Control device for vehicle on/off control valve

A control device, control valve technology, applied in the direction of transmission control, components with teeth, belts/chains/gears, etc., to achieve the effect of minimizing power consumption and reducing current value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

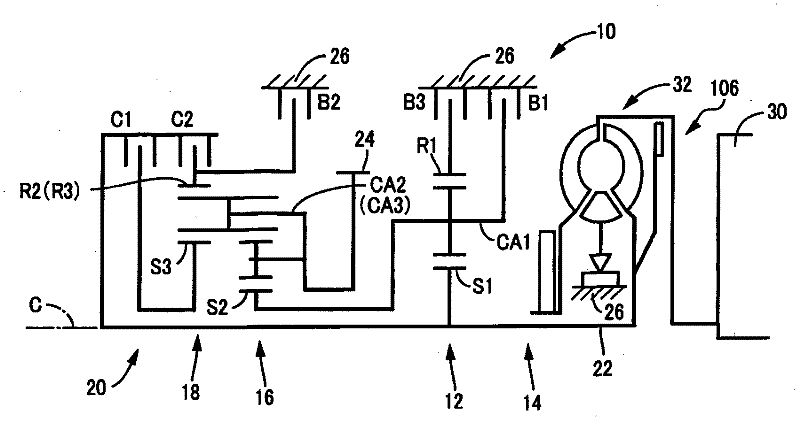

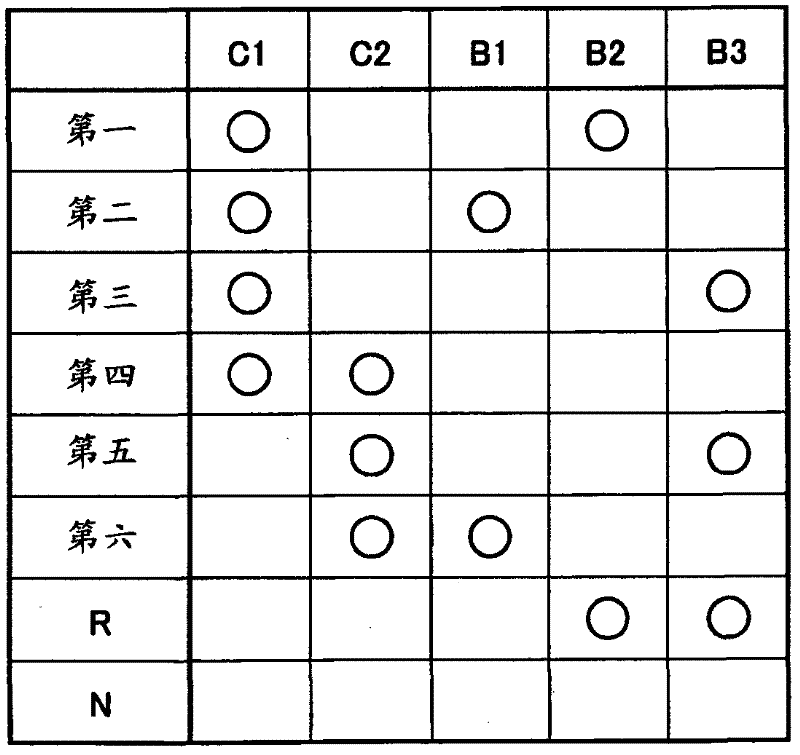

Method used

Image

Examples

no. 2 example

[0192] The first embodiment has been explained above with reference to the case where the present invention is applied to the control apparatus of an engine-propelled vehicle. In contrast, the second embodiment will be described below with reference to a case where the present invention is applied to a control device of a hybrid vehicle. Also, for brevity of description, description will be provided focusing on different points.

[0193] Figure 16 is a schematic configuration diagram showing a hybrid drive apparatus 510 including a vehicle 508 to which the control device of the present invention is applied. exist Figure 16 In the hybrid drive apparatus 510, the first drive power source 12, which is the main drive power source in the vehicle 508, supplies torque transmitted to the output shaft 514 serving as an output member, and the torque is transferred from the output shaft 514 via the differential gear device 516. is further transmitted to a pair of left and right driv...

no. 3 example

[0227] The first embodiment has been explained above with reference to the case where the present invention is applied to a control device with feedback control in which feedback control is performed to control the holding current value I HD (Solenoid current value I RL ) to operate with the predetermined target starting current value I TRN unanimous. Conversely, the third embodiment will be described below with reference to a case where the present invention is applied to a control device with feedforward control in which feedforward control is performed to control the holding current value I HD (Solenoid current value I RL ) to start the current value I close to the predetermined target operation TRN .

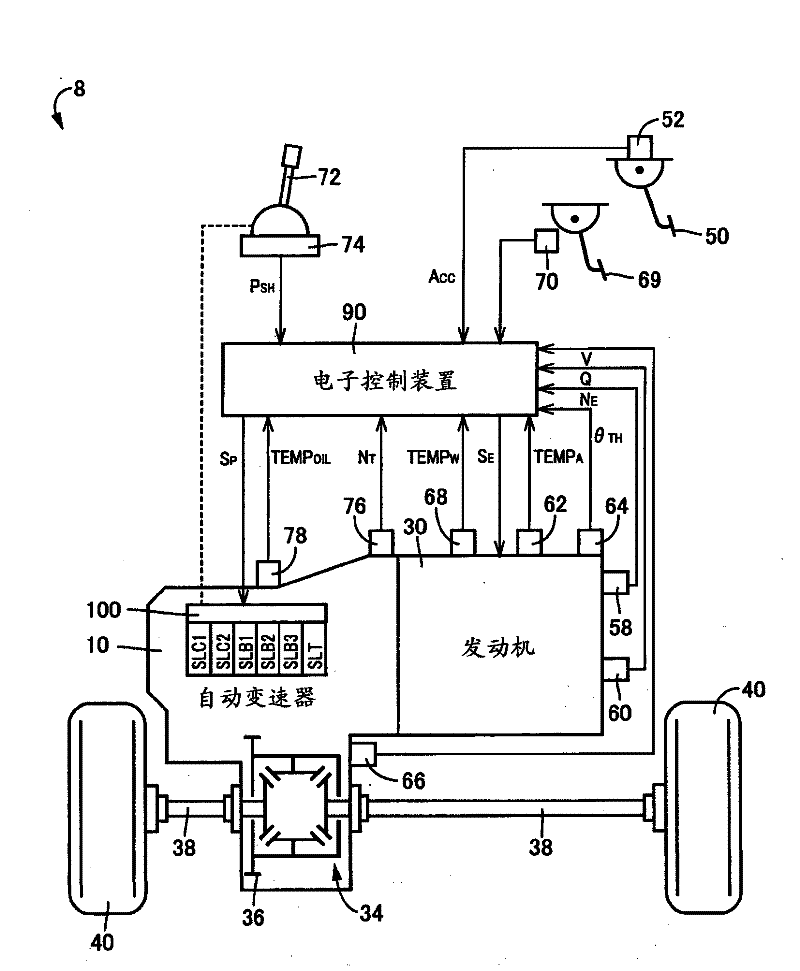

[0228] Figure 20 is a schematic diagram showing the main part of the solenoid valve driving circuit 632 for controlling the operation of the switching electromagnetic solenoid valve 104 corresponding to the on / off control valve of the present invention, which represent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com