High-light low-haze PE heat shrinkable film and preparation method thereof

A heat-shrinkable film, low haze technology, applied in the field of film materials, can solve the problems that the package contents and printed information cannot be well presented, the transparency and gloss of the shrink film color film are general, etc., so as to improve the packaging production efficiency, The effect of uniform distribution of shrinkage tension and high shrinkage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

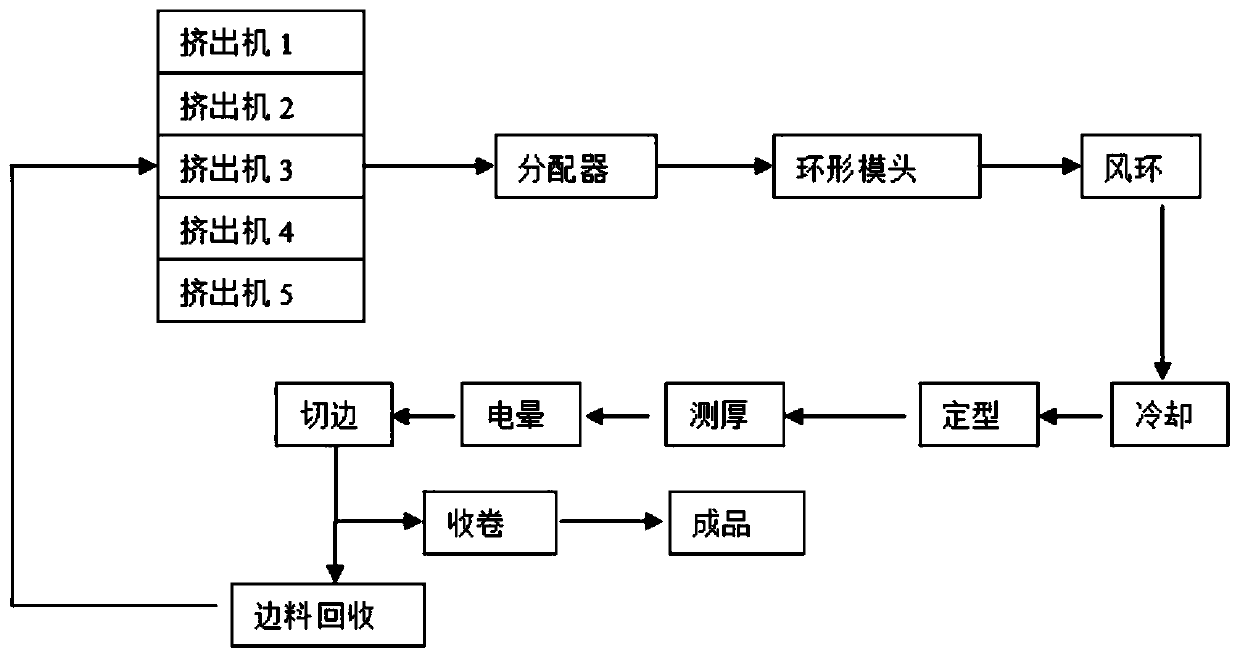

[0038] The preparation method of the high light and low haze PE heat shrinkable film of the present invention comprises the following steps:

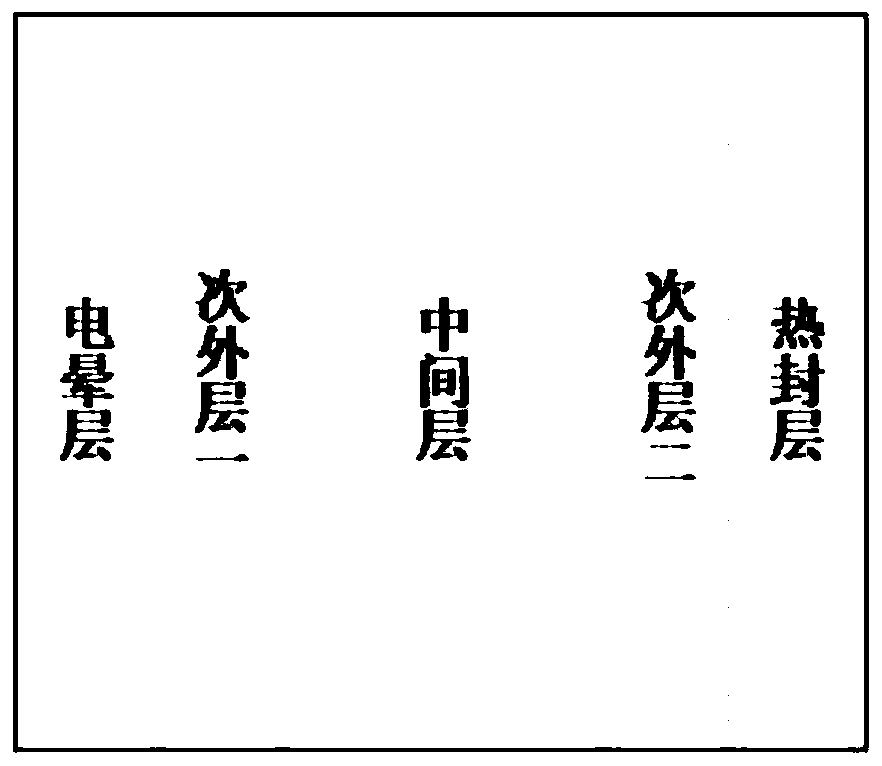

[0039] Step 1, Extrusion: Add the corona layer, sub-outer layer 1, middle layer, sub-outer layer 2, and PE resin and additives of the heat-sealing layer into German WH5 layer co-extruded blown film respectively according to the above component ratio requirements In the hopper of the machine, the melt is formed by the heating device and the extruder, and the melt is extruded into a tube through the ring die;

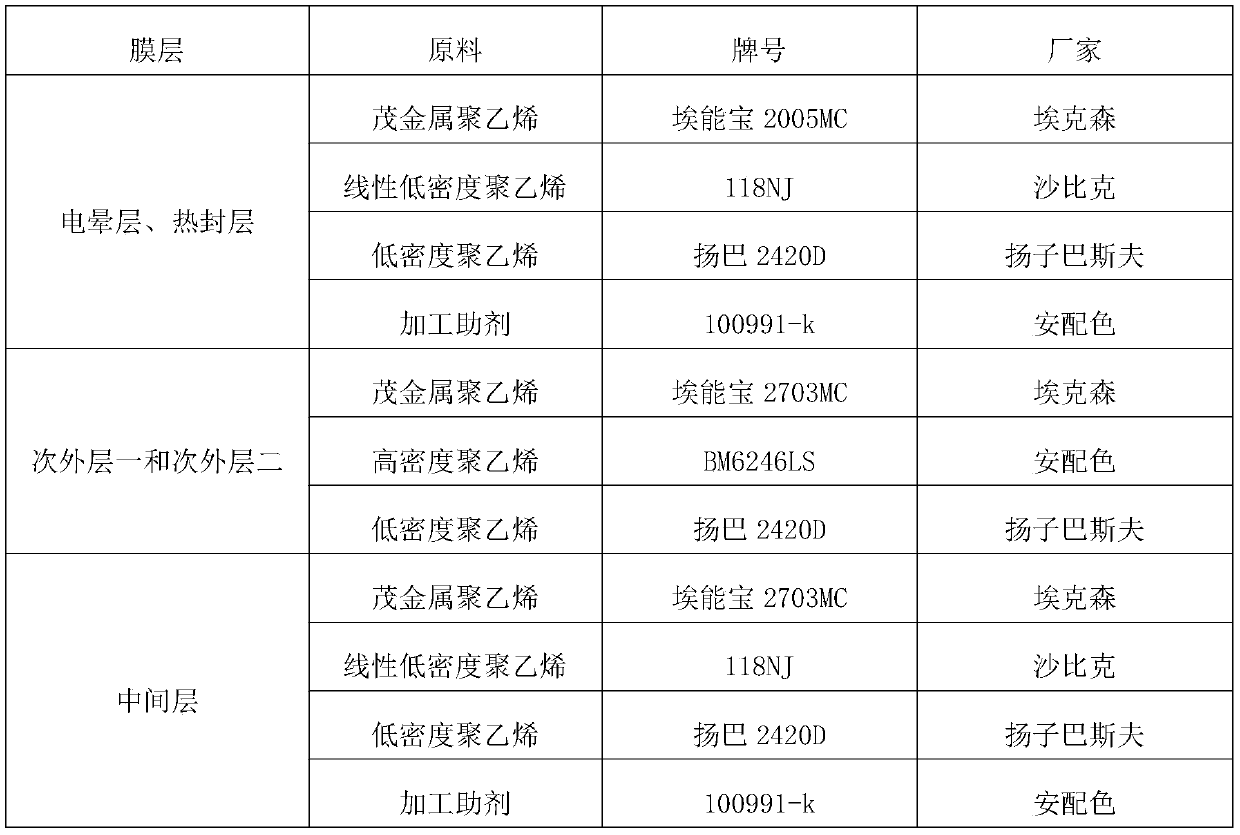

[0040] The corona layer, the intermediate layer, and the heat-sealing layer all include metallocene polyethylene, linear low-density polyethylene, low-density polyethylene and processing aids with a mass ratio of 30:10:60:0.2;

[0041] Both the first outer layer and the second outer layer include metallocene polyethylene, high density polyethylene and low density polyethylene with a mass ratio of 30:30:40.

[0042] German WH5 layer ...

Embodiment 2

[0057] The preparation method is the same as in Example 1, only the formulation of each film layer is adjusted, specifically: the corona layer, the intermediate layer, and the heat-sealing layer all include metallocene polyethylene with a mass ratio of 28:8:58:0.1, Linear low-density polyethylene, low-density polyethylene and processing aids; the second outer layer one and the second outer layer both include metallocene polyethylene, high-density polyethylene and low-density polyethylene with a mass ratio of 28:28:38 vinyl.

Embodiment 3

[0059] The preparation method is the same as in Example 1, only the formulation of each film layer is adjusted, specifically: the corona layer, the intermediate layer, and the heat-sealing layer all include metallocene polyethylene, linear Low-density polyethylene, low-density polyethylene and processing aids; the second outer layer one and the second outer layer both include metallocene polyethylene, high-density polyethylene and low-density polyethylene with a mass ratio of 32:32:42 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com