Drying device and drying method for high-purity silicon materials

A technology of drying device and silicon material, applied in the field of high-purity silicon material drying, high-purity silicon material drying device field, can solve the problems of uneven drying of materials, reduce material purity, material surface pollution, etc. The effect of fast drying speed, good drying effect and short drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

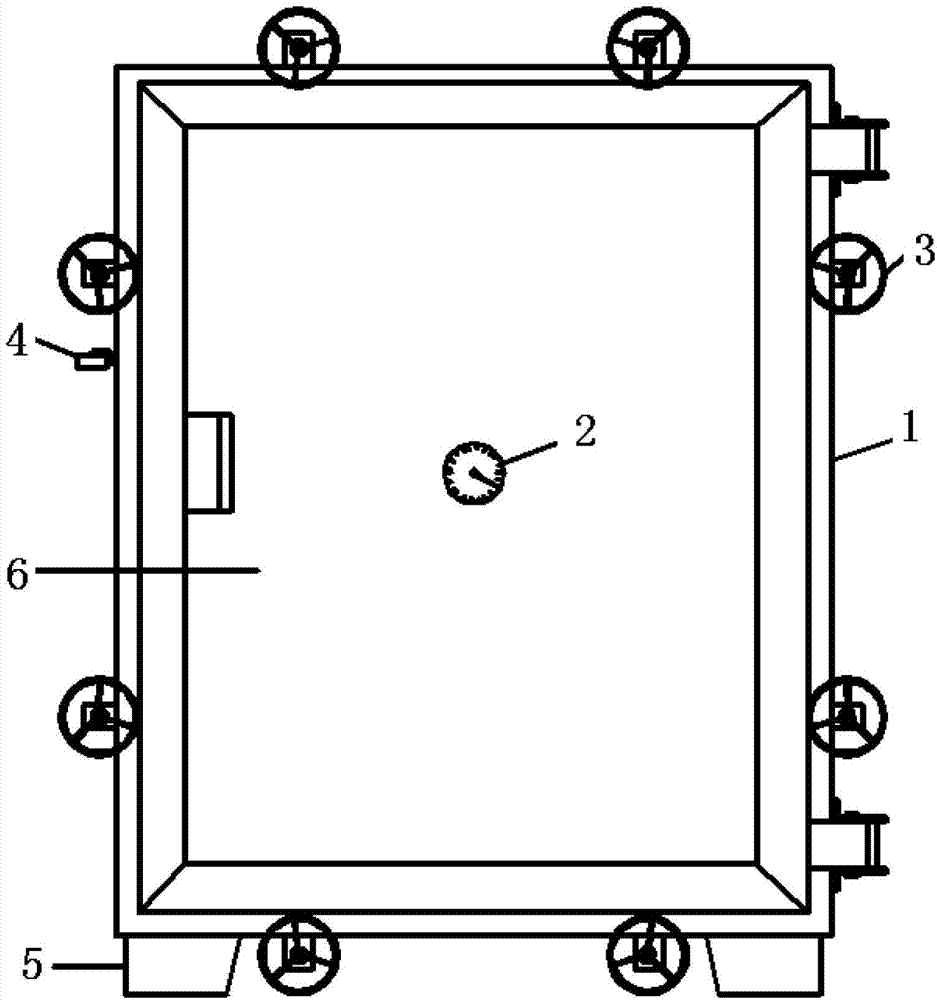

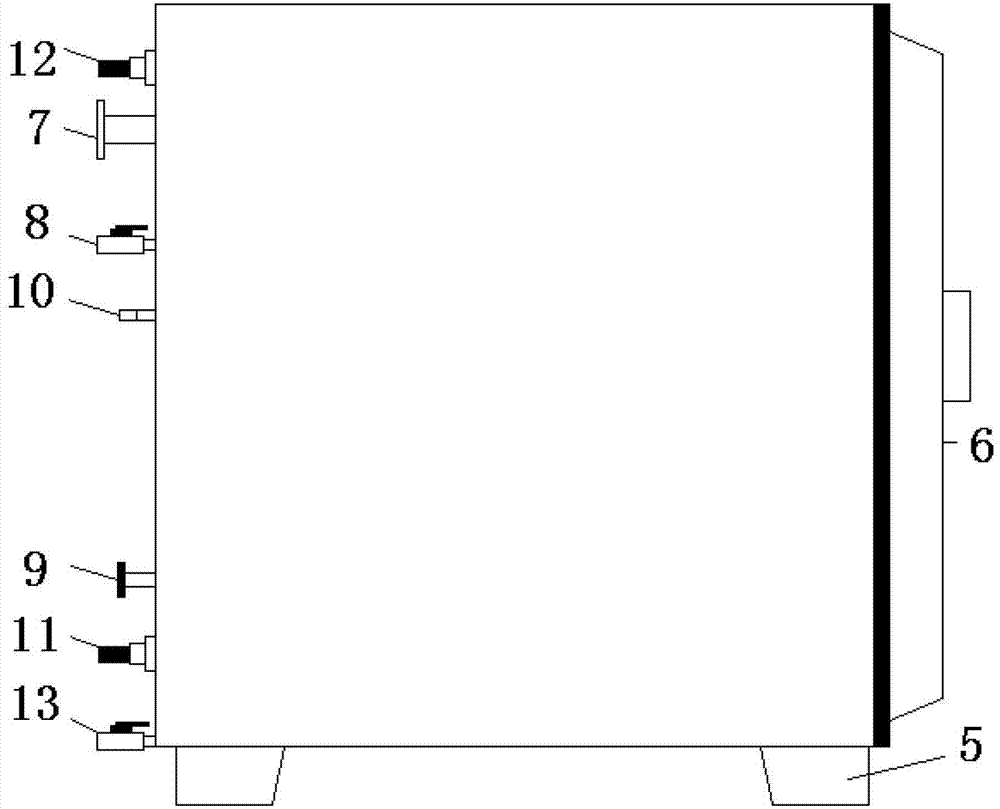

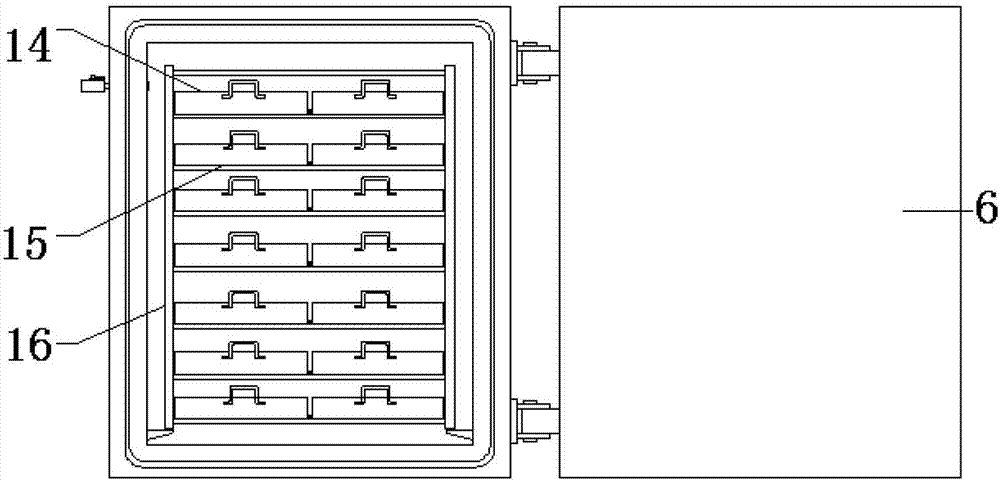

[0027] refer to figure 1 , figure 2 and image 3 , the structure of the device of the present invention is to include a box body 1, the box body 1 is connected to a vacuum device and a medium circulation heating device through a pipeline, and the vacuum pumping device and the medium circulation heating device are connected to the control device signal respectively;

[0028] The box 1 is a sealed box with a sealed door 6, which is made of corrosion-resistant and high-temperature-resistant stainless steel; the main body of the box 1 and the sealed door 6 are sealed and connected through eight locking valves 3 (locking valves The setting of 3 is two groups of upper, lower, left and right, and two are installed on each side, or more than two locking valves are installed on each side according to needs. The inner cavity of the box body 1 is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com