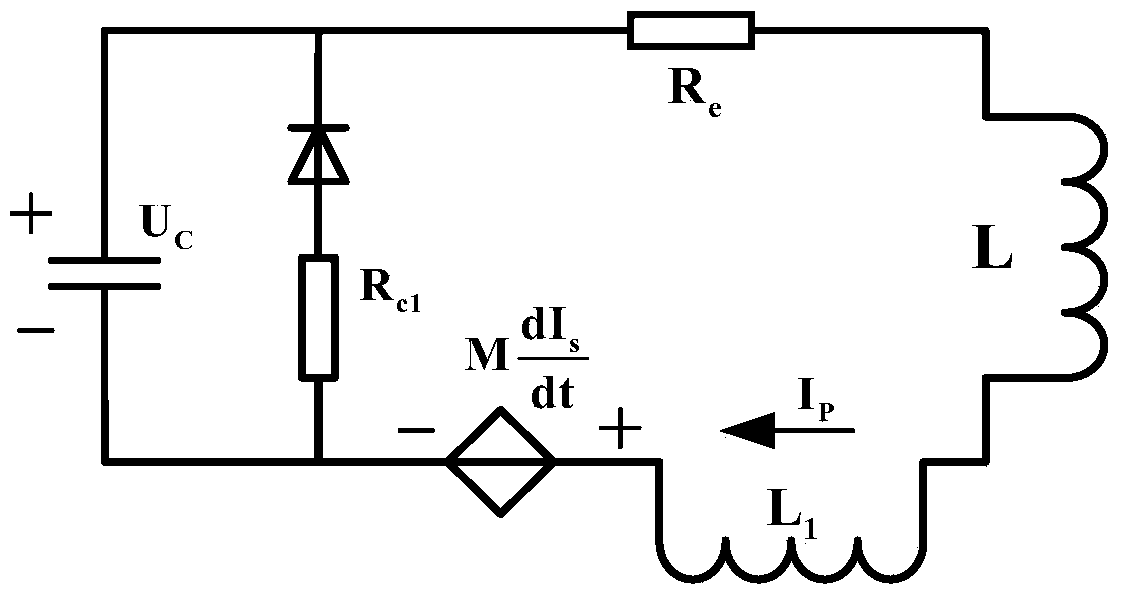

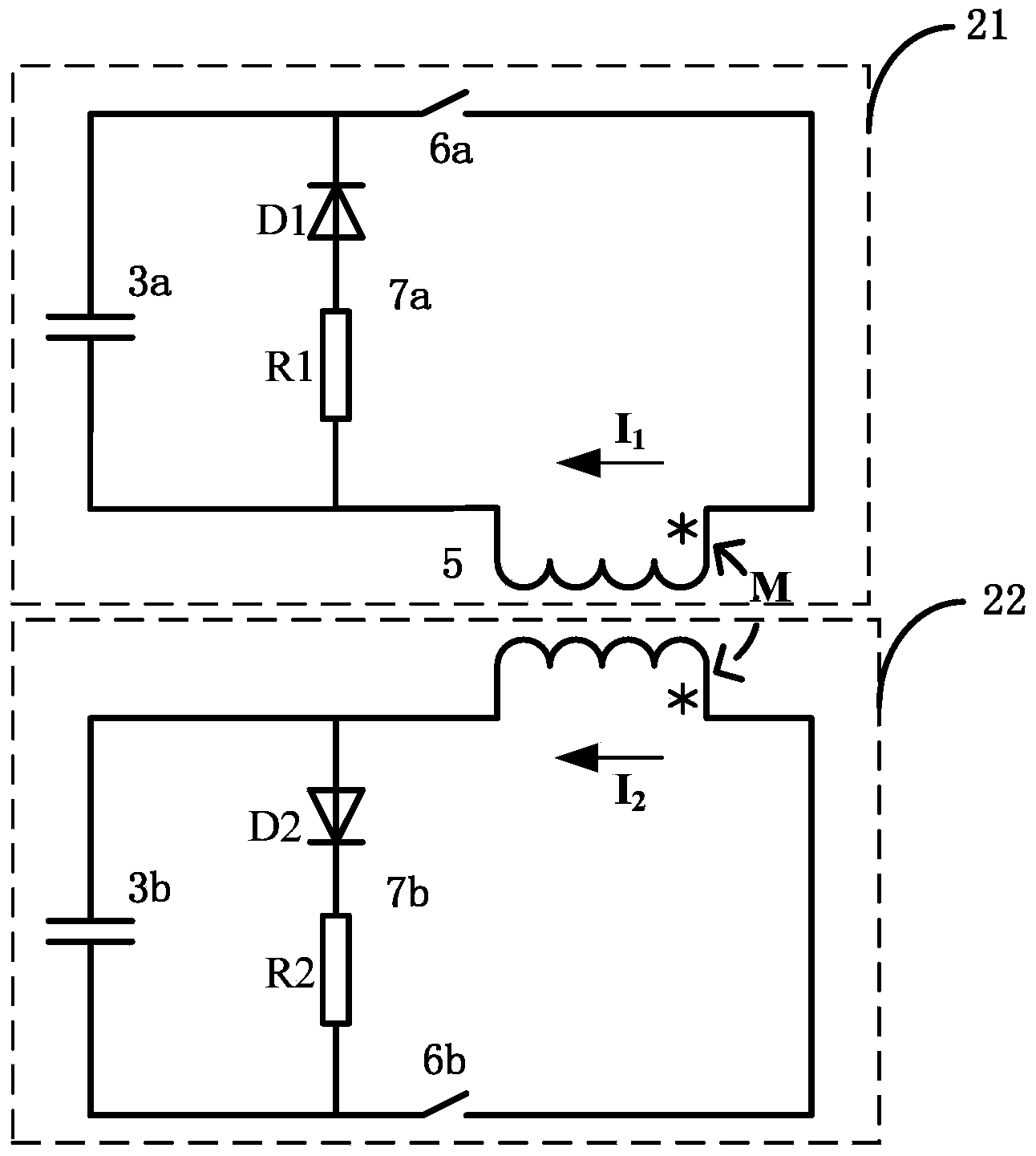

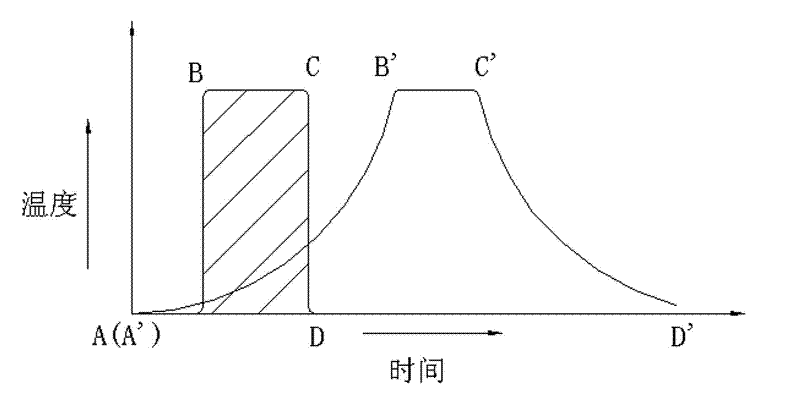

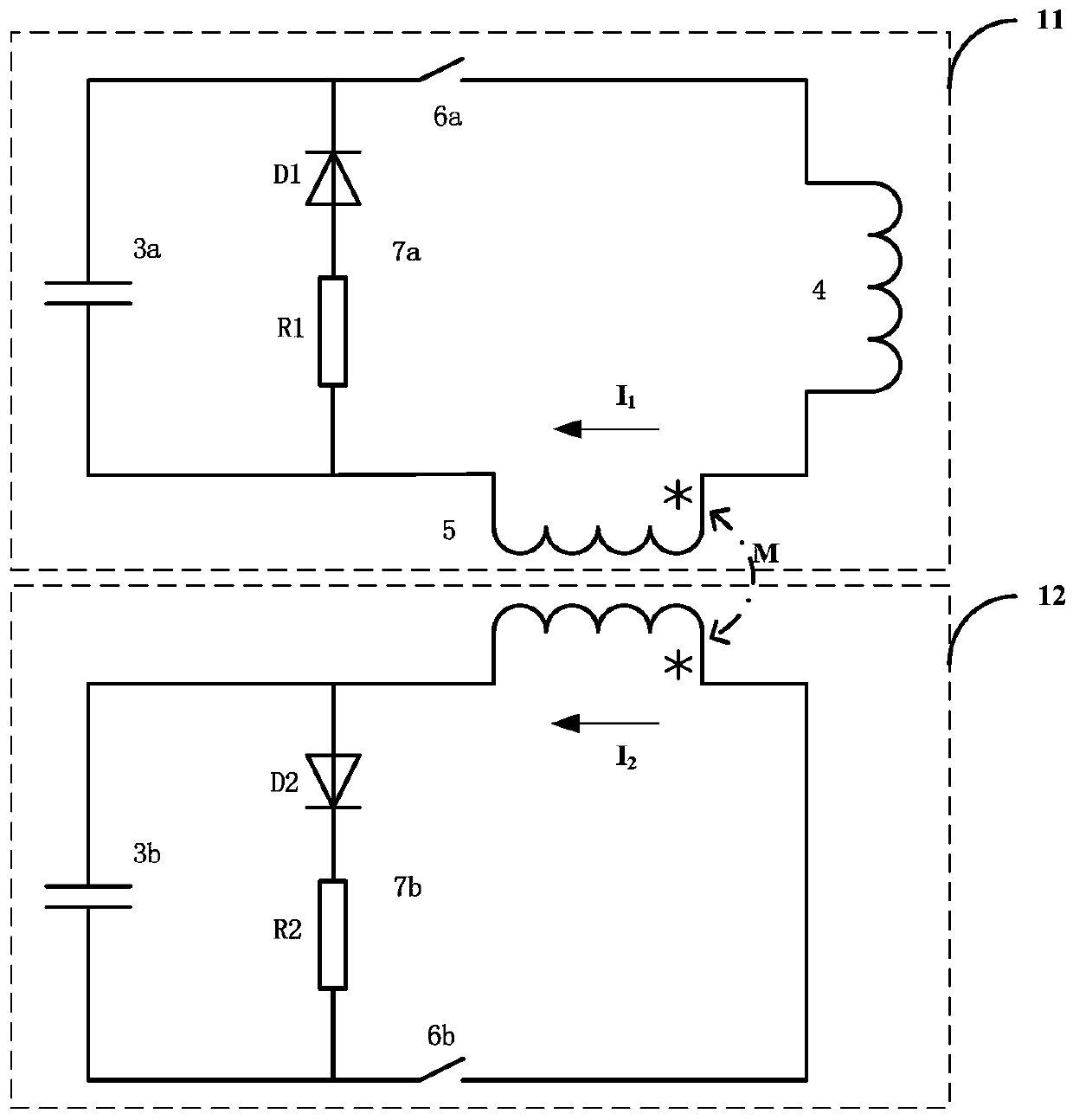

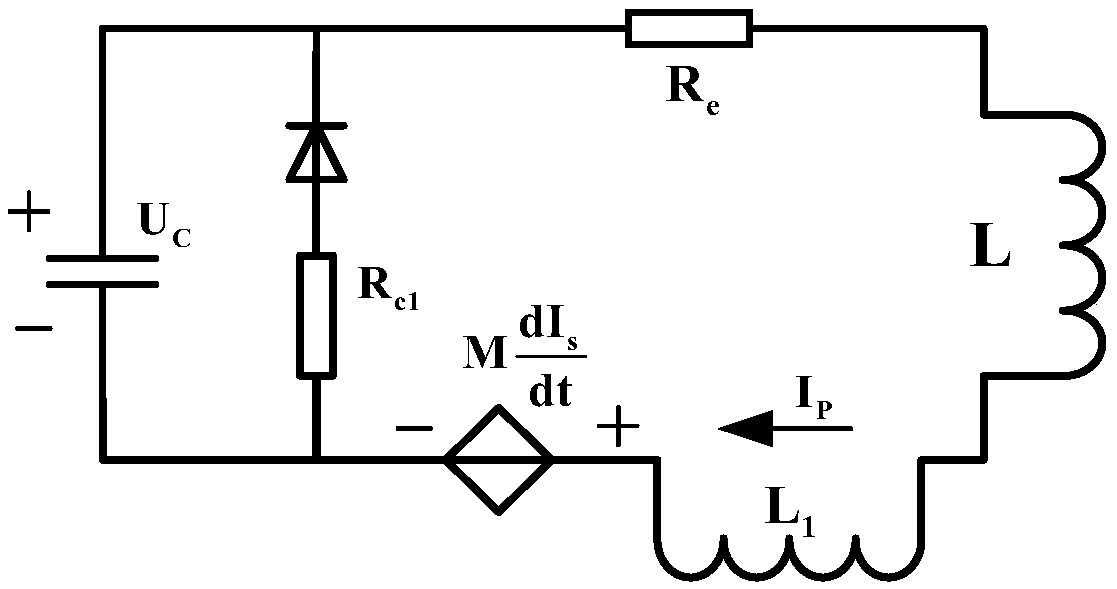

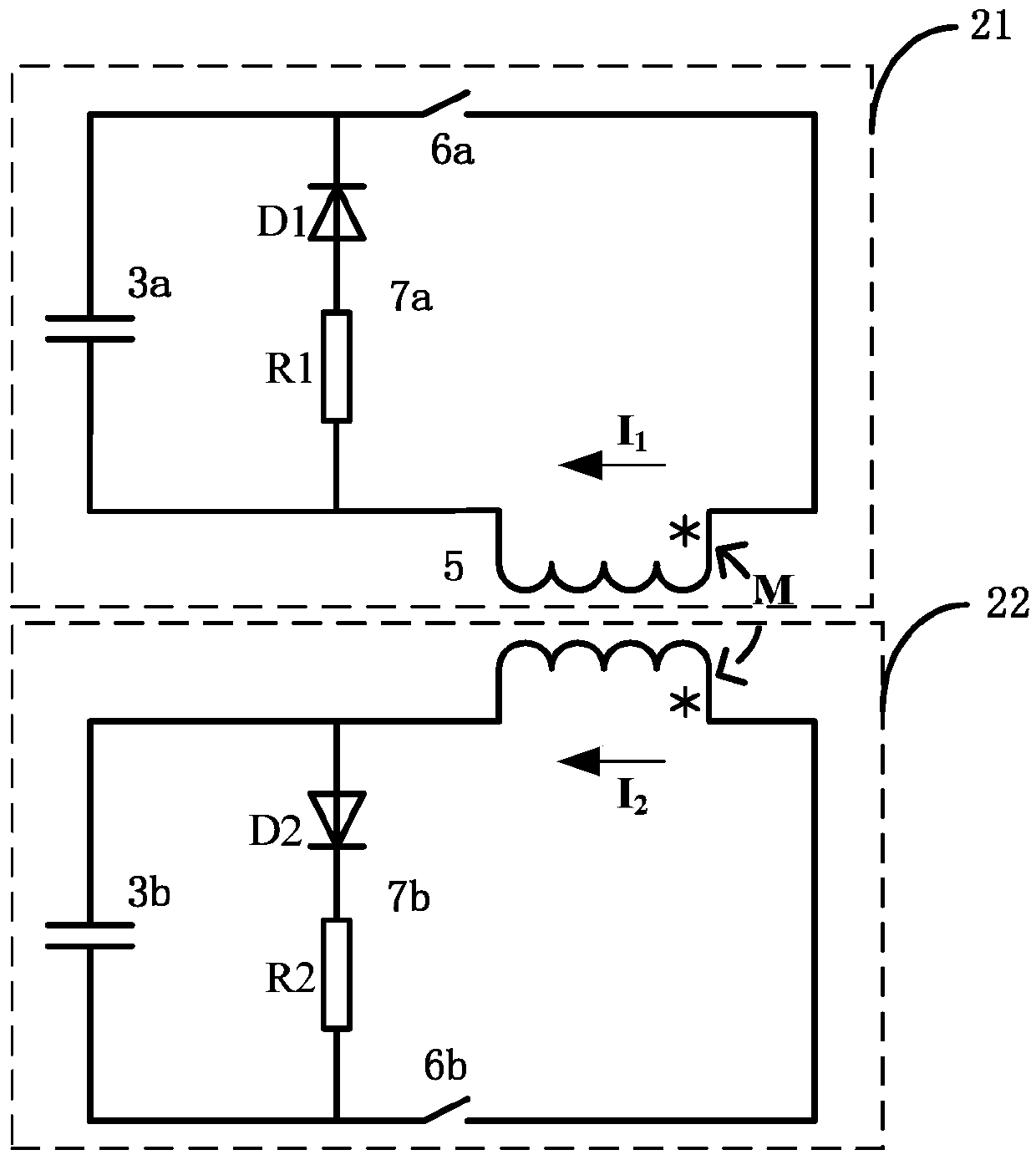

Flat-topped pulse magnetic field generating device and flat-topped pulse current generating device

The invention provides a flat-topped pulse magnetic field generating device and a flat-topped pulse current generating device. The flat-topped pulse magnetic field generating device comprises a transformer, a first loop and a second loop, wherein the first loop is formed by serial connection of primary side coils of the transformer, a first capacitor, a first switch and a magnet in sequence, and the second loop is formed by serial connection of secondary side coils of the transformer, a second capacitor and a second switch in sequence. The first loop further comprises first follow current loops connected to the two ends of the first capacitor in parallel, and the second loop further comprises second follow current loops connected to the two ends of the second capacitor in parallel. Each first follow current loop comprises a first resistor and a first one-way conducting element, wherein the first resistor and the first one-way conducting element are sequentially connected to the two ends of the first capacitor. Each second follow current loop comprises a second resistor and a second one-way conducting element, wherein the second resistor and the second one-way conducting element are sequentially connected to the two ends of the second capacitor. Flat-topped currents / magnetic fields can be generated through the coupling effect of the primary side coils and the secondary side coils of the transformer, and the flat-topped pulse magnetic field generating device and the flat-topped pulse current generating device have the advantages that manufacturing cost is low, the process is simple, circuit control is convenient and quick, and the flat-topped currents / magnetic fields do not have ripple waves.

Owner:HUAZHONG UNIV OF SCI & TECH

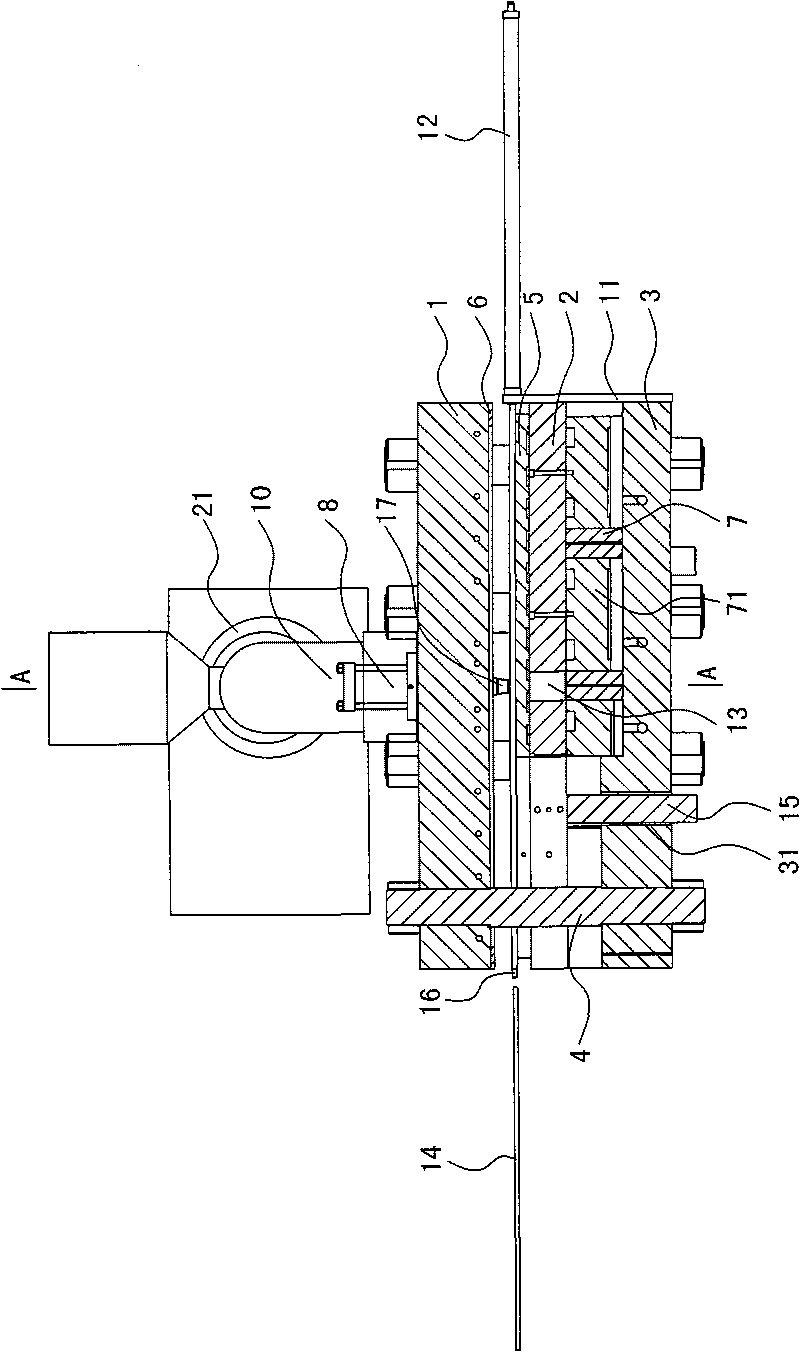

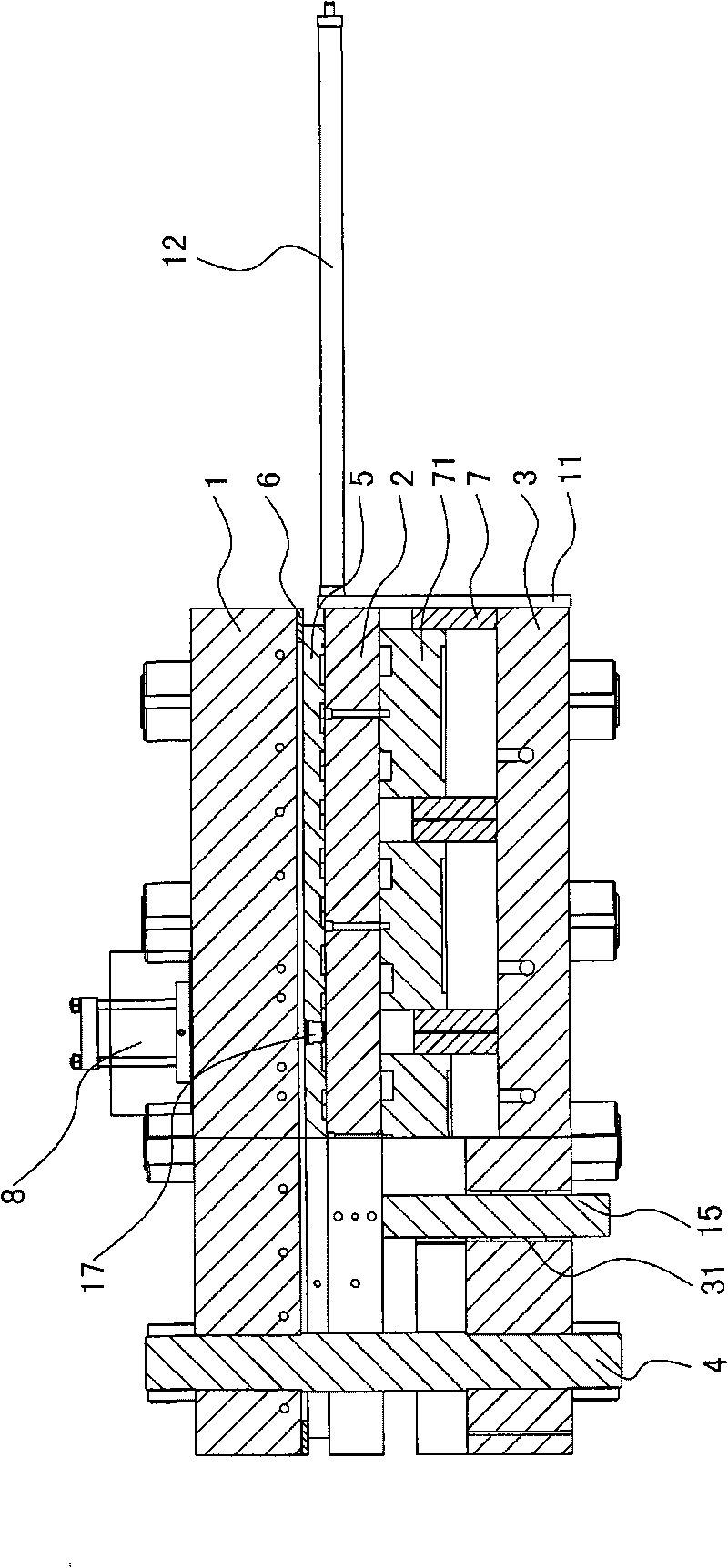

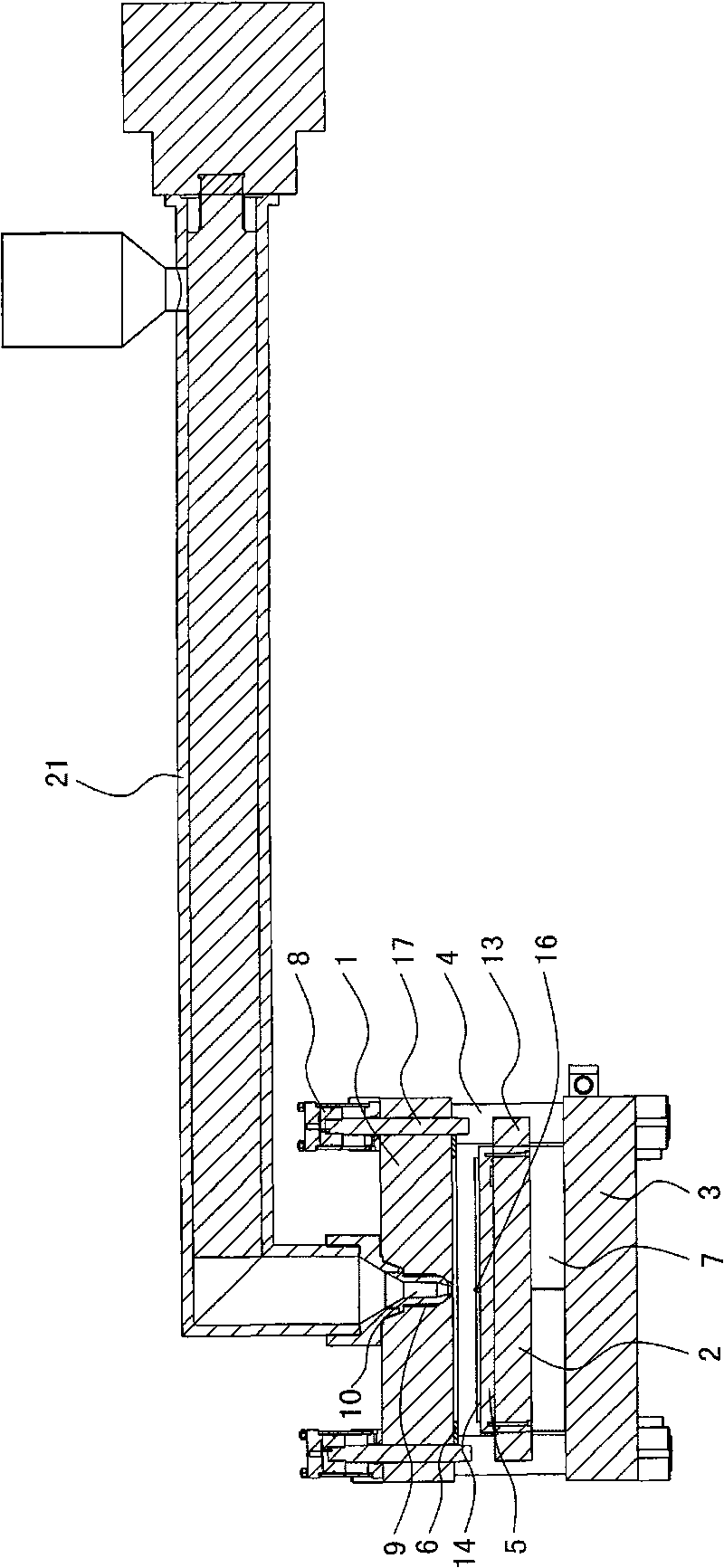

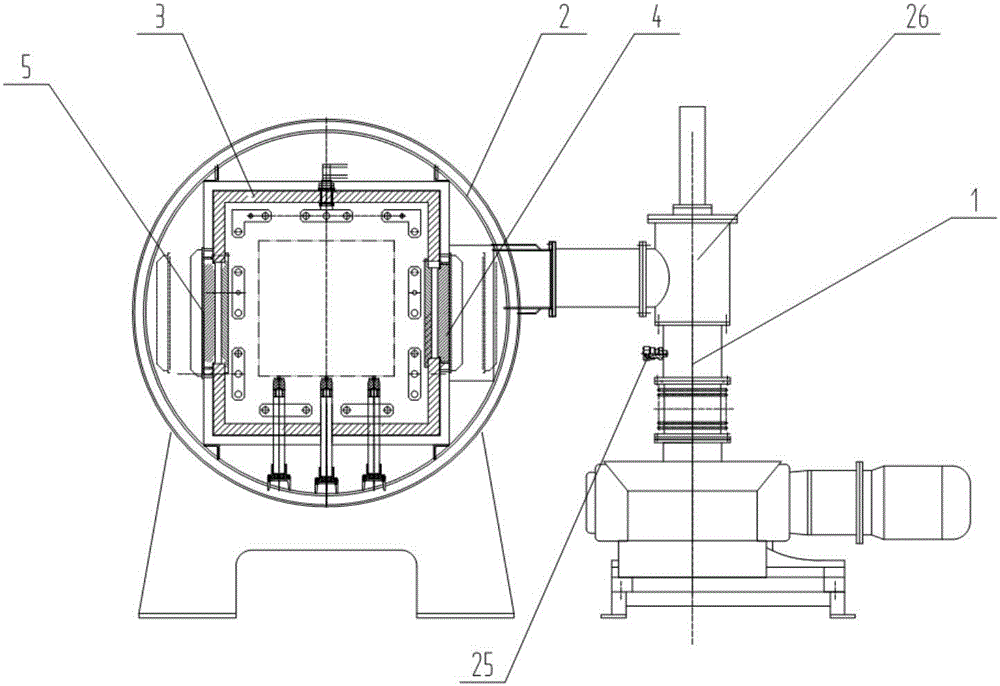

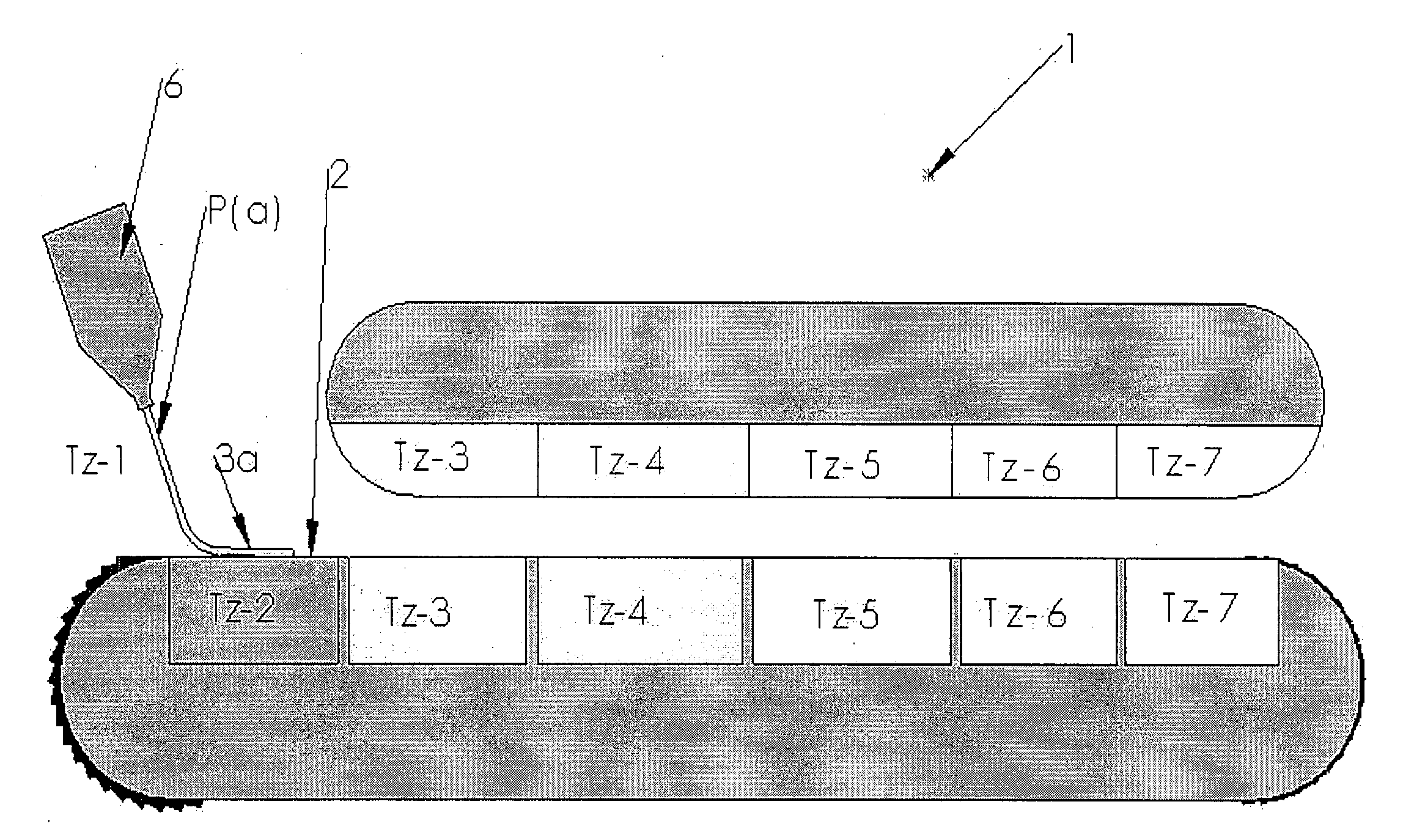

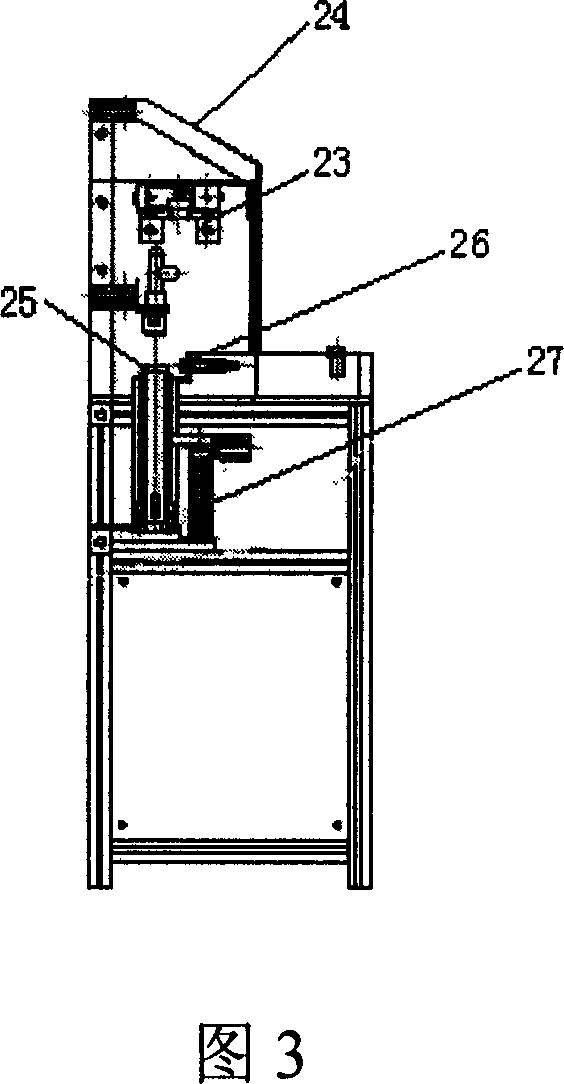

Mould opening and closing mechanism of wood-plastic board injection machine

The invention relates to a mould opening and closing mechanism of a wood-plastic board injection machine, which is characterized in that the mould opening and closing mechanism comprises an upper fixed moulding board and a lower fixed moulding board which are connected by a pull rod; a moving moulding board is arranged on the lower moulding board; a moulding board is arranged on the moving moulding board; charging holes are manufactured in the upper fixed moulding board and are matched with an injection head; a mould bolster is arranged below the upper fixed moulding board and is matched with the moulding board; a mould closing oil cylinder is arranged on the lower fixed moulding board or the upper fixed moulding board; a piston of the mould closing oil cylinder is connected with the moving moulding board and drives the moving moulding board and the moulding board; a mould opening oil cylinder is arranged on the upper fixed moulding board or the lower fixed moulding board; jacking blocks are arranged on both sides of the moving moulding board and are connected with a jacking rod of the mould opening oil cylinder. The scheme injects and forms wood-plastic boards in an injection structure mode, and has the advantages of high forming speed, short cooling time, uniform product specification, high density, good quality and improved production efficiency.

Owner:蔡业

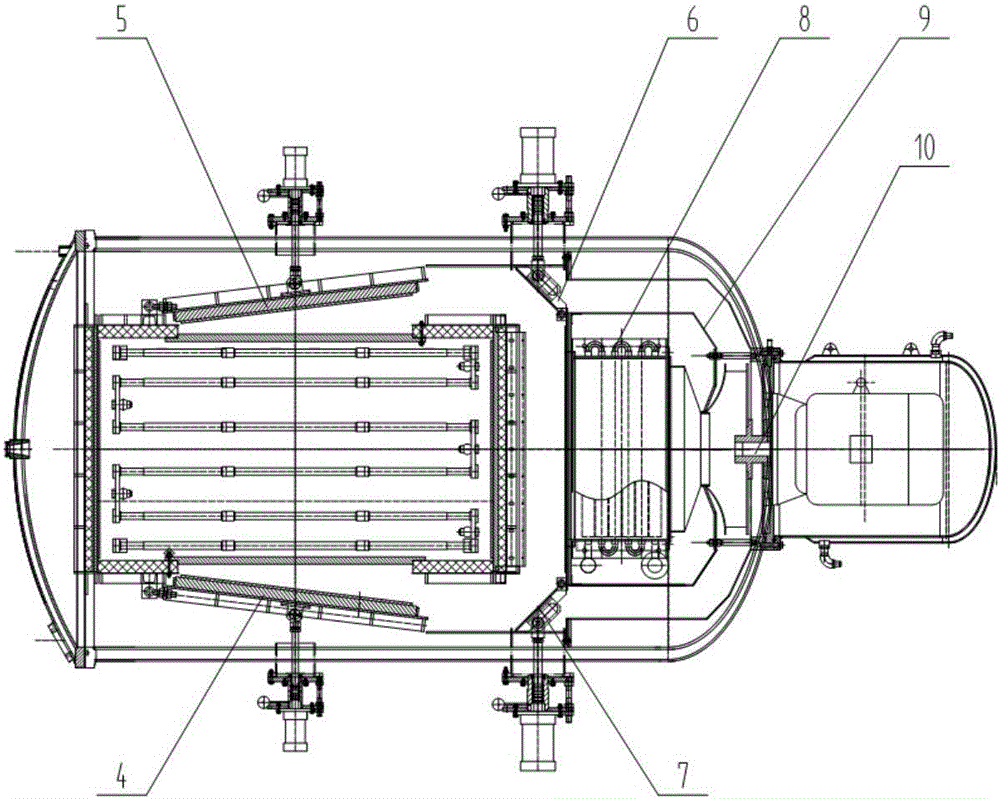

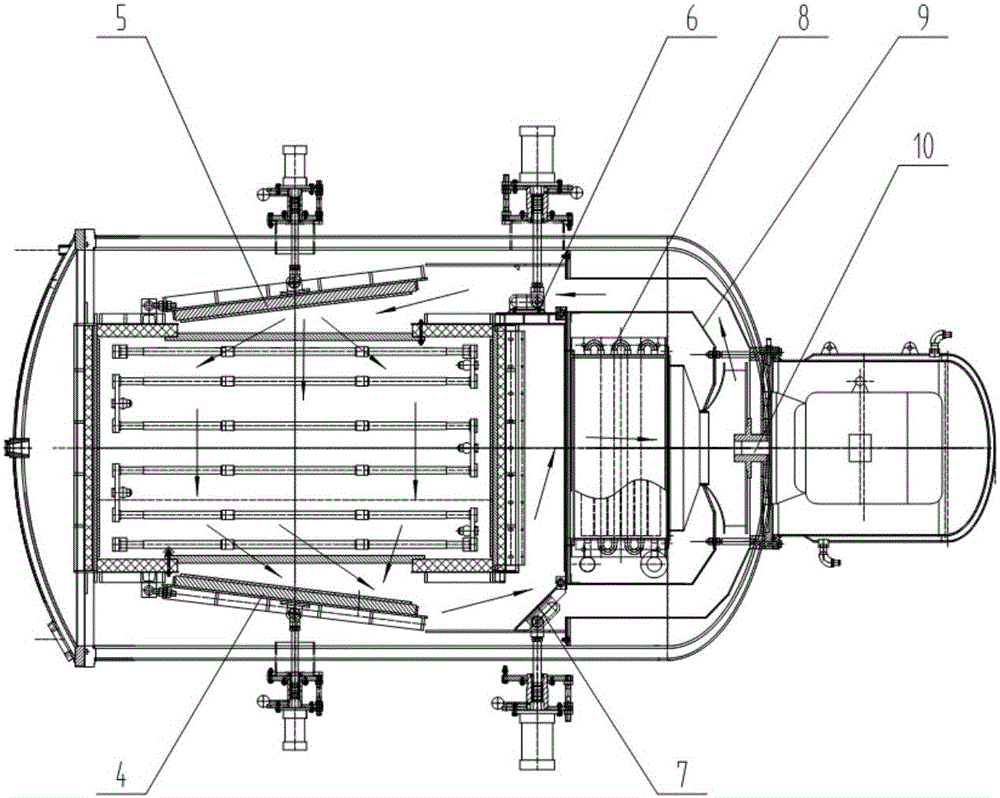

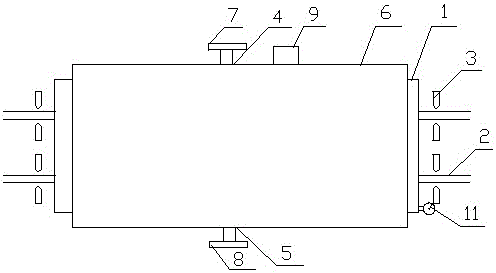

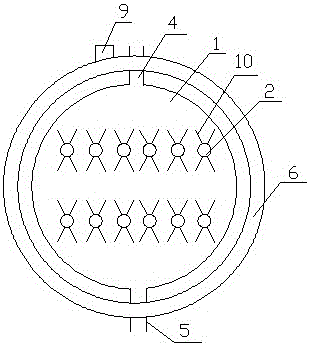

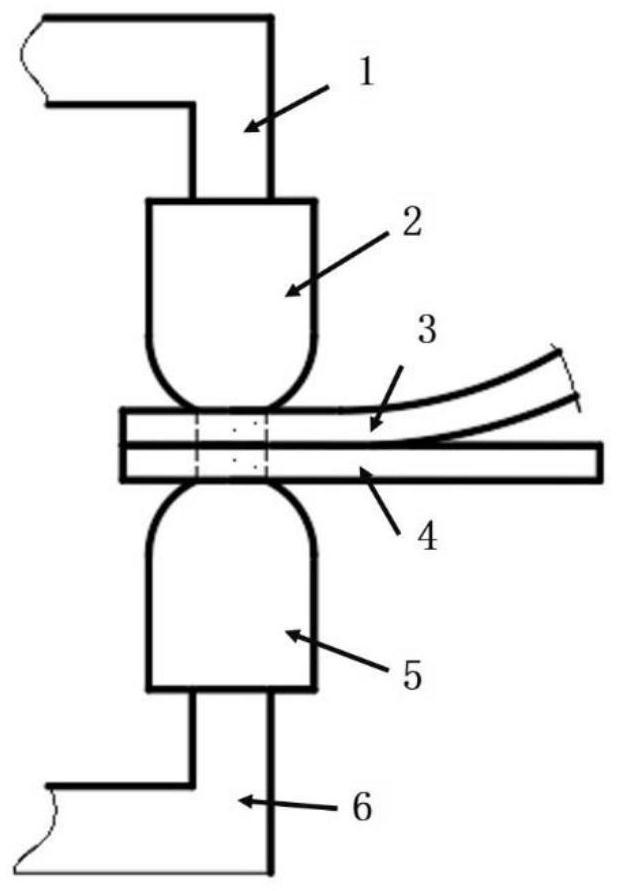

Multifunctional vacuum furnace

InactiveCN106500503AAvoid energy lossHeating evenlyMuffle furnacesRetort furnacesVacuum furnaceReverse mode

Disclosed is a multifunctional vacuum furnace. The multifunctional vacuum furnace is characterized in that the front portion of the body of a heating chamber is provided with a movable front left air door and a movable front right air door, a rear left reversing air door and a rear right reversing air door are symmetrically installed at the air flue end outside the heating chamber, air door air cylinders are installed outside a furnace shell, and air cylinder piston rods penetrate through the furnace shell to be connected with air door pin shafts through sealing structures. The multifunctional vacuum furnace has the advantages that in the heating process, the front left air door and the front right air door are closed, no air through hole is formed, energy loss in the heating process is avoided, energy is saved, and it is ensured that heating is more uniform; and in the cooling process, the opening degree of the front left air door and that of the front right air door are large, meanwhile, the rear left air door and the rear right air door can achieve reversing, in other words, airflow alternately flows in a reversing mode inside the heating chamber, outside the heating chamber, on the left of the heating chamber and on the right of the heating chamber, reversing time can be set, accordingly, workpieces are uniformly cooled, the cooling speed is increased, and the furnace discharge time is shortened. The problem that production efficiency is affected is solved, energy consumption is lowered to minimum, product performance is higher, and production efficiency is improved.

Owner:SHENYANG HENGJIN VACUUM TECH

Controlled cooling and controlled rolling method for control over bearing steel wire network carbide

ActiveCN109402356APrevent precipitationUniform temperatureRolling contact bearingsShaftsWire rodWater baths

The invention relates to a controlled cooling and controlled rolling method for control over bearing steel wire network carbide. The controlled cooling and controlled rolling method is characterized by comprising the steps that a bar is quickly rolled into a wire with the specified specification to be subjected to spinning, scattered rolls are made, the final rolling temperature is controlled to be 780- 880 DEG C; the spitting temperature is controlled to be 750-850 DEG C; the continuous scattered rolls are subjected to on-line controlled cooling through EDC water bath isothermal quenching cooling, the cooling speed is controlled to be 2.0- 10 DEG C / s, and the final cooling temperature is controlled to be 620-630 DEG C; cover-adding slow cooling is conducted after EDC water bath isothermalquenching cooling, and the temperature when the scattered rolls are taken out from a cover is controlled to be 400-500 DEG C; and the rolls are collected after slow cooling, and air cooling is conducted to the room temperature. The disc rolls are subjected to controlled cooling through a mode of EDC water bath isothermal quenching cooling and cover-adding slow cooling, precipitation of the carbide in the cooling process can be effectively inhibited, a non-equilibrium microstructure is obtained, the small-strip-shaped or hemispheric carbide is formed, and finally, the network carbide is controlled.

Owner:JIANGYIN XINGCHENG GOLD MATERIALS CO LTD +1

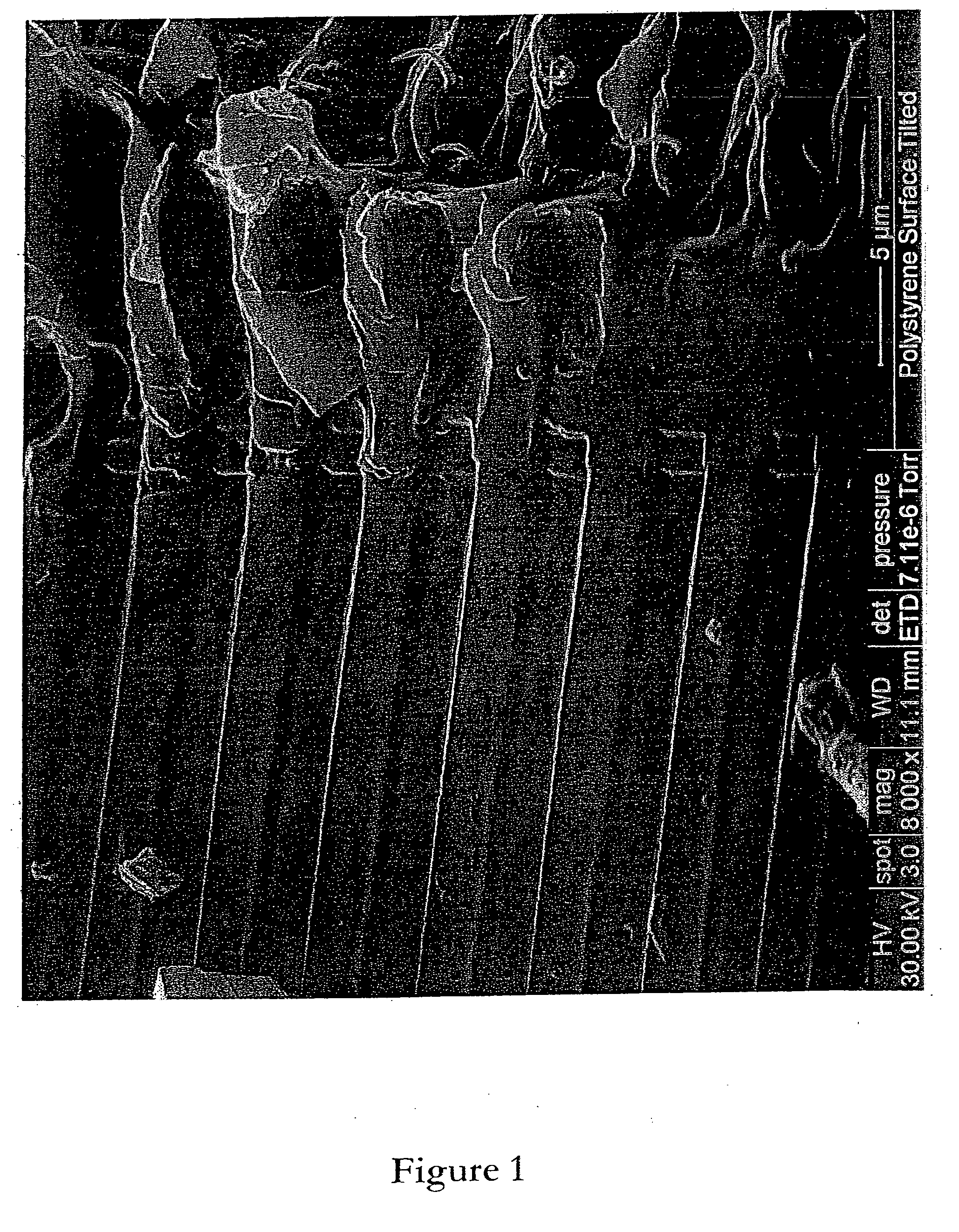

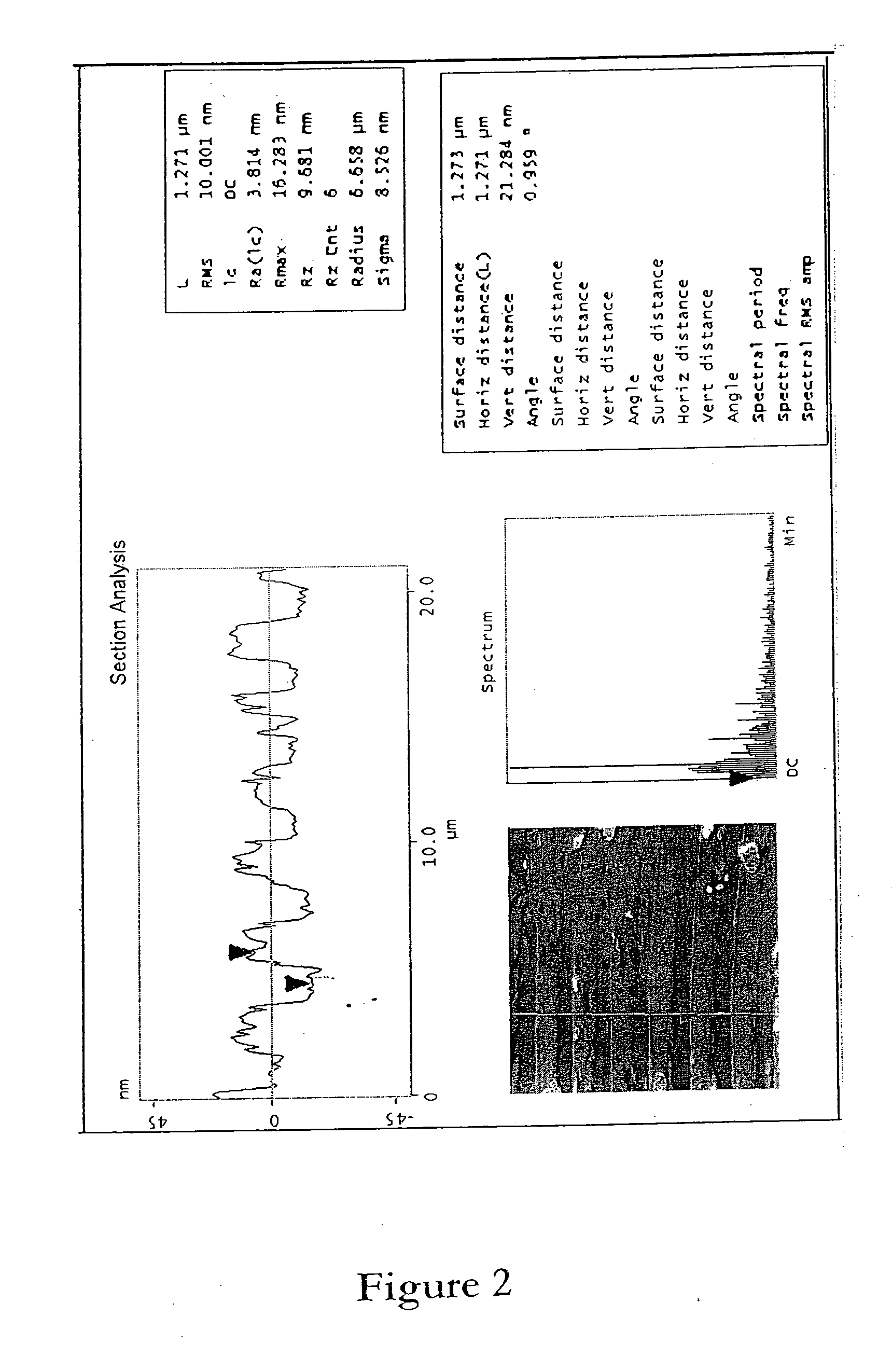

Forming methods

ActiveUS20120100339A1Faster forming (compressionFaster imprinting) processNanostructure manufactureLayered productsVitrificationShear stress

This invention relates to methods for forming polymer(s) including heating of a polymer to be formed to a temperature above its glass transition temperature, continuously depositing (preferably by flowing or laying) the polymer onto a moulding surface (herein the “lower moulding surface”) of a first mould, (preferably in a manner that reduces, eliminates or minimises shear stress or other stress in the polymer so deposited), the polymer remaining above the glass transition temperature, applying a moulding surface (herein the “upper surface”) of the polymer while the polymer remains at a temperature above the glass transition temperature, and allowing the polymer to transition to below the glass transition temperature while within or between the upper and lower moulding surfaces, wherein the polymer is removed from the moulding surfaces. Apparatus is also provided.

Owner:MFG SYST LTD

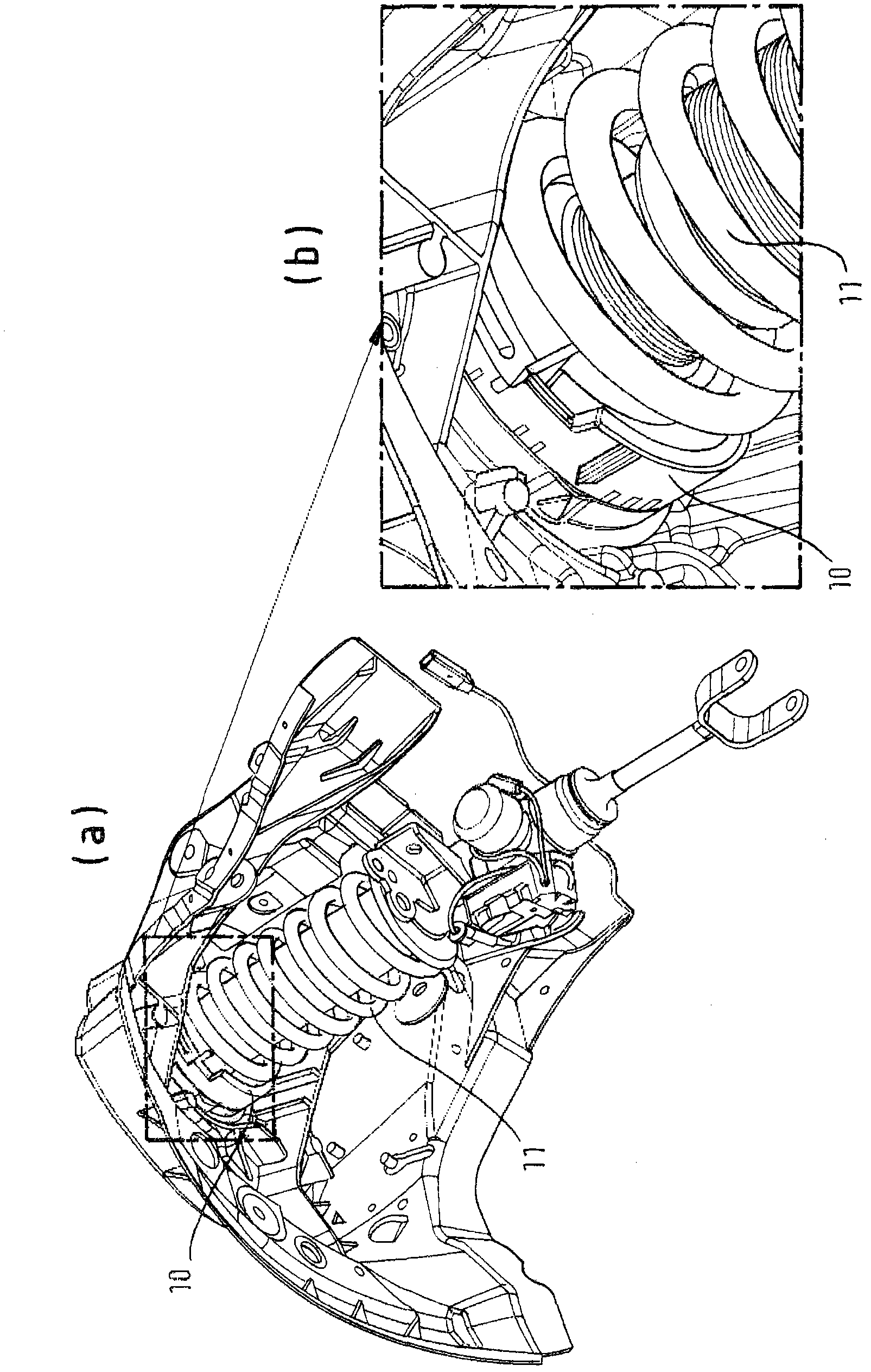

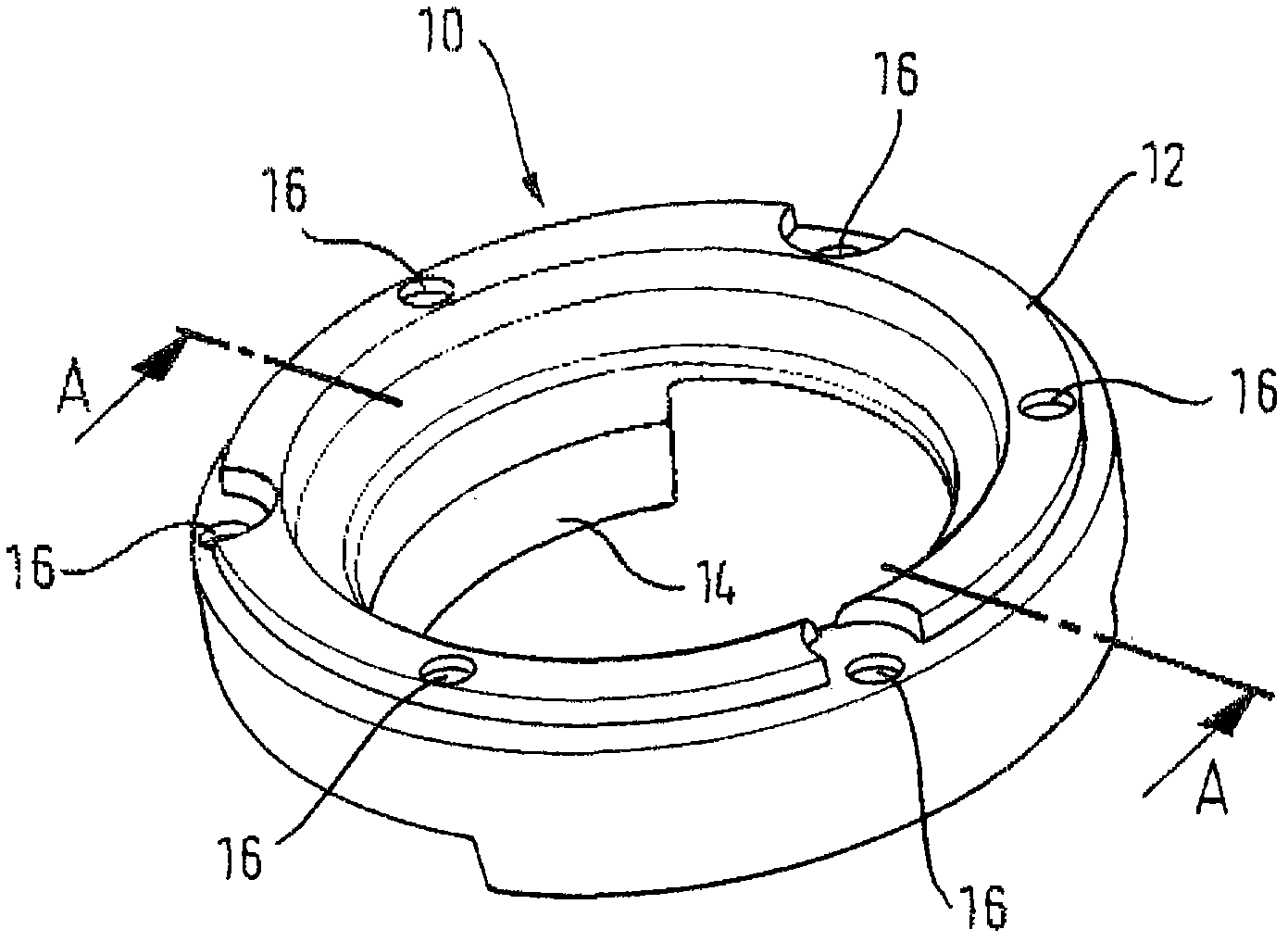

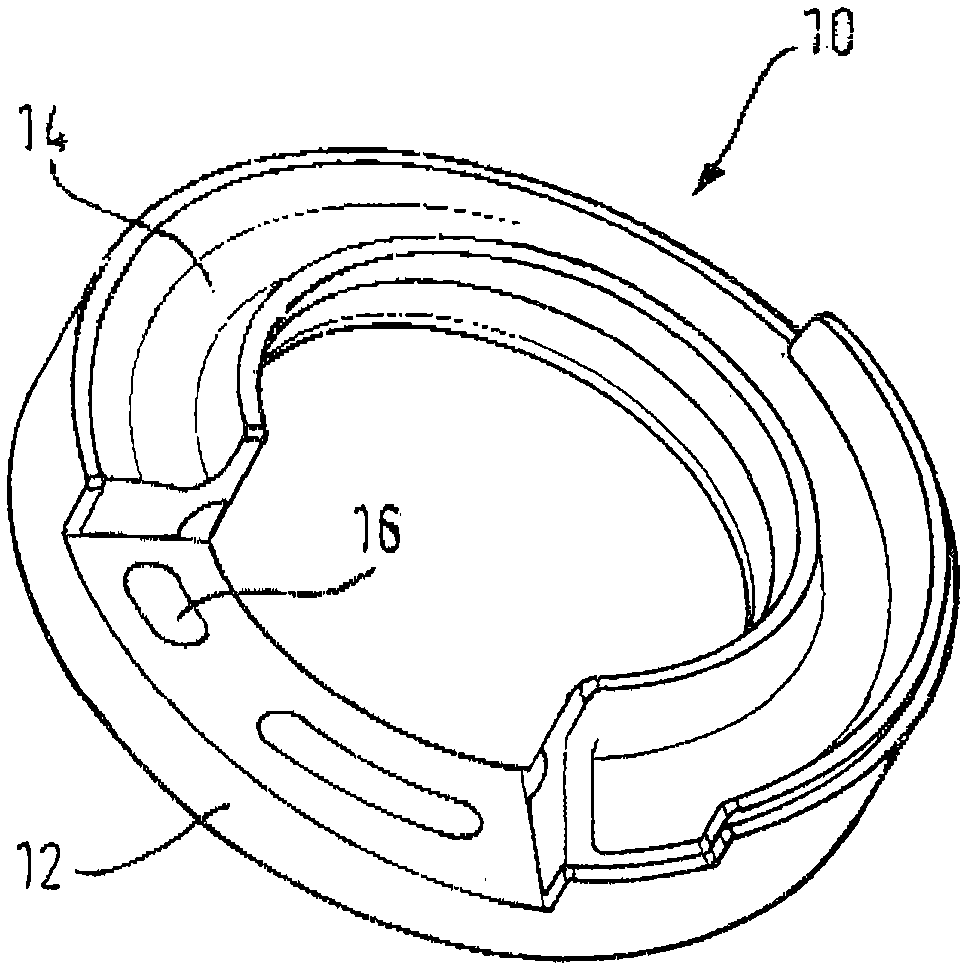

Spring support and method for producing the same

InactiveCN102639897AReduce consumptionPrevent penetrationResilient suspensionsVehicle springsElastomerMechanical engineering

Owner:T 迪泰特

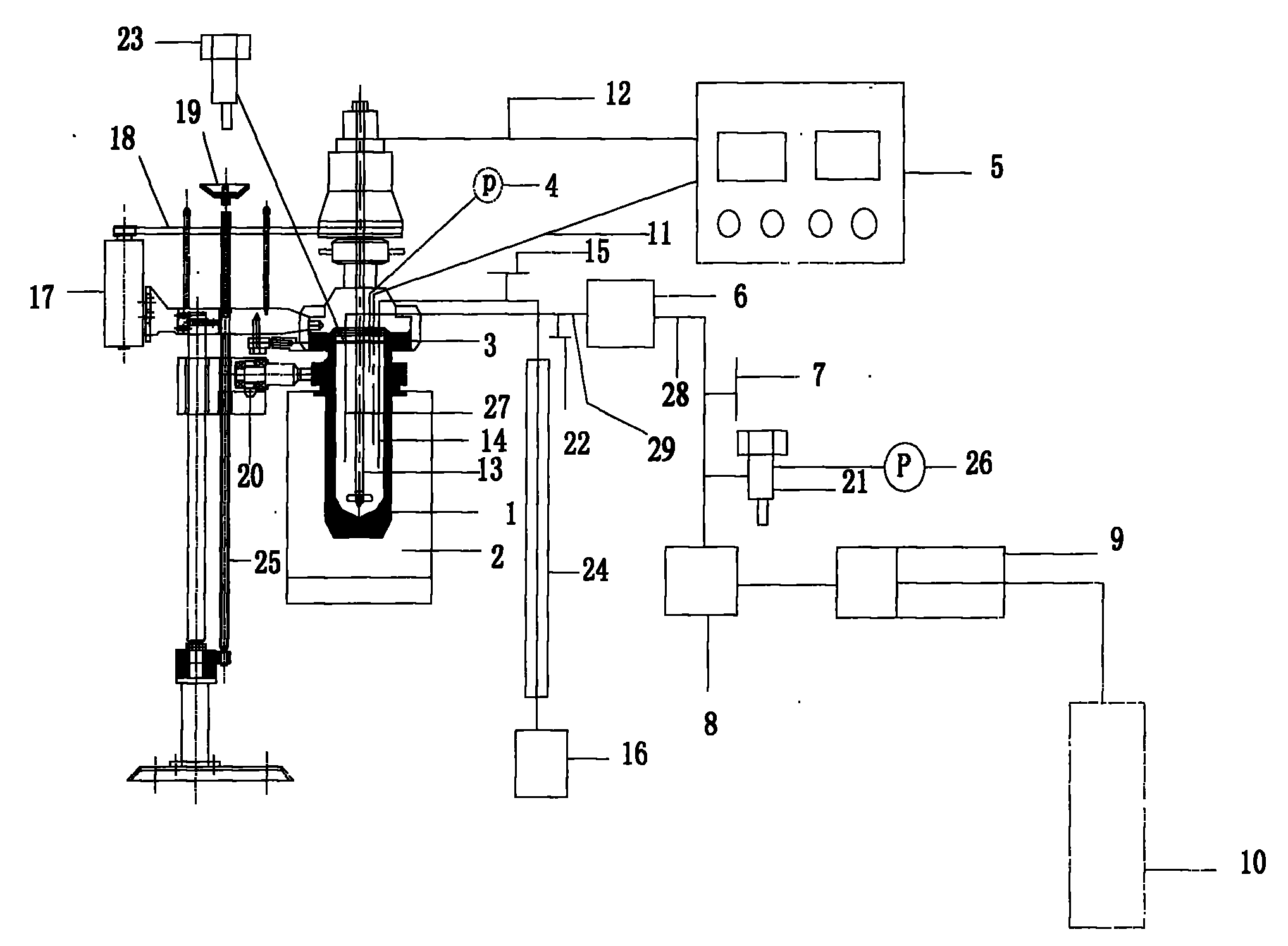

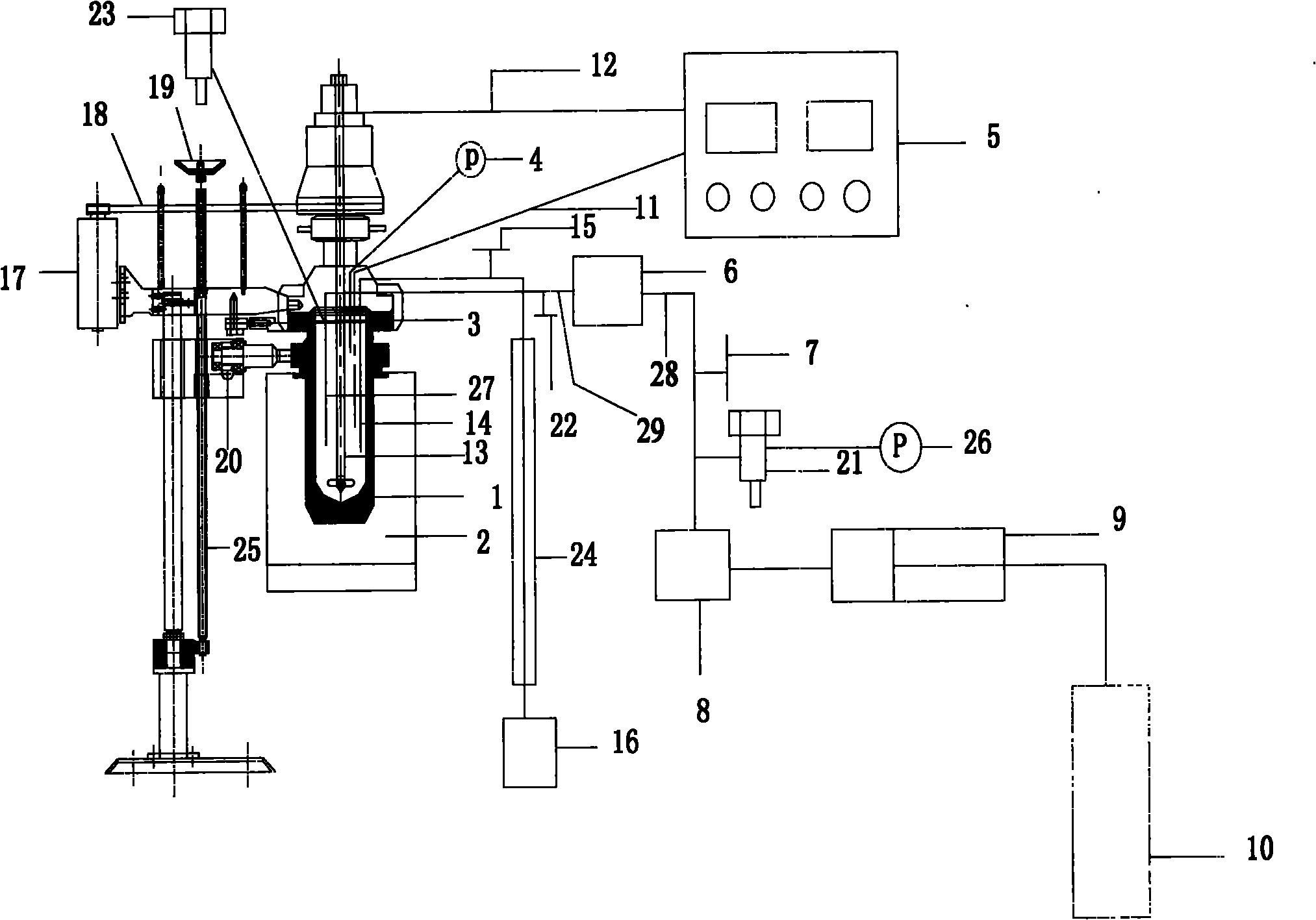

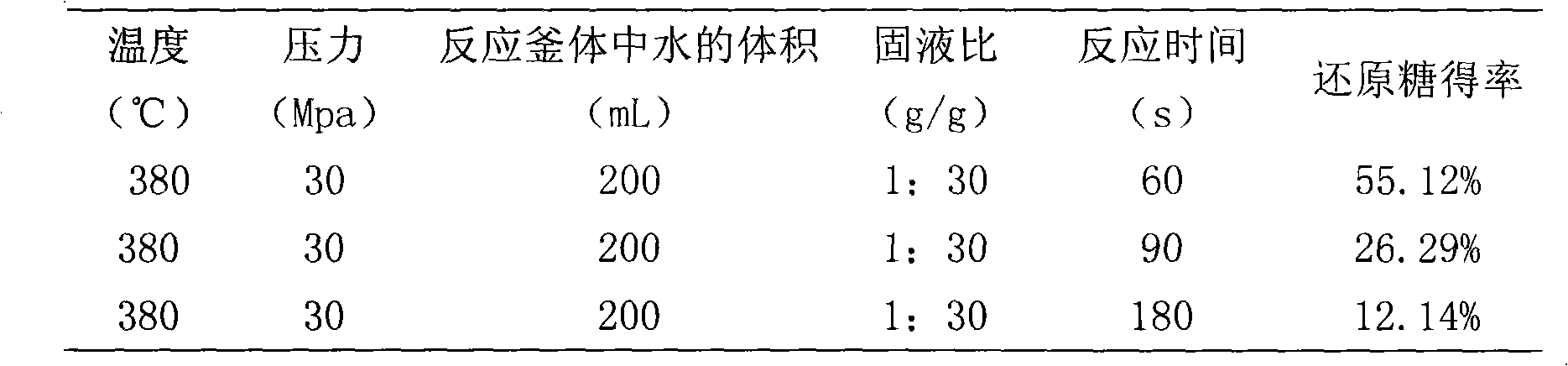

Method for preparing reducing sugar by supercritical hydrolysis of plant fibers and semi-continuous reactor thereof

InactiveCN101899537AAvoid coolingAvoid decompositionChemical/physical/physico-chemical stationary reactorsMonosaccharidesContinuous reactorFiber

The invention discloses a method for preparing reducing sugar by the supercritical hydrolysis of plant fibers and a semi-continuous reactor thereof. According to the method, supercritical hydrolysis is realized by high-pressure feeding and high-pressure sampling. The reaction conditions of a reactor are that: the temperature is between 380 and 400 DEG C; the pressure is 24 to 30MPa; the volume ofwater in a kettle is 150 to 200mL; solid-liquid ratio (g / g) of added plant fiber slurry is 1:30-1:65; and reaction time is 5s to 5min. The reactor comprises a feeding part, a reactor body and a product collecting part, wherein the feeding part presses materials into the reactor by the high pressure stored in a material storage tank; and the sampling part presses a reaction product into a sample receiving bottle through a sampling tube by the high pressure in the reactor. Because the volume of the supercritical water is much more than that of the materials, the materials can smoothly exchange heat in an instant to reach the set condition. The process is considered not to be subjected to other reactions beyond the supercritical condition. The yield of the reducing sugar prepared by the method can be over 50 percent.

Owner:SOUTH CHINA UNIV OF TECH

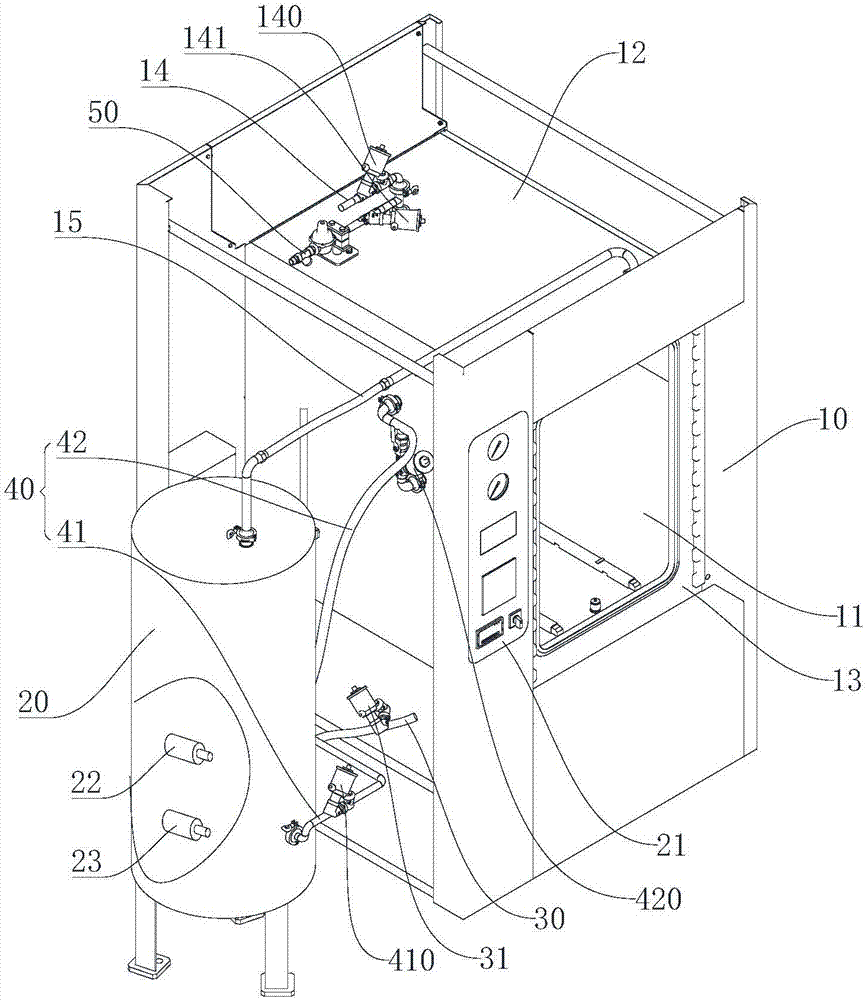

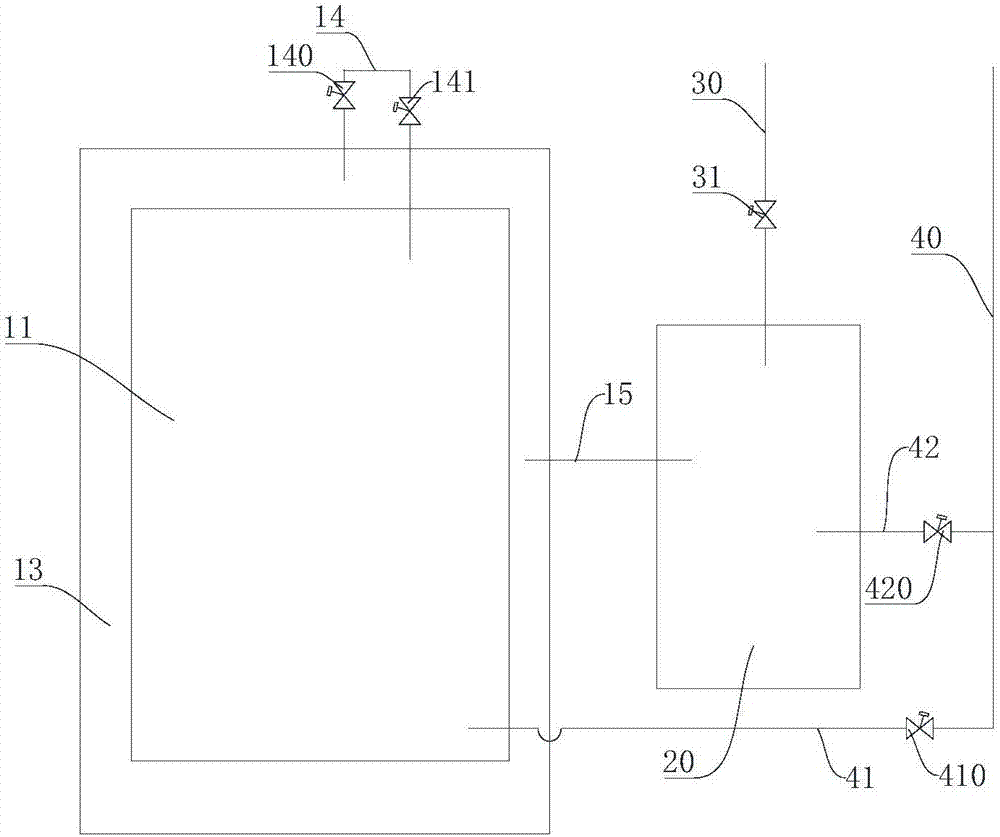

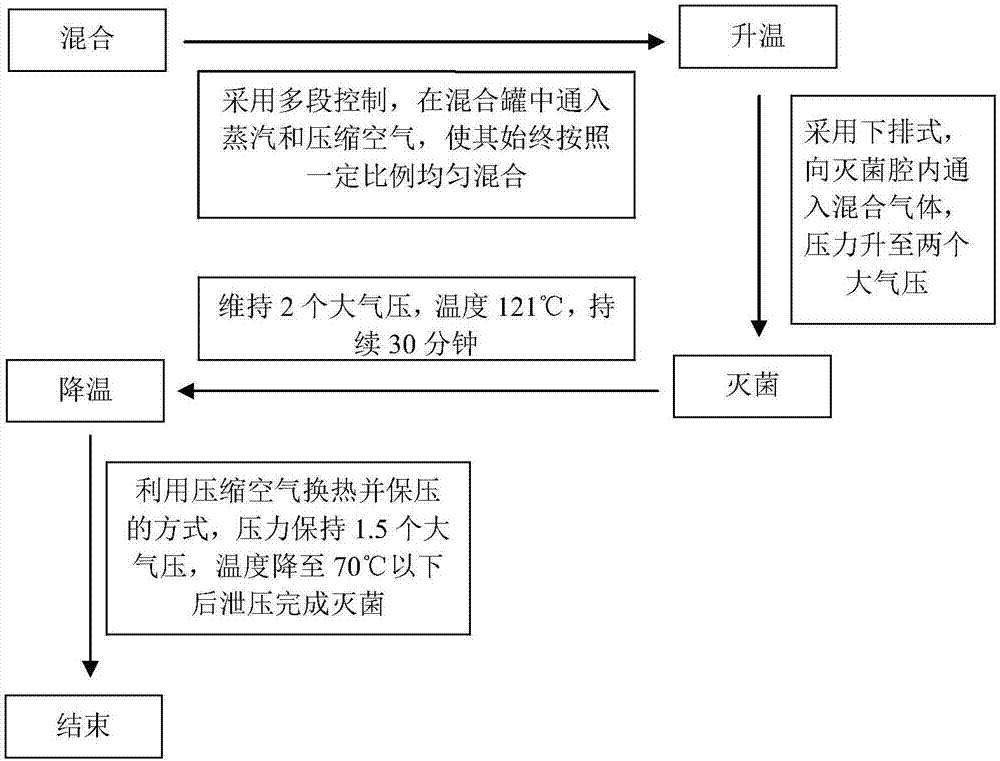

High-temperature sterilizer and sterilizing method adopting high-temperature sterilizer

The invention provides a high-temperature sterilizer and a sterilizing method adopting the high-temperature sterilizer, and relates to the field of article disinfecting and sterilizing. The high-temperature sterilizer comprises a sterilizing tank, a mixing tank, a steam pipeline, a compressed air pipeline and a water inlet pipeline, wherein the sterilizing tank comprises an inner chamber and a housing; a jacket is defined between the housing and the inner chamber; the inner chamber communicates with the jacket by virtue of a first connecting pipe; the jacket communicates with the mixing tank by virtue of a second connecting pipe; the steam pipeline communicates with the mixing tank; the compressed air pipeline communicates with the mixing tank and the inner chamber; and the water inlet pipeline communicates with the inner chamber. The sterilizing method comprises such steps as mixing, heating up, sterilizing, cooling down, ending and the like. According to the high-temperature sterilizer and the sterilizing method provided by the invention, compressed air and steam, after being mixed according to a certain proportion, are filled into the inner chamber, so that good sterilizing temperature uniformity and relatively low temperature fluctuation in the sterilizing chamber are guaranteed; sterilized articles are sterilized, and liquid in sterilized article packaging is constantly kept below a boiling point of corresponding pressure, so that a circumstance that the packaging gets broken due to boiling is prevented and small packaging deformation can be guaranteed.

Owner:LAOKEN MEDICAL TECH

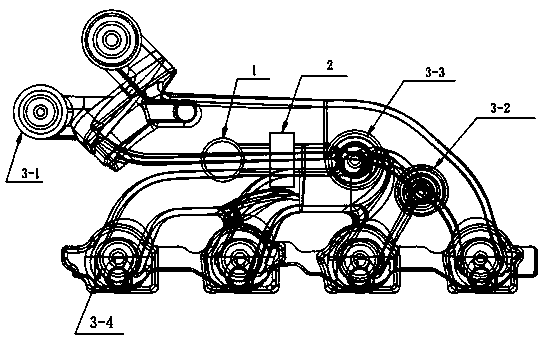

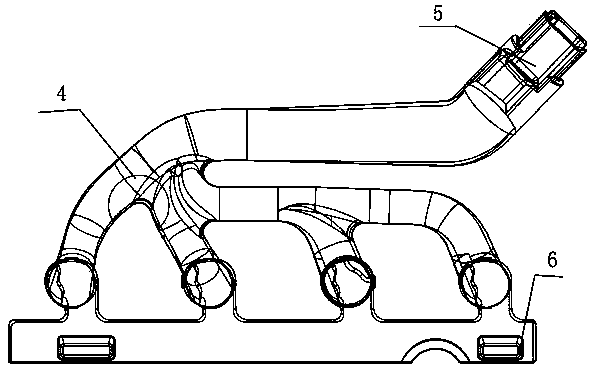

Thick-wall cast steel exhaust manifold casting process

ActiveCN108655348AReality GuaranteeComplex structureFoundry mouldsFoundry coresPass rateCasting mold

The invention discloses a thick-wall cast steel exhaust manifold casting process and belongs to the technical field of exhaust manifold casting. According to the thick-wall cast steel exhaust manifoldcasting process, a thick-wall cast steel exhaust manifold casting mold and method are included. The casting mold comprises a sand mold, feeder heads, a sand core and a pouring system. The sand core is provided with multiple sand jetting openings. The pouring system comprises a sprue bar, a cross gate and an ingate. The sprue bar communicates with the cross gate in a perpendicular manner. A filteris arranged in the middle of the cross gate. The feeder heads comprise the large-face feeder heads, the triangular flange feeder heads, the fire inlet feeder head and the heat preservation feeder head. The fire inlet feeder head is arranged at the tail end of the cross gate. The thick-wall cast steel exhaust manifold casting process is good in mechanical performance, uniform in wall thickness andresistant to high temperature. The thick-wall cast steel exhaust manifold casting mold and method are included. The wall thickness of a casting ranges from 5.5 mm to 6.5 mm, and the weight ranges from 8 Kg to 12 Kg. Technical requirements are met; performance is stable; the problem that molding is difficult to achieve when common casting processes are adopted is solved; and the qualification rateof products is high.

Owner:NANYANG FEILONG AUTOMOBILE PARTS CO LTD

Gas auxiliary injection molding process for household electrical appliance casing

InactiveCN101077612AImprove appearance qualityImprove mechanical propertiesDomestic articlesState of artNitrogen

The present invention relates to one kind of improved gas aided injection molding process for producing casing for electric appliance. The process includes the first injecting plastic melt in the amount of 95-97 % of the casing weight into the mold cavity and the subsequent injecting high pressure nitrogen through the preset gas channel, which is set in the place near the interjunction between the front side and the lateral side of the casing. Compared with available technology, the present invention has the advantages of raised casing forming efficiency, lowered cost and good appearance of the product.

Owner:TAICANG QIUJING PLASTIC MOLD

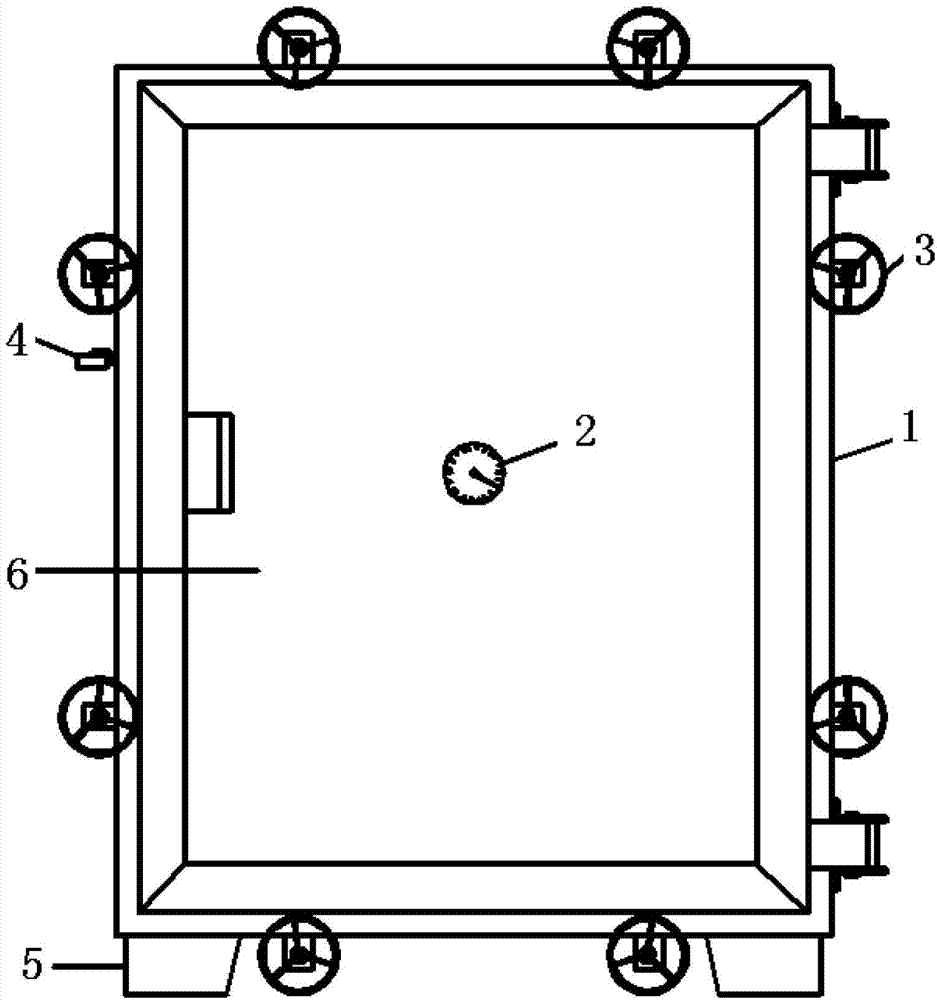

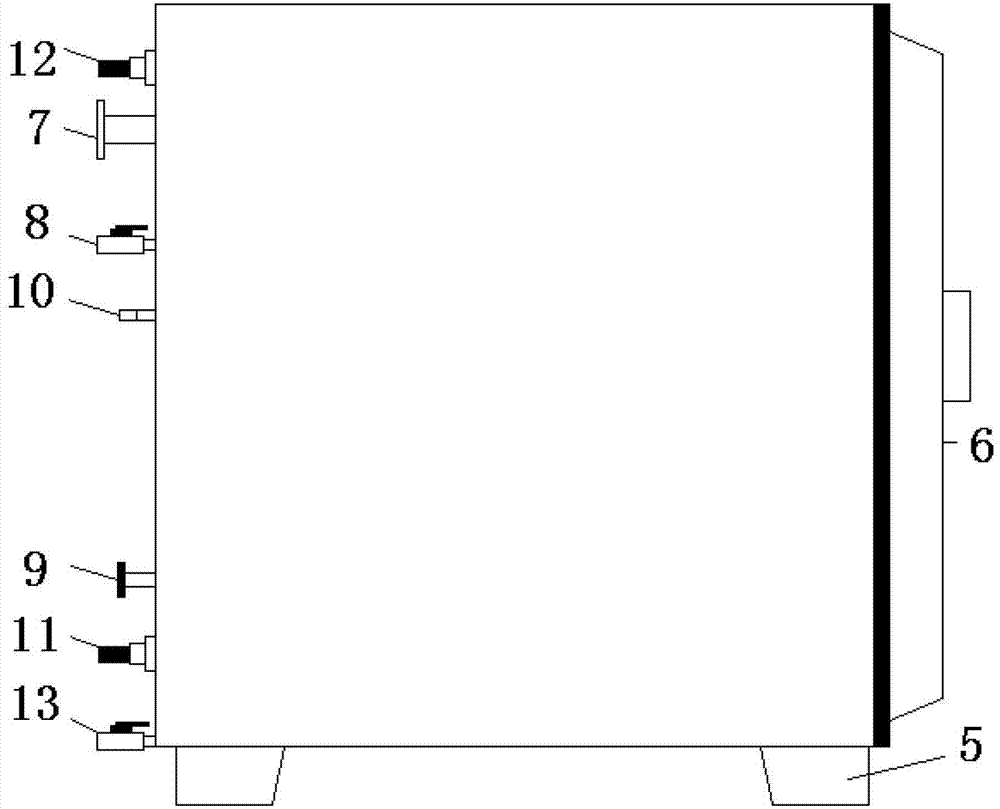

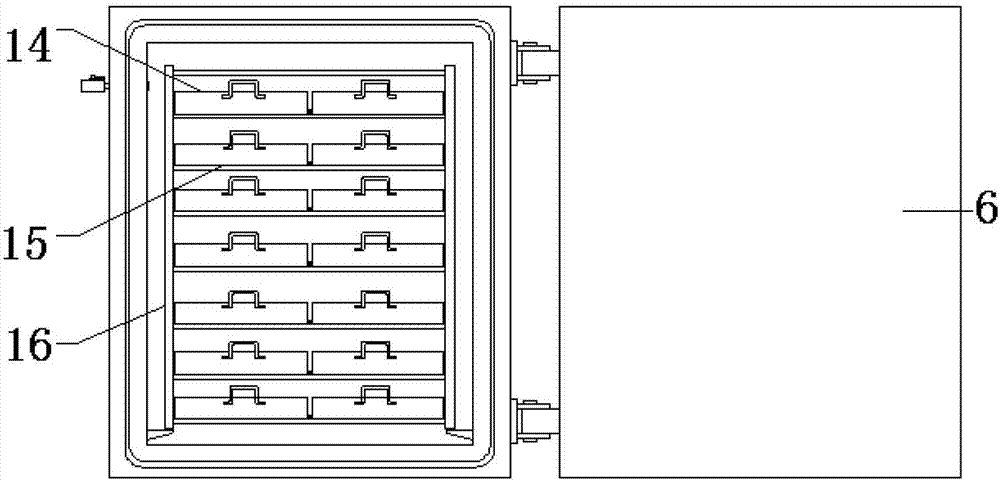

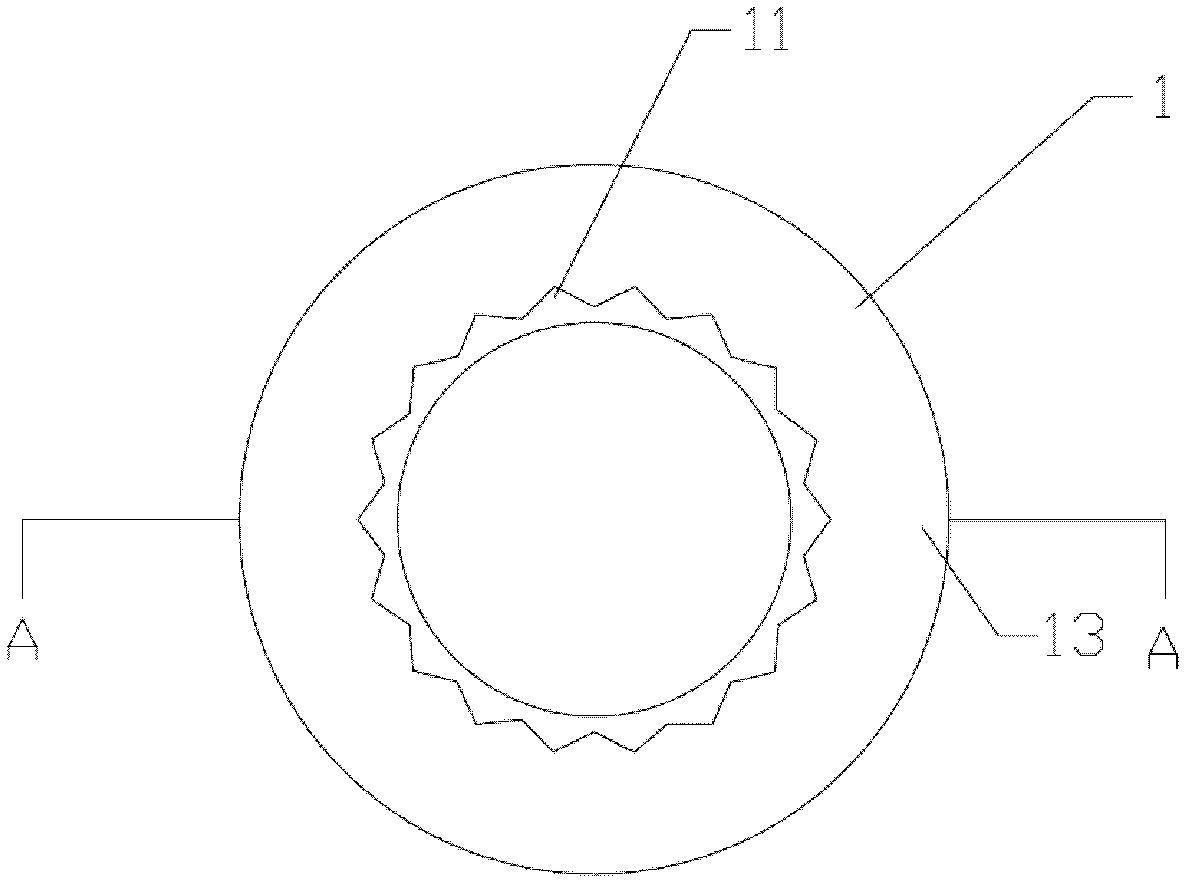

Drying device and drying method for high-purity silicon materials

ActiveCN102818439AEvenly heatedSimple structureDrying using combination processesDrying chambers/containersEngineeringVacuum pump

The invention discloses a drying device for high-purity silicon materials. The drying device comprises a case. The case is a sealed case with a sealing door, multiple layers of drying plate supports are arranged in an inner cavity of the case, toothed rails are arranged on each layer of drying plate supports, and drying plates are disposed on the toothed rails; two vacuum breaking ports are respectively arranged on side walls of the case; the case is communicated with a vacuumizing device via a vacuumizing port on a side wall, is communicated with a vacuum gauge via a vacuum verifying hole on the side wall and is communicated with a medium circulating heating device via a heat-conduction medium inlet and a heat-conduction medium outlet on the side wall simultaneously; and the vacuumizing device and the medium circulating heating device are respectively connected with a control device via signals. The invention further discloses a drying method for the high-purity silicon materials. The drying method includes placing the to-be-dried high-purity silicon materials in the sealed case; vacuumizing the case by a vacuum pump; heating to dry the high-purity silicon materials; detecting a drying effect in real time; and heating the high-purity silicon materials until technical requirements are met. The drying device and the drying method have the advantages of simple structure and high drying efficiency.

Owner:LONGI GREEN ENERGY TECH CO LTD

Quick-cooling device for fiber yarn pipelines

The invention discloses a quick-cooling device for fiber yarn pipelines. The quick-cooling device comprises a horizontal cooking box, fiber channels, air nozzles, a water inlet pipe, a water outlet pipe and a radiating box, wherein the cooling box adopts a cylinder structure; the fiber channels penetrate through two ends of the cooling box; the air nozzles are arranged at the two ends of the radiating box, and are aligned with the fiber channels; the water inlet pipe is arranged at the upper part of the side surface of the cooling box; the water outlet pipe is arranged at the lower part of the side surface of the cooling box; the radiating box is arranged outside the cooling box; a three-way valve I is arranged at the connection part between the water inlet pipe and the radiating box; a three-way valve II is arranged at the connection part between the water outlet pipe and the radiating box; a water pump is arranged on the radiating box; V-shaped radiating fins are arranged on the surfaces of the fiber channels inside the cooling box. The combined action of air cooling and water cooling is adopted, so that the cooling time is short; the radiating box is arranged outside the cooling box, and the radiating fins are arranged outside the fiber channels, so that the radiating area is increased, the radiating speed is high, and the radiating effect is good.

Owner:JIANGSU ZHONGSHI FIBER CO LTD

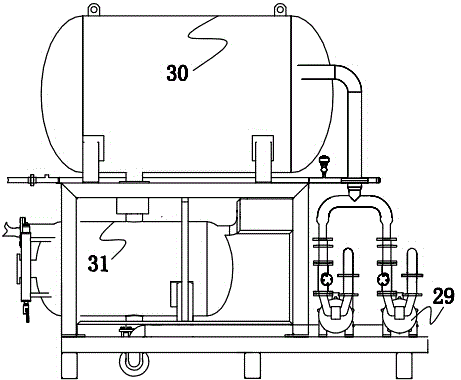

Sterilizing method and device for jam and fruit juice which are heated directly by steam and cooled by flash evaporation

ActiveCN102232499AGood sensory and quality propertiesGuarantee product qualityFood preservationFood preparationFruit juiceEngineering

The invention discloses a sterilizing method for jam and fruit juice which are heated directly by steam and cooled by flash evaporation, which comprises the following steps of: 1) mixing jam or fruit juice raw materials and the steam, and heating quickly to the sterilizing temperature to obtain high-temperature materials; 2) keeping the temperature and sterilizing the materials obtained in the step 1); and 3) cooling the materials obtained in the step 2) quickly by a flash evaporation process. The invention also aims to provide a sterilizing device for the jam and the fruit juice, which comprises a steam injection heater, a maintaining tank and flash evaporation equipment which are connected sequentially, wherein the flash evaporation equipment comprises a flash evaporation cooler connected with the maintaining tank and a vacuum pump connected with the flash evaporation cooler. By the sterilizing method and the sterilizing device for the jam and the fruit juice which are heated directly by the steam and cooled by the flash evaporation, the pasteurization of the jam and the fruit juice can be realized, the concentration and viscosity of products can be improved, the color and luster of the products can be protected, so that the high-quality jam and fruit juice products are obtained, and the products can be widely used.

Owner:孔凡东

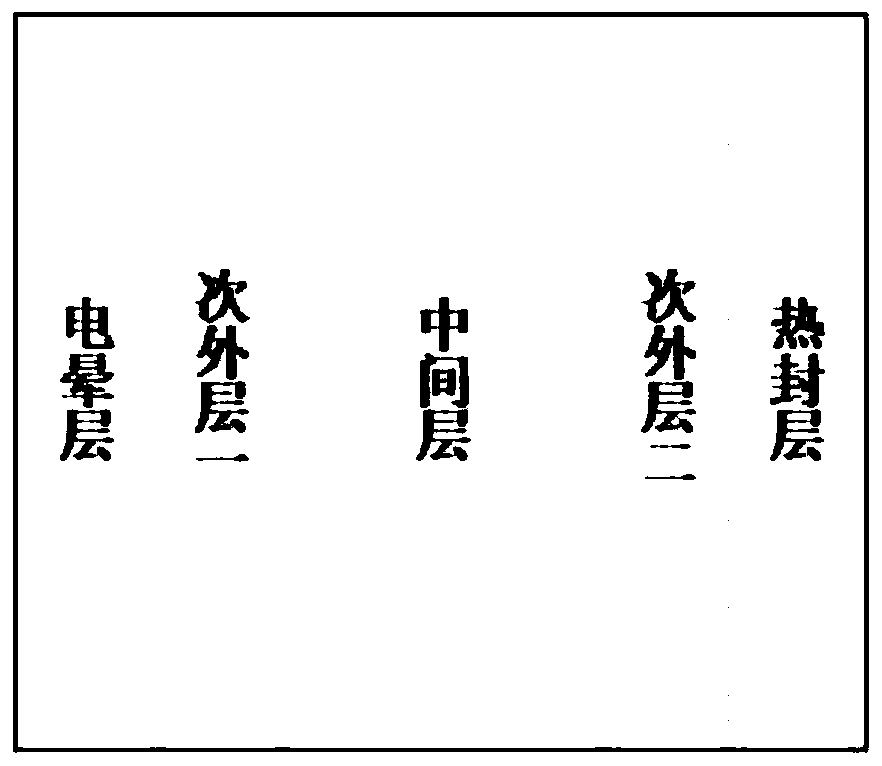

High-light low-haze PE heat shrinkable film and preparation method thereof

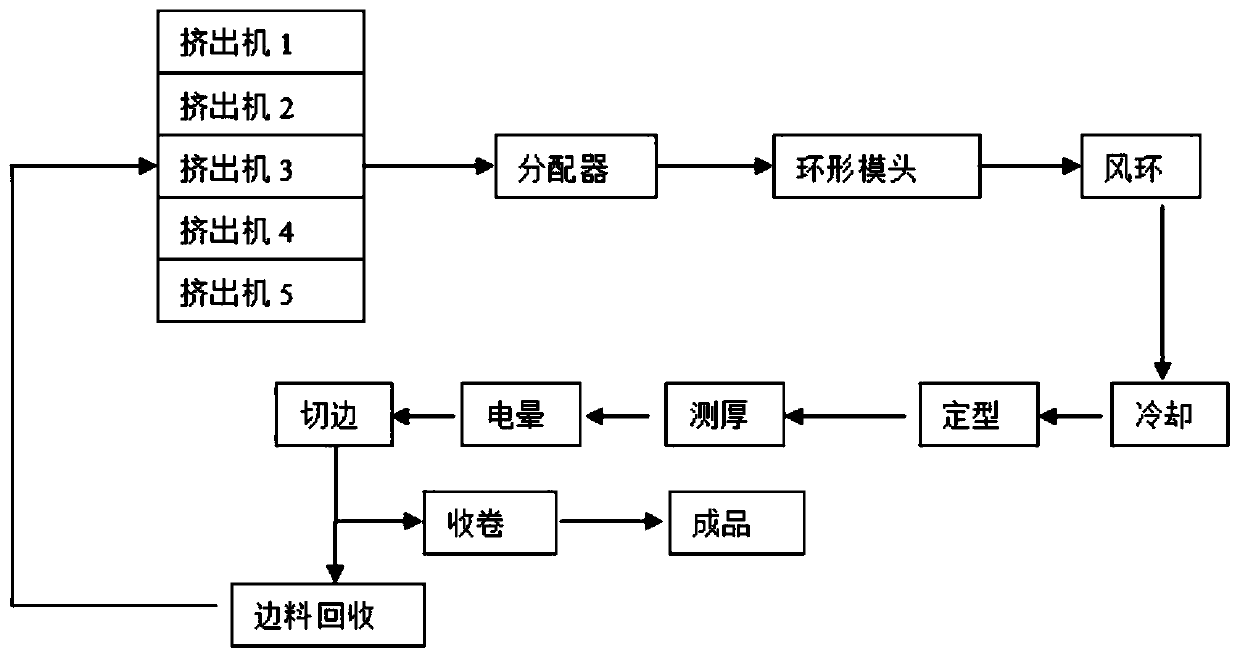

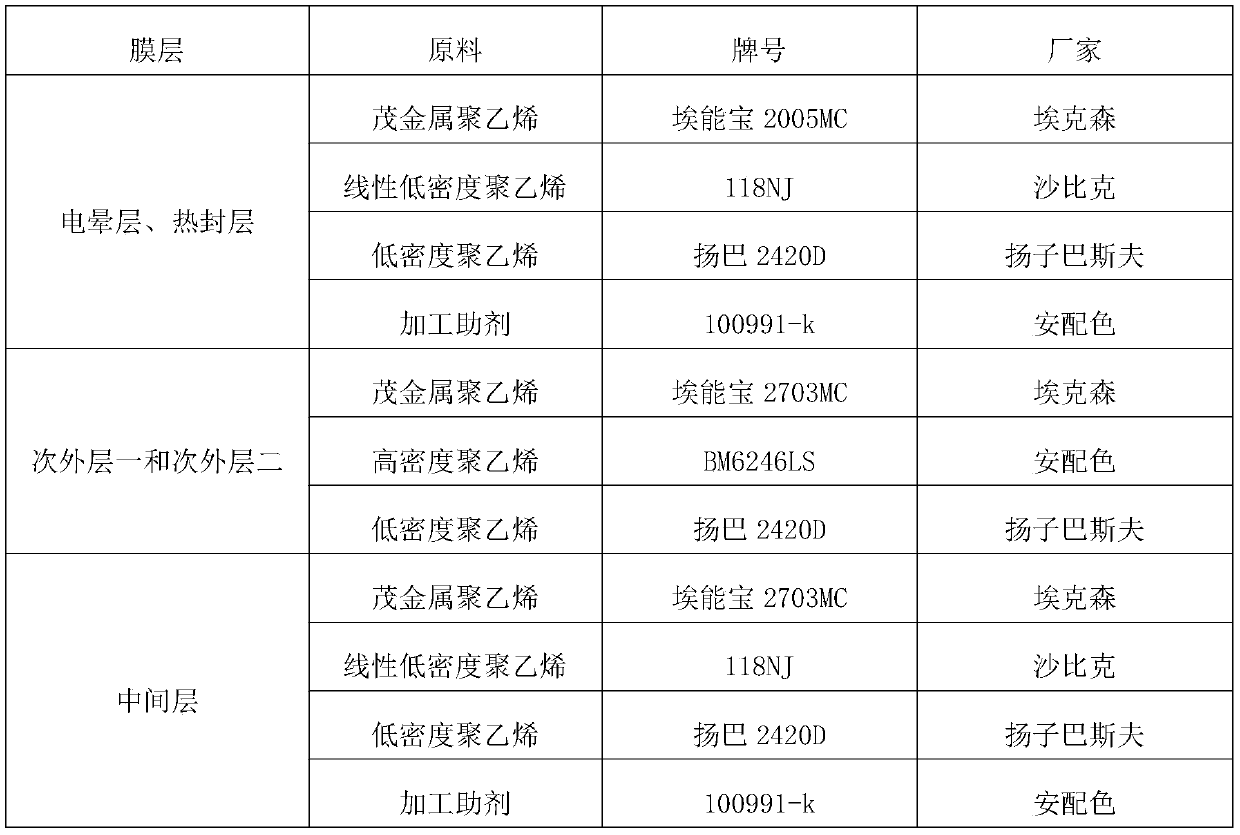

ActiveCN110216960AFlat forceIncrease productivitySynthetic resin layered productsLaminationLow-density polyethyleneLinear low-density polyethylene

The invention relates to a high-light low-haze PE heat shrinkable film and a preparation method thereof. A film layer structure of the PE heat shrinkable film successively comprises a corona layer, afirst sub-outer layer, an intermediate layer, a second sub-outer layer and a heat sealing layer; the corona layer, the intermediate layer and the heat sealing layer separately comprise metallocene polyethylene, linear low-density polyethylene, low-density polyethylene and a processing aid in a mass ratio of (28-32):(8-12):(58-62):(0.1-0.3); and the first sub-outer layer and the second sub-outer layer separately comprise metallocene polyethylene, high-density polyethylene and low-density polyethylene in a mass ratio of (28-32):(28-32):(38-42). The PE heat shrinkable film has high shrinkage rate, powerful shrinkage memory function, large tensile strength, powerful puncture resistance and anisotropic tearing resistance, and has the characteristics of low haze, high transparency and high gloss, the friction coefficient is moderate and stable, thickness uniformity and flatness are good, and printing adaptability is good.

Owner:HUANGSHAN NOVEL

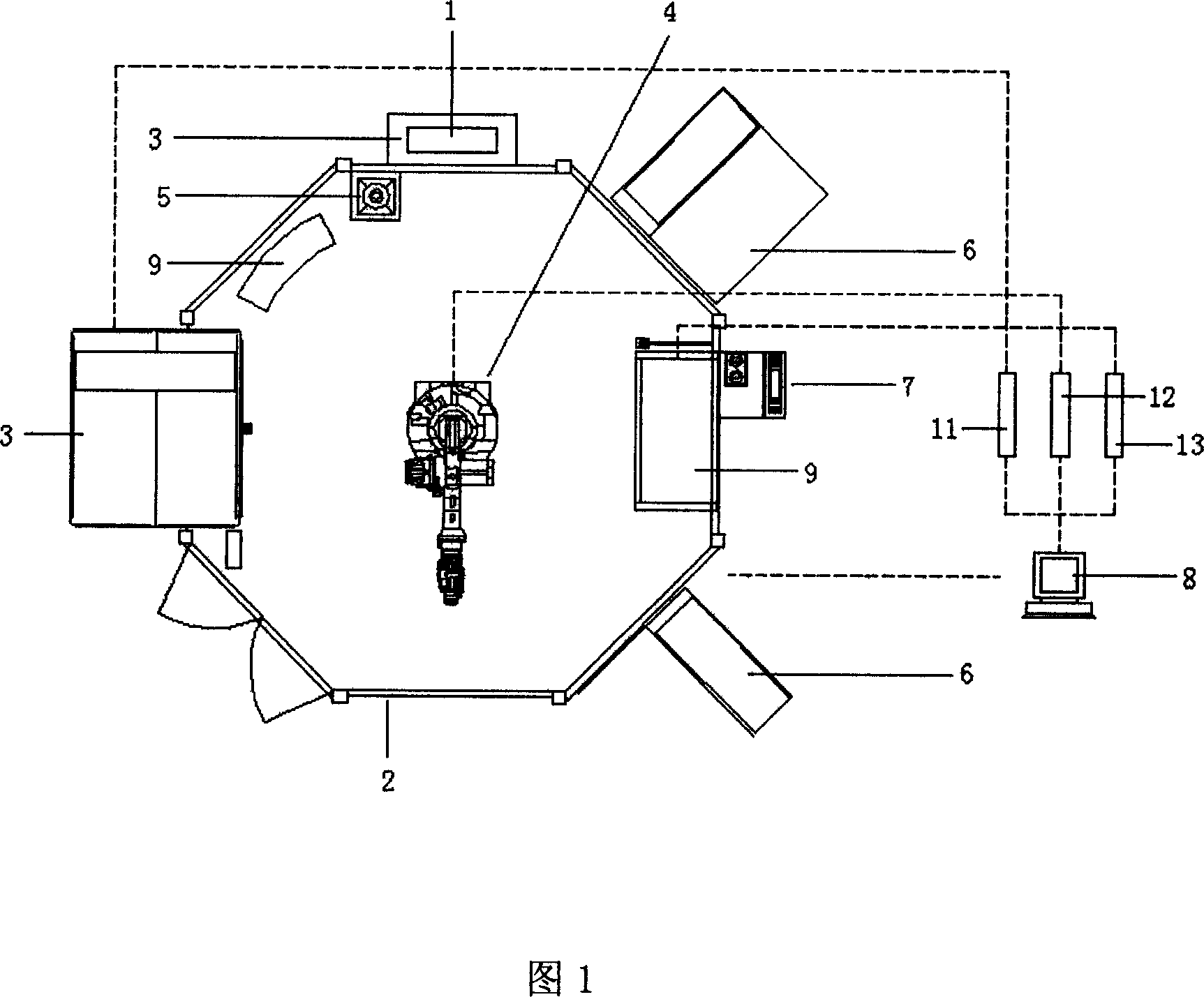

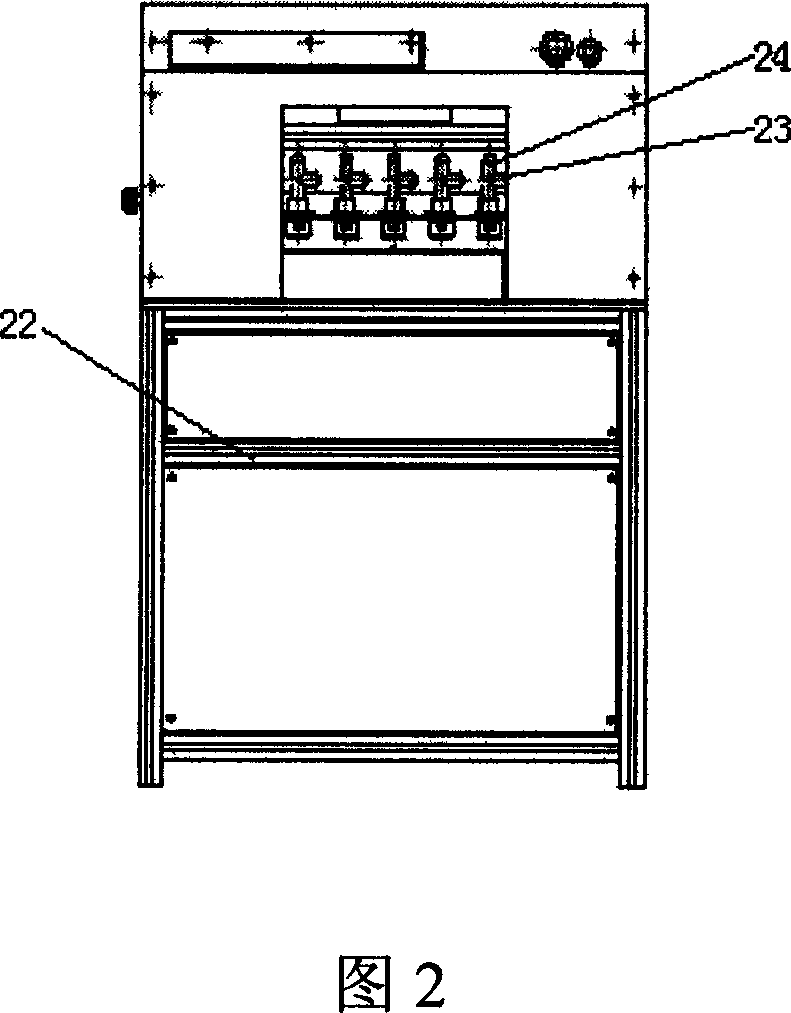

Unmanned analysis experiment lab system and its usage method

InactiveCN101078684AIntelligently optimize the running pathImprove job stabilityColor/spectral properties measurementsSpectrum analyzerEngineering

The invention relates to an unmanned analysis lab system and the using method. It comprises two spectrum analyzers, of which all work in parallel or one works and the other prepares. Furthermore, the sample cooling system comprises bracket, sample setting platform, probe, control unit, air cooling structure and water cooling structure set near the sample setting platform. Air cooling structure and water cooling structure are connected with the control unit and each has open port facing to the sample position on the sample setting platform. Because two spectrum analyzers works at the same time system working stability is improved fully; reliability of no-failure running of system is ensured; and system power efficiency is made the maximum. The cooling device adopts air and water cooling combination method. According to different sample temperature cooling method is selected automatically to decrease the probability that bug is generated in sample greatly. It is provide with very fast cooling speed.

Owner:陈波

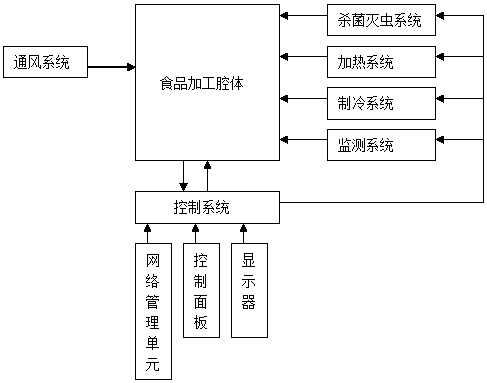

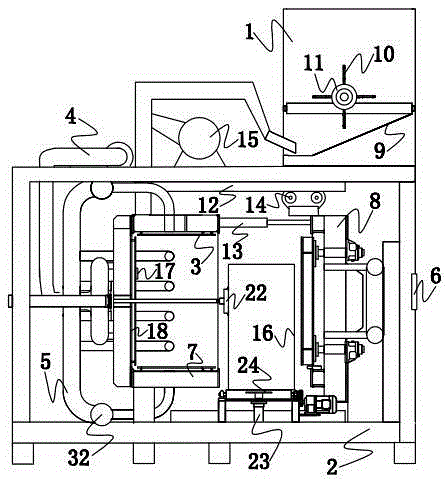

Processing method and equipment for performing safe fresh keeping on raw sliced fish and sliced meat

PendingCN108157482AThe condition is not damagedNot spoil the tasteFood thermal treatmentMeat/fish preservation by heatingFlavorControl system

The invention discloses a food processing method and equipment capable of performing safe fresh keeping on raw sliced fish and sliced meat and quickly killing pathogenic bacteria and parasites. The equipment mainly comprises a food processing cavity, a control system, a sterilizing and parasite killing system, a heating system, a refrigeration system, a monitoring system and a power system, is mainly applied to fresh food materials of the raw sliced fish, the sliced meat or fruits and vegetables and the like, and can quickly kill pathogenic bacteria and the parasite in the fresh food materials. While in use, foods to be processed are placed in the food processing cavity and are processed according to requirements; sterilizing and parasite killing are performed through corresponding operations; and the change of temperature of the foods is controlled and managed, so as to obtain better condition, better mouth feel and better flavor of foods. I In addition, the operating power and the operating manner of each system can be intelligently adjusted by the equipment disclosed by the invention through monitoring the change of the state in the course of processing the food materials, so that the effect of performing sterilizing and parasite killing on different bacterium species and different parasites of the different food materials is achieved; the equipment is safe and hygienic; andbesides, the purposes that the condition, the mouth feel and the flavor of the foods are maintained is achieved.

Owner:GUANGXI NQT ELECTRONICS TECH CO LTD

Production technology of Teflon film

InactiveCN104249466AReduce the temperatureSpecial craftFlat articlesVolumetric Mass DensityPolytetrafluoroethylene

The invention discloses a production technology of a Teflon film. The production technology comprises a material temperature-keeping process, a compacting process, a sintering process and a turning process. The material temperature-keeping process and the compacting process utilize dust-free purified workshops as production workshops. A vacuum automatic feeding technology is used in all feeding processes. The Teflon film obtained by the production technology has uniform density, is prepared by special processes, has a low treatment cost and has thickness tolerance within + / -2% improved by five times than that of the traditional technology.

Owner:曹建林

Plastic foam plate forming machine

The invention discloses a plastic foam plate forming machine. A storage box is arranged above a rack. A main die cavity fixed to the rack and an auxiliary die are arranged in the rack, the auxiliary die is in sliding connection with the rack, and a closed hexahedron container is formed by the main die cavity and the auxiliary die. The auxiliary die is driven by a hydraulic cylinder installed on the main die cavity to achieve slippage die stripping on the rack. A die plate is arranged on the main die cavity and the auxiliary die and provided with a face pressure inductor. An air distributing plate is arranged between the main die cavity and the die plate. A steam pipeline is communicated with the main die cavity. A push device is fixedly connected to the outer side of the main die cavity. A material supporting device and a conveying device are arranged below the rack. A cooling system connected with the main die cavity through a cooling pipeline is further included. The face pressure inductor, a drive device, the material supporting device, the conveying device and the cooling system are controlled through a control system. The plastic foam plate forming machine is high in automation degree, short in cooling time, good in cooling effect and high in efficiency and safety, and die stripping is convenient.

Owner:QINGDAO HEINOSKY TECH CO LTD

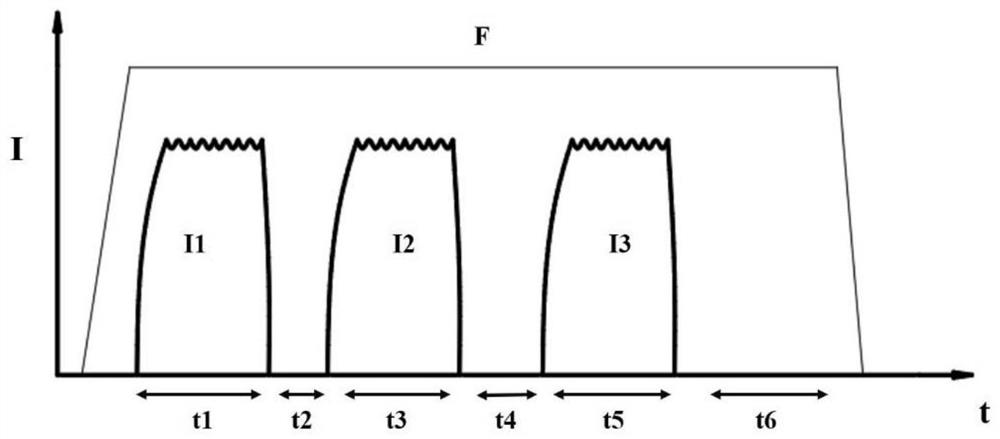

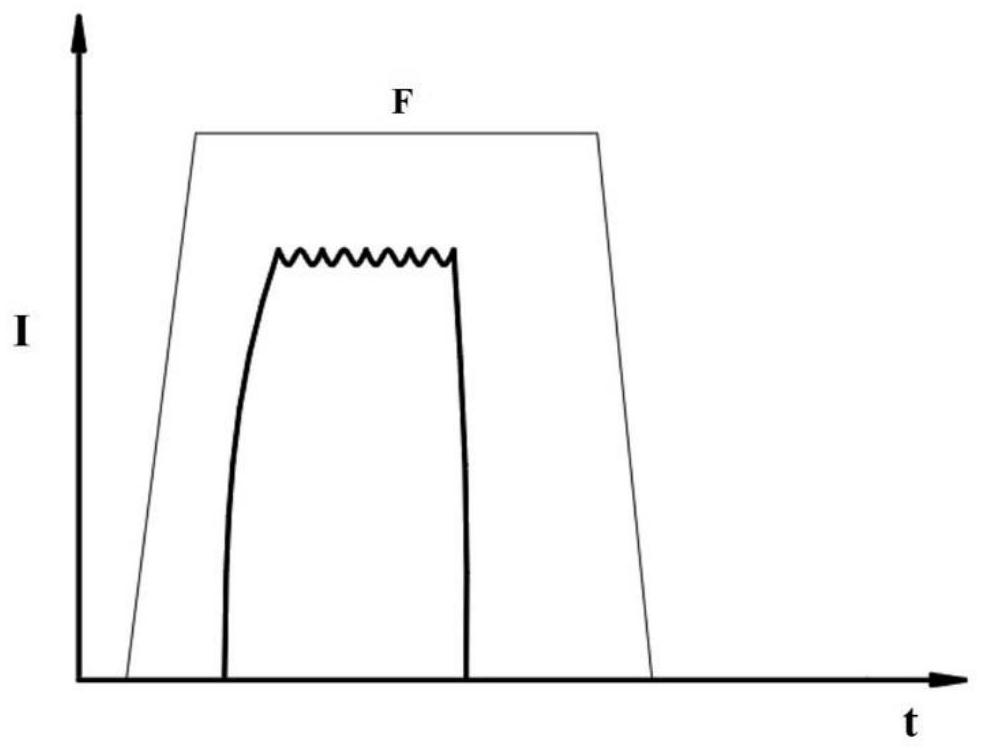

Method for inhibiting generation of internal defects of aluminum alloy resistance spot welding nugget

ActiveCN112570867ALess shrinkage and crystallizationReduce tensile stressWelding electric supplyElectrical resistance and conductanceSpot welding

The invention discloses a method for inhibiting generation of internal defects of an aluminum alloy resistance spot welding nugget, and belongs to the technical field of resistance spot welding. A welding current is divided into an electrifying heating stage, a cooling stage and a pressure maintaining stage, wherein in the electrifying heating stage, the current amplitude of the welding current is15KA-60KA, and the electrifying time is 50ms-200ms; and in the cooling stage, the current is 0-15KA, and the cooling time is 2ms-40ms. According to the welding method, due to the existence of the cooling stage, welding heat input is stable, and internal stress of a welding spot is reduced, so that the generation of the defects such as cracks and air holes in the nugget is inhibited, and the effect of improving the strength of the welding spot is achieved.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

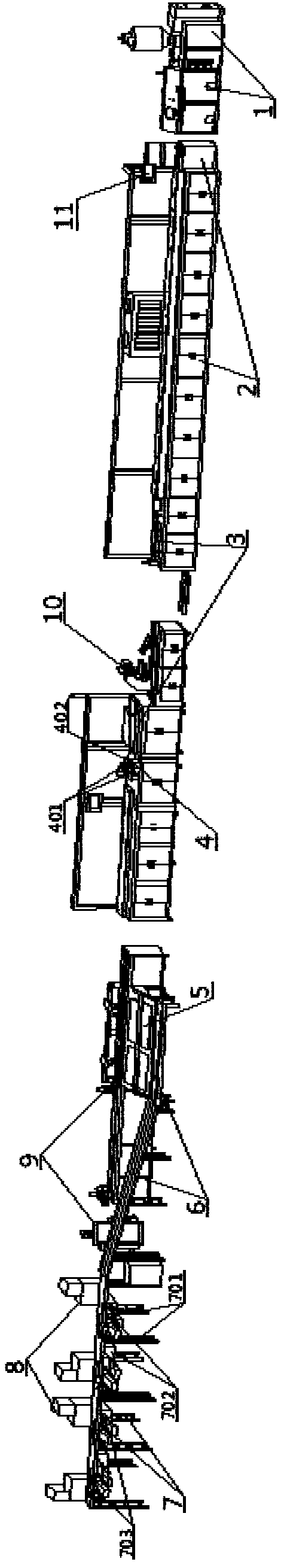

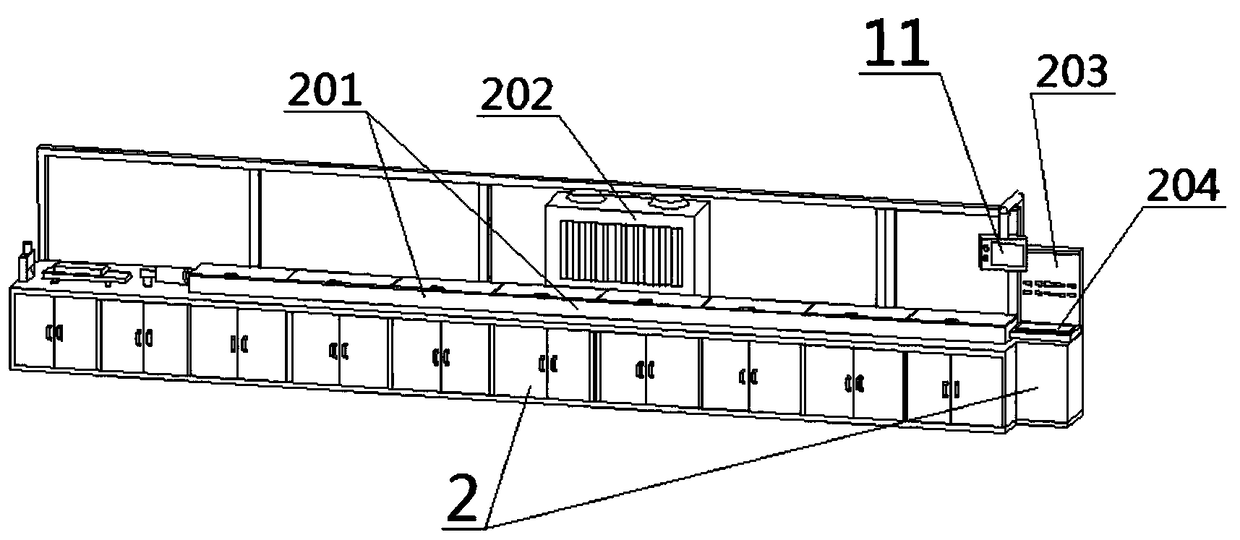

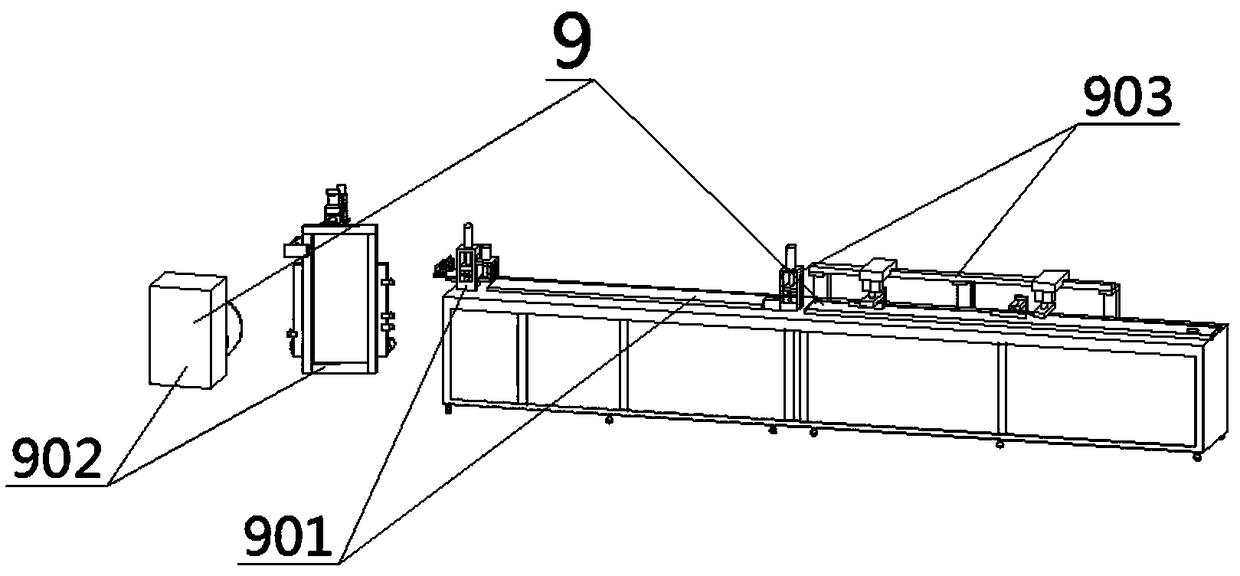

Production line of intelligent refrigerator door seal

InactiveCN108973156ARapid cooling and settingReduce CooldownDomestic cooling apparatusLighting and heating apparatusProduction lineEngineering

The invention discloses a production line of an intelligent refrigerator door seal. The production line is characterized by comprising an extrusion machine, a cooling device, a traction machine, a perforating machine, a cutting device, a magnet penetrating device, a slope guide drive device, a conveying belt, a distribution device, a welding device and a control device, wherein the perforating machine is arranged at the starting end of the production line; the cooling device, the traction device, the perforating machine, the cutting device and the magnet penetrating device are sequentially arranged at the left side of the extrusion machine; the slope guide drive device is arranged in front of the magnet penetrating device; one end of the conveying belt is connected with the slope guide device, and the other end of the conveying belt is connected with the distribution device; the welding device is arranged behind the distribution device; the control device is respectively connected withthe extrusion machine, the cooling device, the cutting device, the magnet penetrating device and the distribution device through wire bundles. The production line has the advantages that the multipleprocedures of extrusion, cooling, cutting, magnet penetrating, welding and the like are jointly completed in the production process of the door seal, so as to realize the whole intelligent unmanned production; the production efficiency is high, the continuity is good, the product quality is stable, and the production line is suitable for being popularized and applied in the production process ofthe refrigerator door seal.

Owner:ANHUI HIGASKET PLASTICS CO LTD

Polytetrafluoroethylene film for filtering air

ActiveCN104497454AImprove toughnessReduce thicknessSemi-permeable membranesDispersed particle filtrationAir filtrationPolymer science

The invention relates to a preparation method of a film, and particularly relates to a polytetrafluoroethylene film for filtering air. According to the film, the thickness is 15-20nm, the air permeability is 100-120L / m<2> / s; and the filtering accuracy is over 99.99%. The preparation method comprises the following steps: lubricating and mixing, namely mixing PTFE micropowder with a liquid lubricating agent, and standing at 85-90 DEG C for 3-6 hours, so as to form a PTFE material, wherein the liquid lubricating agent comprises aviation kerosene and silicon oil; the adding amount of the aviation kerosene is 10%-30% of mass of the PTFE powder; and the adding amount of the silicon oil is 1-10% of mass of the PTFE powder; forming a blank, and rolling; degreasing and modifying, namely adding an assistant which accounts for 1%-3% of mass of the PTFE powder; longitudinally stretching a PTFE base band for 1.5-2.5 times at 200-250 DEG C, and then forming a degreasing base band, wherein the assistant comprises first elastic rubber and second elastic rubber, which are mixed at the mass ratio of (1-3) to 1; and stretching and sizing, namely transversely stretching the degreasing base band at 215-235 DEG C, sintering, sizing, cooling and solidifying. The PM2.5 intercepting effect of the PTFE film disclosed by the invention is good.

Owner:ZHEJIANG LUCKING ENVIRONMENTAL PROTECTION CO LTD

Glue injection and injection molding method for inductors

The invention discloses a glue injection and injection molding method for inductors, which includes inner glue injection and outer injection molding. In inner glue injection, at least a through hole of one inductor is filled with a circular glue layer the same as the through hole in shape, two ends of the circular glue extend out of two end faces of the inductor, the outer peripheral face of the extension end is serrated, and accordingly a semi-finished inductor is obtained. In outer injection molding, subjecting the outer periphery and the through hole of the semi-finished inductor element are subjected to injection molding. A plastic layer at least covers an extension end of the circular glue, so that the plastic layer is meshed with the serrated outer periphery of the extension end. The inductors produced by the method are high in temperature and humidity resistance, fine in insulativity, stable in inductance and low in cost.

Owner:广州易力日拓电子科技有限公司

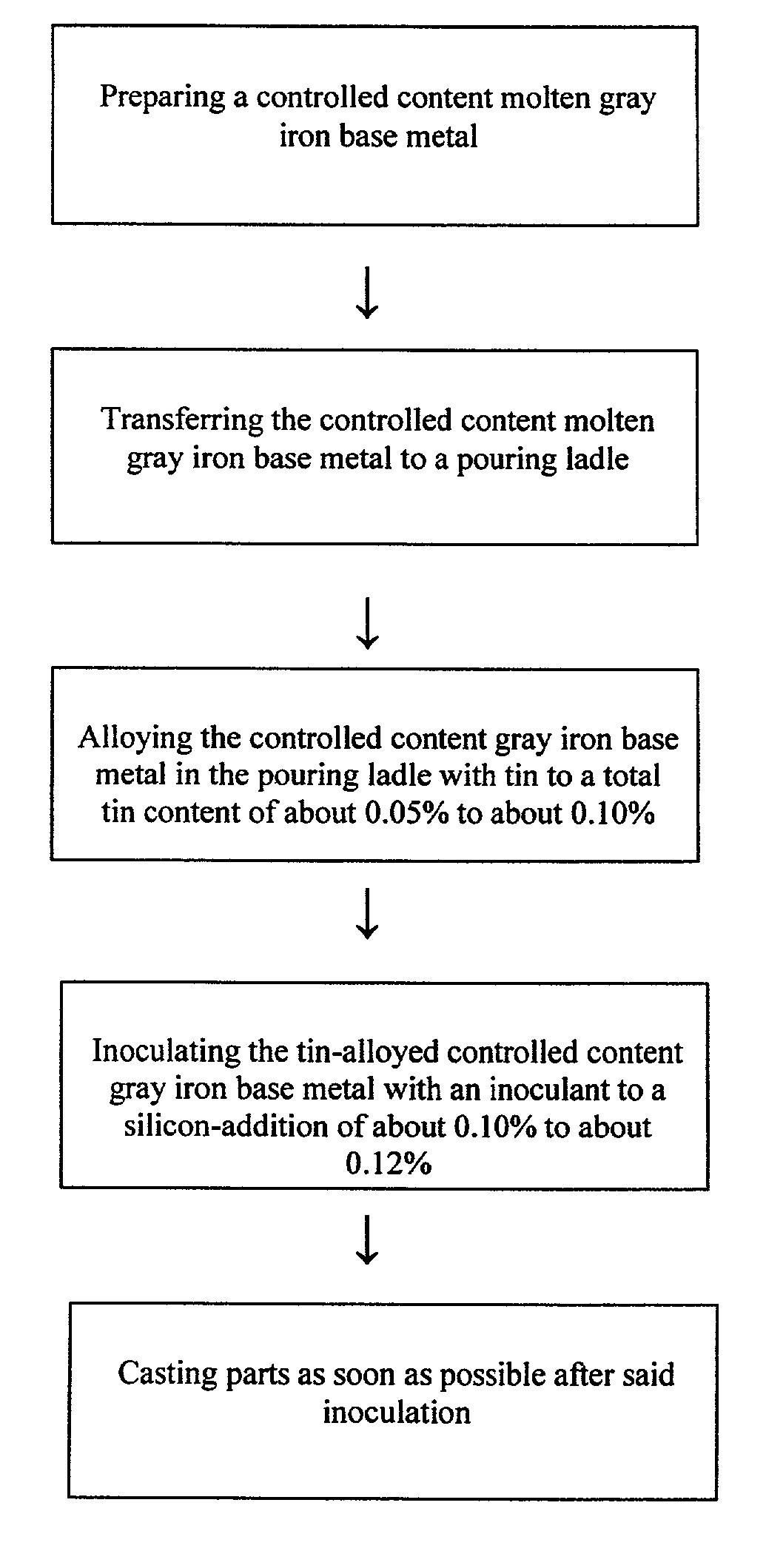

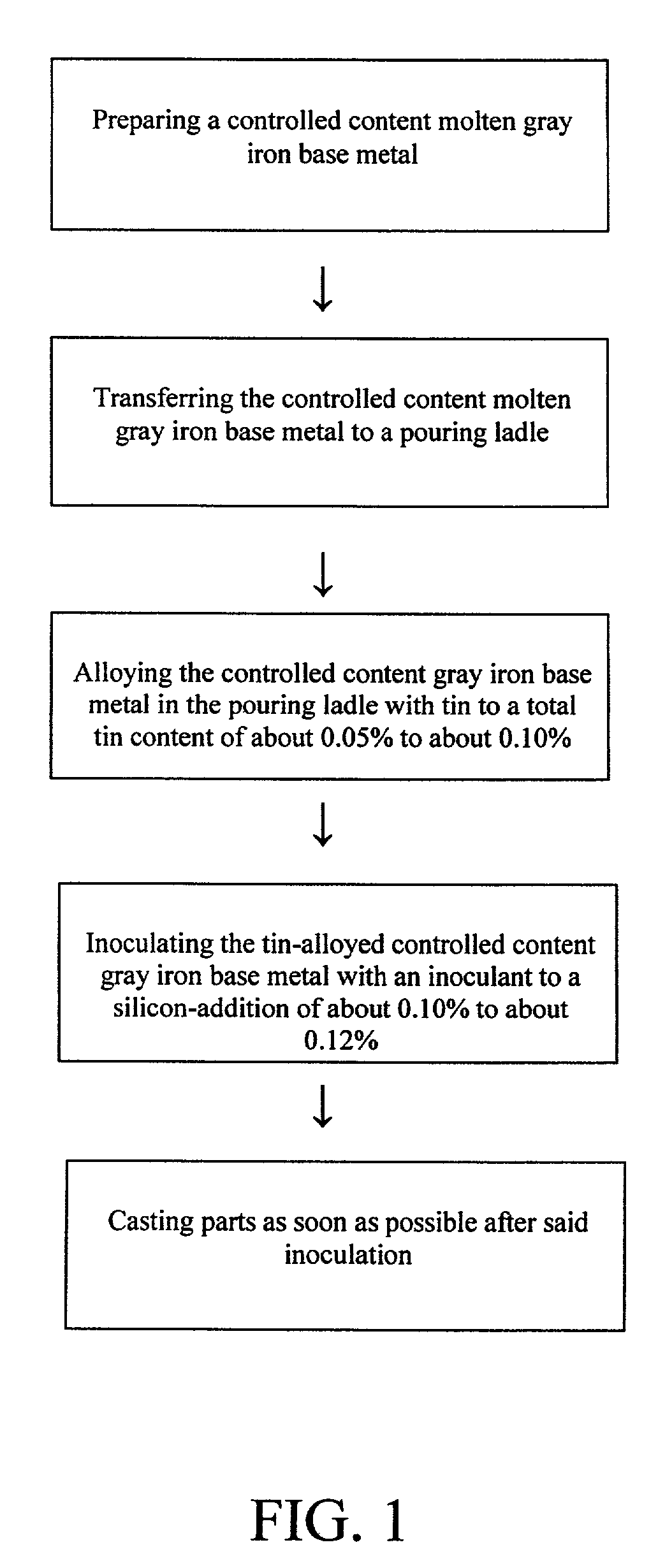

Method for manufacture of gray cast iron for crankcases and cylinder heads

InactiveUS6973954B2Reduce silicon contentMinimal inoculant additionCasingsCylinder headsCylinder headSulfur

A method of casting parts with gray iron includes the steps of providing molten gray iron metal with controlled carbon, silicon, phosphorous, sulfur, manganese and chromium content; alloying said molten gray iron metal, prior to pouring, with tin to a total tin content of about 0.05% to about 0.10%; inoculating said molten tin-alloyed gray iron metal, prior to pouring, with a gray iron inoculant to an additional silicon addition of from about 0.10% to about 0.12%; and casting the gray iron part from said molten, tin-alloyed inoculated gray iron metal as son as possible after said inoculation.

Owner:INT ENGINE INTPROP CO LLC

A flat-top pulse magnetic field generating device and a flat-top pulse current generating device

The invention provides a flat-topped pulse magnetic field generating device and a flat-topped pulse current generating device. The flat-topped pulse magnetic field generating device comprises a transformer, a first loop and a second loop, wherein the first loop is formed by serial connection of primary side coils of the transformer, a first capacitor, a first switch and a magnet in sequence, and the second loop is formed by serial connection of secondary side coils of the transformer, a second capacitor and a second switch in sequence. The first loop further comprises first follow current loops connected to the two ends of the first capacitor in parallel, and the second loop further comprises second follow current loops connected to the two ends of the second capacitor in parallel. Each first follow current loop comprises a first resistor and a first one-way conducting element, wherein the first resistor and the first one-way conducting element are sequentially connected to the two ends of the first capacitor. Each second follow current loop comprises a second resistor and a second one-way conducting element, wherein the second resistor and the second one-way conducting element are sequentially connected to the two ends of the second capacitor. Flat-topped currents / magnetic fields can be generated through the coupling effect of the primary side coils and the secondary side coils of the transformer, and the flat-topped pulse magnetic field generating device and the flat-topped pulse current generating device have the advantages that manufacturing cost is low, the process is simple, circuit control is convenient and quick, and the flat-topped currents / magnetic fields do not have ripple waves.

Owner:HUAZHONG UNIV OF SCI & TECH

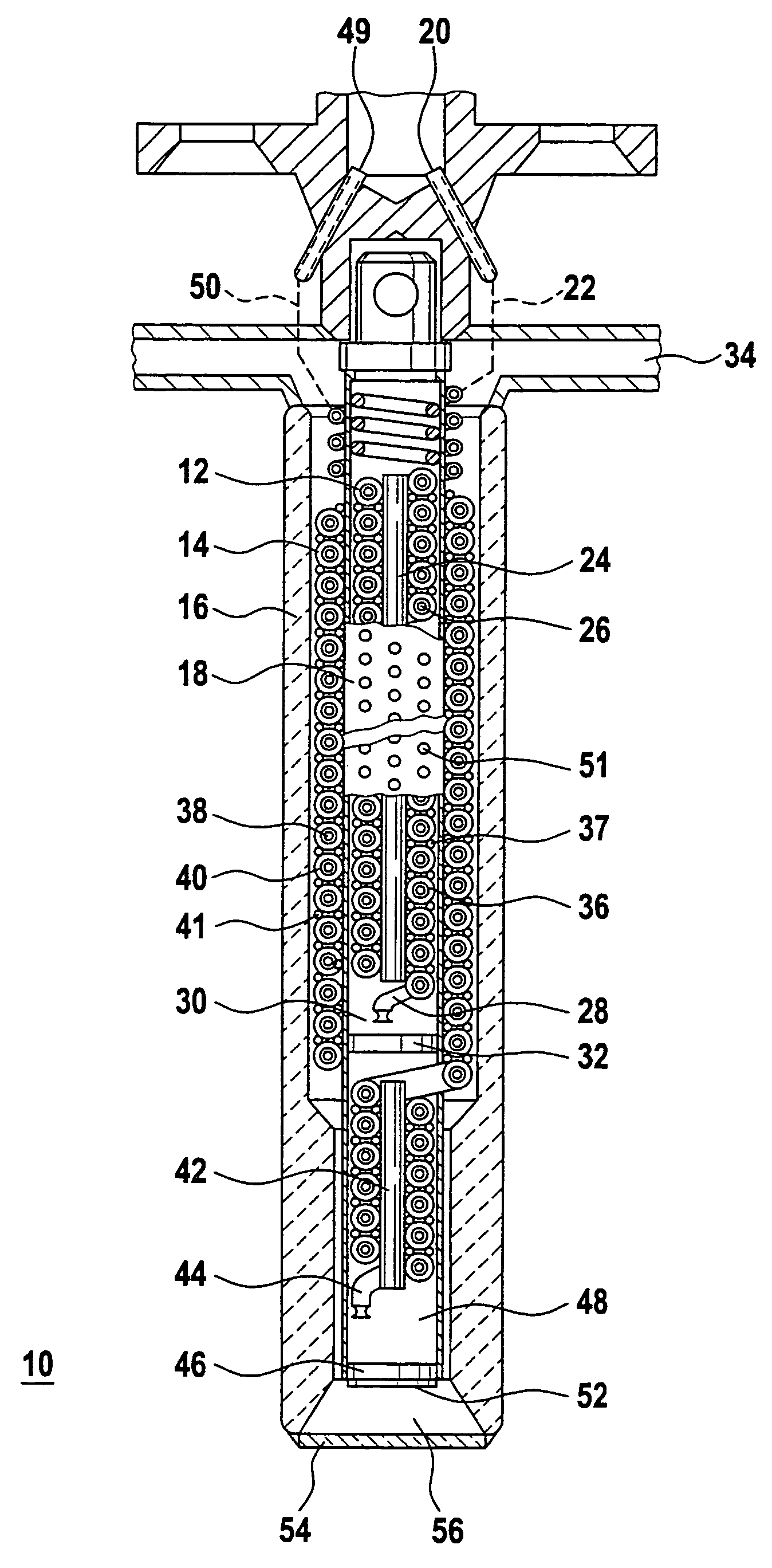

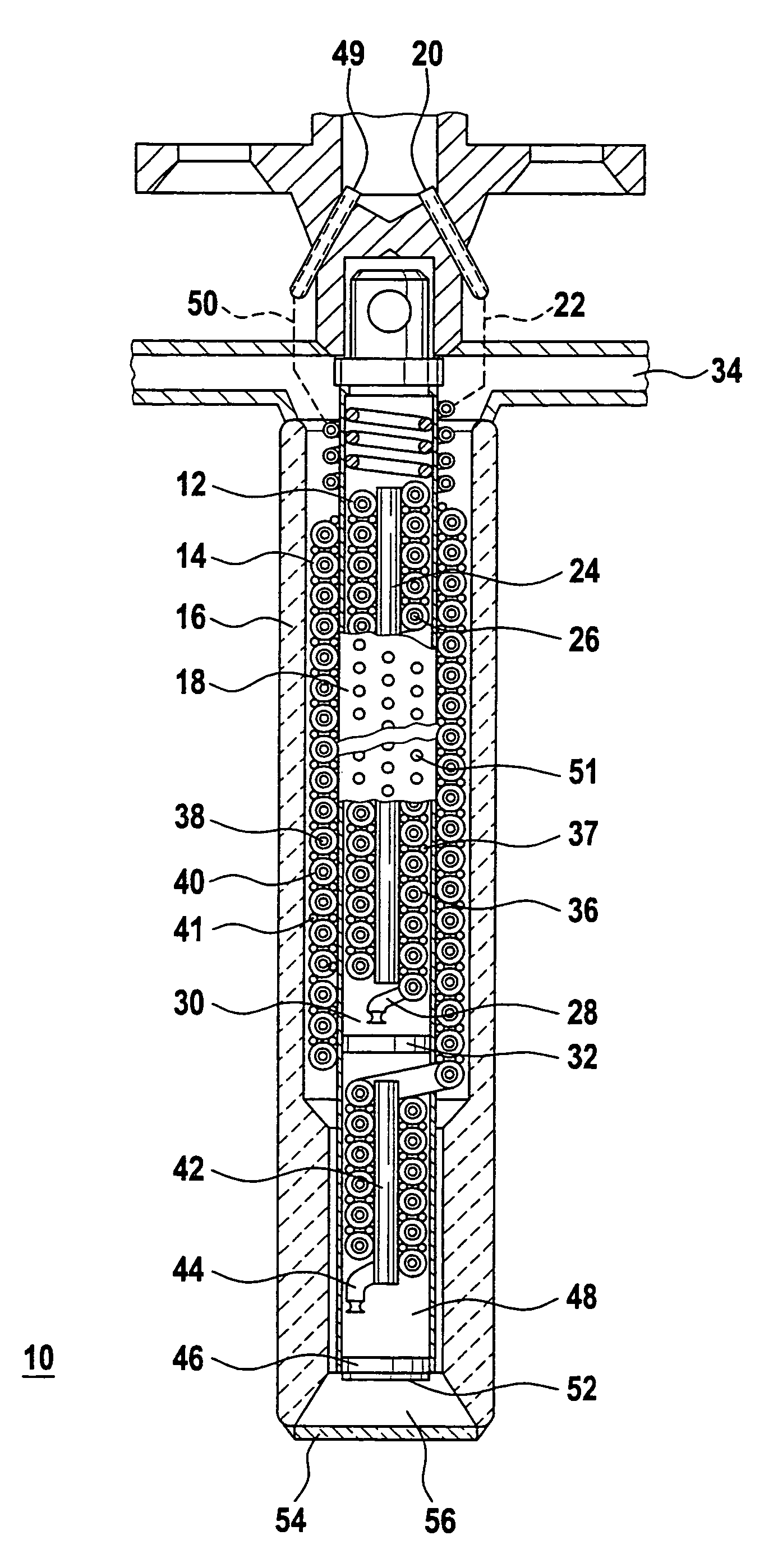

Cooling apparatus

InactiveUS7205533B2Reduce cooling effectImprove heat transfer performanceDomestic cooling apparatusTemperatue controlEngineeringHeat exchanger

A cooling apparatus (10) for cooling a detector (52), the cooling apparatus including an inner and an outer countercurrent heat exchanger (12 and 14, respectively) for a first and a second gas in a thermally insulating housing (16), the inner countercurrent heat exchanger (12) being arranged within a sublength of the outer countercurrent heat exchanger (14), and the inner countercurrent heat exchanger (12) being spatially separated from the outer countercurrent heat exchanger (14) by an outer sleeve (18). In this apparatus, the outer sleeve (18) has a partition plate (32) between an expansion nozzle (28) for the first gas located at the end of the inner countercurrent heat exchanger (12) and the remaining part of the outer countercurrent heat exchanger (14).

Owner:DIEHL BGT DEFENCE GMBH & CO KG

Production method of foodstuff of boxed dietary fish product

InactiveCN102726758AReduce the impact of color, smell and shapeKeep the featuresFood preparationAquatic productFish products

The invention discloses a production method of a foodstuff which is a boxed dietary fish product, and belongs to the technical field of aquatic product processing. According to the invention, hairtail or small yellow croaker is adopted as a raw material, and the boxed dietary fish product is obtained through the processing steps of selecting, pre-treating, washing, salting, frying, weighing, flavoring liquid adding, membrane sealing, sterilizing, temperature-preserving, packaging, and storing. The obtained foodstuff which is the boxed dietary instant fish product is advantaged in unique and good appearance, convenient unsealing, delicious taste, and high safety. The foodstuff is suitable for family dishes, hotels, and field trips. According to the invention, membrane sealing and packaging are carried out by using special foodstuff boxes, and the sterilizing conditions are relatively mild, such that loss and waste during the processing process are reduced, a yield is ensured, and high-efficiency and low-loss production of the advantaged instant fish product are realized. The production process is simple and environment-friendly, such that real continuous clean production can be realized. The product can satisfy the requirements by the current market for high-grade instant dietary marine products, and provides good production demand and economical benefit.

Owner:CNFC ZHOUSHAN MARINE FISHERIES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com