Patents

Literature

166results about How to "Reduce the current value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

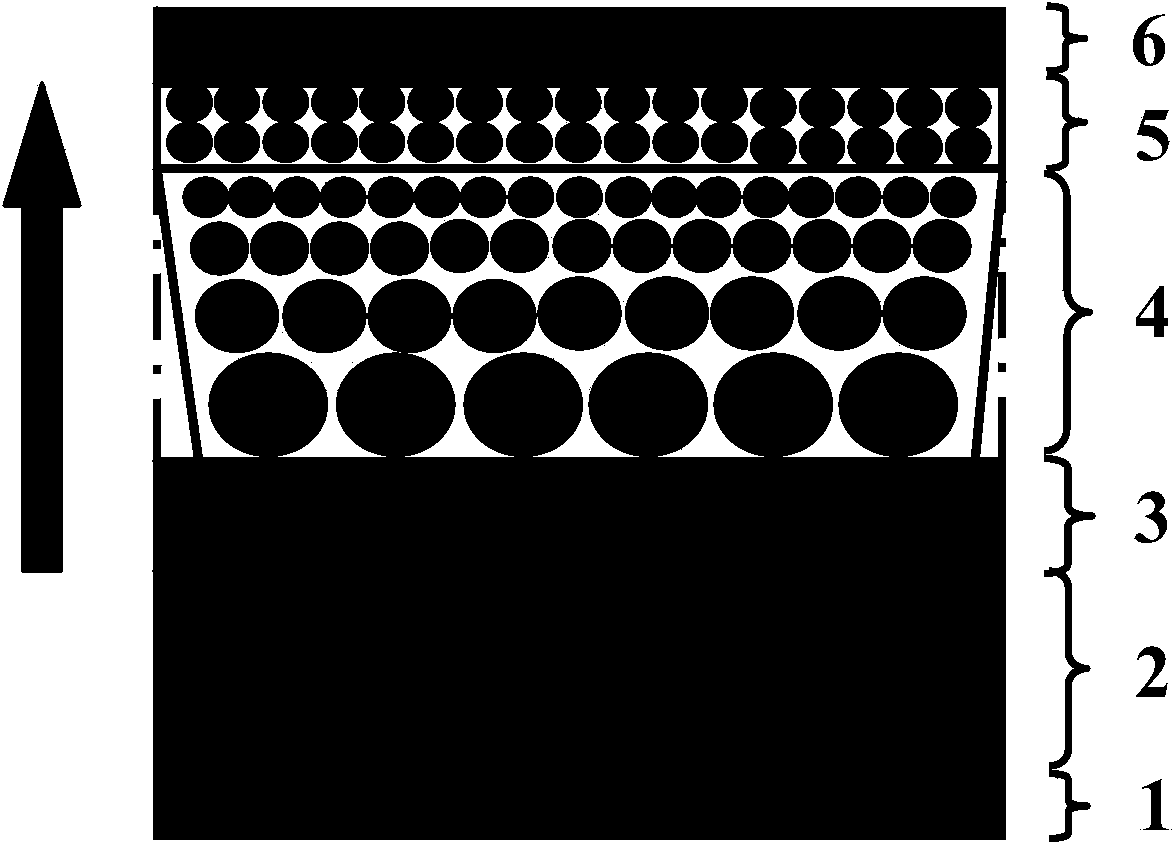

Lithium ion battery positive current collector high in safety performance, preparing method thereof and lithium ion battery

InactiveCN104966840AAdd resistanceReduce the current valueElectrode carriers/collectorsSecondary cellsPhysicsComposite material

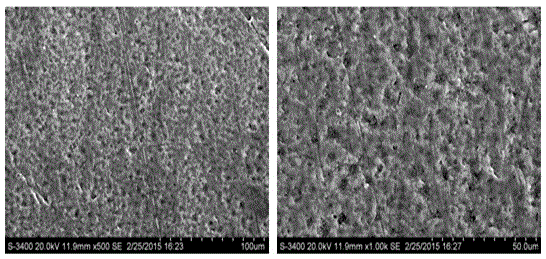

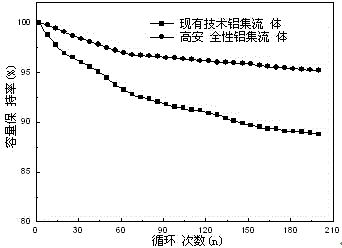

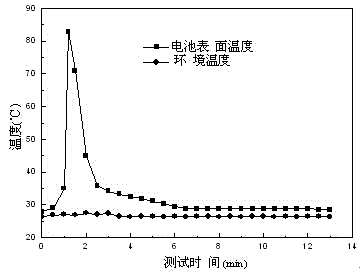

The invention provides a lithium ion battery positive current collector high in safety performance, a preparing method thereof and a lithium ion battery. The positive current collector comprises an aluminum layer and a porous anodic alumina resistive layer which covers the surface of the aluminum layer. The thickness of the porous anodic alumina resistive layer is 10-100 nm. The porous structure of the porous anodic alumina resistive layer is a blind hole structure. The diameter of blind holes is 0.01-5 microns. The porous anodic alumina resistive layer can effectively increase the resistance of the positive current collector so that the current value generated when a short circuit happens to the battery can be lowered, and accordingly the temperature is decreased when the short circuit happens to the battery and the dangers of firing and exploding caused by heat generated by the battery is avoided. In addition, the adhesive strength of the positive current collector and positive active substances can be improved through the blind hole structure of the positive current collector, so that the probability of falling of the positive active substances during charging and discharging is lowered, and accordingly the cycle life of the lithium ion battery is prolonged.

Owner:GUANGZHOU GREAT POWER ENERGY & TECH CO LTD

Data writing-in method of magnetic memory

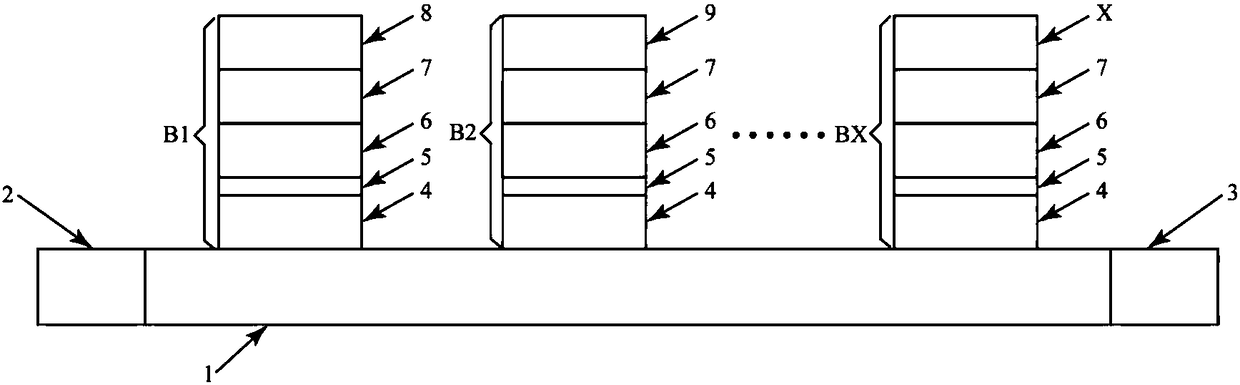

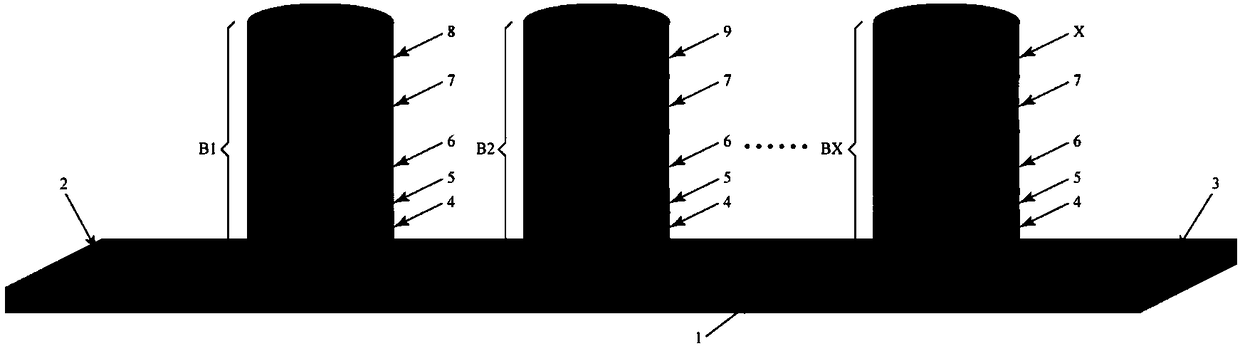

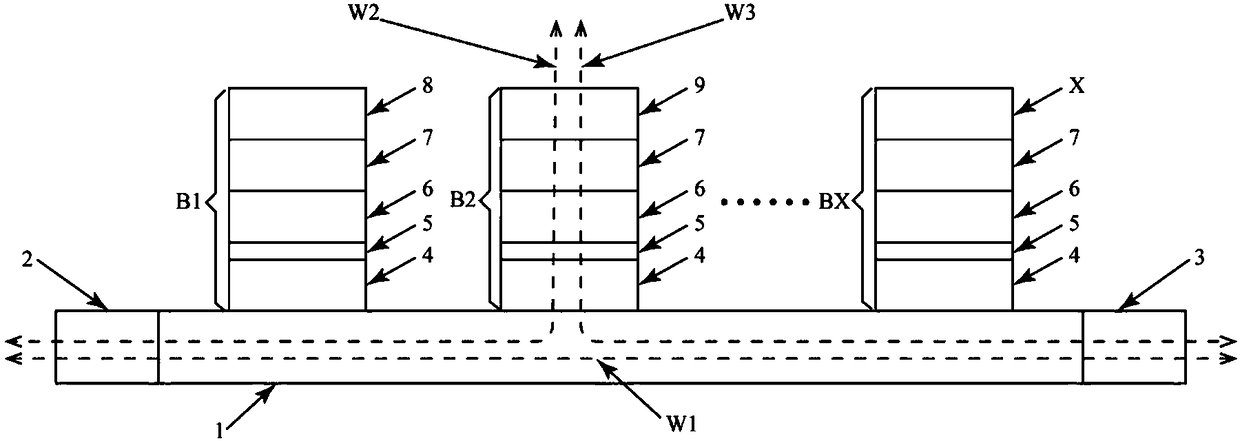

The invention provides a data writing-in method of a magnetic memory. A plurality of magnetic tunnel junctions are manufactured on a heavy metal strip-shaped thin film or an antiferromagnetic strip-shaped thin film. Each magnetic tunnel junction represents a storage unit. Each magnetic tunnel junction is composed of five layers including first ferromagnetic metal, first oxide, second ferromagneticmetal, a first synthetic antiferromagnetic layer and an Xth top end electrode, wherein the value of X is a bit number represented by each magnetic tunnel junction; two ends of the heavy metal strip-shaped thin film or the antiferromagnetic strip-shaped thin film are plated with a first bottom end electrode and a second bottom end electrode respectively. According to the data writing-in method provided by the invention, data writing-in is realized by adopting a manner of combining a self-spinning transfer torque and a self-spinning rail torque; two paths of current need to be applied to the magnetic tunnel junctions, the heavy metal strip-shaped thin film or the antiferromagnetic strip-shaped thin film respectively at the same time. The data writing-in cannot be finished by only one path of the current. According to the data writing-in method provided by the invention, the circuit integration degree of the magnetic memory can be improved, the writing-in power consumption is reduced andthe complexity and manufacturing cost of a technology are easy to reduce.

Owner:BEIHANG UNIV

Energy-saving environment-protecting abrasion-proof canned carbon-hydrogen refrigerant

InactiveCN101270274ASolve the problem of cylinder wear and tearLittle effect of loadChemical industryHeat-exchange elementsAlkaneSolubility

The invention relates to an energy-saving environmental-protection type abrasion resistant canned hydrocarbon refrigerant, which comprises propane and isobutane. The energy-saving environmentally-protective abrasion resistant canned hydrocarbon refrigerant is characterized in that the energy-saving environmentally-protective abrasion resistant canned hydrocarbon refrigerant further comprises low temperature refrigeration lubricating oil; the propane accounts for 54 to 65 percent; the isobutane accounts for 30 to 40 percent, and the low temperature refrigeration lubricating oil accounts for 3 to 8 percent. The hydrocarbon refrigerant is prepared by mixing mixed alkane with certain proportion and the low-temperature refrigeration lubricating oil in proper amount, thus effectively solving the problem of the prior hydrocarbon refrigerant that a compressor is abraded frequently and a cylinder bore is scuffed frequently due to the characteristics of being too dry and excellent oil solubility, The hydrocarbon refrigerant with mixed alkane disclosed by the invention belongs to natural working fluid, is free of fluorine without influence on warming-up of the global climate. Compared with R12 and R134a, the freezing point is lower; the latent heat of vaporization is larger; the specific energy of constant entropy compression is smaller so that the compressor works more easily. The flowing property is better; the delivery pressure is lower; the load of the compressor is lower; fuel consumption is reduced and the energy-saving rate can reach 10 percent to 20 percent when the air conditioners are running.

Owner:周飞

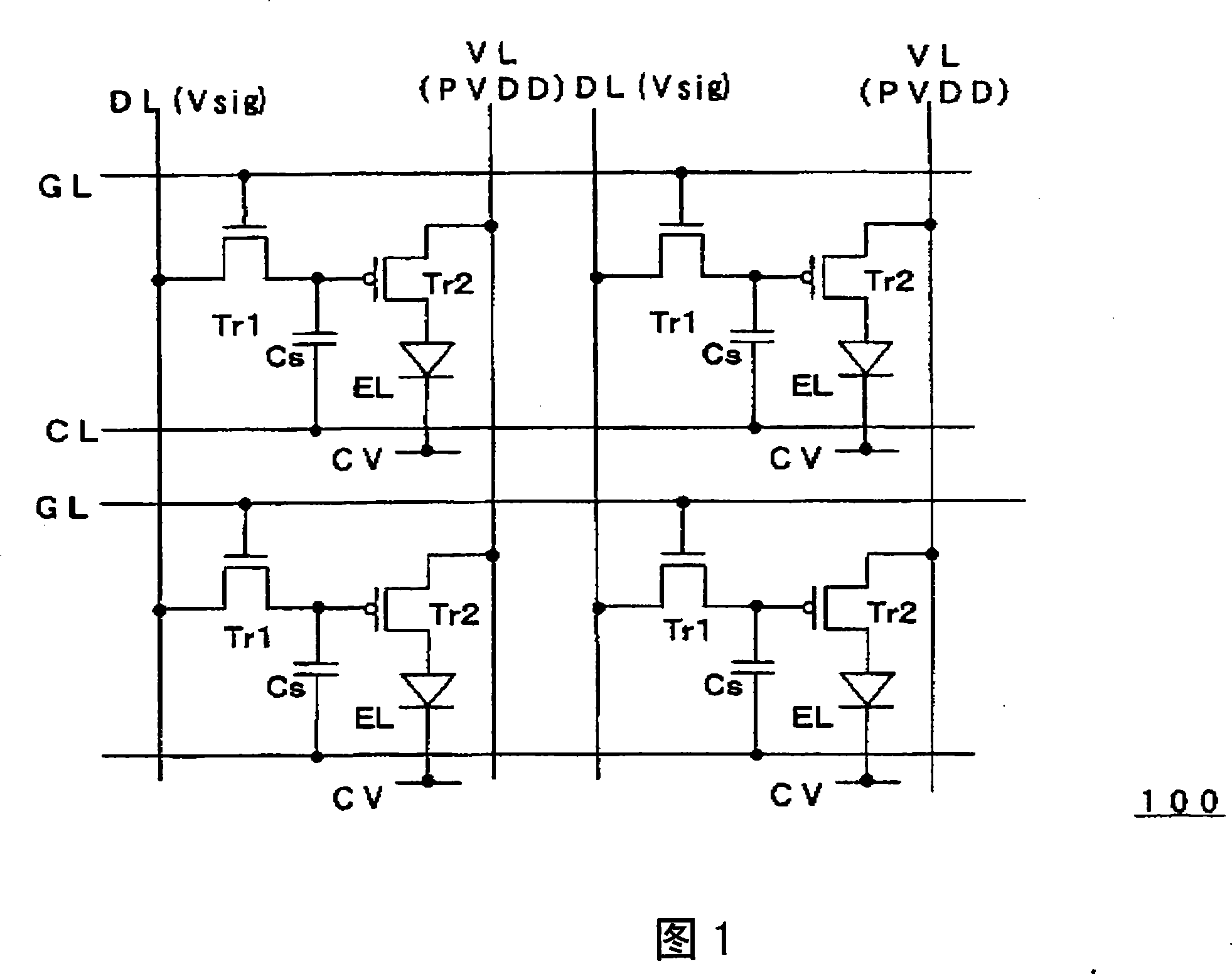

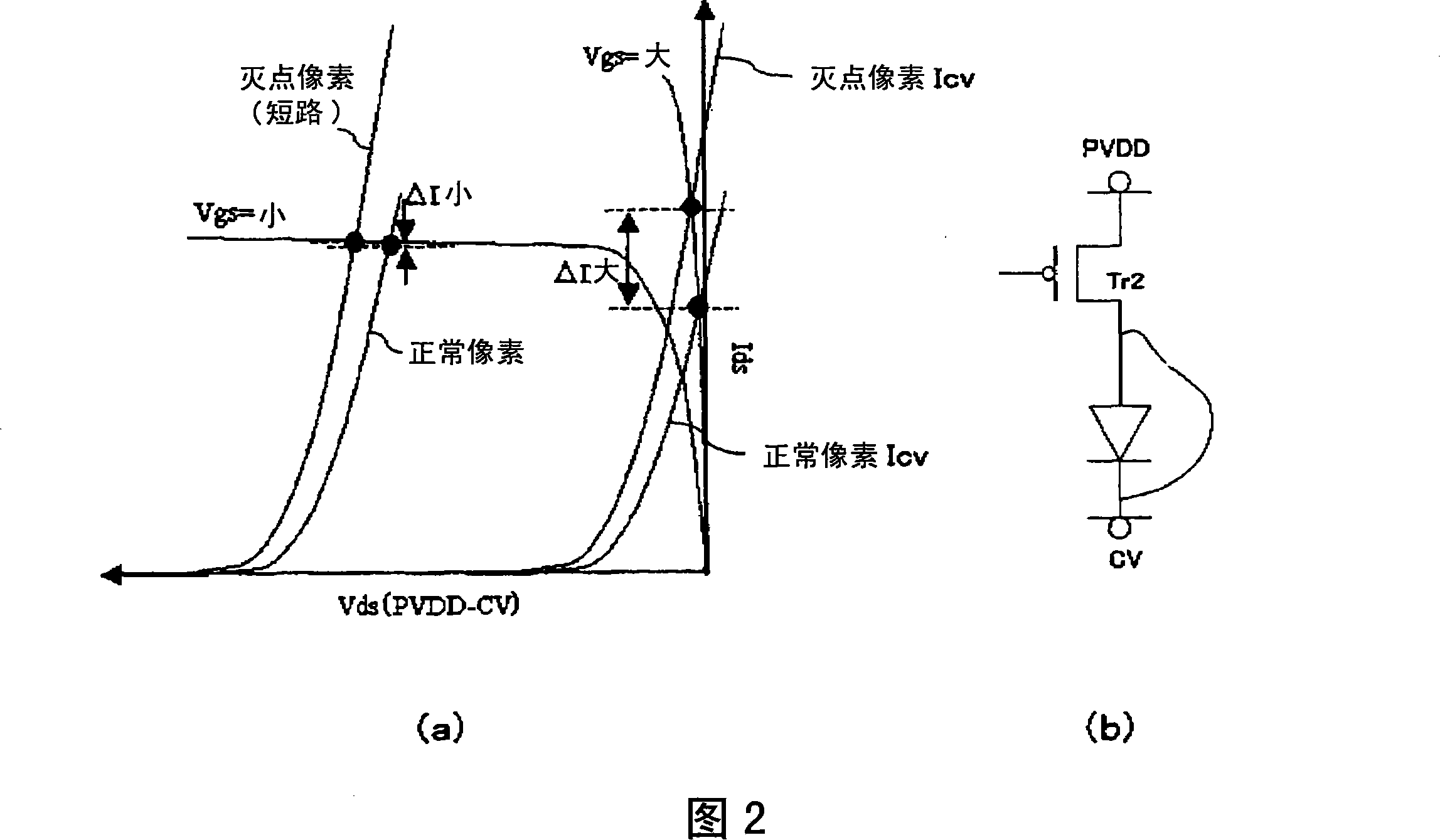

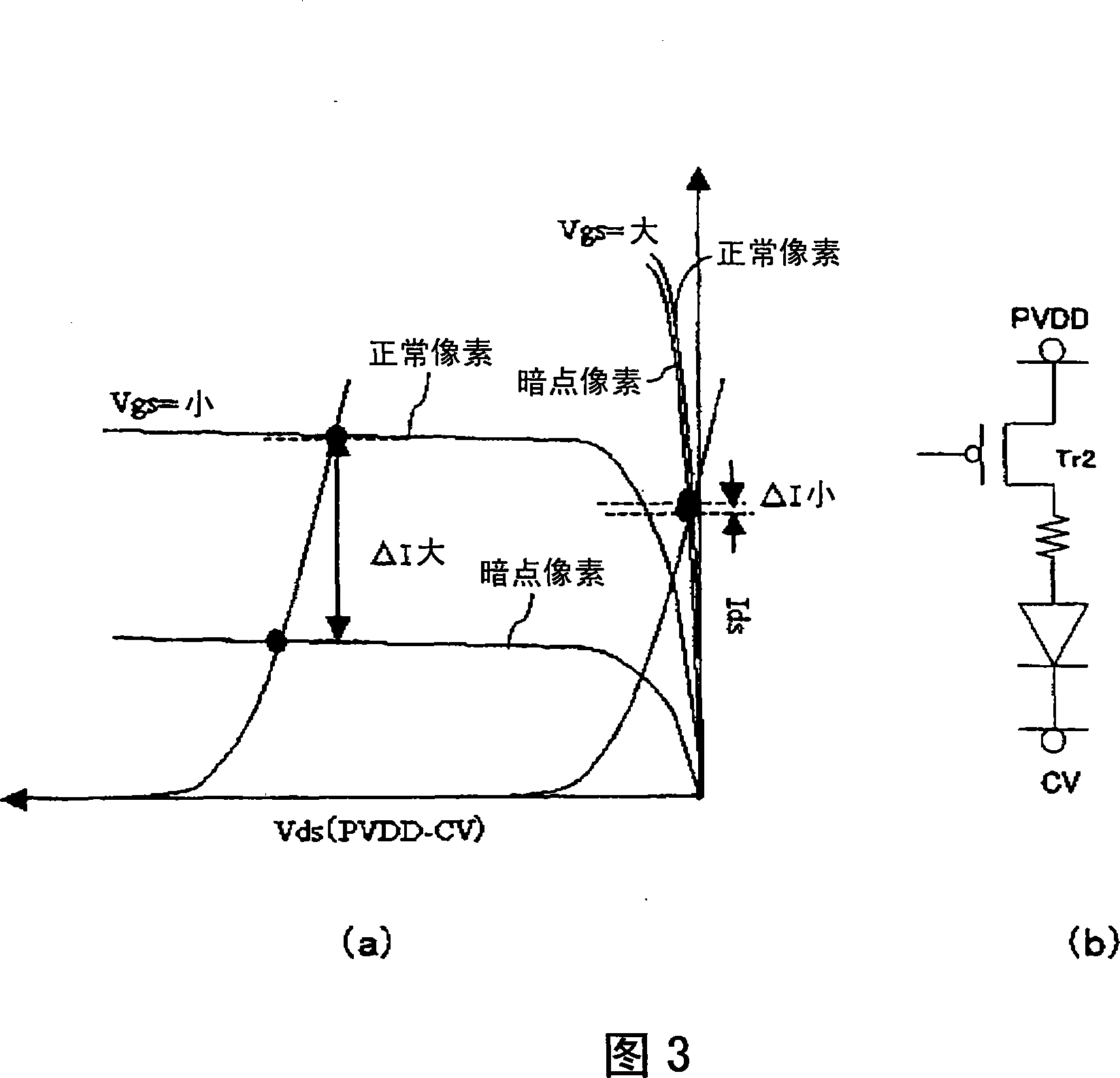

Method of inspecting defect for electroluminescence display apparatus, repairing method and manufacturing method

InactiveCN101174376AReduce the current valueHigh-precision detectionElectrical apparatusStatic indicating devicesDim spotEngineering

The present invention provides a defect detecting method for electroluminescent display device. A dark spot defect caused by short-circuiting in an electroluminescence element is detected based on an emission brightness or a current flowing through the electroluminescence element when an element driving transistor which controls a drive current supplied to the electroluminescence element is operated in its linear operating region and the electroluminescence element is set to an emission level. Prior to the dark spot defect inspection, the dark spot defect is screened by applying a reverse bias voltage between an anode and a cathode of the electroluminescence element. With this process, disappearance of the dark spot defect at a later time resulting in an impossibility of laser repairing or the like is prevented, and inspection and repairing efficiencies are improved. A dim spot defect caused by a characteristic variation of the element driving transistor is detected based on a current flowing through the electroluminescence element or an emission brightness when the element driving transistor is operated in its saturation operating region and the electroluminescence element is set to an emission level.

Owner:SANYO ELECTRIC CO LTD +1

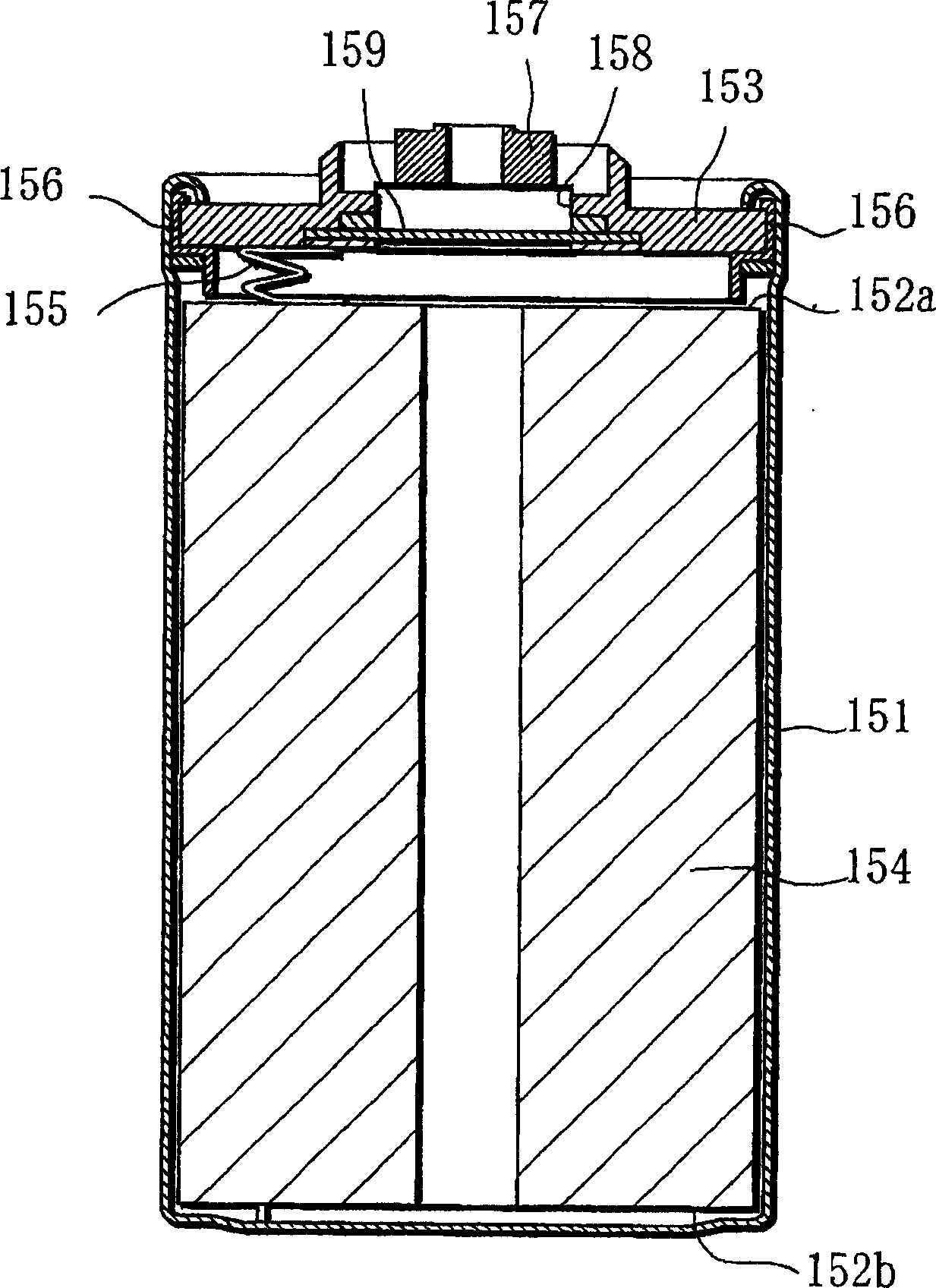

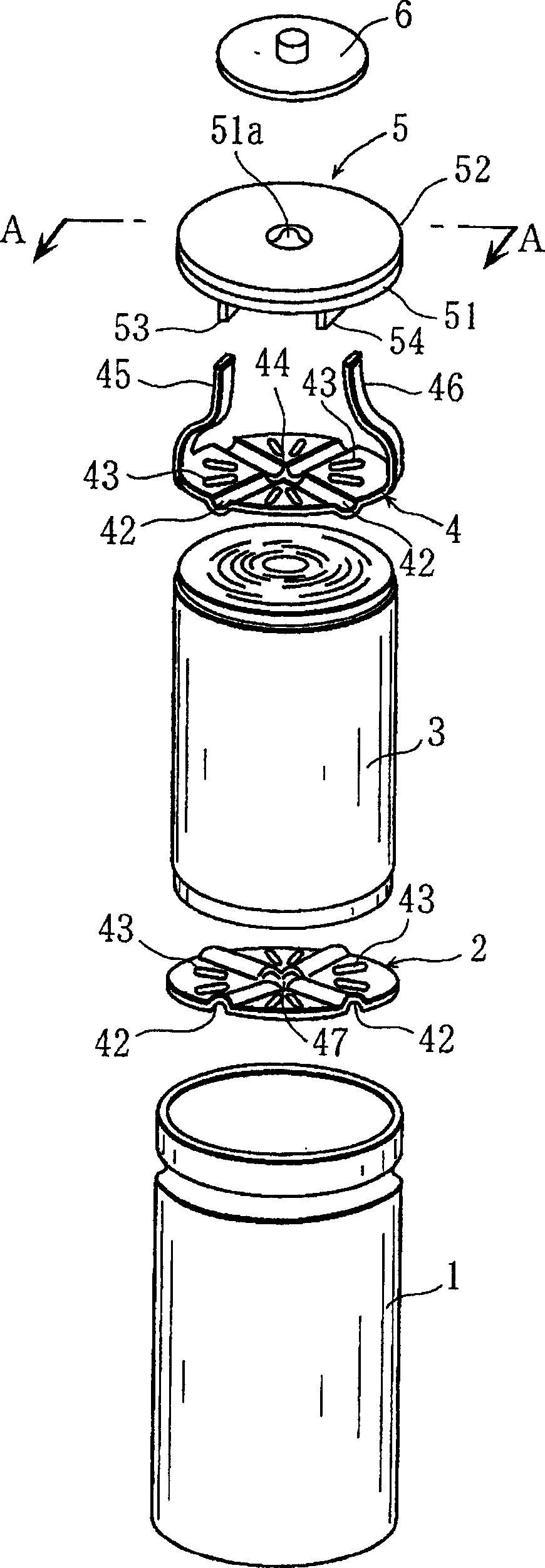

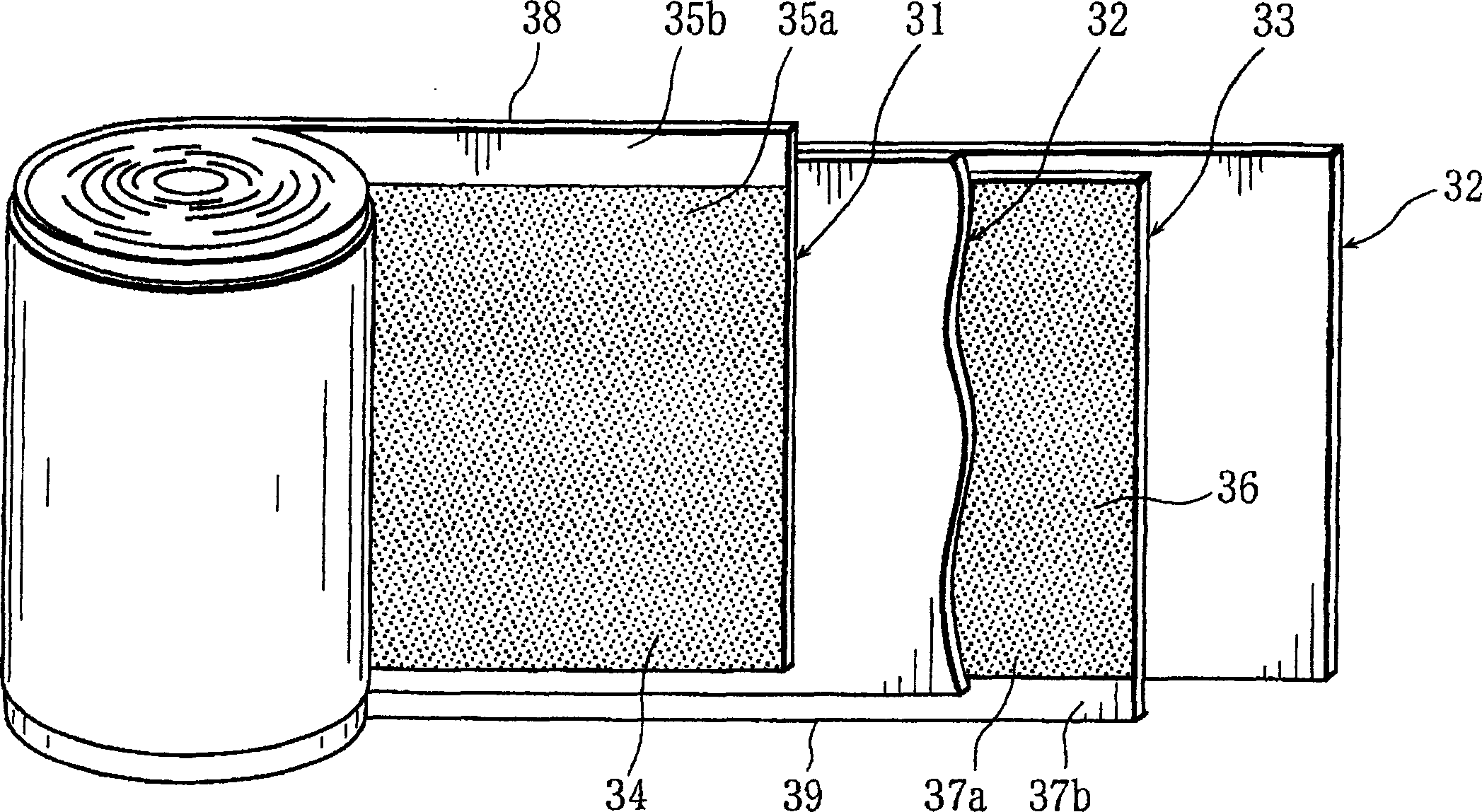

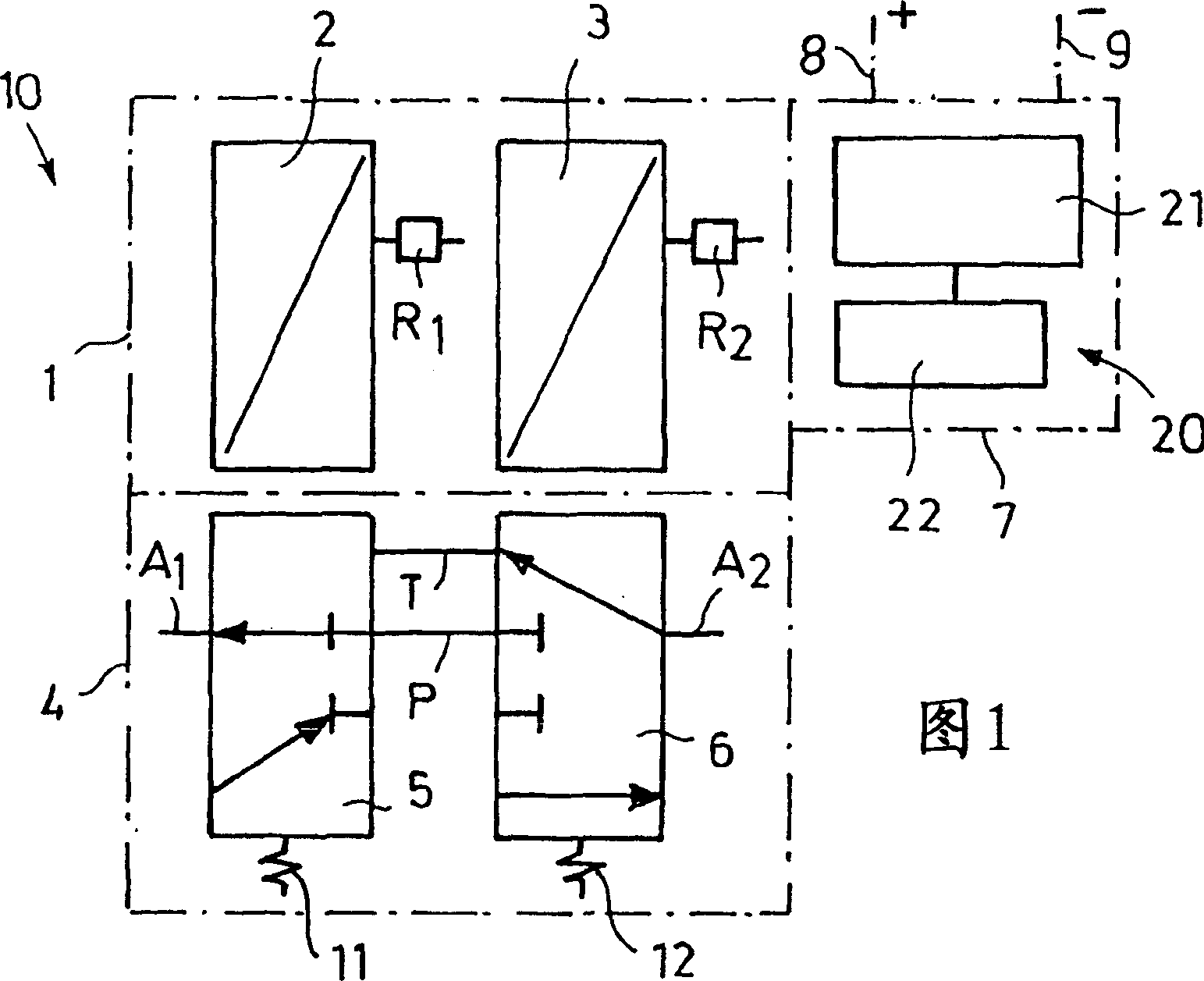

Battery and method of manufacturing the same

InactiveCN1832228AEasy to assembleReduce the current valueCell sealing materialsInternal resistanceEngineering

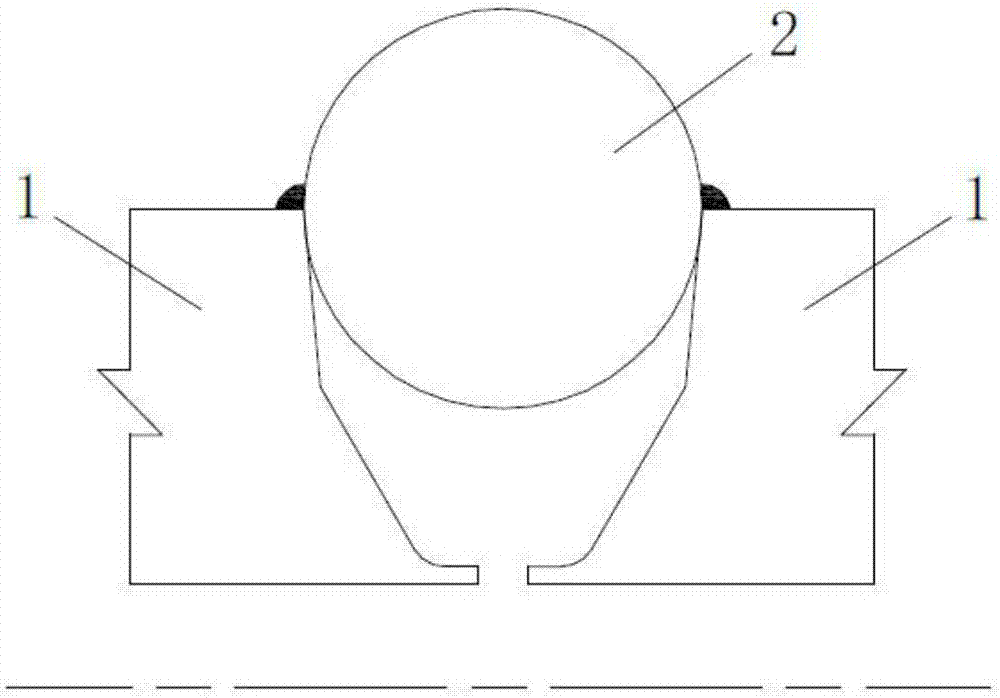

PROBLEM TO BE SOLVED: To provide a cylinder-shaped secondary battery, capable of easily connecting a current collector plate to a sealing plate and reducing internal resistance, and to provide a manufacturing method of the same.SOLUTION: The cylinder-shaped secondary battery is constituted by storing an electrode body 2, impregnated with nonaqueous electrolyte in a battery can 10 formed by fixing a sealing plate 4 to the opening of a bottomed cylindrical body 11. A pair of electrodes 21, 22 are made to protrude at both end parts of the electrode body 2, disc-shaped first and second current collector plates 31, 32 are connected to the end part of both electrodes 21, 22 respectively; and the surface of the second current collector plate 32 is resistance-welded to a bottom face of the bottomed cylindrical body 11. A plate-shaped projection piece 33, extending from the surface of the first current collector plate 31 toward the sealing plate 4 is protrusively arranged on the first current collector plate. A slit 41, into which the protrusion piece 33 is to be inserted, is opened at a position corresponding to the position of the protrusion piece 33, and laser welding is applied to a part where the projection piece 33 is fitted to the slit 41.

Owner:SANYO ELECTRIC CO LTD

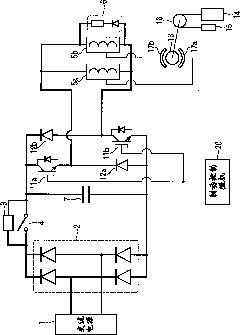

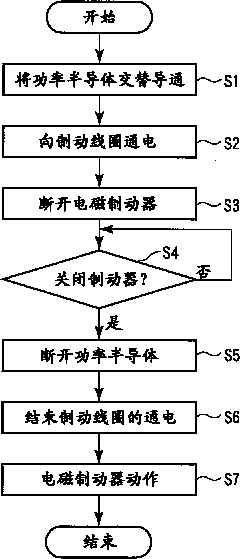

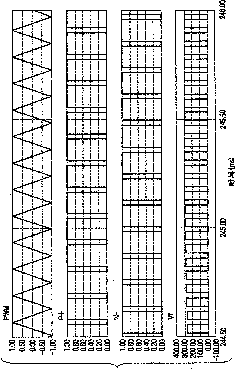

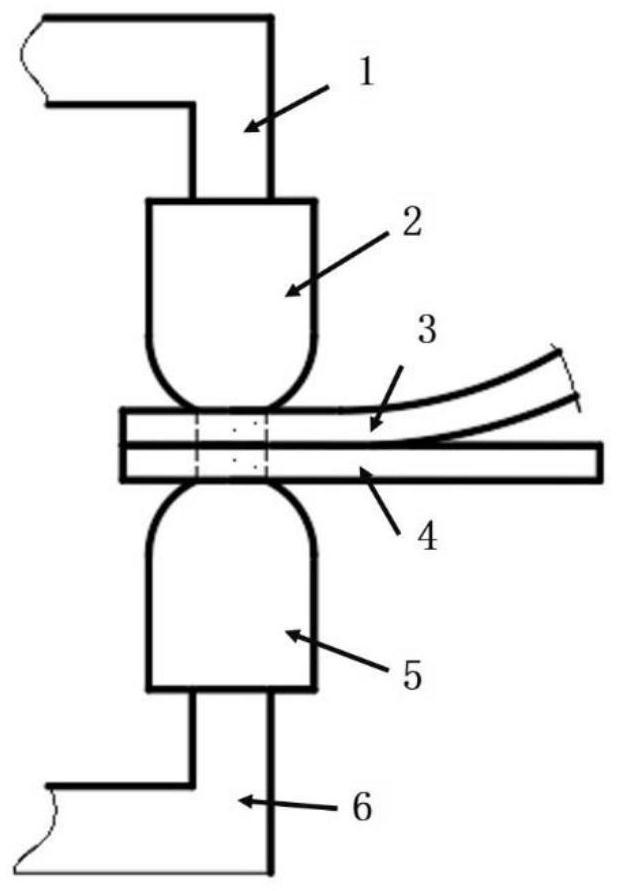

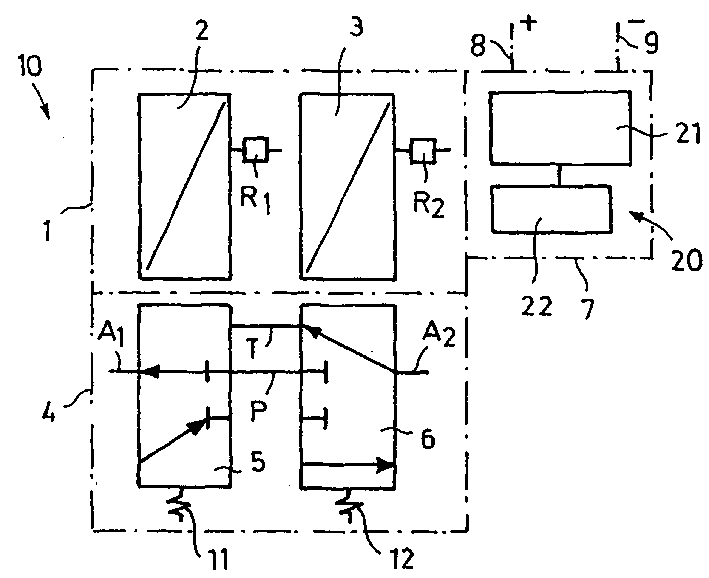

Brake control device for elevator

InactiveCN102190222AReduce the current valueBrake actuating mechanismsElevatorsElectric current flowSemiconductor

The present invention provides a brake control device for an elevator, which is provided with a brake control part (20) that energizes a first brake coil and a second brake coil (5a,5b) for performing energization and cutoff control for semiconductor switches (11a,11b) so one part of a period of energizing the first brake coil is overlapped with one part of a period of energizing the second brake coil. After energization and cutoff is started, motion start of each brake sheet (17a,17b) is determined according to the detection result which is detected by a current detector (25). Along with the determination, the energization and shutoff control is performed for the semiconductor switch so the current value of each brake coil is smaller than that in determination.

Owner:TOSHIBA ELEVATOR KK

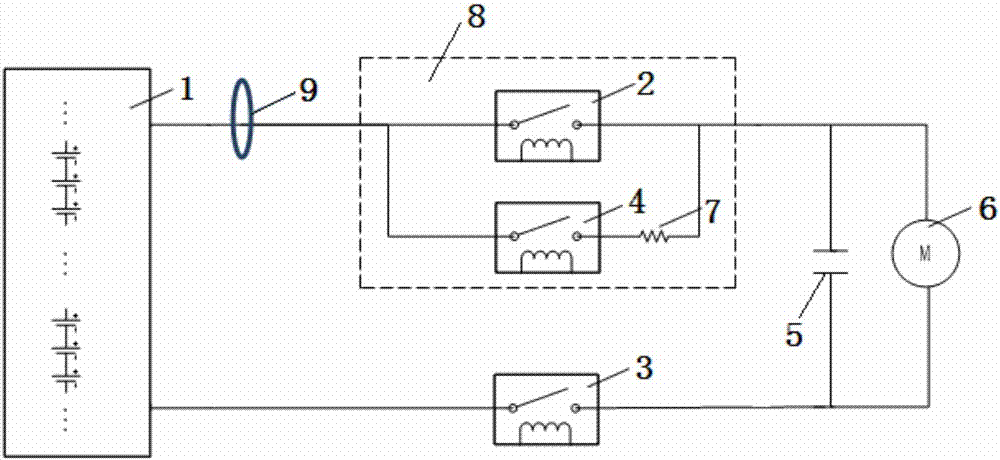

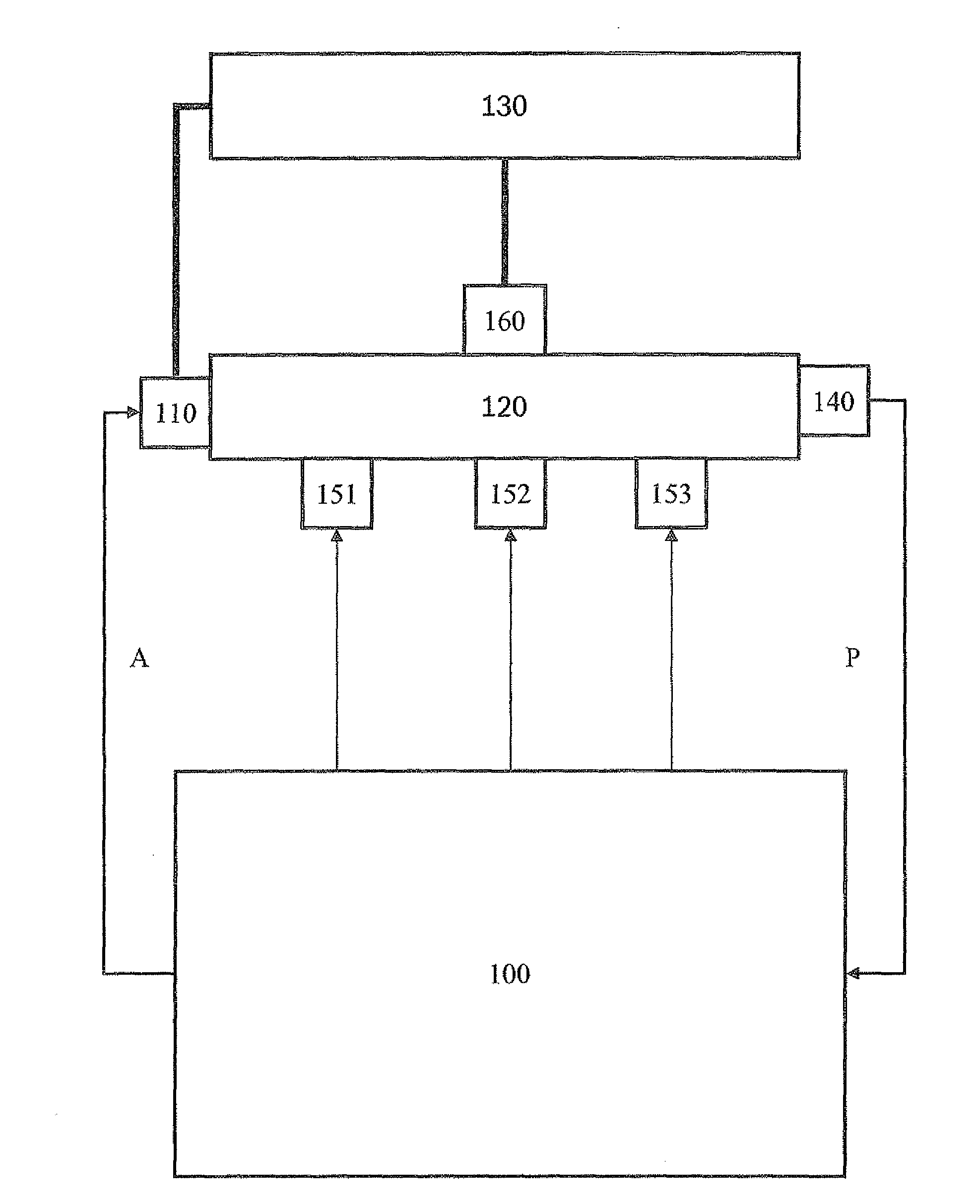

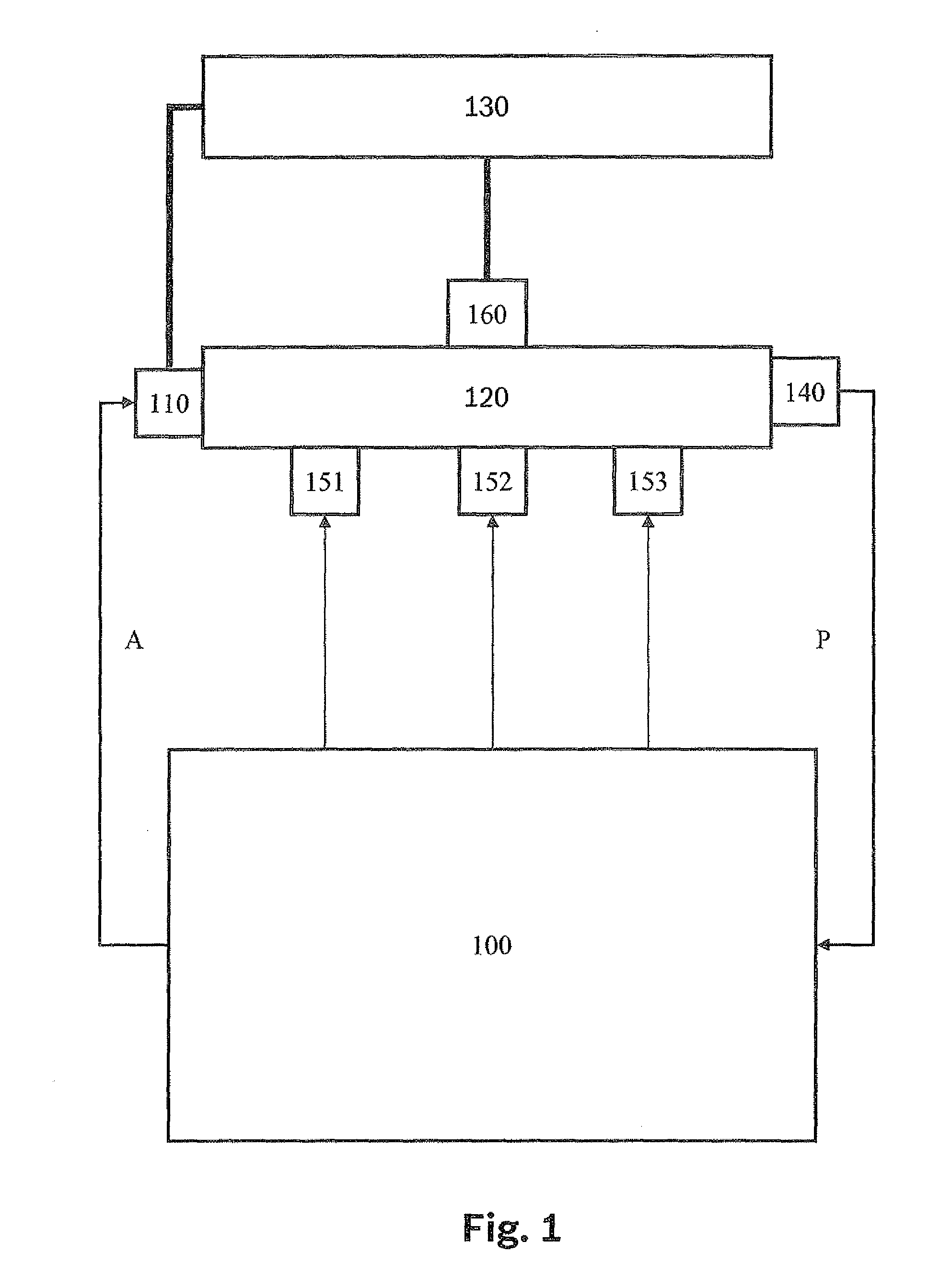

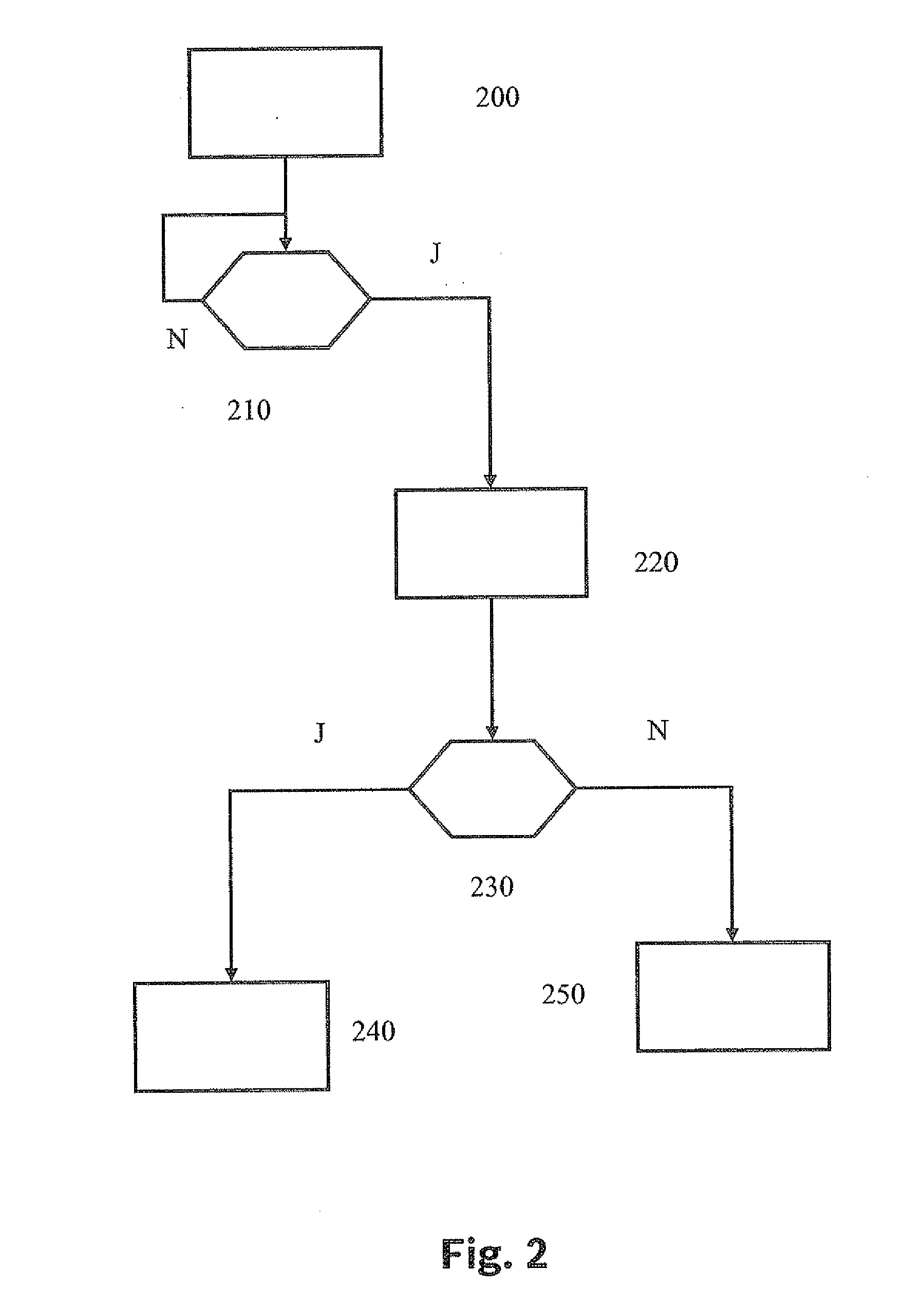

Precharge control circuit and control method for high-voltage system of hybrid electric vehicle

ActiveCN107253439AImprove the safety of useSimple control circuitElectric devicesCapacitanceElectrical current

The invention provides a precharge control circuit for a high-voltage system of a hybrid electric vehicle. The precharge control circuit for the high-voltage system of the hybrid electric vehicle comprises a power battery pack, a main positive relay, a main negative relay, a precharge relay, a capacitor and a motor; one end of the main positive relay and one end of the main negative relay are correspondingly connected to the positive electrode and the negative electrode of the power battery pack, and the other end of the main positive relay and the other end of the main negative relay are connected with the motor; the capacitor is connected to both ends of the motor in parallel; the precharge relay is connected with a precharge resistor in series and then connected to both ends of the main positive relay to form a parallel circuit; and a shunt is arranged between the parallel circuit and the positive electrode of the power battery pack. Meanwhile, a precharge control method using the precharge control circuit is provided. According to the precharge control circuit and the control method for the high voltage system of the hybrid electric vehicle, through the current value collected by the shunt and the current slope value in the interval time, whether precharging of the high voltage system is completed or not is judged, the method is simple, the high voltage part does not need to be introduced into a BMS, and the safety is high.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

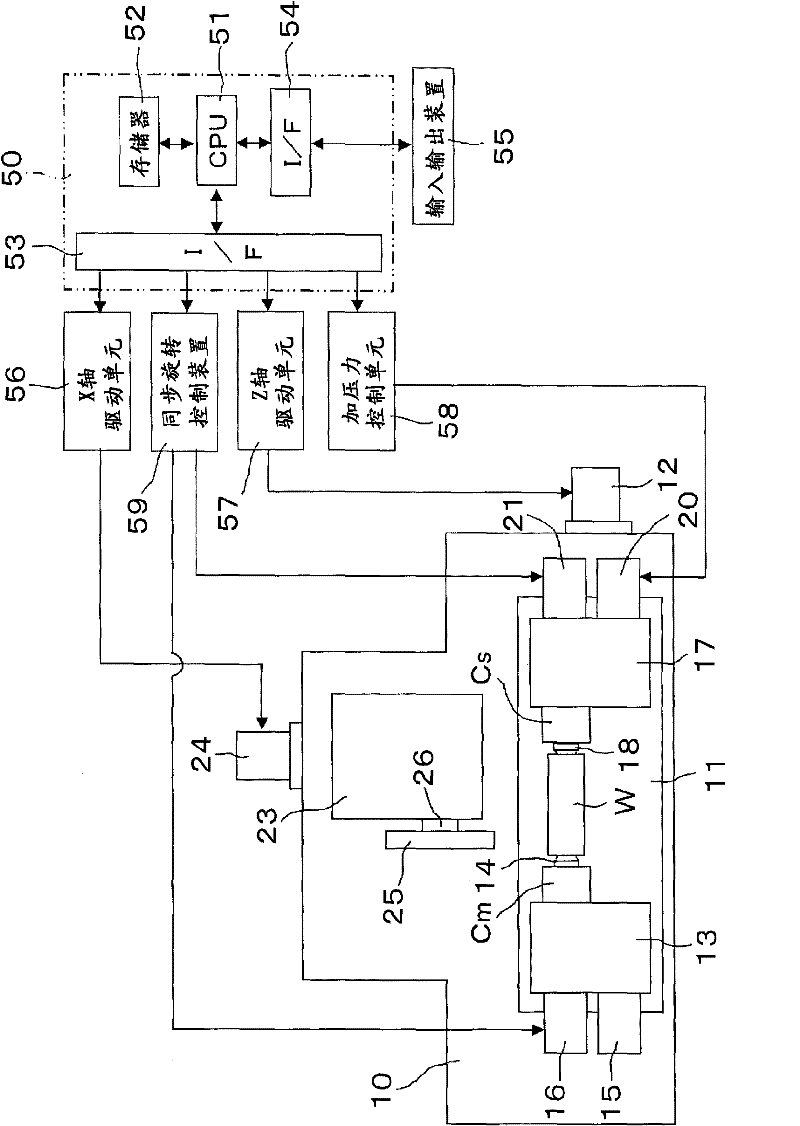

Method and device for controlling a fuel metering system

InactiveUS20110016959A1Reduce the current valueGuaranteed uptimeInternal-combustion engine testingElectrical controlRail pressureInternal combustion engine

A method and a device for controlling a fuel metering system are described. The fuel metering system includes at least one injector for injecting fuel into an internal combustion engine. An electric current value is applied to the at least one injector, and a rail pressure value is determined based on the electric current value.

Owner:ROBERT BOSCH GMBH

Base region gradient P<+>-N-N<+> type SiC ultrafast recovery diode manufactured on 4H type single crystal silicon carbide epitaxial layer and process

ActiveCN104201211AShort reverse recovery timeSuppress surge currentSemiconductor/solid-state device manufacturingSemiconductor devicesReverse recoveryCarbide

The invention discloses a base region gradient P<+>-N-N<+> type SiC ultrafast recovery diode manufactured on a 4H type single crystal silicon carbide epitaxial layer and a process. An anode / (P<+>)4H-nc-SiC / (N) slowly changes into a 6H-nc-SiC / (N)4H-c-SiC / (N<+>)4H-c-SiC / cathode. The base region gradient P<+>-N-N<+> type SiC ultrafast recovery diode comprises an N<+> type 4H-c-SiC substrate, an N type 4H-c-SiC epitaxial layer, an N type 6H-nc-SiC gradually-doped and grain-gradient multilayer film and a P<+> type 4H-c-SiC single layer film, wherein the outer sides of the N<+> type 4H-c-SiC substrate and the P<+> type 4H-c-SiC single layer film are in ohm connection with an anode NiAu and an anode TiAu respectively. The device structure is made by using a PECVD (Plasma Enhanced Chemical Vapor Deposition) technology. The process has the advantages of shortening the reverse recovery time, inhibiting surge current and lowering the process temperature.

Owner:广州奔瑞电子科技有限公司

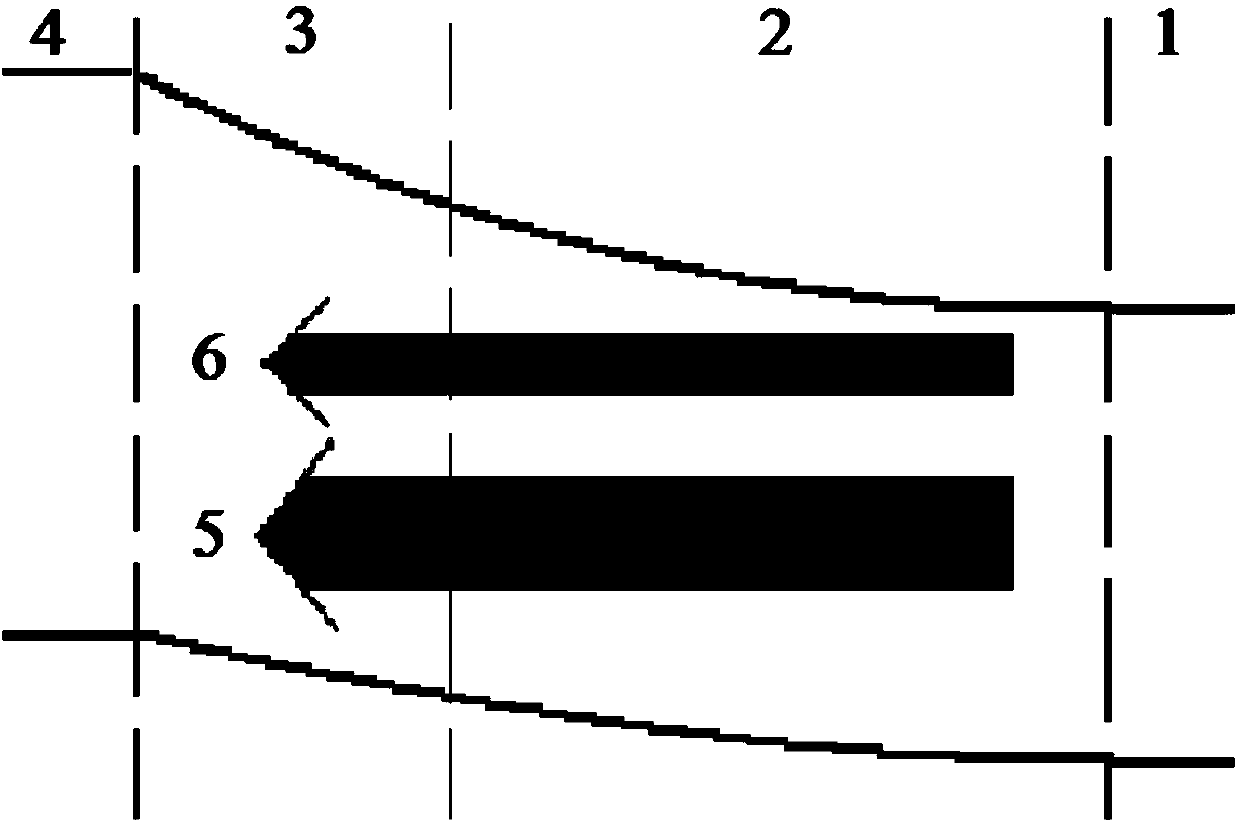

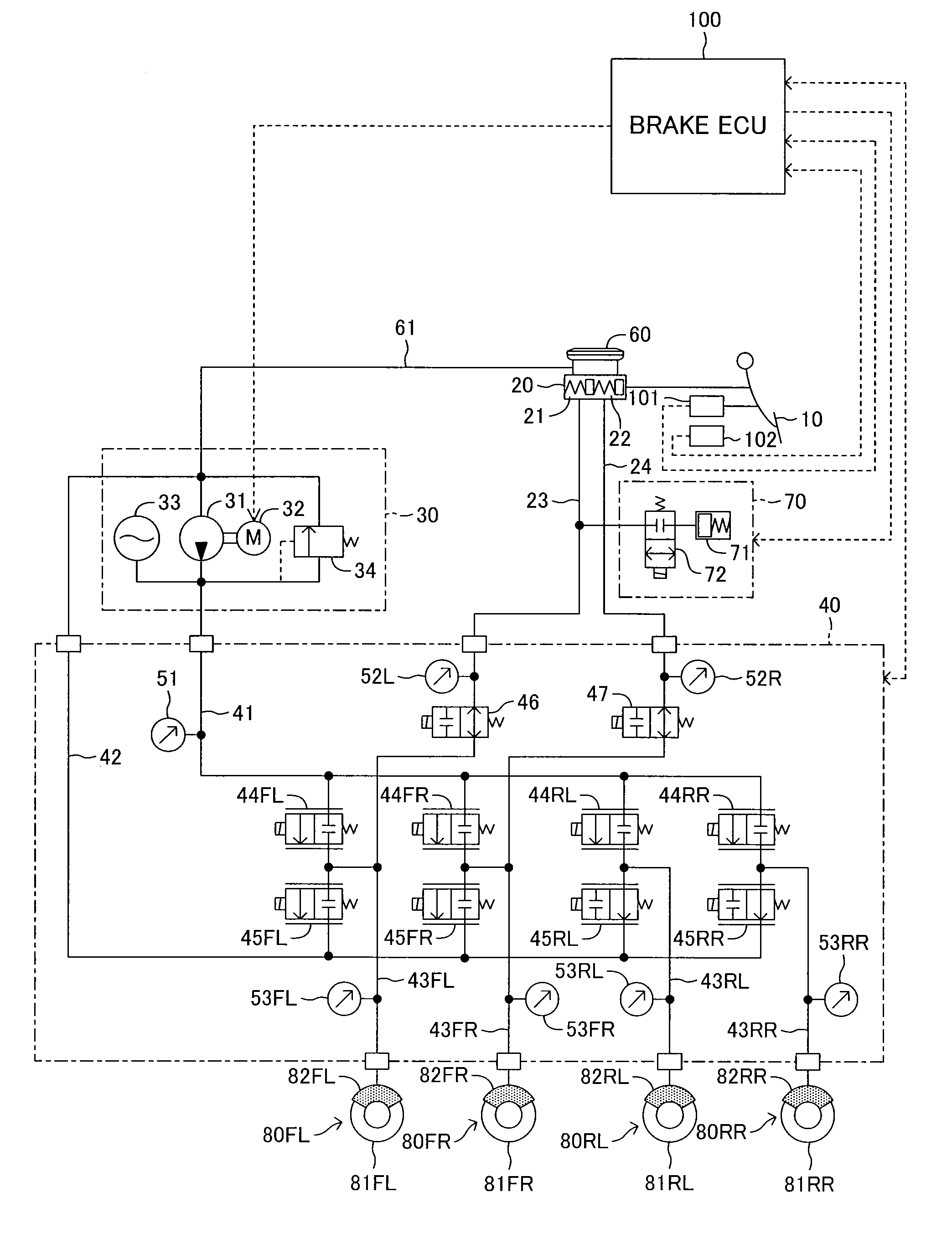

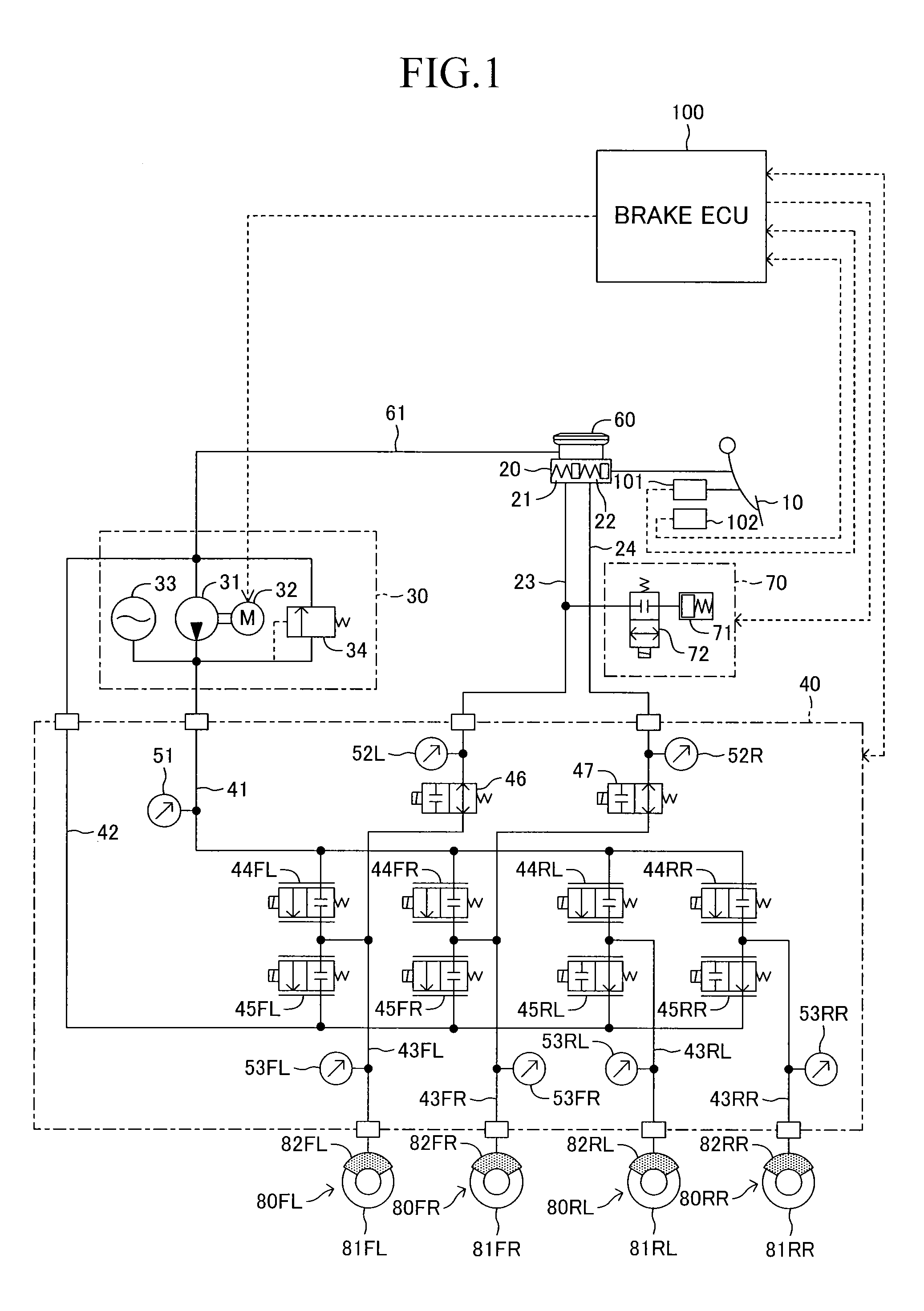

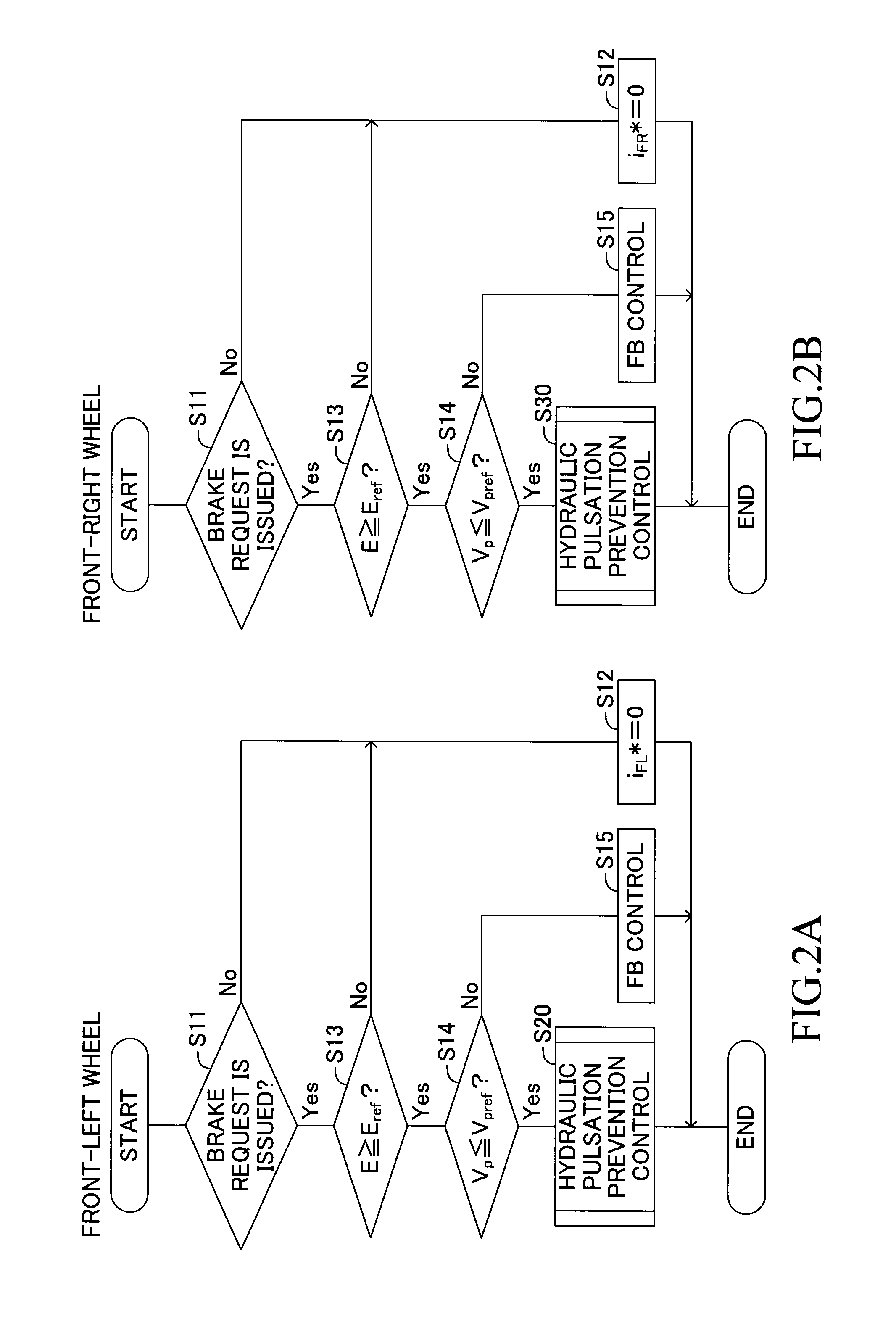

Vehicle brake control device

ActiveUS20150298664A1Increase valueReduce the valueAnalogue computers for trafficBrake control systemsLinear controlControl valves

When a brake pedal is slowly depressed, a brake ECU sets a target current iFL* of a pressure-increasing linear control valve for a front-left wheel to increase from a current value lower than a valve-opening current i open by a decrease set value i1, and sets a target current iFL* for a pressure-increasing linear control valve for a front-right wheel to increase from a current value lower than a valve-opening current i open by a decrease set value i2 (<i1). This prevents a timing at which the pressure-increasing linear control valve is closed and a timing at which the pressure-increasing linear control valve is closed from matching, whereby a variation in a vehicle deceleration G can be suppressed.

Owner:TOYOTA JIDOSHA KK

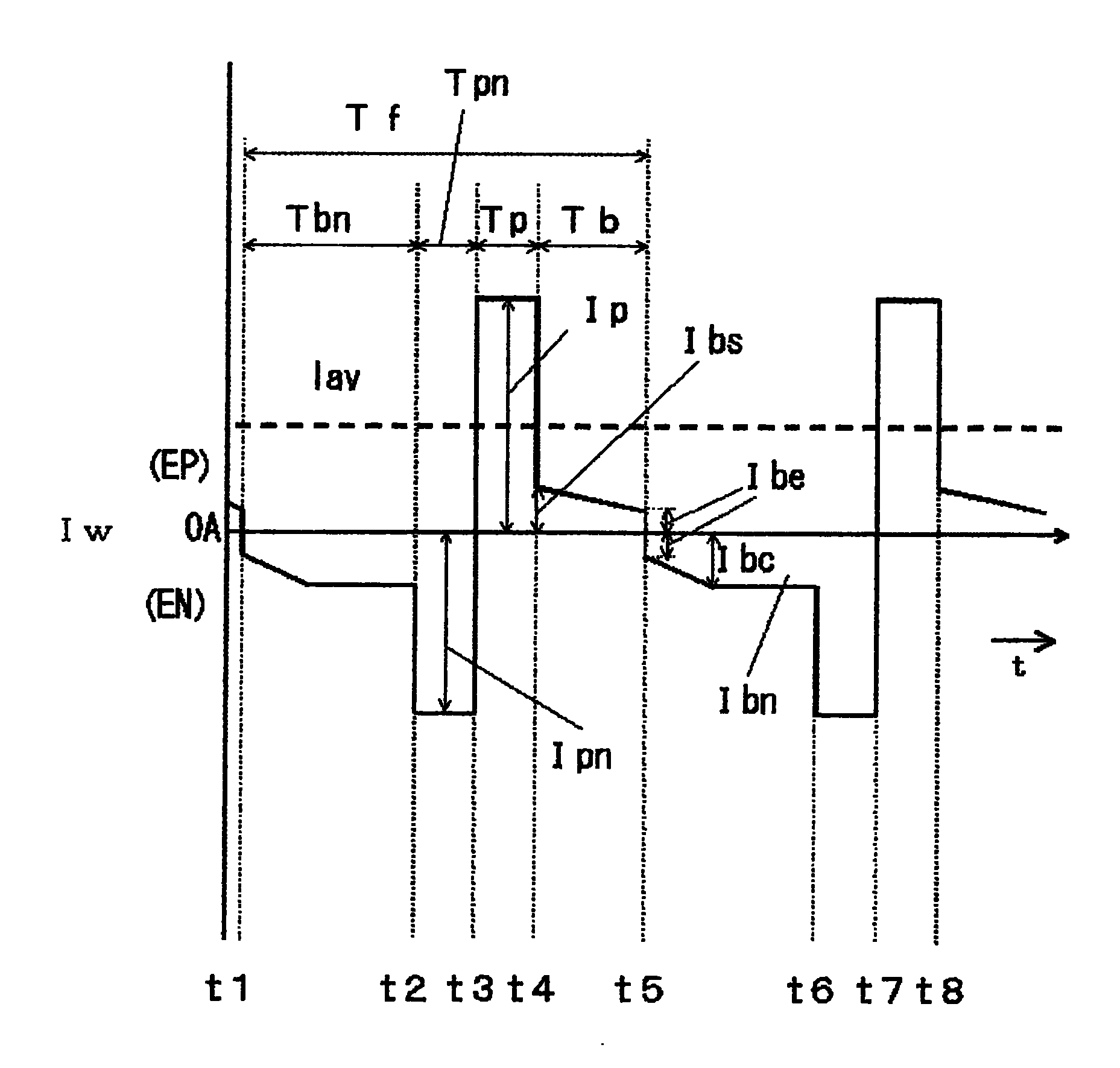

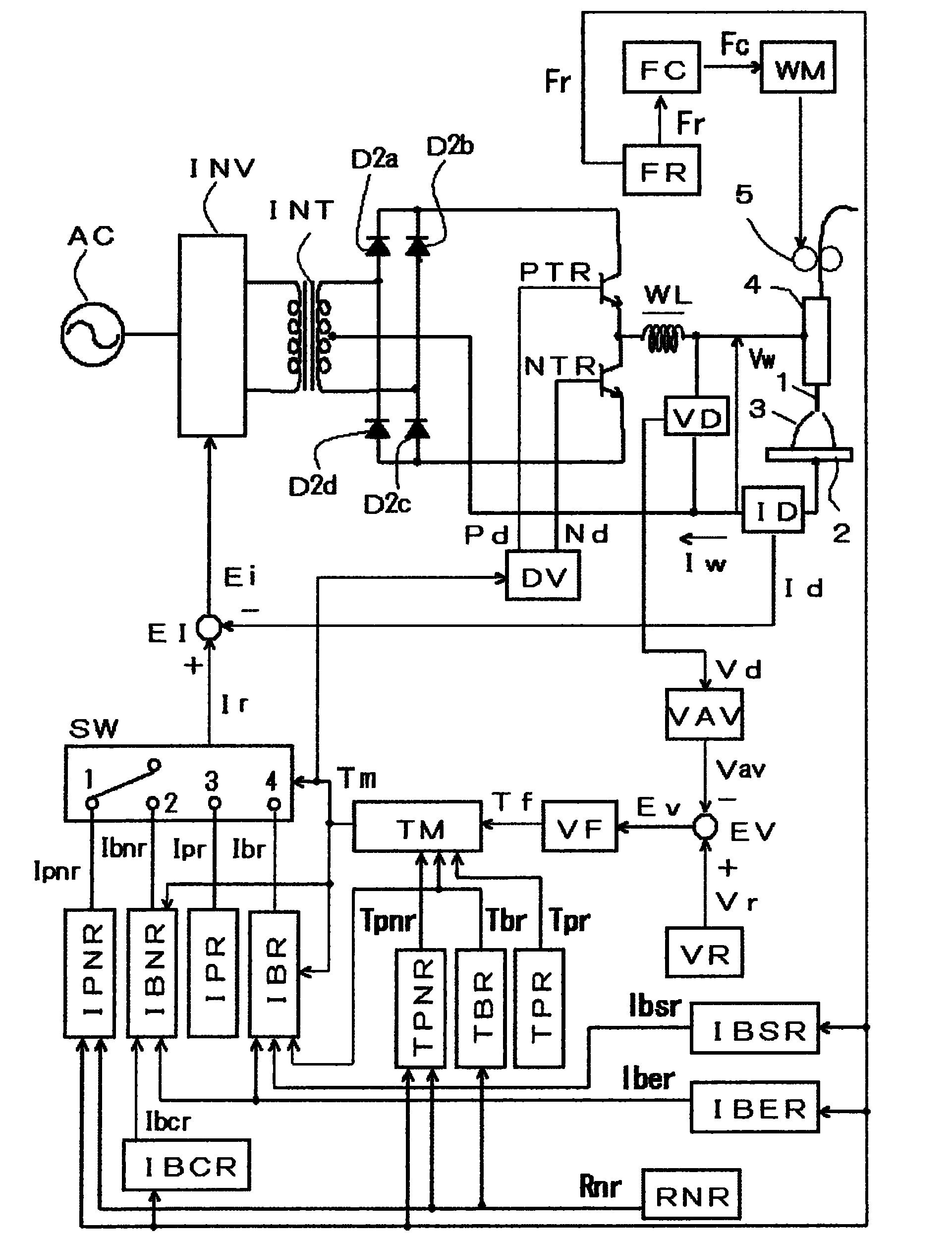

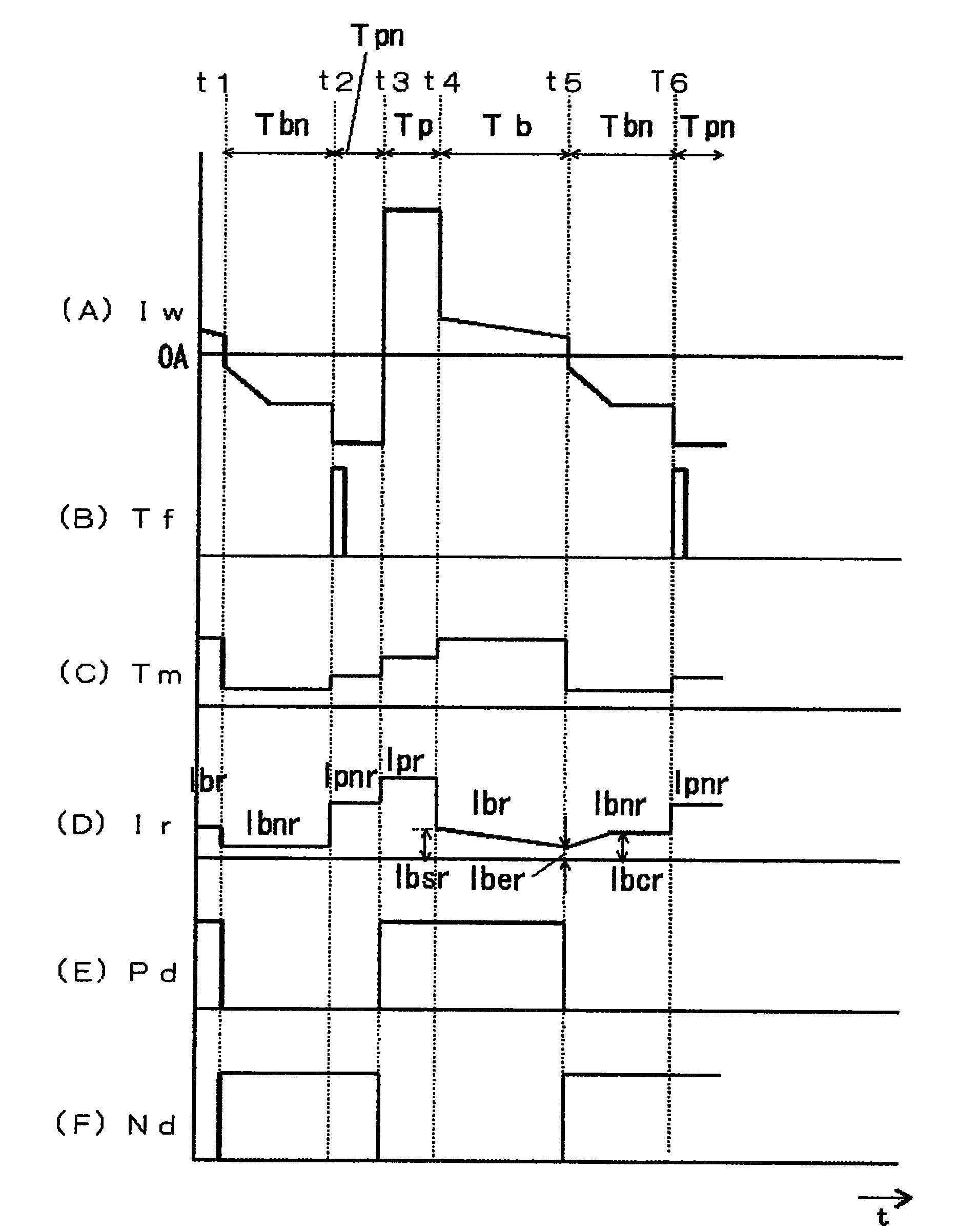

AC pulse arc welding control method

ActiveCN102430840AInhibition lossReduce the current valueArc welding apparatusSputteringElectrode polarity

The invention provides an AC pulse arc welding control method, wherein during the negative electrode polarity-based period (Tbn), the negative electrode polarity-based current (Ibn) smaller than the critical value is electrified. During the negative electrode peak-based period (Tpn), the negative electrode peak-based current (Ipn) greater than the negative electrode polarity-based current is electrified. During the positive electrode peak-based period (Tp), the positive electrode peak-based current (Ip) greater than the critical value is electrified. During the positive electrode polarity-based period (Tb), the positive electrode polarity-based current (Ib) smaller than the critical value is electrified. Therefore, the welding can be performed. The positive electrode polarity-based current (Ib) is inclined to be smaller along the passing of time. The front half part of the positive electrode polarity-based current (Ib) is capable of increasing so as to inhibit the disappearing of electric arc. The rear half part of the positive electrode polarity-based current (Ib) is capable of decreasing so as to reduce the sputtering of electric arc.

Owner:DAIHEN CORP

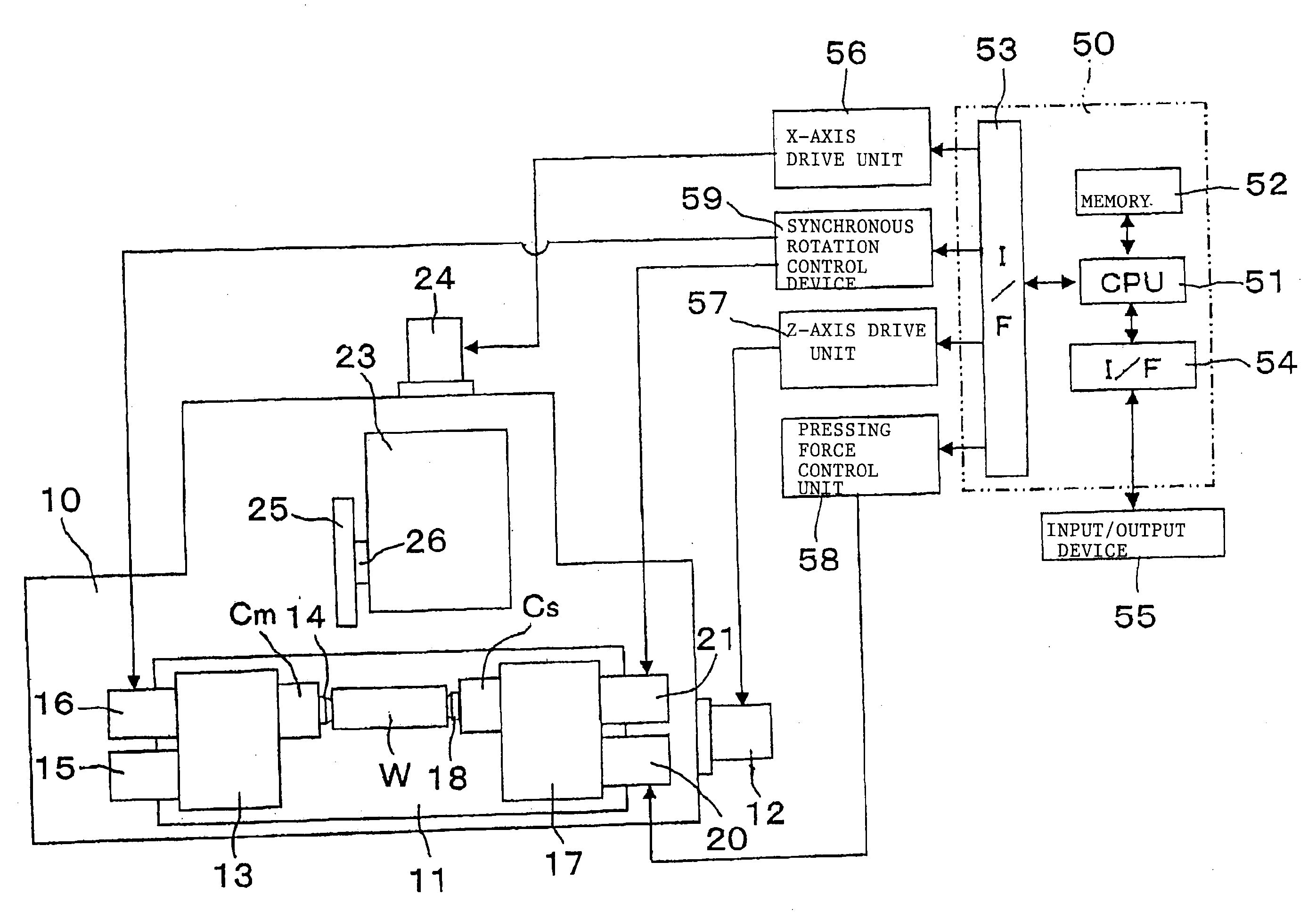

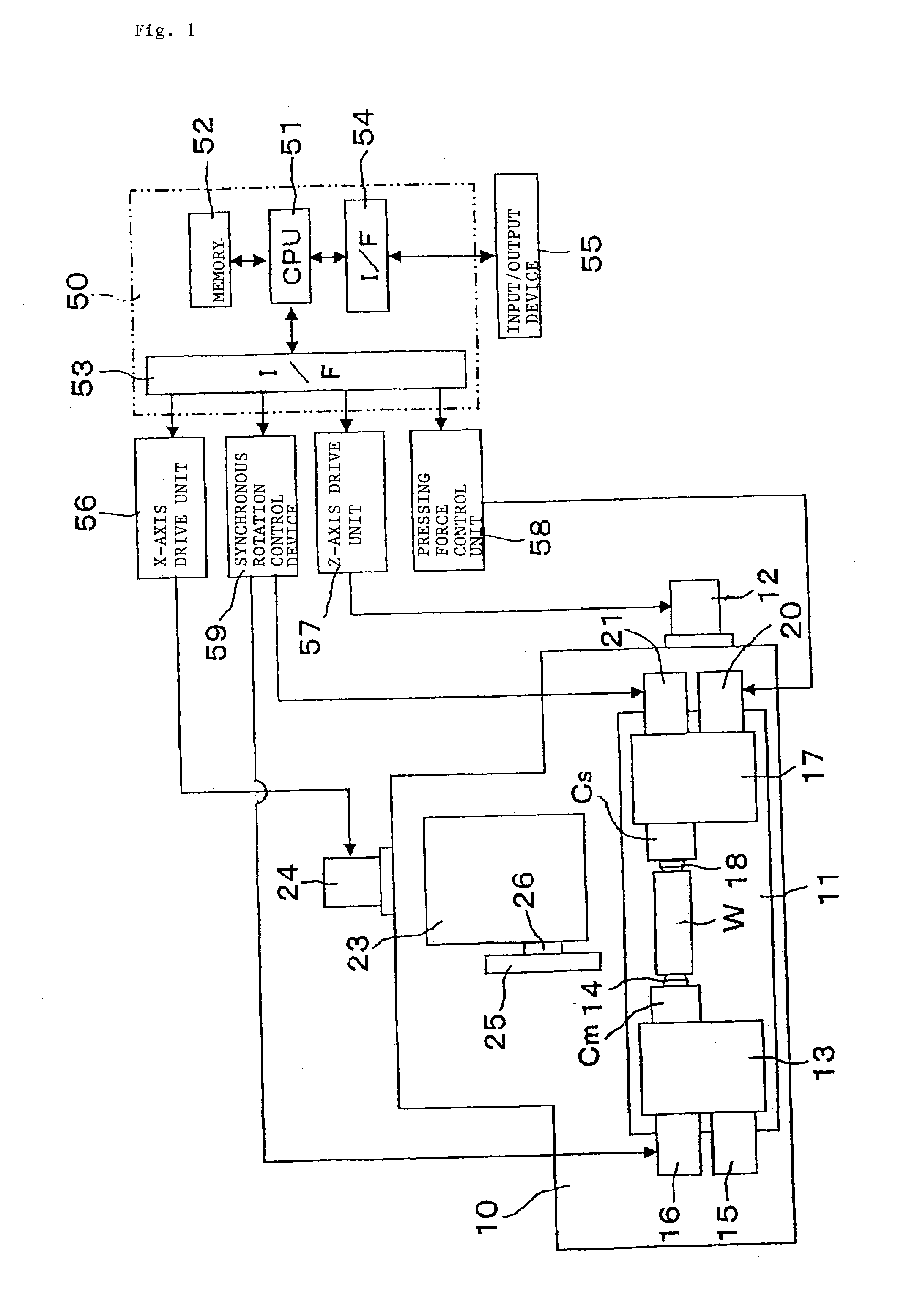

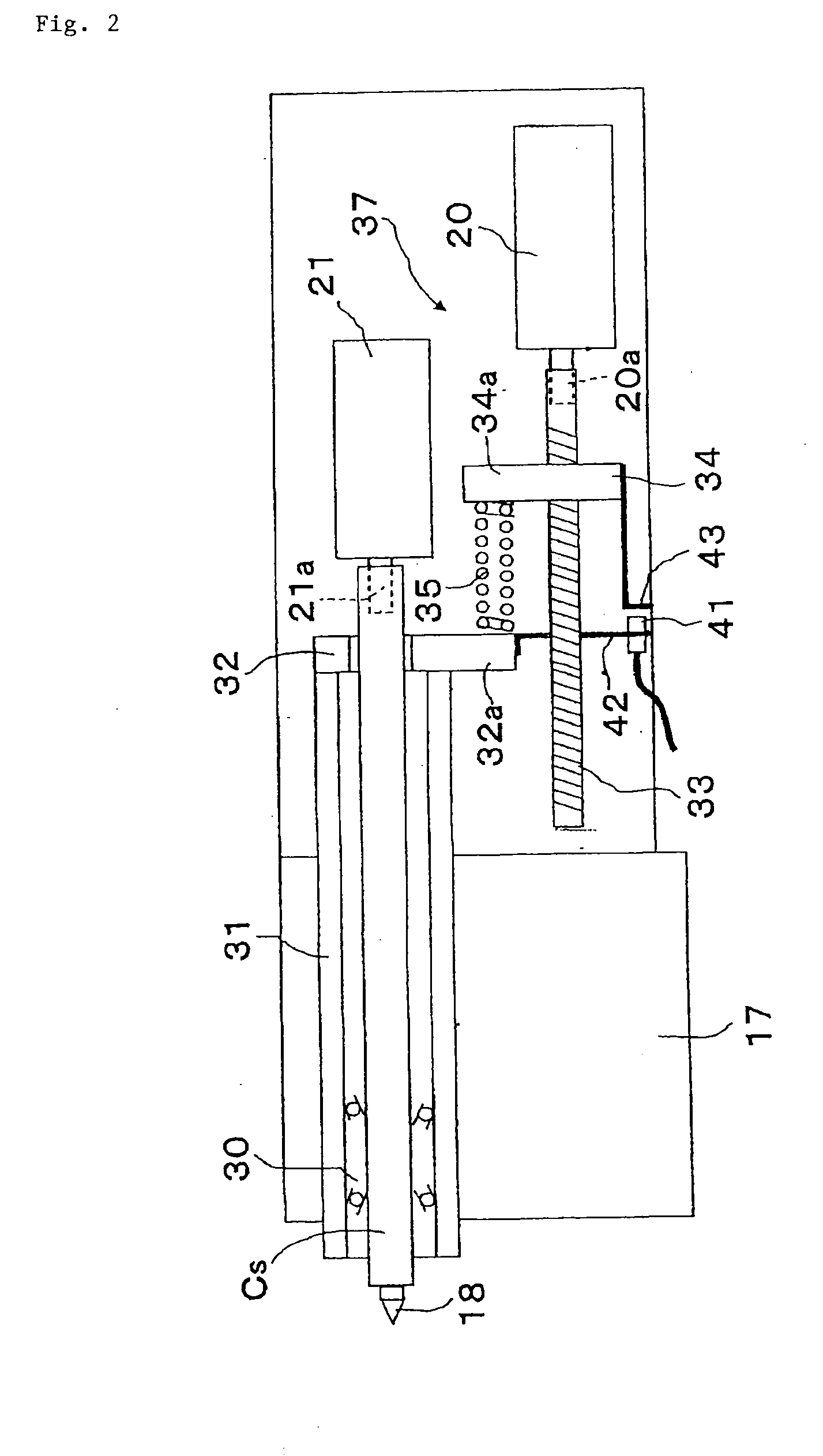

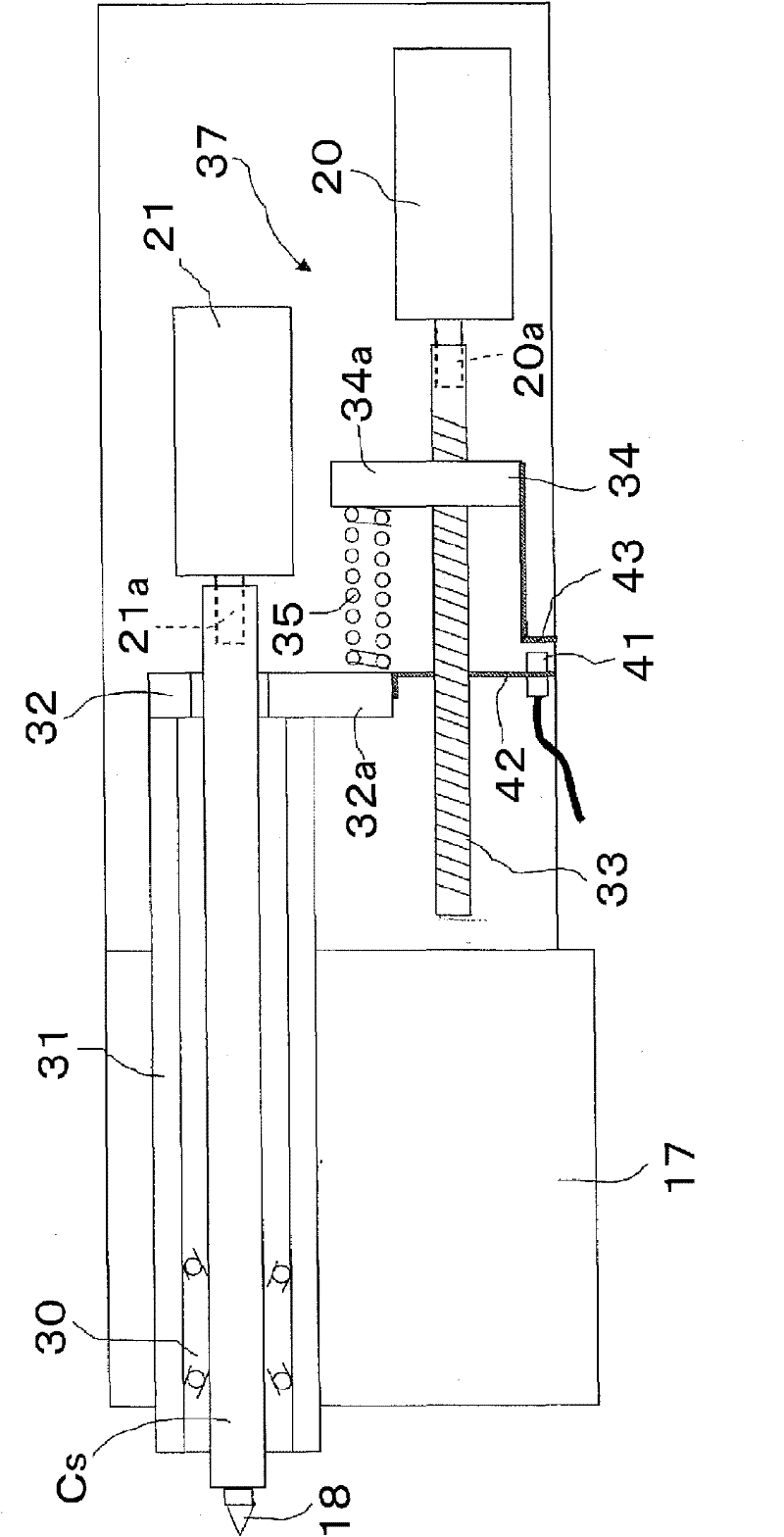

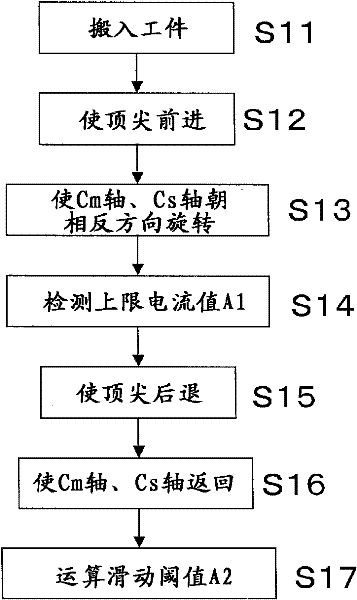

Method and device for preventing slip of work piece

InactiveUS20120129433A1Avoid reliabilityImprove accuracyRevolution surface grinding machinesGrinding feed controlValue setControl theory

A master servo motor and a slave servo motor that synchronously drive for rotation a master main spindle provided with a center that supports one end of a work piece and a slave main spindle provided with a center that supports the other end of the work piece are included. Before grinding, a slip detection cycle that detects a limit current value for the servo motors, at which the work piece and the centers slip, is executed and, during grinding, a grinding condition is changed to prevent a slip between the work piece and the centers in advance at the time when any one of current values of the servo motors has reached a slip threshold value set on the basis of the limit current value.

Owner:JTEKT CORP

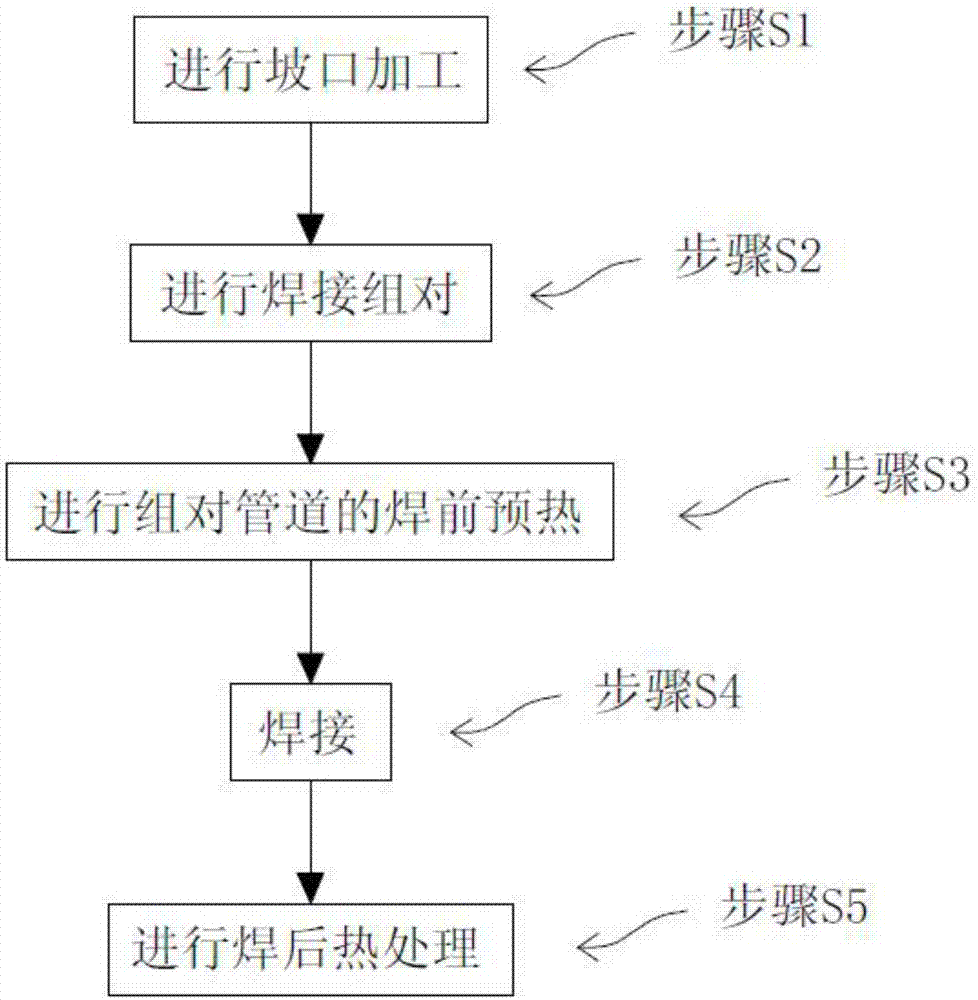

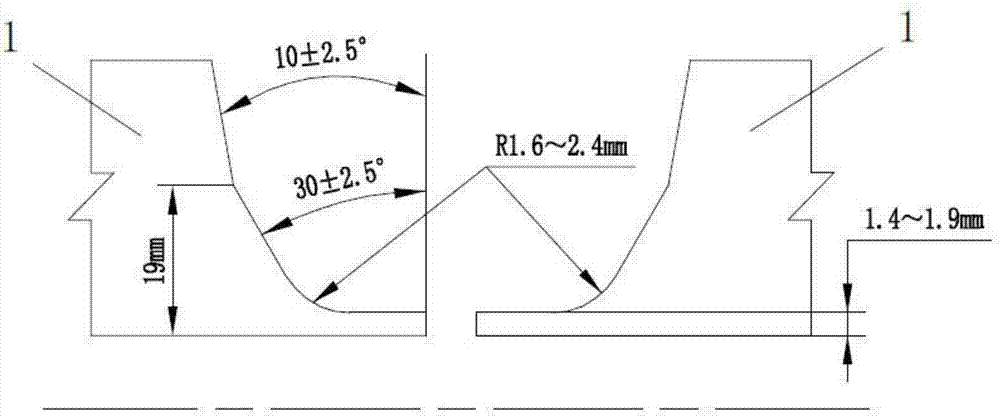

AP1000 main steam pipeline welding method

InactiveCN107457473AAvoid indentation defectsPrevent collapseArc welding apparatusNuclear powerShielding gas

The invention belongs to the technical field of AP1000 nuclear power, and particularly relates to an AP1000 main steam pipeline welding method. In order to solve the problems that an air filling protection device is difficult to install and potential safety hazards exist in the good health of operators when a conventional air filling protection device is used for auxiliary welding of an AP1000 main steam pipeline, the AP1000 main steam pipeline welding method is disclosed. The welding method particularly includes the following several steps of S1, chamfering; S2, welding assembly; S3, weld preheating; S4, welded connection; and S5, postweld heat treatment. When the welding method is used for welding the AP1000 main steam pipeline, through adjustment matching of the groove dimensions and welding parameters, welded joints formed in the welding process can still achieve a continuous and uniform forming effect without the supporting action of backing gas, and therefore installation of the air filling protection device is omitted and the influence on the good health of the operators by protective gas is avoided.

Owner:CHINA NUCLEAR IND FIFTH CONSTR CO LTD

Ground fault protection type electronic tripper tripping device

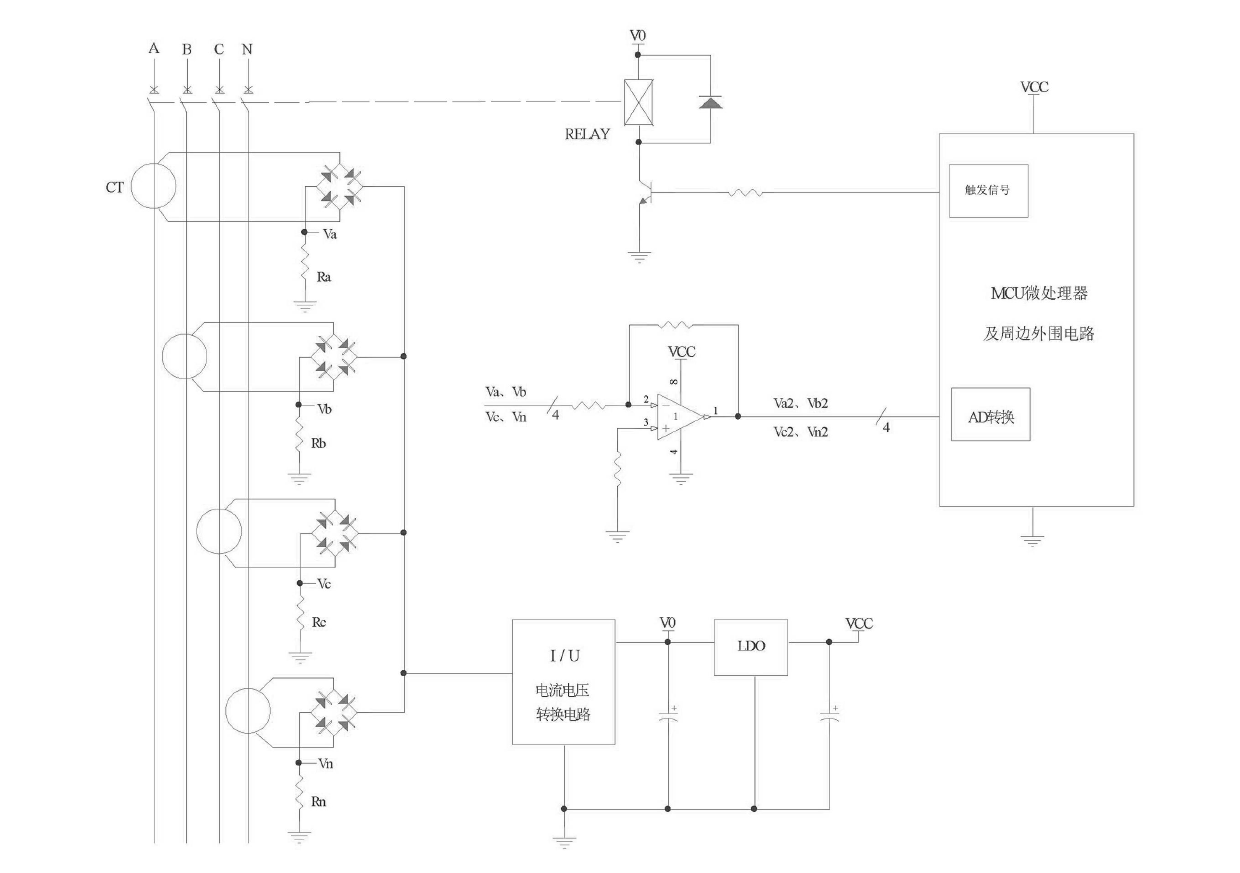

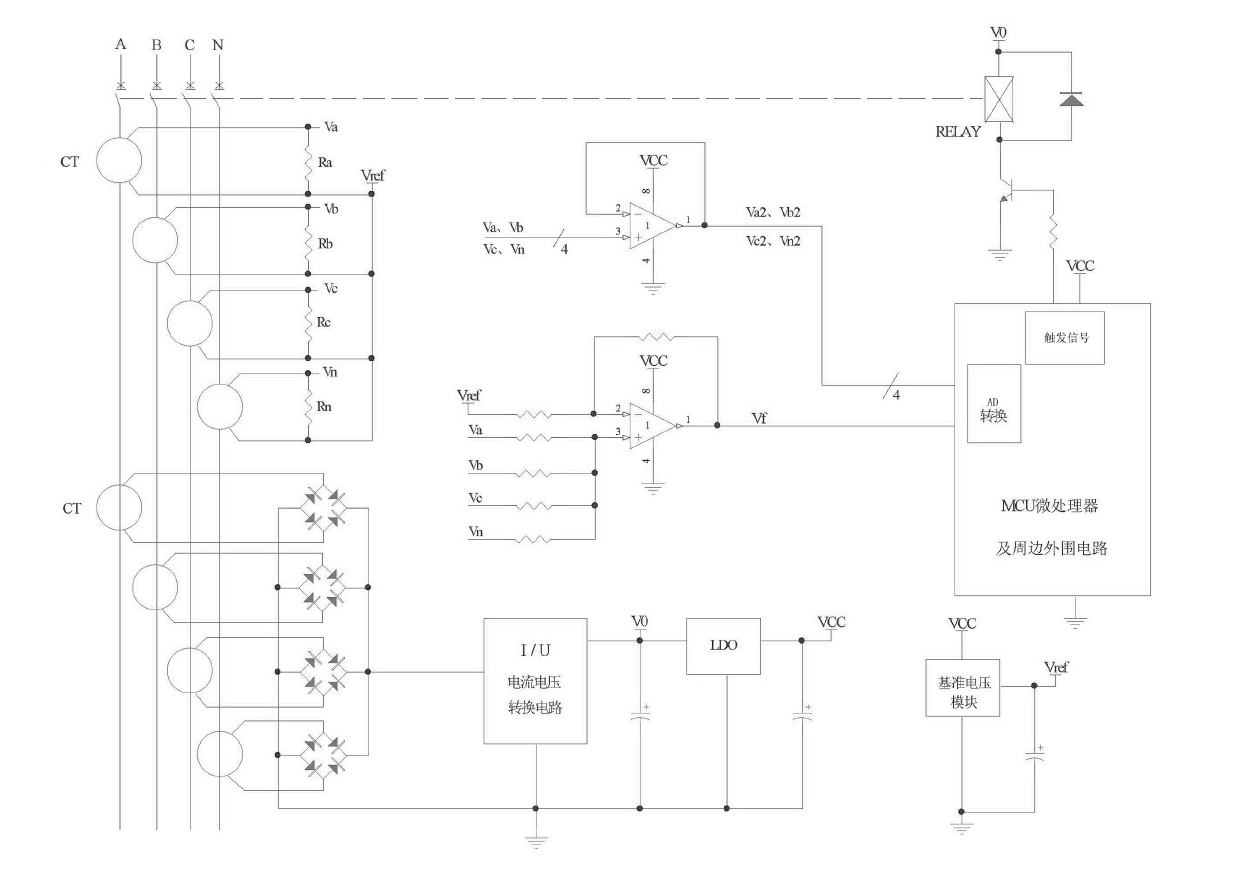

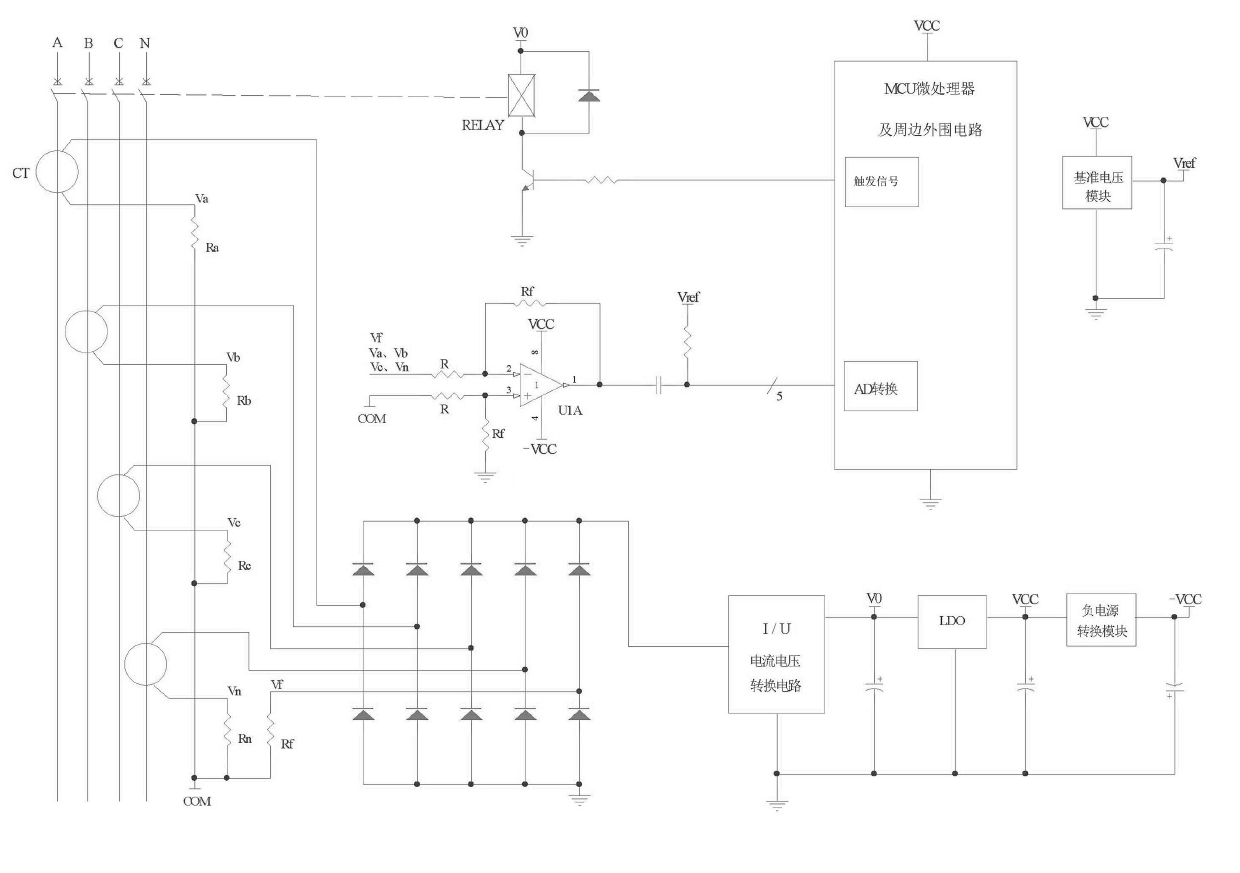

InactiveCN102170105ALow costAchieve isolationEmergency protective arrangements for automatic disconnectionLinear regulatorSignal processing circuits

Owner:XIAMEN SHIHLIN ELECTRIC CO LTD

Device and method for in-situ remediation of fluoride-polluted soil

The invention discloses a device and method for in-situ remediation of fluoride-polluted soil, which can adopt a permeable reactive barrier in combination with an electrodynamics technology to performin-situ remediation on fluoride-polluted soil. The remediation method comprises the steps of performing physicochemical property measurement on soil, performing fluorine elution on the surface of thesoil using a soil eluent, laying an electrode capable of being repaired in situ, constructing an electrolyte continuous cycle loop between an electrolysis chamber and an electrolyte storage tank of the in situ electrode, and applying a direct-current electric field between the anode and cathode with a low-pressure pulsed power supply. Fluorinion carrying negative charge moves towards an anode chamber through electromigration under the action of the electric field and is adsorbed by a permeable reactive barrier in the anode chamber, meanwhile, fluorine, in the form of fluoride or other solubleions, moves towards a cathode chamber through electrodialysis and is adsorbed by a permeable reactive barrier in the cathode chamber, after the remediation is completed, the electrode is taken out, thereby completing the removal and remediation of fluorine pollutants in the soil.

Owner:HENAN UNIV OF SCI & TECH

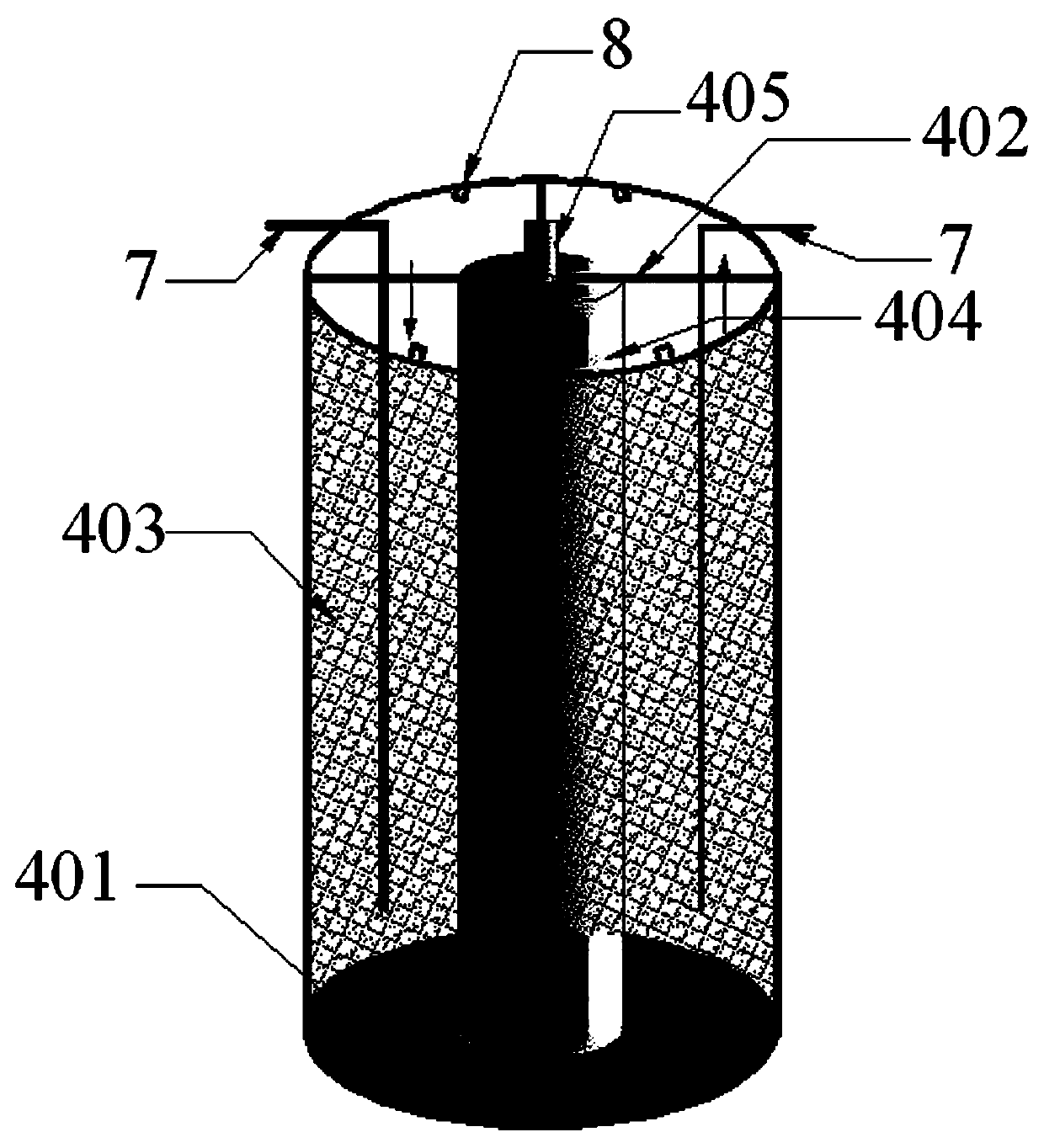

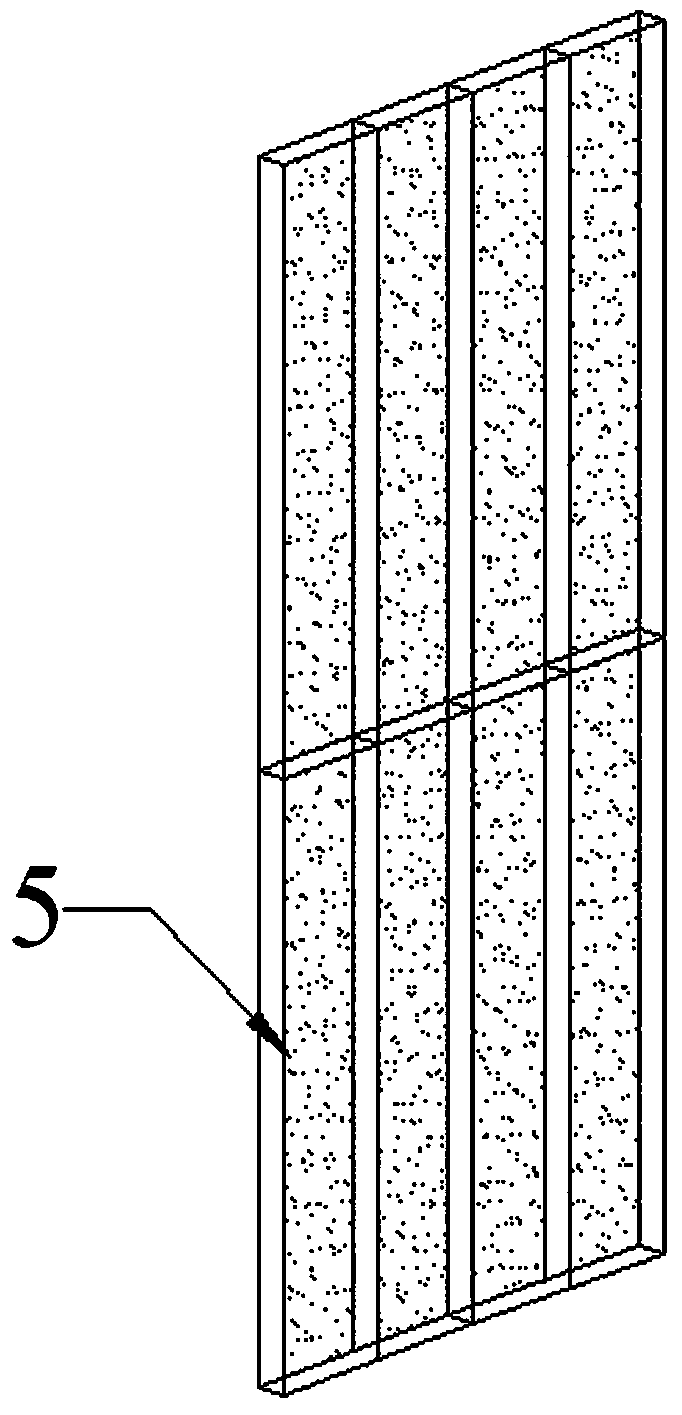

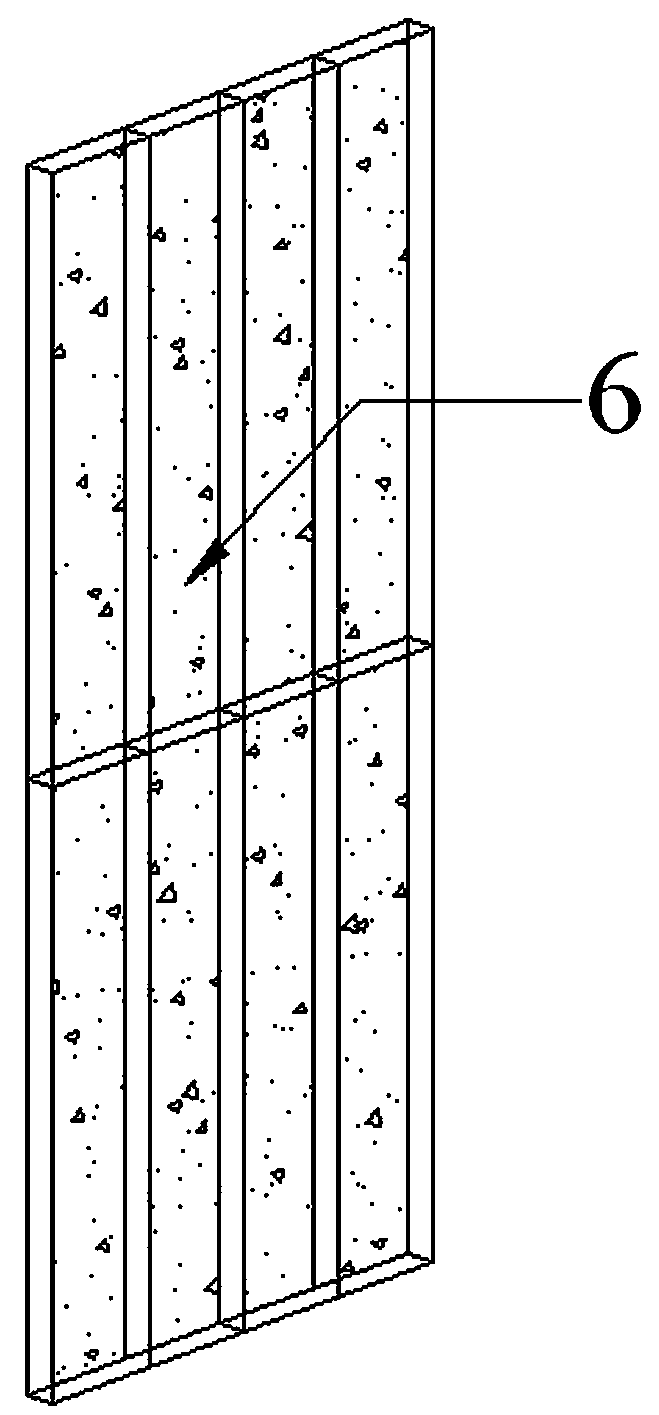

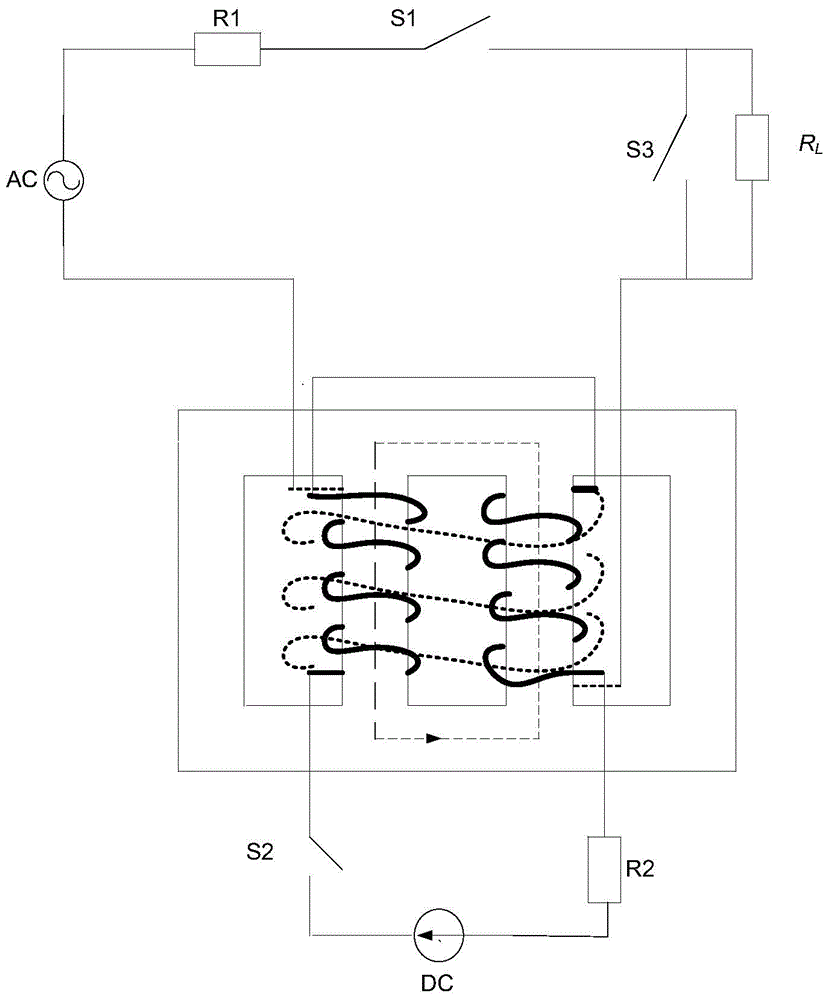

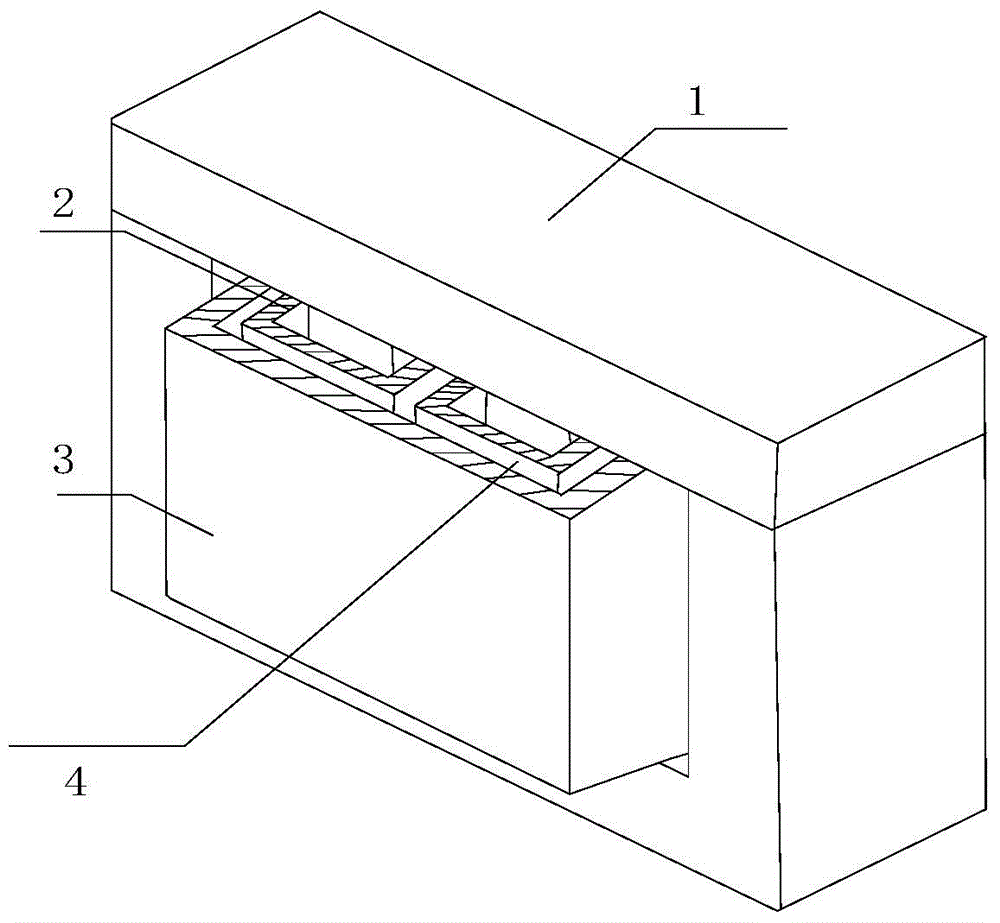

Saturated iron core type fault current limiter

InactiveCN104836216AReduce the current valueImprove cooling effectEmergency protective arrangements for limiting excess voltage/currentFault current limiterAC power

The invention discloses a saturated iron core type fault current limiter, comprising a four-column type iron core, two sets of DC windings, and one set of AC winding. The two sets of DC windings are in series connection, and are connected to a DC power source, and respectively wind around the two core columns at the middle of the four-column type iron core, and the magnetic field directions generated by the two sets of DC windings in the iron core are of the same. The AC winding is in series connection between the AC power supply and a load RL. The AC winding winds around the outer side of the DC winding in a manner that the middle two core columns are used as the winding shaft. The saturated iron core type fault current limiter is advantageous in that the structure is simple; short circuit current can be effectively restricted; power consumption is little and heat radiation is good.

Owner:SOUTHEAST UNIV +4

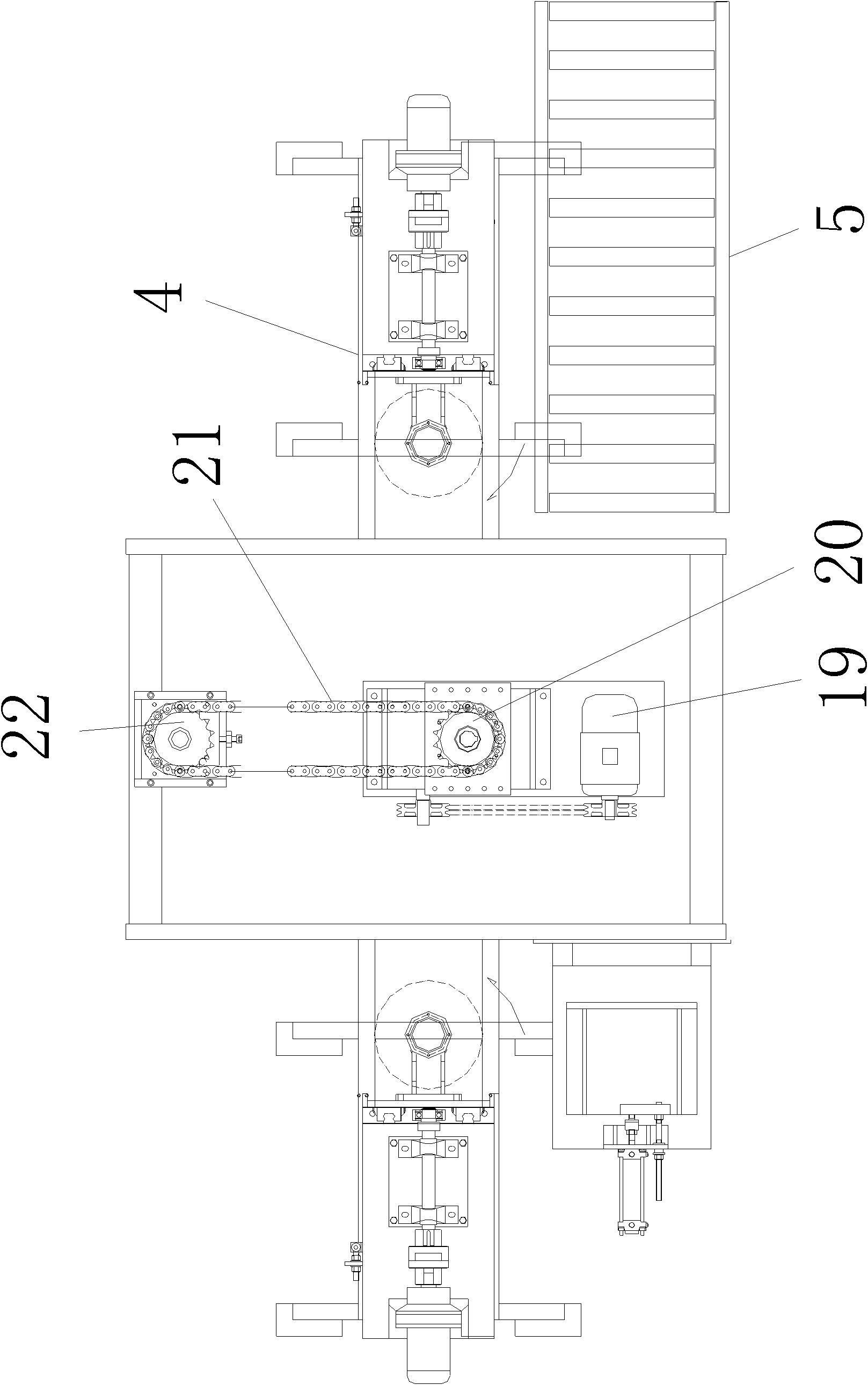

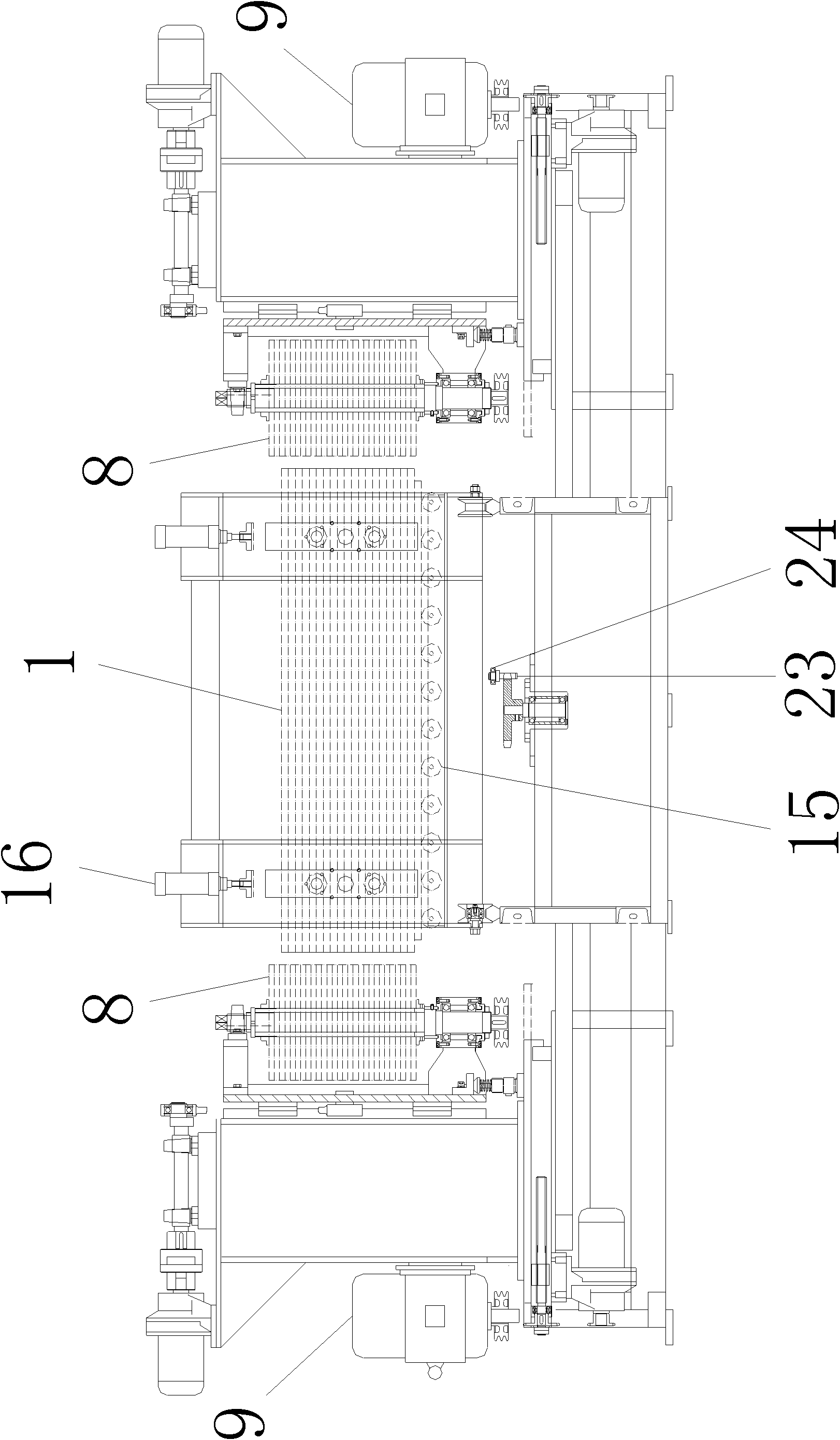

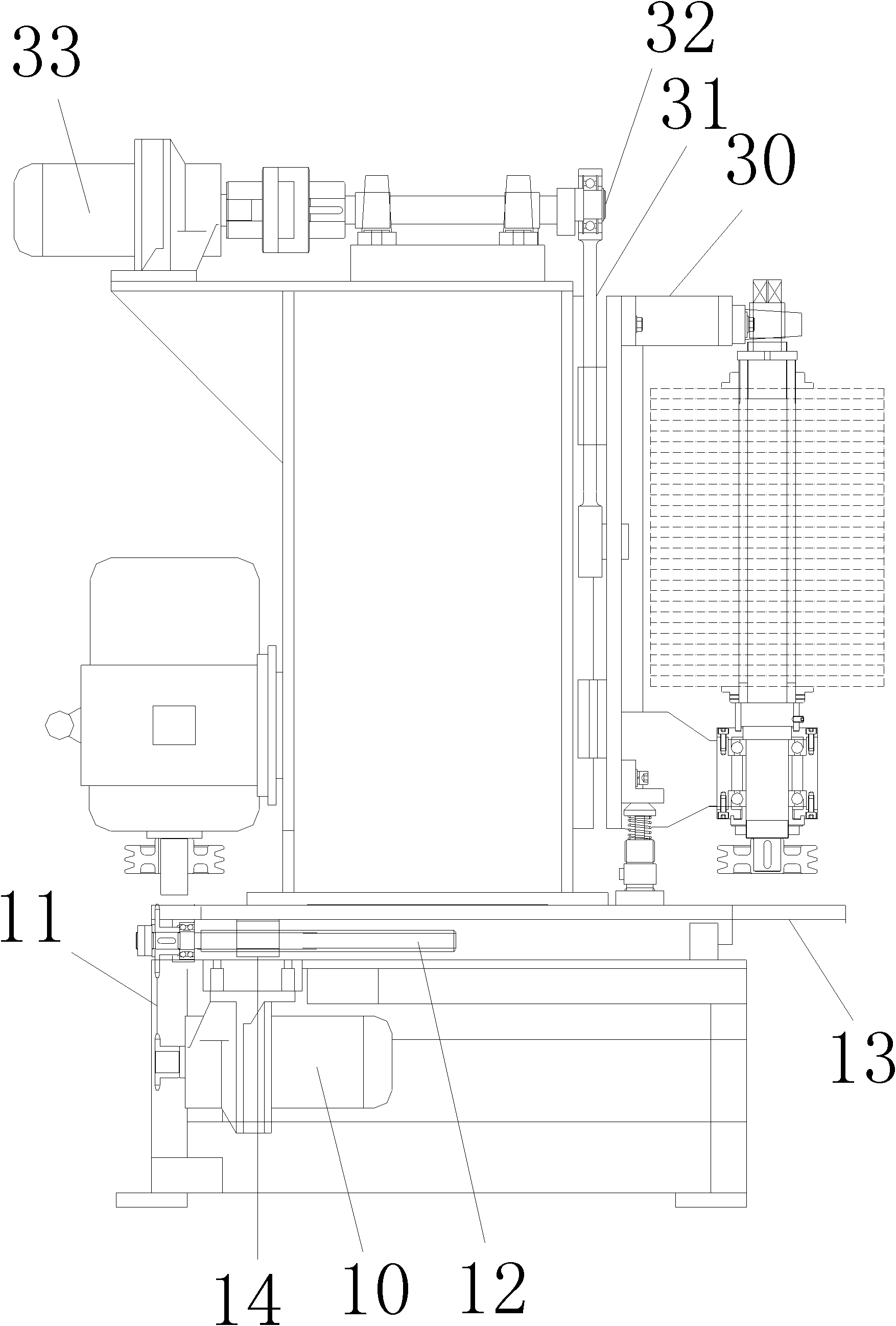

Piano paint piece edge polishing equipment and polishing method thereof

ActiveCN102248473AReduce labor intensityEasy to masterPolishing machinesVertical edgeProgrammable logic controller

The invention discloses piano paint piece edge polishing equipment. An edge in the advancing direction of a piano paint piece is a straight edge; and an edge on the horizontal surface vertical to the straight edge is a transverse edge. The polishing equipment comprises a transverse edge polishing machine and a straight edge polishing machine which are sequentially arranged, wherein in the transverse edge polishing machine, two transverse edges of the piano paint piece are provided with at least one polishing wheel respectively; in the straight edge polishing machine, two vertical edges on thepiano paint piece are provided with at least one polishing wheel respectively; each polishing wheel is individually connected and driven through one motor; each motor is provided with a current sensor; all current sensors on the transverse edge are connected to a transverse edge programmable logic controller (PLC); all current sensors on the straight edge are connected to a straight edge PLC; andeach polishing wheel and the motor connected with the polishing wheel are arranged on one feeding fine turning mechanism. The invention also provides a polishing method for the piano paint piece edgepolishing equipment. By the equipment and the method, automatic intelligent polishing can be realized.

Owner:PEARL RIVER PIANO GROUP

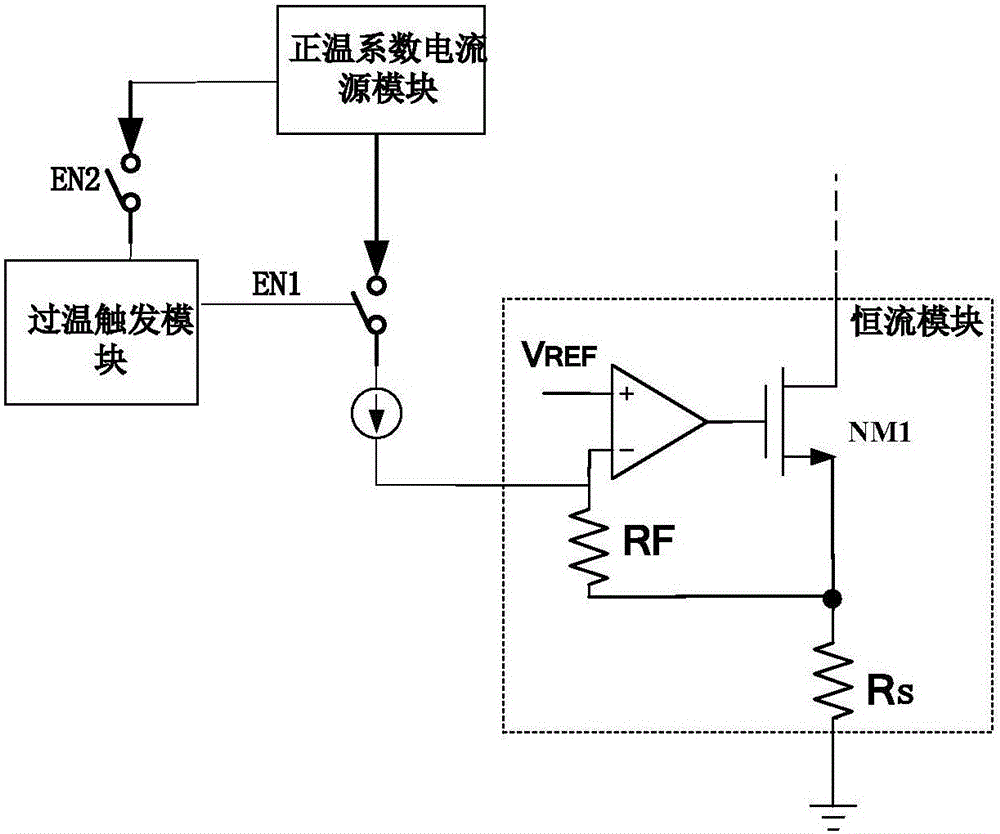

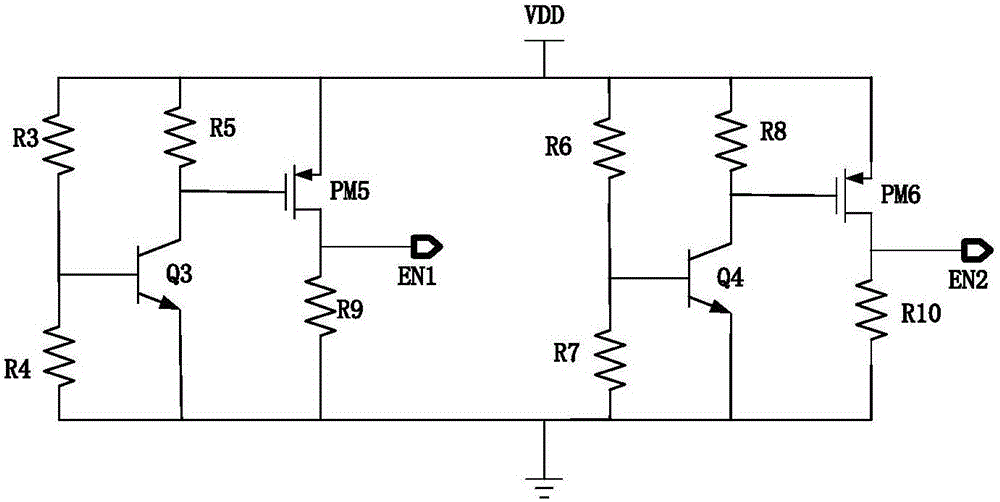

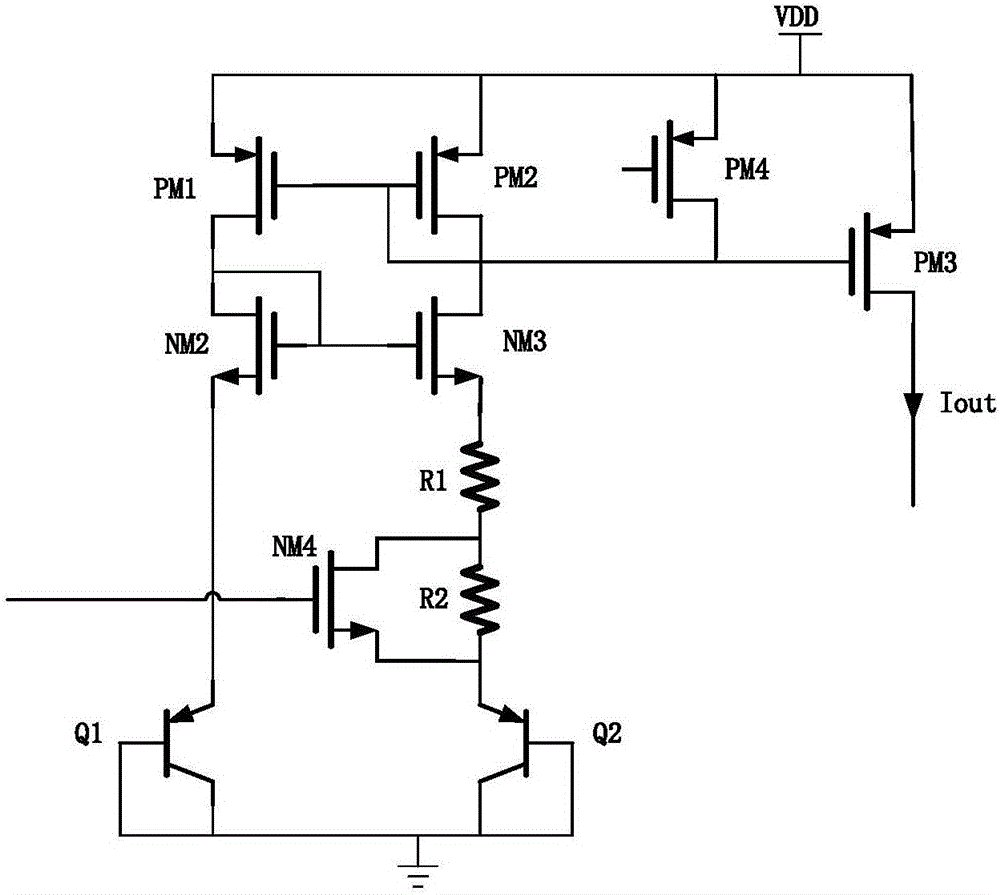

Sectional temperature compensation circuit

InactiveCN105867511AReduce power consumptionReduce the temperatureElectric variable regulationElectrical resistance and conductancePositive temperature

The invention belongs to electronic circuit technologies, and particularly relates to a sectional temperature compensation circuit which comprises a constant-current module, an over-temperature trigger module and a current source module with positive temperature coefficients. Constant currents can flow through load under the effect of the constant-current module; the over-temperature trigger module is connected with the current source module with the positive temperature coefficients, the current source module with the positive temperature coefficients can be switched on under the control of the over-temperature trigger module, and currents of the current source module with the positive temperature coefficients are controlled by the over-temperature trigger module; an output end of the current source module is connected with an inverted input end of the constant-current module, and compensation currents can be outputted from the output end of the current source module. The sectional temperature compensation circuit has the advantages that voltages of input power sources of chips can rise, the temperatures of the chips can be increased, the chips cannot be immediately switched off, voltages on a resistor Rs are linearly reduced, current values are decreased, and accordingly power consumption and the temperatures of the chips can be further reduced; the different temperature coefficients are adopted in different temperature ranges, accordingly, the temperature application ranges of the chips can be expanded, and the load and devices can be effectively protected.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

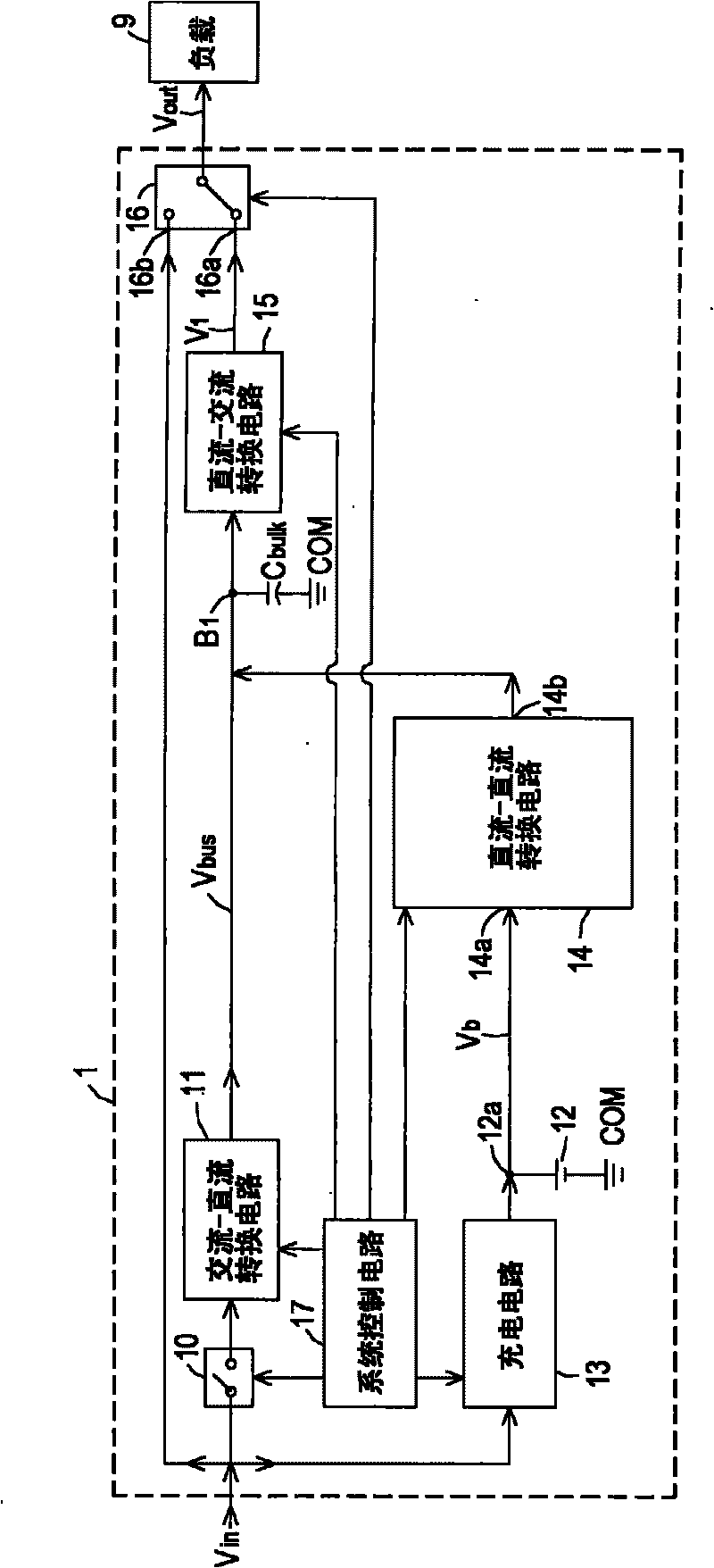

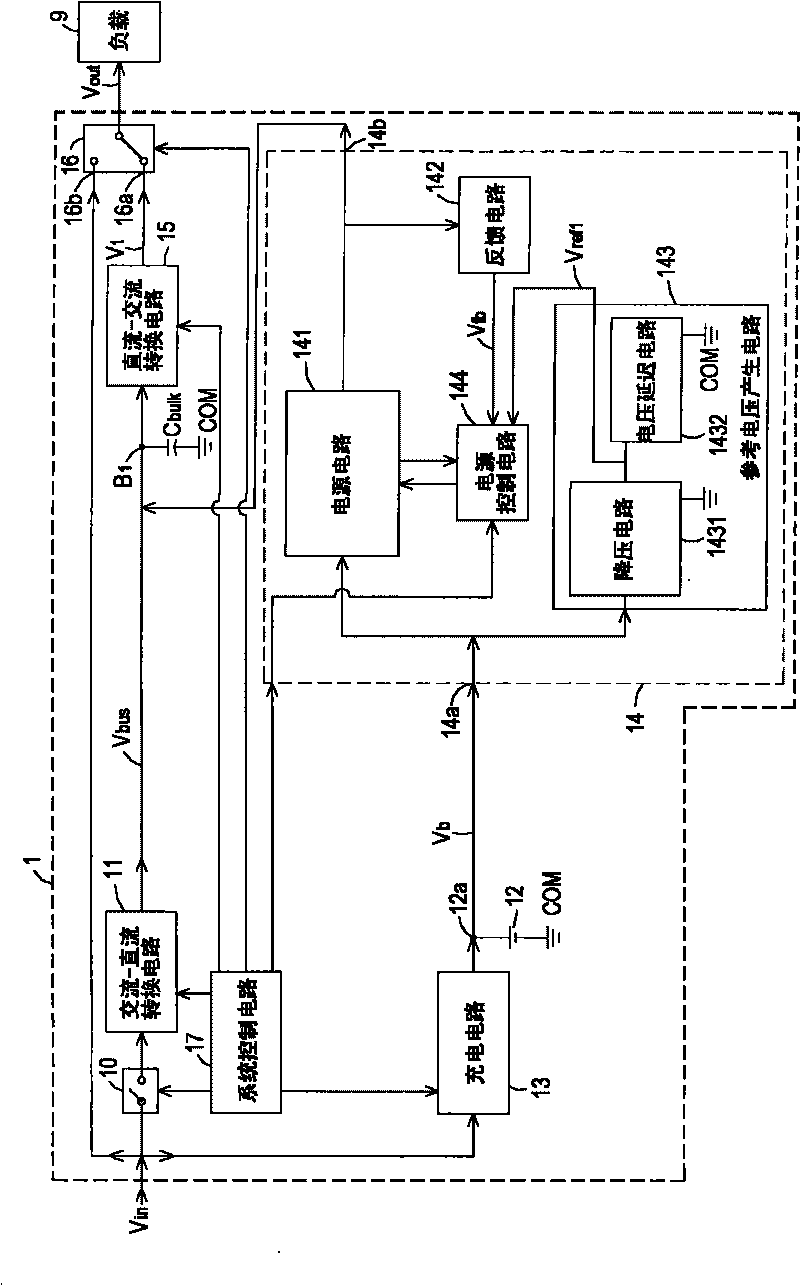

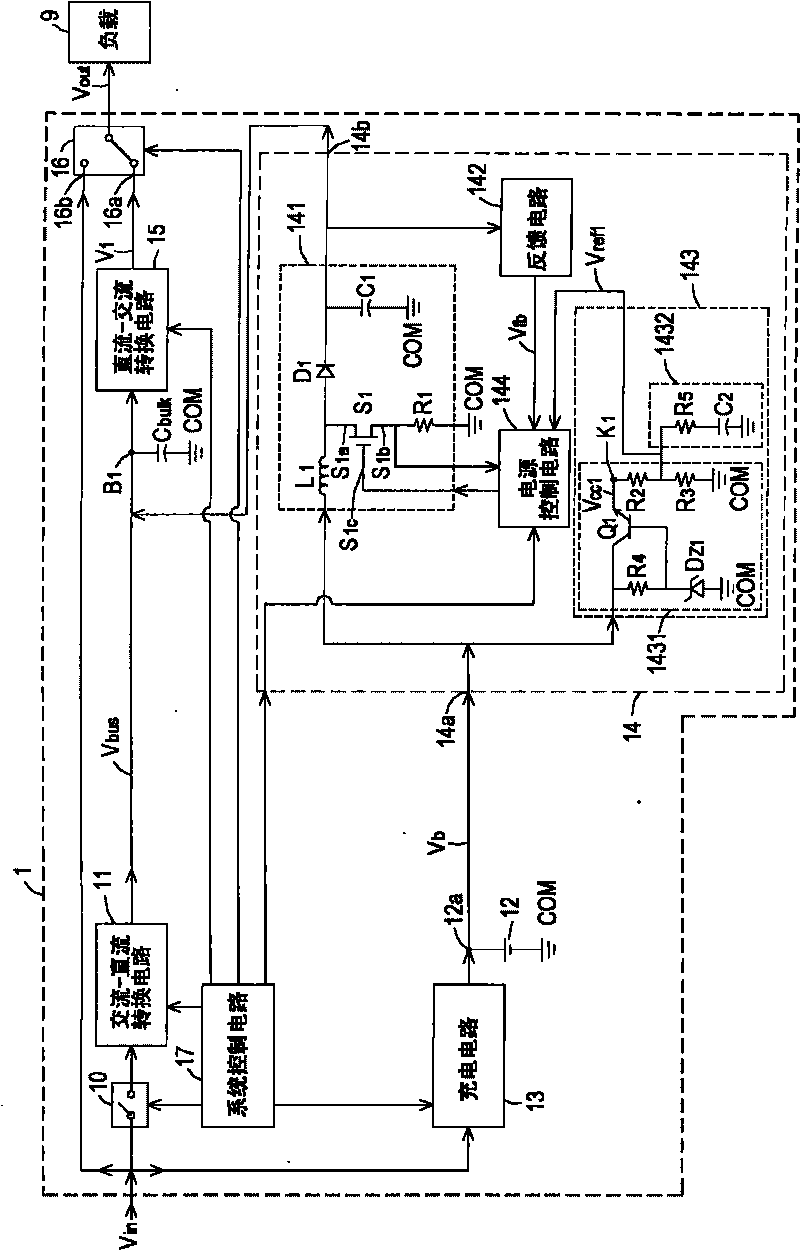

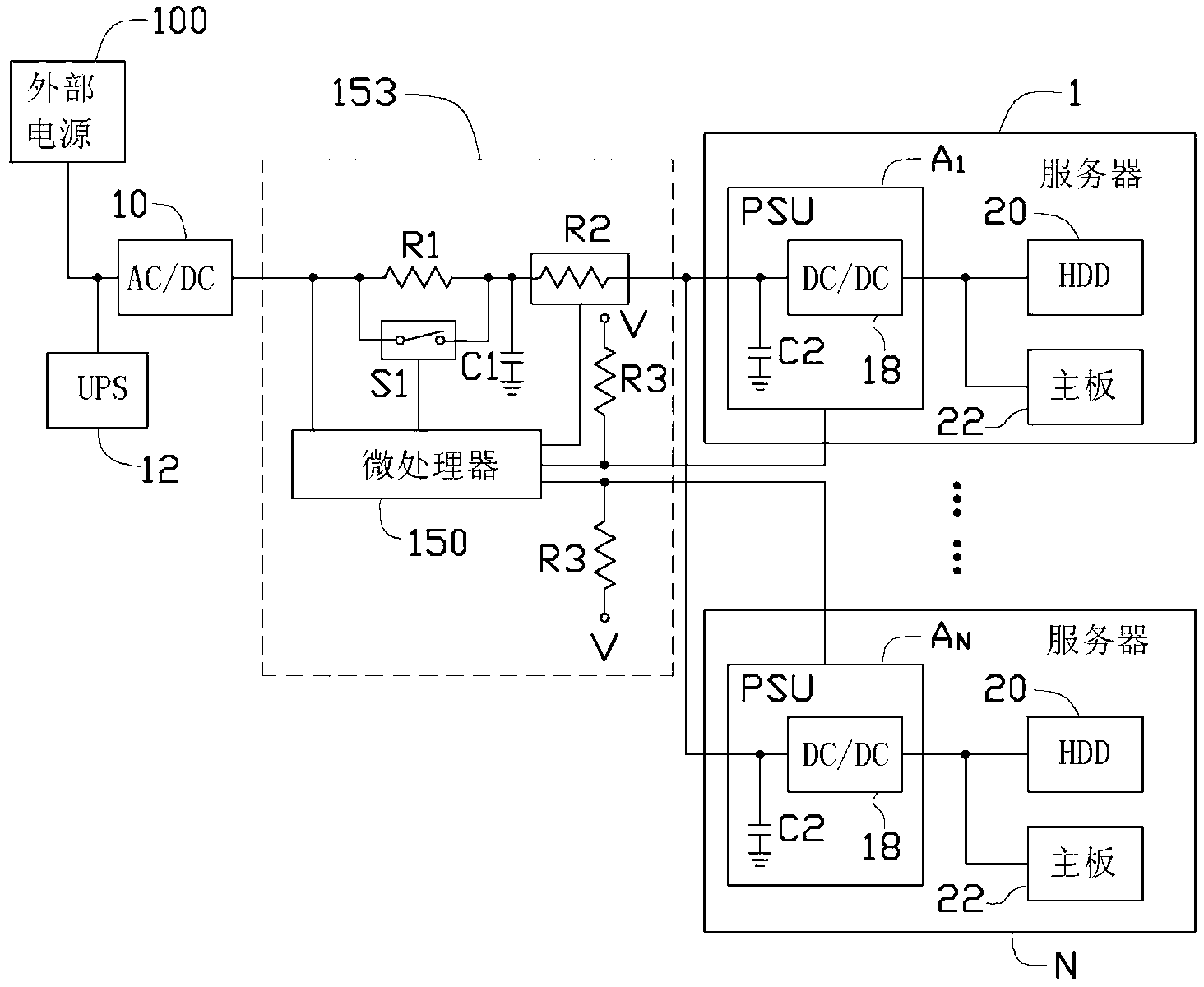

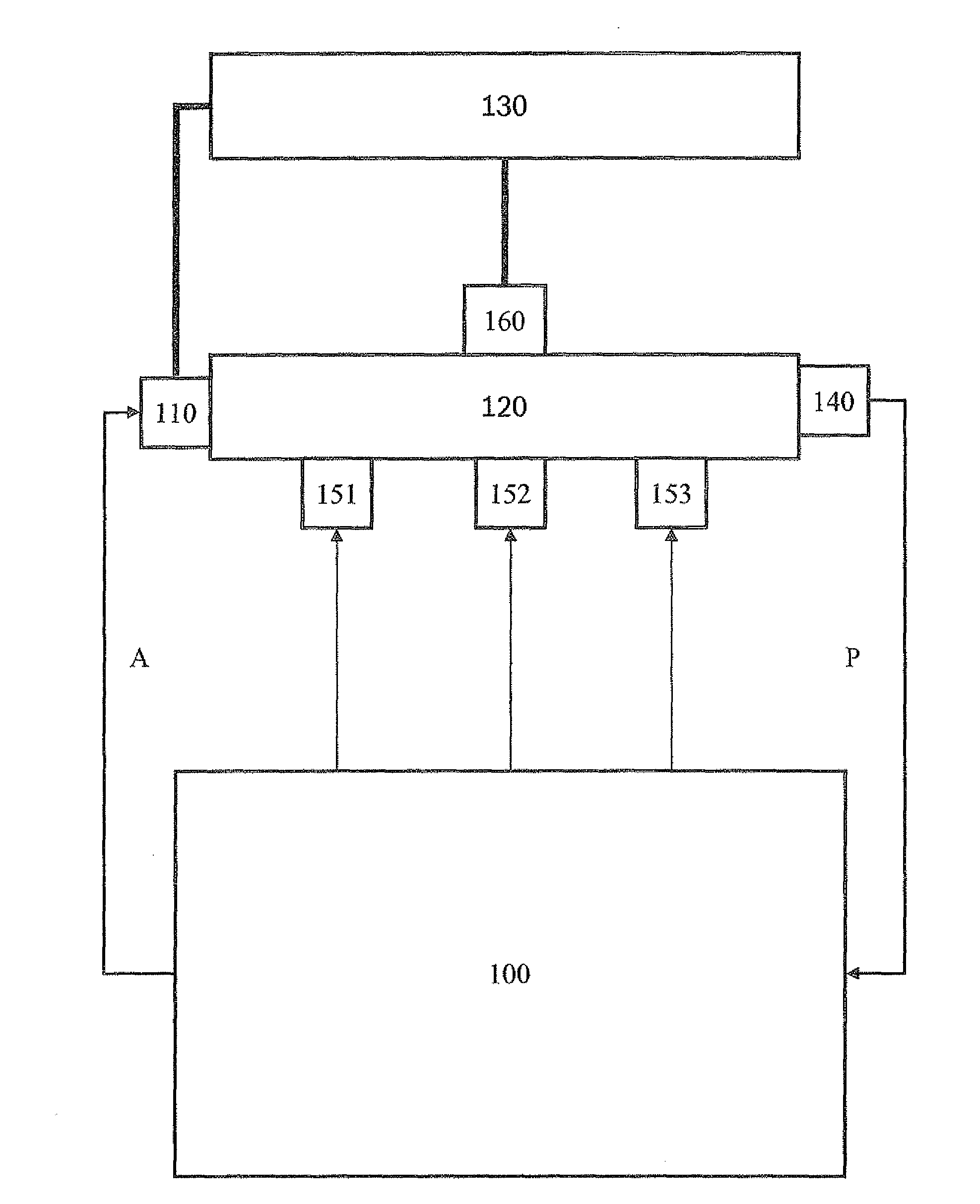

Uninterruptible power supply provider

ActiveCN101752880ASituations that cause inrush currentReduce the charging current valueBatteries circuit arrangementsElectric powerCapacitanceEngineering

The invention relates to an uninterruptible power supply provider, which comprises an input switch circuit, an AC-DC conversion circuit, a bus capacitor, an energy storage unit, a charging circuit, a DC-AC conversion circuit and a system control circuit, wherein the AC-DC conversion circuit is connected between the input switch circuit and a direct current bus, the bus capacitor is connected with the direct current bus, the energy storage unit is selectively connected with a connecting end and a common connecting end of the energy storage unit, the charging circuit is connected with the input switch circuit and the connecting end of the energy storage unit, the DC-AC conversion circuit is connected with the connecting end of the energy storage unit and the direct current bus, and the system control circuit is connected with the input switch circuit, the AC-DC conversion circuit, the charging circuit and the DC-AC conversion circuit to be used for controlling operation and controls the AC-DC conversion circuit to stop operation when the uninterruptible power provider starts so as to enable the DC-AC conversion circuit to charge the bus capacitor. According to the invention, the condition that impact currents exist in the uninterruptible power provider because of overlarge start currents of the uninterruptible power provider can be prevented from occurring.

Owner:DELTA ELECTRONICS INC

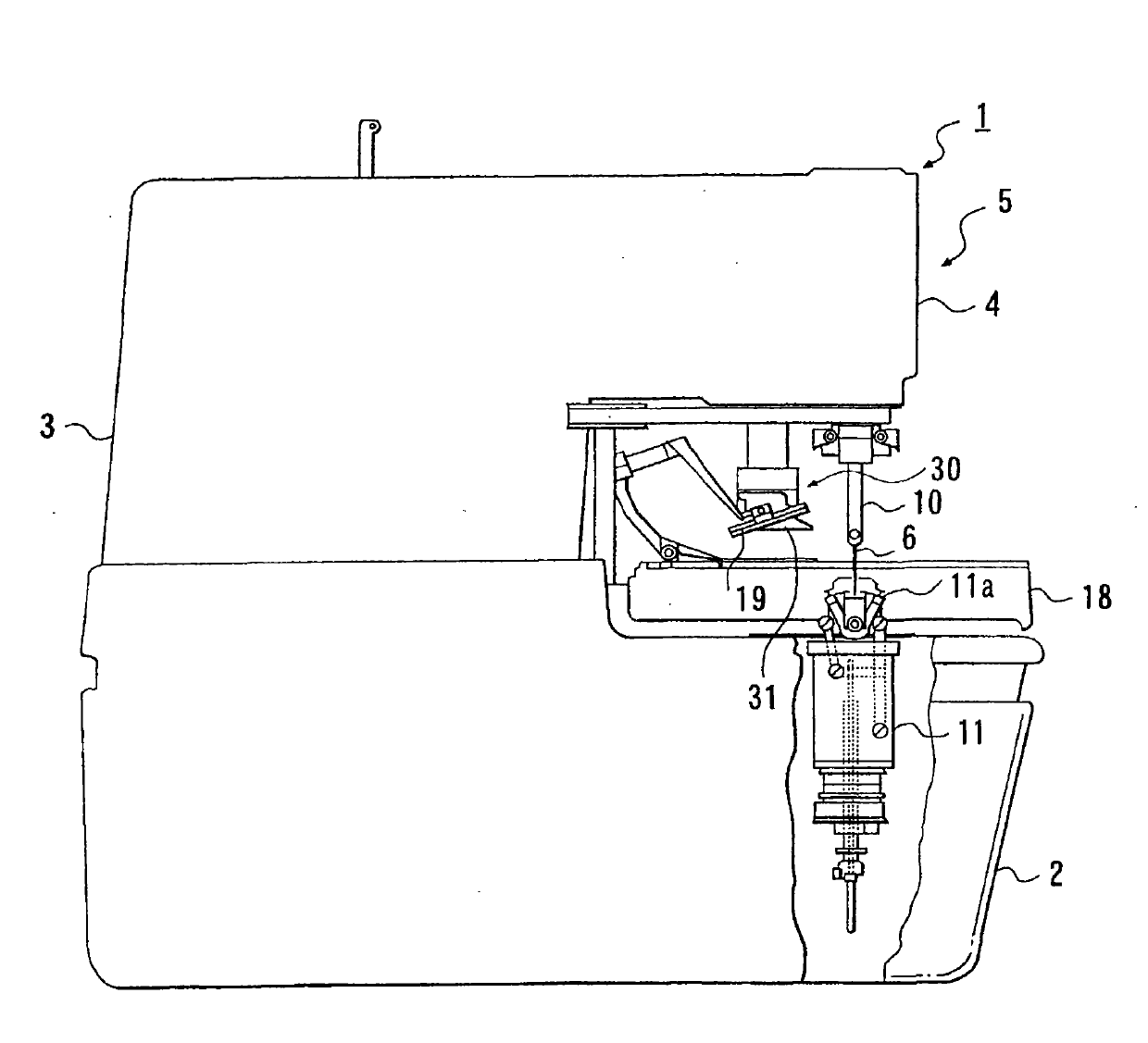

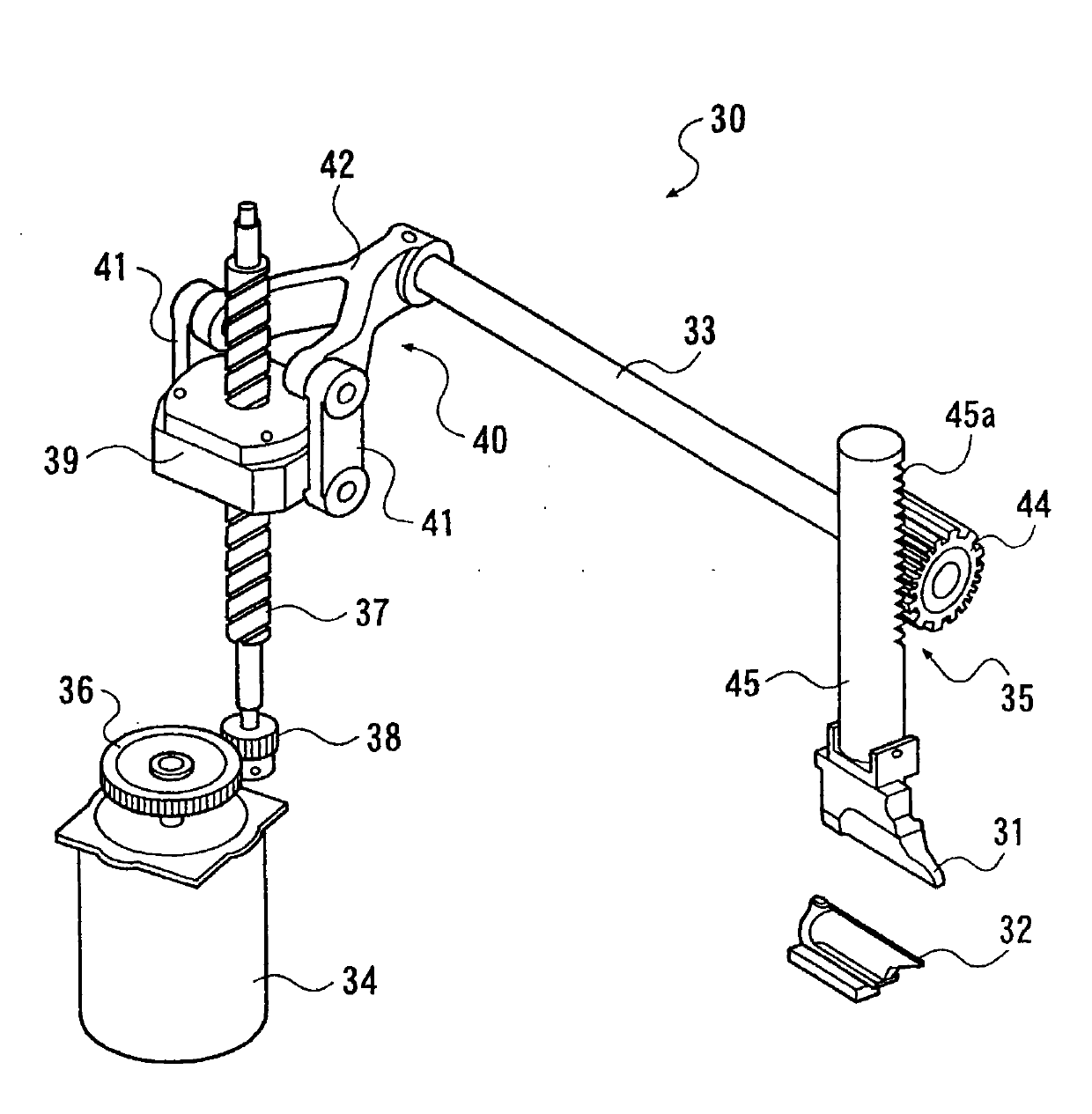

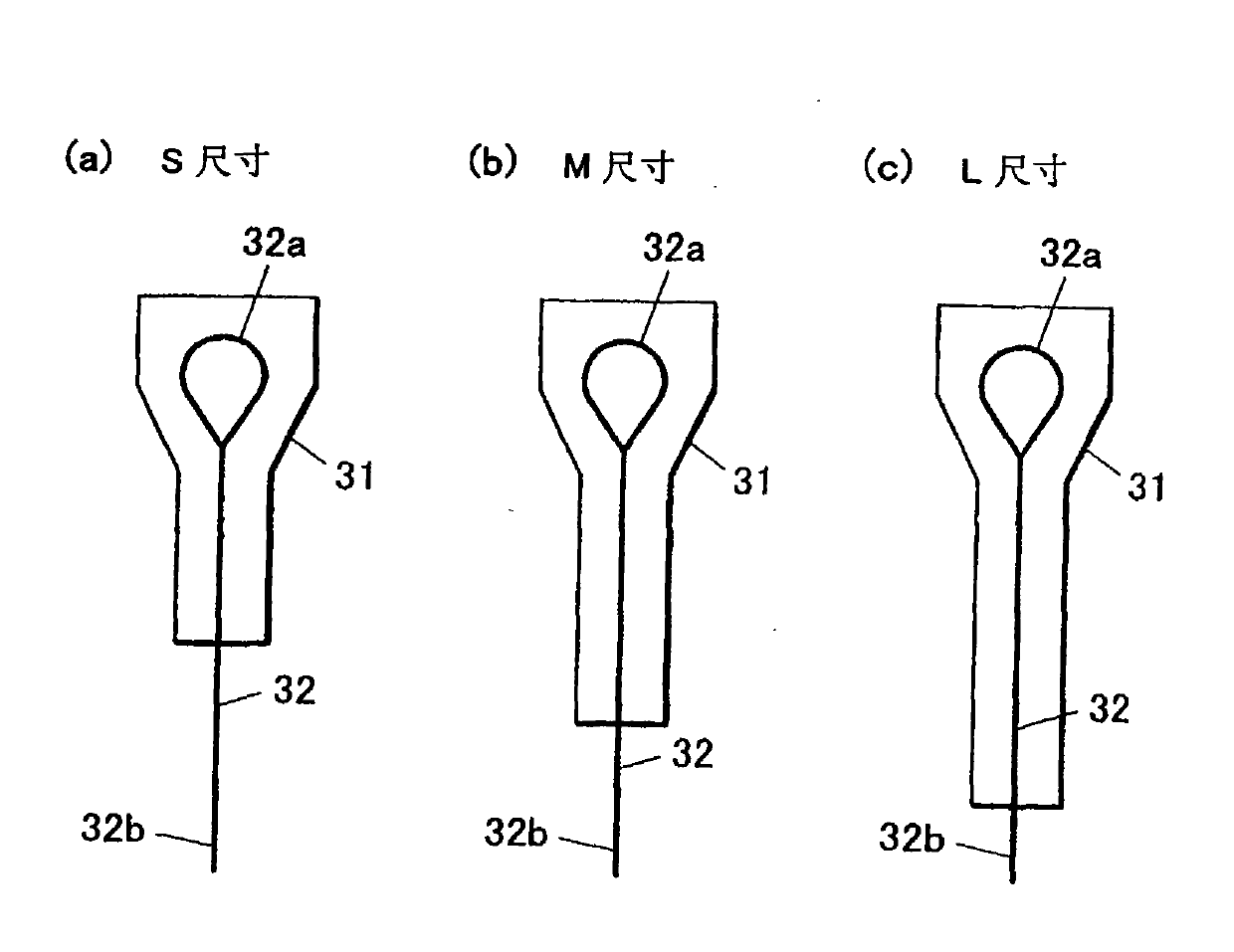

Cloth cutting device of hole stitching machine

ActiveCN102021765ARelaxed contact pressurePrevent each other from damagingProgramme-controlled sewing machinesWorkpiece carriersEngineeringLow speed

The invention relates to a cloth cutting device of hole stitching machines, wherein period time is not lost and right pressing force is easily to be set.The cloth cutting device (30) comprises a knife (32), a knife receiver (31), a moving mechanism (35) which moves the knife (32) or the knife receiver (31), a pulse motor (34) which serves as a drive source of the movement of the knife or the knife receiver, a rotation amount detector (55) which detects a rotation amount of the pulse motor, and a controller (50) which controls the pulse motor.; The controller executes a control to switch the movement of the knife or the knife receiver to be low speed on its way, and includes a cutting control means (50c) which controls the pulse motor to stop driving if a deviation determining means determines that the deviation of the pulse motor reaches the set value, and a current control means (50c) which limits, during the low-speed movement, a current value applied to the pulse motor to be lower than that during a high-speed movement.

Owner:JUKI CORP

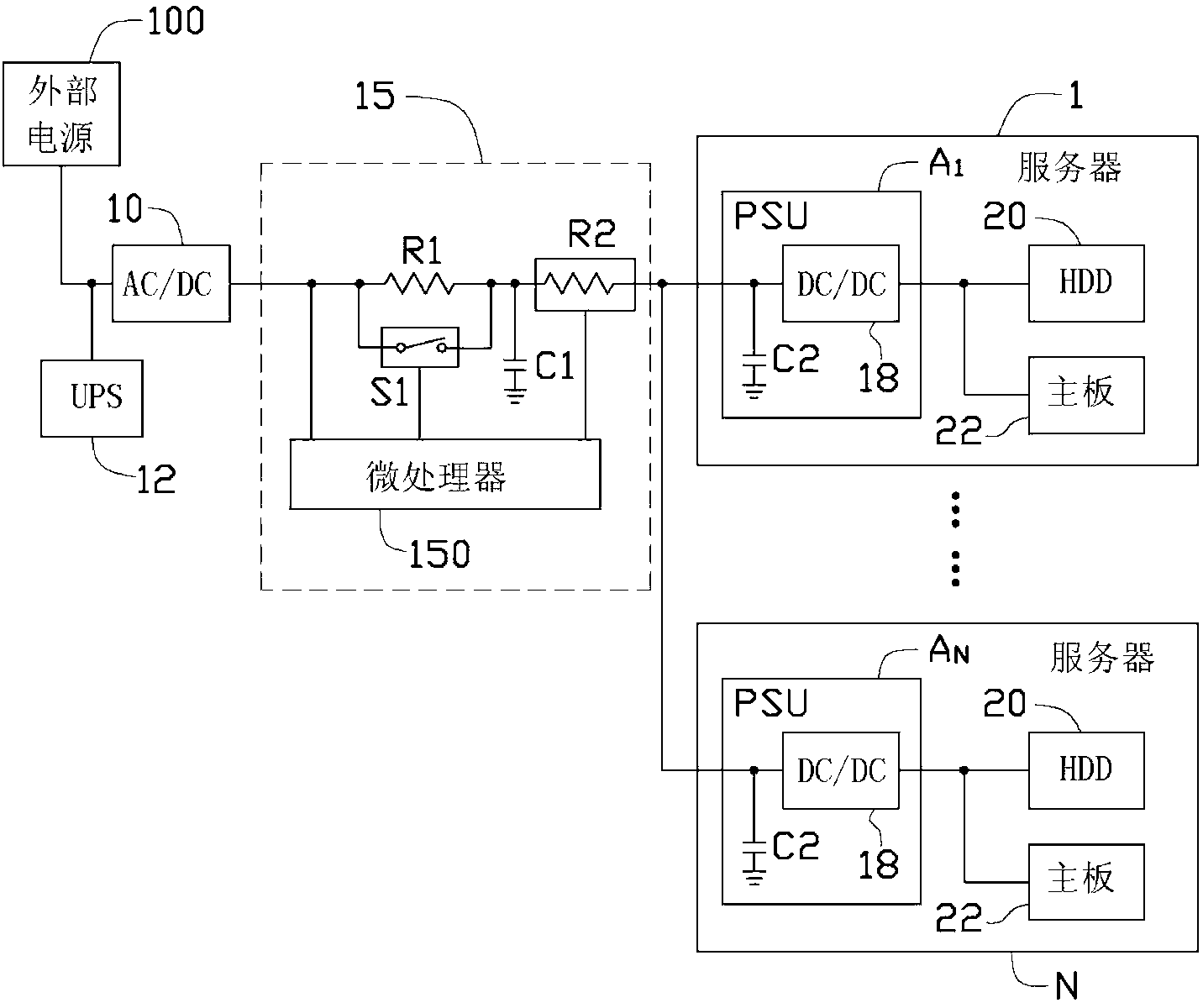

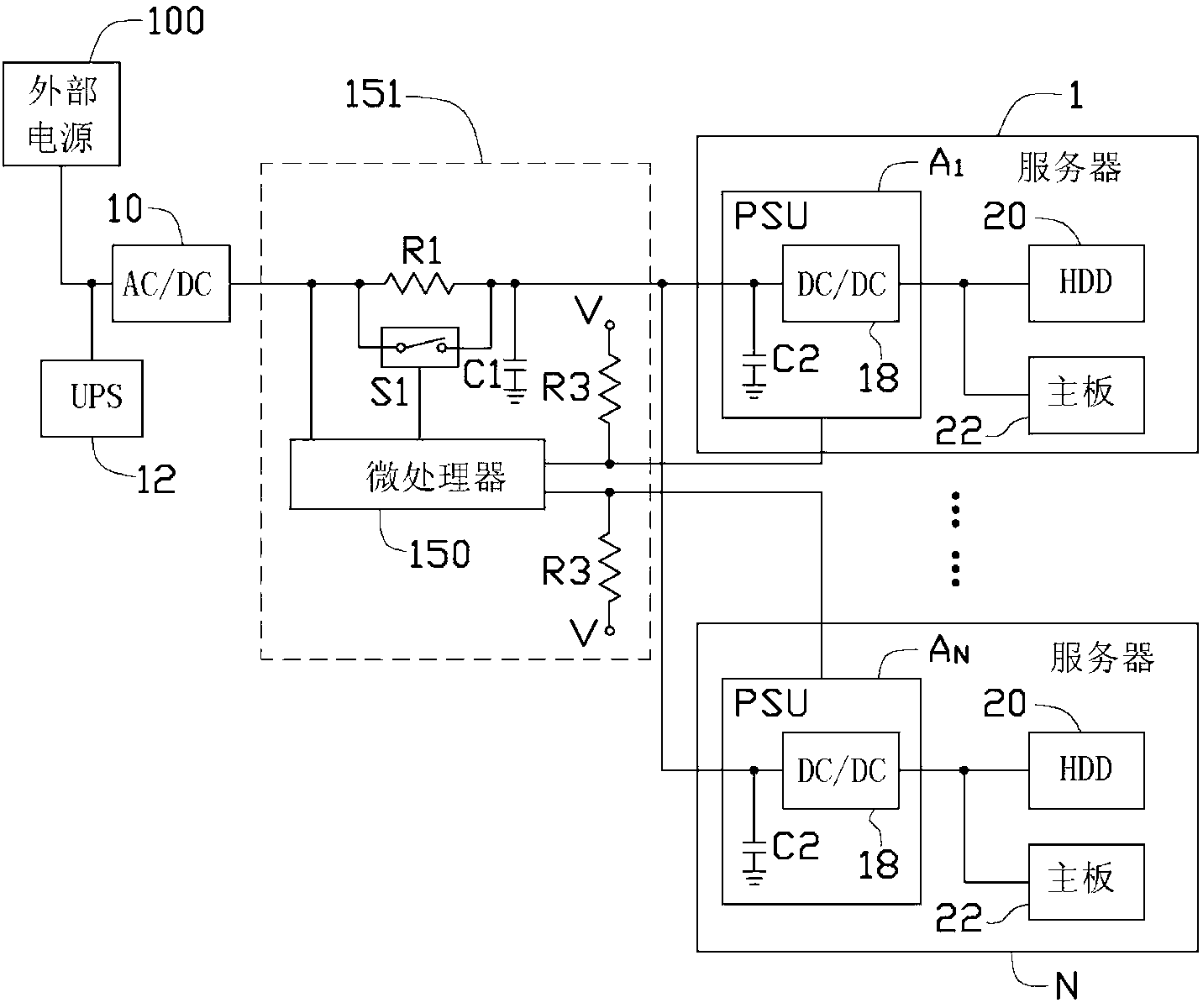

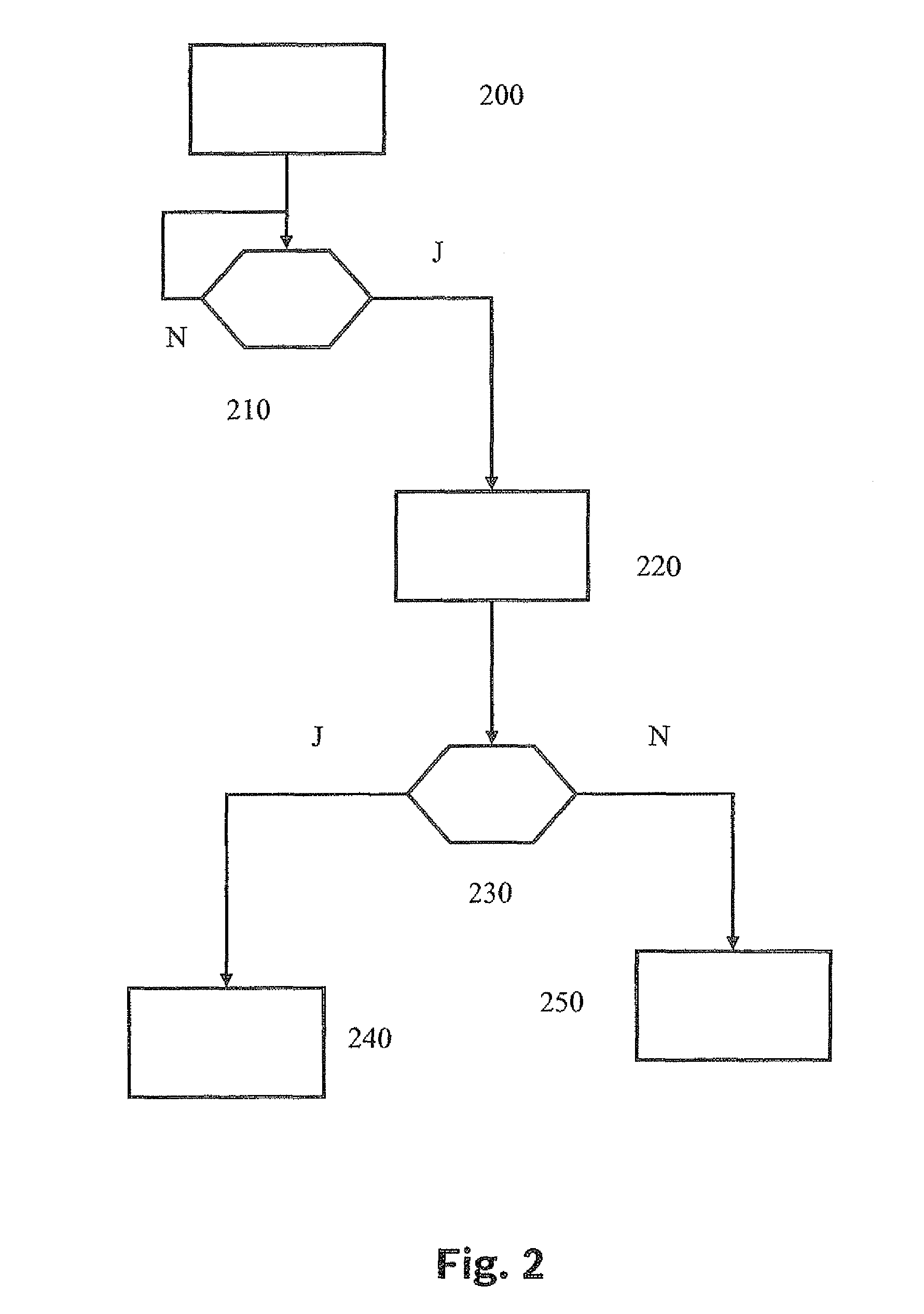

Power supply circuit

InactiveCN103151909AReduce the current valueAvoid damagePower conversion systemsCapacitanceAC - Alternating current

The invention discloses a power supply circuit which comprises an alternating current / direct current converting unit, an uninterruptible power supply, a protective circuit and a power supply unit. The alternating current / direct current converting unit is used for converting voltage of the uninterruptible power supply into direct voltage and providing a direct-current power supply for the power supply unit through the protective circuit. The protective circuit comprises a first resistance, a switch, a first capacitor and a microprocessor. The first terminal of the first resistance is connected with the alternating current / direct current converting unit. The second terminal of the first resistance is connected with the power supply unit and connected with ground through the first capacitor. The microprocessor is connected with the first terminal of the first resistance and the switch. At the initial time of power supplying of the uninterruptible power supply, the microprocessor controls the switch to be opened, and after preset delay time is used up, the microprocessor control the switch to be closed. The power supply circuit controls the switch to be closed and opened in delay time through the microprocessor, and damages caused by the fact that at the initial time of power supplying of the uninterruptible power supply, a surge current occurs can be avoided.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Method and device for controlling a fuel metering system

InactiveUS8261605B2Reduce the current valueGuaranteed uptimeInternal-combustion engine testingElectrical controlRail pressureInternal combustion engine

A method and a device for controlling a fuel metering system are described. The fuel metering system includes at least one injector for injecting fuel into an internal combustion engine. An electric current value is applied to the at least one injector, and a rail pressure value is determined based on the electric current value.

Owner:ROBERT BOSCH GMBH

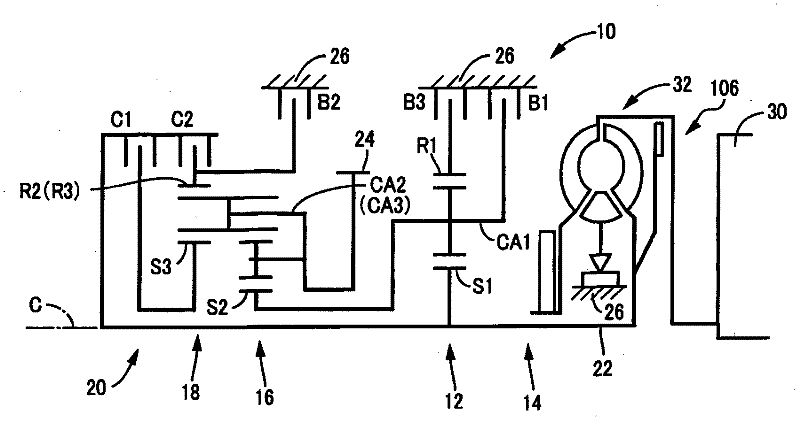

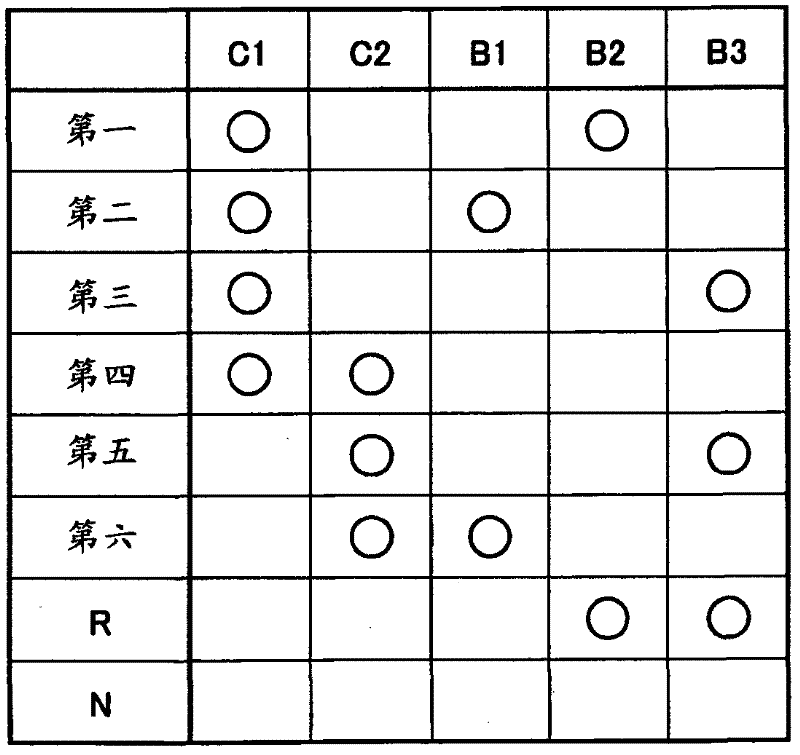

Control device for vehicle on/off control valve

InactiveCN102272487AMinimize power consumptionReduce the current valueGearing controlSolenoid valveControl valves

Owner:TOYOTA JIDOSHA KK

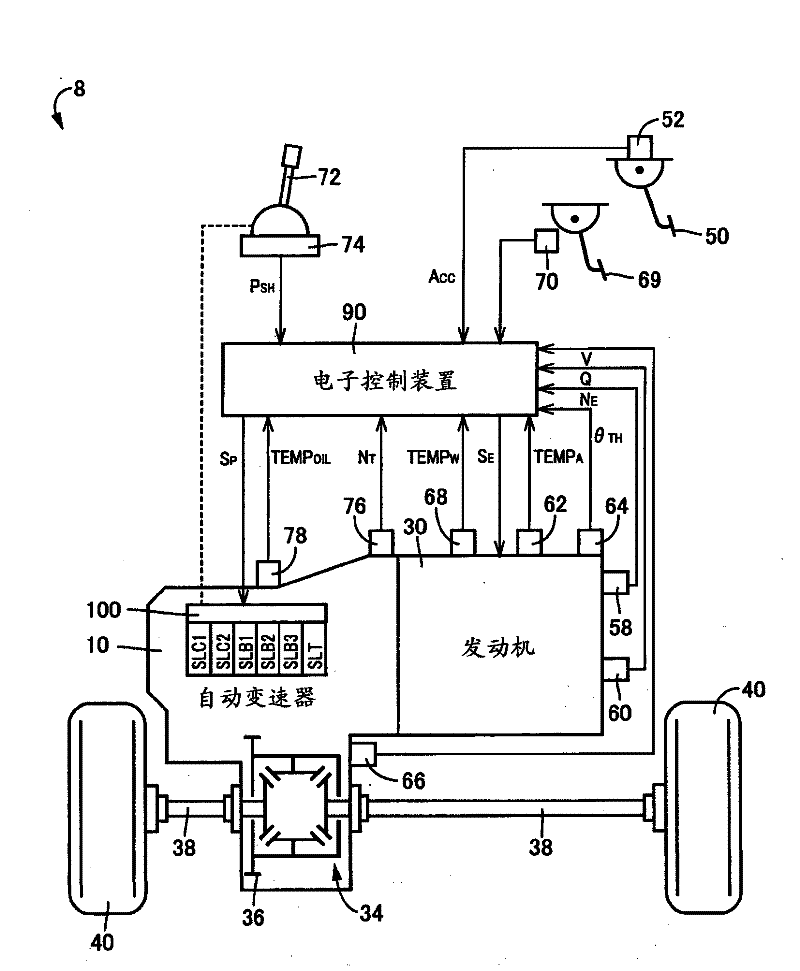

Method and device for preventing slip of work piece

InactiveCN102470506APrevent slidingSafe GrindingRevolution surface grinding machinesGrinding feed controlControl theoryLimiting current

A master servo motor (16) and a slave servo motor (21) that synchronously drive for rotation a master main spindle Cm provided with a center (14) that supports one end of a work piece W and a slave main spindle Cs provided with a center (18) that supports the other end of the work piece are included. Before grinding, a slip detection cycle that detects a limit current value (A1) for the servo motors, at which the work piece and the centers slip, is executed and, during grinding, a grinding condition is changed to prevent a slip between the work piece and the centers in advance at the time when any one of current values of the servo motors has reached a slip threshold value (A2) set on the basis of the limit current value.

Owner:JTEKT CORP

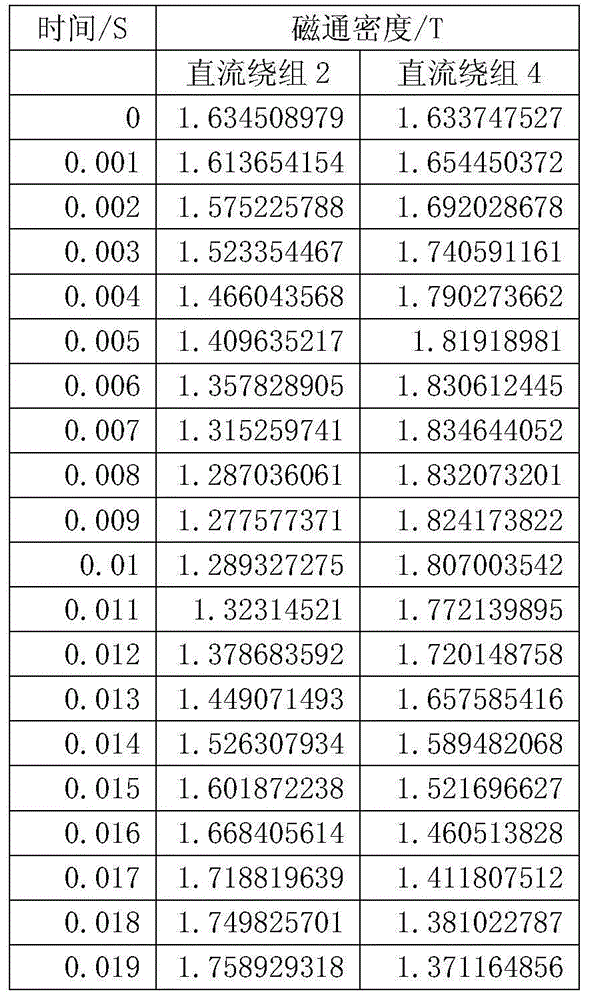

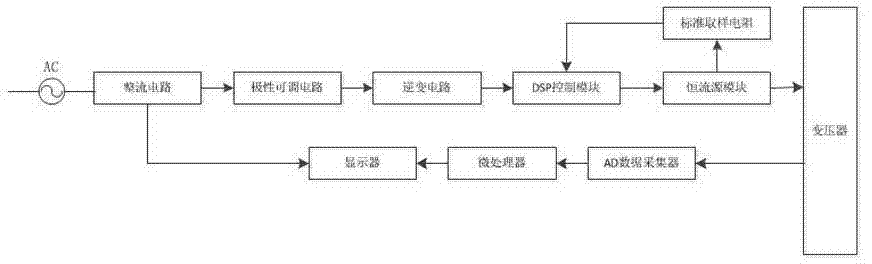

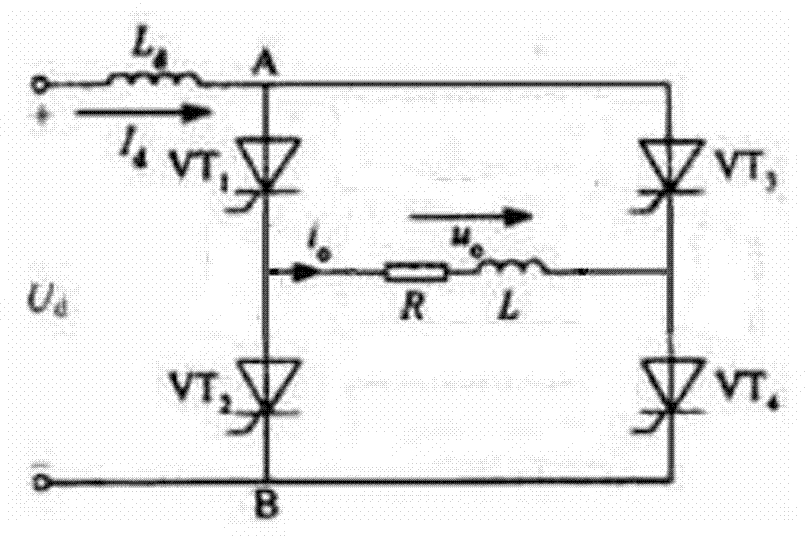

500KV transformer direct-current resistance and direct-current demagnetization intelligent test instrument and method

ActiveCN104330637AShorten DC test timeImprove work efficiencyResistance/reactance/impedenceTransformerDisplay device

The invention discloses a 500KV transformer direct-current resistance and direct-current demagnetization intelligent test instrument comprising a rectifier circuit, a polarity-adjustable circuit, an inverter circuit, a constant current source module, a DSP control module, a standard sampling resistor, an AD data collector, a microprocessor used for controlling a display to display, and the display. The rectifier circuit, the polarity-adjustable circuit, the inverter circuit, the DSP control module and the constant current source module are connected sequentially. The standard sampling resistor is connected between the DSP control module and the constant current source module. The AD data collector, the microprocessor and the display are connected sequentially. The rectifier circuit is connected with the display. By adopting the instrument of the invention, single-phase and three-phase direct-current resistance test is realized, and the direct-current test time of transformer direct-current resistance test is shortened. Because the instrument is integrated with a direct-current demagnetization function, direct-current resistance test can be carried out at high current, and the test time can be shortened. Demagnetization is carried out in a timely manner after test, so that a large amount of detachment and installation time is saved, and the work efficiency is improved.

Owner:STATE GRID CORP OF CHINA +2

Method for inhibiting generation of internal defects of aluminum alloy resistance spot welding nugget

ActiveCN112570867ALess shrinkage and crystallizationReduce tensile stressWelding electric supplyElectrical resistance and conductanceSpot welding

The invention discloses a method for inhibiting generation of internal defects of an aluminum alloy resistance spot welding nugget, and belongs to the technical field of resistance spot welding. A welding current is divided into an electrifying heating stage, a cooling stage and a pressure maintaining stage, wherein in the electrifying heating stage, the current amplitude of the welding current is15KA-60KA, and the electrifying time is 50ms-200ms; and in the cooling stage, the current is 0-15KA, and the cooling time is 2ms-40ms. According to the welding method, due to the existence of the cooling stage, welding heat input is stable, and internal stress of a welding spot is reduced, so that the generation of the defects such as cracks and air holes in the nugget is inhibited, and the effect of improving the strength of the welding spot is achieved.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

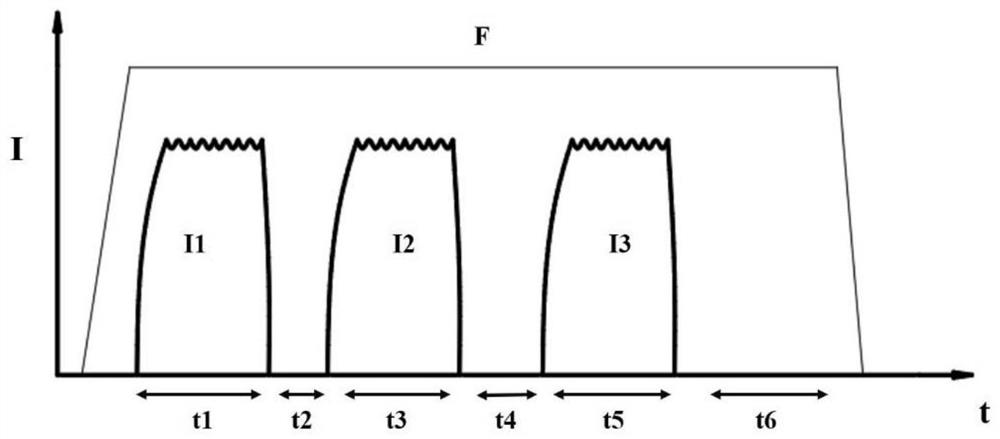

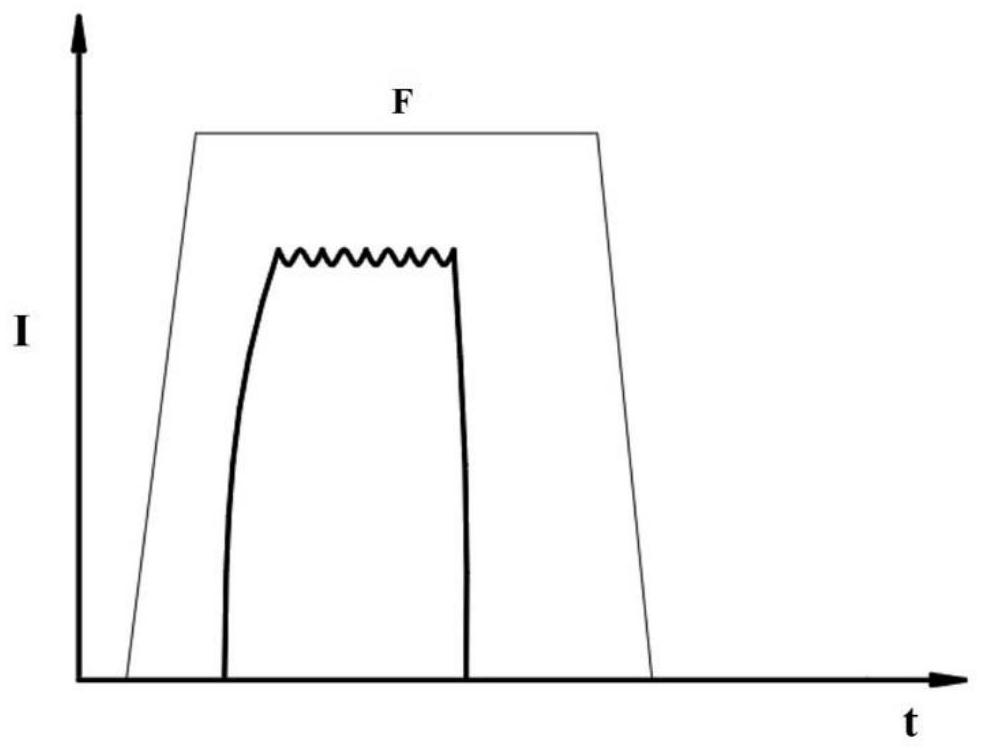

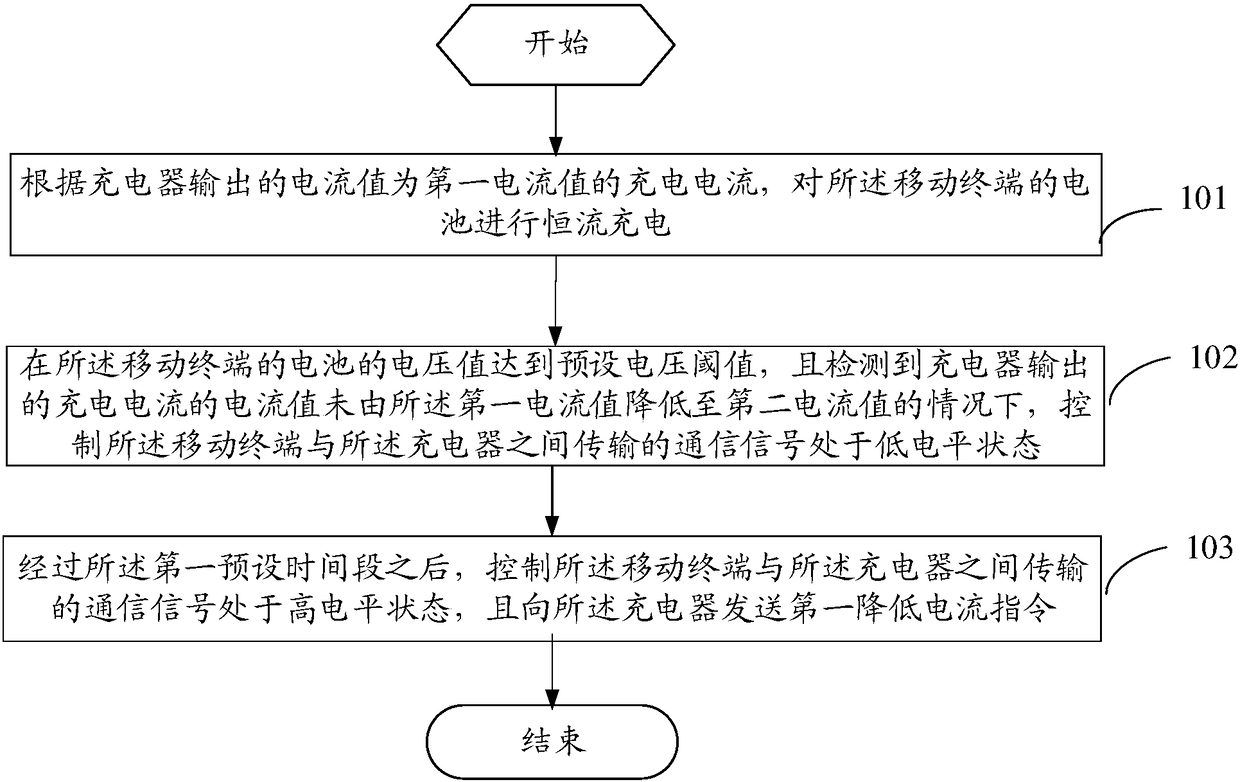

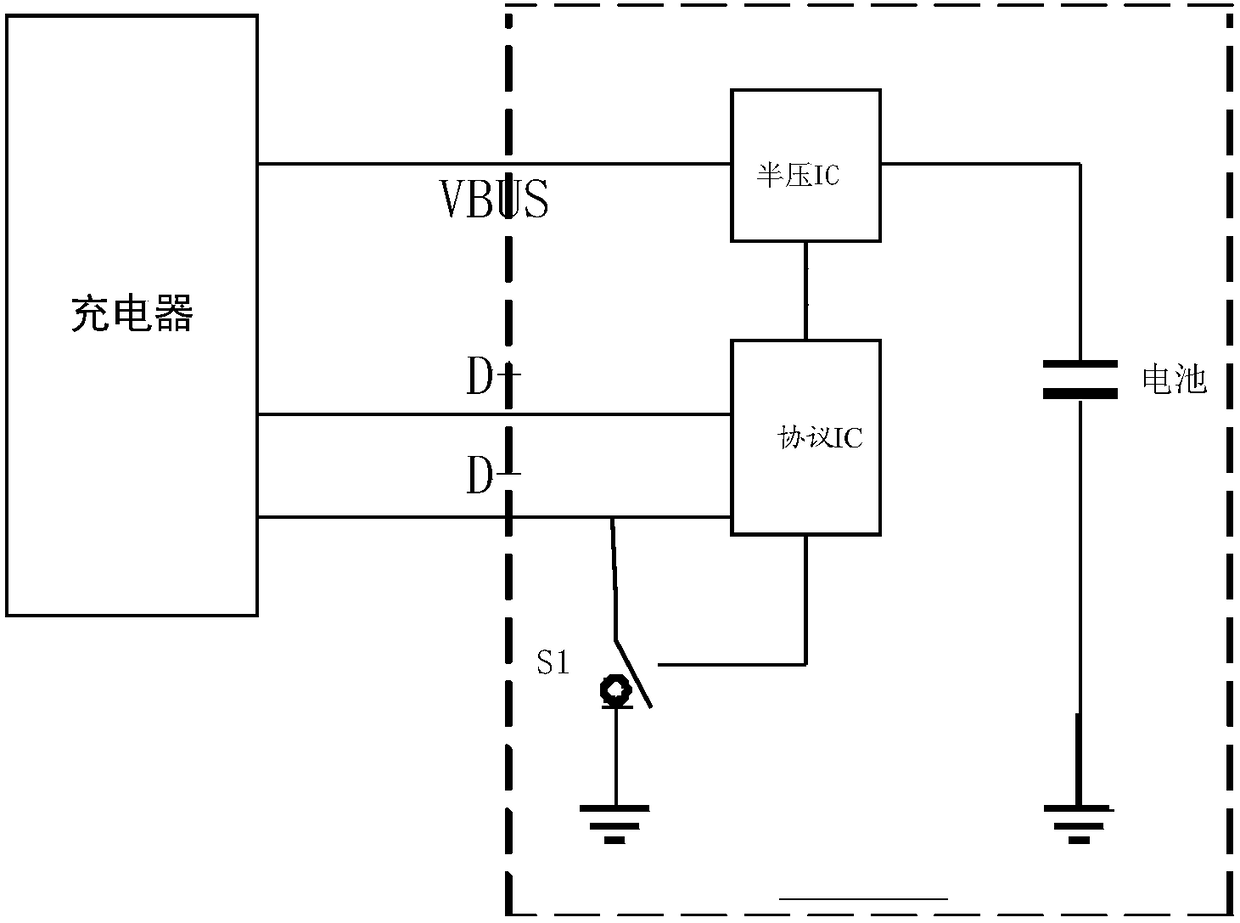

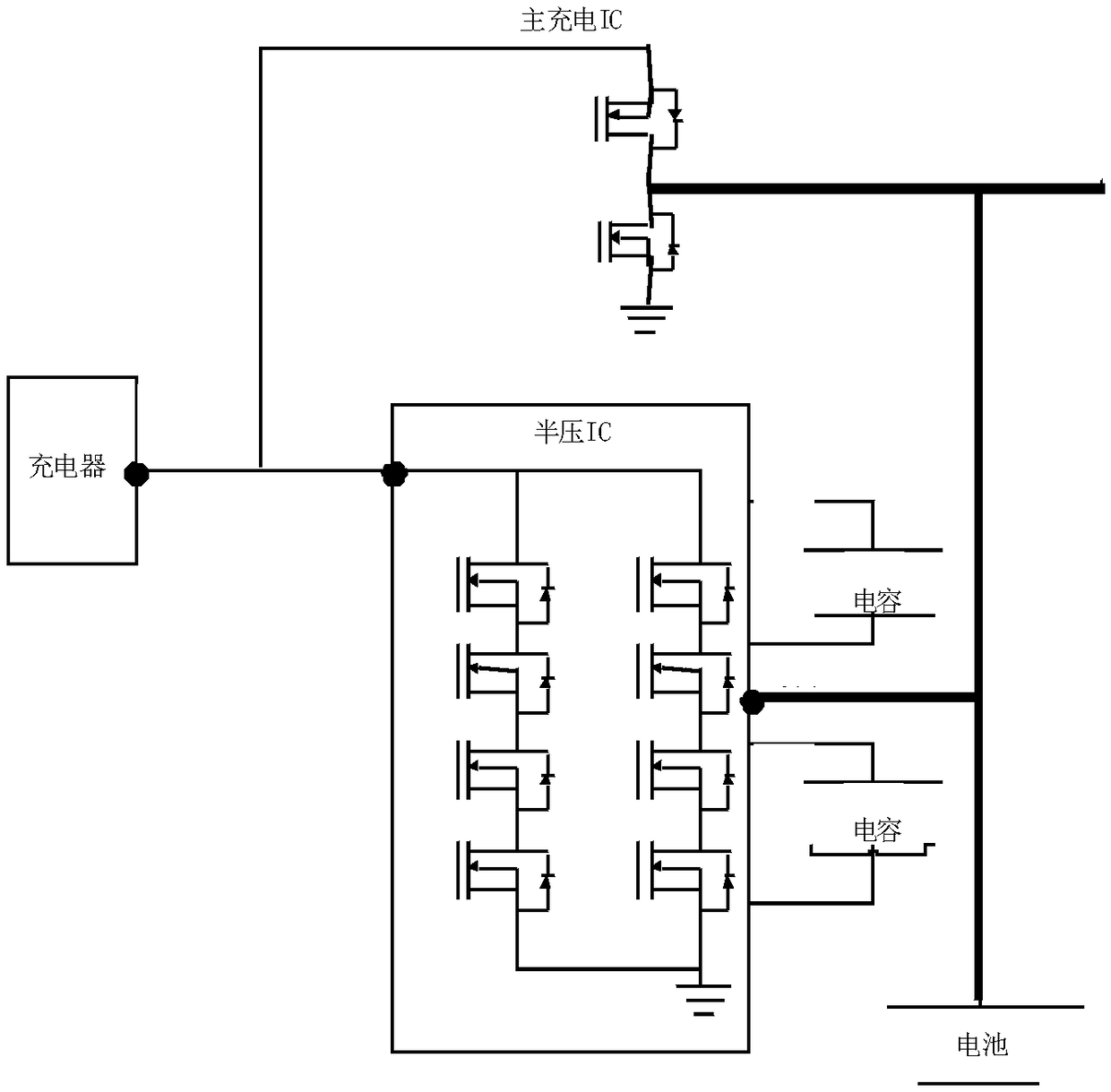

Charging method, mobile terminal and charger

ActiveCN108448673AReduce risk of damageReduce the current valueBatteries circuit arrangementsElectric powerCharge currentConstant current

The invention provides a charging method, a mobile terminal and a charger. The charging method comprises the steps of performing constant current charging on a battery of the mobile terminal; when thevoltage value of the battery of the mobile terminal reaches a preset voltage threshold value, and when it is detected that the current value of a charging current output by the charger is not loweredfrom a first current value to a second current value, controlling a communication signal transmitted between the mobile terminal and the charger to be in a low-level state; and after the first presettime frame, controlling the communication signal transmitted between the mobile terminal and the charger to be in a high-level state, and transmitting a first current lowering instruction to the charger. Therefore, by controlling the communication signal transmitted between the mobile terminal and the charger to be in the low-level state for a certain while, the charger can perform a reset communication access operation to further respond the first current lowering instruction transmitted by the mobile terminal, thereby lowering the current value of the charging current output by the charger,and lowering risk of battery damage of the mobile terminal.

Owner:VIVO MOBILE COMM CO LTD

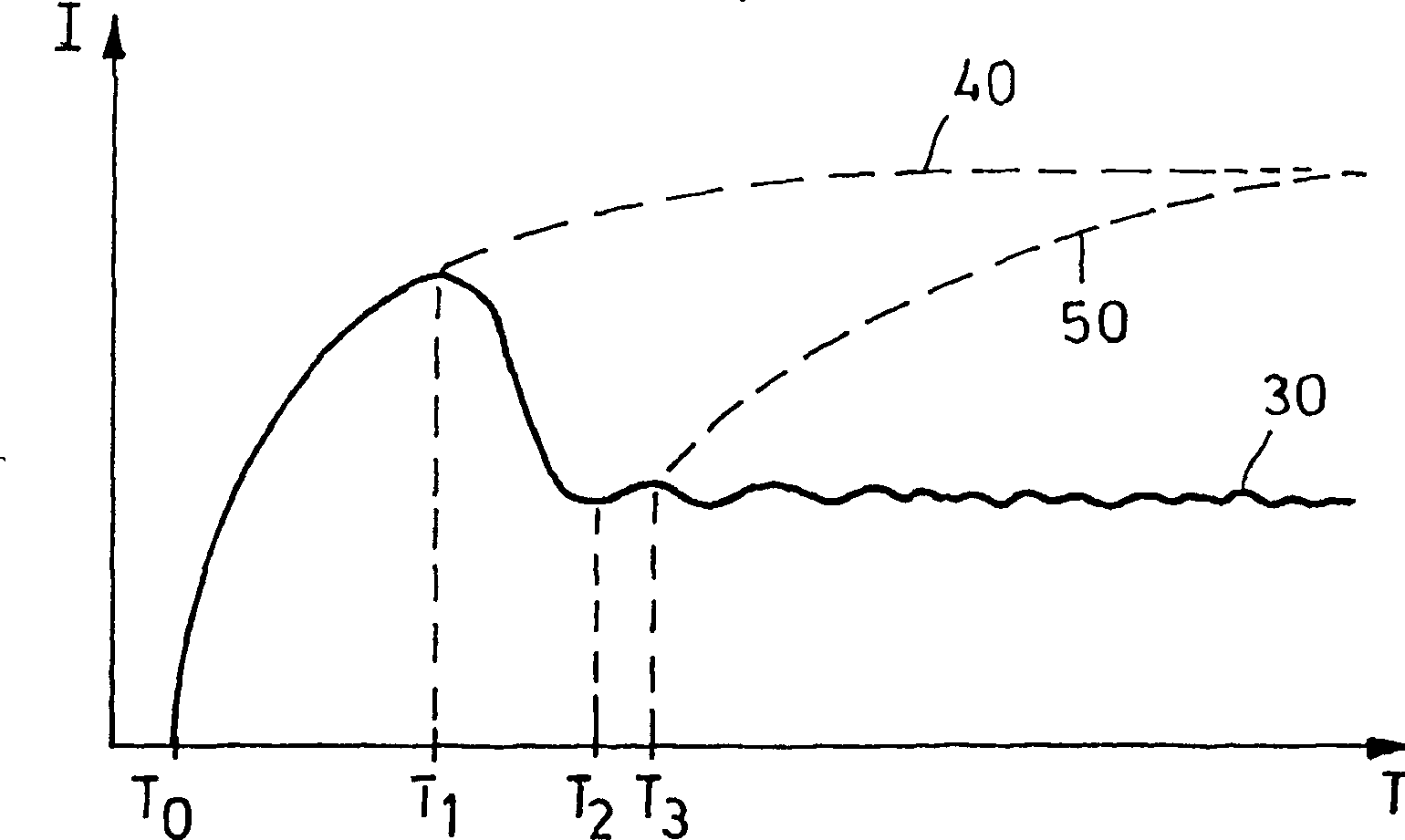

Method and device for controlling electromagnet in self-protection D.C. circuit

InactiveCN1445798AReduce the current valueOptimal energy regulationOperating means/releasing devices for valvesRelaysEnergy regulationEngineering

The invention relates to a method for controlling an electromagnet connected in a self-protected DC circuit, which can be controlled to switch back and forth between two switching positions, and is used to actuate a locking object of a hydraulic valve, wherein by means of an electronic control device in the The coil of the electromagnet is fed with an excitation current under the suction state of the electromagnet armature, and a holding current smaller than the excitation current is fed to the coil of the electromagnet under the holding state of the armature. The present invention also relates to A device used to achieve a reduction in the holding current. According to the invention, the actual current in the coil is continuously measured after the electromagnet is controlled, and this current is evaluated for the movement of the armature. The method of the present invention is based on the one hand that the force of the electromagnetic movable part is proportional to the current flowing, and on the other hand that the movement of the movable part causes a reverse inductance in the magnetic coil, which reduces the measured actual current value in the coil. The movement of the armature is detected immediately at the beginning of the movement or shortly thereafter, so that energy regulation can be carried out in an optimal manner, preferably by reducing the current to the clamping current value by means of pulse width modulation.

Owner:CATERPILLAR INC

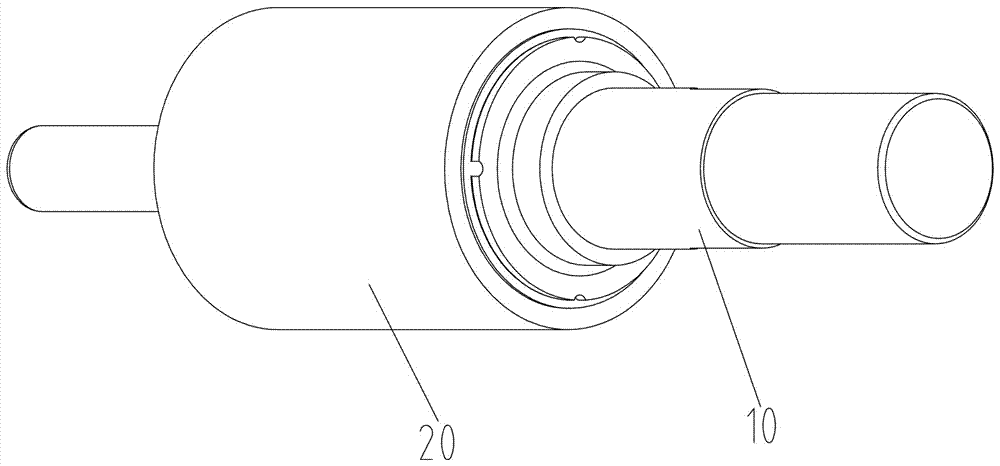

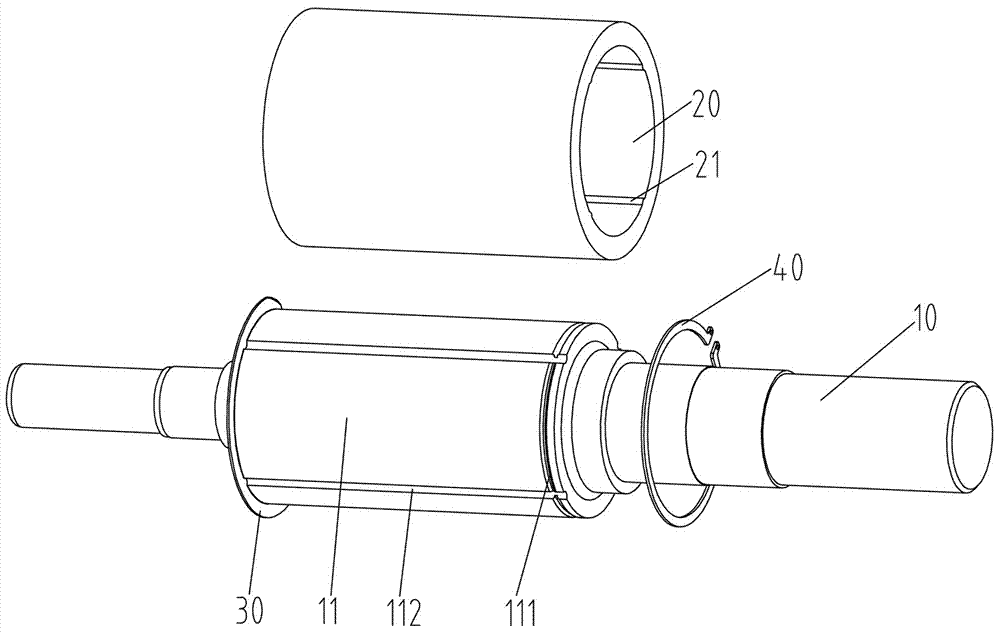

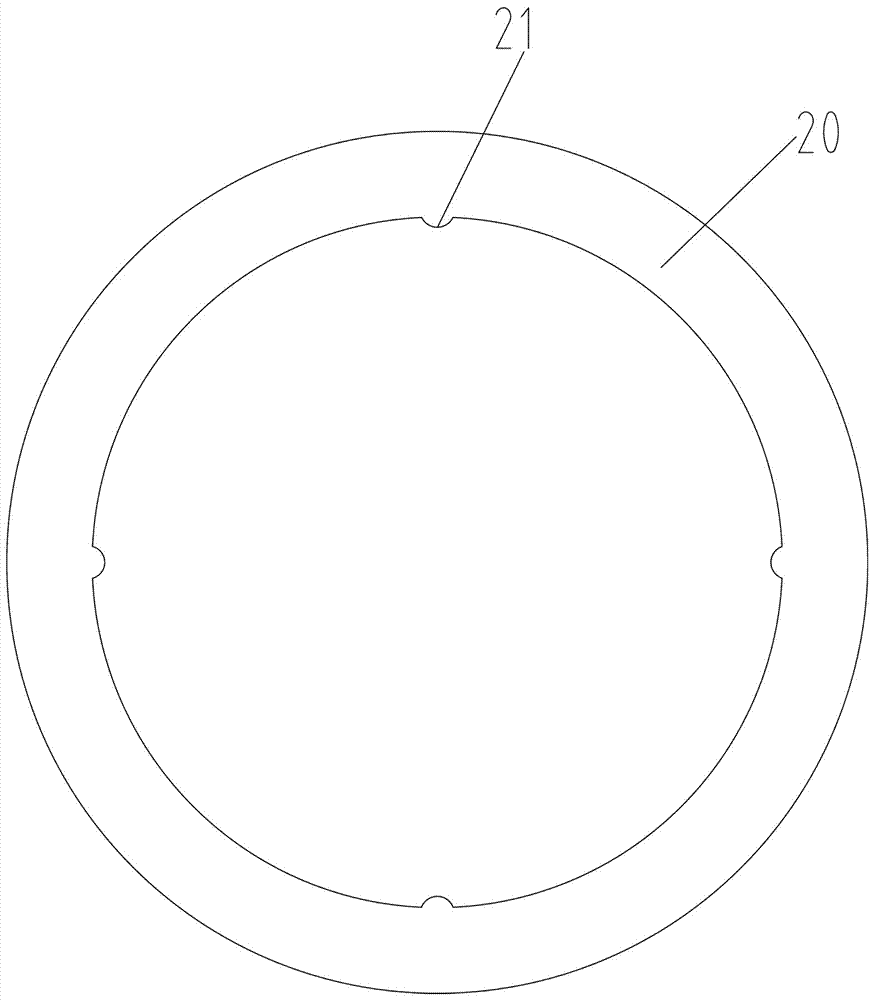

Rotor and servo motor

PendingCN107394928AImprove reliabilityReduce the current valueMagnetic circuit rotating partsMagnetControl theory

The invention discloses a rotor and a servo motor. The rotor comprises a rotating shaft and a magnet ring, the magnet ring sleeves at the magnet ring position of the rotating shaft, an axial limit device is arranged at the magnet ring position and limits the magnet ring to axially move on the rotating shaft, and a circumferential limit structure is arranged on the opposite surface of the magnet ring and the magnet ring position and limits the magnet ring to rotate on the rotating shaft. According to the rotor, the magnet ring is fixed on the rotating shaft through the axial limit device and the circumferential limit structure, glue is omitted, failure of the glue is avoided, the magnet ring still cannot move or fly off even if the surface temperature of the rotating shaft rises after the motor bears load or overload for a long time, and reliability of the motor is improved.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

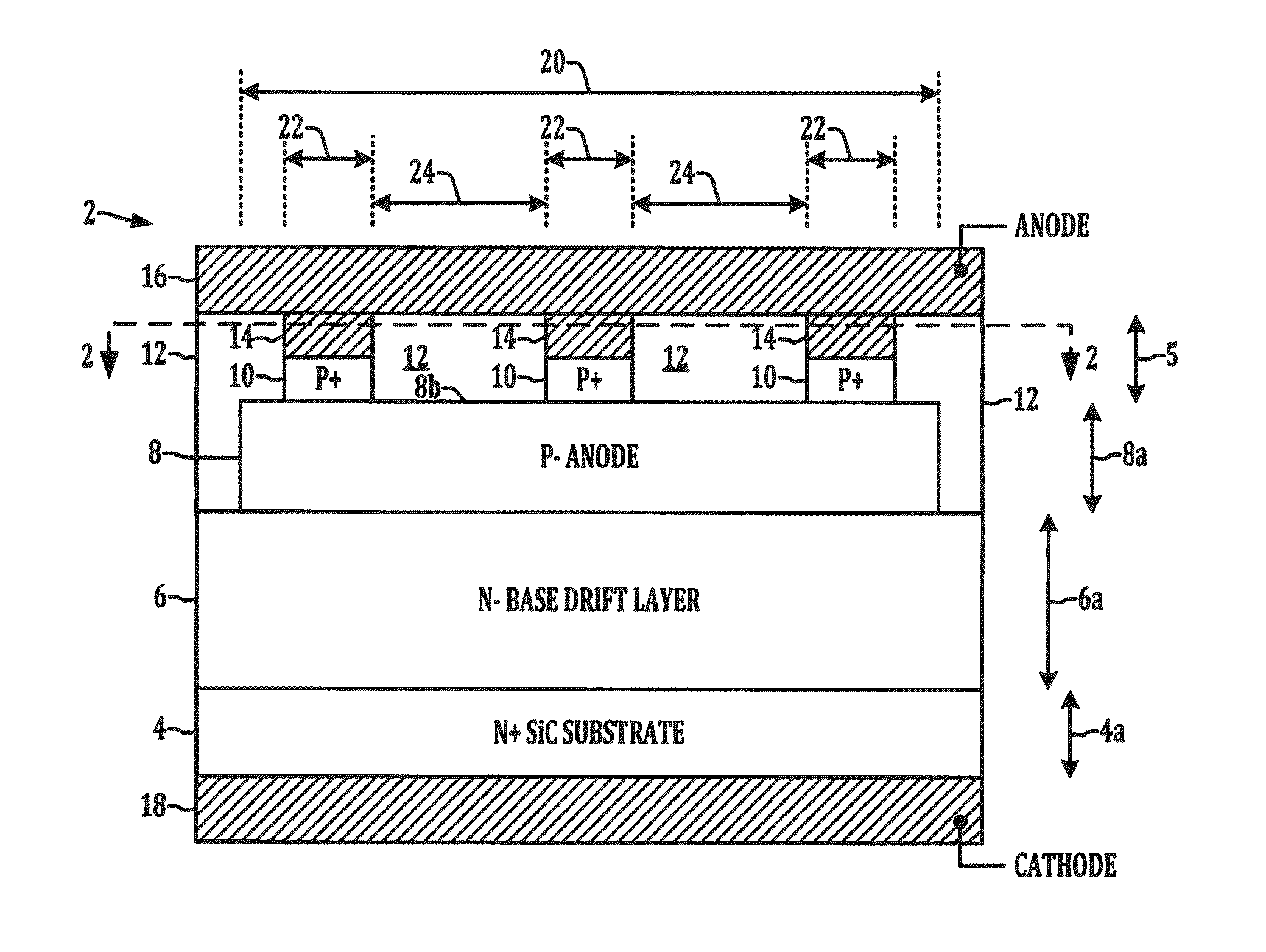

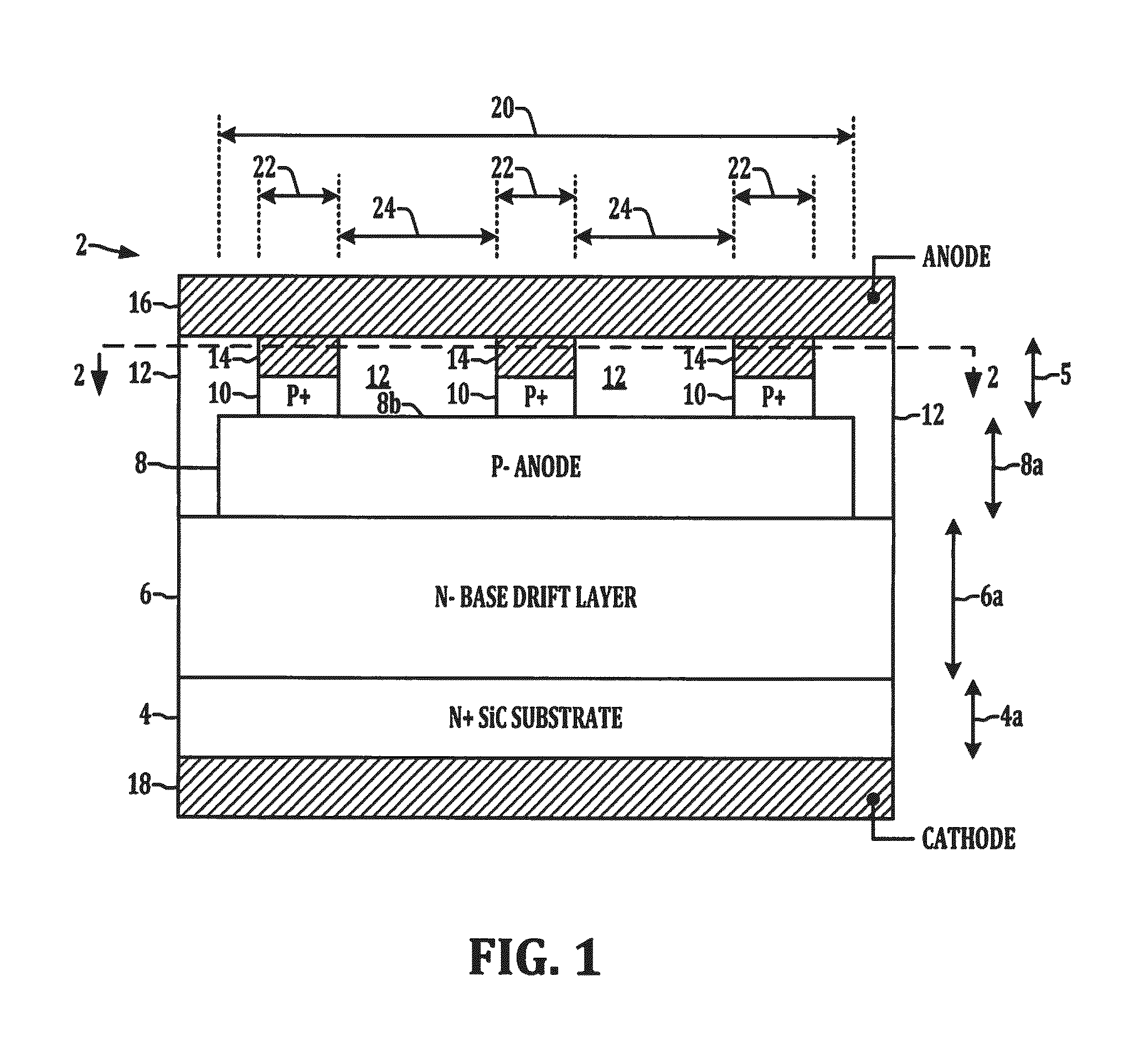

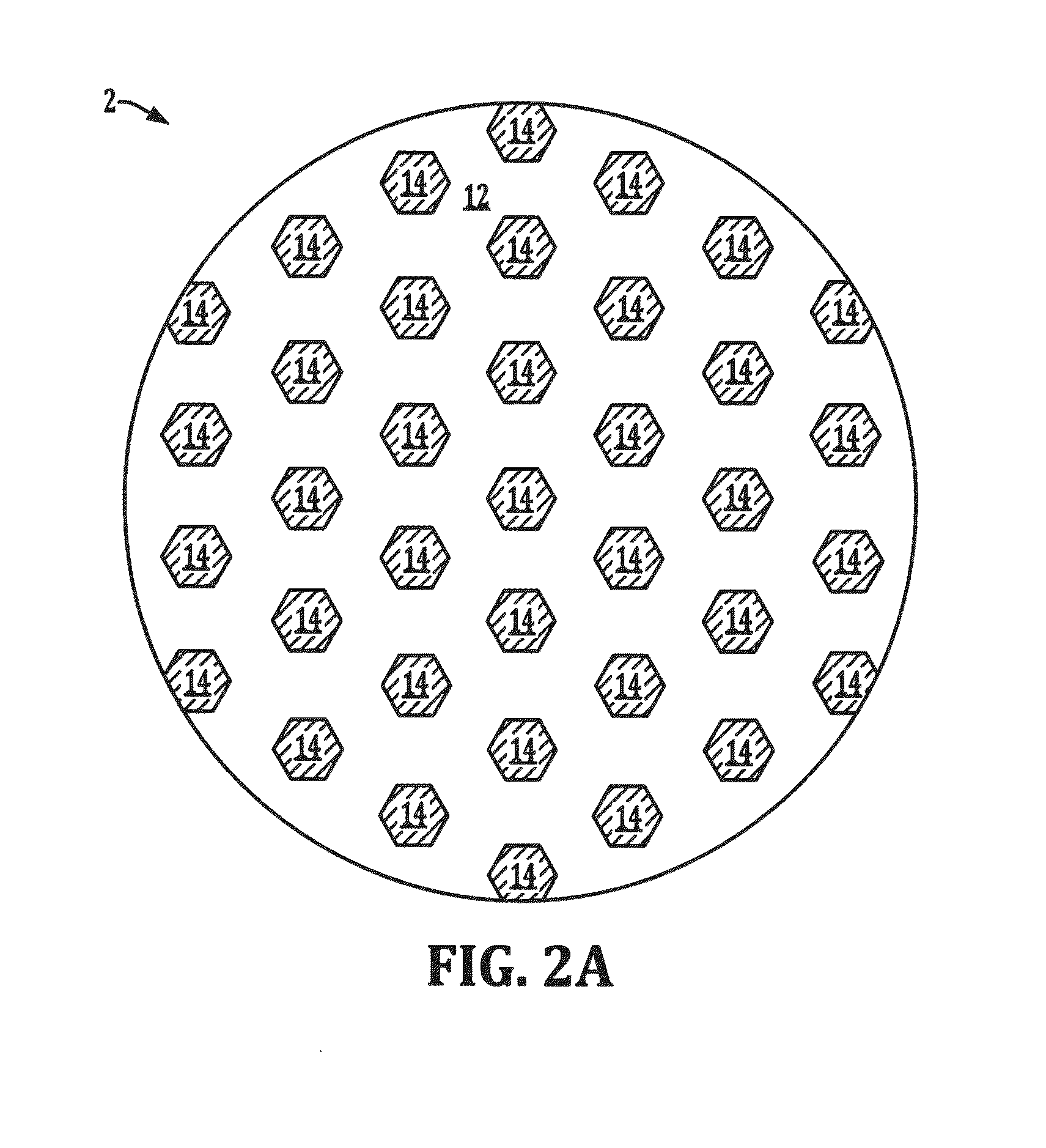

Silicon Carbide Rectifier

ActiveUS20130240905A1Current valueReduce carrier densitySemiconductor/solid-state device manufacturingSemiconductor devicesPower flowNegative temperature

Silicon carbide PiN diodes are presented with reduced temperature coefficient crossover points by limited p type contact area to limit hole injection in the n type drift layer in order to provide a lower current at which the diode shifts from negative temperature coefficient to a positive temperature coefficient of forward voltage for mitigating thermal runaway.

Owner:U S A AS RPRESENTED BY THE SEC OF THE NAVY THE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com