Plastic foam plate forming machine

A sheet forming machine and plastic foam technology, which is applied in the field of plastic foam sheet forming machines, can solve the problems of poor cold forming effect, troublesome demoulding, manual handling of foam sheets, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

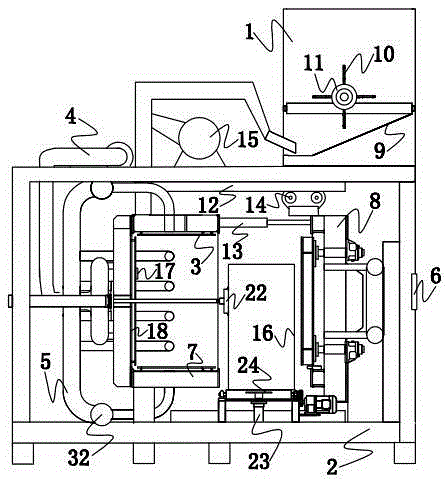

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

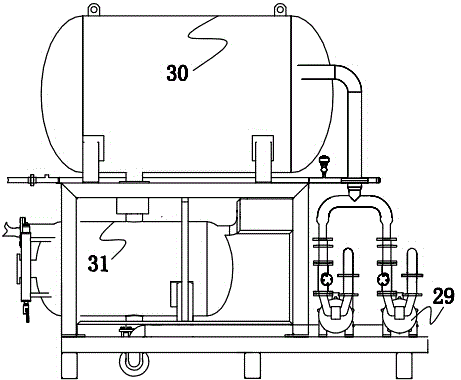

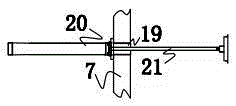

[0019] Such as figure 1 , 2 , 3, and 4, a plastic foam sheet forming machine includes a storage box 1, a frame 2, a template 3, a steam pipeline 4, a cooling pipeline 5 and a control system 6, and the storage box 1 is located at Above the frame 2, in order to facilitate the foam particles to enter the airtight hexahedron container formed by the main mold cavity 7 and the auxiliary mold body 8, the storage box 1 can be provided with a slant plate 9 at an angle of 45° with the horizontal plane or Adopt the mode that is provided with the cross-shaped rotating block 10 that is used to dial foam particle, further describe the mode of cross-shaped rotating block 10, described cross-shaped rotating block 10 drives 11 through the servomotor that is installed on the material storage box 1, and servo The motor 11 is controlled by the control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com