Method for inhibiting generation of internal defects of aluminum alloy resistance spot welding nugget

A technology of resistance spot welding and internal defects, which is applied in resistance welding equipment, manufacturing tools, welding equipment, etc., can solve problems such as internal defects of high-strength aluminum alloy spot welding nuggets, so as to improve the strength of solder joints, reduce stress, and suppress internal defects. The effect of the crack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

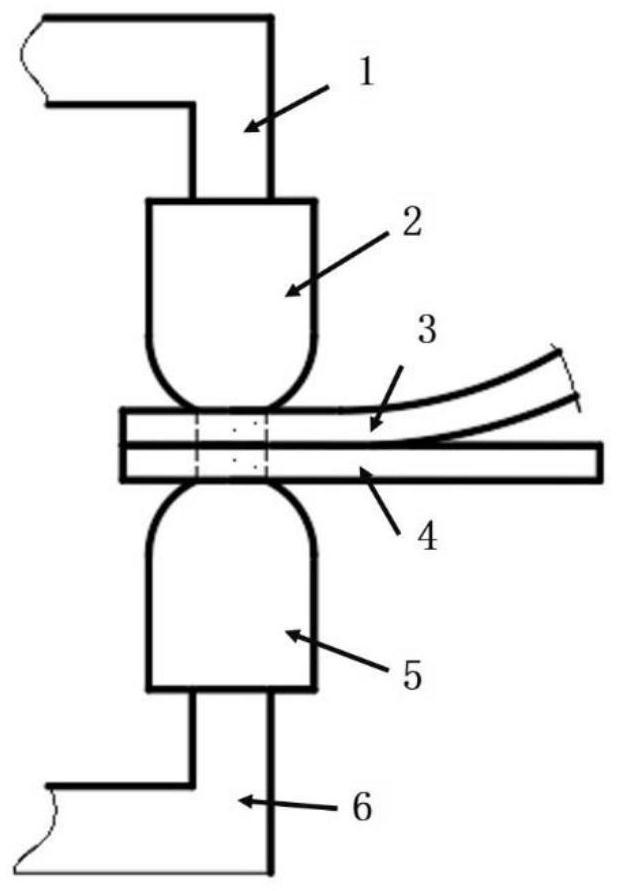

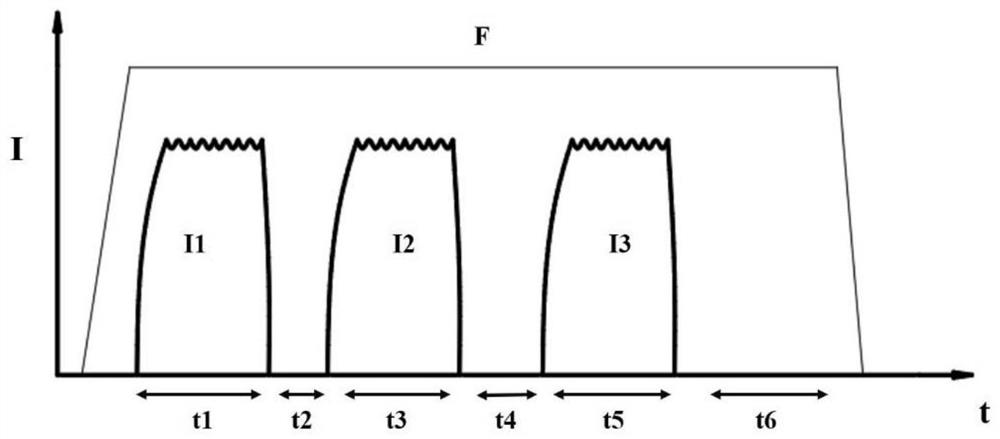

[0041] Two 7075-T6 aluminum alloy workpieces with a thickness of 2mm are stacked together to form a laminate, which is placed on the resistance spot welding equipment so that both ends of the laminate are in contact with the welding electrode cap. Such as figure 2 As shown, firstly, a constant pressure F of 4000N is applied to the stack by welding the electrode caps on both sides. The duration of this pressure is preferably 50ms-300ms, more preferably 60-200ms, and then the first welding Current I1, the current value is reduced to zero after passing through the first stage of welding current for a period of time, entering the first cooling stage, and then passing through the second stage of welding current I2 after cooling, and then reducing the current value to zero, entering the second stage In the cooling stage, after the second cooling stage, the third stage of welding current I3 is passed, and finally enters the third cooling stage, which is the pressure holding stage. ...

Embodiment 1

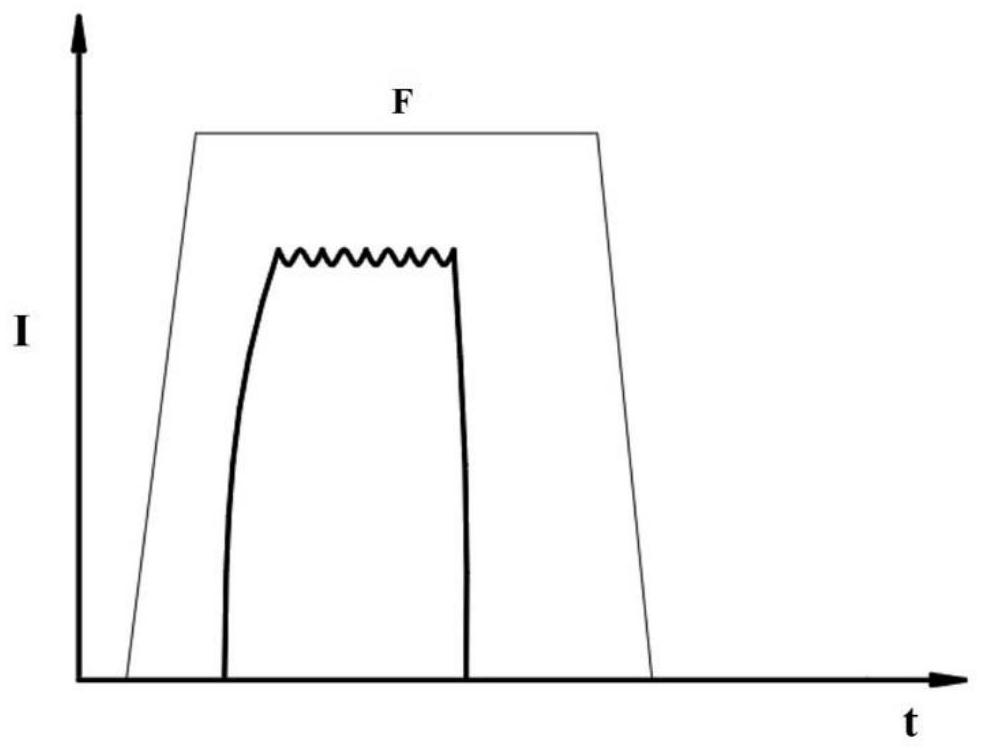

[0044] Embodiment 1 Comparative Example

[0045] Such as image 3 Shown, for not using the method of the present invention, adopt the electrode cap identical with embodiment 1, use the method for welding of common single pulse, wherein welding current I is 30KA, and welding time t is 150ms, and electrode pressure F is 4000N, hold pressure The time is 50ms; Figure 7 The metallographic diagram of the cross-section of the solder joint obtained in this example shows that there are a large number of defects such as shrinkage cavities and cracks inside the nugget.

Embodiment 2

[0047] Such as Figure 5 and 9 As shown, this embodiment is similar to Embodiment 1, the difference is that the cross-sectional shape of the welding electrode cap is a concave electrode cap with a ring-shaped protrusion on the edge.

[0048] Such as Figure 8 Shown is the cross-sectional metallographic diagram of the aluminum alloy solder joint obtained by using the method of this embodiment. It can be seen that there are basically no shrinkage cavities, cracks, etc. inside the nugget.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com