Control method for solving flexible job shop scheduling problem based on genetic algorithm

A genetic algorithm and flexible operation technology, applied in program control, comprehensive factory control, electrical program control, etc., can solve problems such as difficult to achieve reasonable allocation of resources and optimal sequencing of operations, not so ideal solution quality, large-scale dynamic uncertainty, etc. , to achieve the effect of short solution time, reduced solution time, and excellent performance

Inactive Publication Date: 2017-07-07

中国科学院沈阳计算技术研究所有限公司

View PDF9 Cites 17 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] Due to the characteristics of large-scale, multi-objective, complex constraints, and dynamic uncertainty in process industry production planning and scheduling problems, it is difficult to use conventional modeling and optimization methods directly, and it is difficult to achieve reasonable allocation of resources and optimal sequencing of jobs using manual scheduling methods

The above solutions not only take a long time to solve, but the quality of the solution is not so ideal, and it is even more powerless when dealing with large-scale FJSSP. Therefore, it is necessary to discuss the modeling optimization and effective solution methods suitable for the production planning and scheduling of the process industry become a key theoretical problem to be solved urgently

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

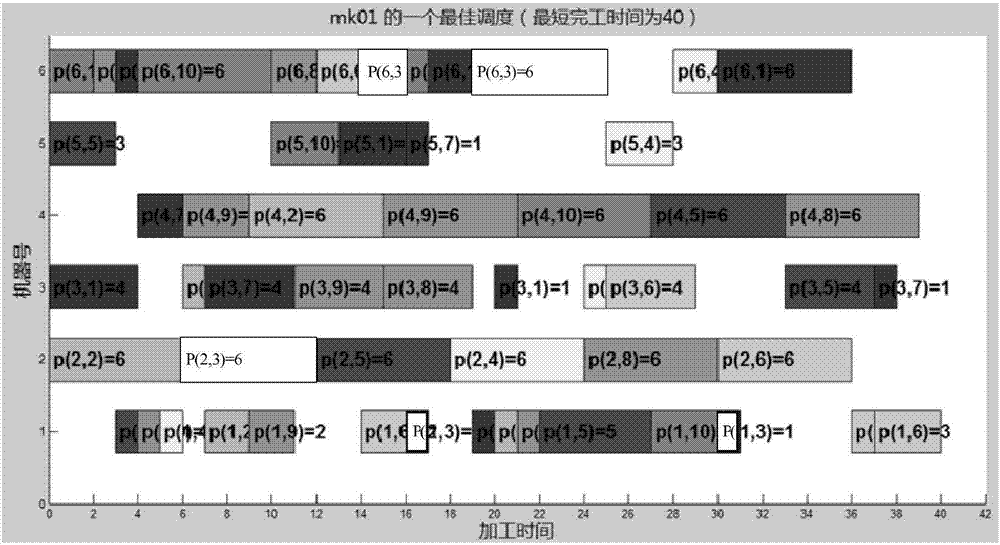

[0033] Embodiment: The method of the present invention is simulated and verified on a PC, and the programming software used is EclipseLuna, and the Java language is used to write the program.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

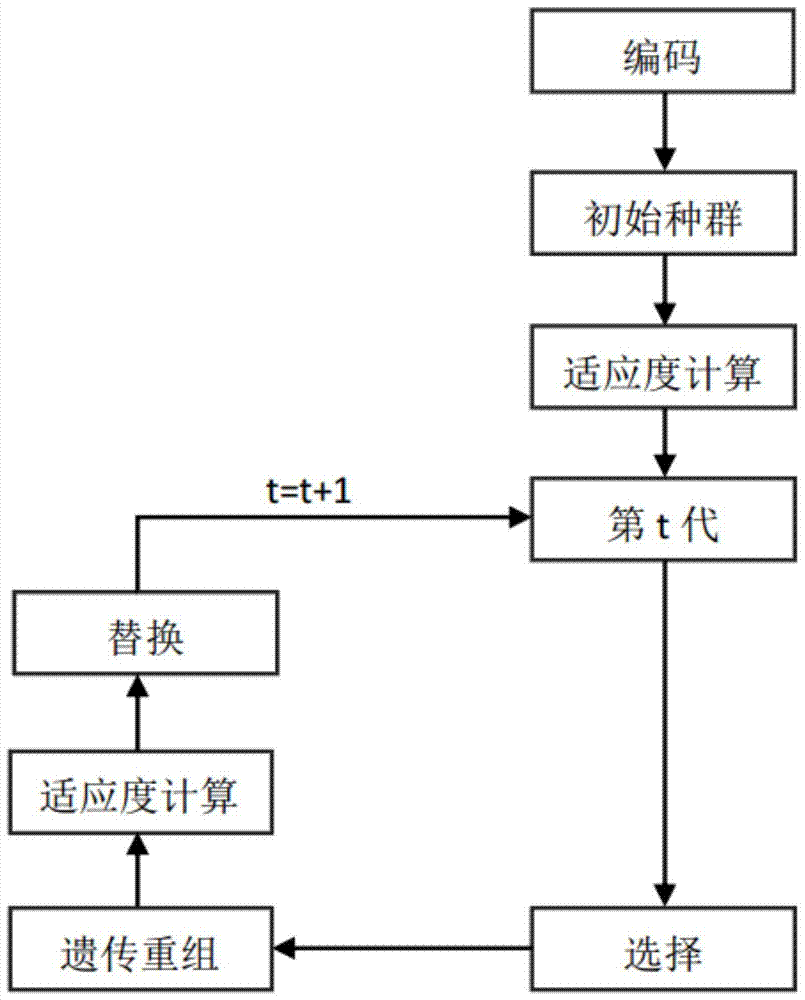

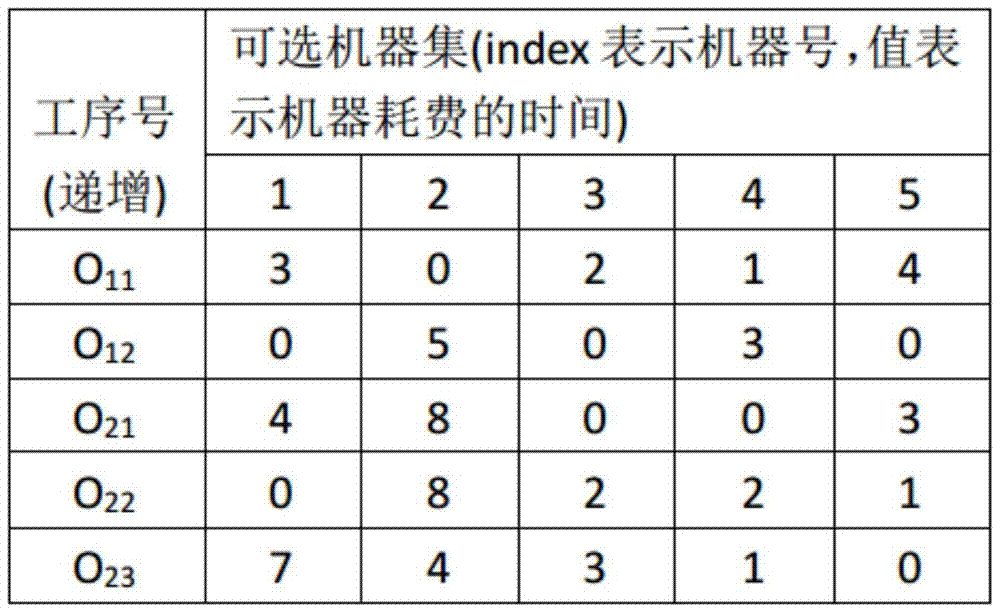

The invention relates to a control method for solving a flexible job shop scheduling problem based on a genetic algorithm, which is divided into six parts such as encoding and decoding, initial population generation, crossover, mutation, fitness calculation and selection. The control method is characterized in that a segmented encoding method is adopted, chromosome encoding is divided into a machine selection part and a procedure selection part, and chromosomes are decoded according to a certain mode so as to acquire corresponding manufacturing procedures and corresponding manufacturing machines; an initial population is generated by adopting a mode of combining various search modes; and fitness calculation aims to solve a problem of how to solve the execution time of certain legal scheduling and judge the quality of the scheduling. The control method provided by the invention not only has great advantages in solving quality, but also has the same excellent performance in improving the solving speed and processing a large-scale flexible job shop scheduling problem.

Description

technical field [0001] The invention relates to a genetic algorithm-based control method for solving the flexible job shop scheduling problem (FJSSP), which belongs to the field of numerical control processing. Background technique [0002] With the advent of the industry 4.0 era, e-commerce continues to prosper globally, customer needs are increasingly personalized, product cycles are shortened, delivery times are shortened, and product categories are increasing. Rapid customization will be a major development trend. . How to accurately estimate the delivery time of the product to the maximum extent and utilize the production materials efficiently has undoubtedly become a very important subject. In order to solve the above problems, it is undoubtedly of great significance to improve the quality of production planning by studying efficient control methods to solve FJSSP. [0003] Due to the characteristics of large-scale, multi-objective, complex constraints, and dynamic u...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G05B19/418

CPCG05B19/41865G05B2219/32252

Inventor 马跃胡毅张腾飞安涛王帅郭安

Owner 中国科学院沈阳计算技术研究所有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com