Battery and method of manufacturing the same

A manufacturing method and battery technology, which are applied to battery pack components, circuits, electrical components, etc., can solve the problems of increased internal resistance of the battery, reduced charge and discharge current values, and complicated lead wires, so as to suppress the decrease in current value and facilitate easy assembly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 2

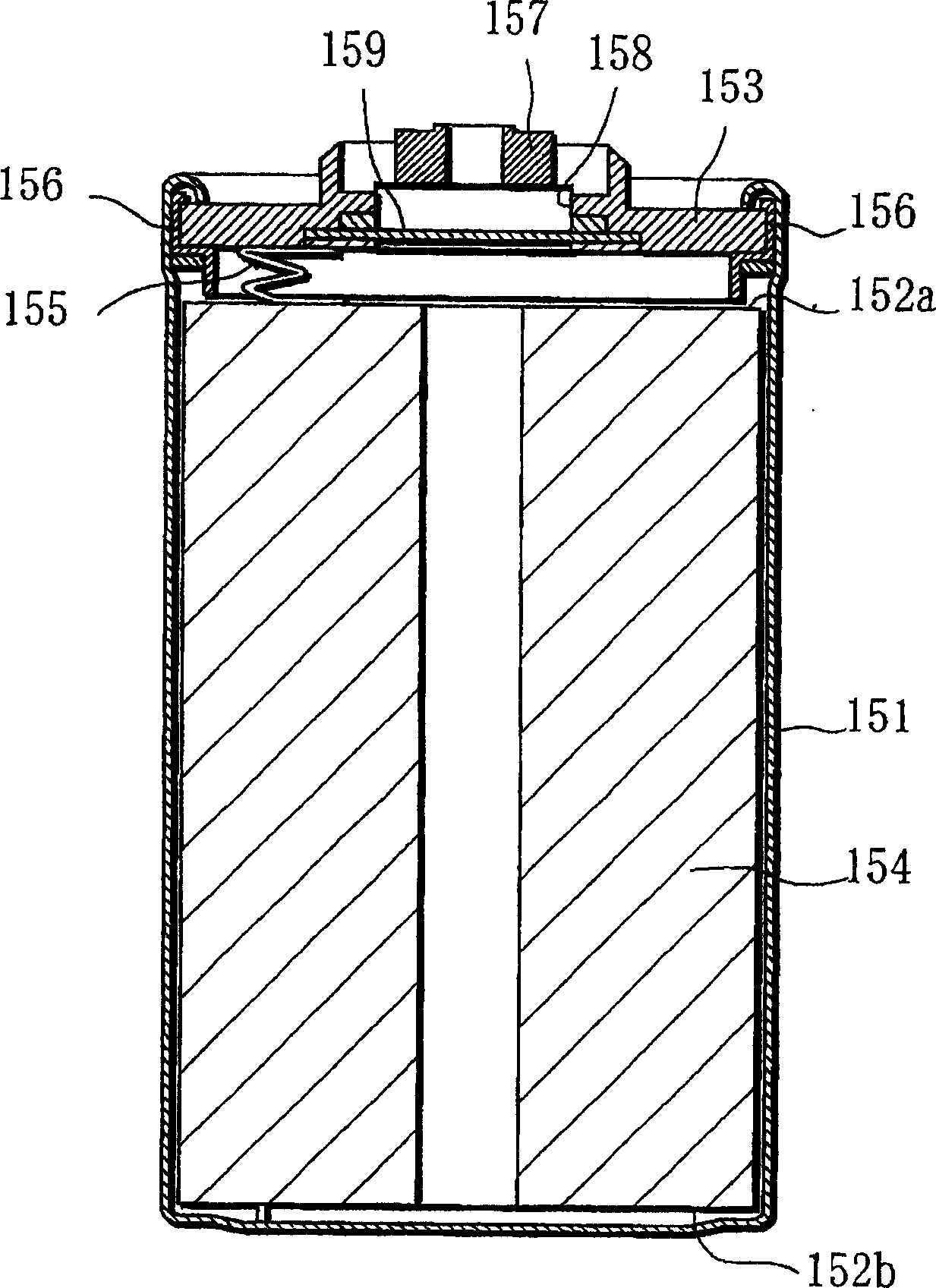

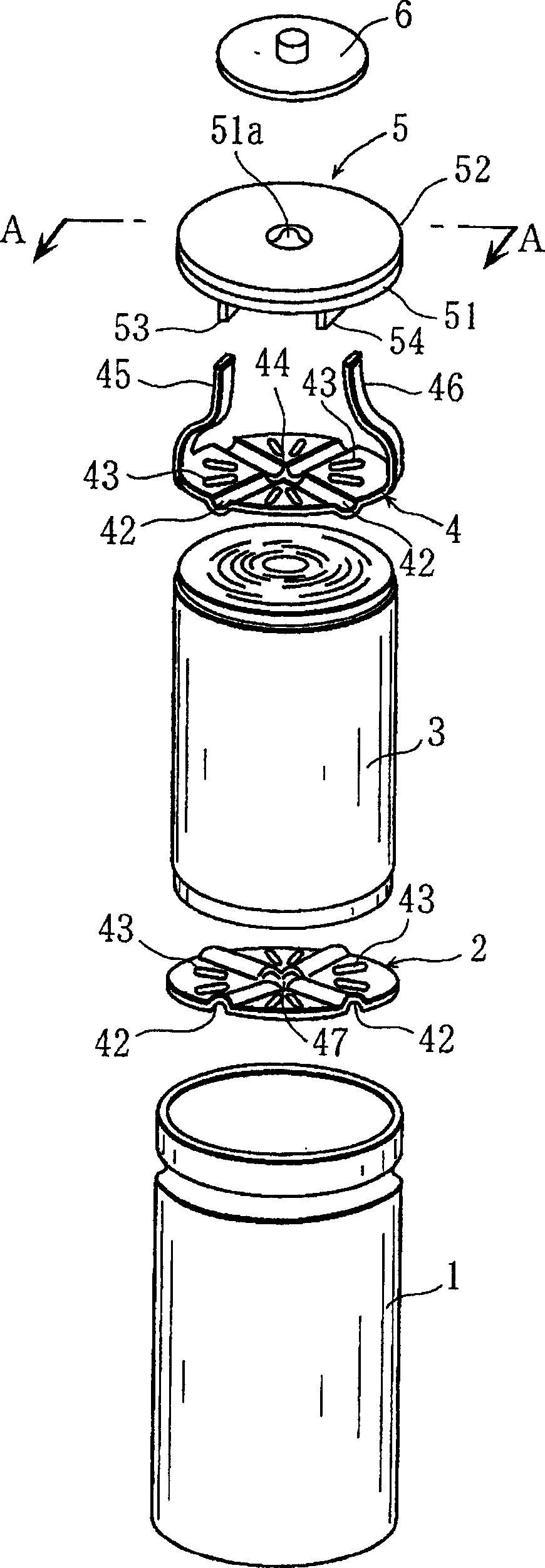

[0090] Hereinafter, Embodiment 2 of the present invention will be specifically described with reference to the drawings. In addition, the same reference numerals are used for members having the same functions as in the first embodiment, and descriptions thereof are omitted.

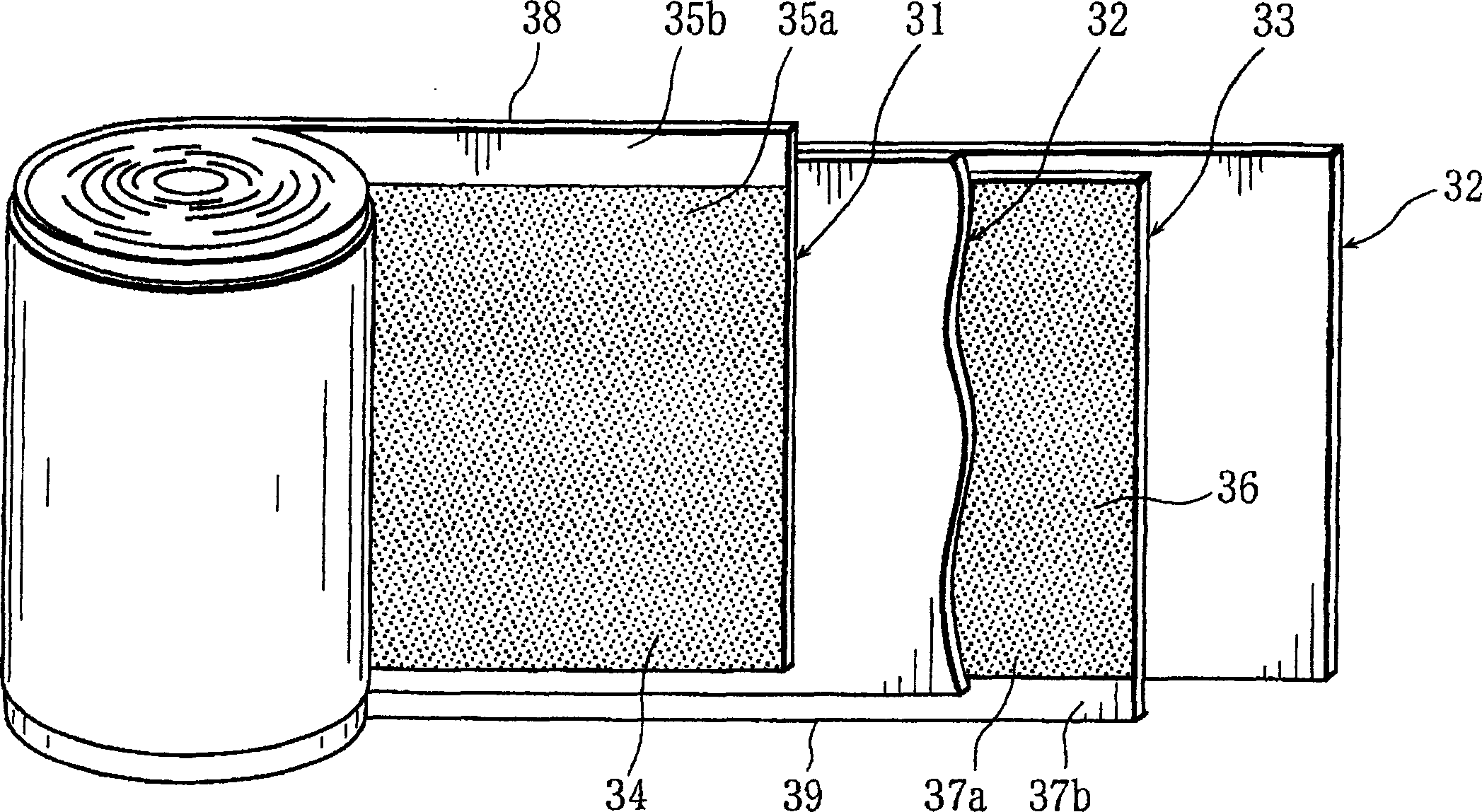

[0091] The battery capacity of the lithium-ion secondary battery of mode 2 is about 5Ah, and the structure of the negative electrode collector plate 2, the positive electrode collector plate 4, and the sealing plate 5 is different. are the same, so only the differences will be described below.

[0092] The positive collector plate 4 is as Figure 10 As shown in FIG. 15 (a) (b), since a part of the positive electrode current collector plate 4 is rolled up substantially perpendicular to its surface to form a plate-shaped lead 45, it is not extended from the end of the positive electrode current collector plate 4. The lead wire 45 is different from Embodiment 1 in that only one lead wire 45 is provided and...

no. 1 Embodiment

[0106] (Example)

[0107] As an example, the lithium ion secondary battery shown in Embodiment 1 was used.

[0108] Hereinafter, the battery produced in this way will be referred to as the battery A of the present invention.

no. 2 Embodiment

[0119] (Example)

[0120] As an example, the lithium ion secondary battery shown in Embodiment 2 was used.

[0121] Hereinafter, the battery produced in this way is referred to as the battery B of the present invention.

[0122] (comparative example)

[0123] As a comparative example, the lead length is 30 mm, the lead width is 15 mm, the lead thickness is 0.5 mm, and the battery capacity is about 5.0 Ah, except that it has the same structure as the comparative example of the first embodiment. Furthermore, the difference in lead wire length and the like from the comparative example of the first embodiment is due to the difference in battery capacity.

[0124] Hereinafter, the battery produced in this way is referred to as a comparative battery Y.

[0125] (experiment)

[0126] Table 2 shows the results of measuring the electrical resistivity of the battery B at a frequency of 1 kHz for the battery B of the present invention and the comparative battery Y.

[0127] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com