Patents

Literature

124 results about "Machine selection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

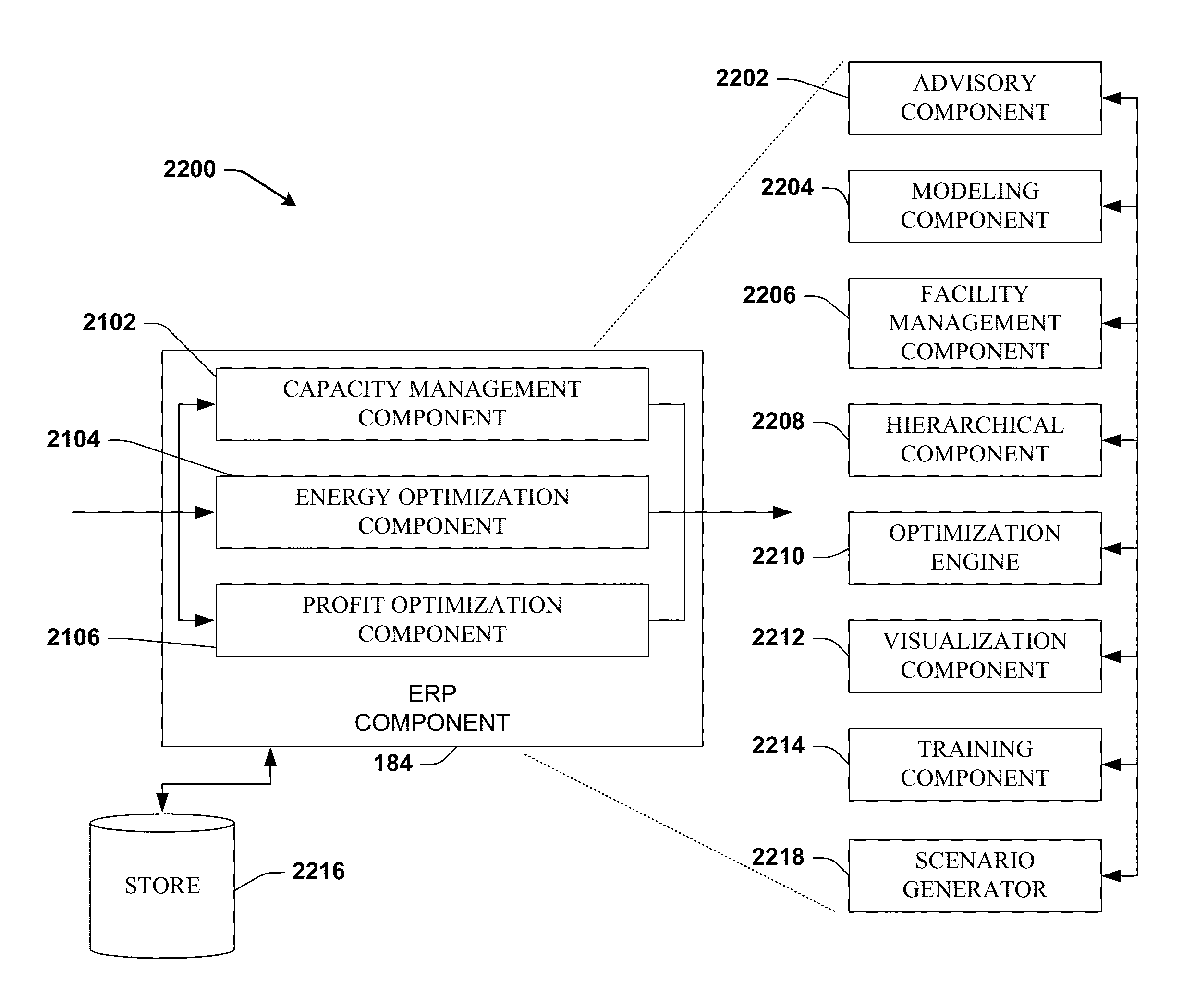

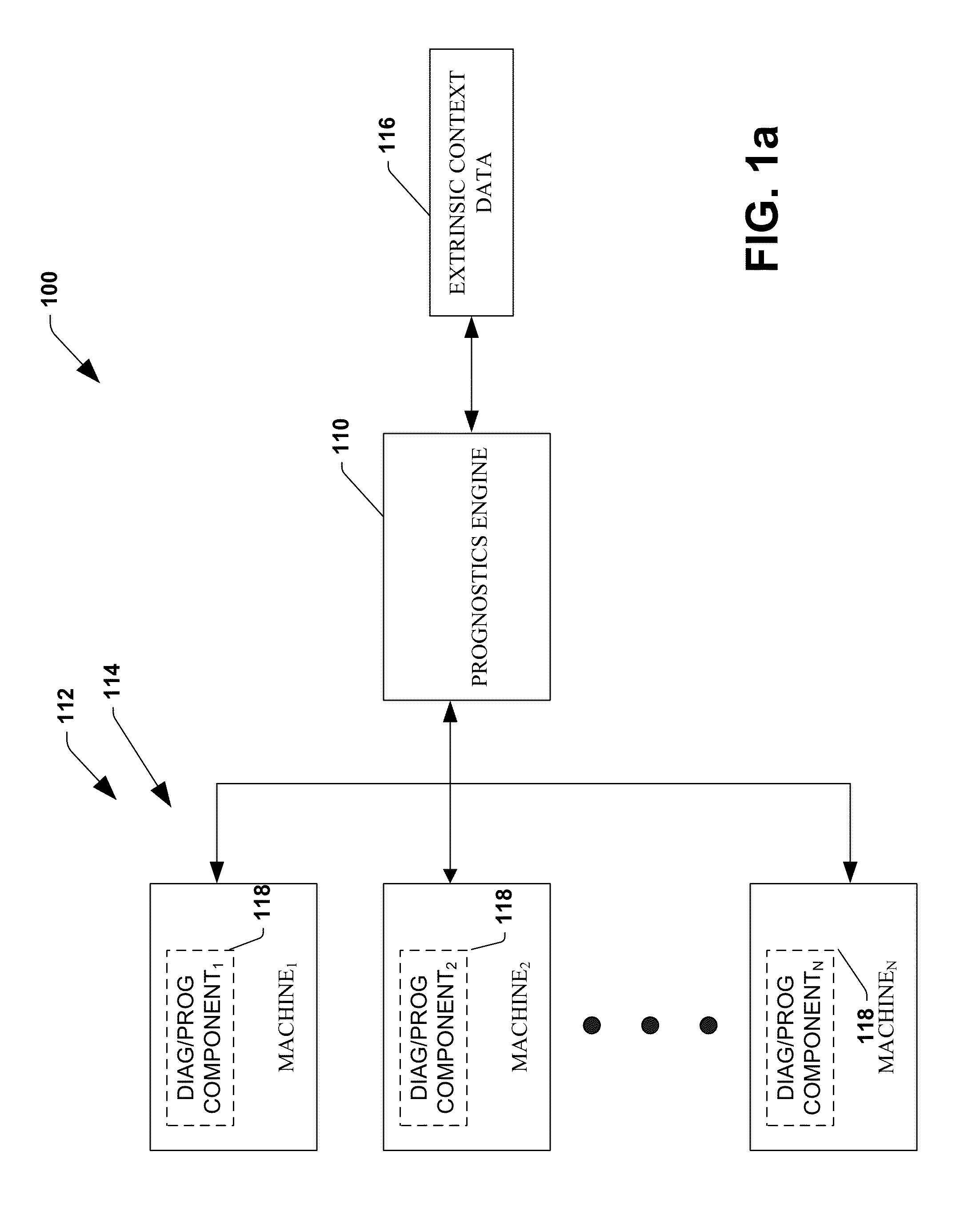

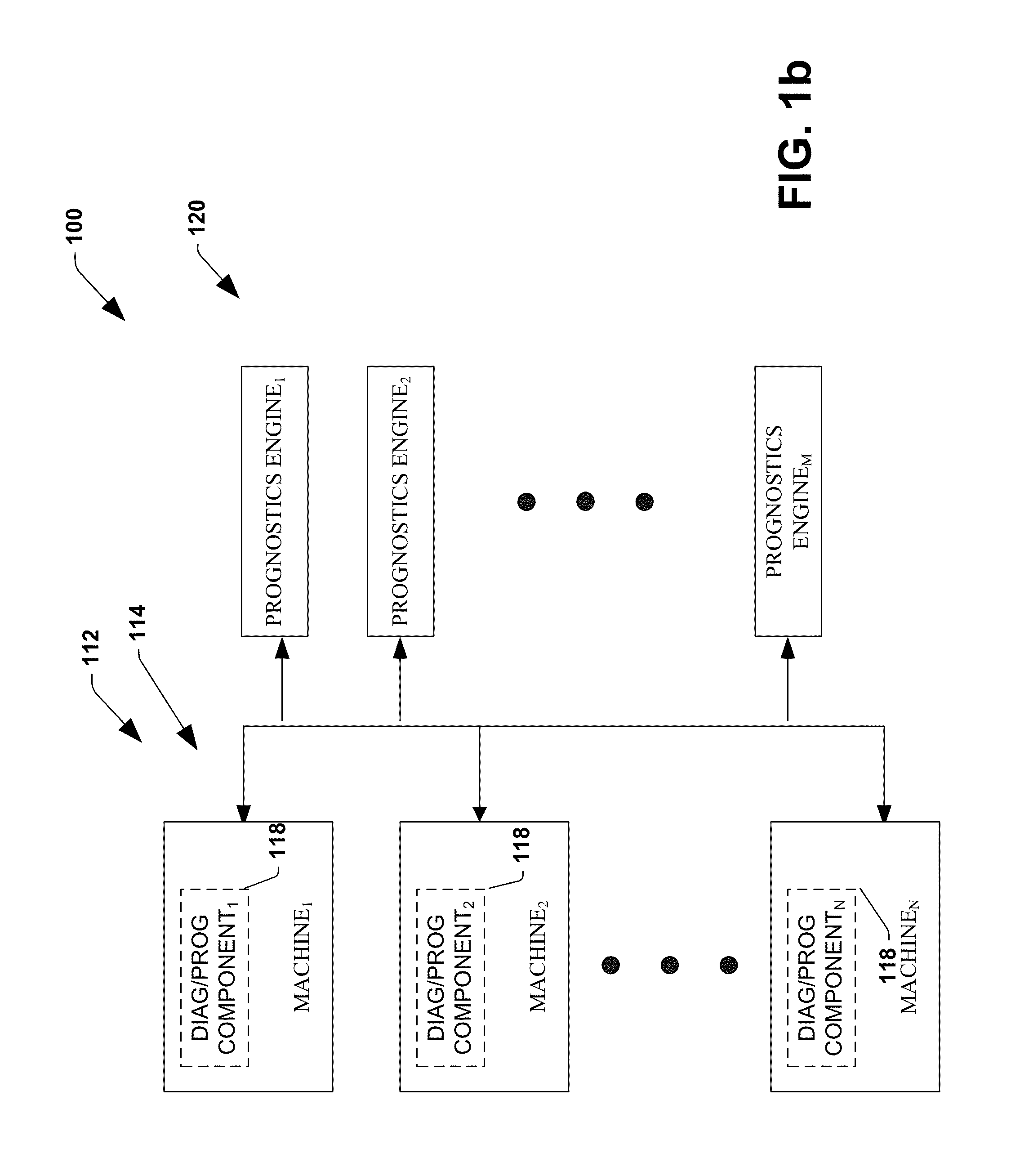

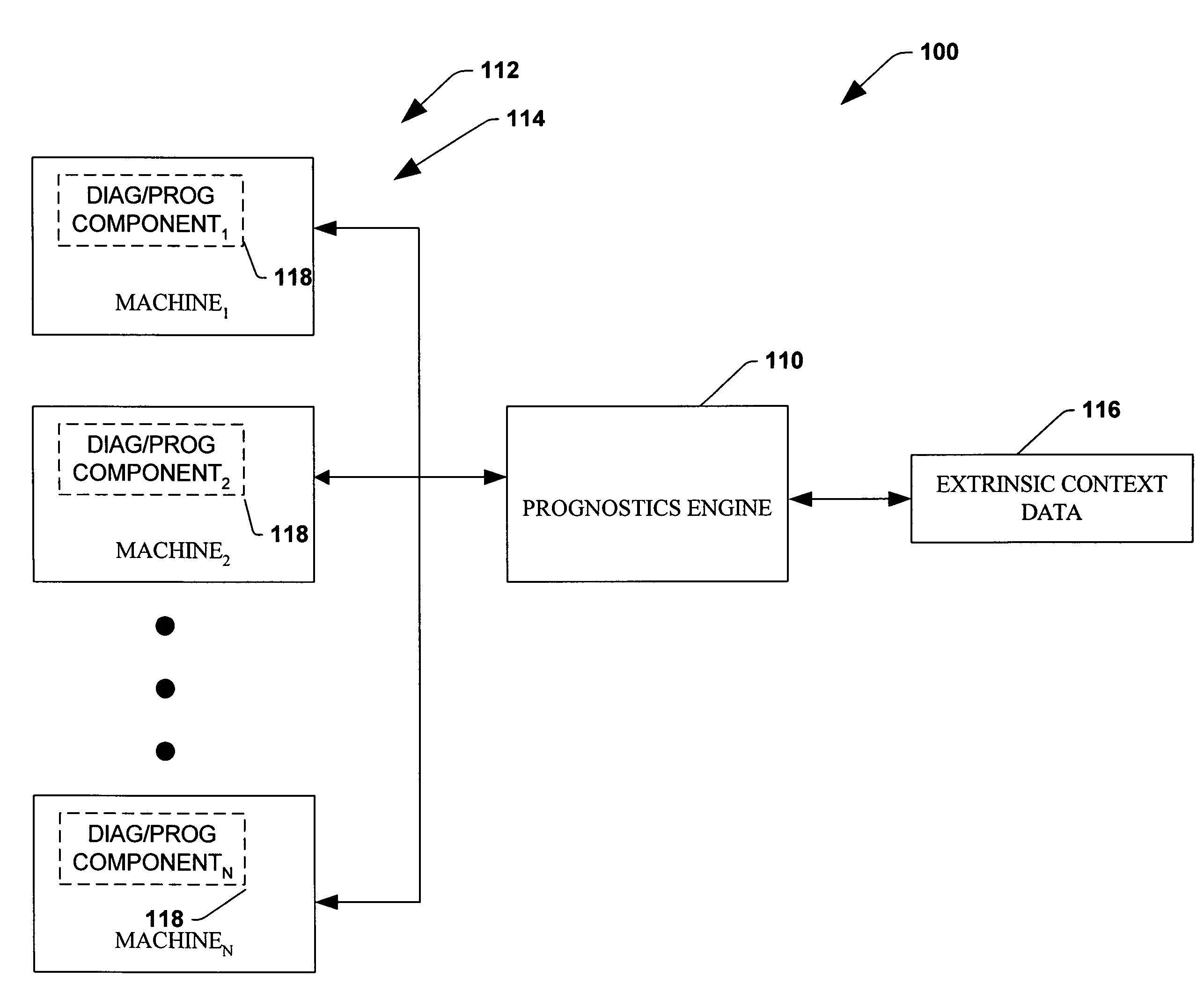

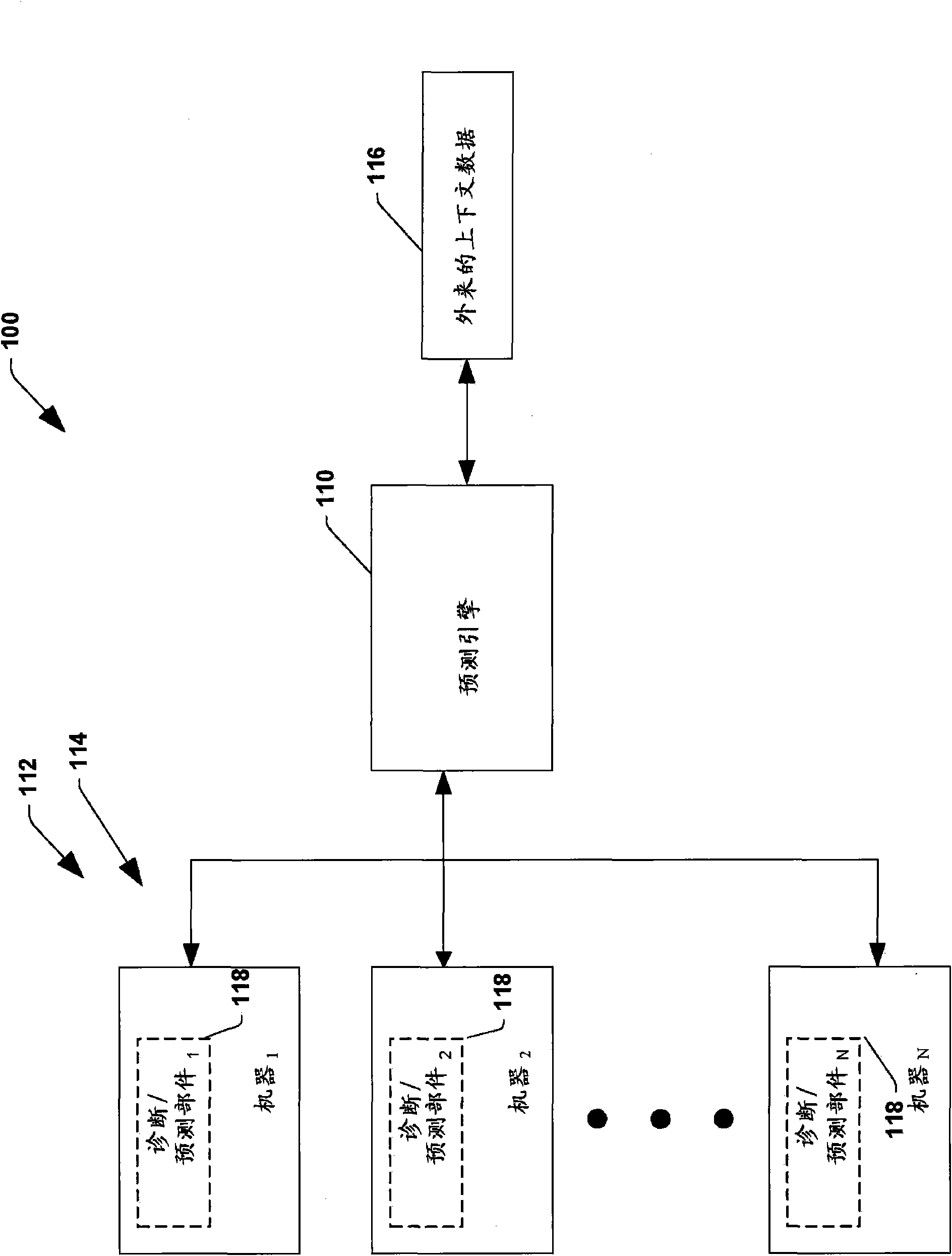

System and method for dynamic multi-objective optimization of machine selection, integration and utilization

InactiveUS20090210081A1Improve overall utilizationImprove efficiencyInput/output for user-computer interactionForecastingMachine selectionOperational costs

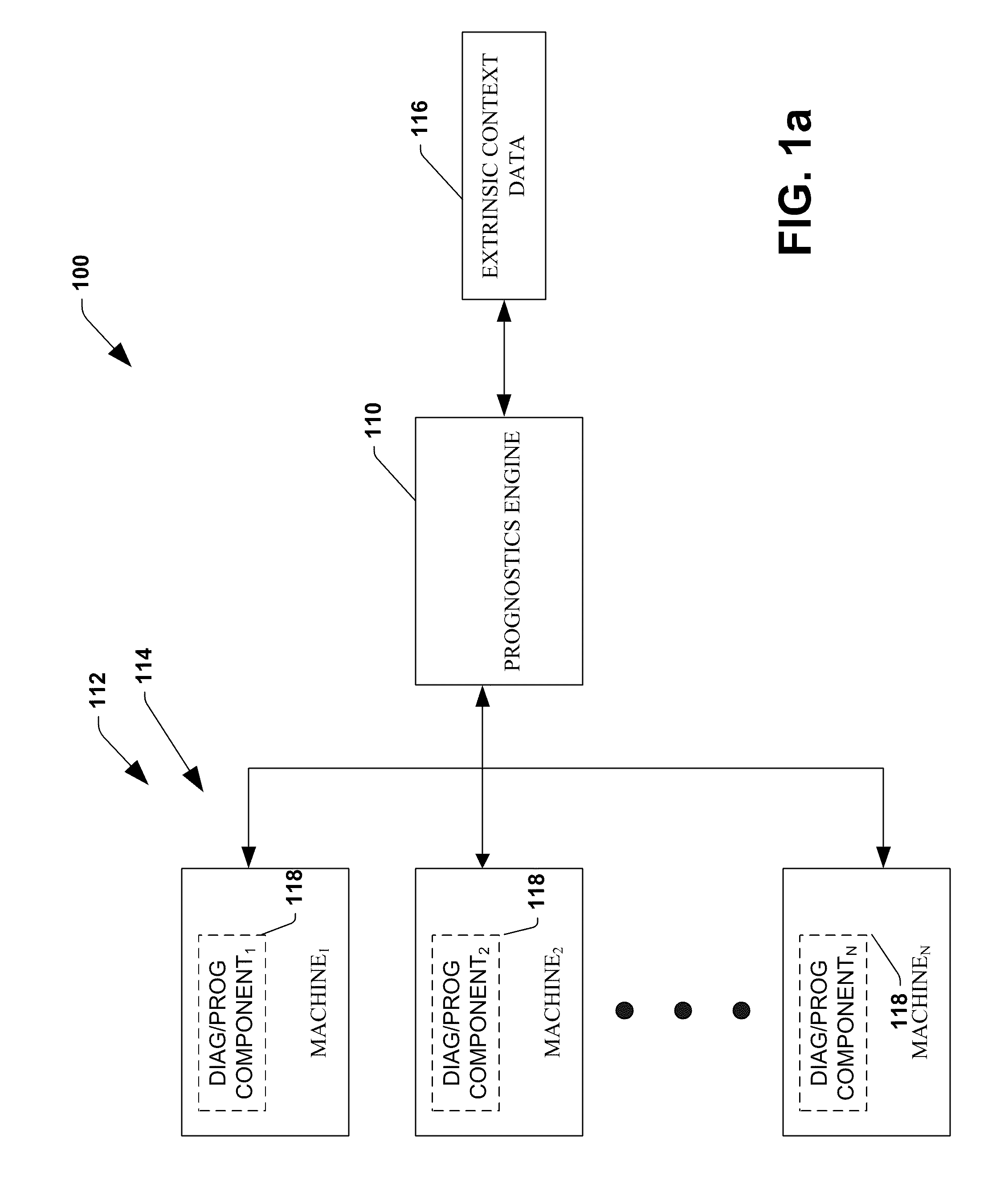

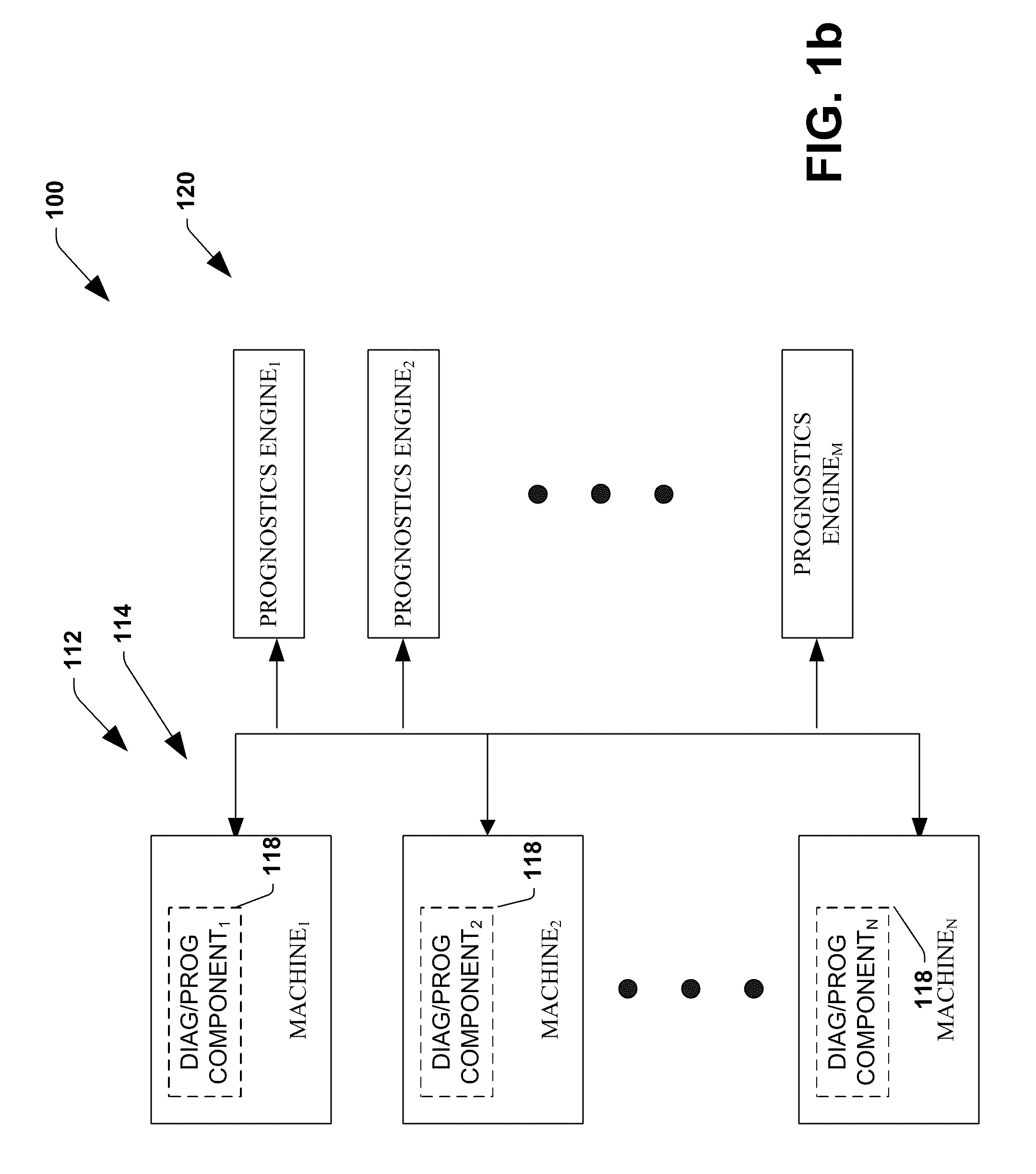

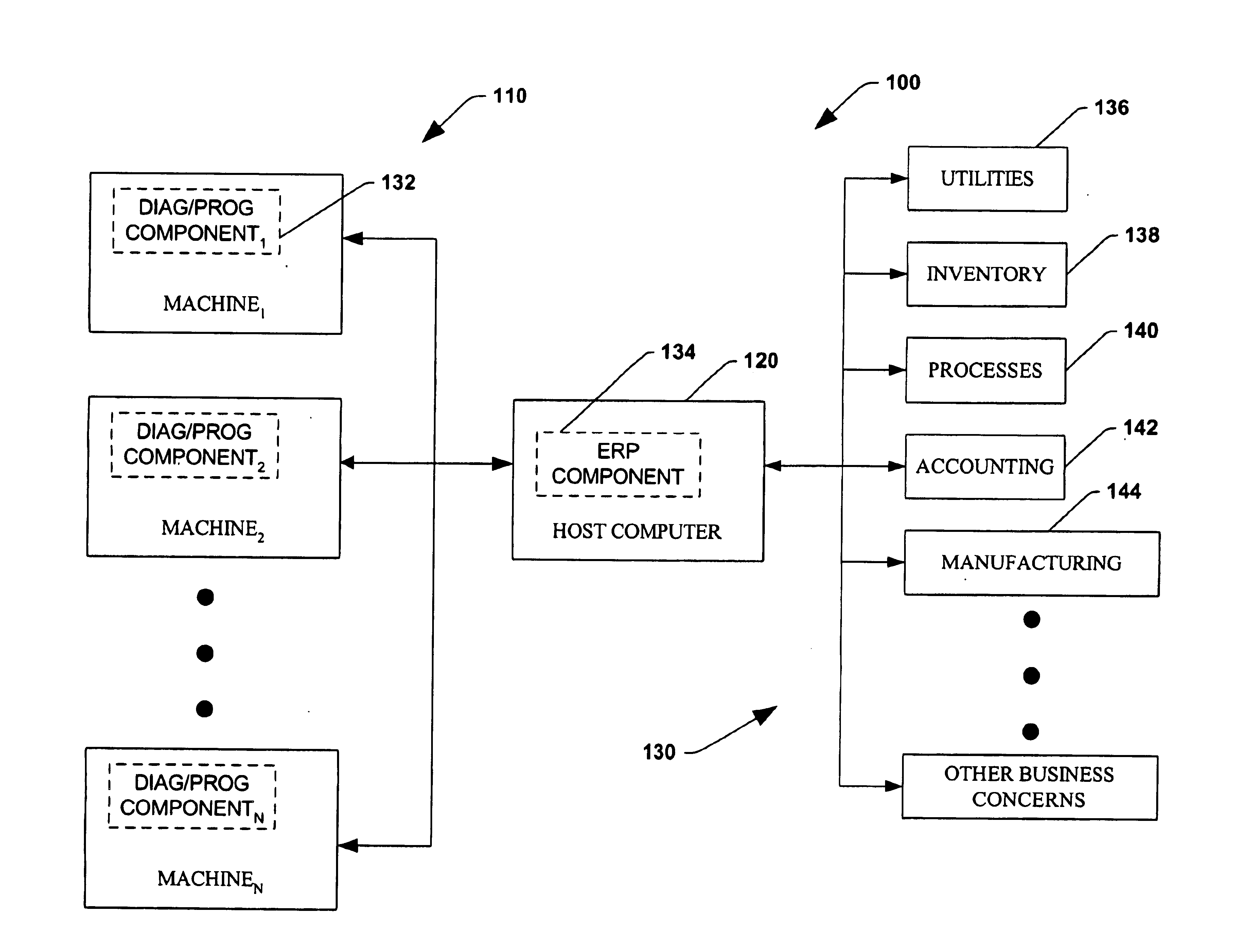

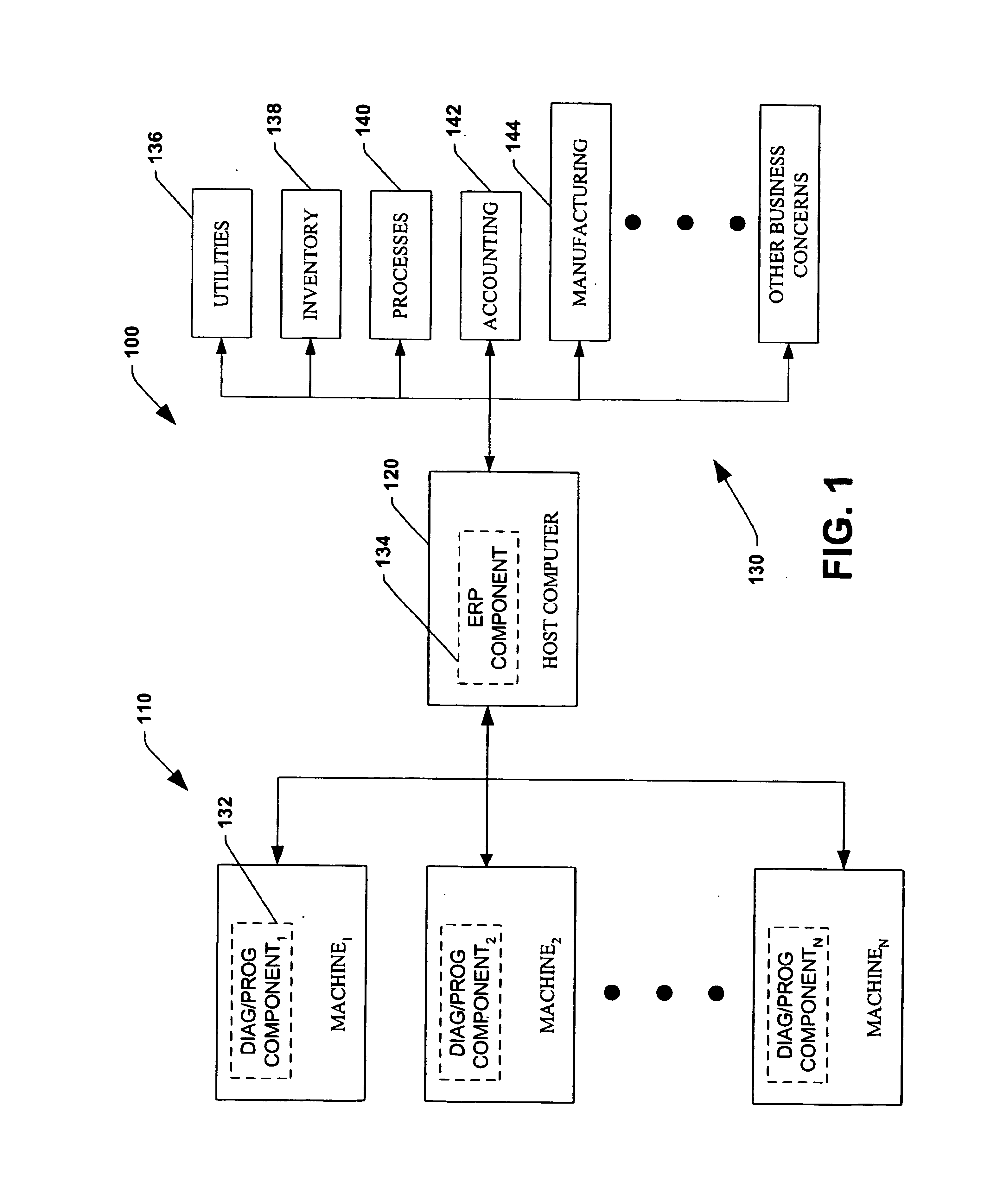

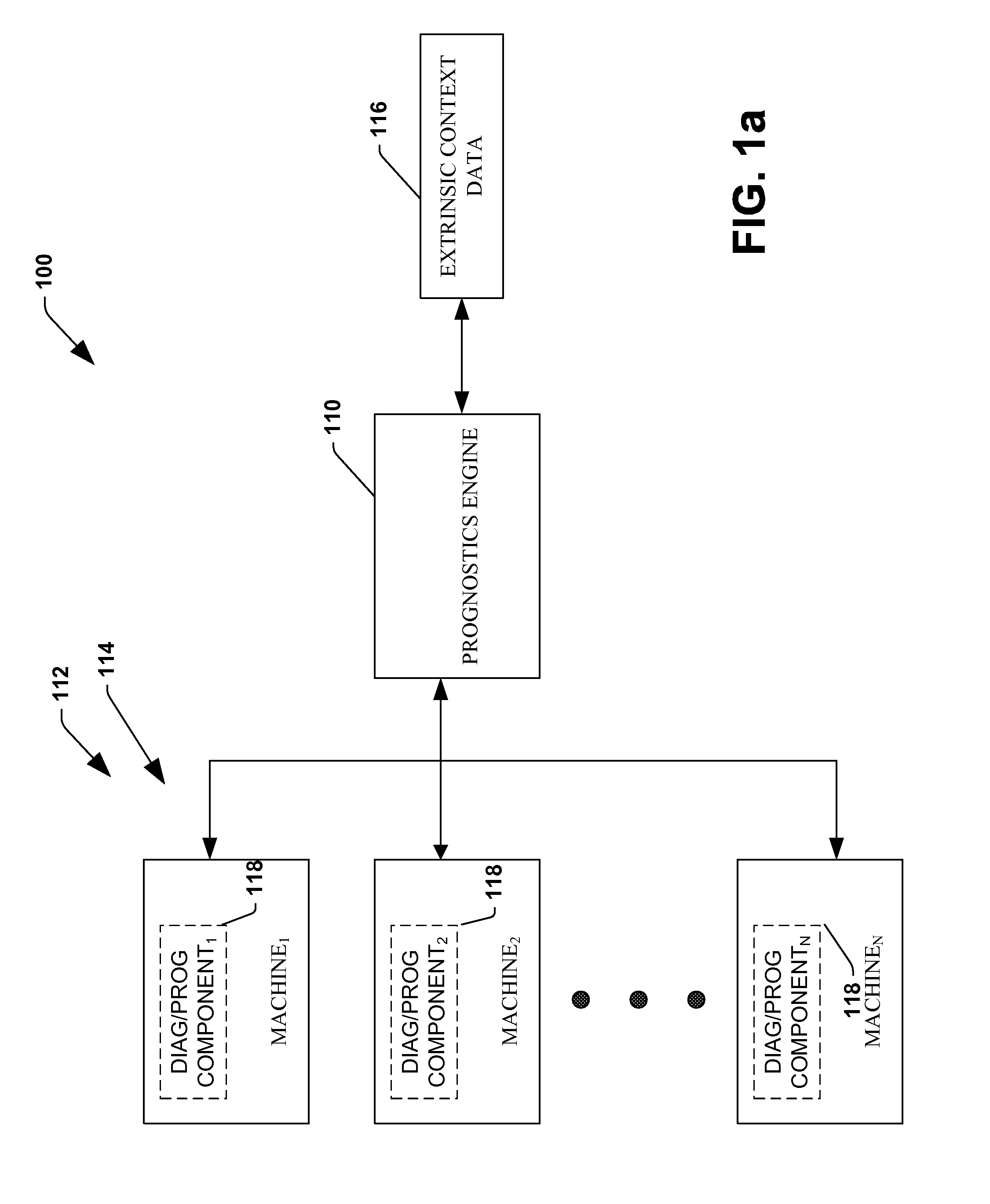

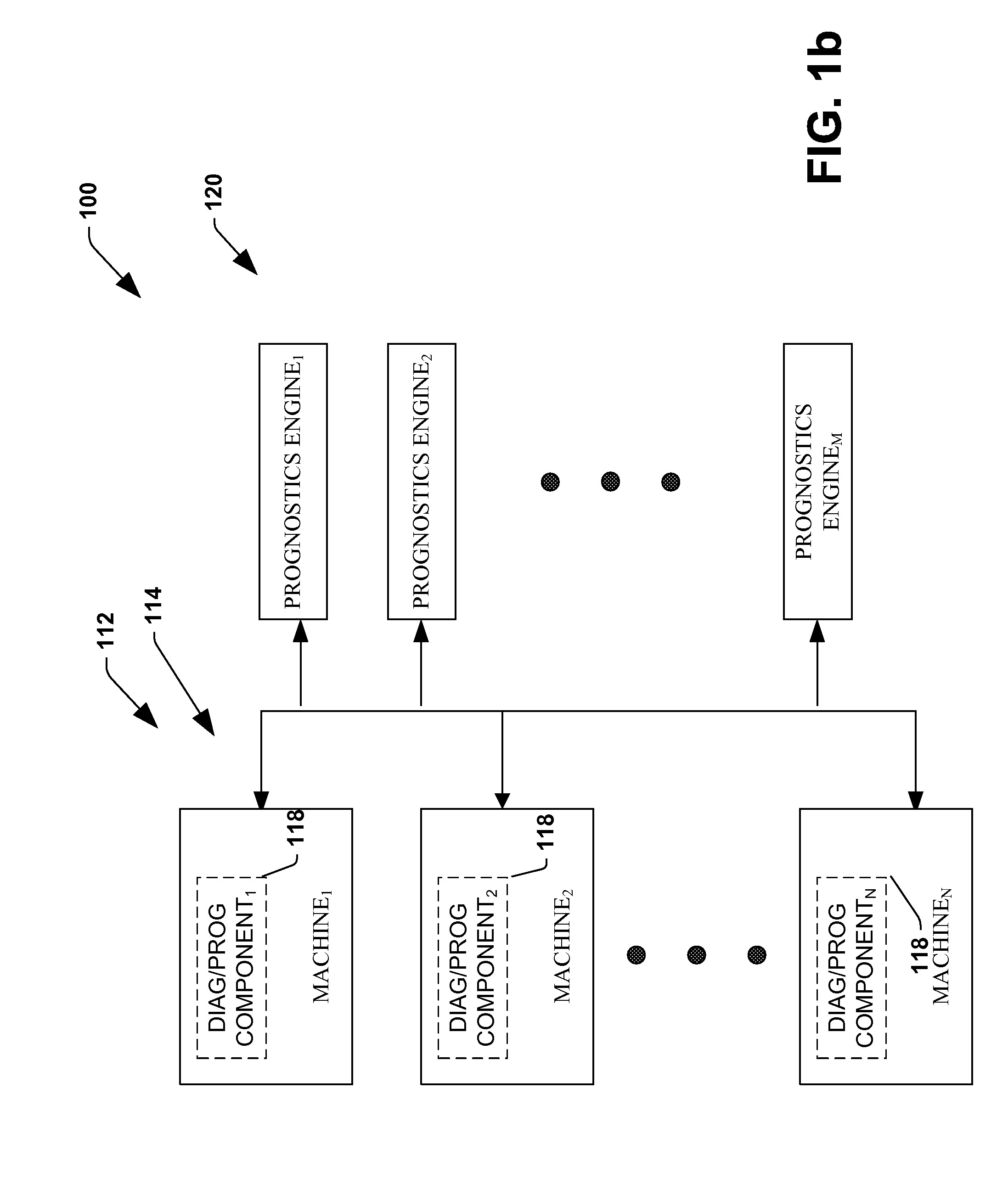

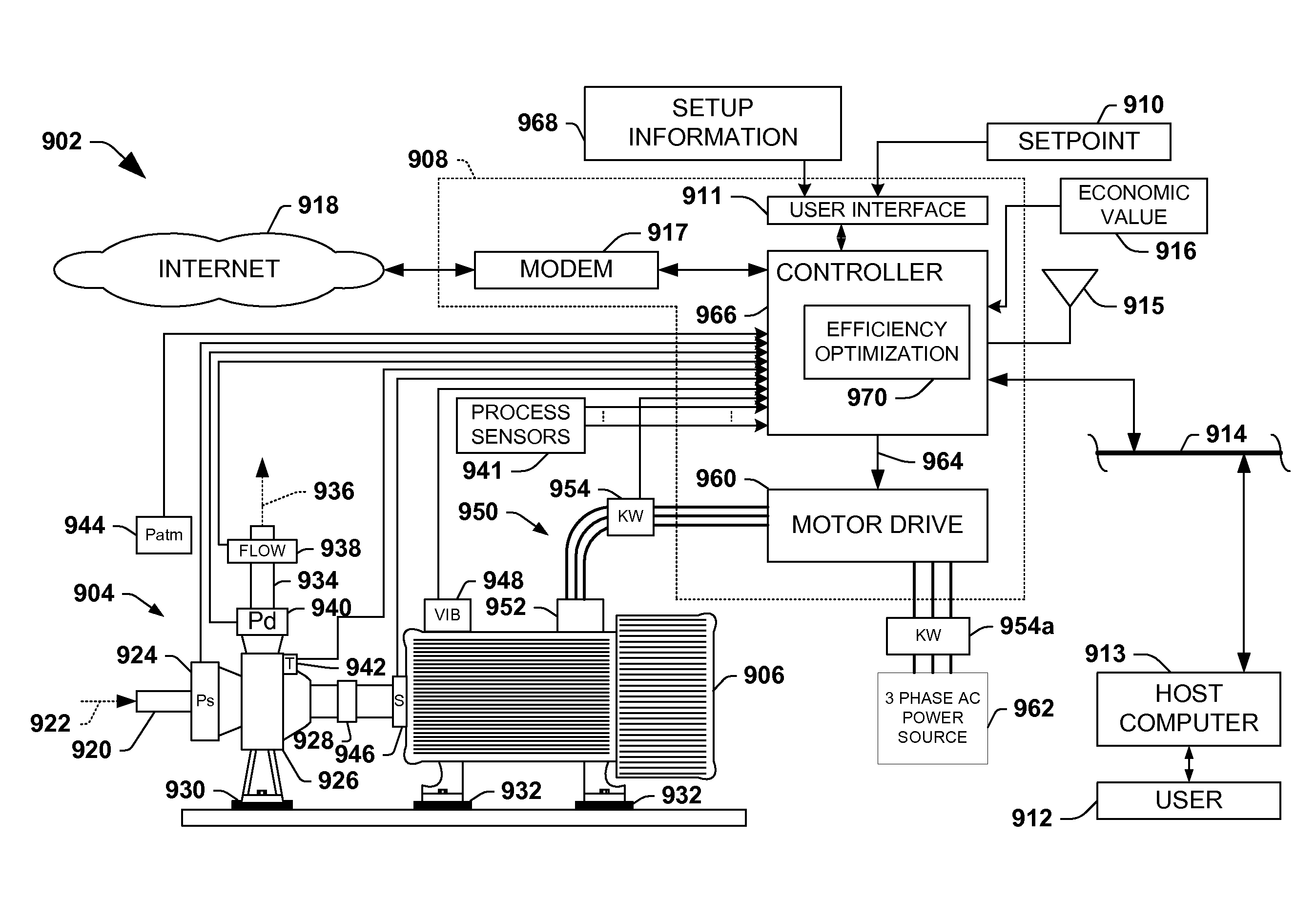

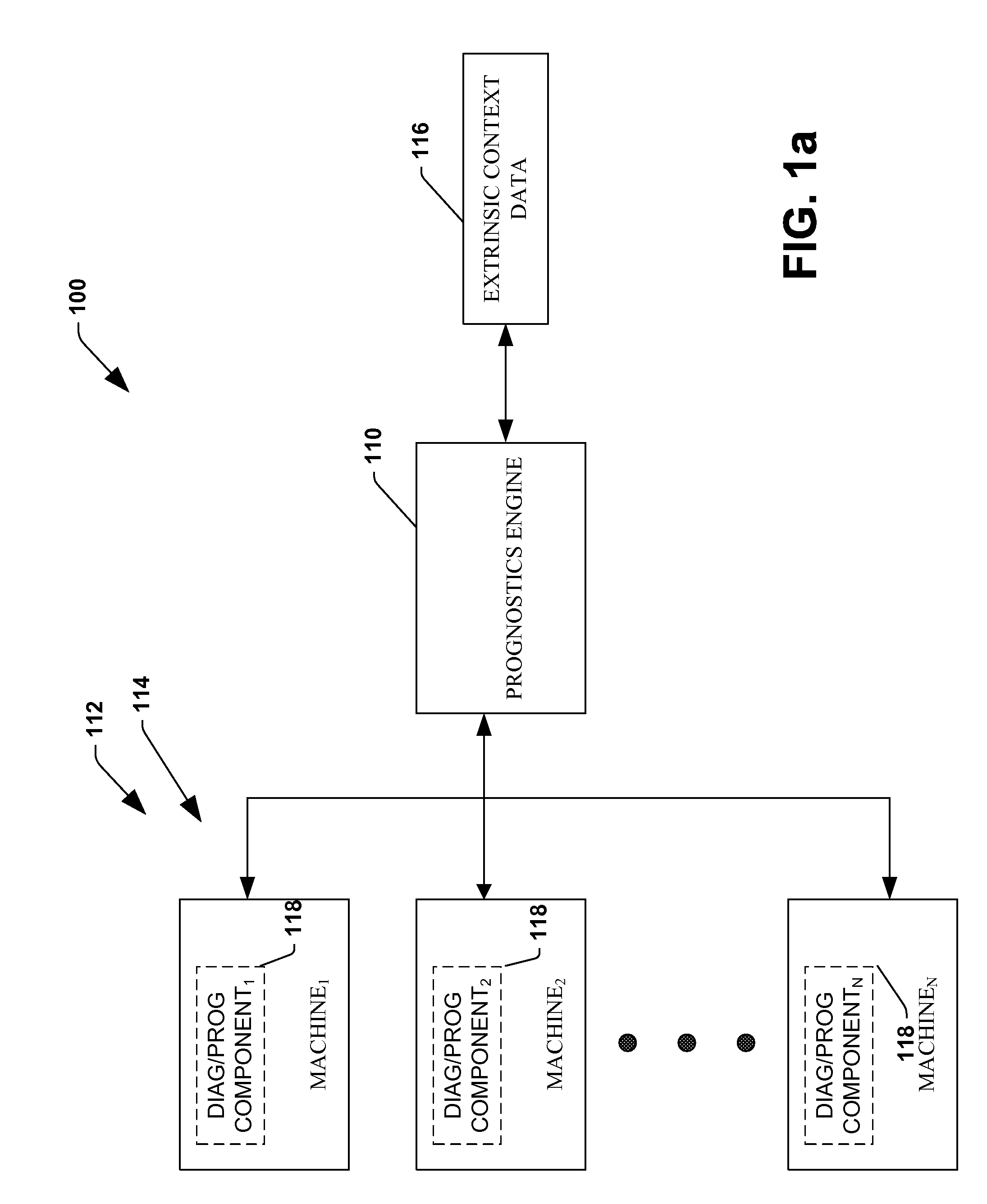

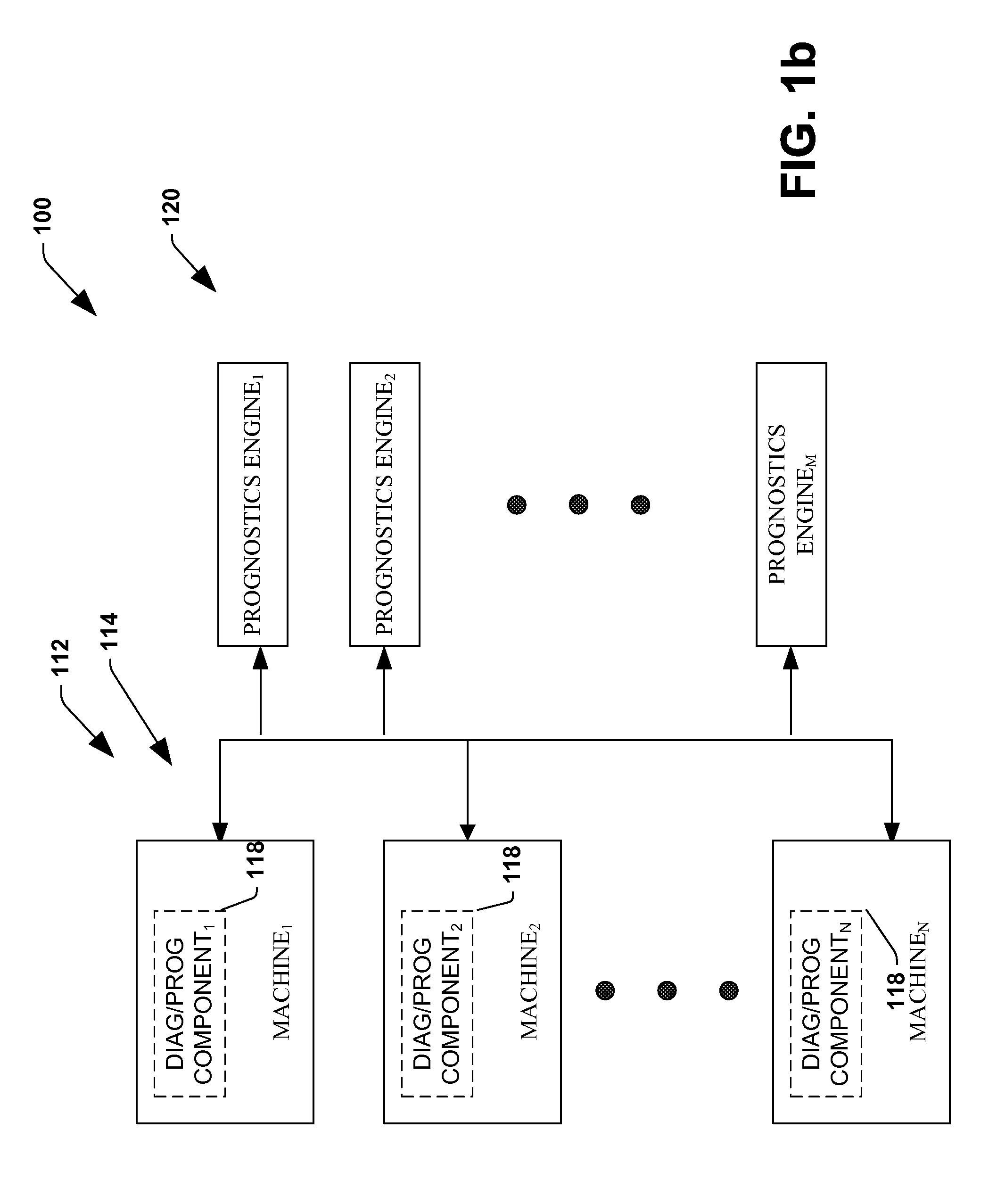

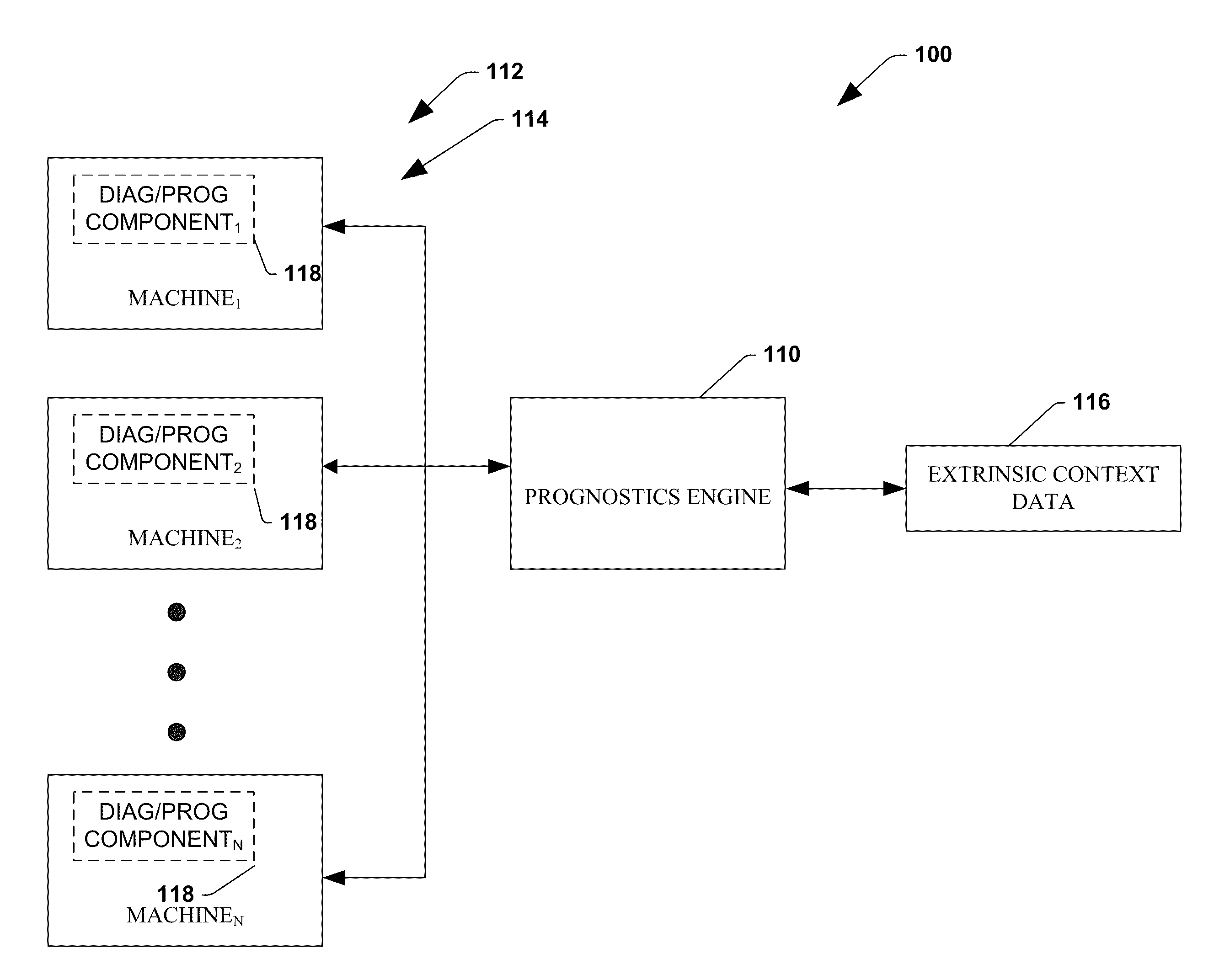

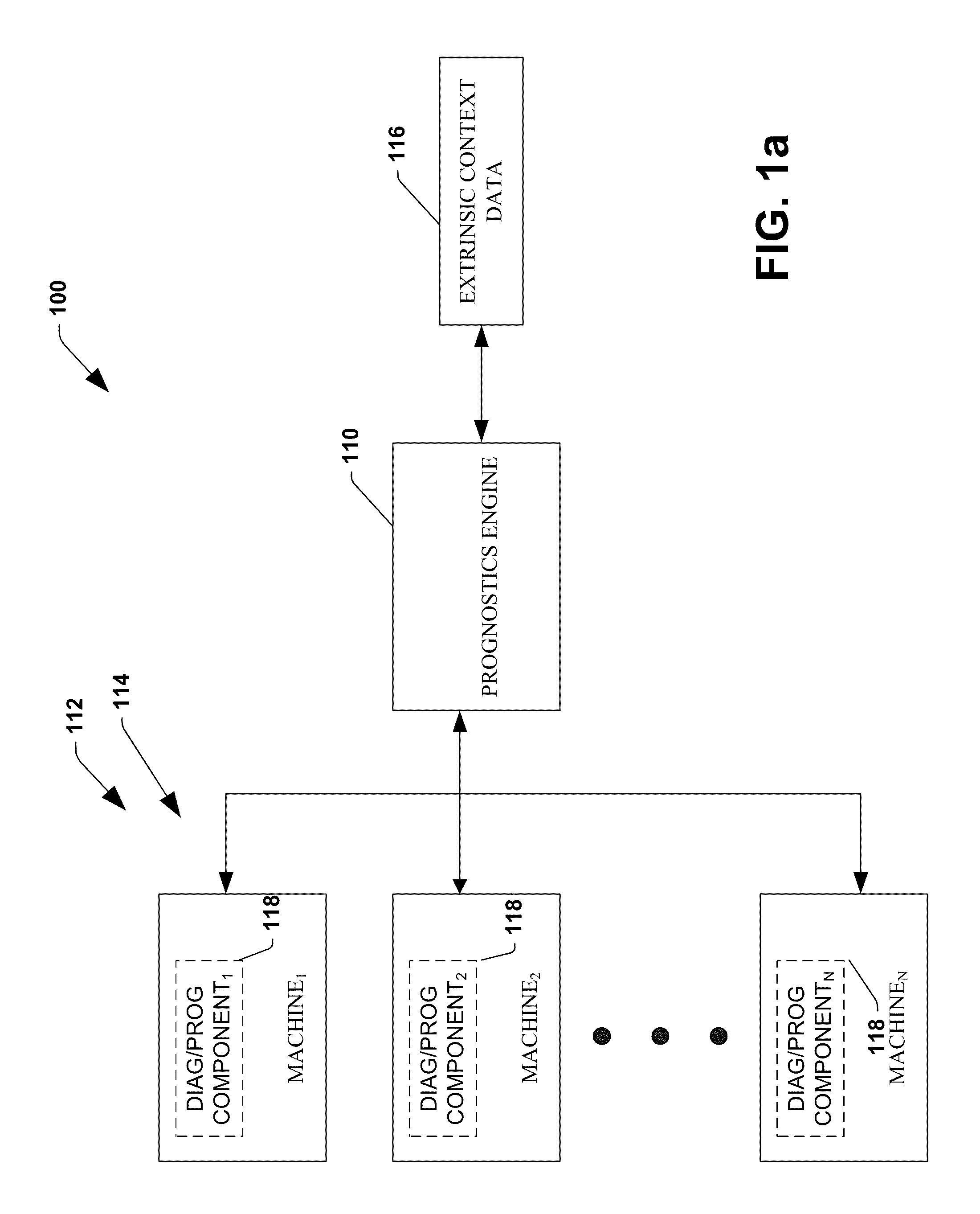

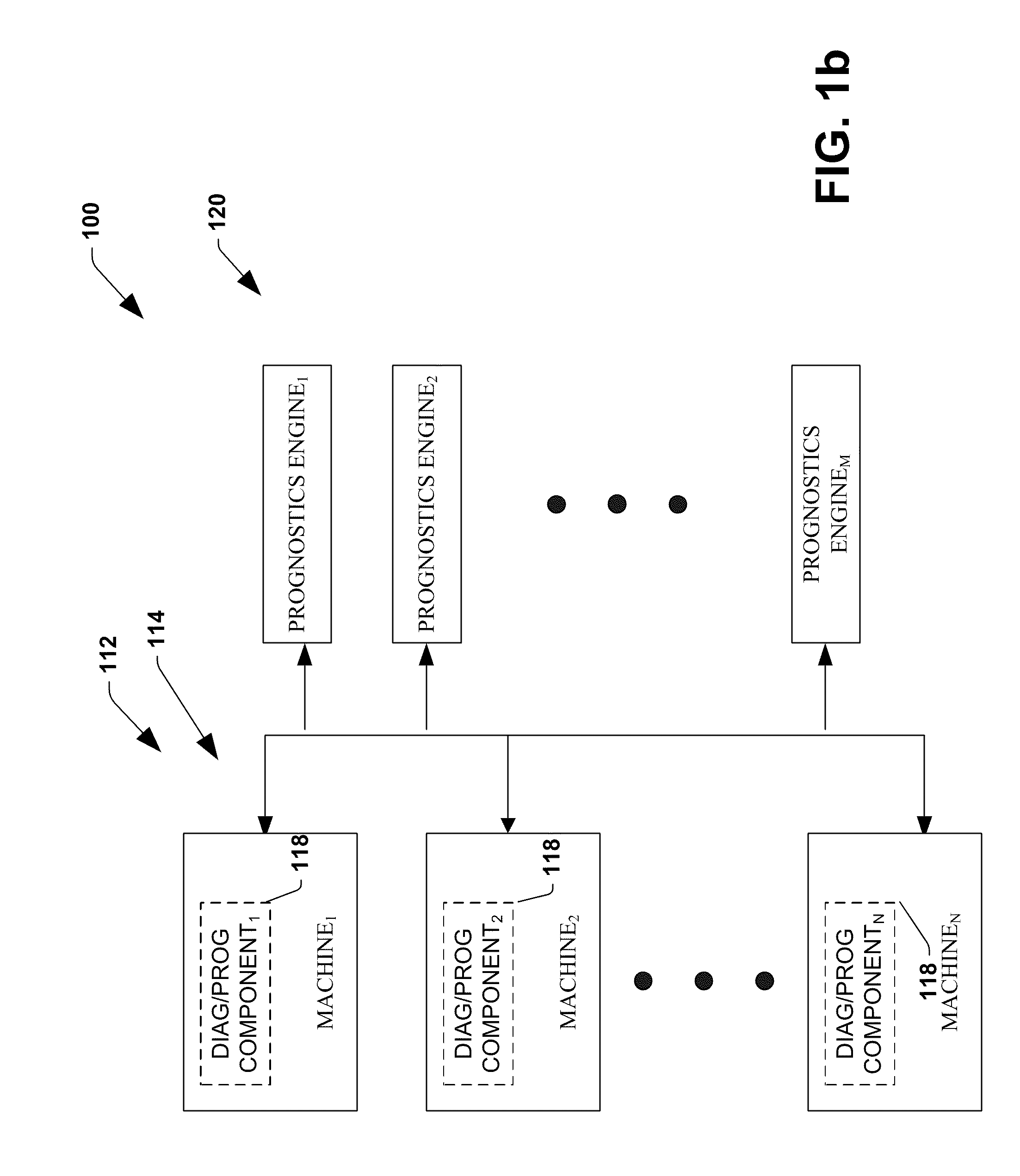

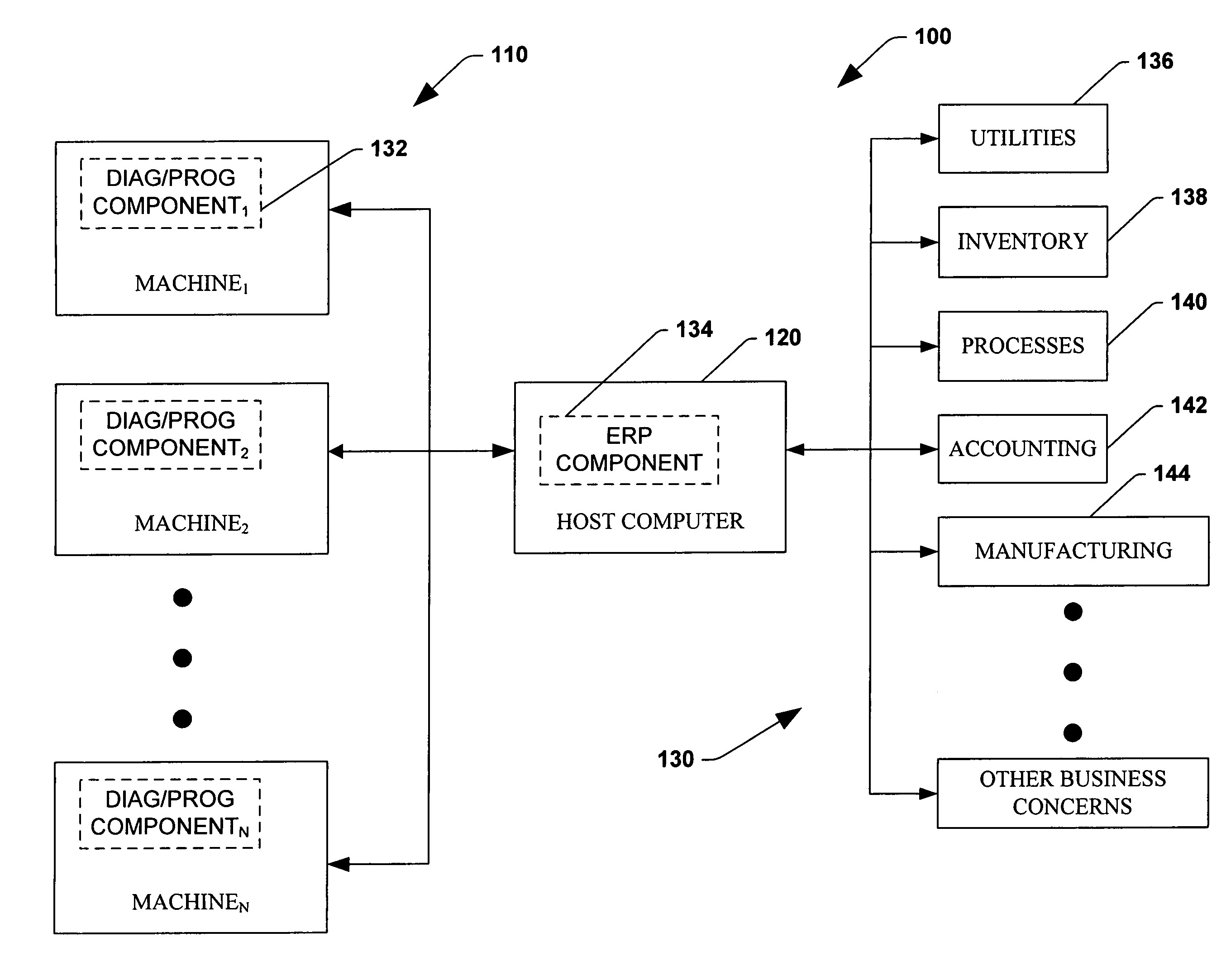

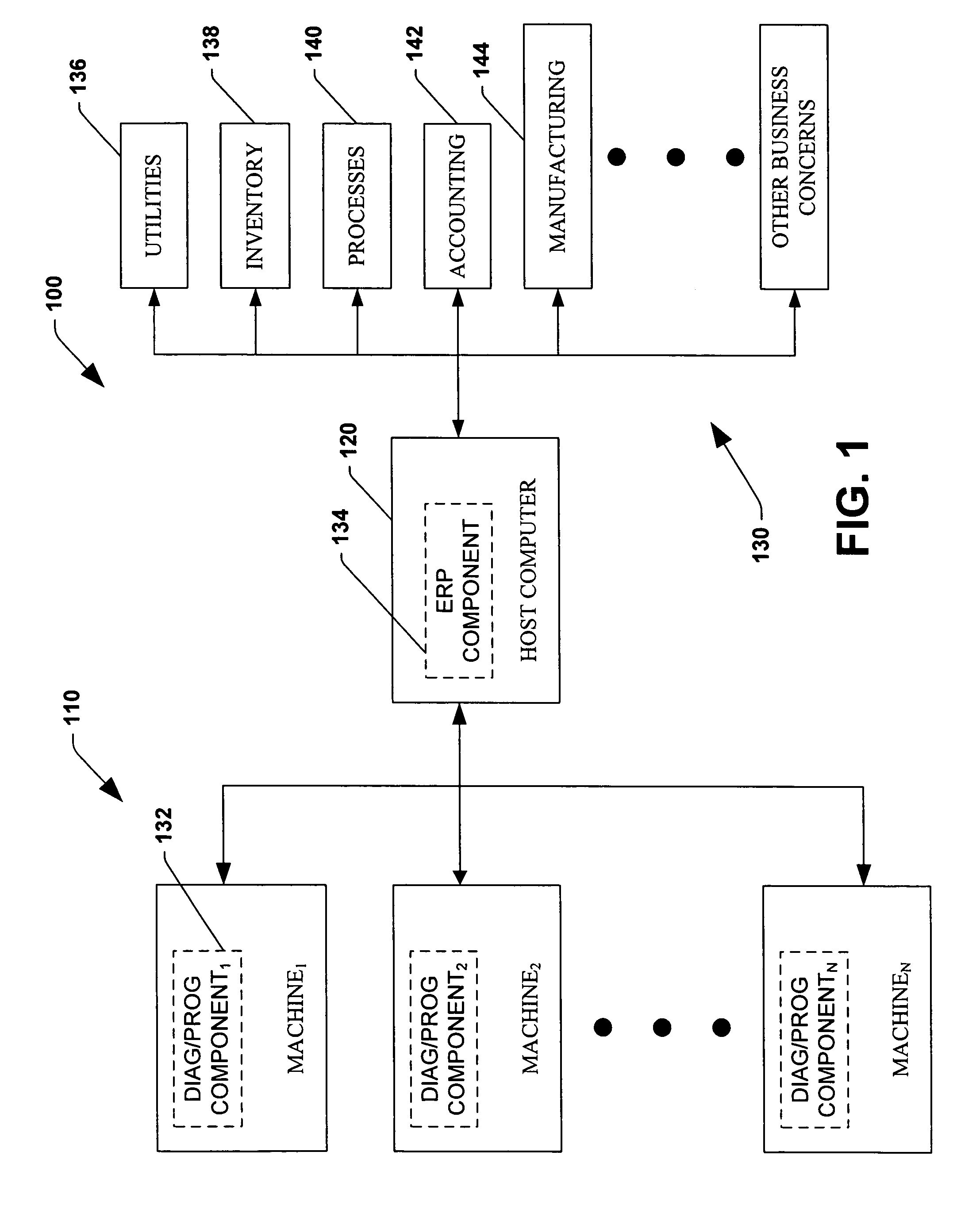

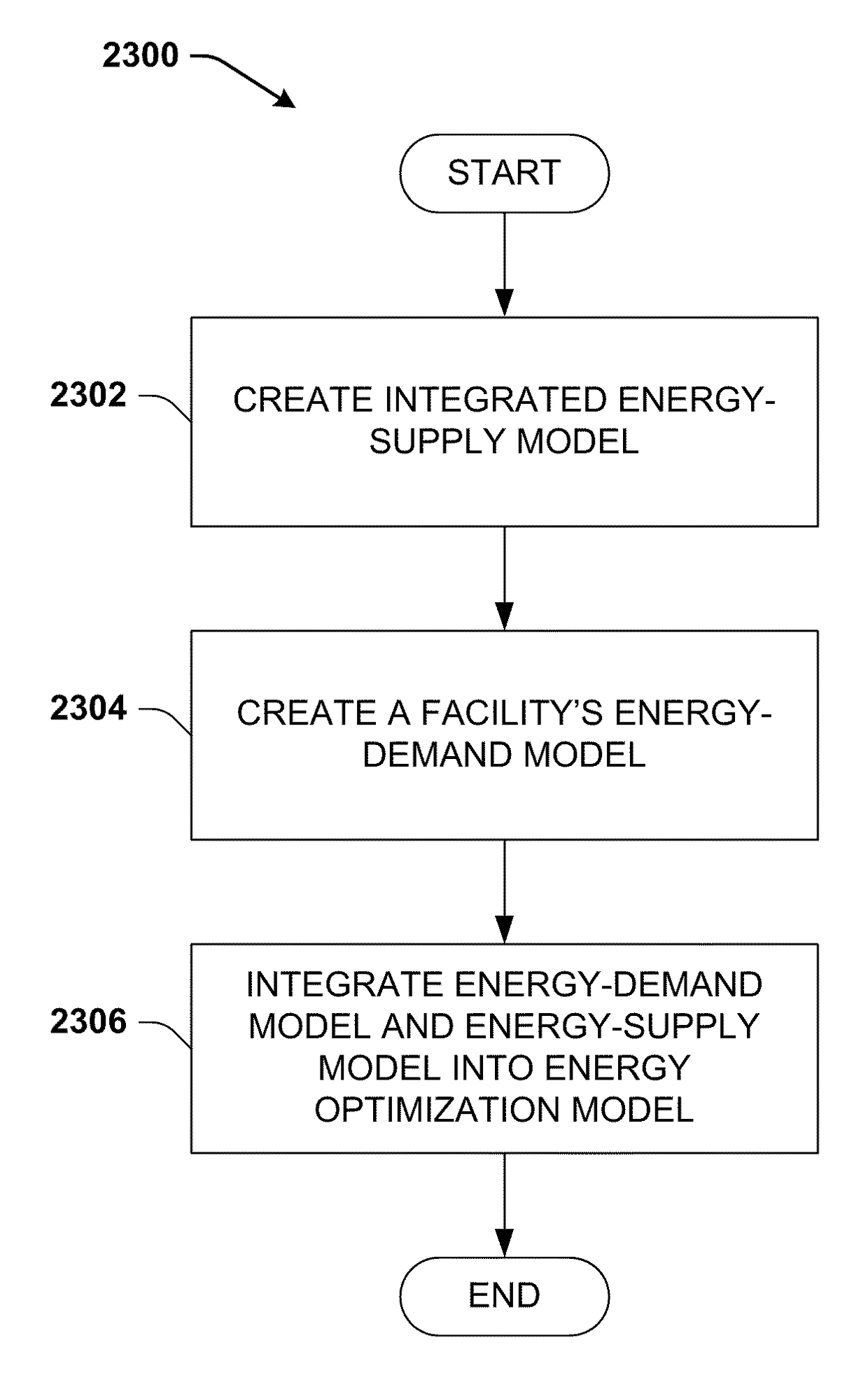

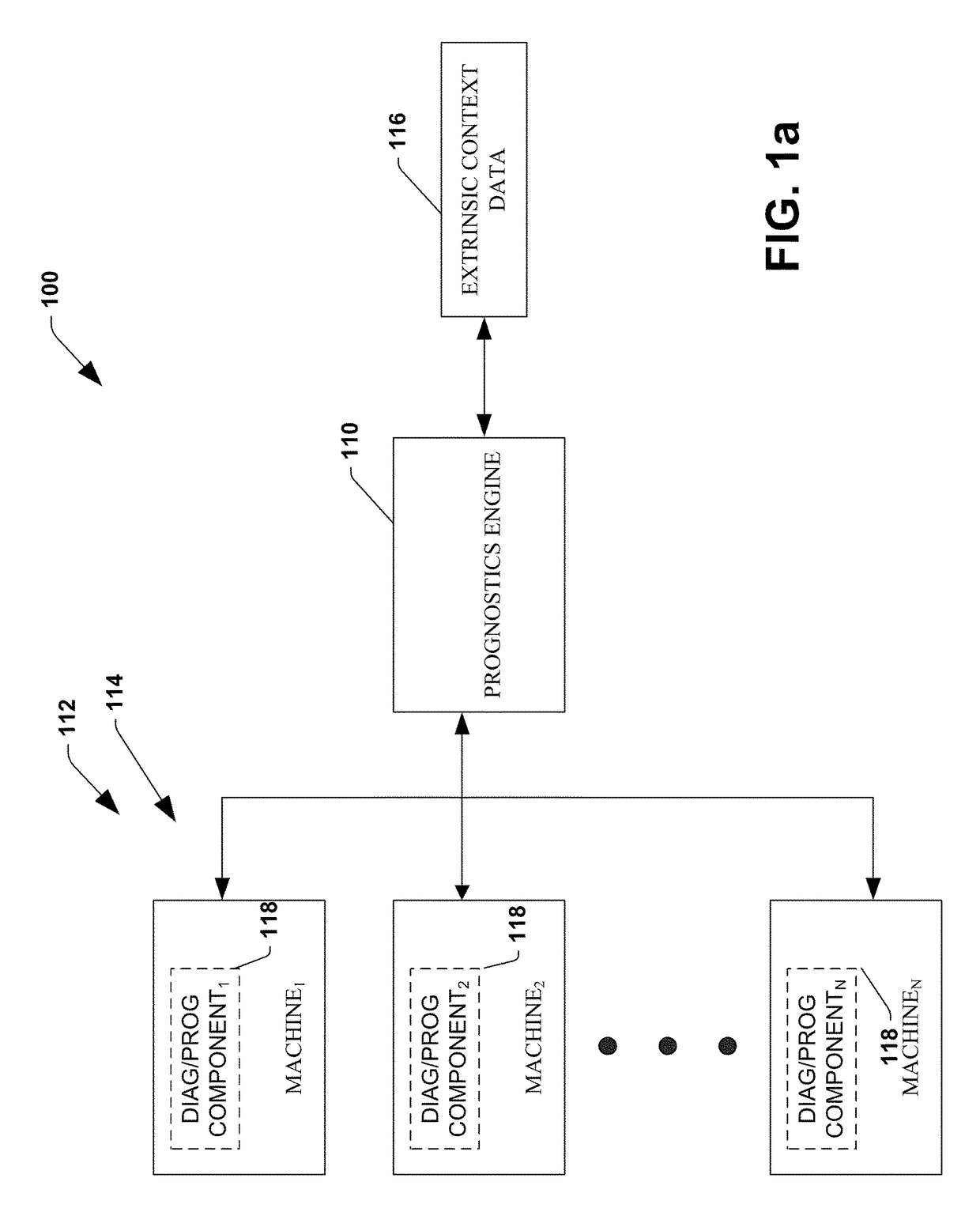

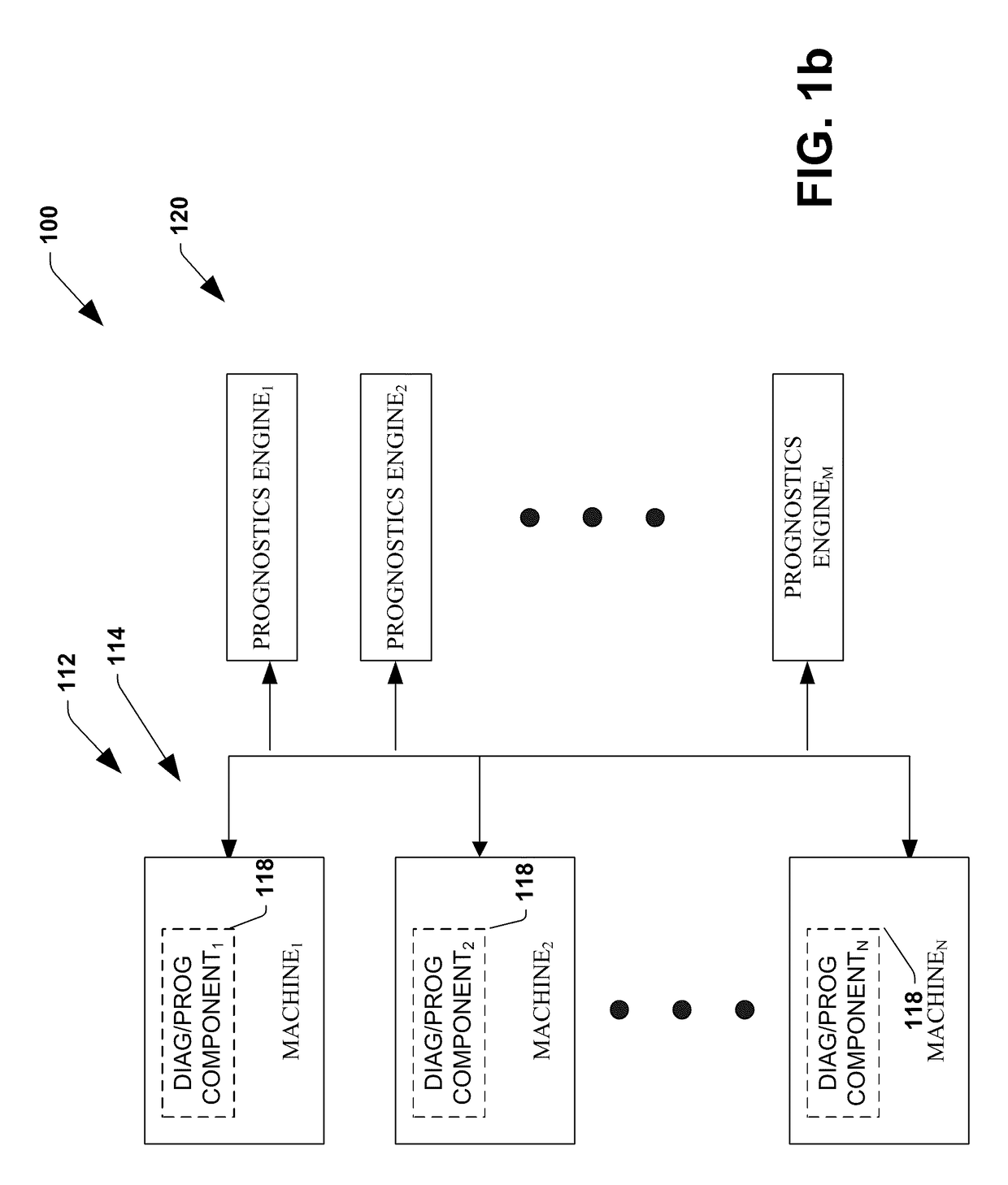

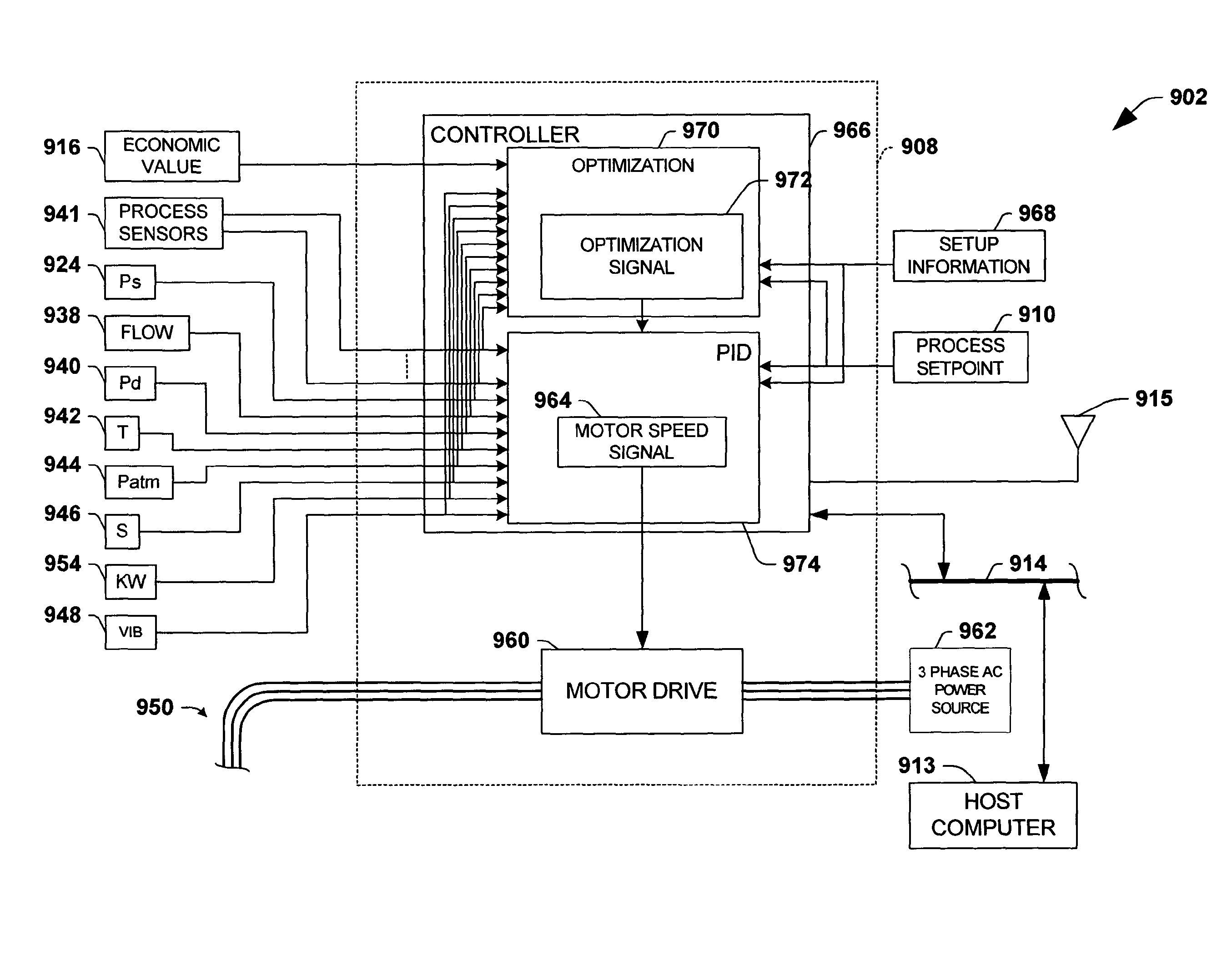

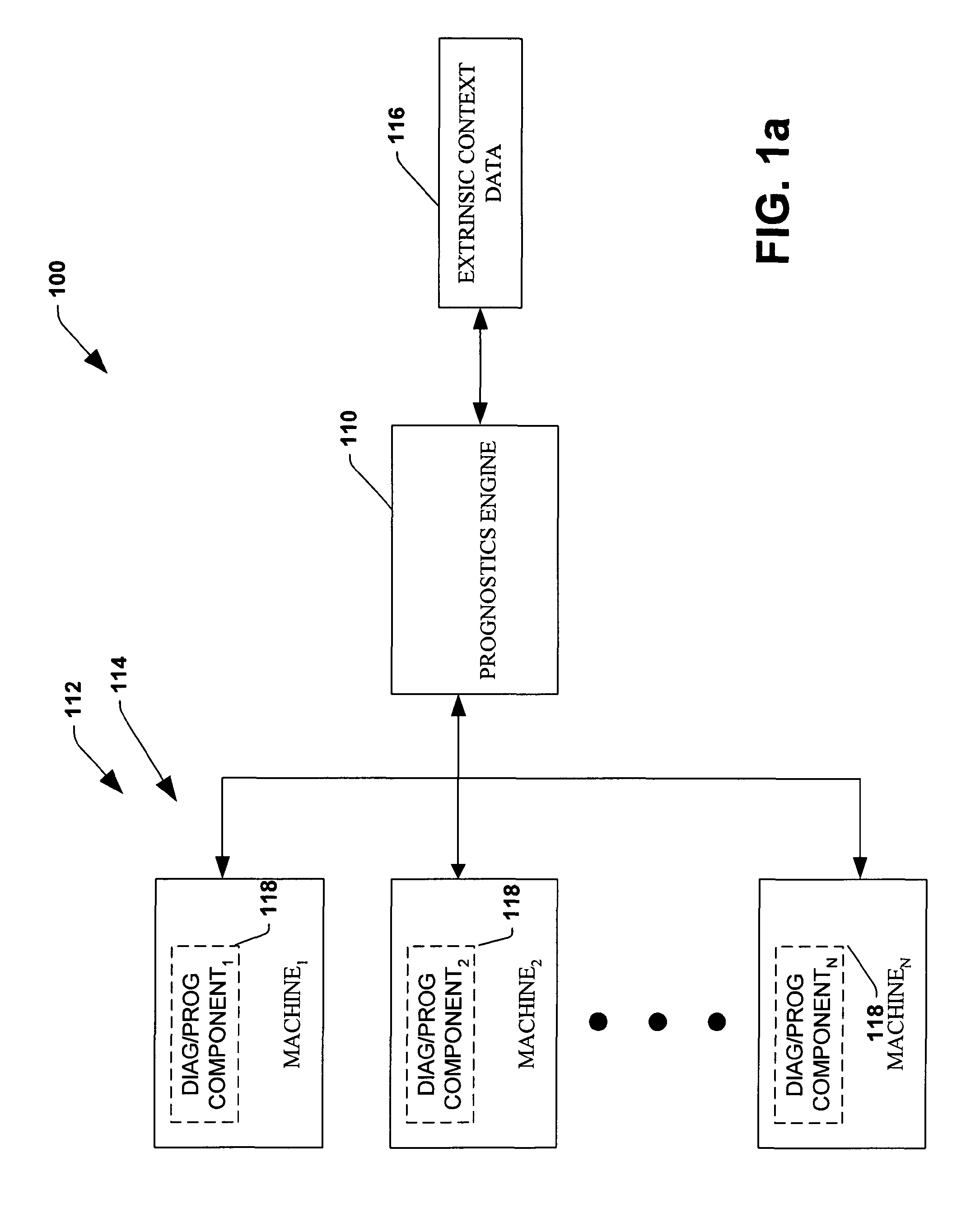

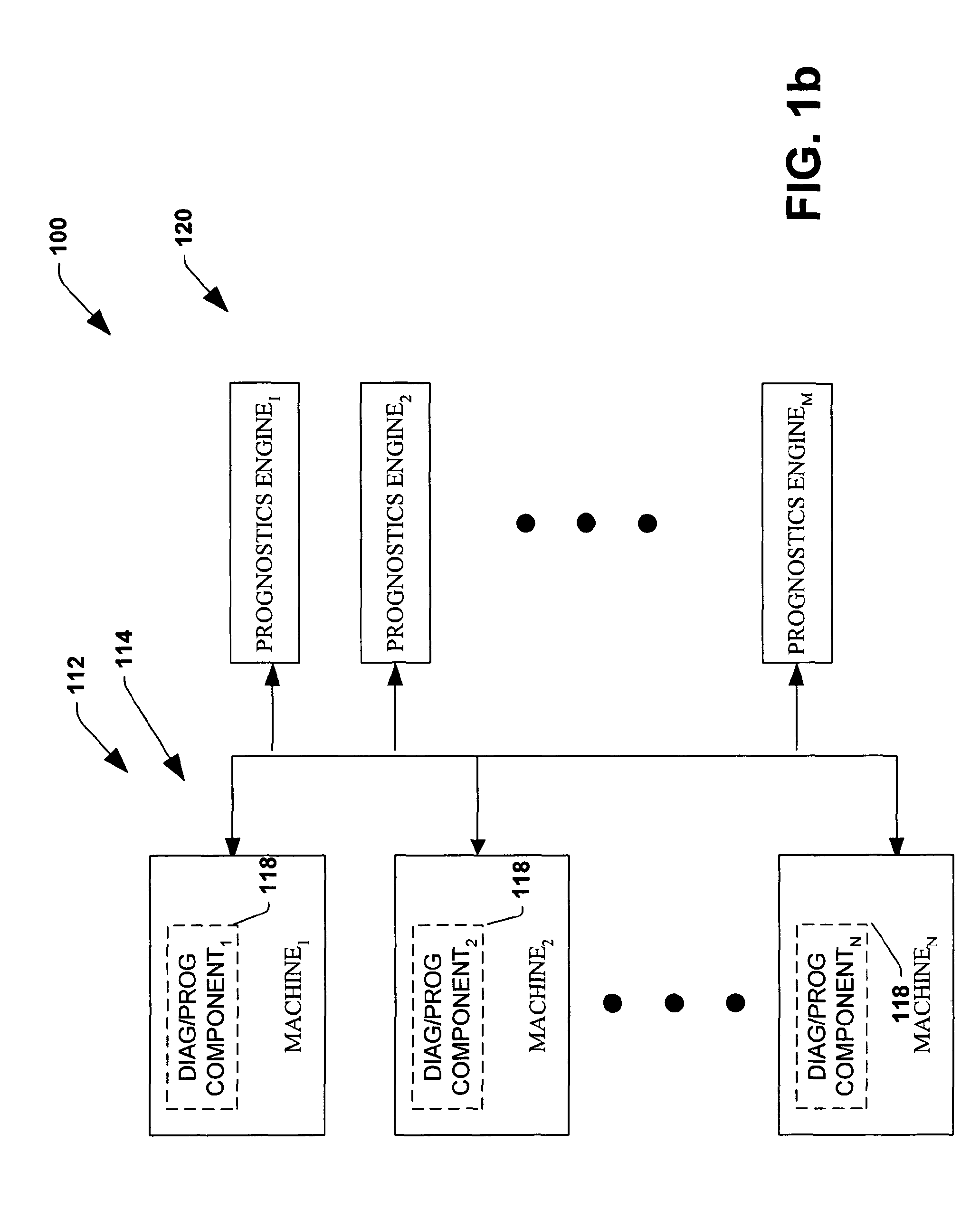

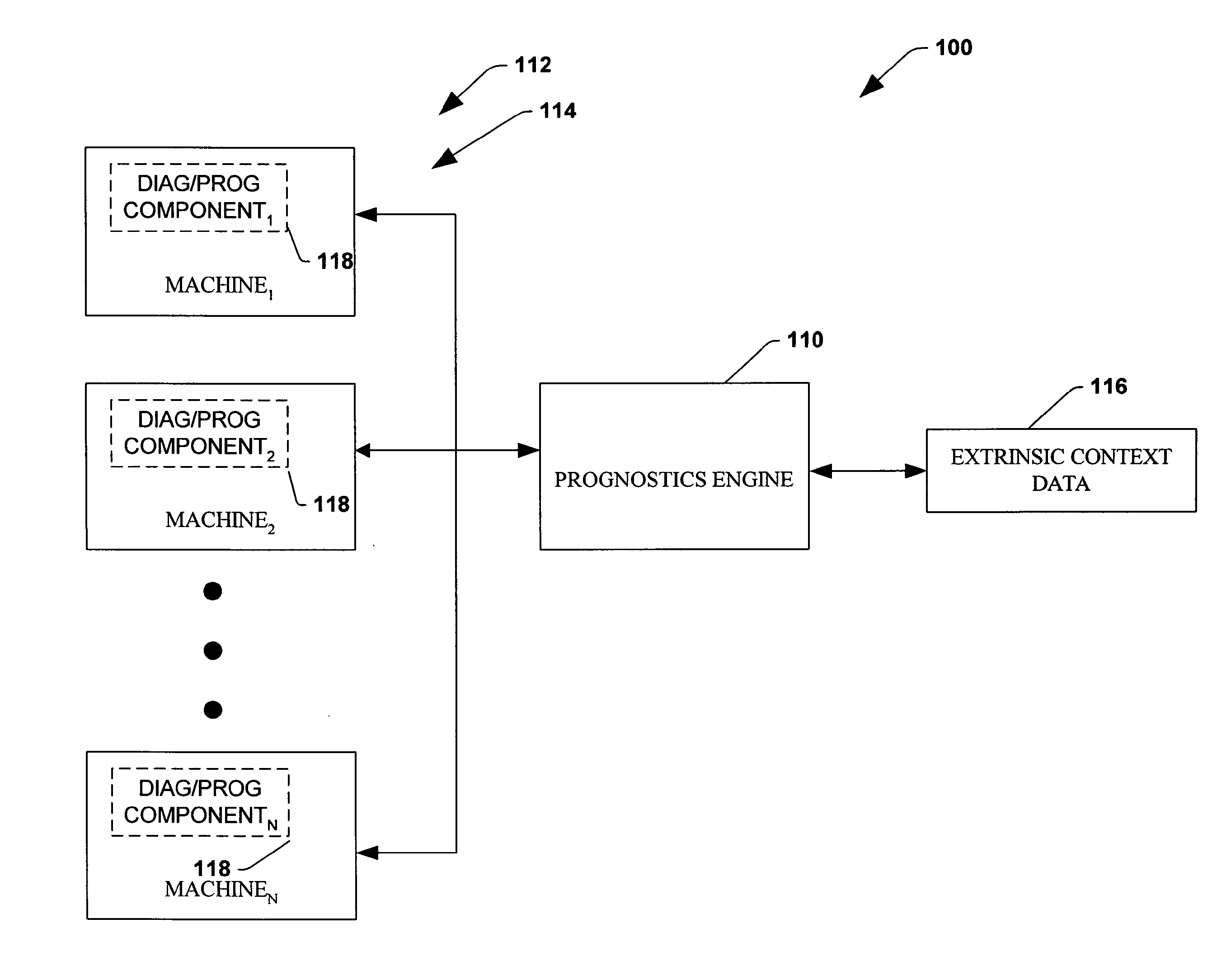

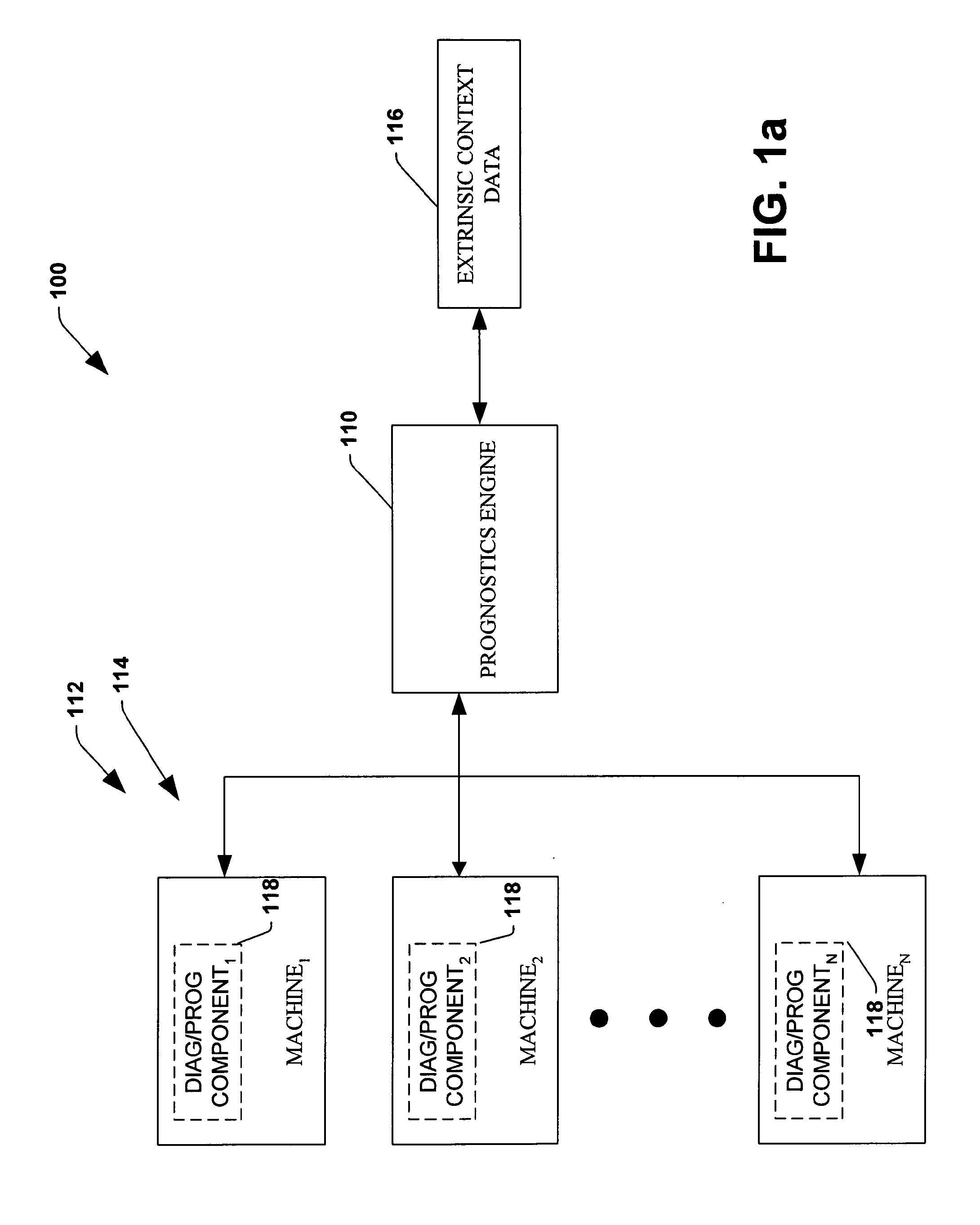

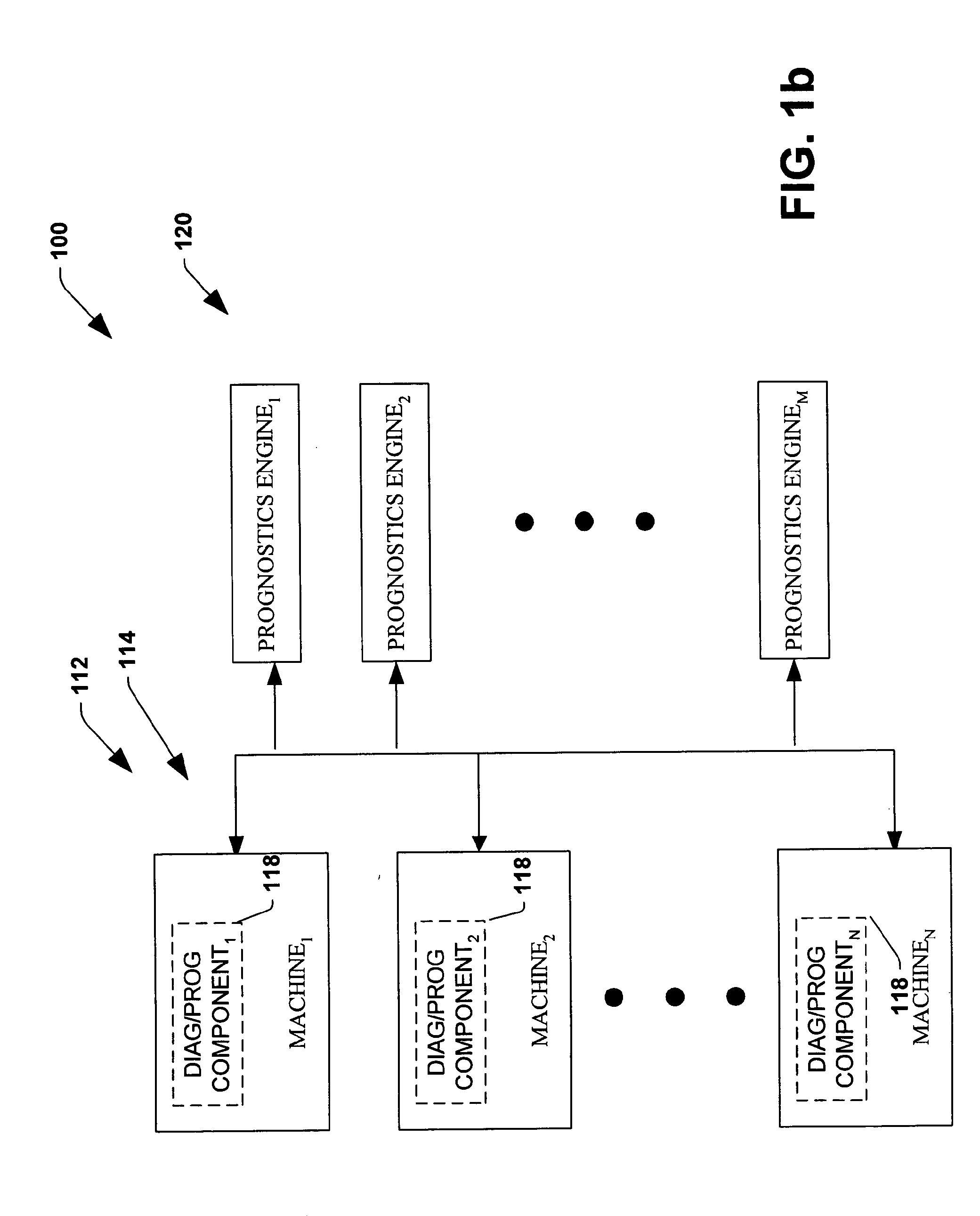

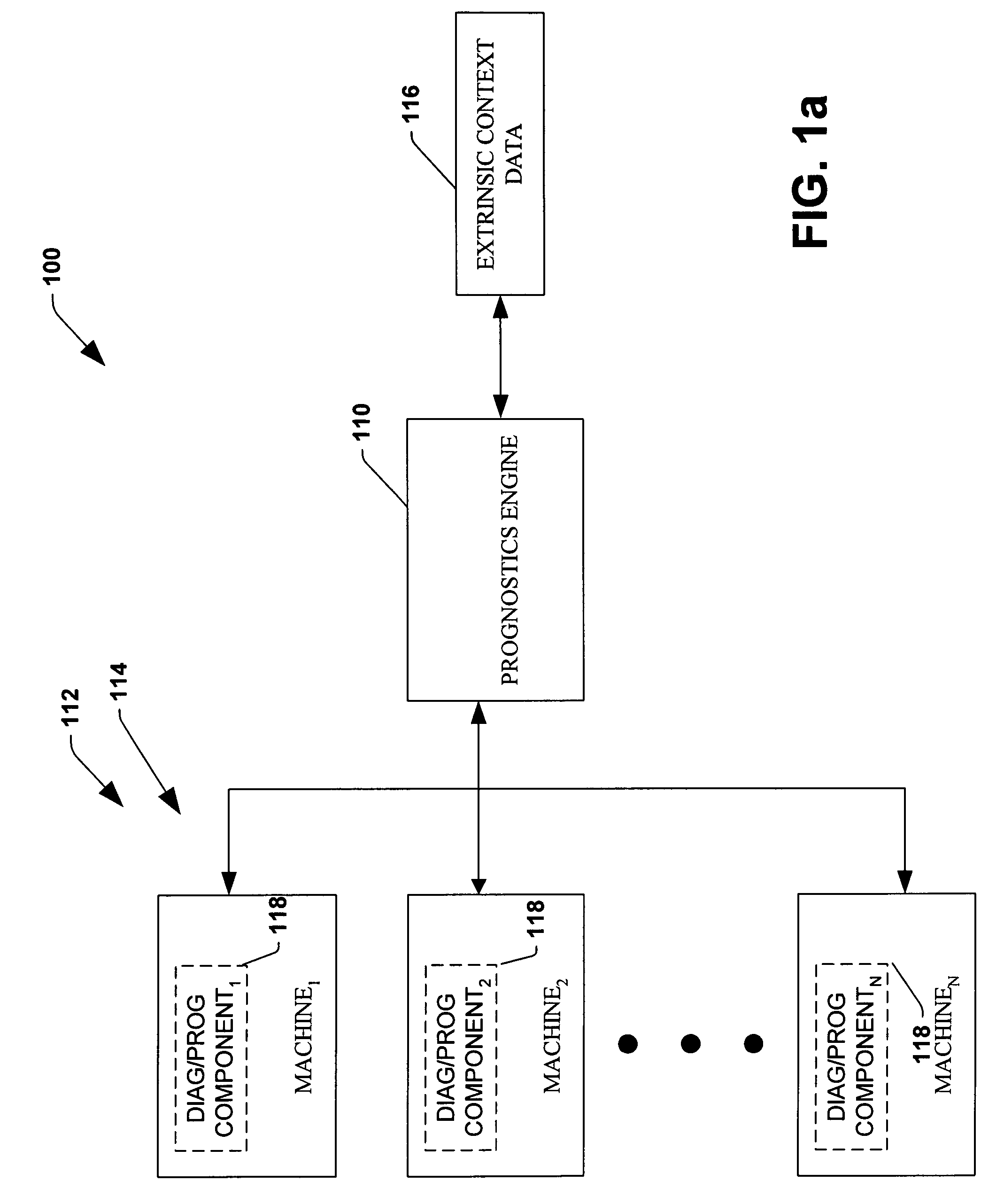

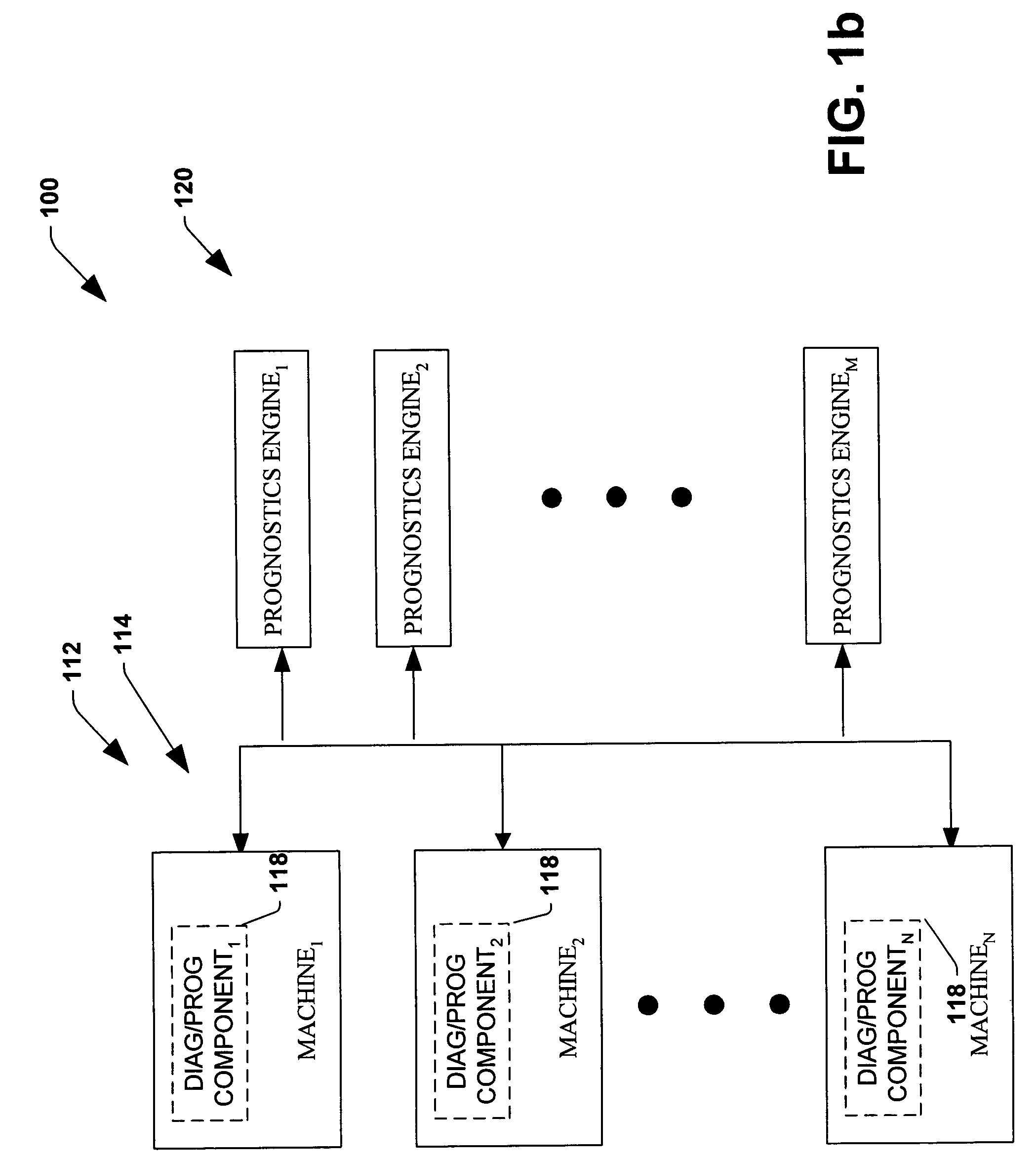

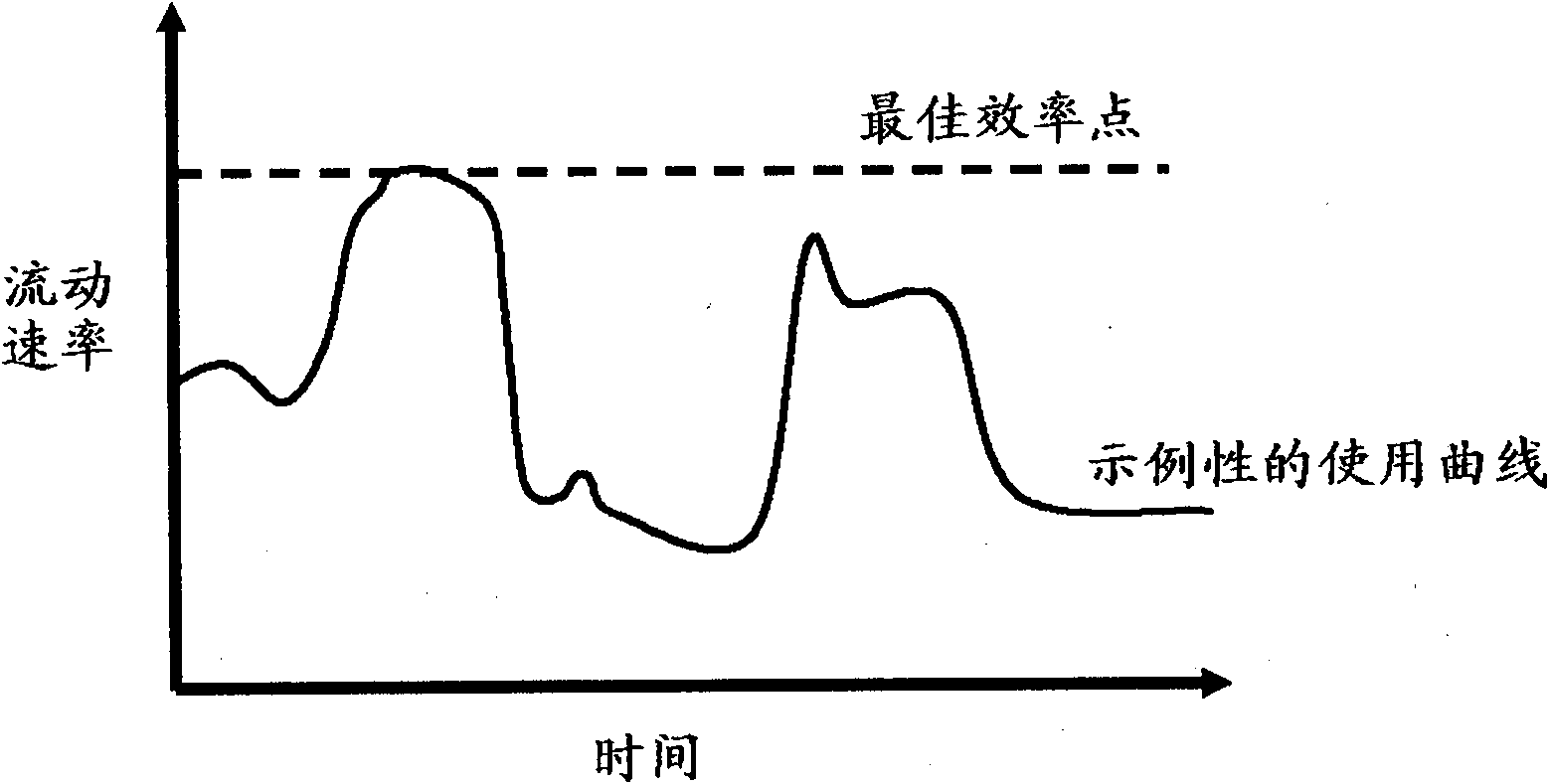

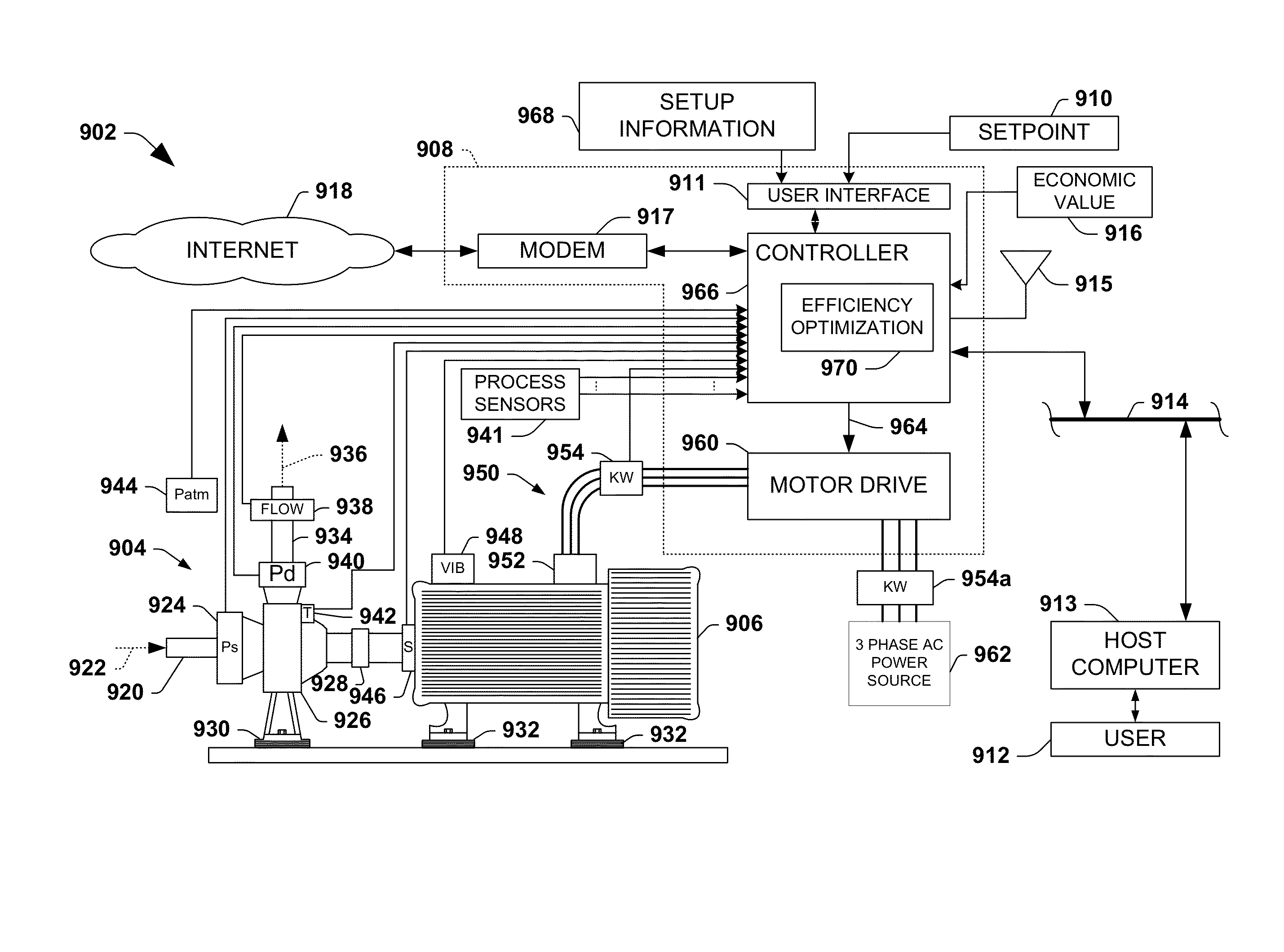

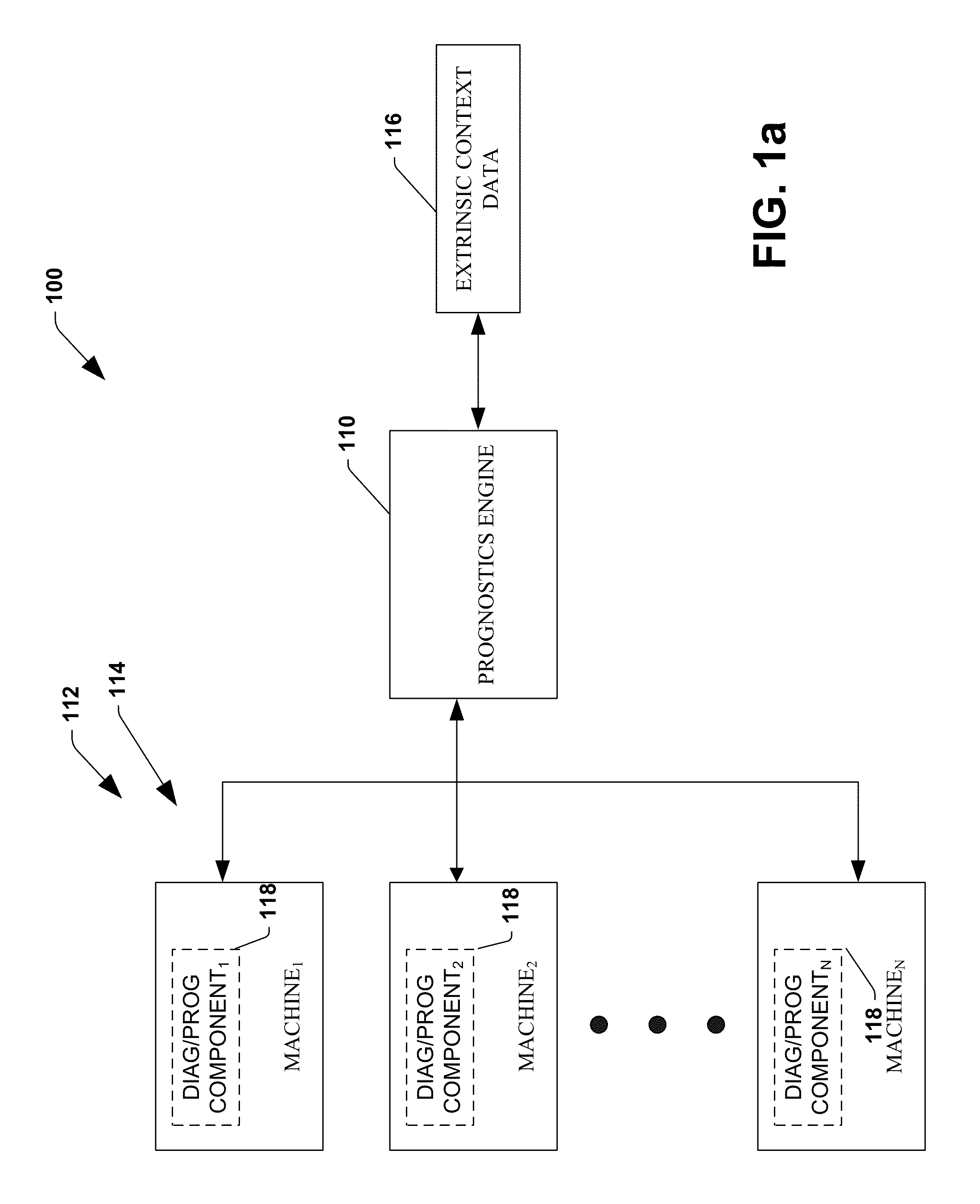

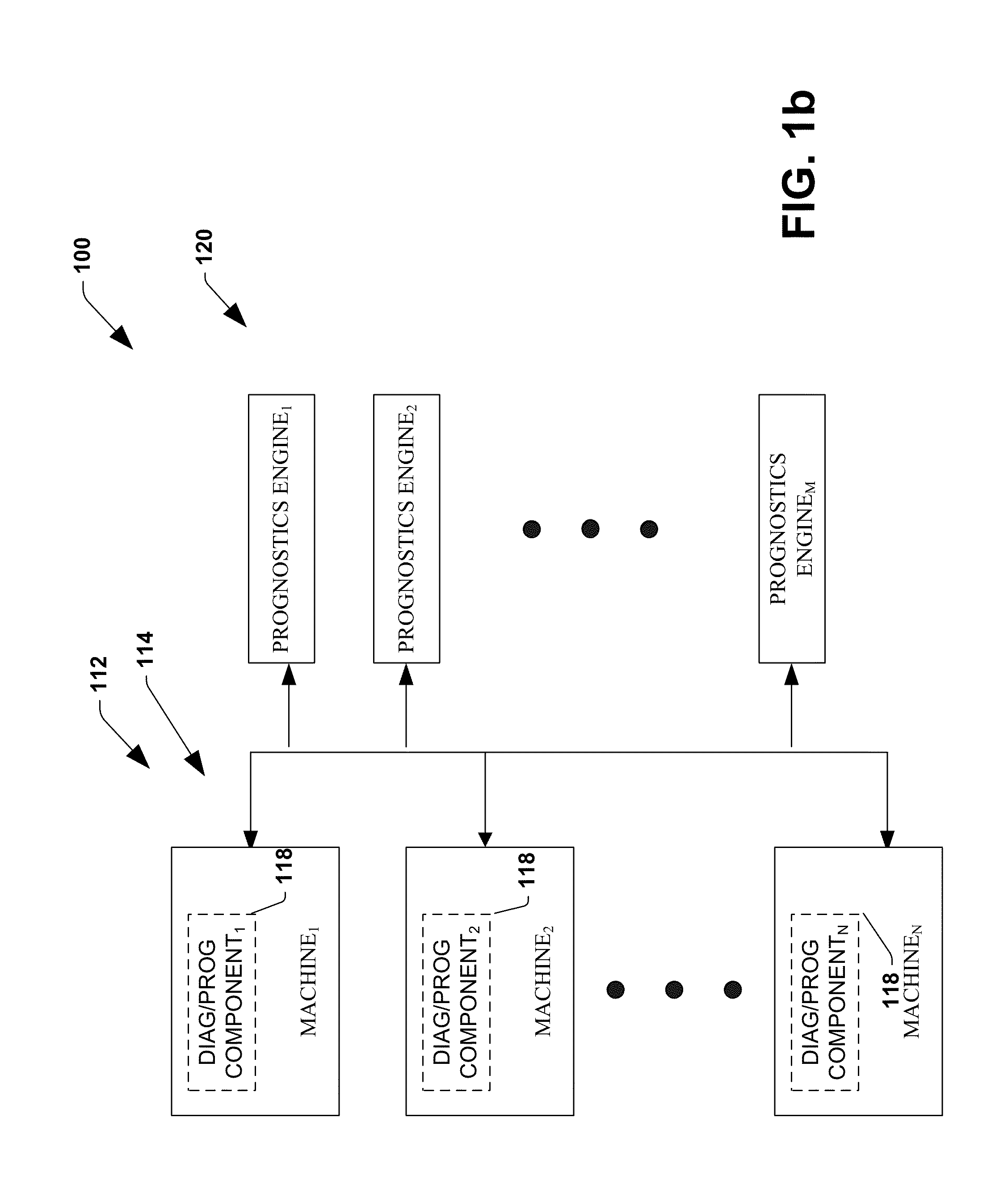

The invention provides control systems and methodologies for controlling a process having computer-controlled equipment, which provide for optimized process performance according to one or more performance criteria, such as efficiency, component life expectancy, safety, emissions, noise, vibration, operational cost, or the like. More particularly, the subject invention provides for employing machine diagnostic and / or prognostic information in connection with optimizing an overall business operation over a time horizon.

Owner:ROCKWELL AUTOMATION TECH

System and method for dynamic multi-objective optimization of machine selection, integration and utilization

InactiveUS6847854B2Improve efficiencyEasy to operateProgramme controlComputer controlMachine selectionOperational costs

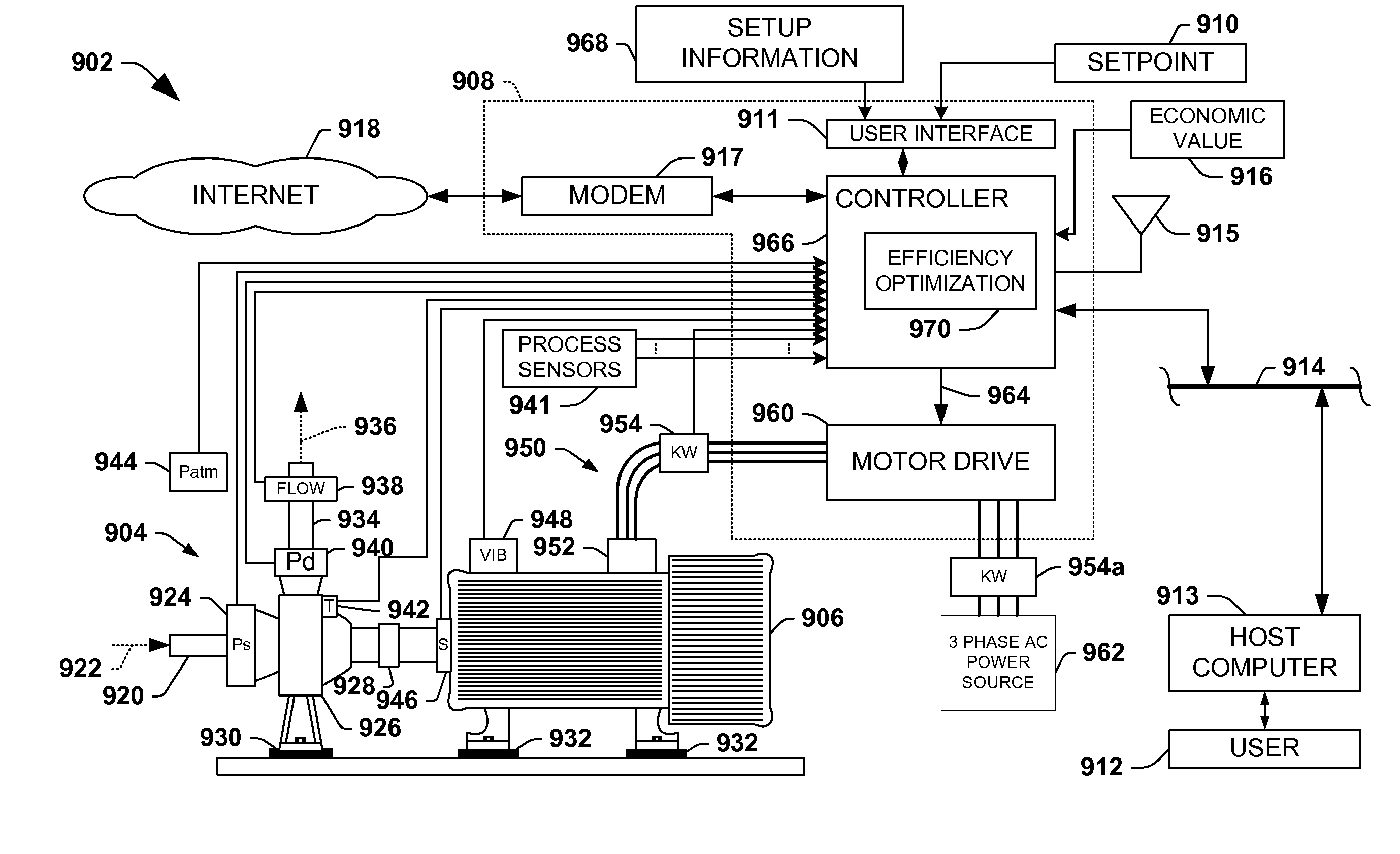

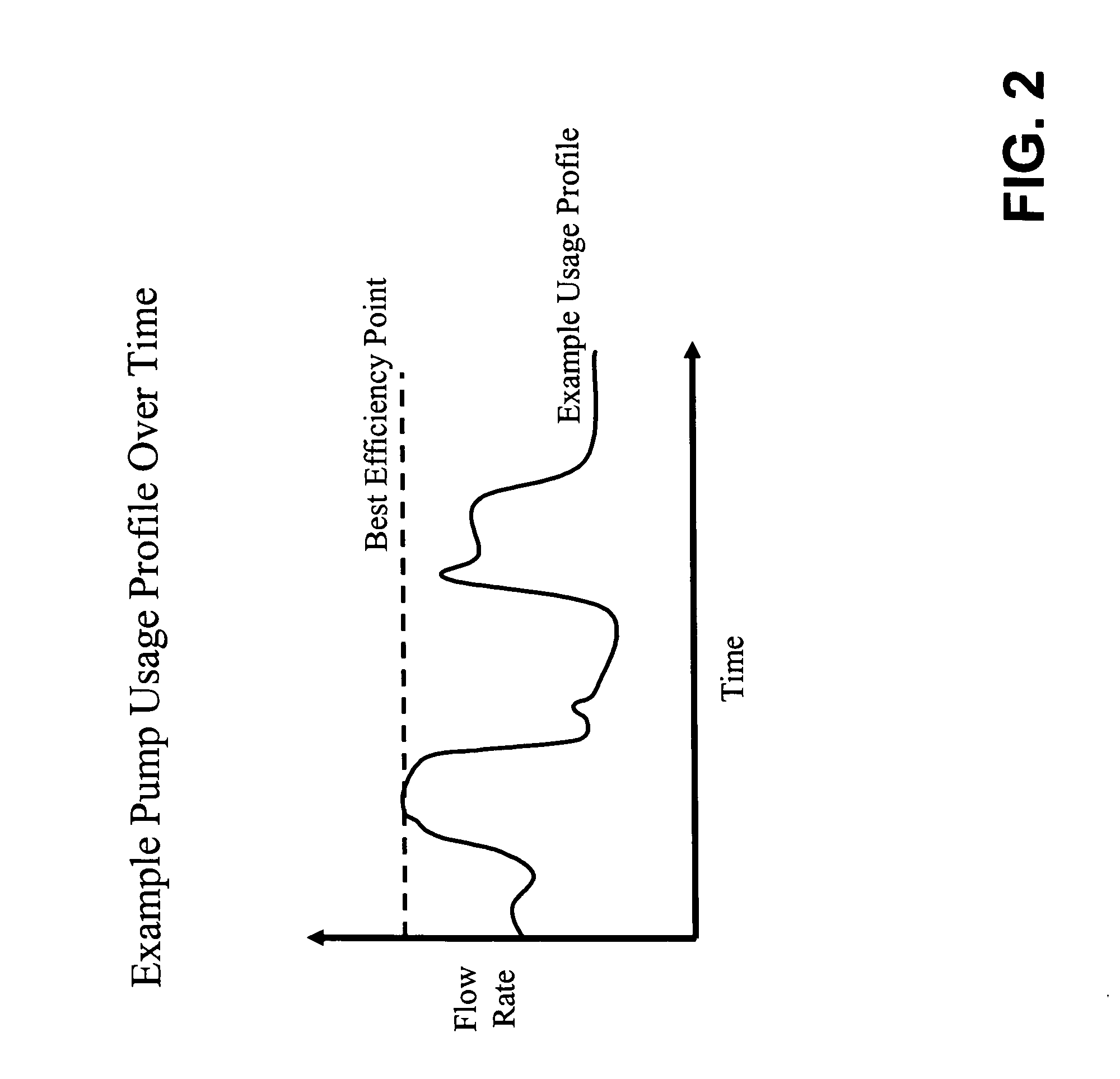

The invention provides control systems and methodologies for controlling a process having one or more motorized pumps and associated motor drives, which provide for optimized process performance according to one or more performance criteria, such as efficiency, component life expectancy, safety, emissions, noise, vibration, operational cost, or the like. More particularly, the subject invention provides for employing machine diagnostic and / or prognostic information in connection with optimizing an overall business operation.

Owner:ROCKWELL AUTOMATION TECH

System and method for dynamic multi-objective optimization of machine selection, integration and utilization

ActiveUS20090204234A1Minimize power consumptionLow costSimulator controlForecastingMachine selectionOperational costs

The invention provides control systems and methodologies for controlling a process having computer-controlled equipment, which provide for optimized process performance according to one or more performance criteria, such as efficiency, component life expectancy, safety, emissions, noise, vibration, operational cost, or the like. More particularly, the subject invention provides for employing machine diagnostic and / or prognostic information in connection with optimizing an overall business operation over a time horizon.

Owner:ROCKWELL AUTOMATION TECH

System and method for dynamic multi-objective optimization of machine selection, integration and utilization

ActiveUS20090204245A1Minimize power consumptionLow costForecastingTechnology managementOperational costsMachine selection

The invention provides control systems and methodologies for controlling a process having computer-controlled equipment, which provide for optimized process performance according to one or more performance criteria, such as efficiency, component life expectancy, safety, emissions, noise, vibration, operational cost, or the like. More particularly, the subject invention provides for employing machine diagnostic and / or prognostic information in connection with optimizing an overall business operation over a time horizon.

Owner:ROCKWELL AUTOMATION TECH

System and method for dynamic multi-objective optimization of machine selection, integration and utilization

InactiveUS20090204237A1Minimize power consumptionLow costForecastingTechnology managementOperational costsMachine selection

The invention provides control systems and methodologies for controlling a process having computer-controlled equipment, which provide for optimized process performance according to one or more performance criteria, such as efficiency, component life expectancy, safety, emissions, noise, vibration, operational cost, or the like. More particularly, the subject invention provides for employing machine diagnostic and / or prognostic information in connection with optimizing an overall business operation over a time horizon.

Owner:ROCKWELL AUTOMATION TECH

System and method for dynamic multi-objective optimization of machine selection, integration and utilization

InactiveUS7050873B1Improve efficiencyEasy to modifyProgramme controlComputer controlOperational costsMotor drive

The invention provides control systems and methodologies for controlling a process having one or more motorized pumps and associated motor drives, which provide for optimized process performance according to one or more performance criteria, such as efficiency, component life expectancy, safety, emissions, noise, vibration, operational cost, or the like. More particularly, the subject invention provides for employing machine diagnostic and / or prognostic information in connection with optimizing an overall business operation.

Owner:ROCKWELL AUTOMATION TECH

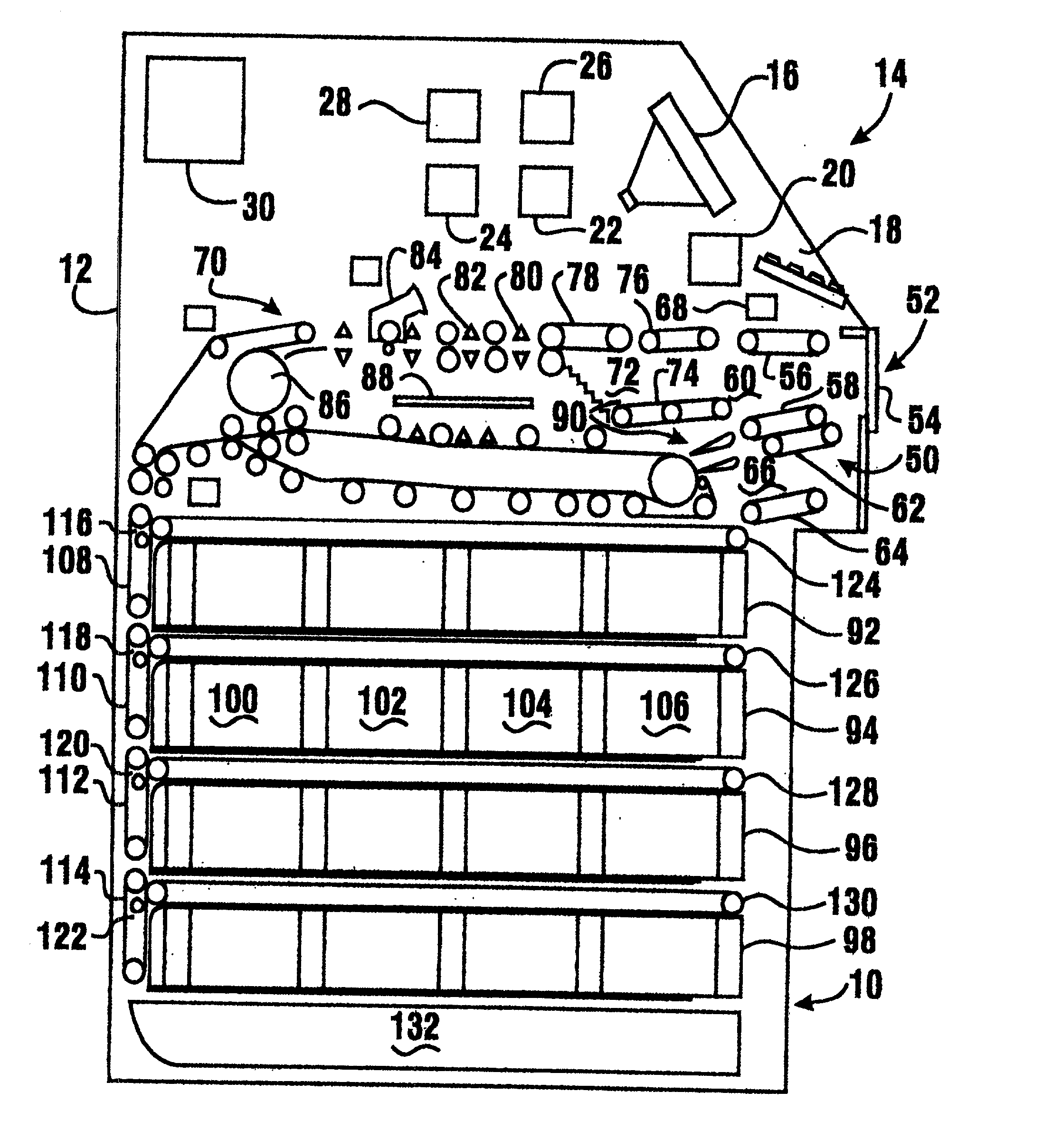

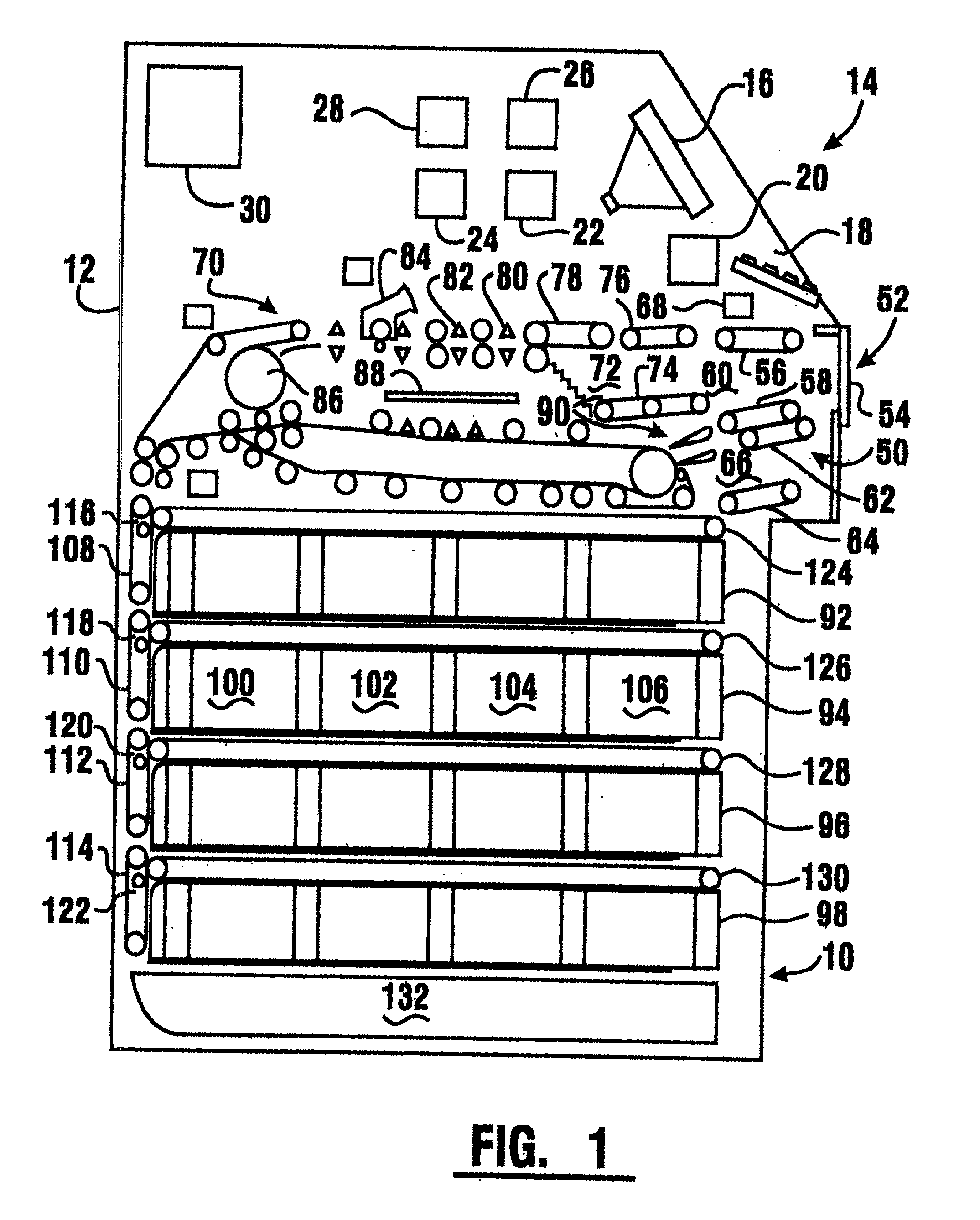

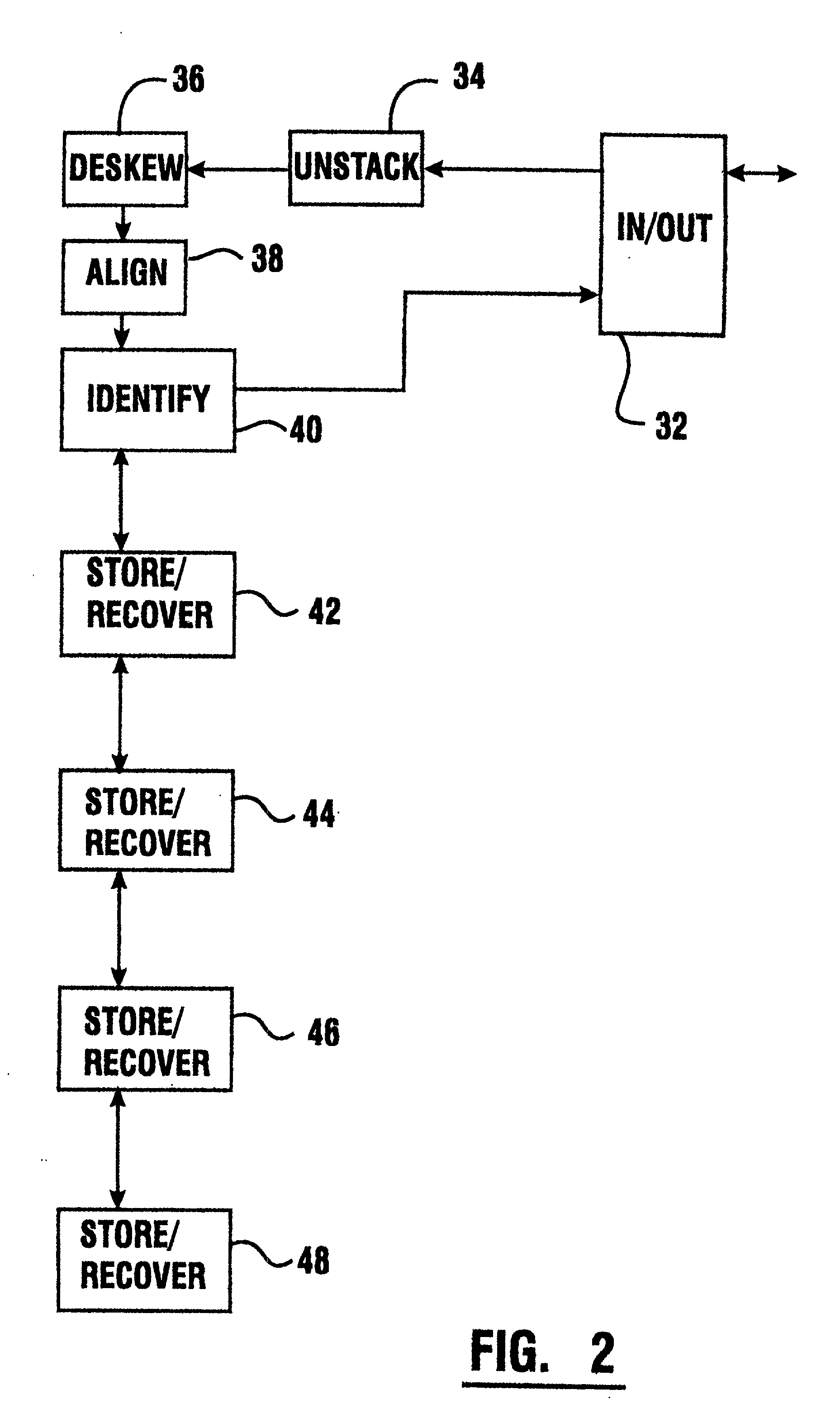

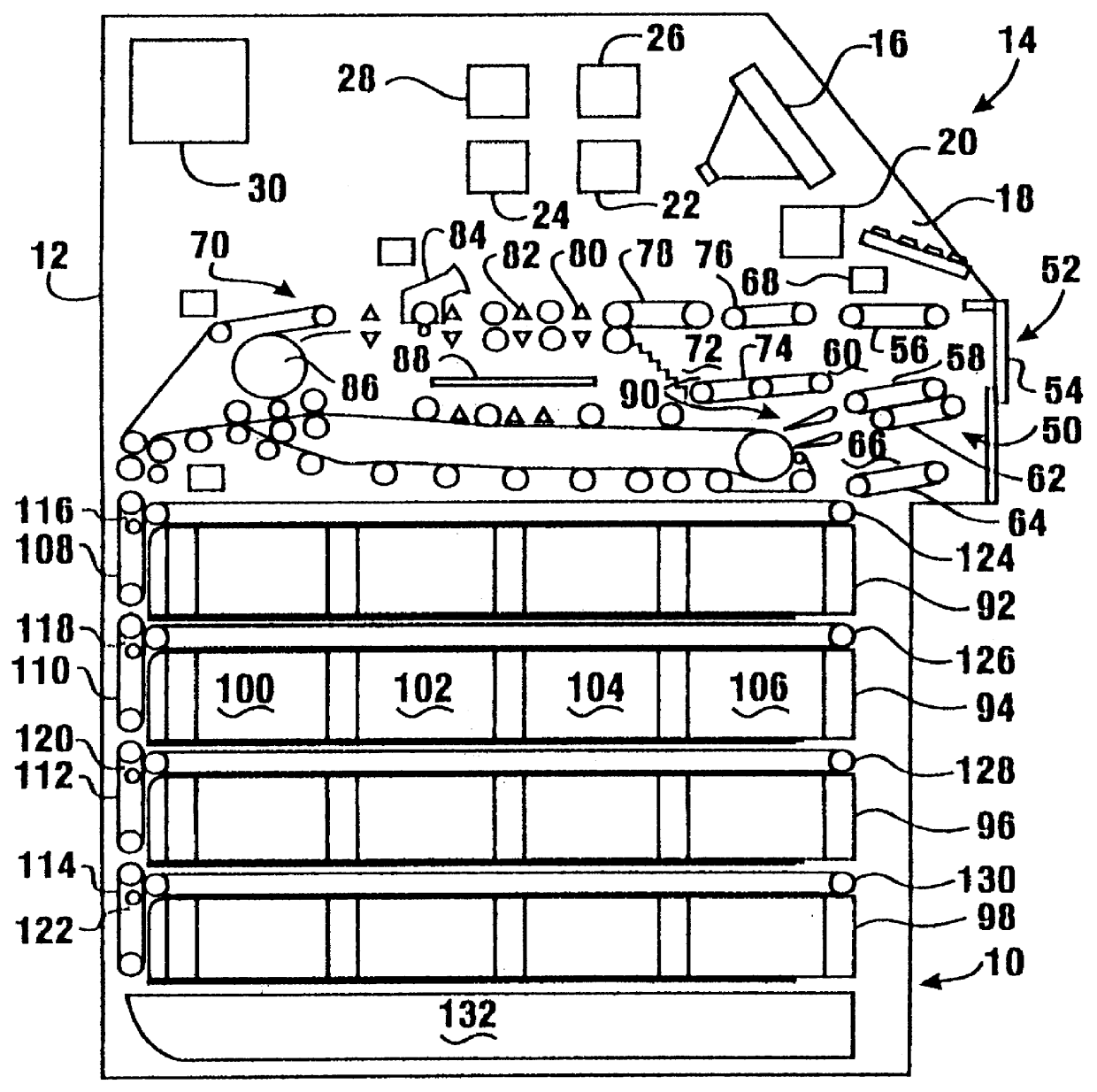

Automated banking machine with self auditing capabilities and system

InactiveUS6109522AEasy to operateRisk minimizationPayment architectureSpecial data processing applicationsMachine selectionDocumentation

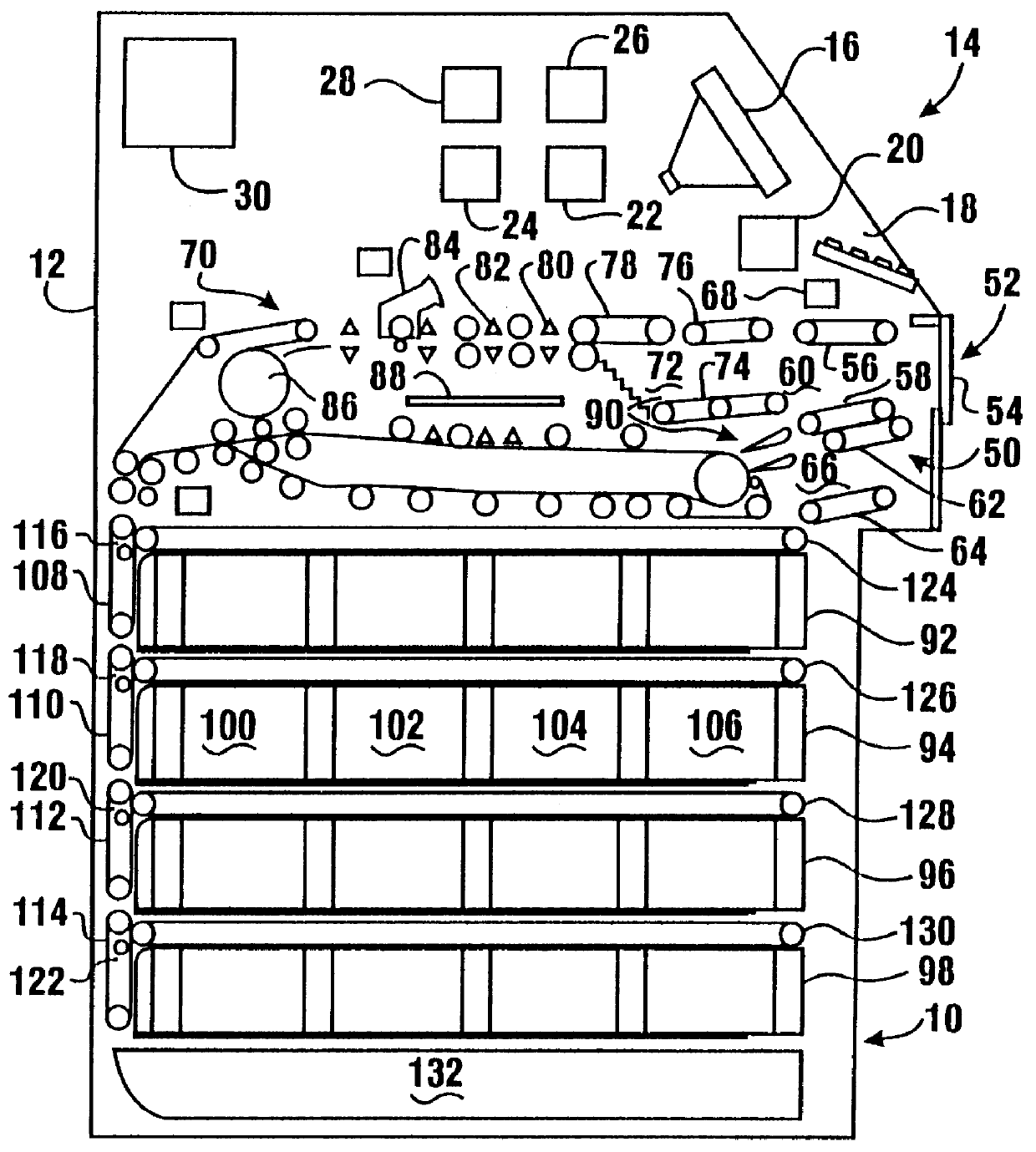

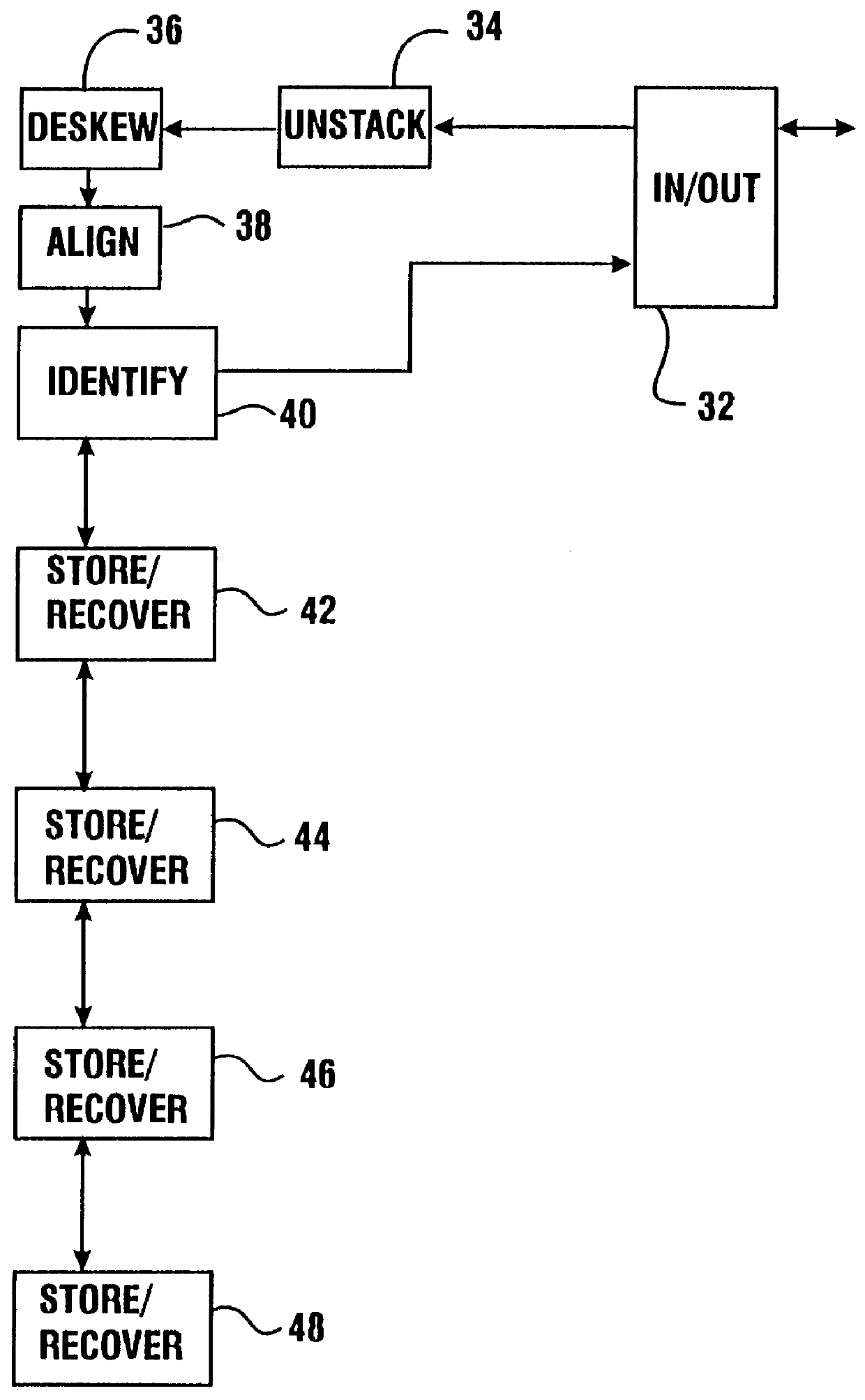

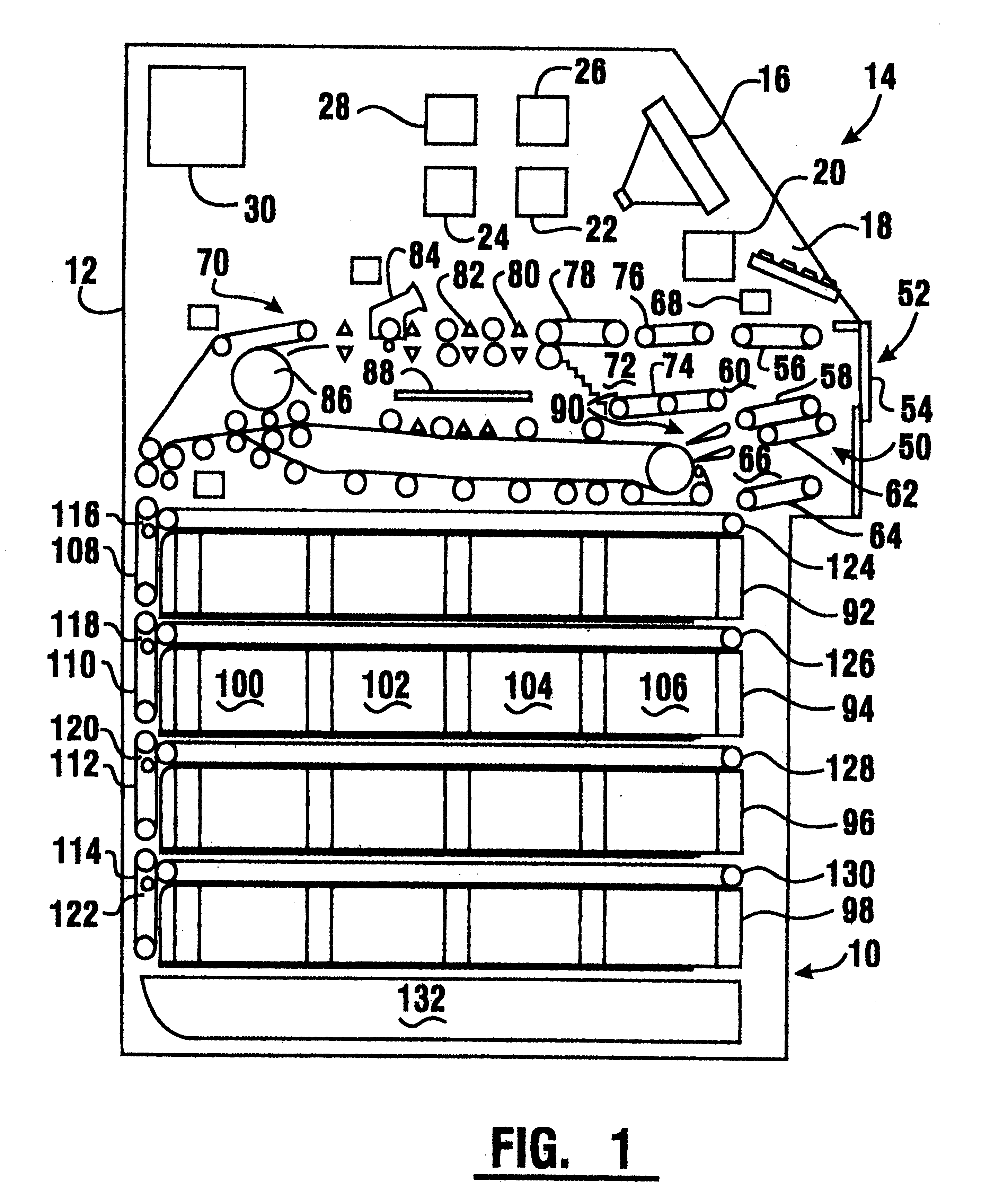

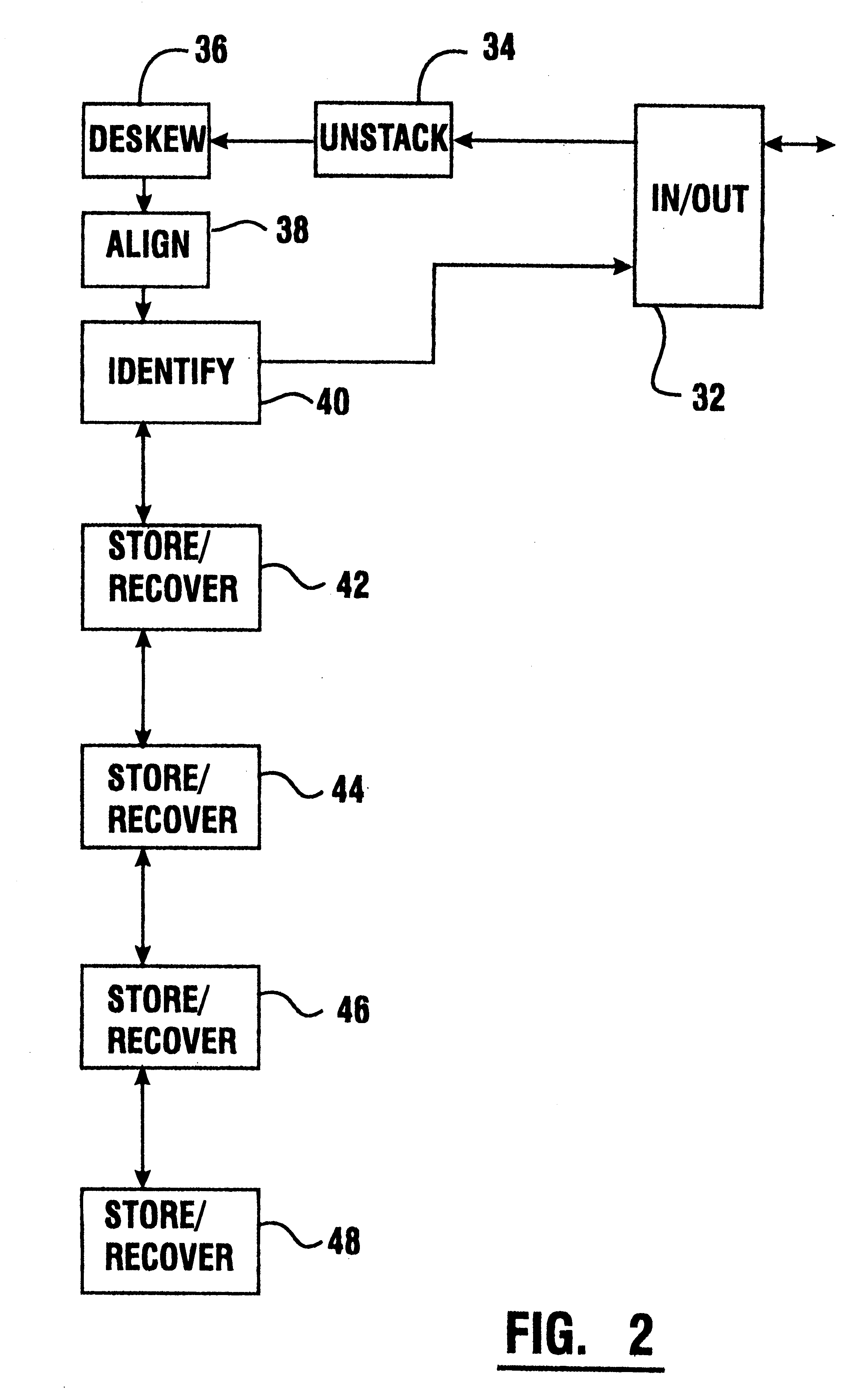

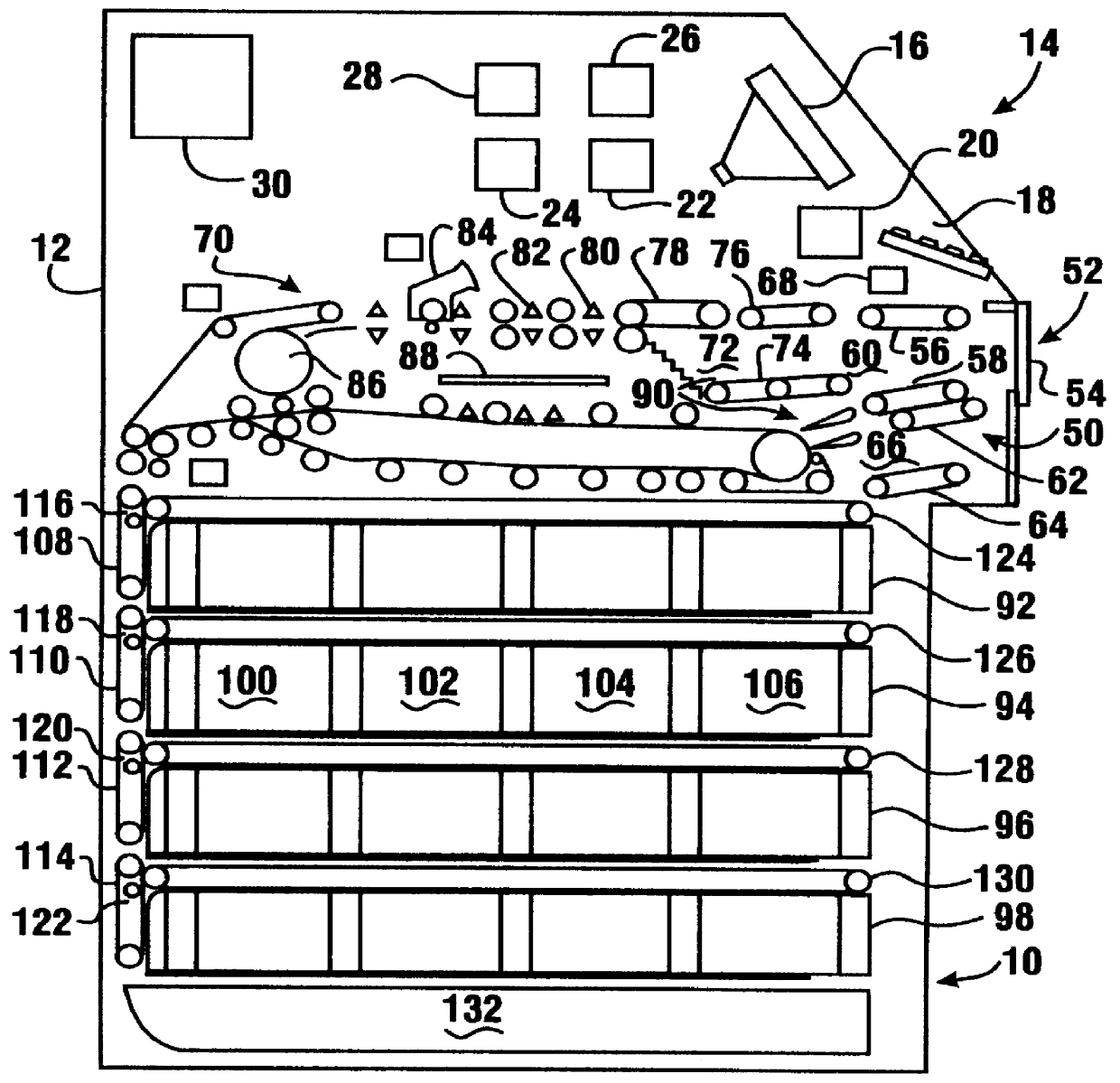

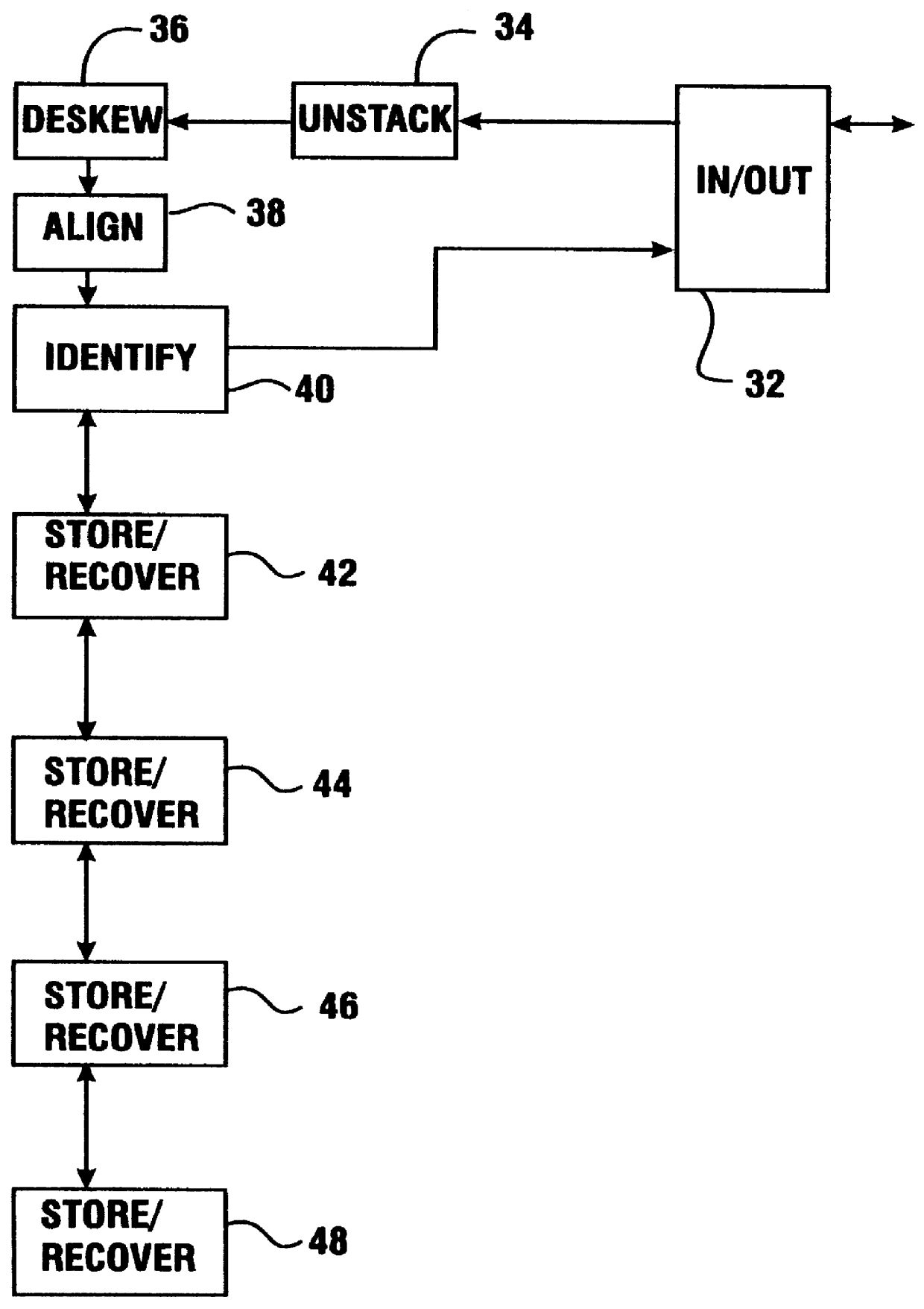

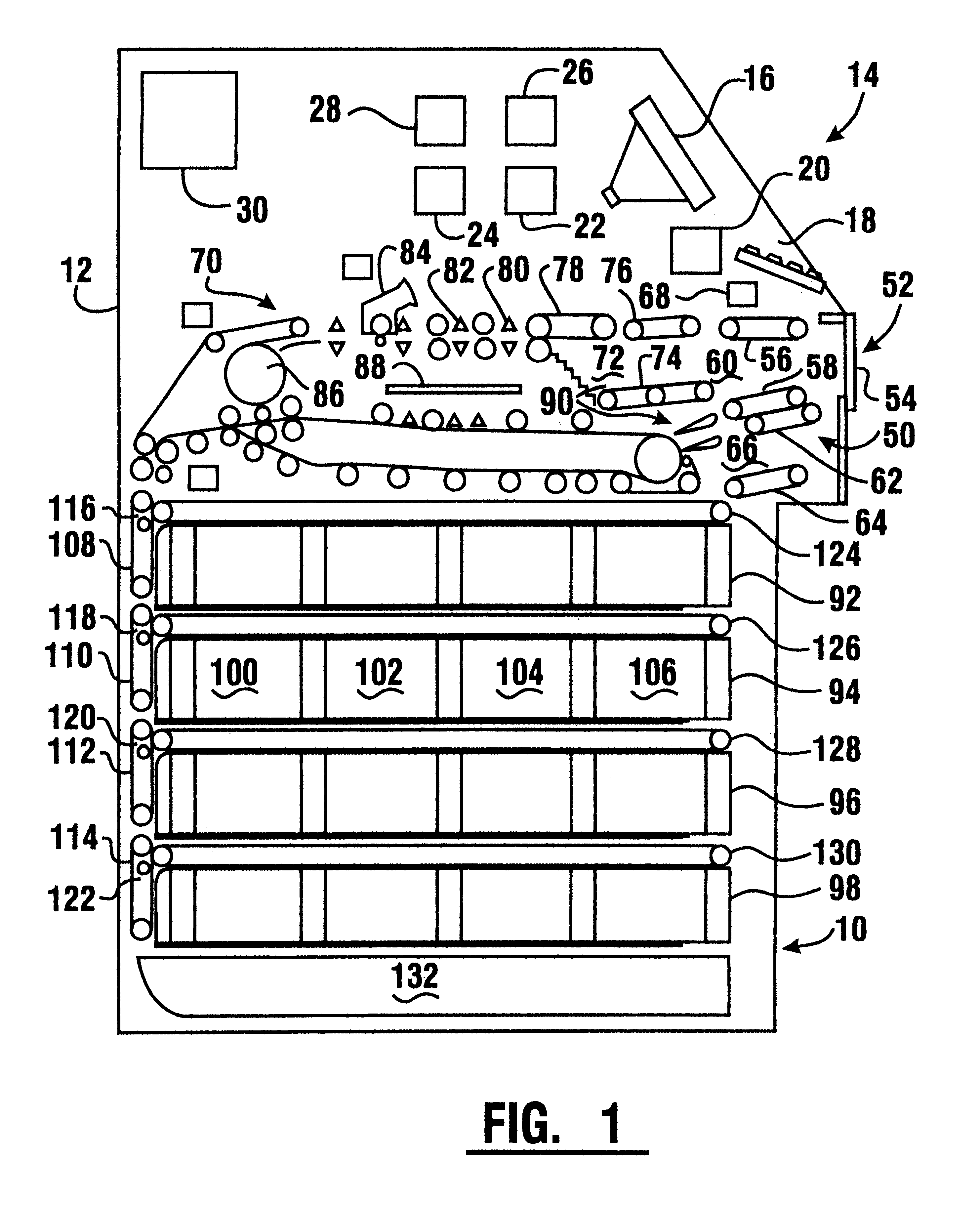

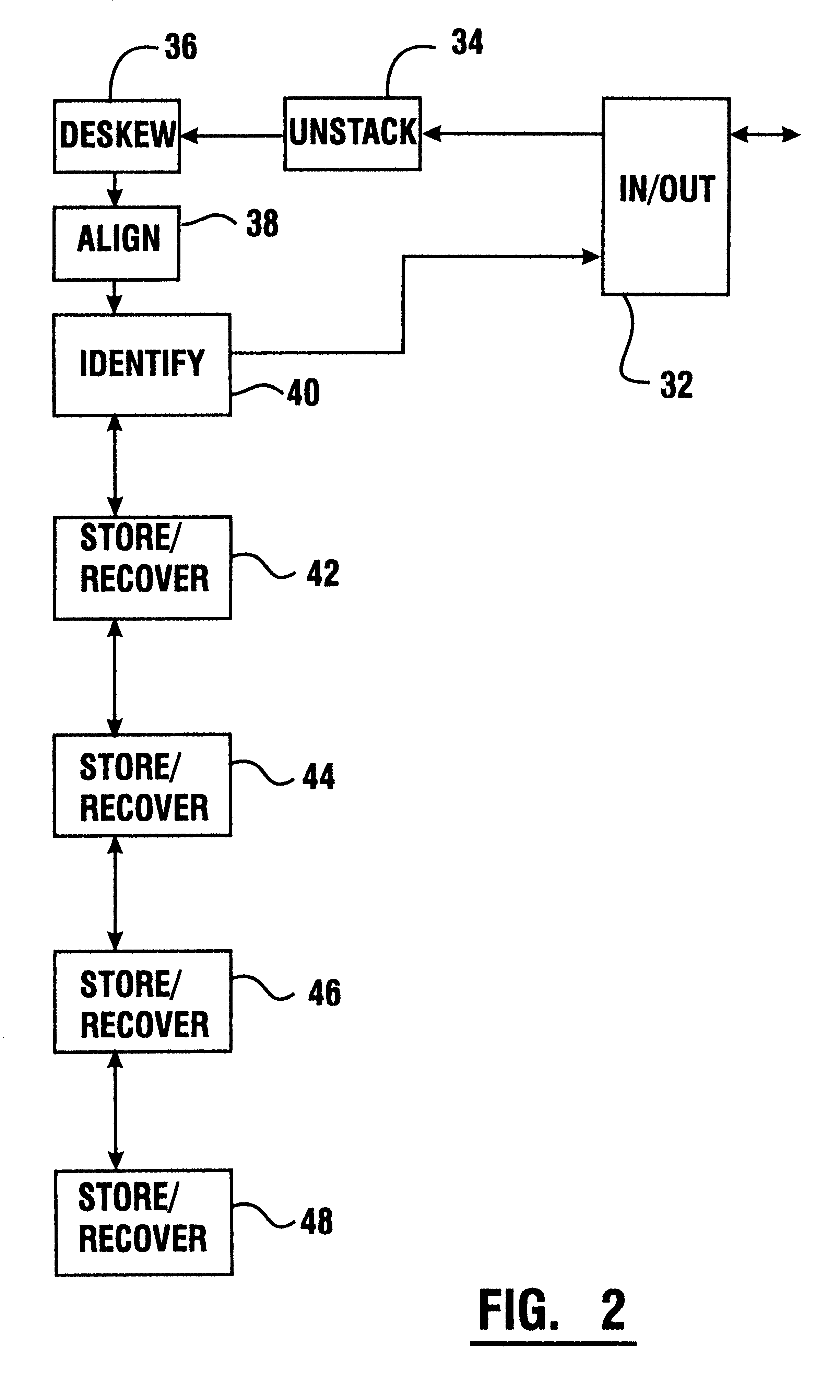

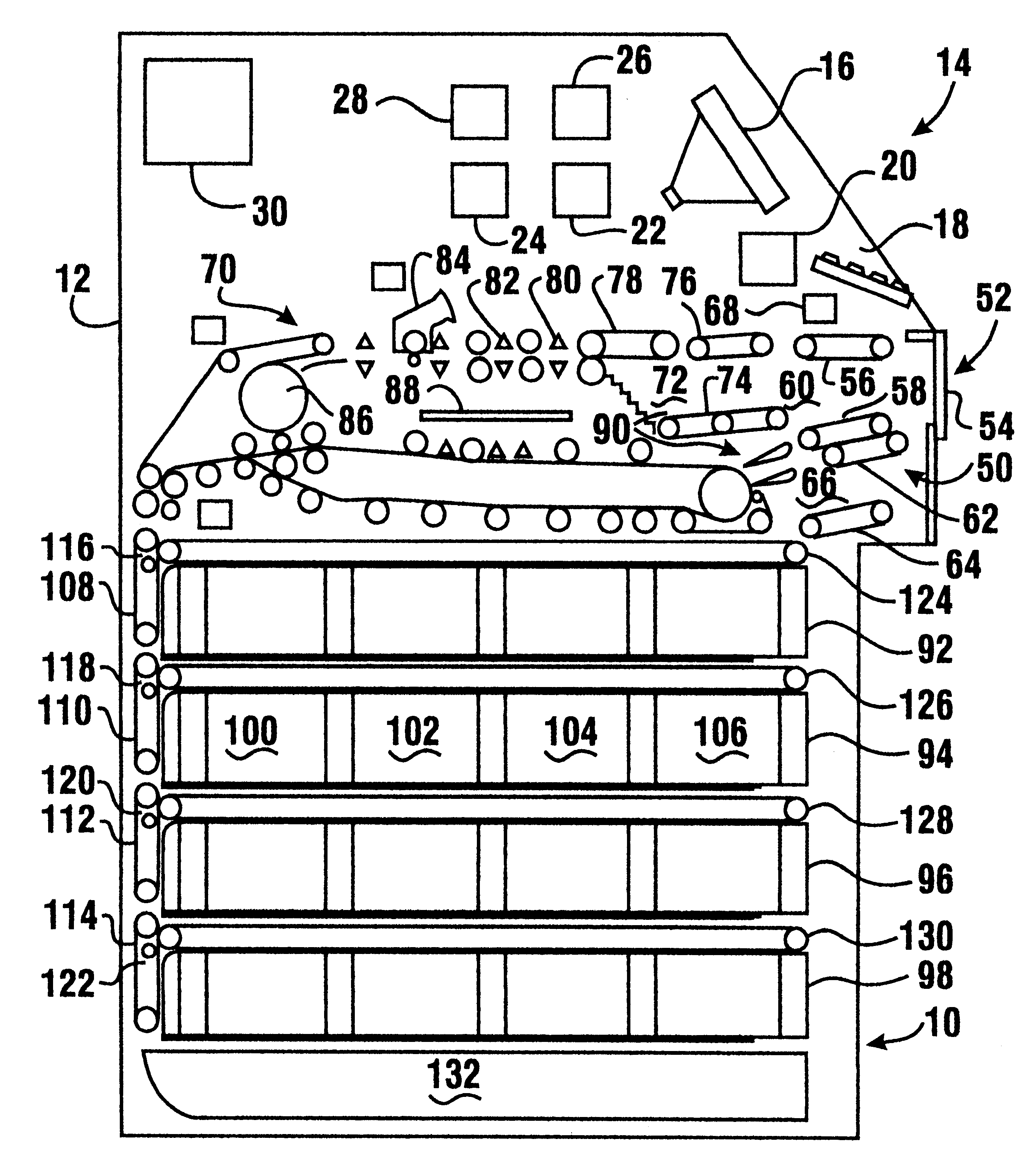

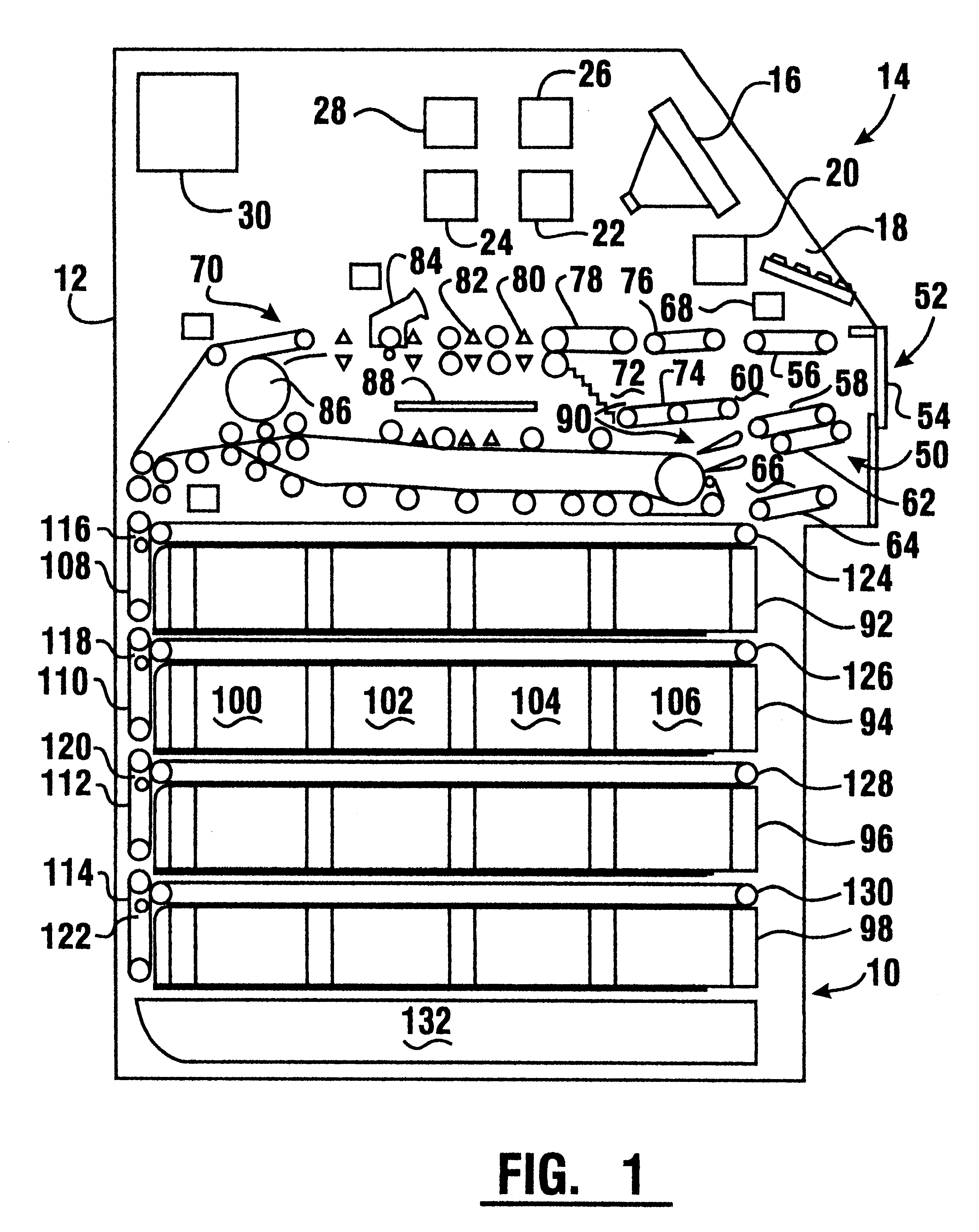

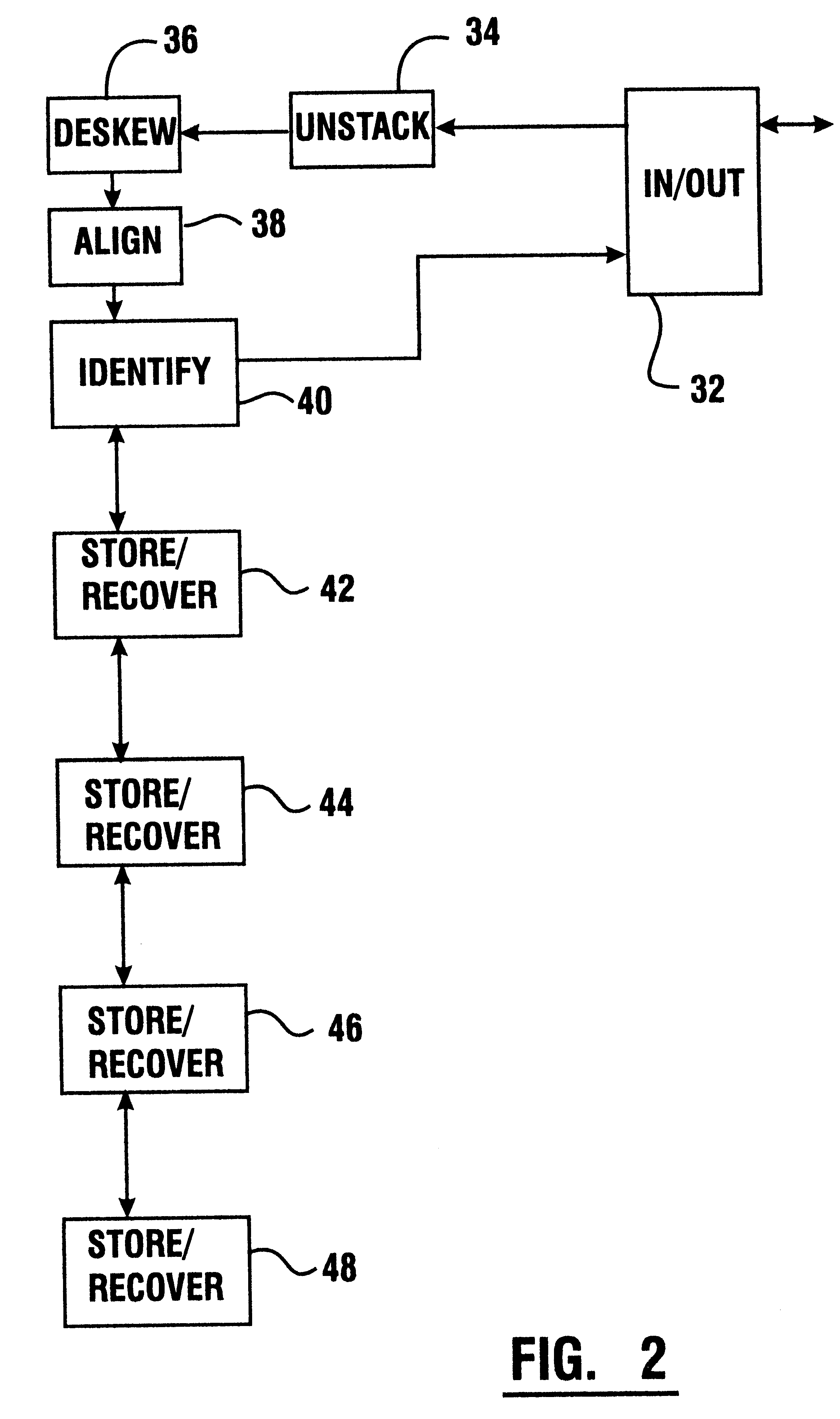

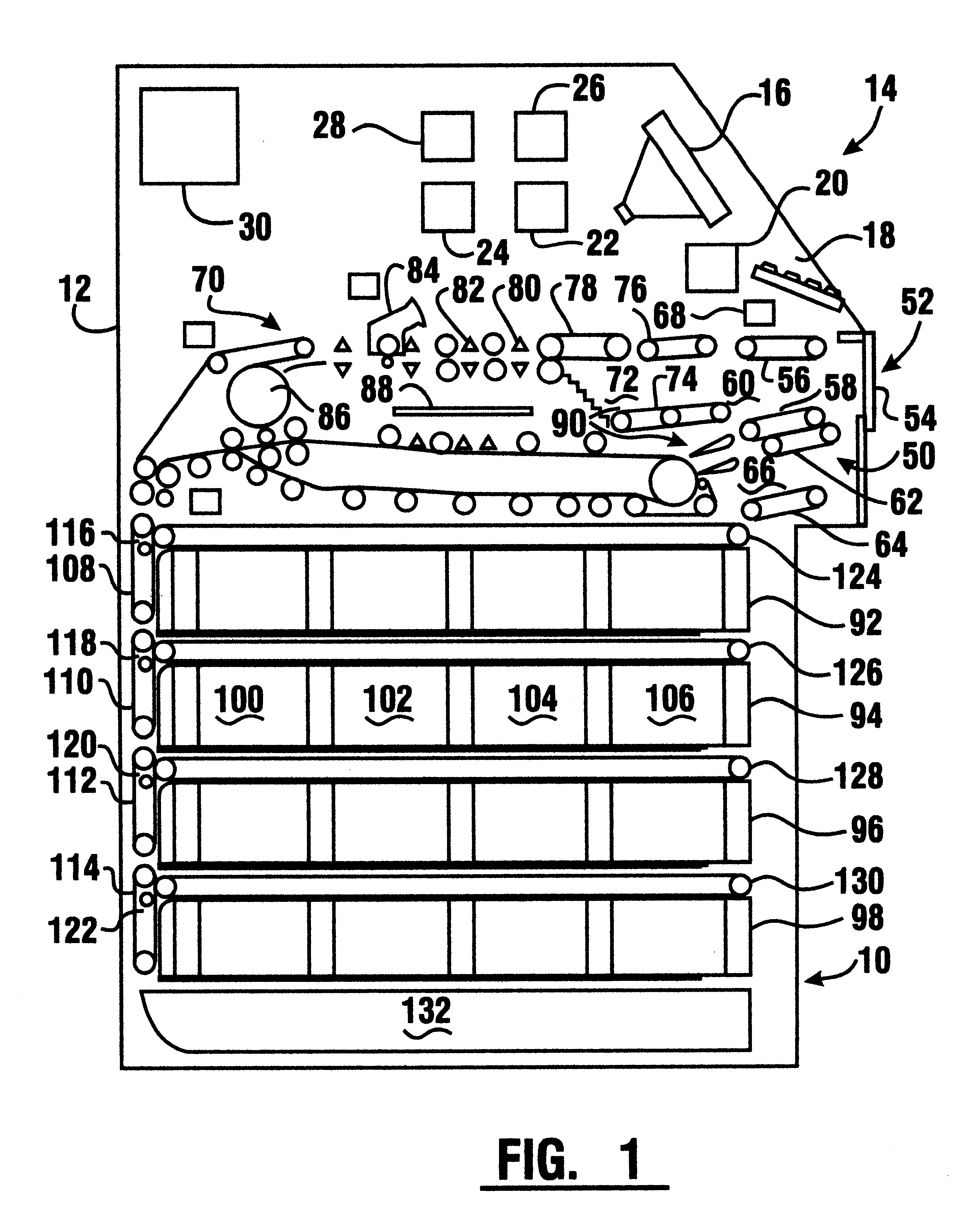

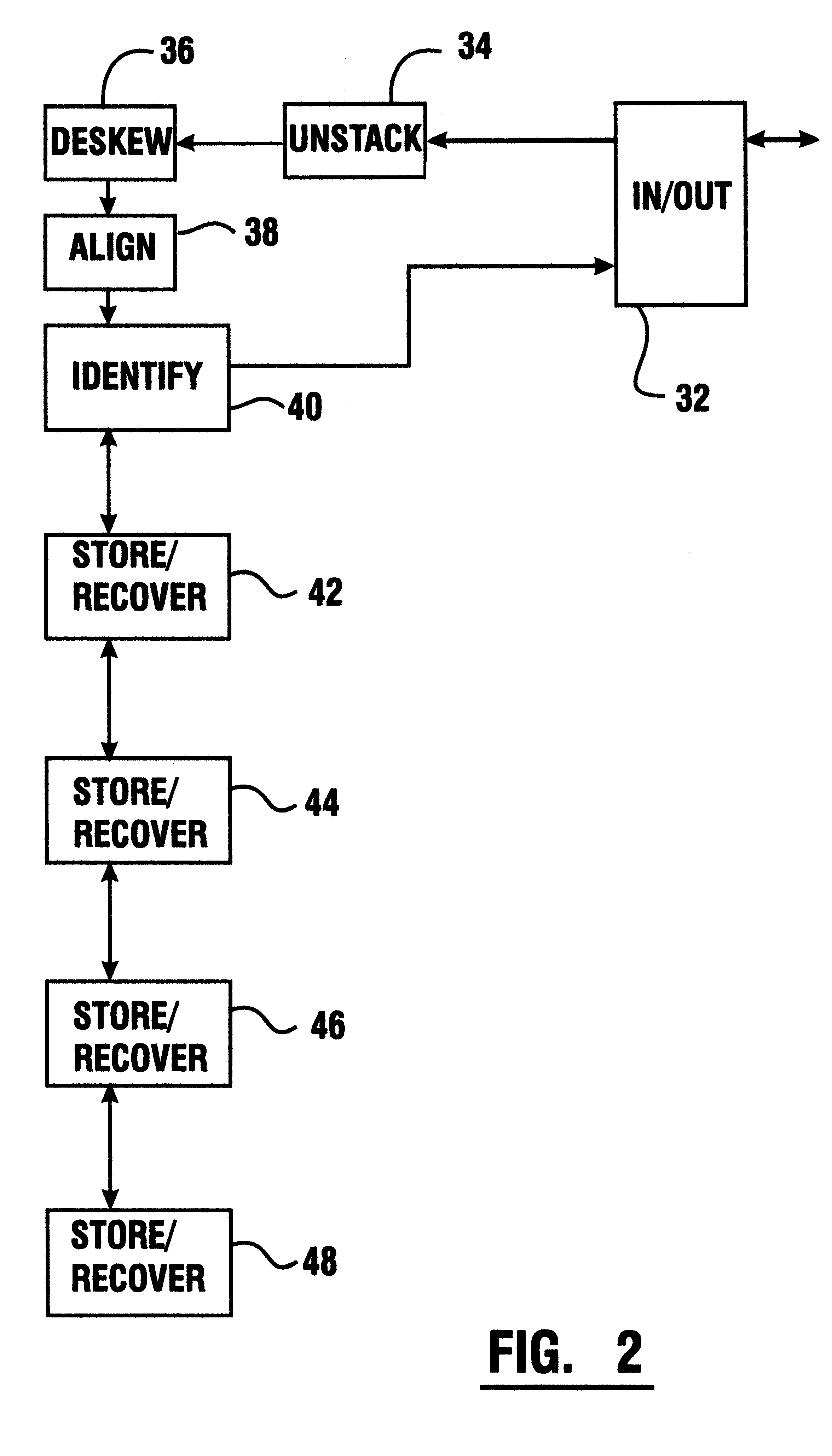

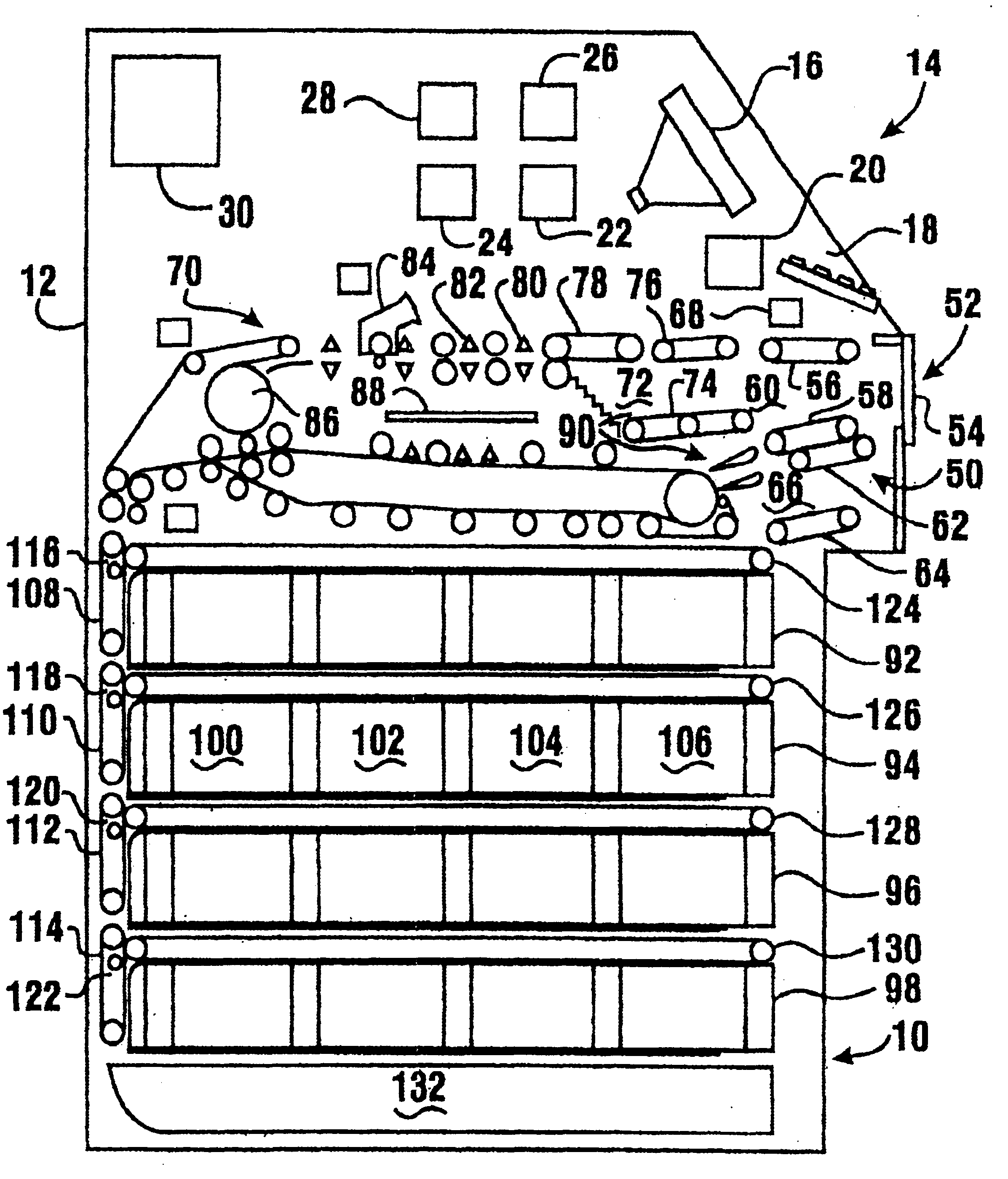

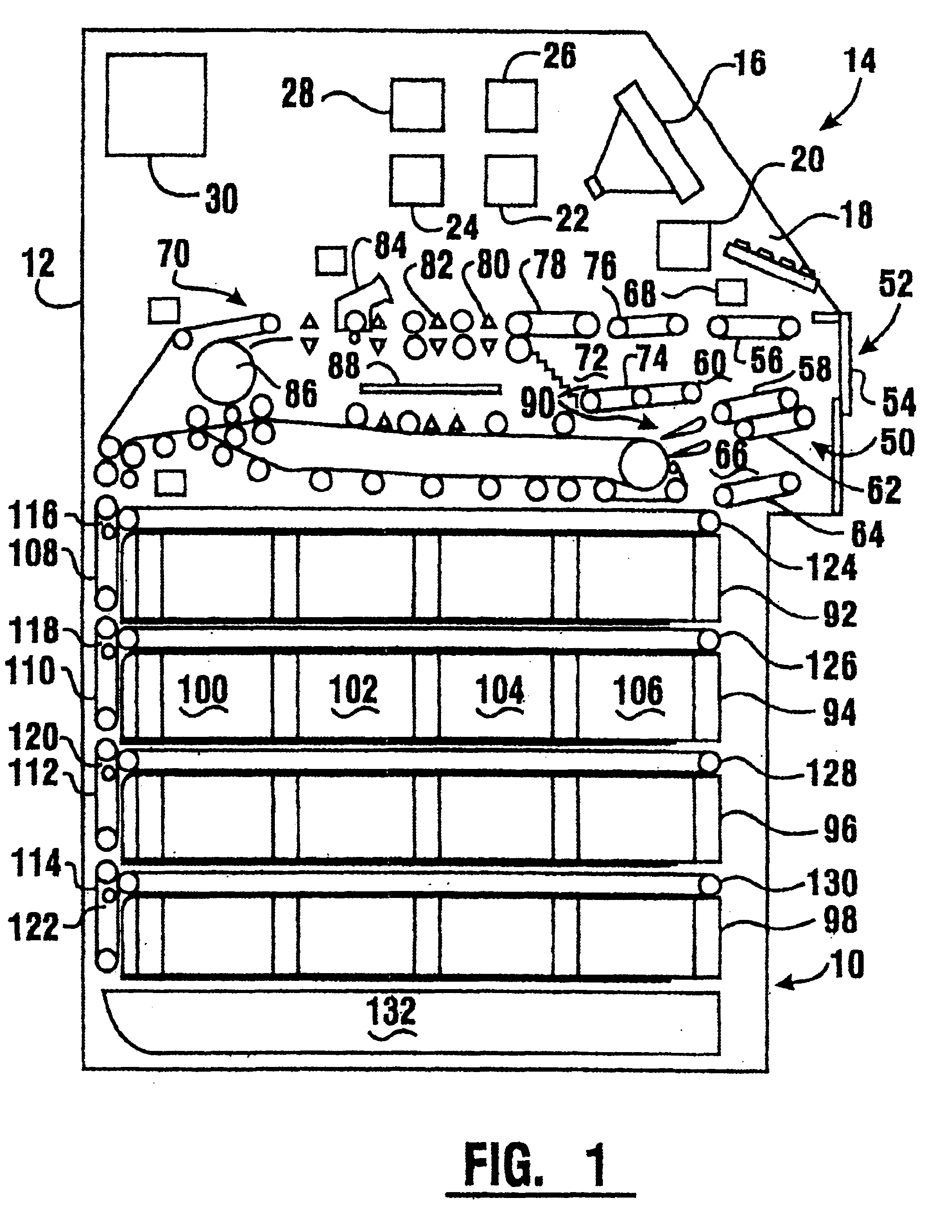

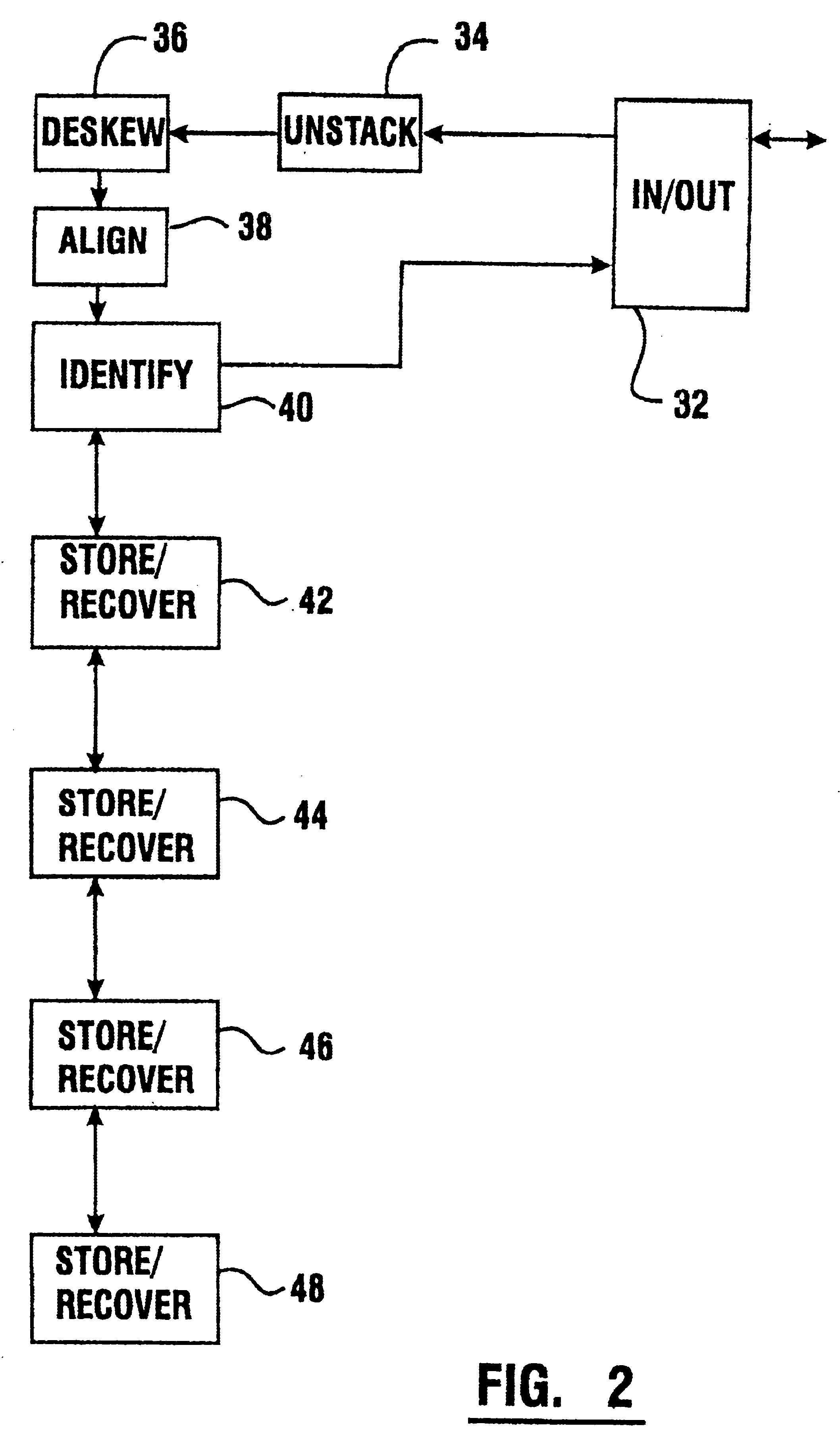

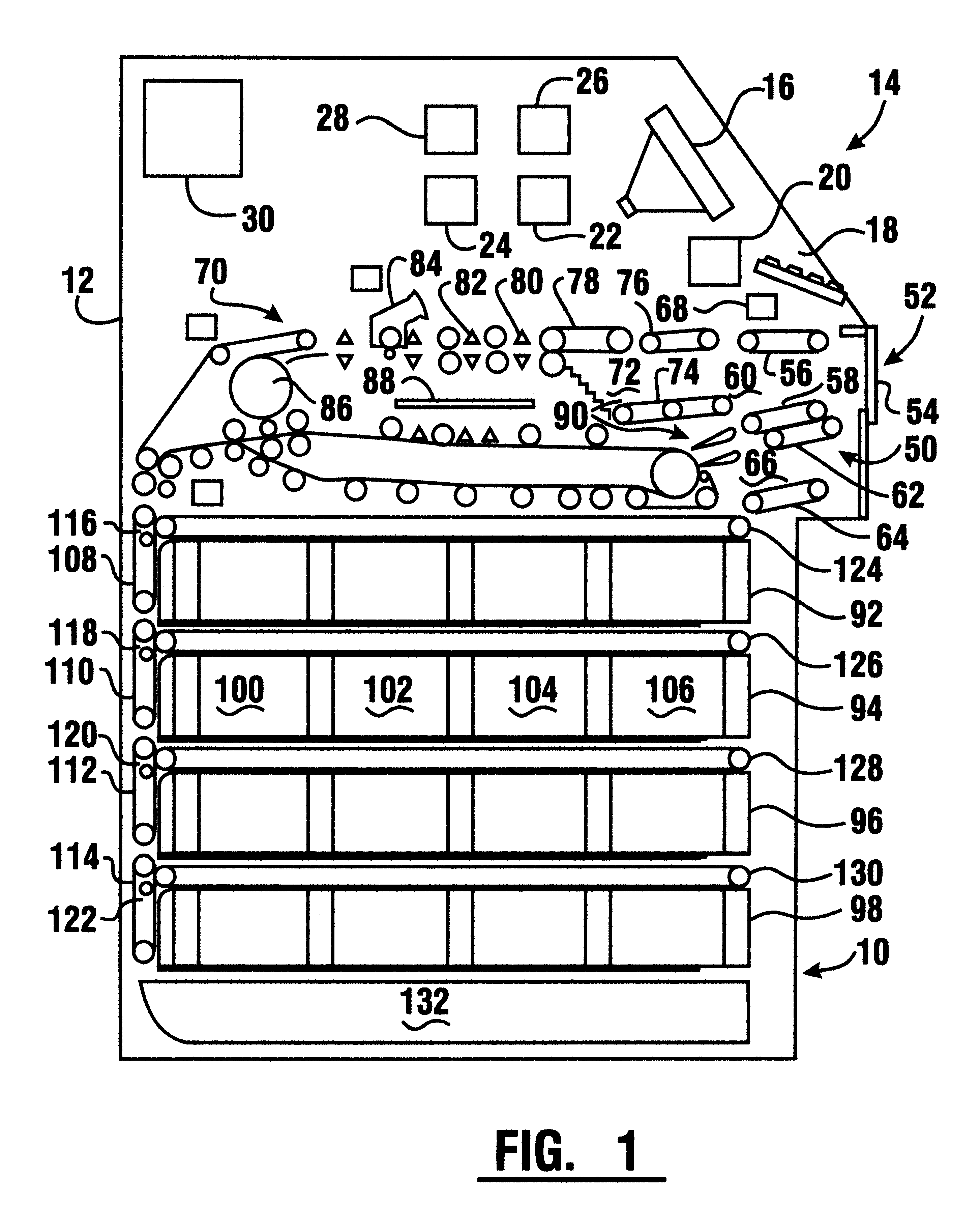

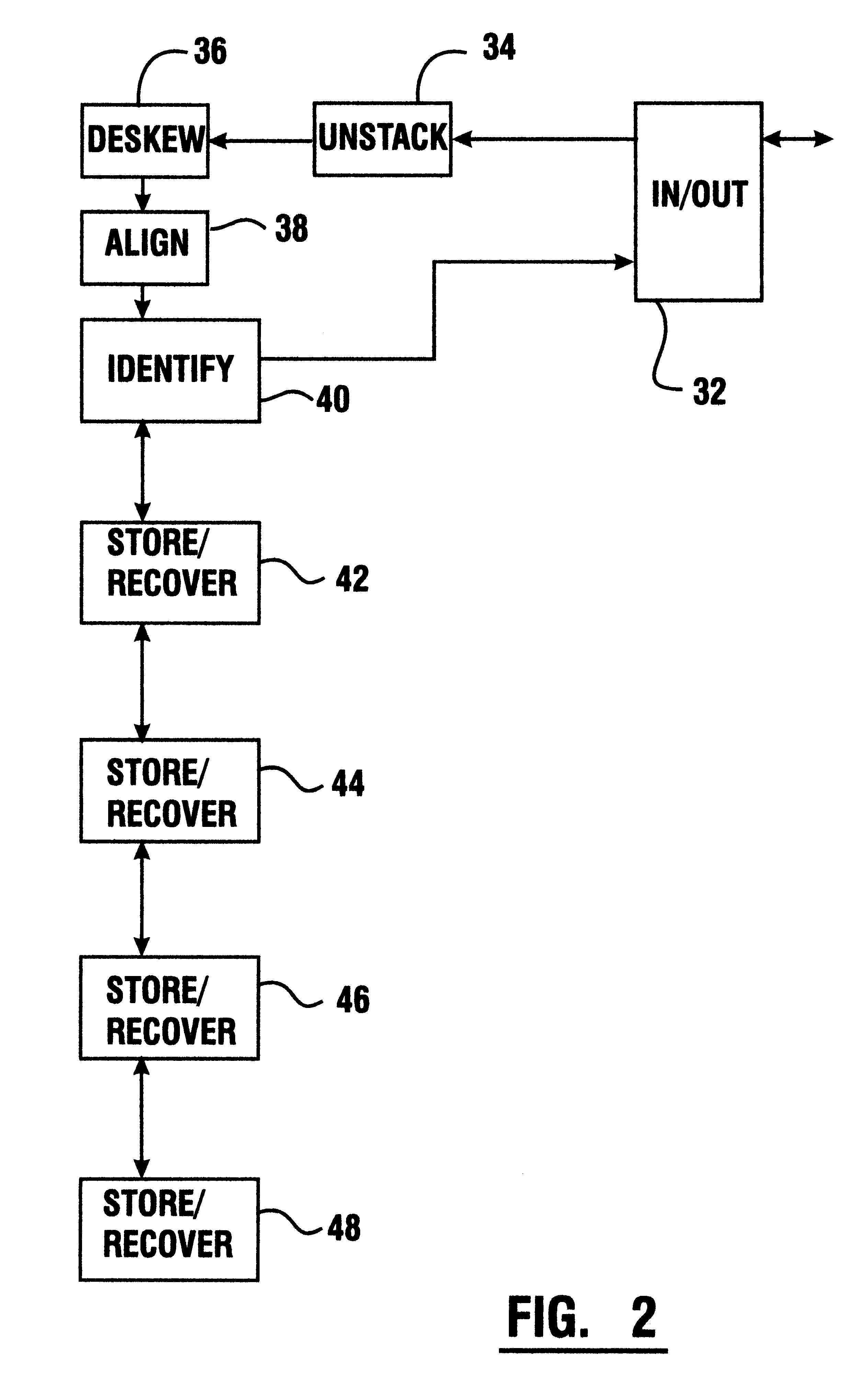

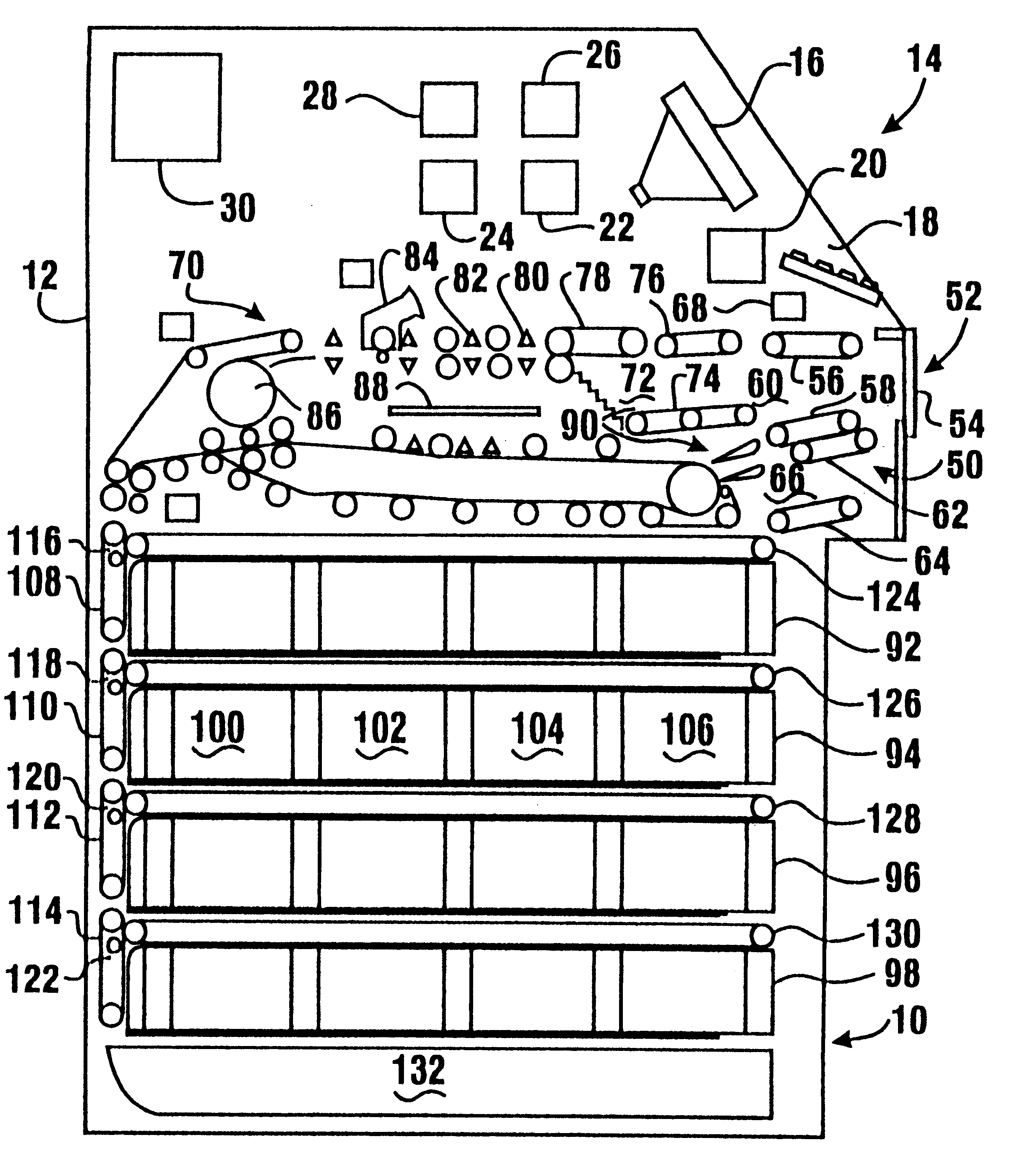

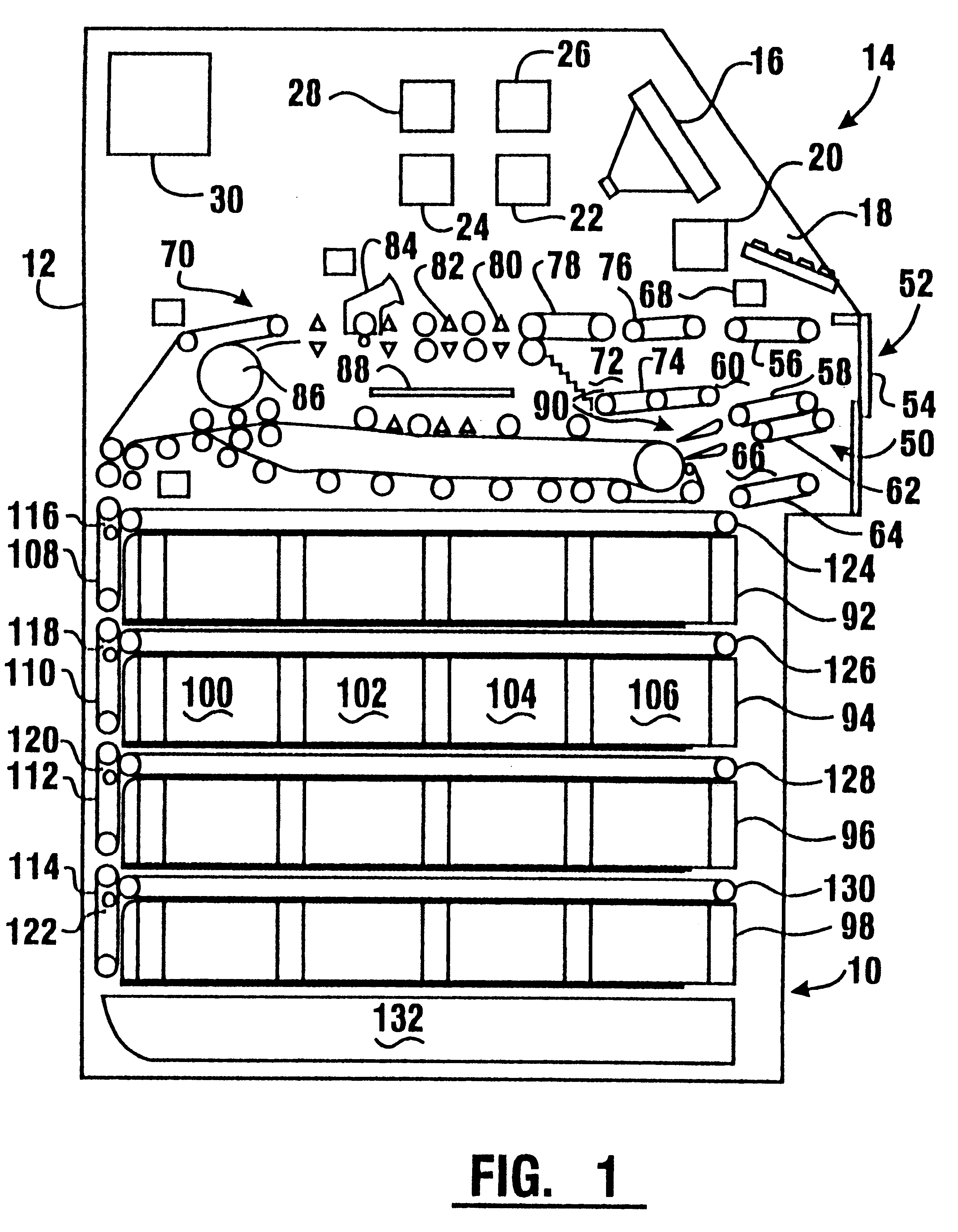

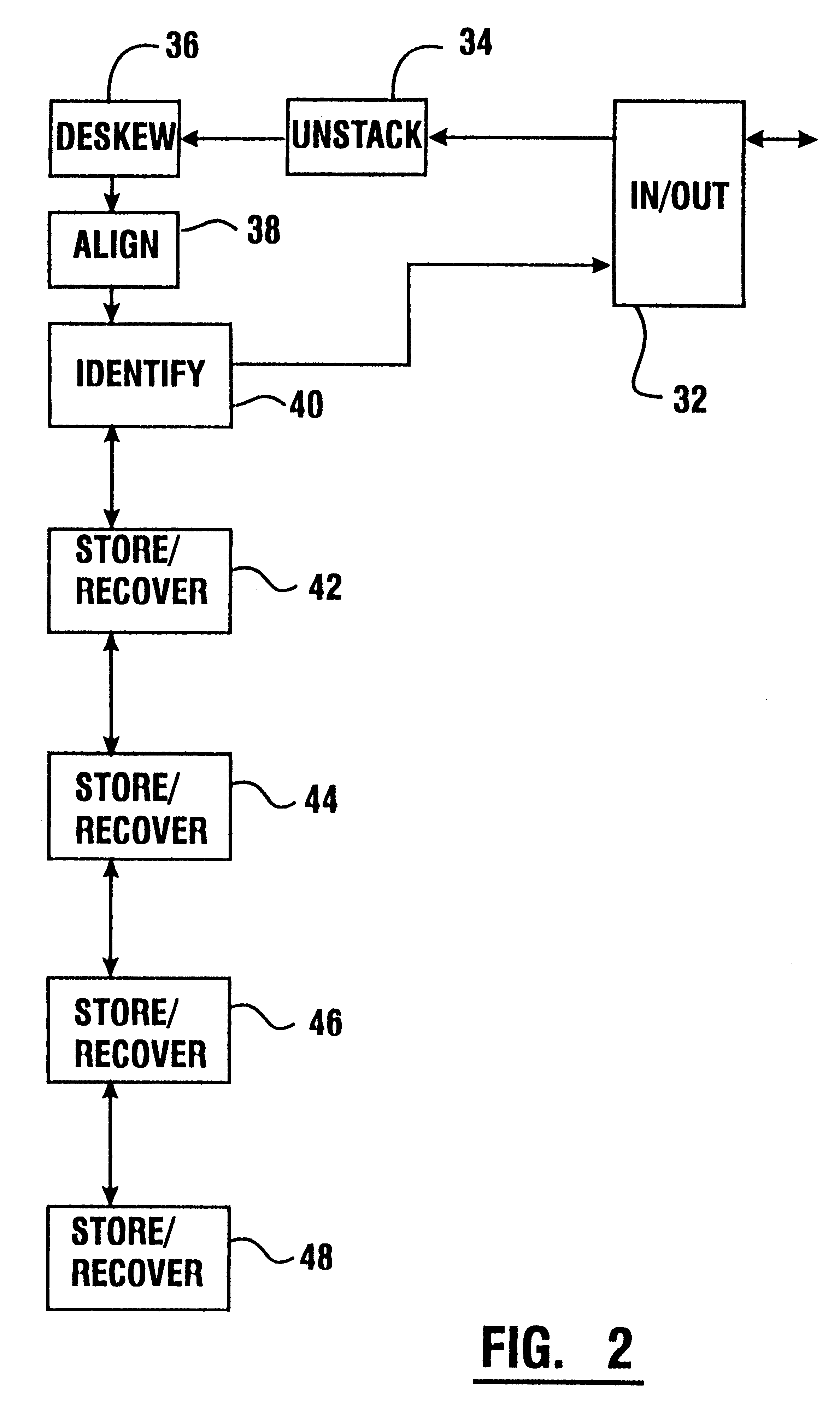

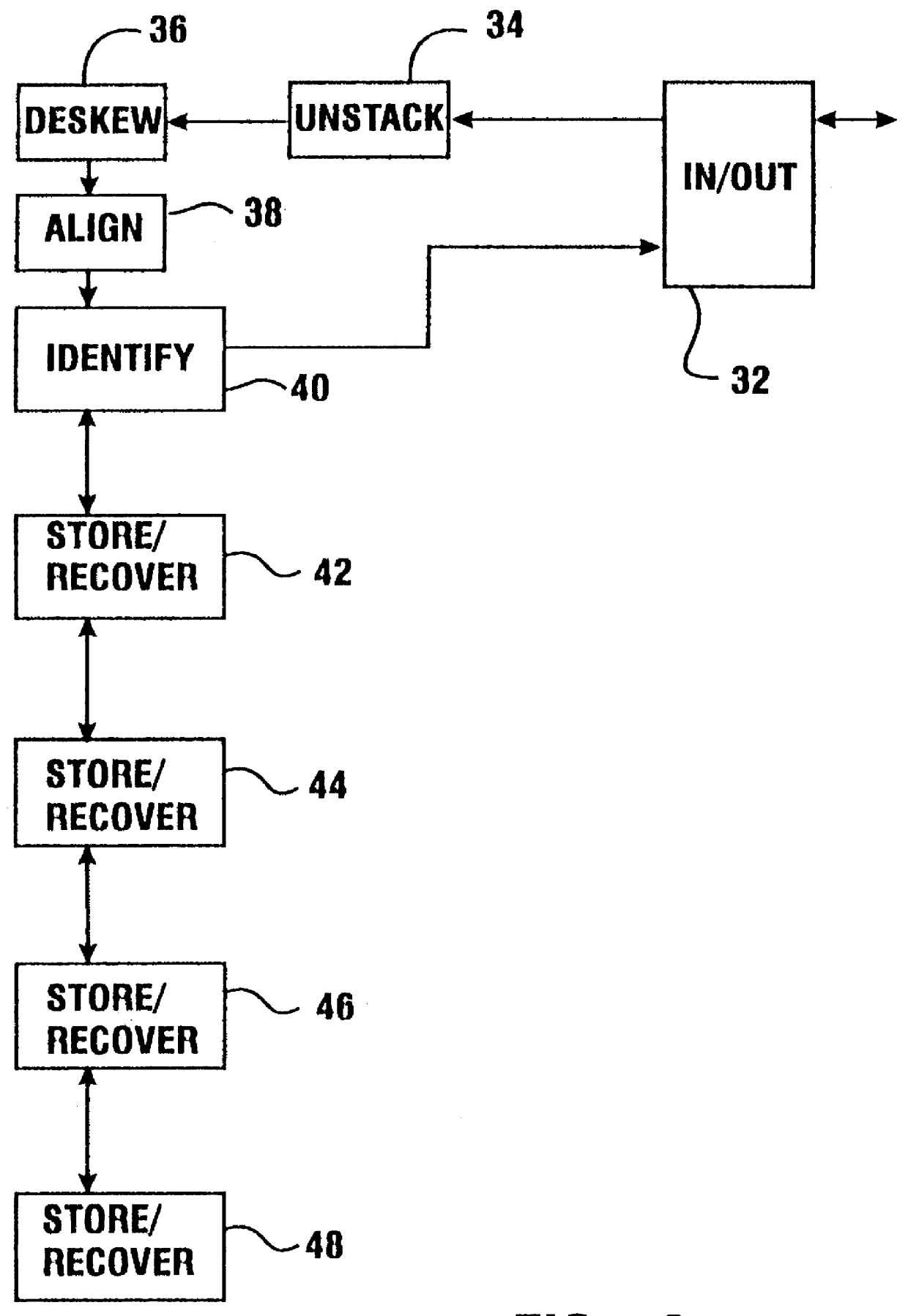

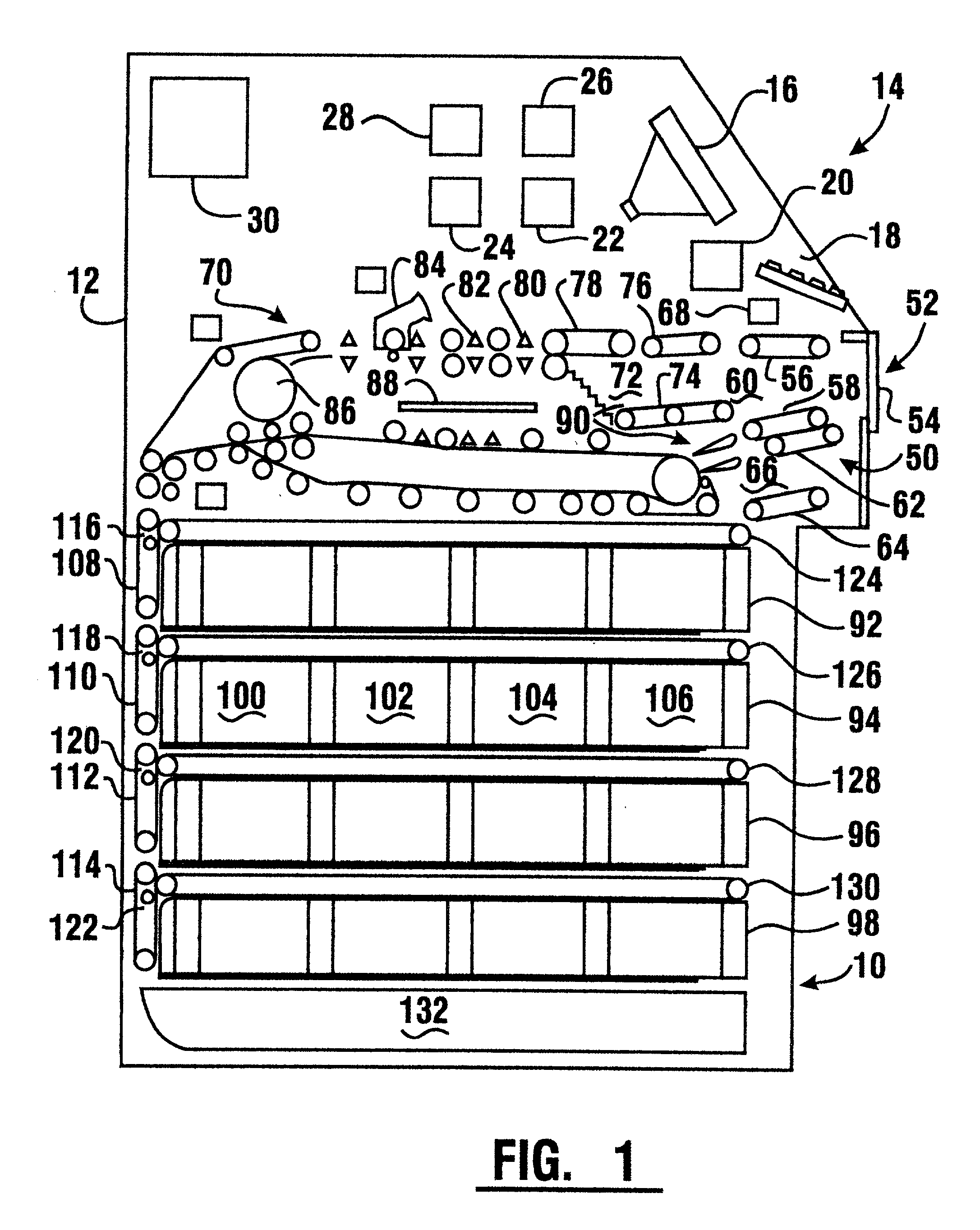

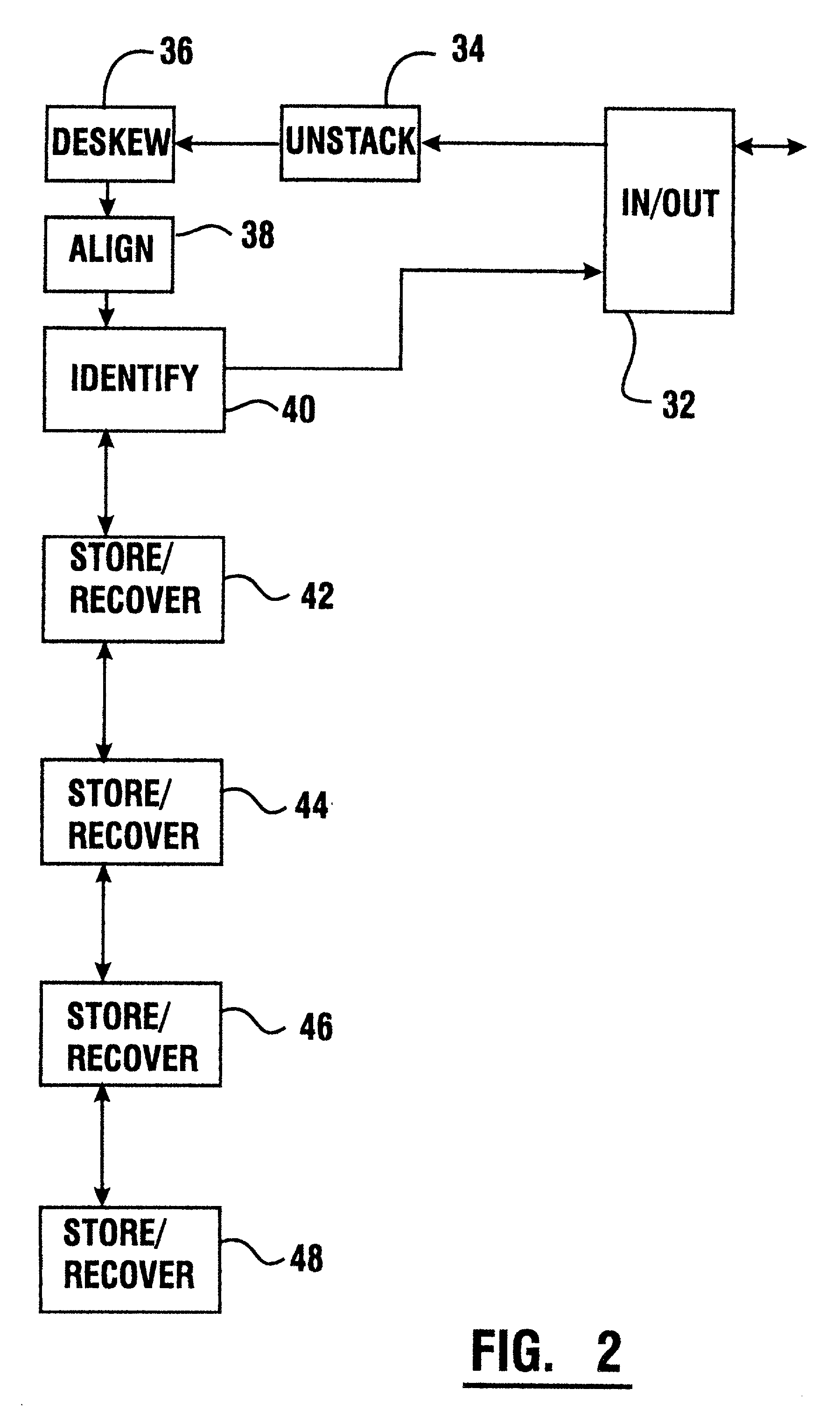

An automated banking machine (10) identifies and stores in storage areas documents such as currency bills deposited by a user. The machine selectively recovers such documents from storage areas and dispenses them. The machine includes a central transport (70) wherein documents deposited in a stack are unstacked, oriented and identified. Such documents are then routed to storage areas in canisters (92, 94, 96, 98). Documents in the storage areas are selectively picked therefrom and delivered to a user through an input / output area (50) of the machine. Each canister includes a memory (626) which holds information concerning the number and type of documents housed in the canister as well as other information concerning the hardware and software resident on the canister. The memory also includes data representative of individuals responsible for loading and transporting the canister. The machine conducts self-auditing activities to verify that the documents held in the storage areas correspond to the information stored in memory and indicate discrepancies.

Owner:DIEBOLD NIXDORF

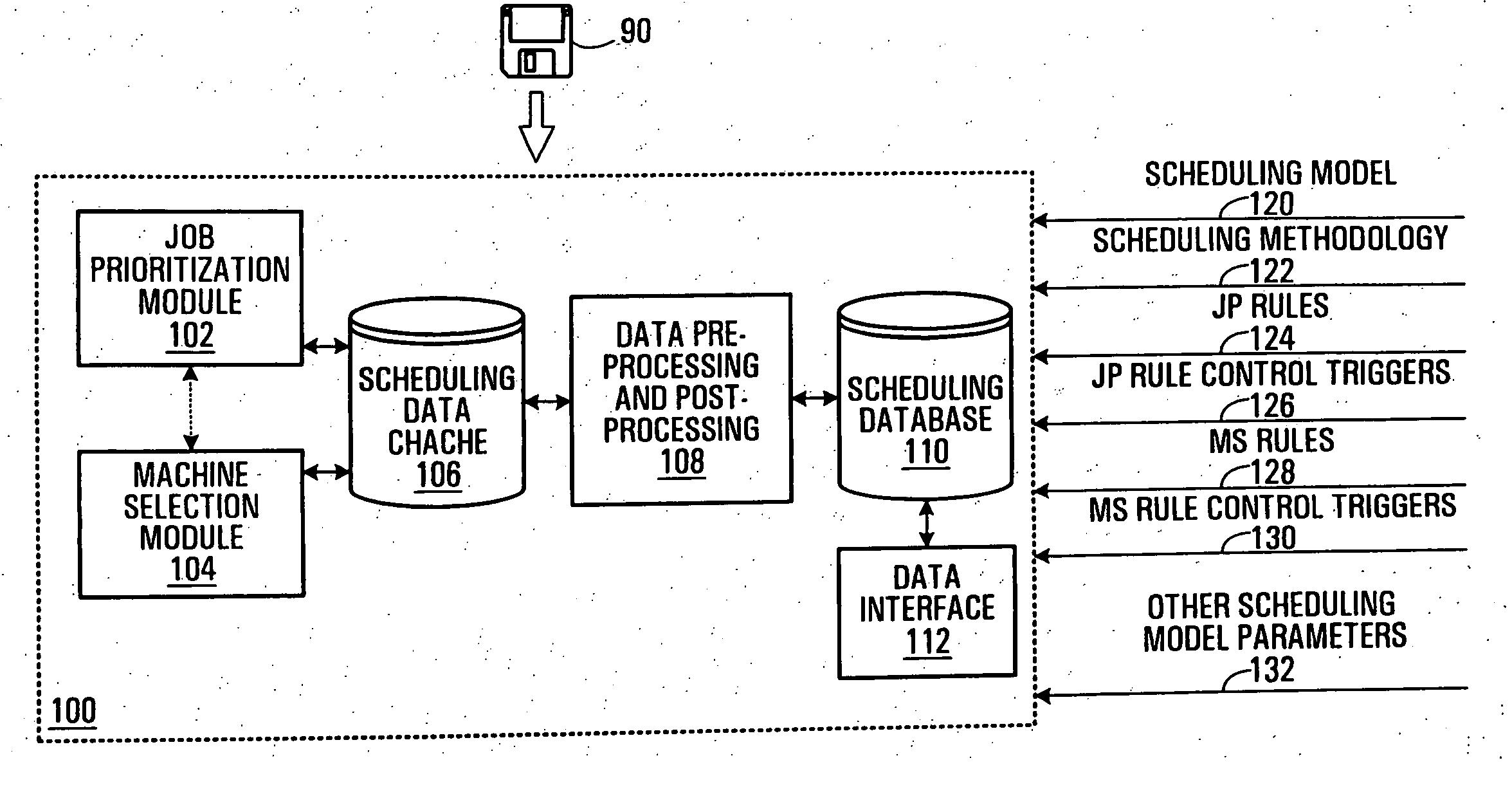

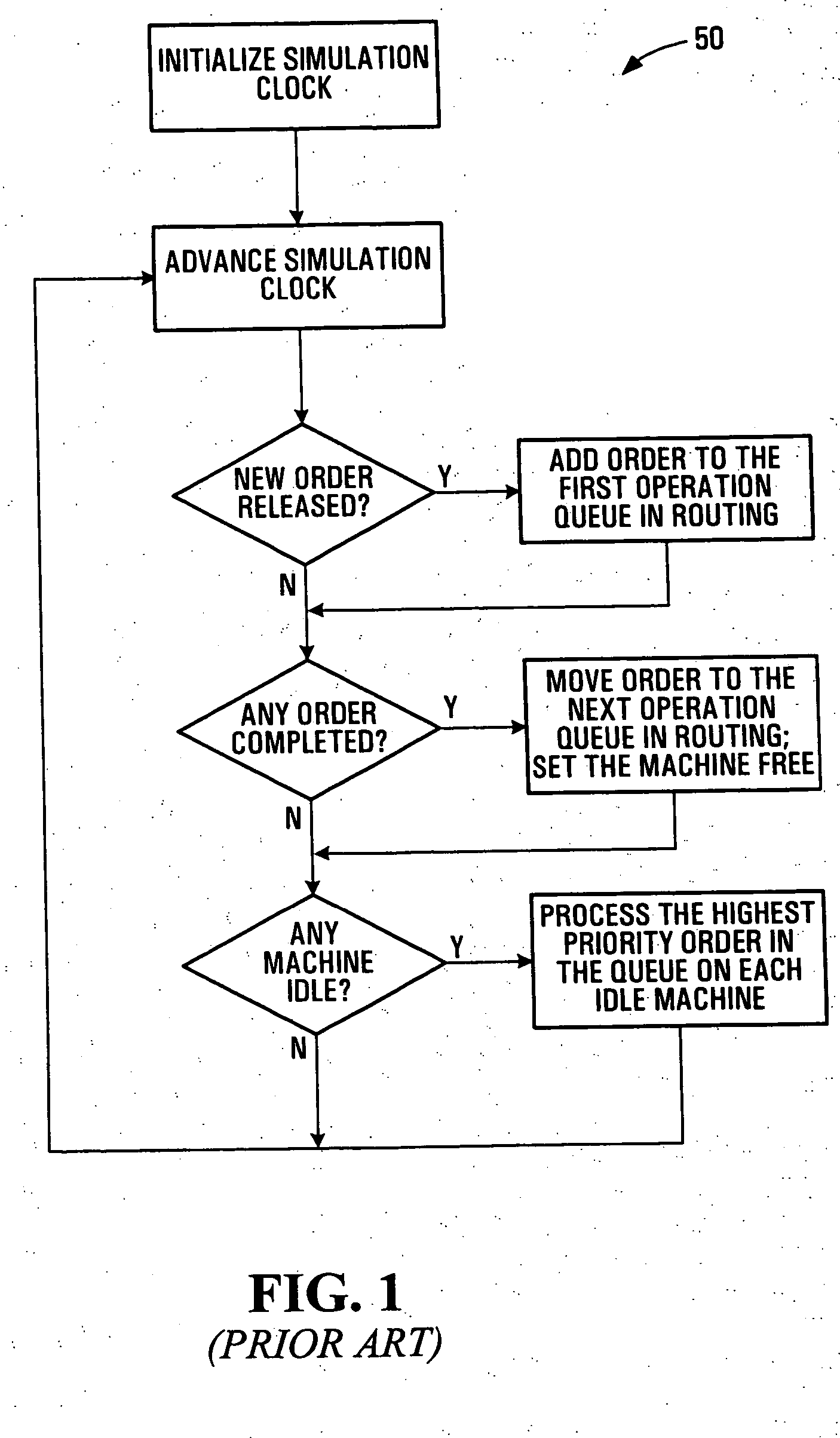

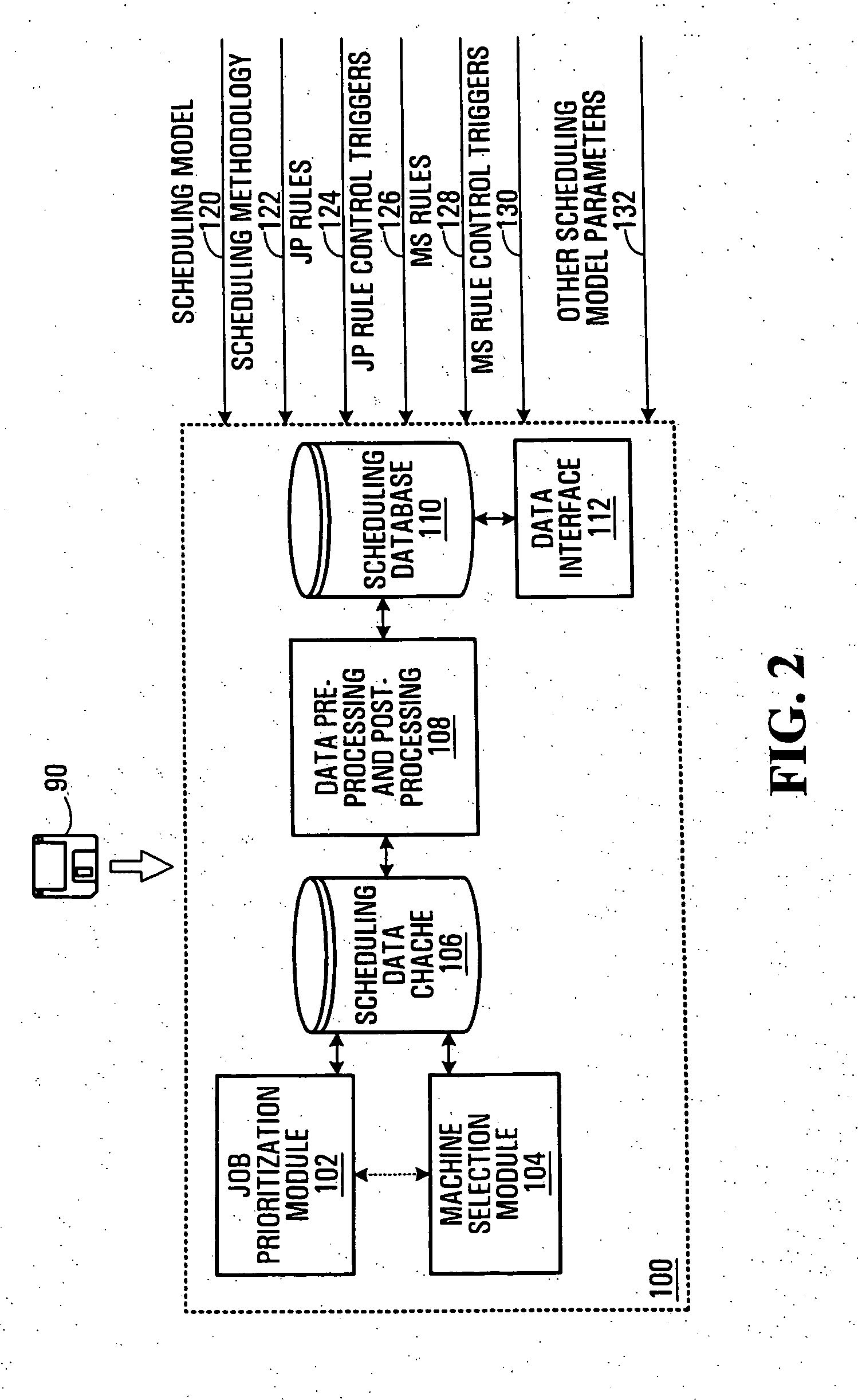

Finite capacity scheduling using job prioritization and machine selection

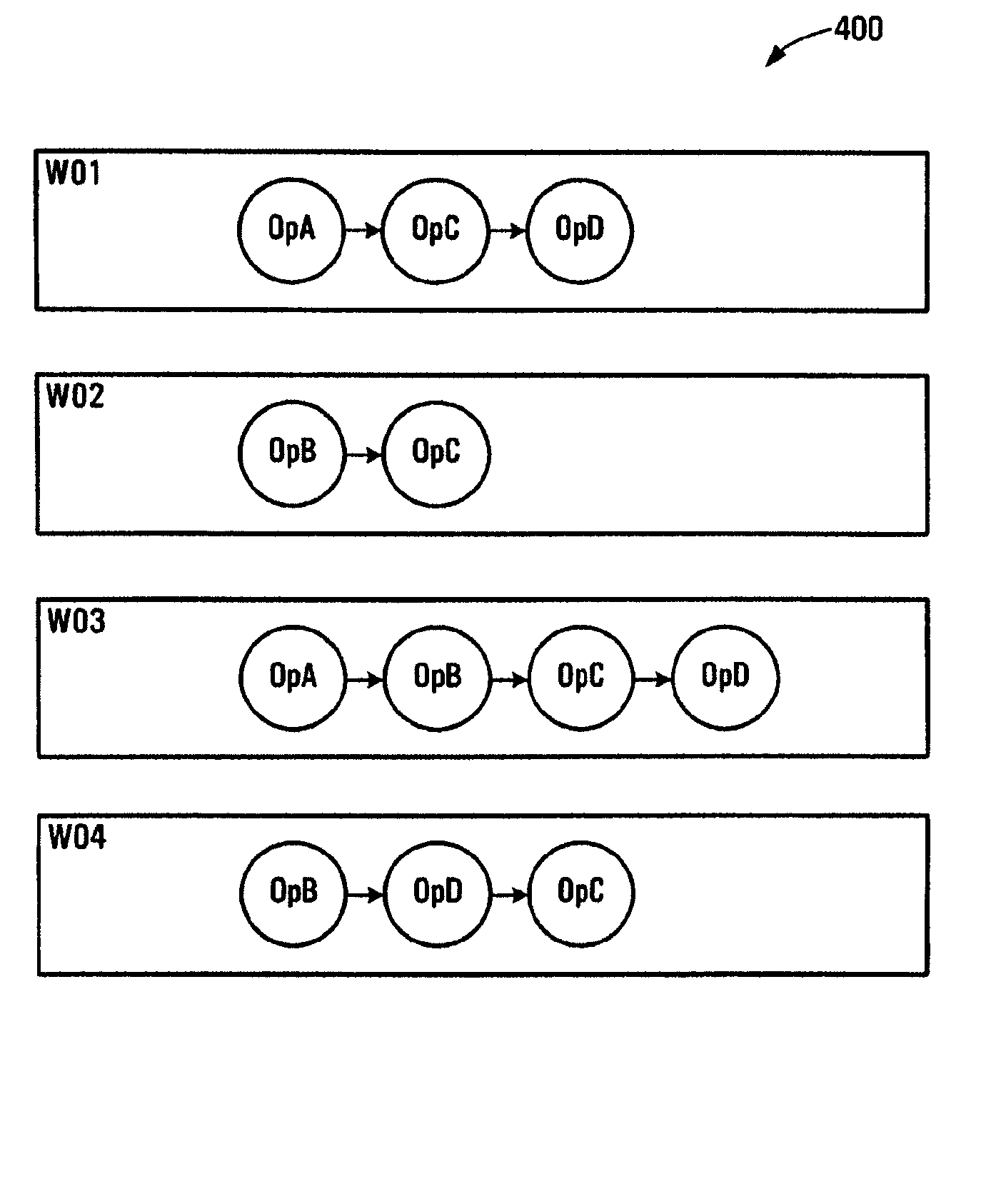

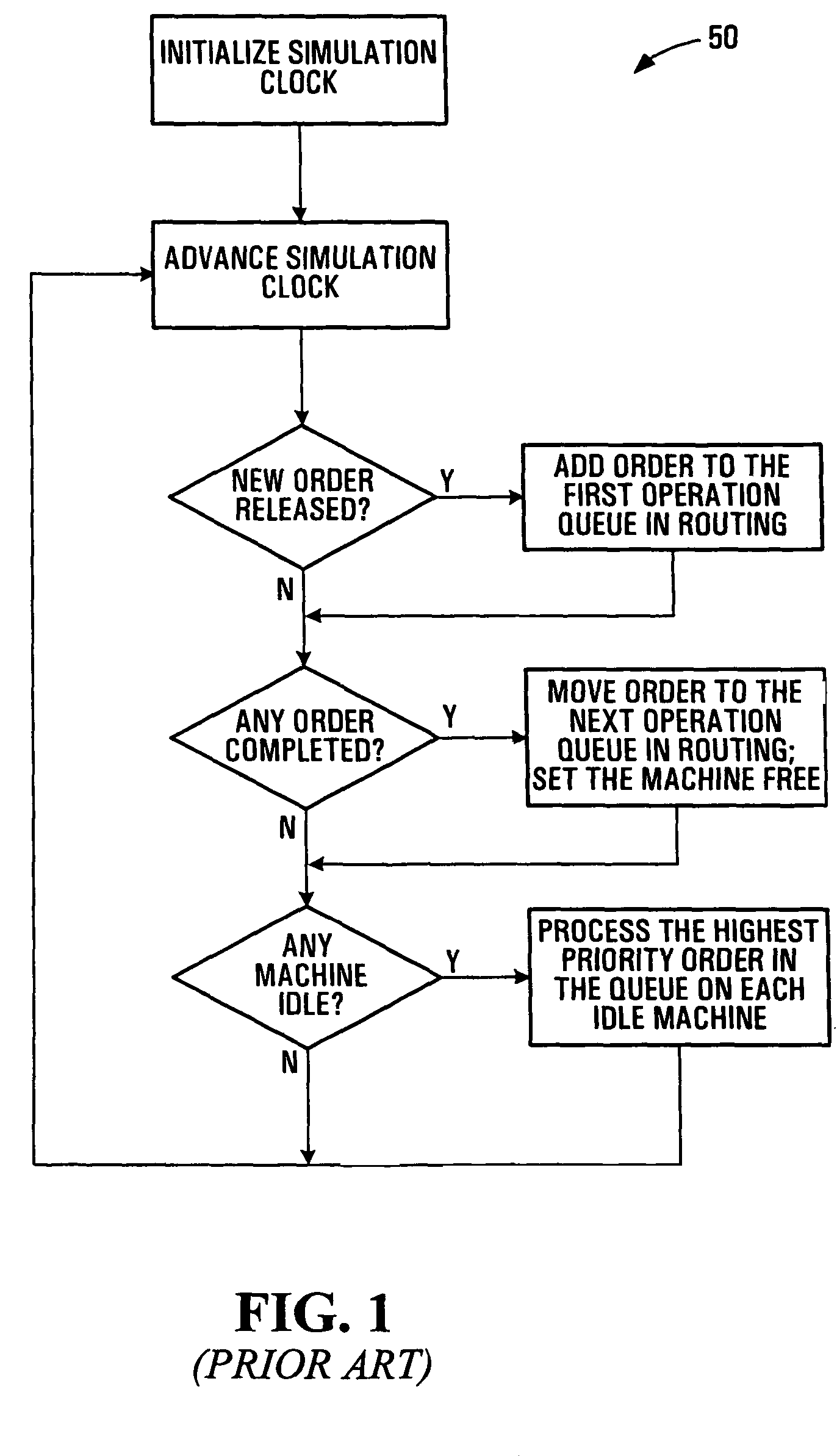

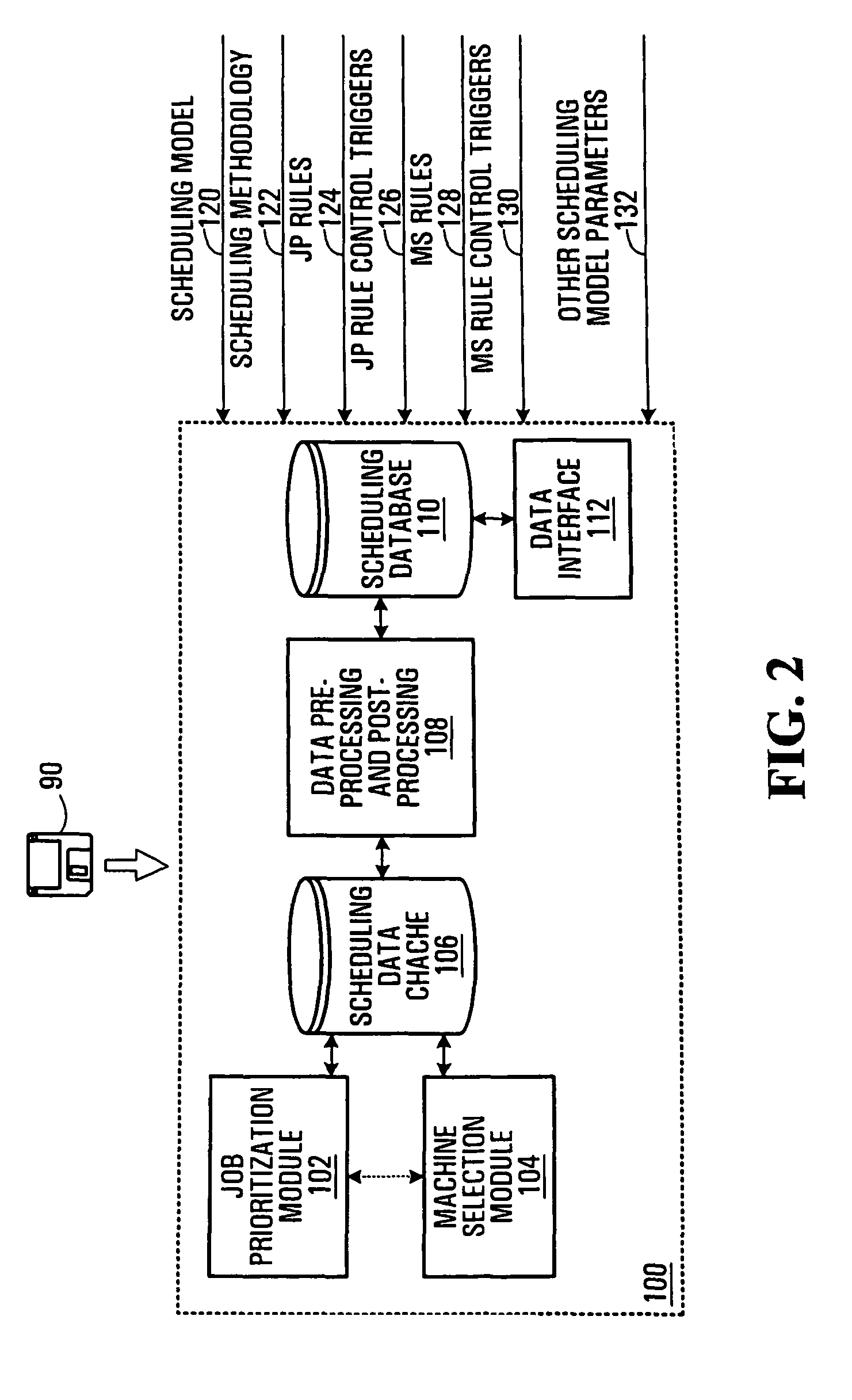

InactiveUS20050154625A1Improve machine utilizationResourcesSpecial data processing applicationsMachine selectionMachine utilization

In a method, device, and computer-readable medium for finite capacity scheduling, heuristic rules are applied in two integrated stages: Job Prioritization and Machine Selection. During Job Prioritization (“JP”), jobs are prioritized based on a set of JP rules which are machine independent. During Machine Selection (“MS”), jobs are scheduled for execution at machines that are deemed to be best suited based on a set of MS rules. The two-stage approach allows scheduling goals to be achieved for performance measures relating to both jobs and machines. For example, machine utilization may be improved while product cycle time objectives are still met. Two user-configurable options, namely scheduling model (job shop or flow shop) and scheduling methodology (forward, backward, or bottleneck), govern the scheduling process. A memory may store a three-dimensional linked list data structure for use in scheduling work orders for execution at machines assigned to work centers.

Owner:AGENCY FOR SCI TECH & RES

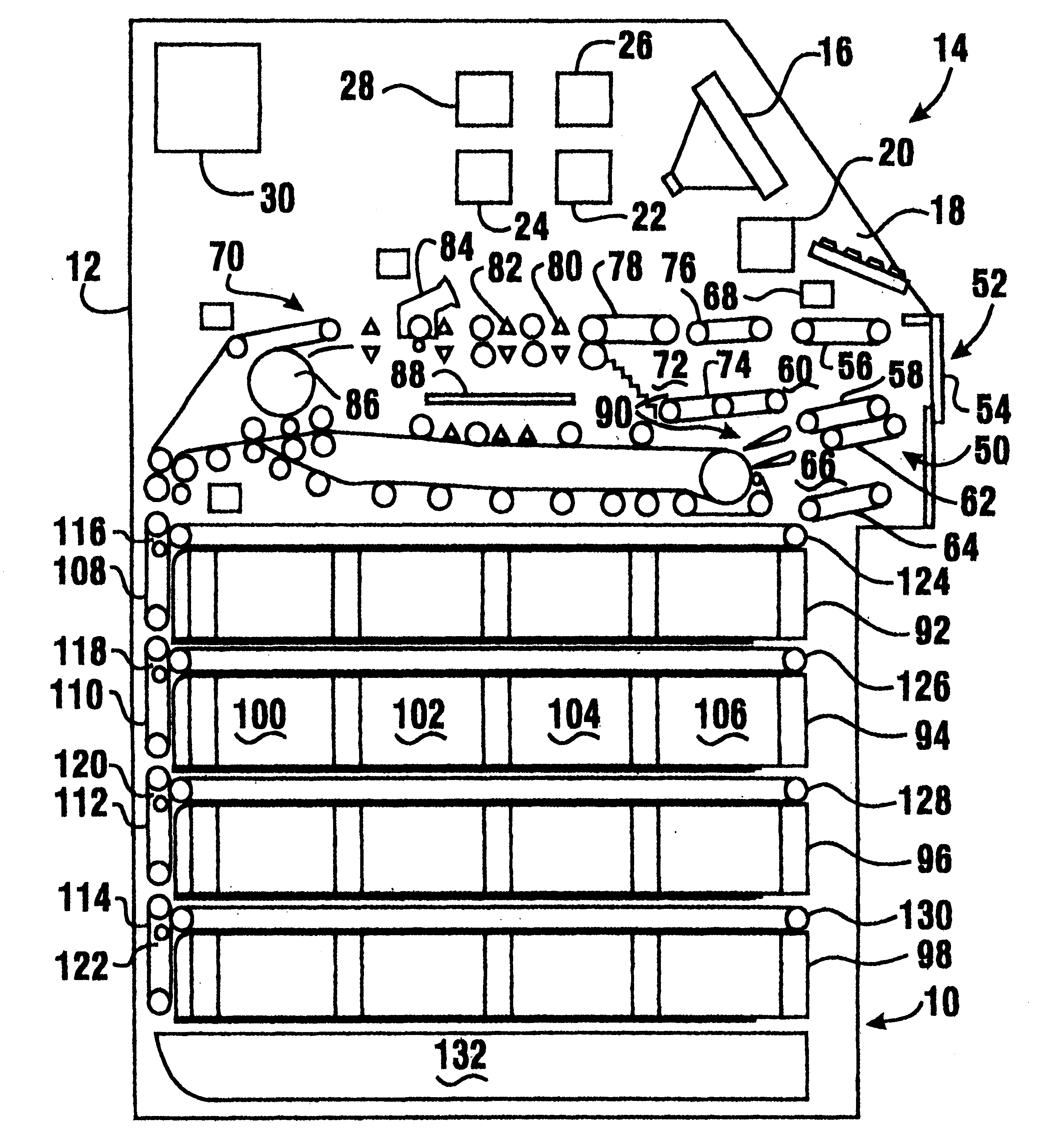

Currency recycling automated banking machine

InactiveUS6290070B1Easy to operateFacilitate rapid operation of machinePayment architectureSortingMachine selectionDocumentation

An automated banking machine (10) identifies and stores documents such as currency bills deposited by a user. The machine then selectively recovers such documents from storage and dispenses them to other users. The machine includes a central transport (70) wherein documents deposited in a stack are unstacked, oriented and identified. Such documents are then routed to storage areas in recycling canisters (92, 94, 96, 98). When a user subsequently requests a dispense, documents stored in the storage areas are selectively picked therefrom and delivered to the user through an input / output area (50) of the machine.

Owner:DIEBOLD NIXDORF

System and method for dynamic multi-objective optimization of machine selection, integration and utilization

ActiveUS9729639B2Improve overall utilizationImprove efficiencyMechanical power/torque controlLevel controlOperational costsMachine selection

The invention provides control systems and methodologies for controlling a process having computer-controlled equipment, which provide for optimized process performance according to one or more performance criteria, such as efficiency, component life expectancy, safety, emissions, noise, vibration, operational cost, or the like. More particularly, the subject invention provides for employing machine diagnostic and / or prognostic information in connection with optimizing an overall business operation over a time horizon.

Owner:ROCKWELL AUTOMATION TECH

System and method for dynamic multi-objective optimization of machine selection, integration and utilization

InactiveUS8126574B2Improve overall utilizationImprove efficiencyLevel controlTechnology managementOperational costsMachine selection

The invention provides control systems and methodologies for controlling a process having one or more motorized pumps and associated motor drives, which provide for optimized process performance according to one or more performance criteria, such as efficiency, component life expectancy, safety, emissions, noise, vibration, operational cost, or the like. More particularly, the subject invention provides for employing machine diagnostic and / or prognostic information in connection with optimizing an overall business operation over a time horizon.

Owner:ROCKWELL AUTOMATION TECH

Control system communication apparatus and method for currency recycling automated banking machine

InactiveUS6131809AEasy to operateEasy to handleComplete banking machinesFinanceMachine selectionControl system

An automated banking machine (10) identifies and stores documents such as currency bills deposited by a user. The machine then selectively recovers documents from storage and dispenses them to other users. The machine includes a central transport (70) wherein documents deposited in a stack are unstacked, oriented and identified. Such documents are then routed to storage areas in recycling canisters (92, 94, 96, 98). When a user subsequently requests a dispense, documents stored in the storage areas are selectively picked therefrom and delivered to the user through an input / output area (50) of the machine. The control system (30) for the machine includes a terminal processor (548). The terminal processor communicates with a module processor (552). The module processor (552) communicates with module controllers (554, 556, 558, 560, 562 and 564) which control the operation of devices. The module processor coordinates the activities of the module controllers to achieve the processing of documents reliably and at high speeds. A special protocol is used to communicate messages between the module processors and module controllers which provides increased reliability.

Owner:DIEBOLD NIXDORF

System and method for dynamic multi-objective optimization of machine selection, integration and utilization

InactiveUS20100306001A1Improve overall utilizationImprove efficiencyTesting/monitoring control systemsForecastingOperational costsMachine selection

The invention provides control systems and methodologies for controlling a process having one or more motorized pumps and associated motor drives, which provide for optimized process performance according to one or more performance criteria, such as efficiency, component life expectancy, safety, emissions, noise, vibration, operational cost, or the like. More particularly, the subject invention provides for employing machine diagnostic and / or prognostic information in connection with optimizing an overall business operation over a time horizon.

Owner:ROCKWELL AUTOMATION TECH

Document sensor for currency recycling automated banking machine

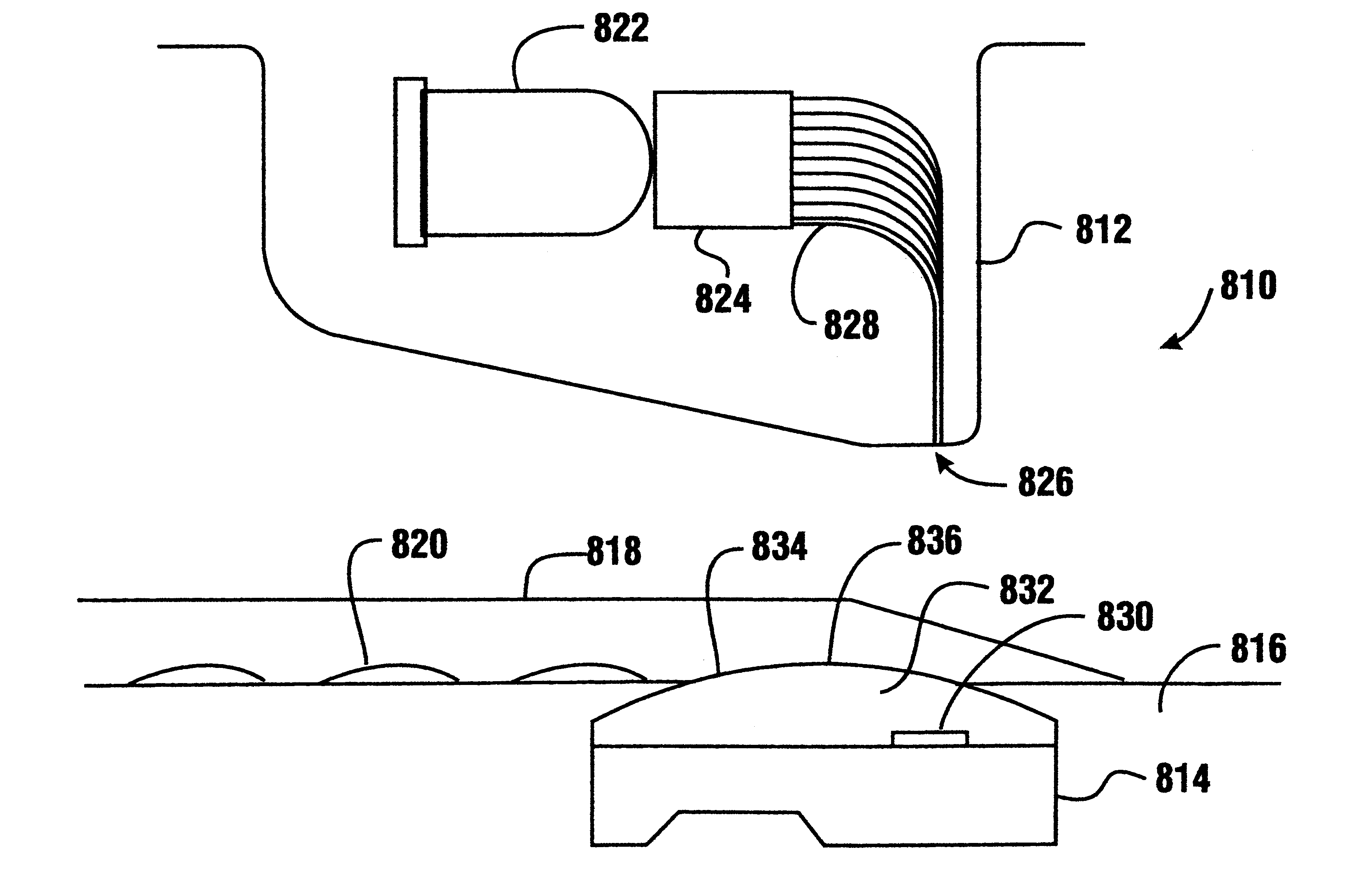

InactiveUS6241244B1Easy to operateFacilitate rapid operation of machinePaper-money testing devicesFunction indicatorsMachine selectionOptoelectronics

An automated banking machine (10) identifies and stores documents such as currency bills deposited by a user. The machine then selectively recovers such documents from storage areas and dispenses them to other users. The machine includes a sheet thickness detector (810) used for distinguishing single sheets from double sheets which pass through the machine. The thickness detector includes a radiation source (822). Radiation from the radiation source is directed by radiation guide (824) to a generally linear elongated radiation outlet (826) which extends transversely to the sheet path. A receiver (814) includes a radiation sensitive element (830) which is also transversely elongated relative to the sheet path. Sheets passing between the emitter and the receiver cause variations in the amount of radiation reaching the receiver. The transversely elongated surface of the sheet through which the transmission of radiation is sense enables accurately distinguishing single sheets from double sheets.

Owner:DIEBOLD NIXDORF

Control system for currency recycling automated banking machine

InactiveUS6264101B1Easy to operateEasy to handleComplete banking machinesFinanceMachine selectionControl system

An automated banking machine (10) identifies and stores documents such as currency bills deposited by a user. The machine then selectively recovers documents from storage and dispenses them to other users. The machine includes a central transport (70) wherein documents deposited in a stack are unstacked, oriented and identified. Such documents are then routed to storage areas in recycling canisters (92, 94, 96, 98). When a user subsequently requests a dispense, documents stored in the storage areas are selectively picked therefrom and delivered to the user through an input / output area (50) of the machine. The control system (30) for the machine includes a terminal processor (548). The terminal processor communicates with a module processor (552). The module processor (552) communicates with module controllers (554, 556, 558, 560, 562 and 564) which control the operation of devices. The module processor coordinates the activities of the module controllers to achieve the processing of documents reliably and at high speeds.

Owner:DIEBOLD NIXDORF

System and method for dynamic multi-objective optimization of machine selection, integration and utilization

ActiveUS8417360B2Improve overall utilizationImprove efficiencySimulator controlForecastingMachine selectionOperational costs

Systems and methodologies are provided for controlling a process having computer-controlled equipment, which provide for optimized process performance according to one or more performance criteria, such as efficiency, component life expectancy, safety, emissions, noise, vibration, operational cost, or the like. The systems and methods provide for employing machine diagnostic and / or prognostic information in connection with optimizing an overall business operation over a time horizon.

Owner:ROCKWELL AUTOMATION TECH

System and method for dynamic multi-objective optimization of machine selection, integration and utilization

InactiveUS7797062B2Improve overall utilizationImprove efficiencyTechnology managementResourcesOperational costsMachine selection

The invention provides control systems and methodologies for controlling a process having one or more motorized pumps and associated motor drives, which provide for optimized process performance according to one or more performance criteria, such as efficiency, component life expectancy, safety, emissions, noise, vibration, operational cost, or the like. More particularly, the subject invention provides for employing machine diagnostic and / or prognostic information in connection with optimizing an overall business operation over a time horizon.

Owner:ROCKWELL AUTOMATION TECH

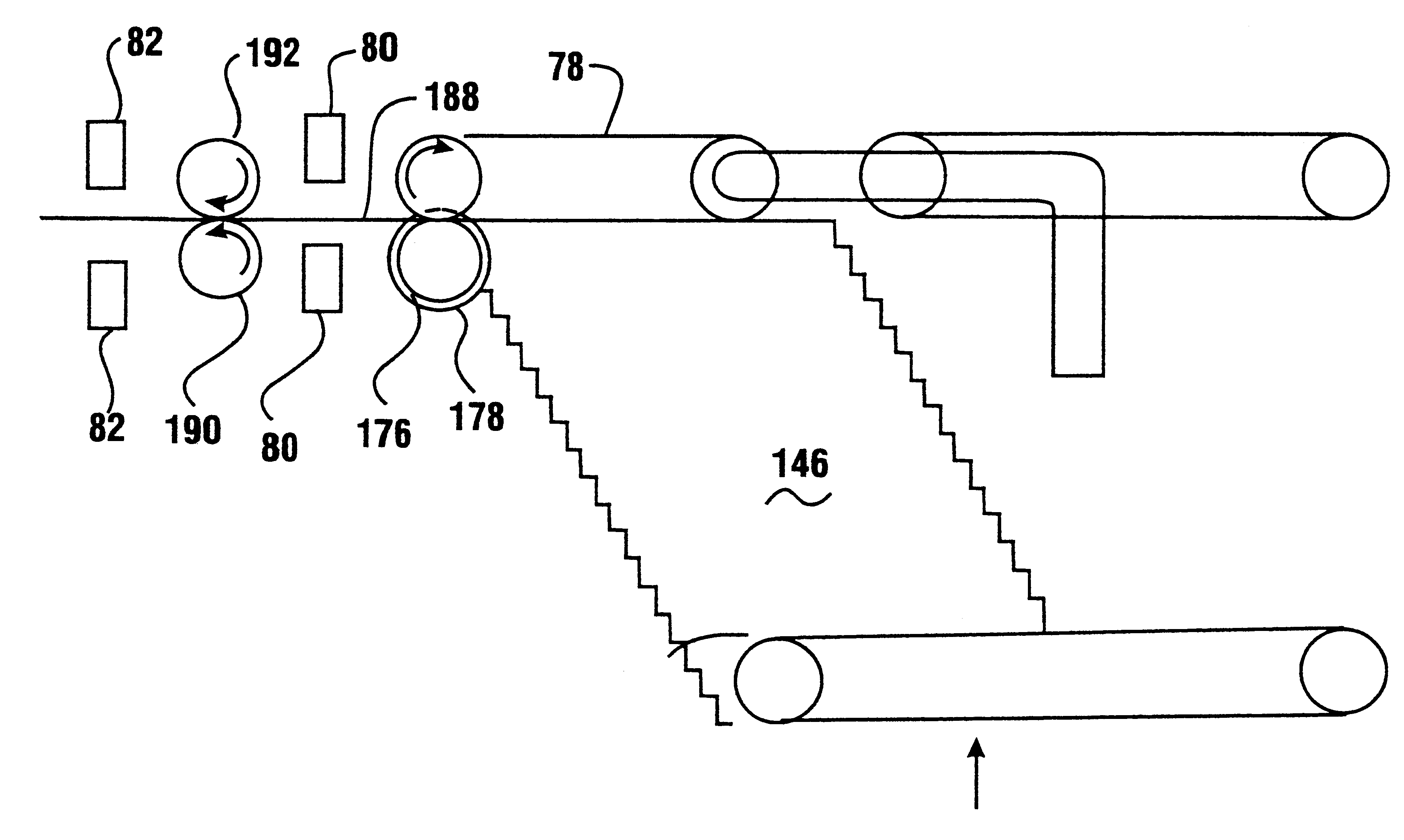

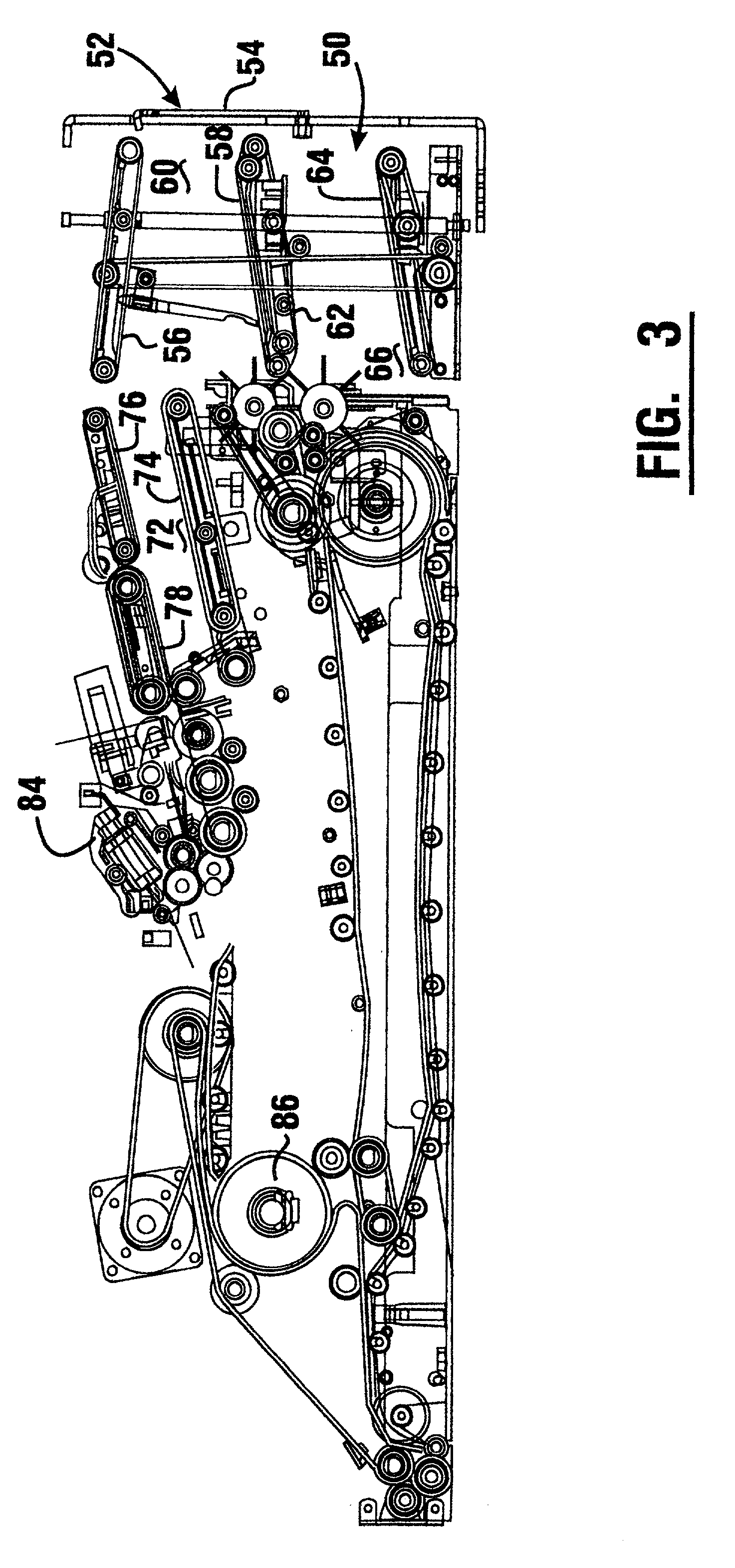

Document unstack system for currency recycling automated banking machine

InactiveUS6318714B1Easy to operateFacilitate rapid operation of machineFunction indicatorsPayment architectureMachine selectionDocumentation

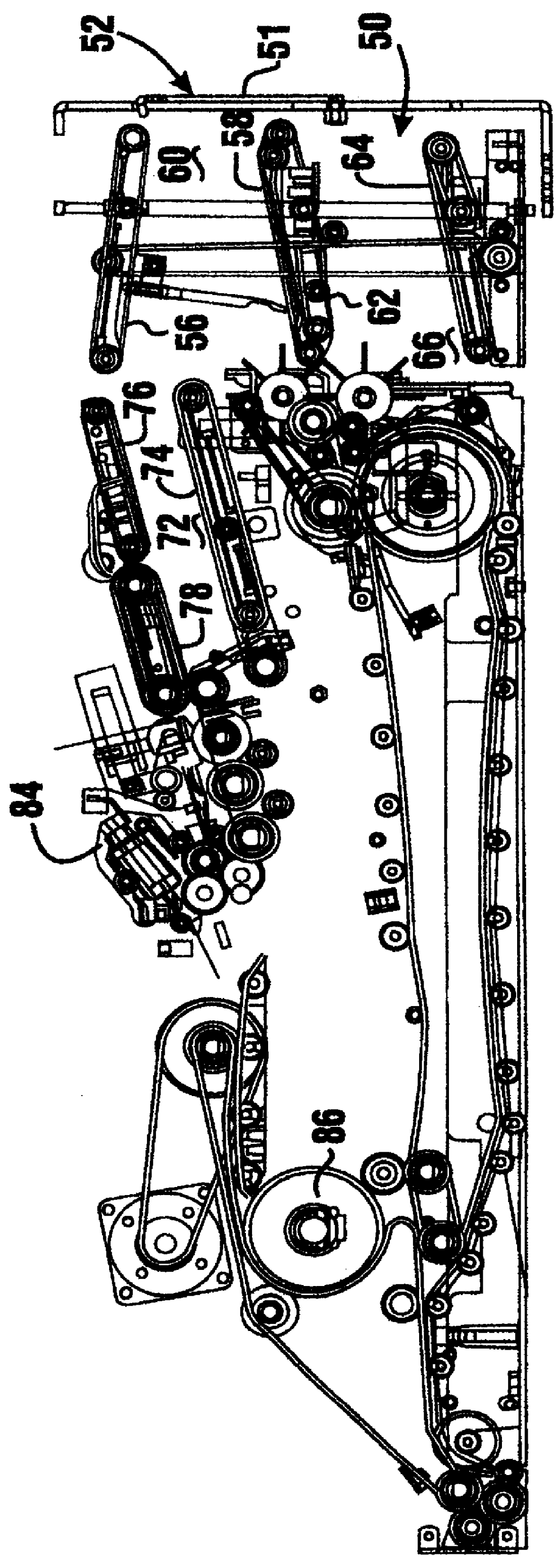

An automated banking machine (10) identifies and stores documents such as currency bills deposited by a user. The machine then selectively recovers such documents from storage and dispenses them to other users. The machine includes a central transport (70) wherein documents deposited in a stack are unstacked, oriented and identified. Such documents are then routed to storage areas in recycling canisters (92, 94, 96, 98). When a user subsequently requests a dispense, documents stored in the storage areas are selectively picked therefrom and delivered to the user through an input / output area (50) of the machine.

Owner:DIEBOLD NIXDORF

Finite capacity scheduling using job prioritization and machine selection

InactiveUS7904192B2Improve machine utilizationMultiprogramming arrangementsResourcesMachine selectionMachine utilization

Owner:AGENCY FOR SCI TECH & RES

Document alignment mechanism for currency recycling automated banking machine

InactiveUS6682068B1Easy to operateFacilitate rapid operation of machineComplete banking machinesRegistering devicesLeading edgeMachine selection

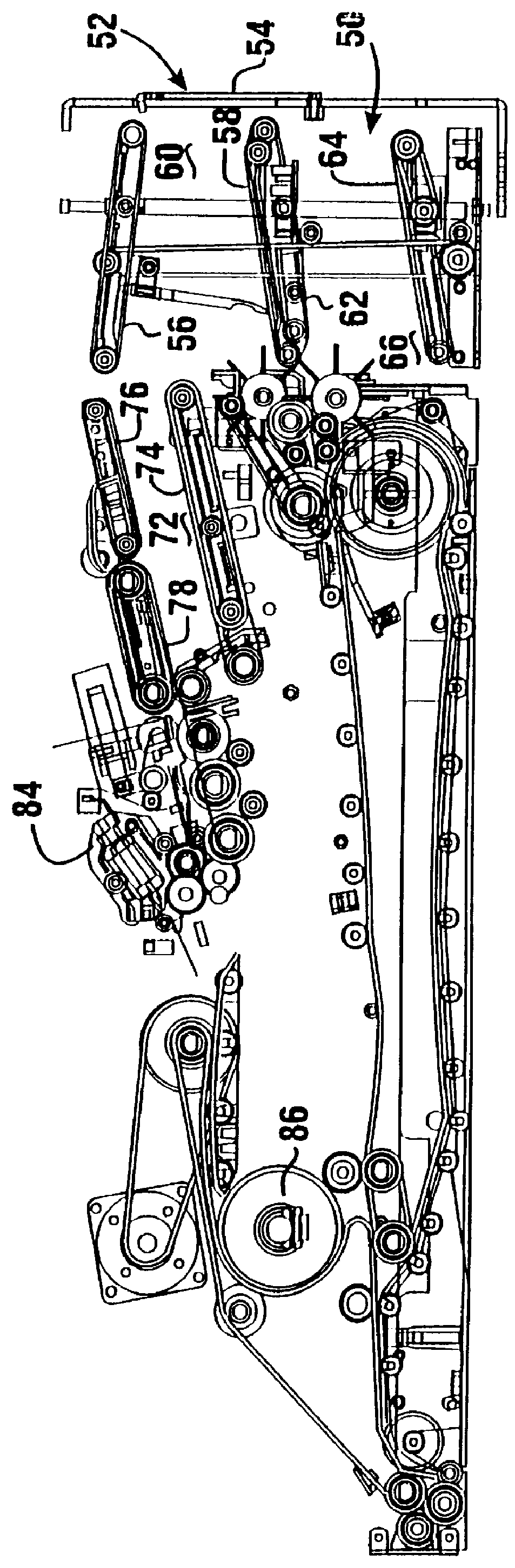

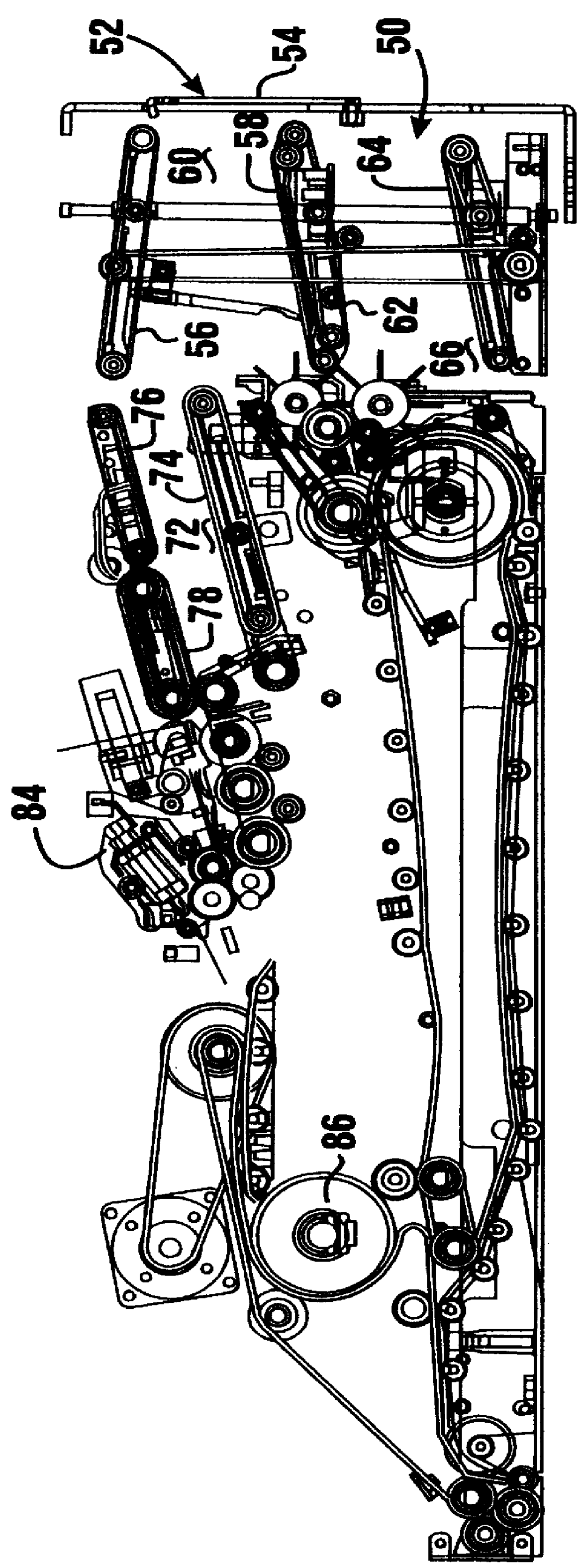

An automated banking machine (10) identifies and stores documents such as currency bills deposited by a user. The machine then selectively recovers such documents from storage and dispenses them to other users. The machine includes a central transport (70) wherein documents deposited in a stack are unstacked, oriented and identified. The documents are then routed to storage areas in recycling canisters (92, 94, 96, 98). When a user subsequently requests a dispense, documents stored in the storage areas are selectively picked therefrom and delivered to the user through an input / output device (50) of the machine. Sheets are oriented in the central transport by a deskewing / centering device (84). The deskewing / centering device includes a shuttle (204). The shuttle includes transversely disposed pinch wheels (212, 214) and sensors (216, 218, 220). The rotation of the pinch wheels is selectively controlled to orient the leading edges of sheets to extend transversely relative to the sheet path. Sheets are also moved transversely in engagement with the shuttle to a desired transverse position in the sheet path and then released.

Owner:DIEBOLD NIXDORF

Currency recycling automated banking machine media gate

InactiveUS6170818B1Easy to operateFacilitate rapid operation of machinePayment architectureSortingMachine selectionDocumentation

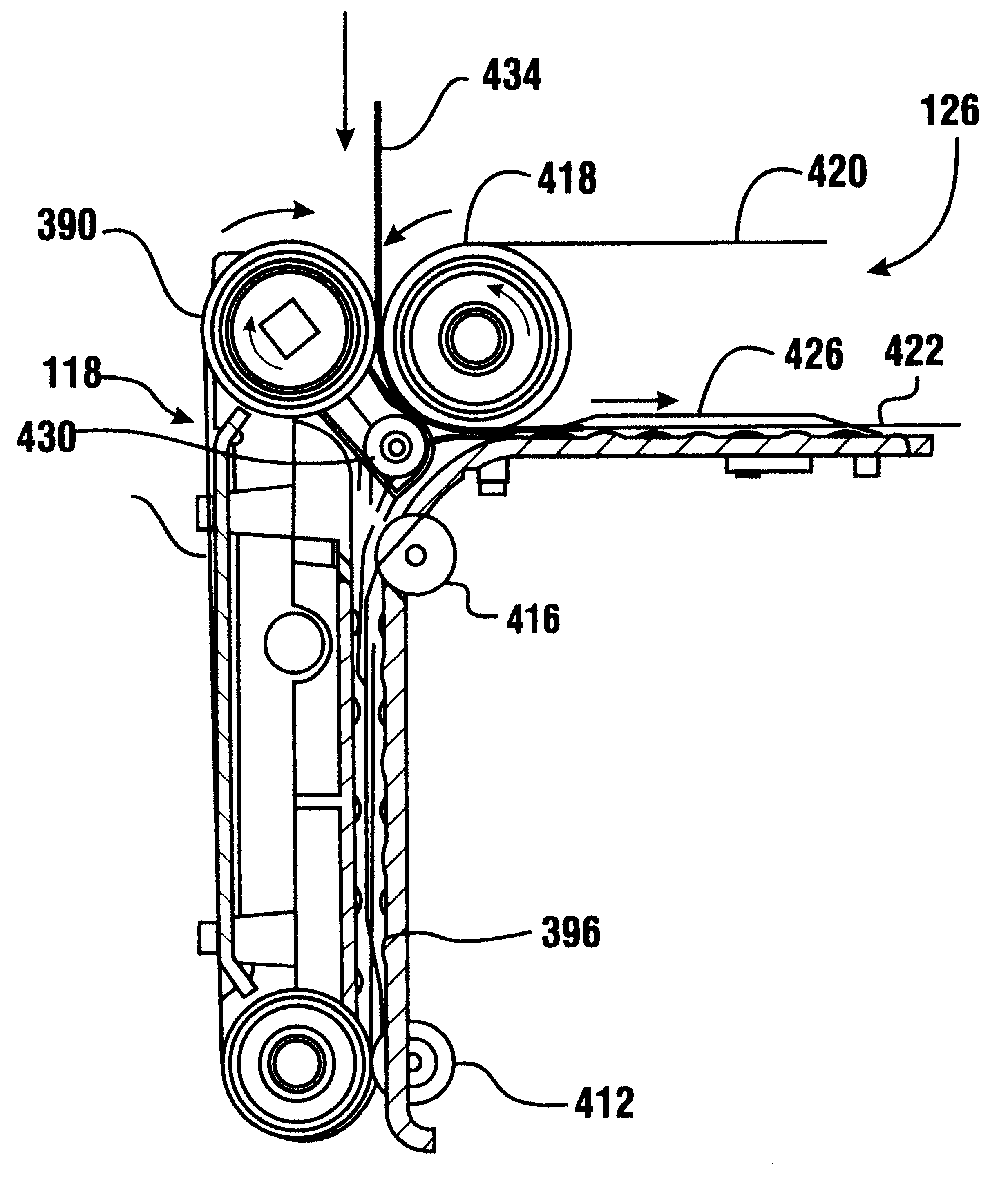

An automated banking machine (10) identifies and stores documents such as currency bills deposited by a user. The machine then selectively recovers such documents from storage areas and dispenses them to other users. The machine includes a central transport (70) in which documents which are deposited are oriented and identified. Such documents are then routed to storage areas in recycling canisters (92, 94, 96, 98) when a user subsequently requests a dispense of documents. Documents are selectively picked from the storage areas and delivered to the customer. Media gates (116, 118, 120, 122) are used to selectively direct documents between remote transport segments (108, 110, 112, 114) and canister delivery transports (124, 126, 128, 130). The media gates operate by selectively directing documents through an intersection (421) in engagement with transversely offset belt flights (396, 422). A diverter member (430) selectively deforms the belt flights of the remote transport segment so as to guide documents to and from an associated canister delivery transport.

Owner:DIEBOLD NIXDORF

System and method for dynamic multi-objective optimization of machine selection, integration and utilization

InactiveCN101807265AImprove efficiencyImprove reliabilityTesting/monitoring control systemsForecastingMachine selectionOperational costs

The invention provides control systems and methodologies for controlling a process having computer-controlled equipment, which provide for optimized process performance according to one or more performance criteria, such as efficiency, component life expectancy, safety, emissions, noise, vibration, operational cost, or the like. More particularly, the subject invention is provided for employing machine diagnostic and / or prognostic information in connection with optimizing an overall business operation over a time horizon.

Owner:ROCKWELL AUTOMATION TECH

Method for operating automated banking machine

InactiveUS6520408B1Easy to operateRisk minimizationPayment architectureVerifying markings correctnessMachine selectionDocumentation

Owner:DIEBOLD NIXDORF

Automated transaction machine system

InactiveUS20020011431A1Easy to operateEasy to handleCharacter and pattern recognitionSortingMachine selectionControl system

An automated banking machine (10) identifies and stores documents such as currency bills deposited by a user. The machine then selectively recovers documents from storage and dispenses them to other users. The machine includes a central transport (70) wherein documents deposited in a stack are unstacked, oriented and identified. Such documents are then routed to storage areas in recycling canisters (92, 94, 96, 98). When a user subsequently requests a dispense, documents stored in the storage areas are selectively picked therefrom and delivered to the user through an input / output area (50) of the machine. The control system (30) for the machine includes a terminal processor (548). Identification devices identify the type and character of a document, and distinguish genuine documents, such as genuine currency bills, from unidentifiable or suspect documents.

Owner:DIEBOLD NIXDORF

Automated banking machine with currency recycling canisters

InactiveUS6164638AEasy to operateFacilitate rapid operation of machineComplete banking machinesRegistering devicesMachine selectionDocumentation

An automated banking machine (10) identifies and stores documents such as currency bills deposited by a user. The machine then selectively recovers such documents from storage and dispenses them to other users. The machine includes a central transport (70) wherein documents deposited in a stack are unstacked, oriented and identified. Such documents are then routed to storage areas in recycling canisters (92, 94, 96, 98). When a user subsequently requests a dispense, documents stored in the storage areas are selectively picked therefrom and delivered to the user through an input / output area (50) of the machine.

Owner:DIEBOLD NIXDORF

Document sensor for currency recycling automated banking machine

InactiveUS20010013541A1Easy to operateFacilitate rapid operation of machineComplete banking machinesFinanceMachine selectionDocumentation

An automated banking machine (10) identifies and stores documents such as currency bills deposited by a user. The machine then selectively recovers such documents from storage areas and dispenses them to other users. The machine includes a sheet thickness detector (810) used for distinguishing single sheets from double sheets which pass through the machine. The thickness detector includes a radiation source (822). Radiation from the radiation source is directed by radiation guide (824) to a generally linear elongated radiation outlet (826) which extends transversely to the sheet path. A receiver (814) includes a radiation sensitive element (830) which is also transversely elongated relative to the sheet path. Sheets passing between the emitter and the receiver cause variations in the amount of radiation reaching the receiver. The transversely elongated surface of the sheet through which the transmission of radiation is sensed enables accurately distinguishing single sheets from double sheets.

Owner:DIEBOLD NIXDORF

System and method for dynamic multi-objective optimization of machine selection, integration and utilization

ActiveUS8914300B2Improve overall utilizationImprove efficiencyForecastingTechnology managementOperational costsMachine selection

Owner:ROCKWELL AUTOMATION TECH

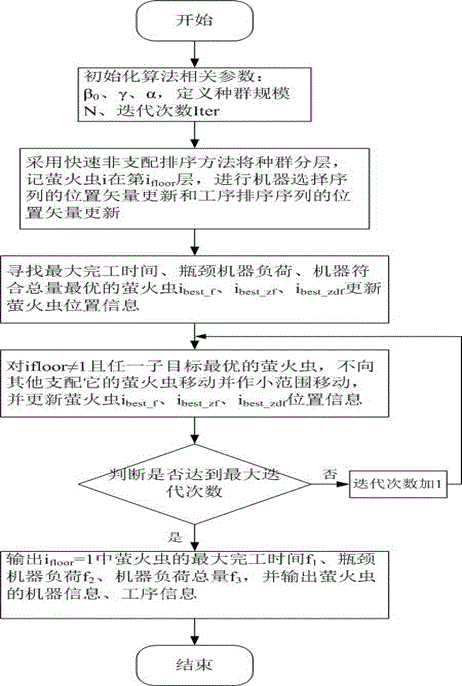

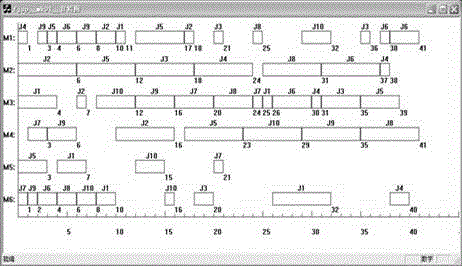

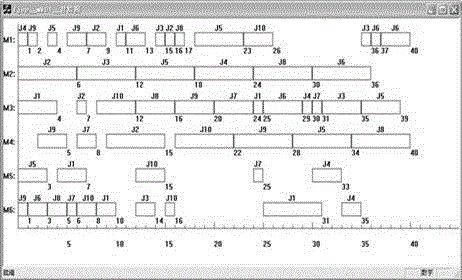

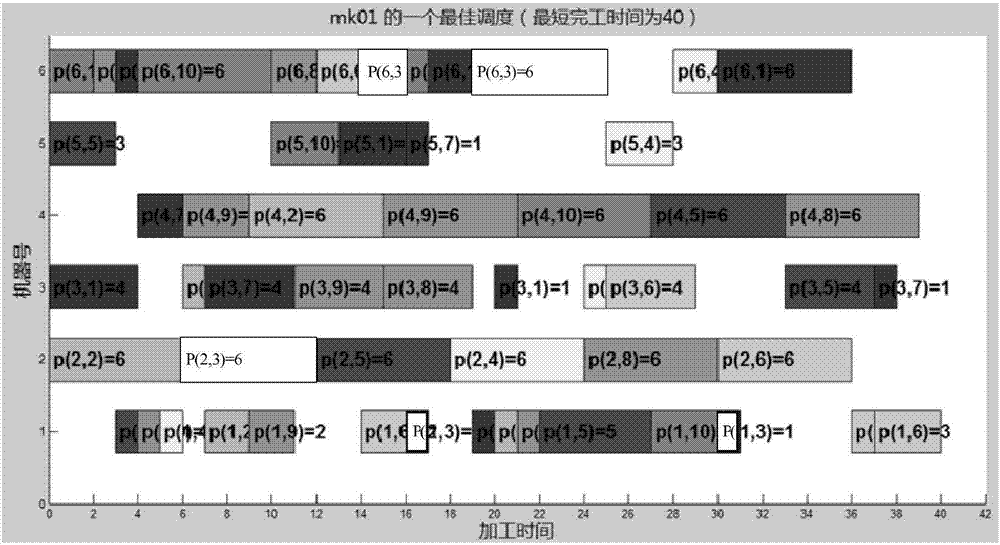

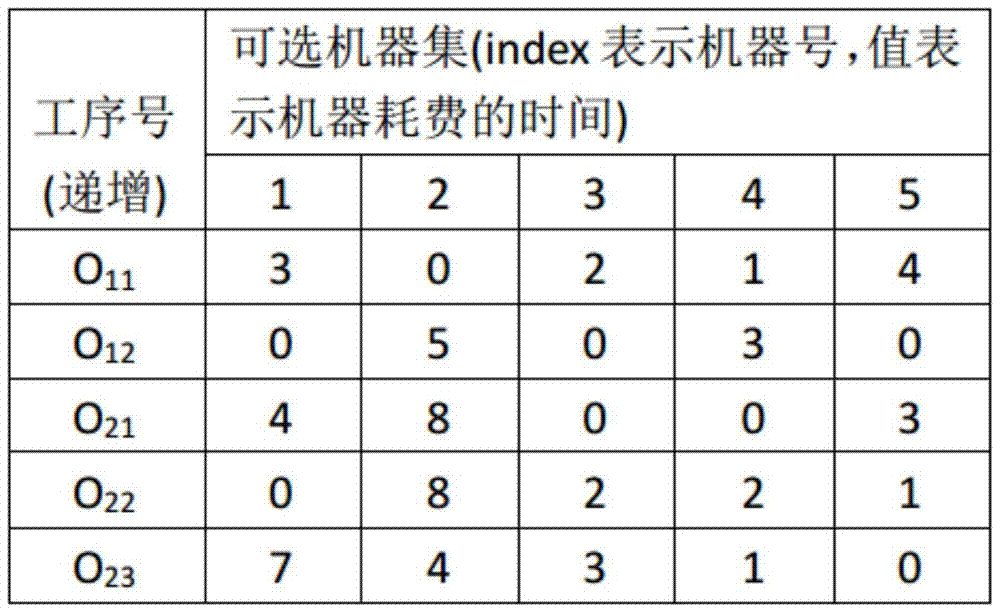

Multi-objective flexible job shop scheduling method based on discrete firefly algorithm

The invention provides a multi-objective flexible job shop scheduling method based on a discrete firefly algorithm. The method comprises the steps that a mathematical model is established for a multi-objective flexible job shop scheduling problem; a segment coding method is used to code a firefly, and a machine selection part and a process sorting part are divided; the discrete firefly algorithm is used to optimize the model to acquire a Pareto optimal solution set; and a solution corresponding to the actual need is selected from the Pareto optimal solution set, and decoding is carried out to output machine selection position information and process sorting position information. Compared with the existing method, the multi-objective flexible job shop scheduling problem optimizing method has the advantages that the global optimization ability of the algorithm is improved; the overall processing time is shortened; the job shop production cost is reduced; and the method meets actual production needs.

Owner:XIANGTAN UNIV

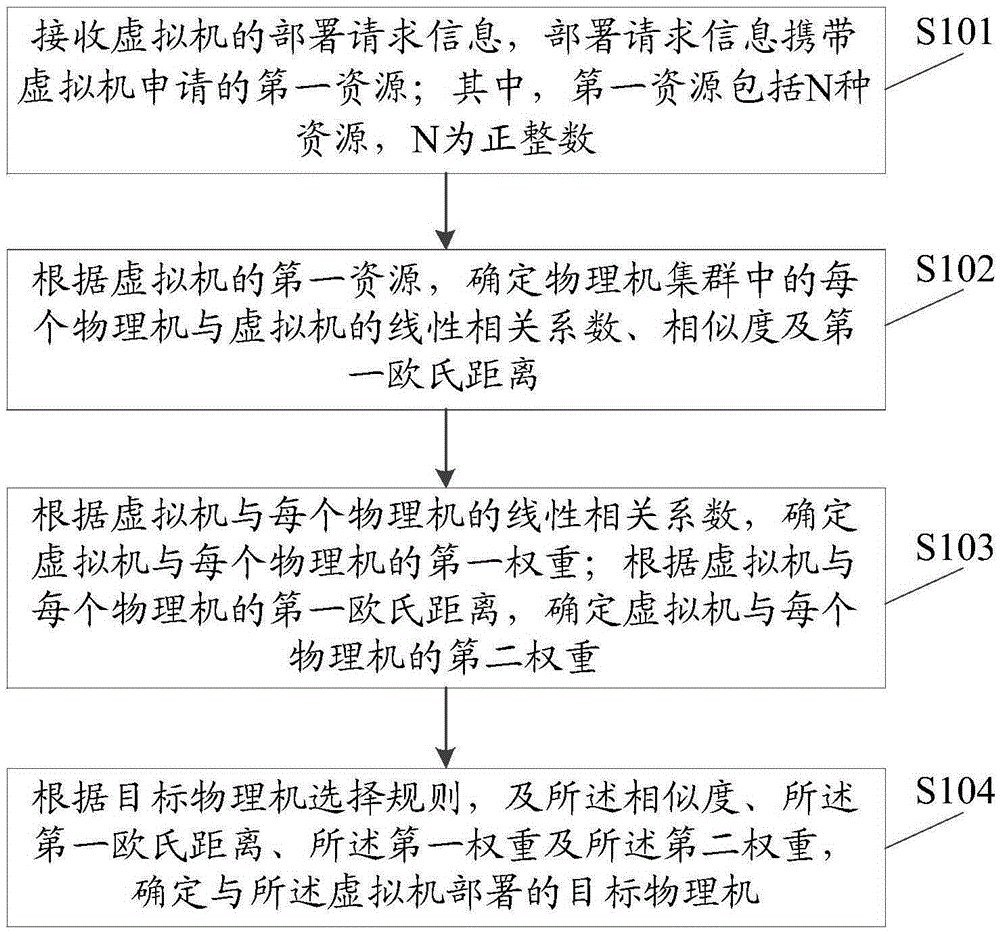

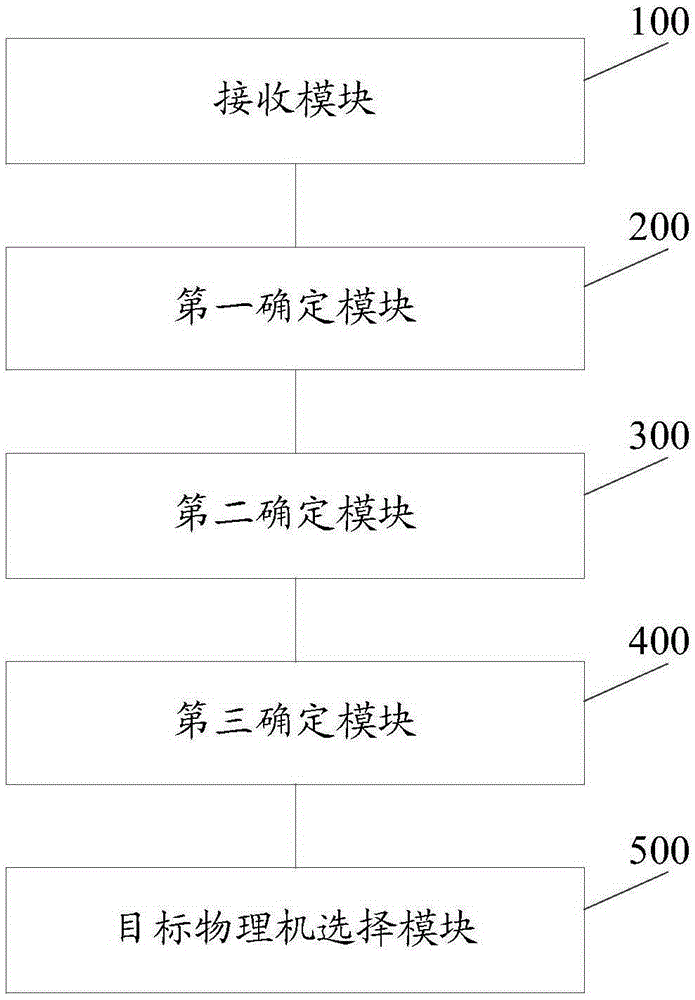

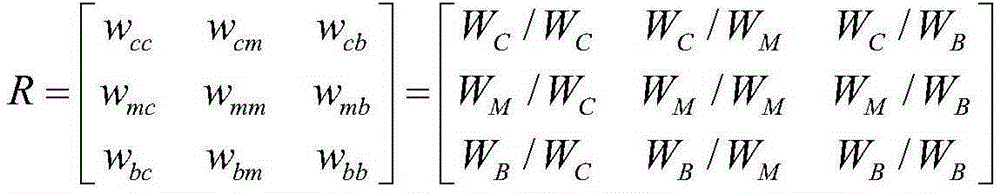

Virtual machine disposition method and apparatus

ActiveCN105279027AOvercome uneven loadingResource allocationSoftware simulation/interpretation/emulationCorrelation coefficientMachine selection

The embodiments of the invention disclose a virtual machine disposition method and apparatus. The method comprises the following steps: receiving disposition request information of a virtual machine, wherein the disposition request information carries a first resource applied for by the virtual machine; according to the first resource of the virtual machine, determining a linearity correlation coefficient, similarity and a first Euclidean distance between each physical machine in a physical machine cluster and the virtual machine; according to the linearity correlation coefficient between the virtual machine and each physical machine, determining first weights of the virtual machine and each physical machine; according to the first Euclidean distance between the virtual machine and each physical machine, determining second weights of the virtual machine and each physical machine; and according to an object physical machine selection rule, the similarity, the first Euclidean distance, the first weights and the second weights, determining an object physical machine disposed to the virtual machine. It can be seen that when the object physical machine is selected, the disposition request information sent by the virtual machine carries N resources, such that the problem of load nonuniformity caused by single-attribute disposition or random disposition in the prior art is overcome.

Owner:INSPUR BEIJING ELECTRONICS INFORMATION IND

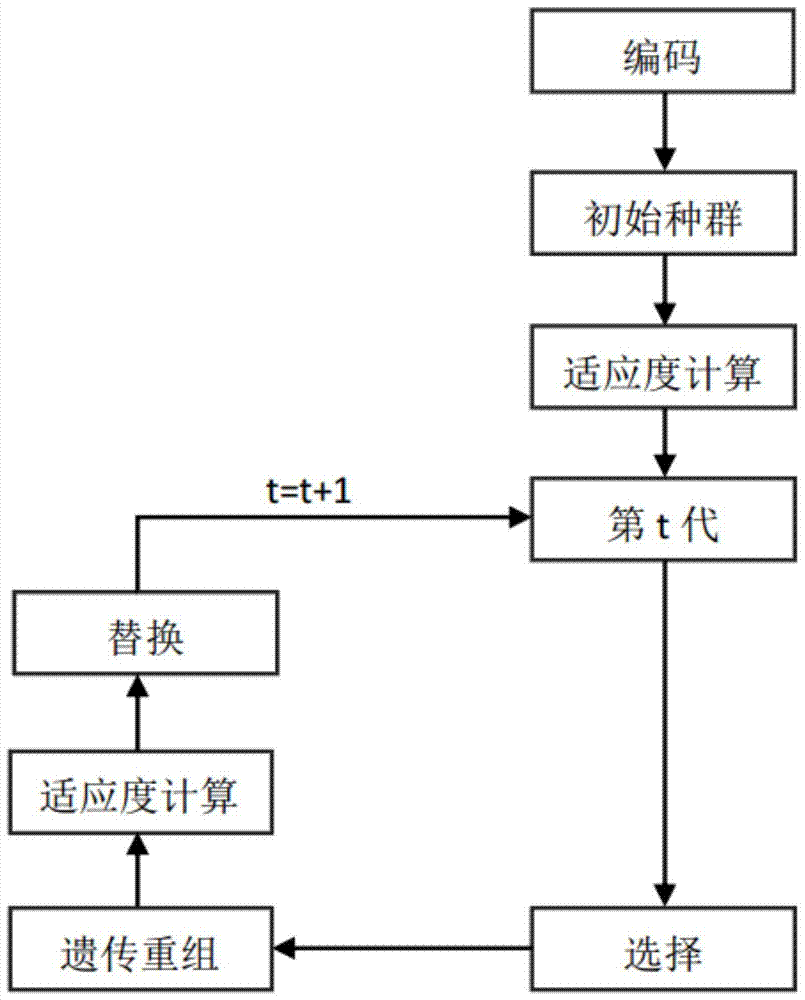

Control method for solving flexible job shop scheduling problem based on genetic algorithm

InactiveCN106933200AHigh genetic diversityImprove performanceProgramme total factory controlMachine selectionGenetic algorithm

The invention relates to a control method for solving a flexible job shop scheduling problem based on a genetic algorithm, which is divided into six parts such as encoding and decoding, initial population generation, crossover, mutation, fitness calculation and selection. The control method is characterized in that a segmented encoding method is adopted, chromosome encoding is divided into a machine selection part and a procedure selection part, and chromosomes are decoded according to a certain mode so as to acquire corresponding manufacturing procedures and corresponding manufacturing machines; an initial population is generated by adopting a mode of combining various search modes; and fitness calculation aims to solve a problem of how to solve the execution time of certain legal scheduling and judge the quality of the scheduling. The control method provided by the invention not only has great advantages in solving quality, but also has the same excellent performance in improving the solving speed and processing a large-scale flexible job shop scheduling problem.

Owner:中国科学院沈阳计算技术研究所有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com