Patents

Literature

153 results about "Machine utilization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

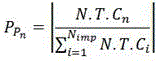

Machine utilization. the extent to which the productive capacity of a machine is used during a specified period of time. Machine utilization can be expressed as a percentage, for example:

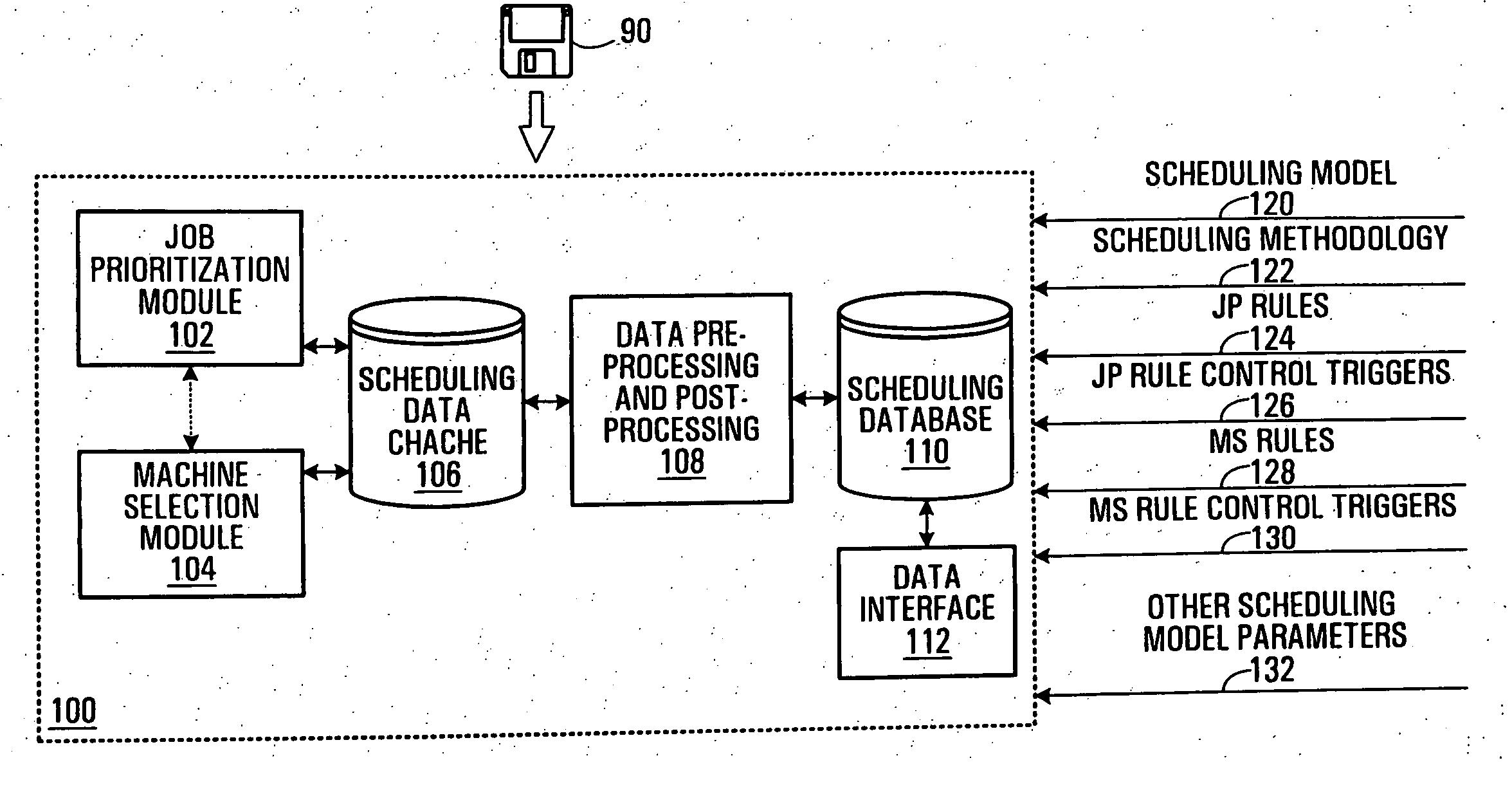

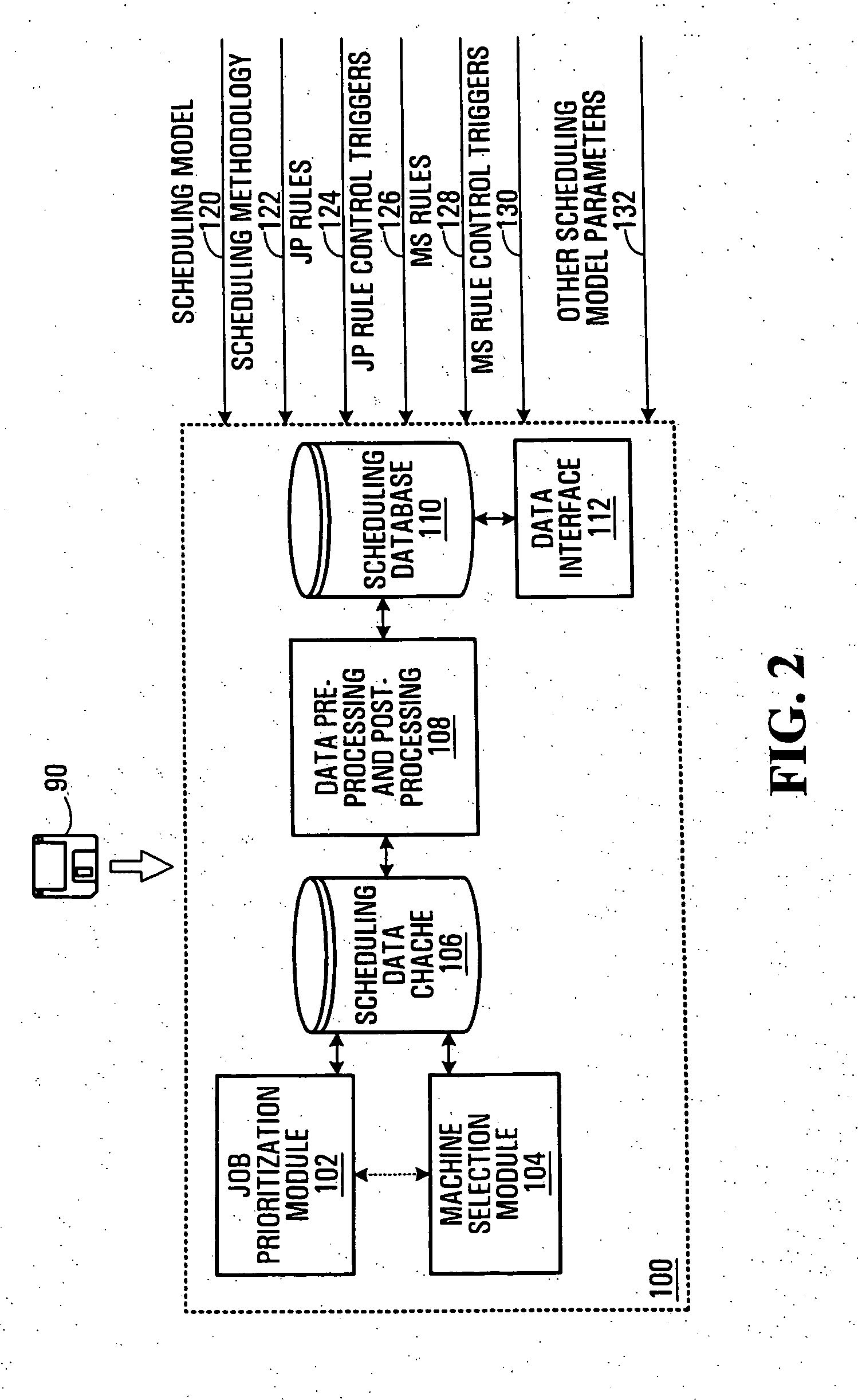

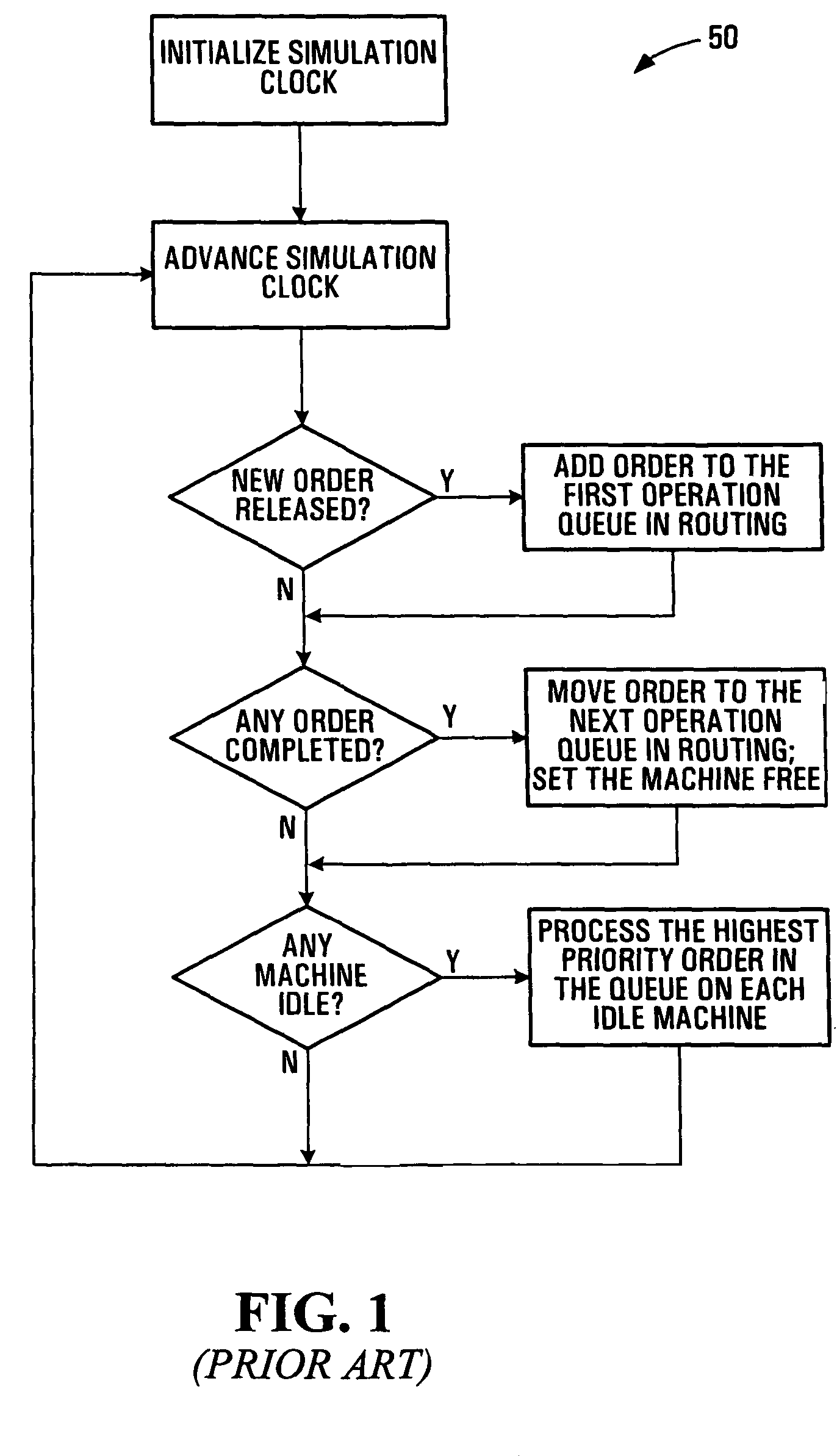

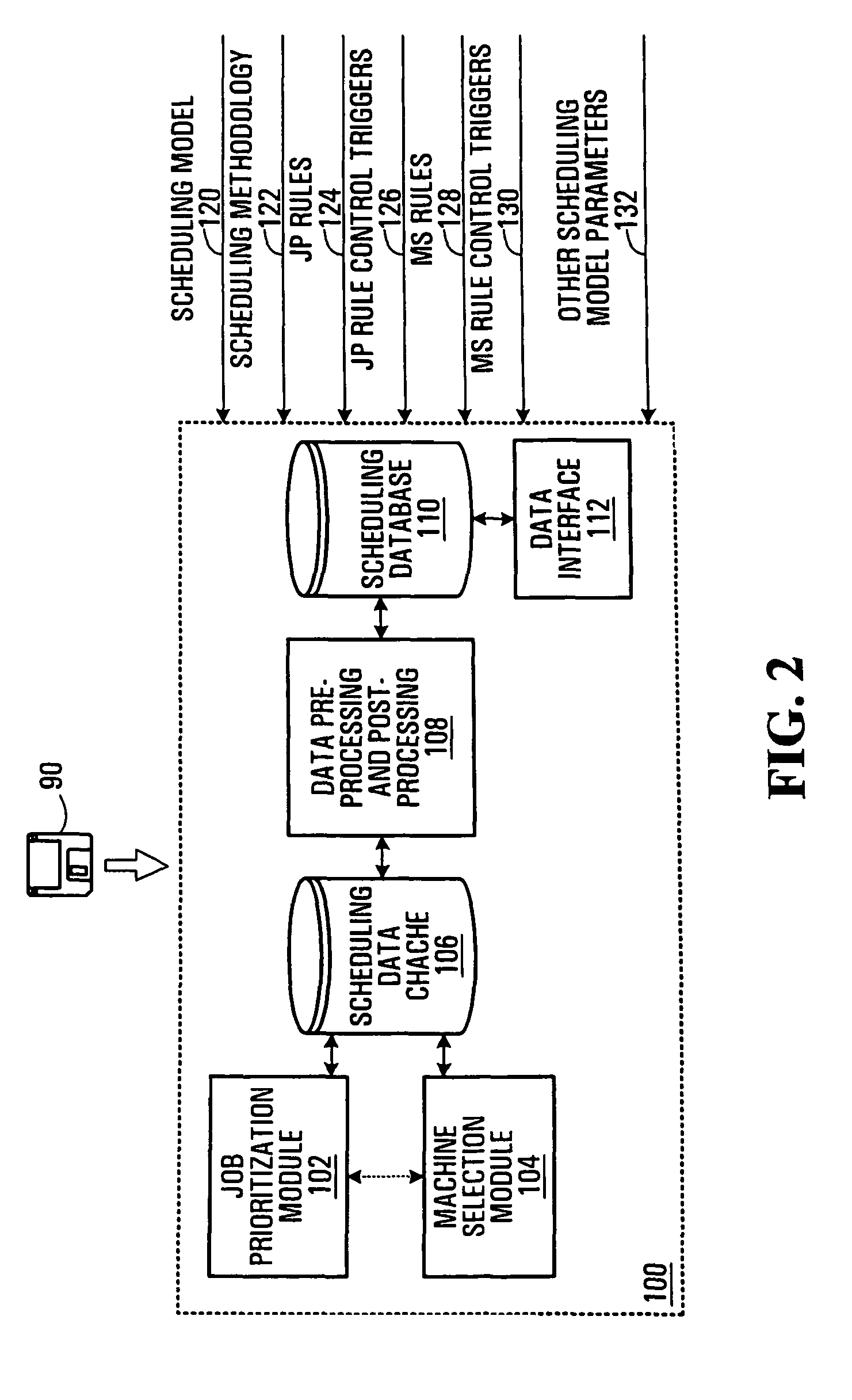

Finite capacity scheduling using job prioritization and machine selection

InactiveUS20050154625A1Improve machine utilizationResourcesSpecial data processing applicationsMachine selectionMachine utilization

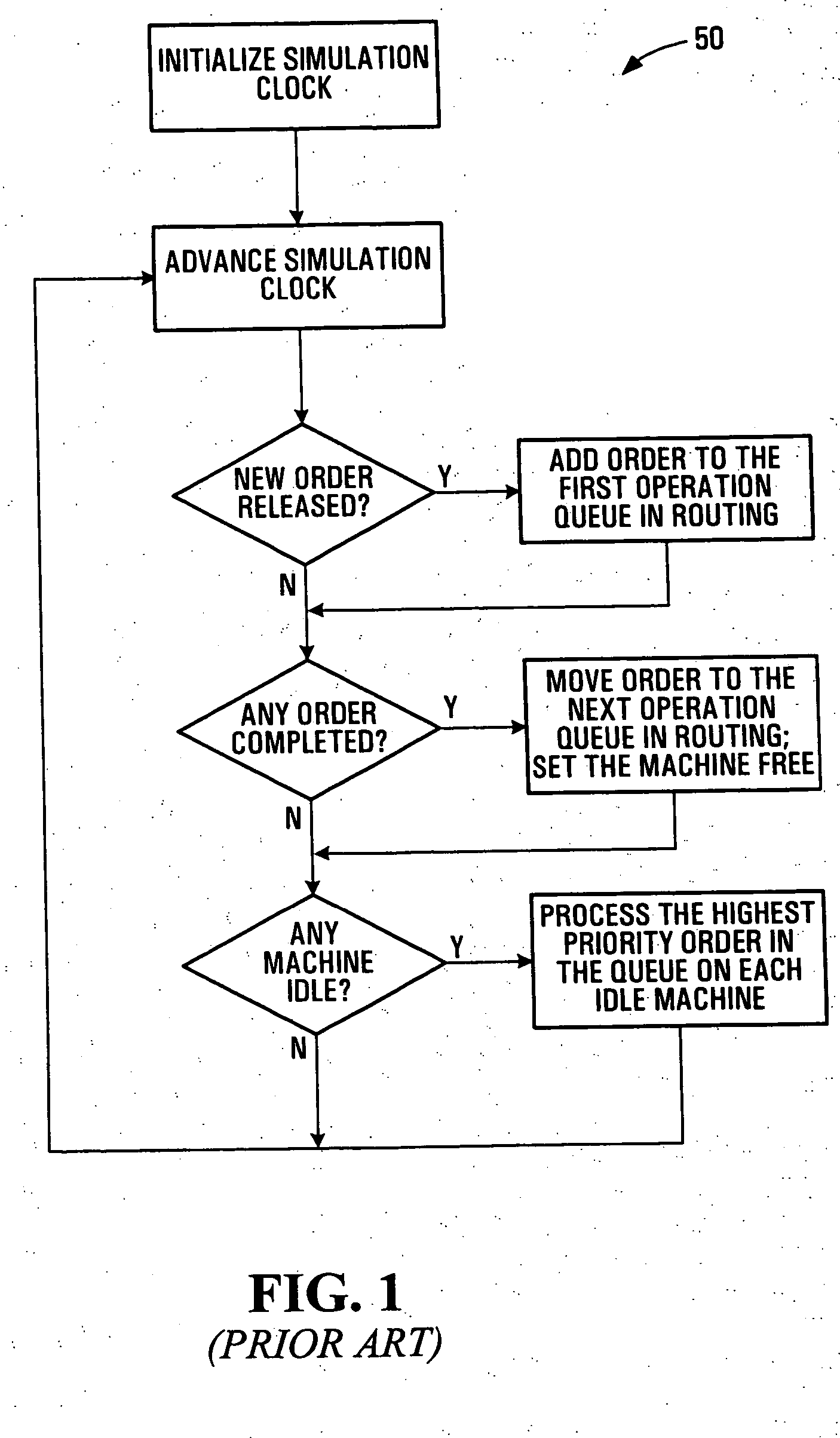

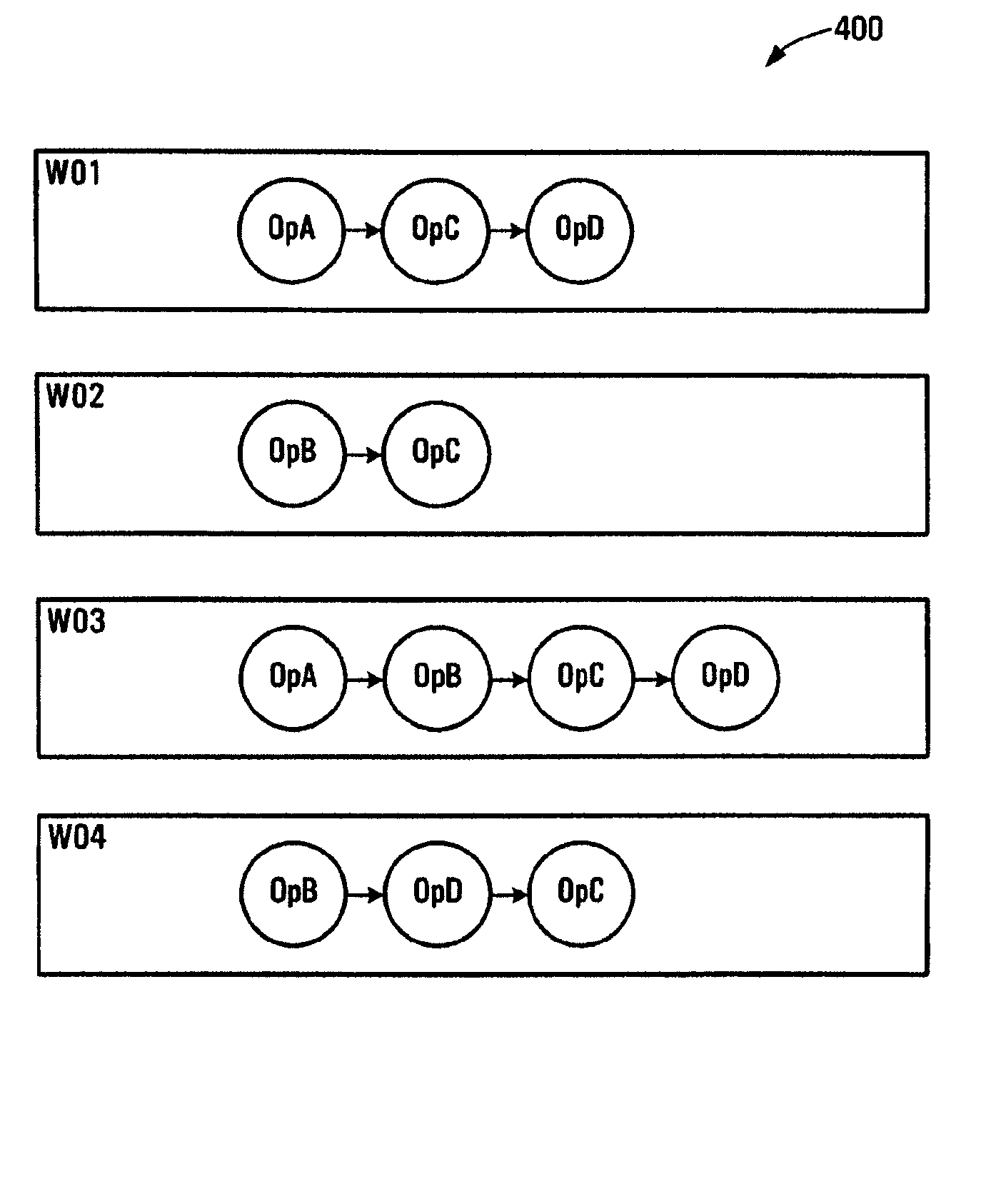

In a method, device, and computer-readable medium for finite capacity scheduling, heuristic rules are applied in two integrated stages: Job Prioritization and Machine Selection. During Job Prioritization (“JP”), jobs are prioritized based on a set of JP rules which are machine independent. During Machine Selection (“MS”), jobs are scheduled for execution at machines that are deemed to be best suited based on a set of MS rules. The two-stage approach allows scheduling goals to be achieved for performance measures relating to both jobs and machines. For example, machine utilization may be improved while product cycle time objectives are still met. Two user-configurable options, namely scheduling model (job shop or flow shop) and scheduling methodology (forward, backward, or bottleneck), govern the scheduling process. A memory may store a three-dimensional linked list data structure for use in scheduling work orders for execution at machines assigned to work centers.

Owner:AGENCY FOR SCI TECH & RES

Finite capacity scheduling using job prioritization and machine selection

InactiveUS7904192B2Improve machine utilizationMultiprogramming arrangementsResourcesMachine selectionMachine utilization

Owner:AGENCY FOR SCI TECH & RES

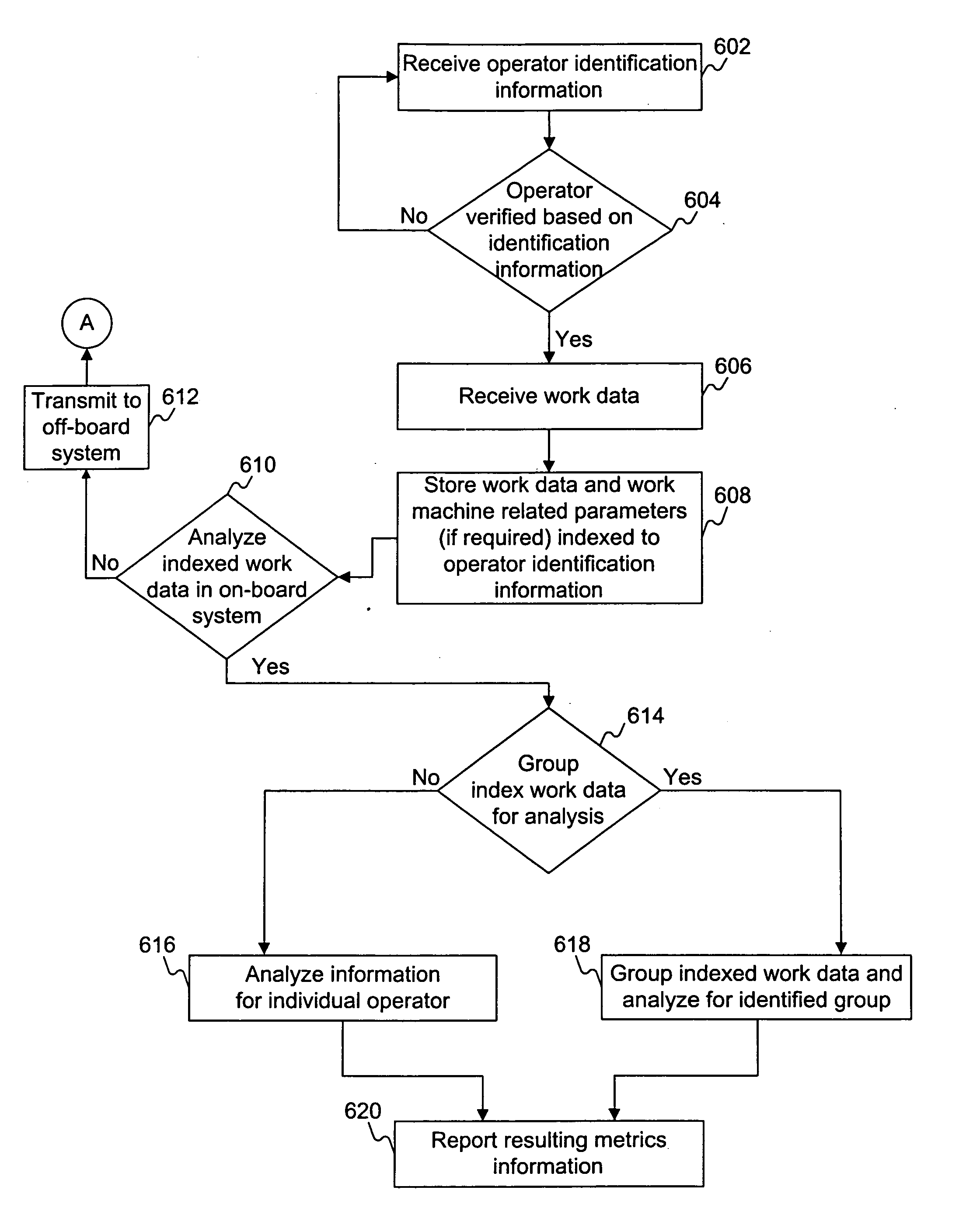

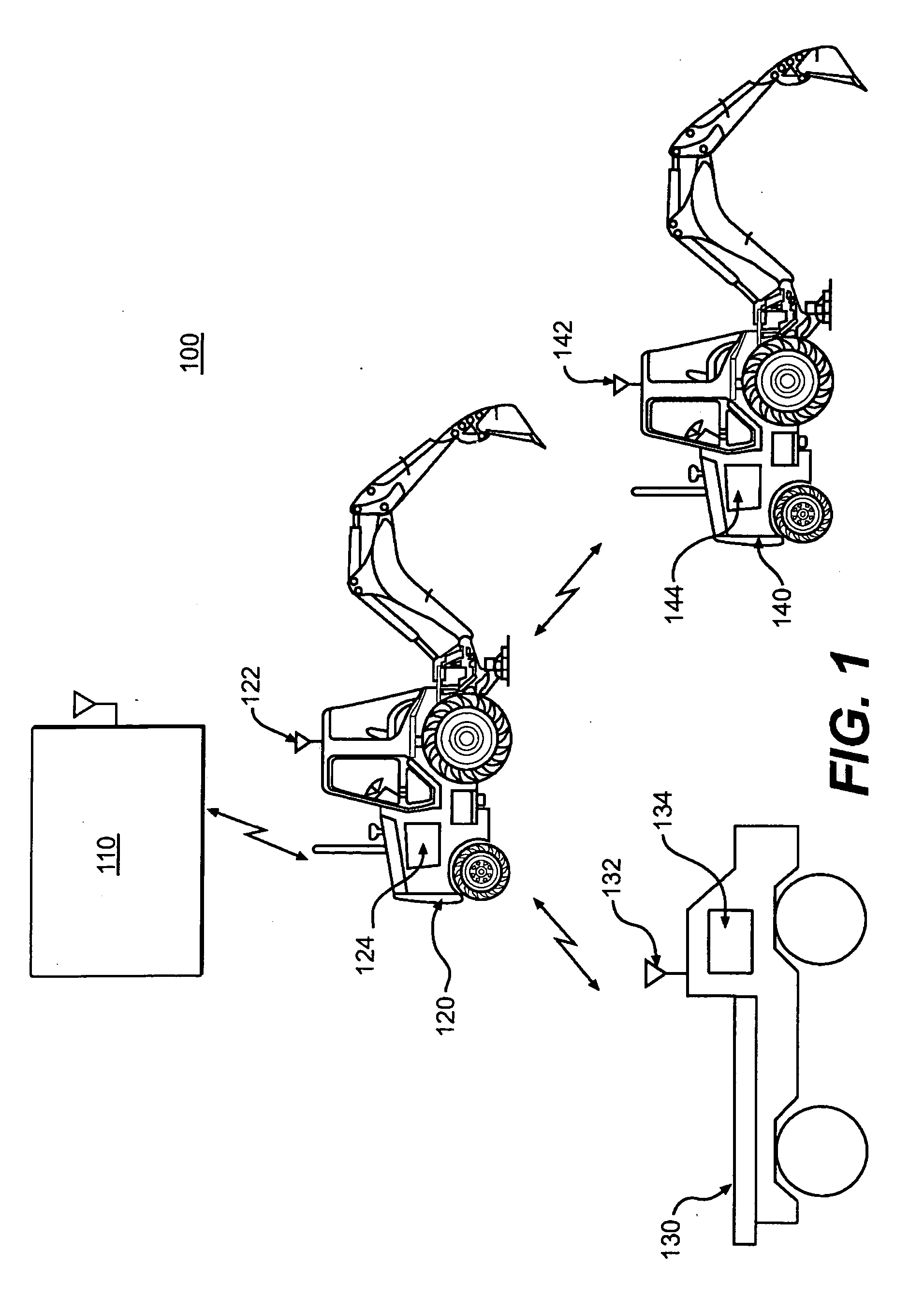

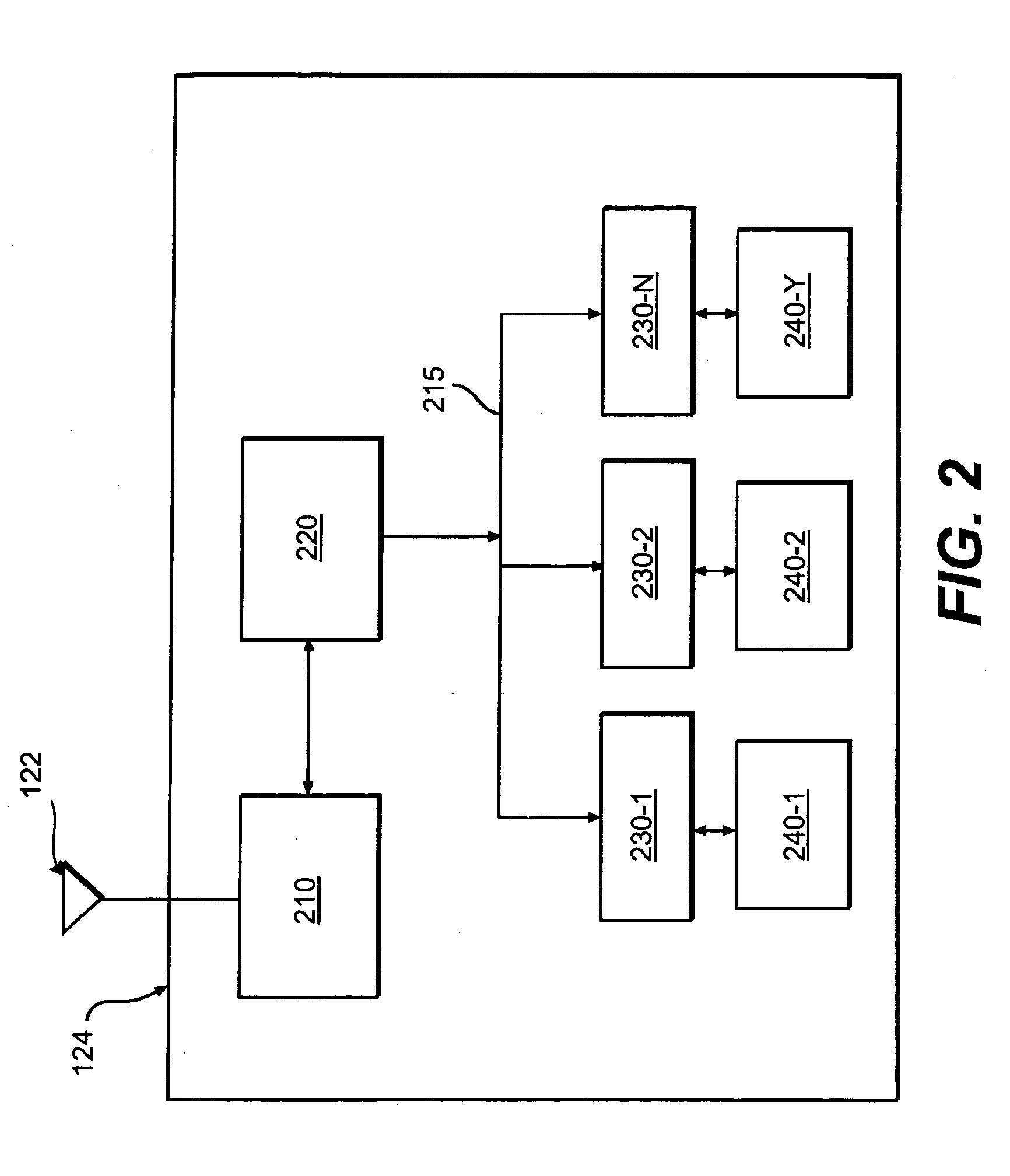

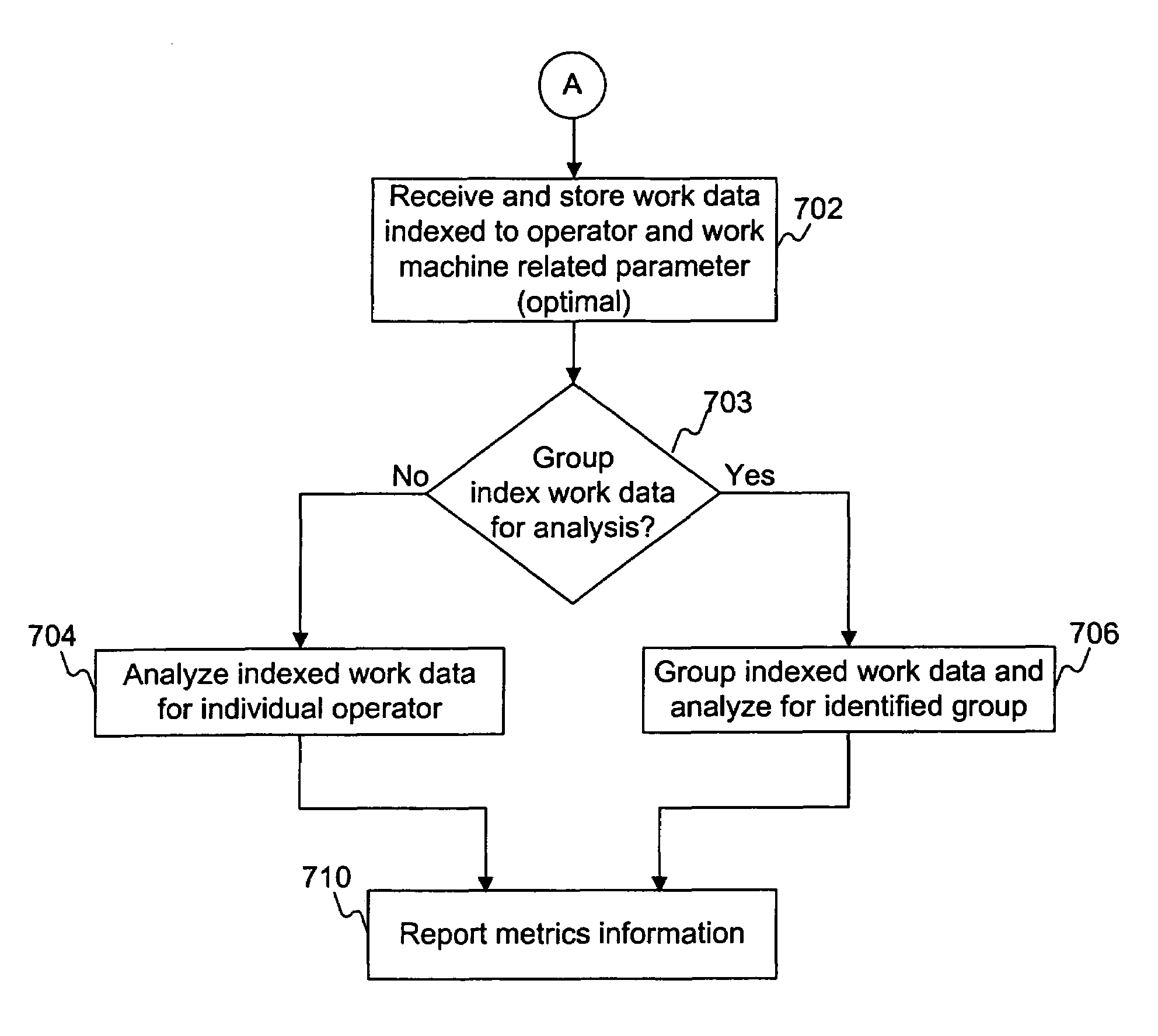

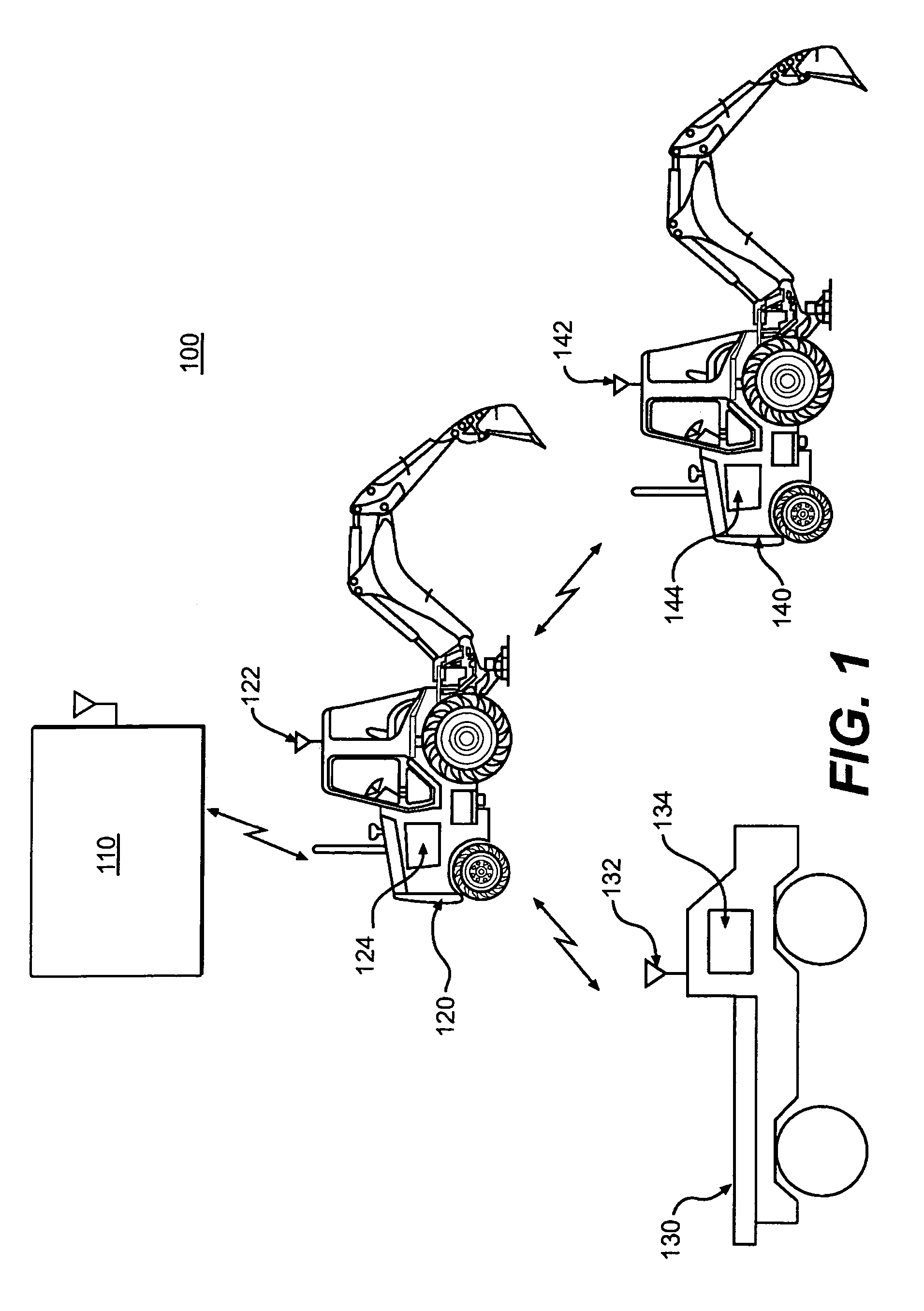

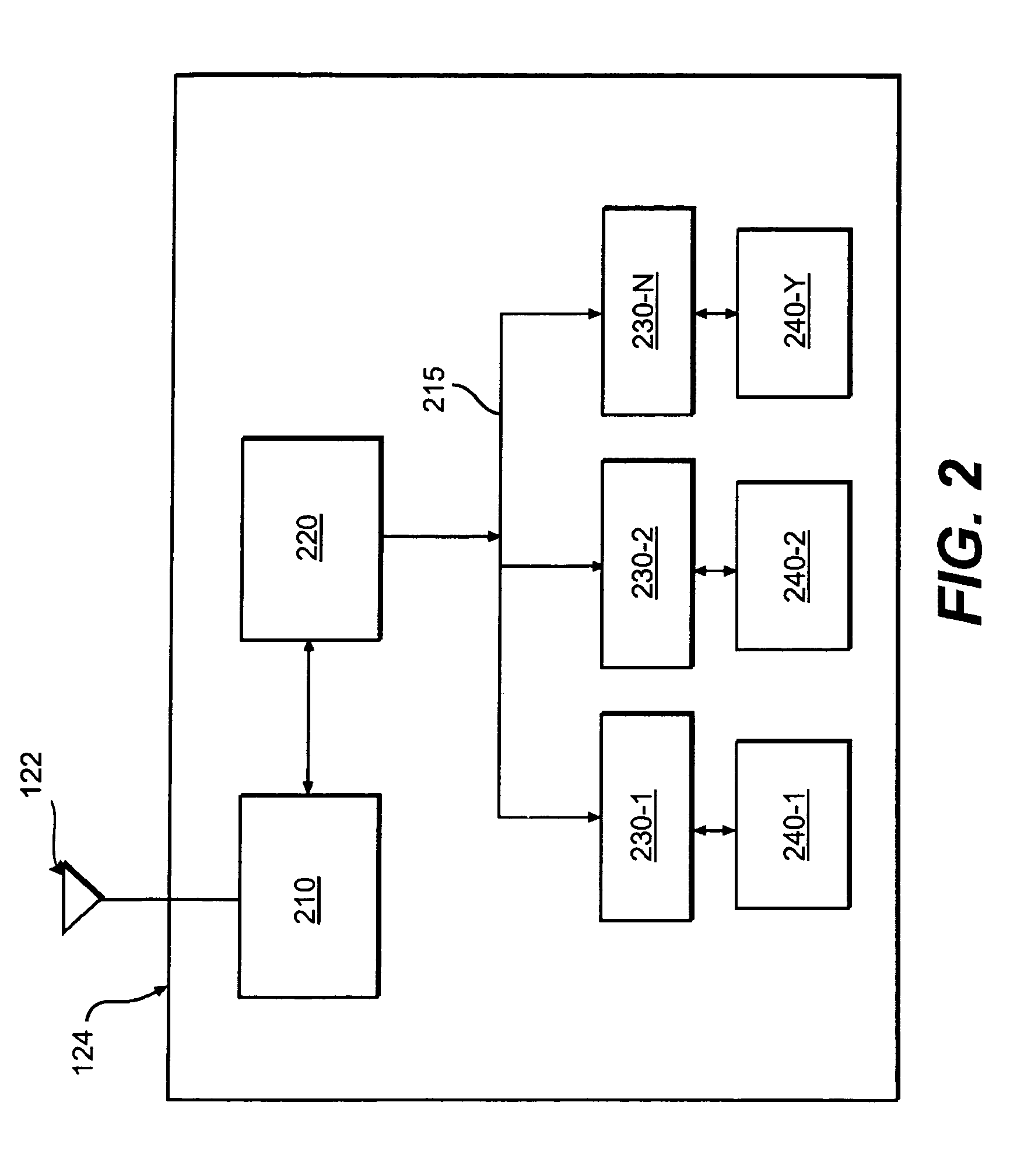

System for providing indexed machine utilization metrics

ActiveUS20050278055A1Vehicle testingRegistering/indicating working of vehiclesMachine utilizationIdentification device

A system and method for providing indexed work machine utilization data. The system implementing the method includes an operator identification device for identifying an operator of a work machine based on operator identification data and a work data collection device for collecting work data related to the work machine. A first processing device indexes the collected work data to the operator identification data and a communication device transmits the indexed work data and operator identification data to a second processing device. The second processing device receives the indexed work data and the operator identification data and provides operator utilization metrics based on the indexed work data that reflect a quantitative performance value associated with at least one of the work machine and operator.

Owner:CATERPILLAR INC

System for providing indexed machine utilization metrics

ActiveUS7113839B2Vehicle testingRegistering/indicating working of vehiclesMachine utilizationIdentification device

A system and method for providing indexed work machine utilization data. The system implementing the method includes an operator identification device for identifying an operator of a work machine based on operator identification data and a work data collection device for collecting work data related to the work machine. A first processing device indexes the collected work data to the operator identification data and a communication device transmits the indexed work data and operator identification data to a second processing device. The second processing device receives the indexed work data and the operator identification data and provides operator utilization metrics based on the indexed work data that reflect a quantitative performance value associated with at least one of the work machine and operator.

Owner:CATERPILLAR INC

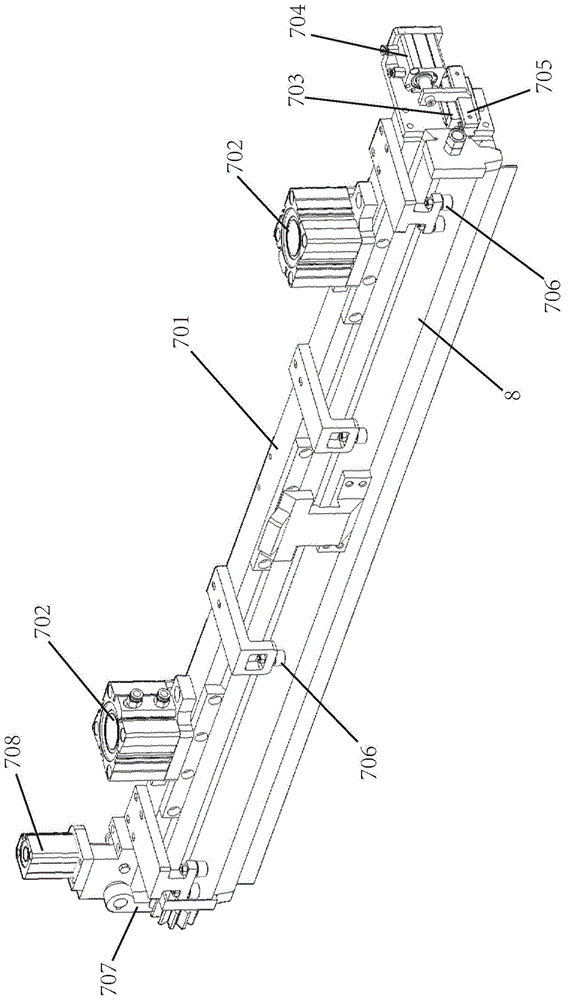

Device and method for simulating the processing of a workpiece on a machine tool

The invention relates to a device and a method for simulating a sequence for machining a workpiece on a machine tool. The invention is characterized by a holistic simulation approach. Particularly, a PLC control means 723 and a PLC sequence simulation means 725 assist in simulating the PLC movement sequences of the machine tool. This enables a realistic simulation of a machine tool in all its substantial aspects, resulting in considerable advantages especially in the field of training and during the determination of machine utilization times.

Owner:DMG ELECTRONICS

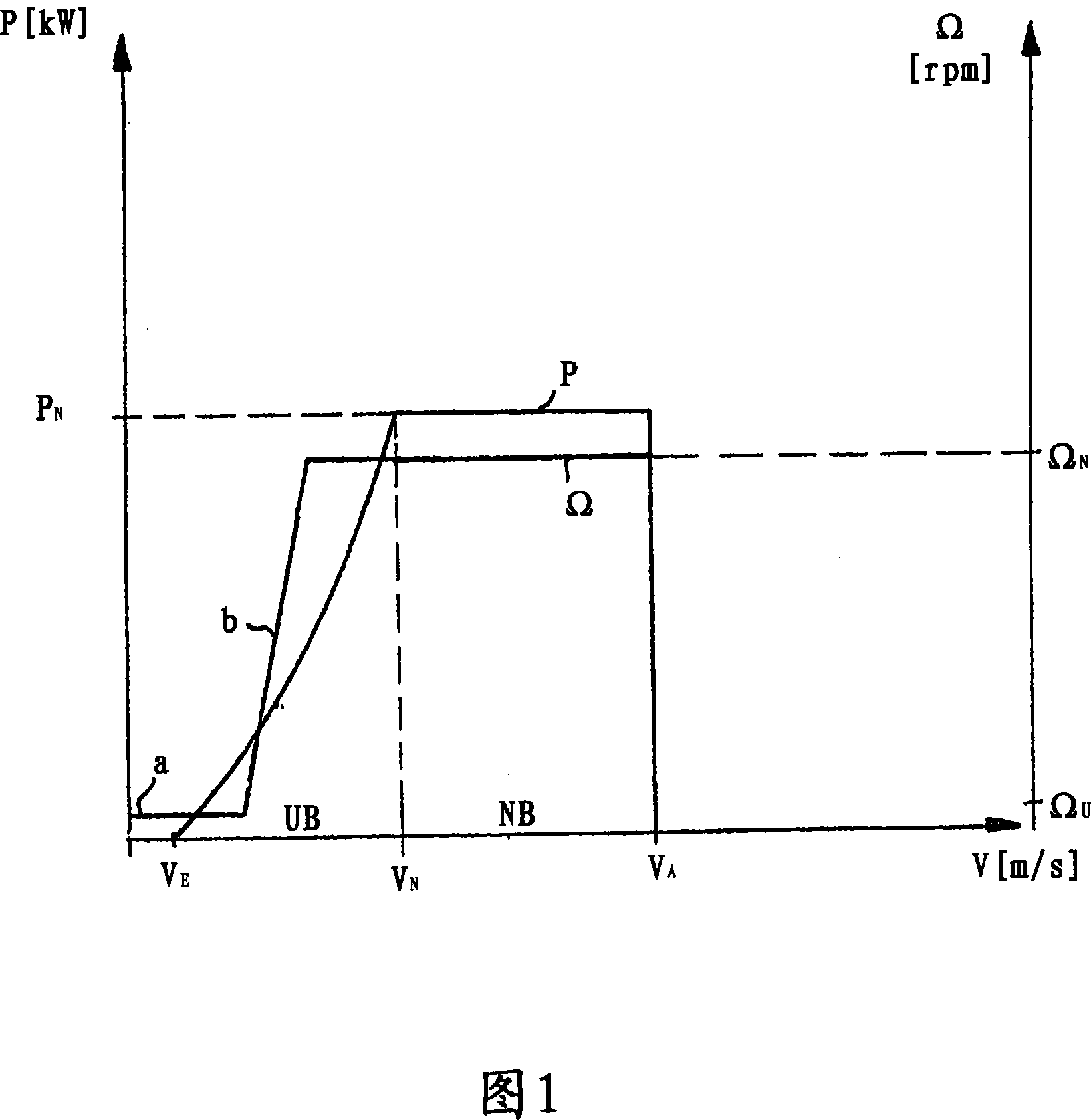

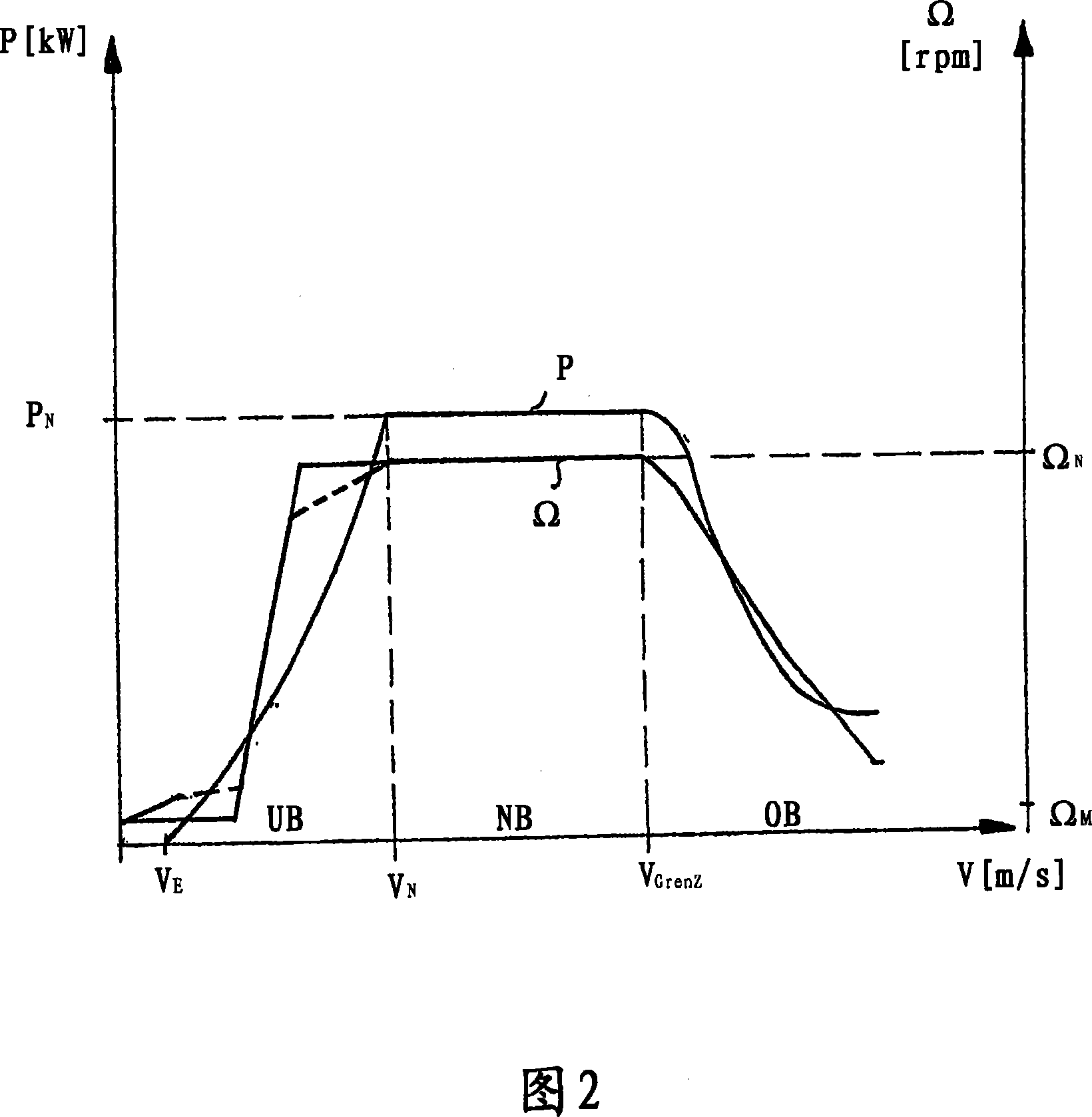

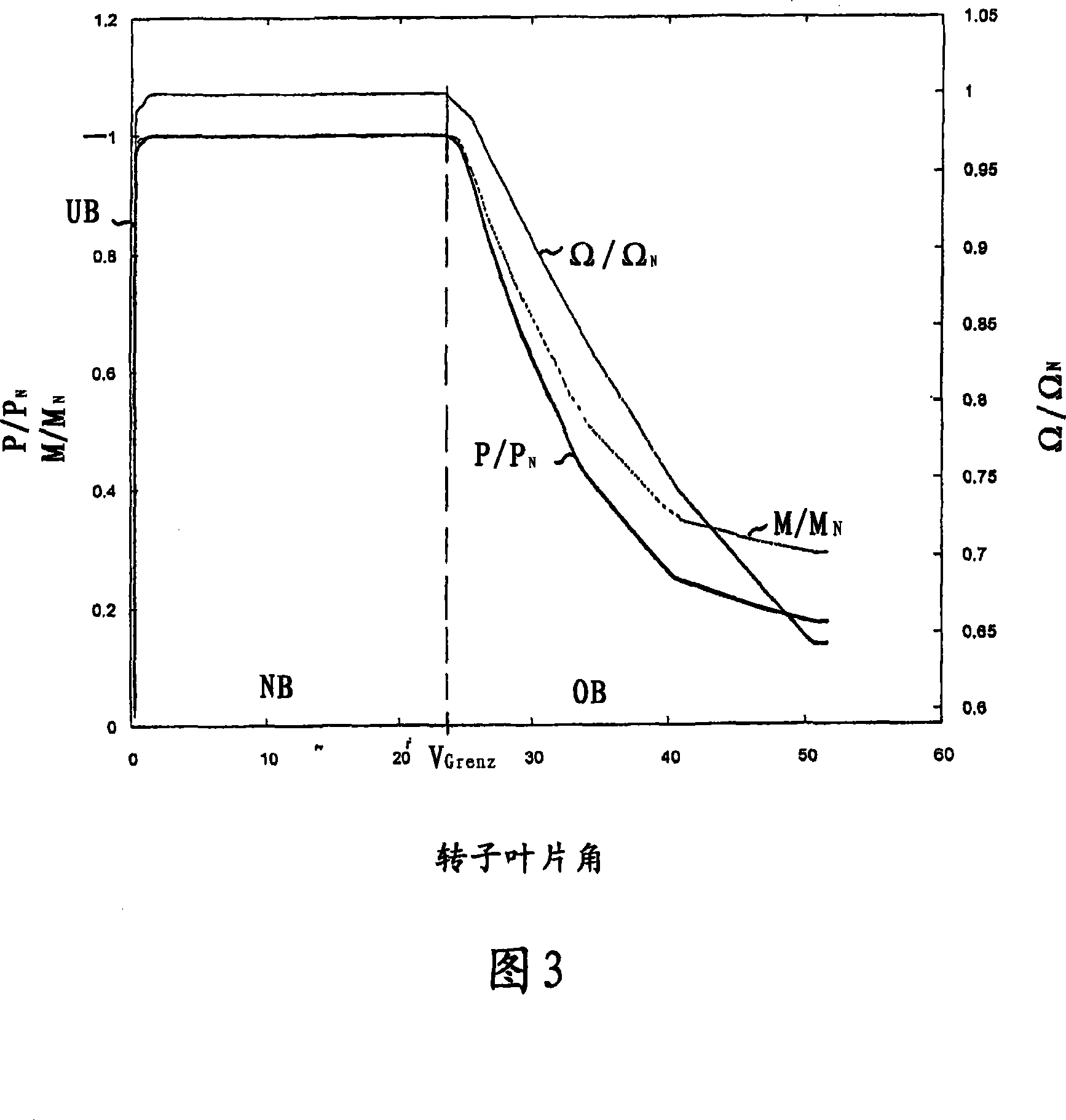

Method for controlling a wind power plant and corresponding wind power plant

InactiveCN101031720AWind motor controlComparison table algorithmsPeaking power plantMachine utilization

The power of wind energy or the revolution rate drive down to the prescribed limit value has been carried based on easily measured in physical and control technique aspect and reflect the input variable of machine utilization but not based on the metrical wind speed. For the assume of this invention, use rotor blade angle as input variable, then when arrive in the limit value adjust power and the drive down of revolution rate based on the rotor blade angle.

Owner:SENVION GMBH

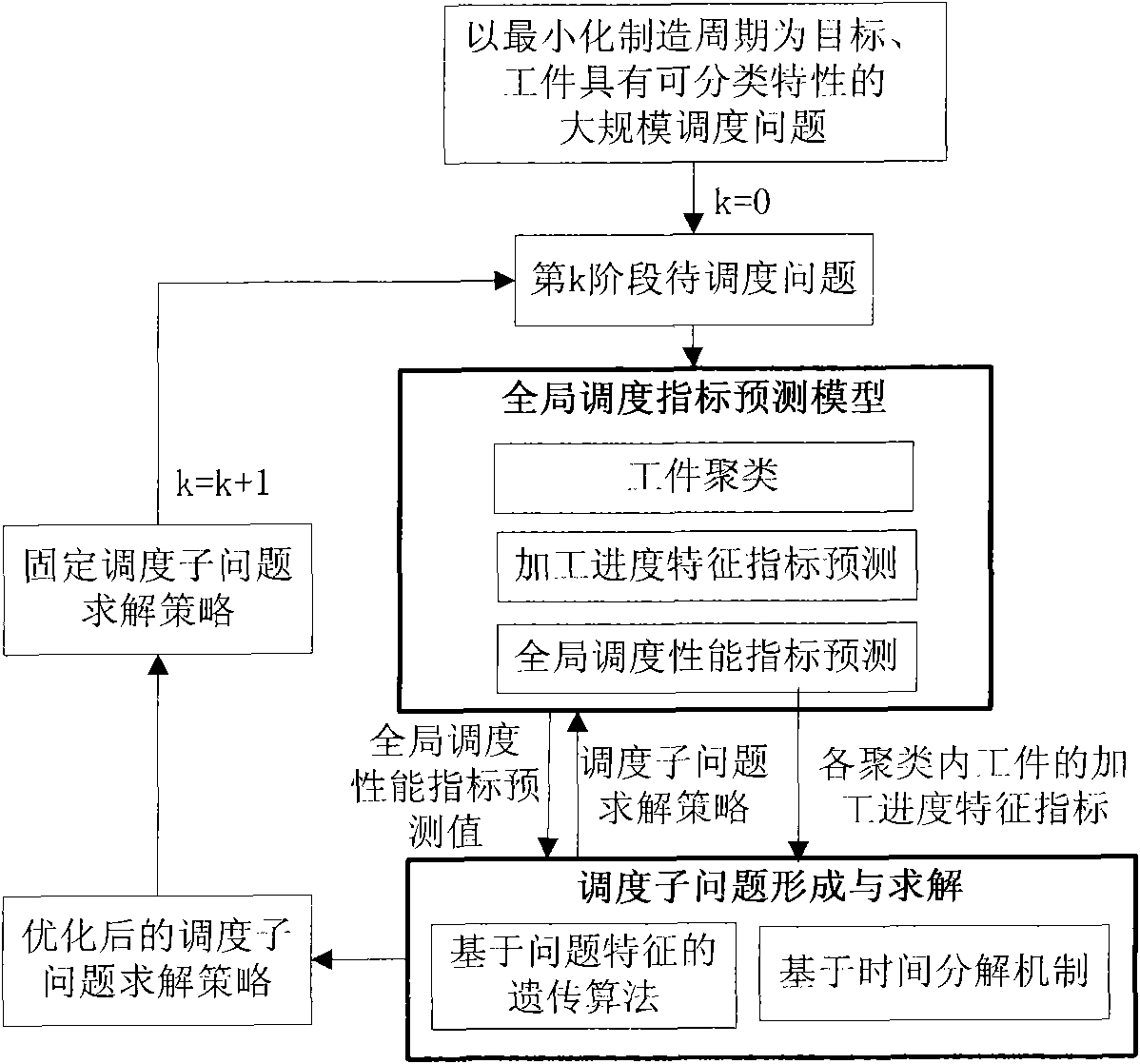

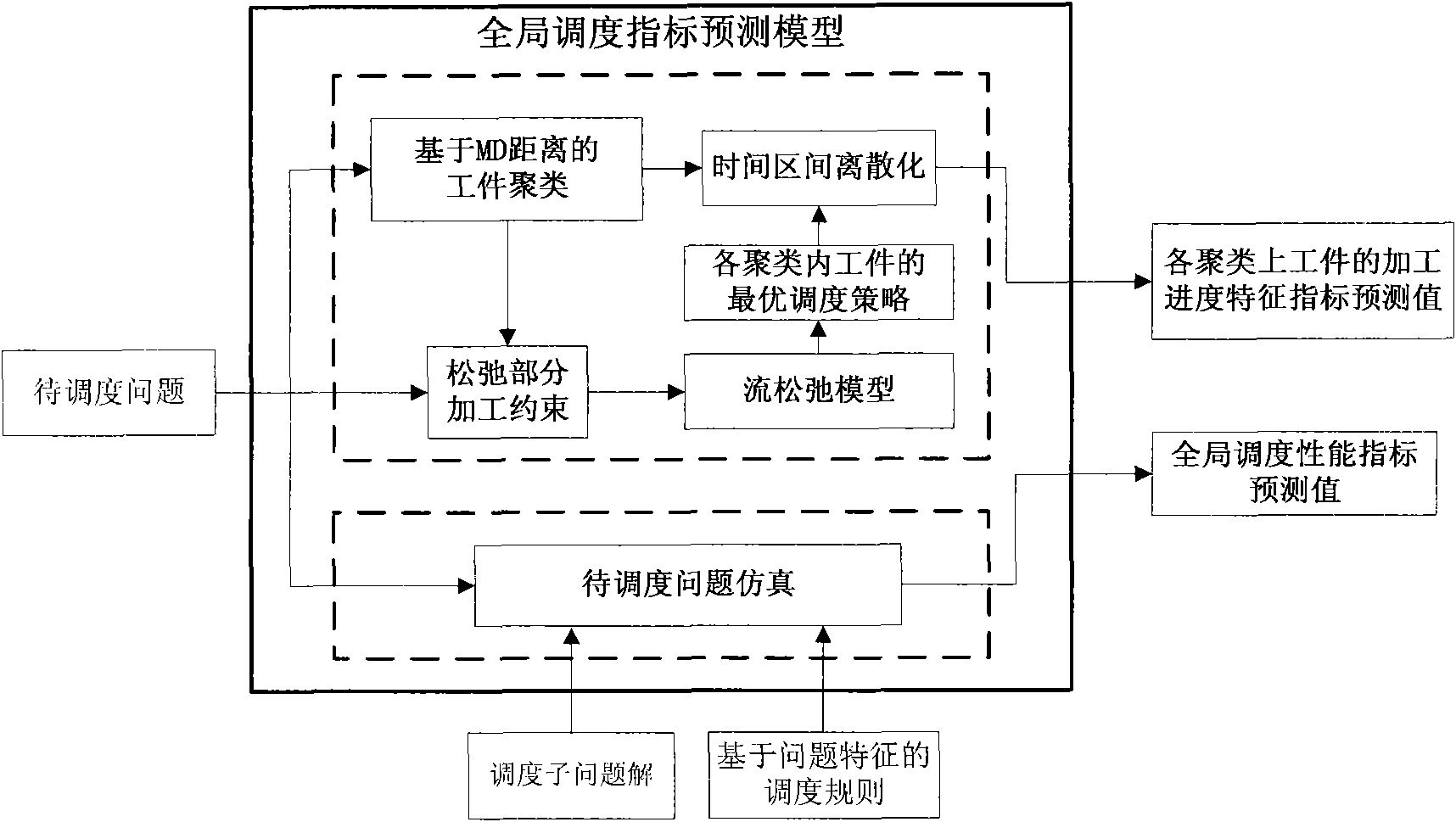

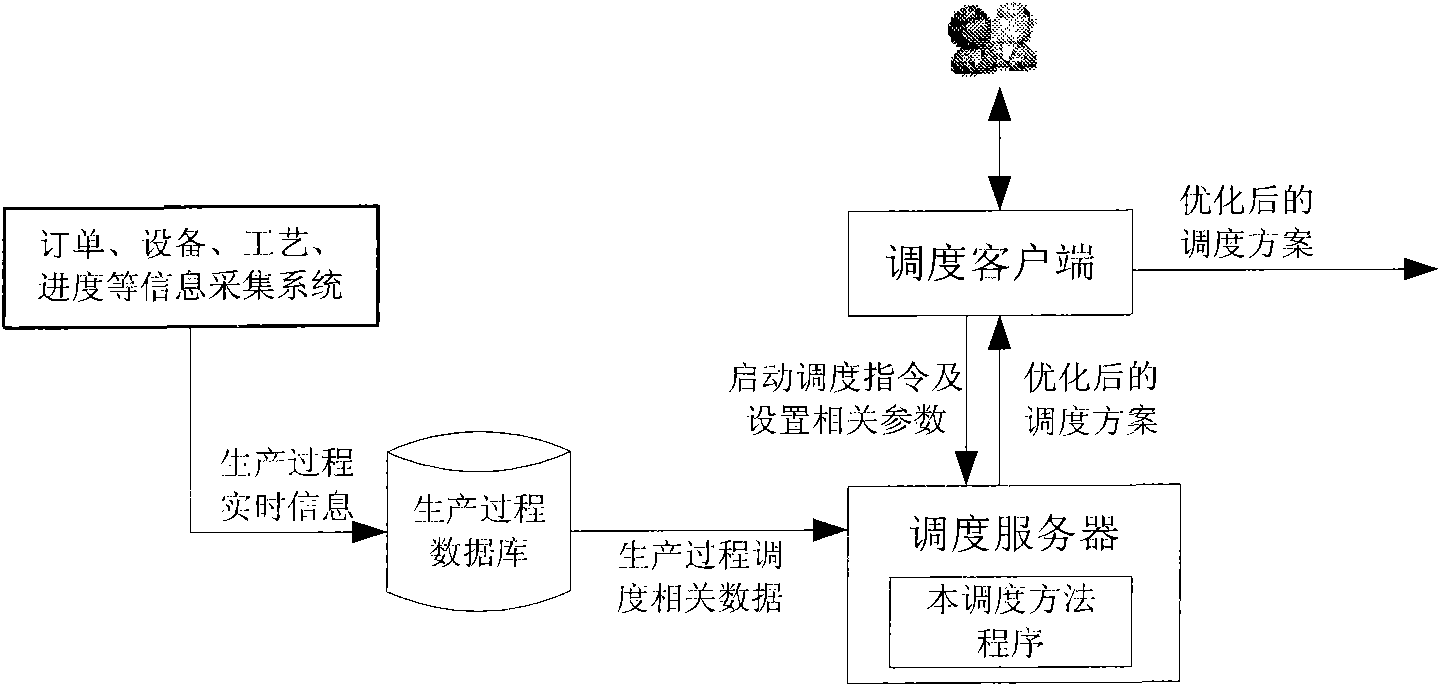

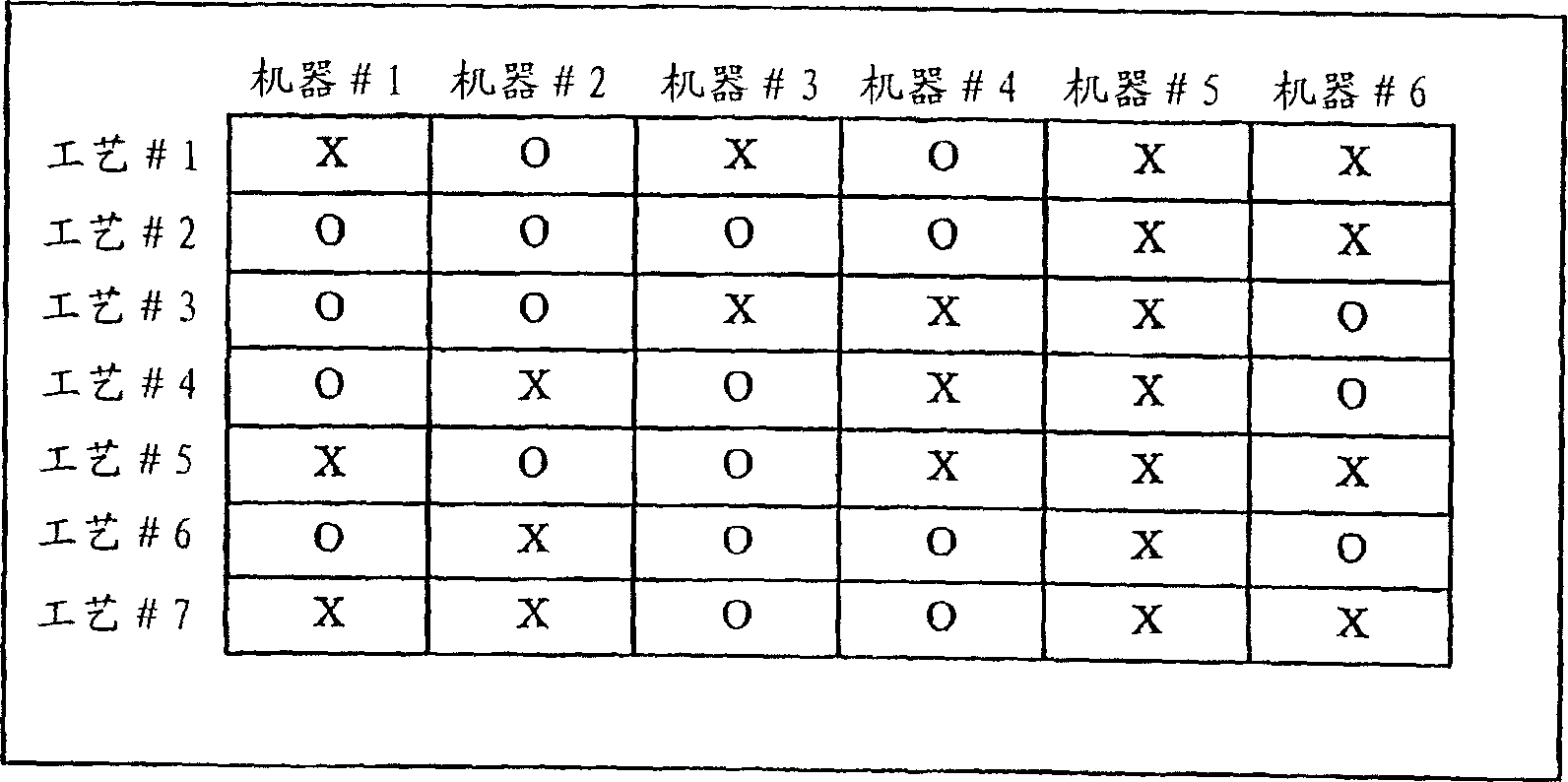

Dispatching method based on iterative decomposition and flow relaxation in large-scale production process

InactiveCN101788819AShorten the manufacturing cycleIncrease productivityTotal factory controlProgramme total factory controlDecompositionMachine utilization

The optimizing dispatch of the production process plays an important role in shortening the manufacture period, improving the utilization ratio of a machine, reducing the production cost, and the like of a manufacture enterprise. The invention discloses a dispatching method based on iterative decomposition and flow relaxation aiming at a large-scale production process by using a minimized manufacture period as a dispatching target and producing the workpiece with the gradable characteristics widely in the discrete industries, such as micro-electronics, machinery, and the like. In the method, the original dispatching problem is iteratively decomposed into a plurality of stages for solving by adopting an iterative decomposition algorithm structure based on a prediction mechanism; at the solving stage, firstly, a global dispatching index predicting model is established on the basis of a workpiece clustering and flow relaxation approach; and then, the formation and optimizing solution of a dispatching subproblem are carried on under the guide of a global dispatching index predicting value obtained by the predicting model. After being applied to the large-scale production process by adopting a minimized manufacture period as the dispatching target and producing the workpiece with the gradable characteristics, the invention can effectively shorten the manufacture period and improve the production efficiency.

Owner:TSINGHUA UNIV

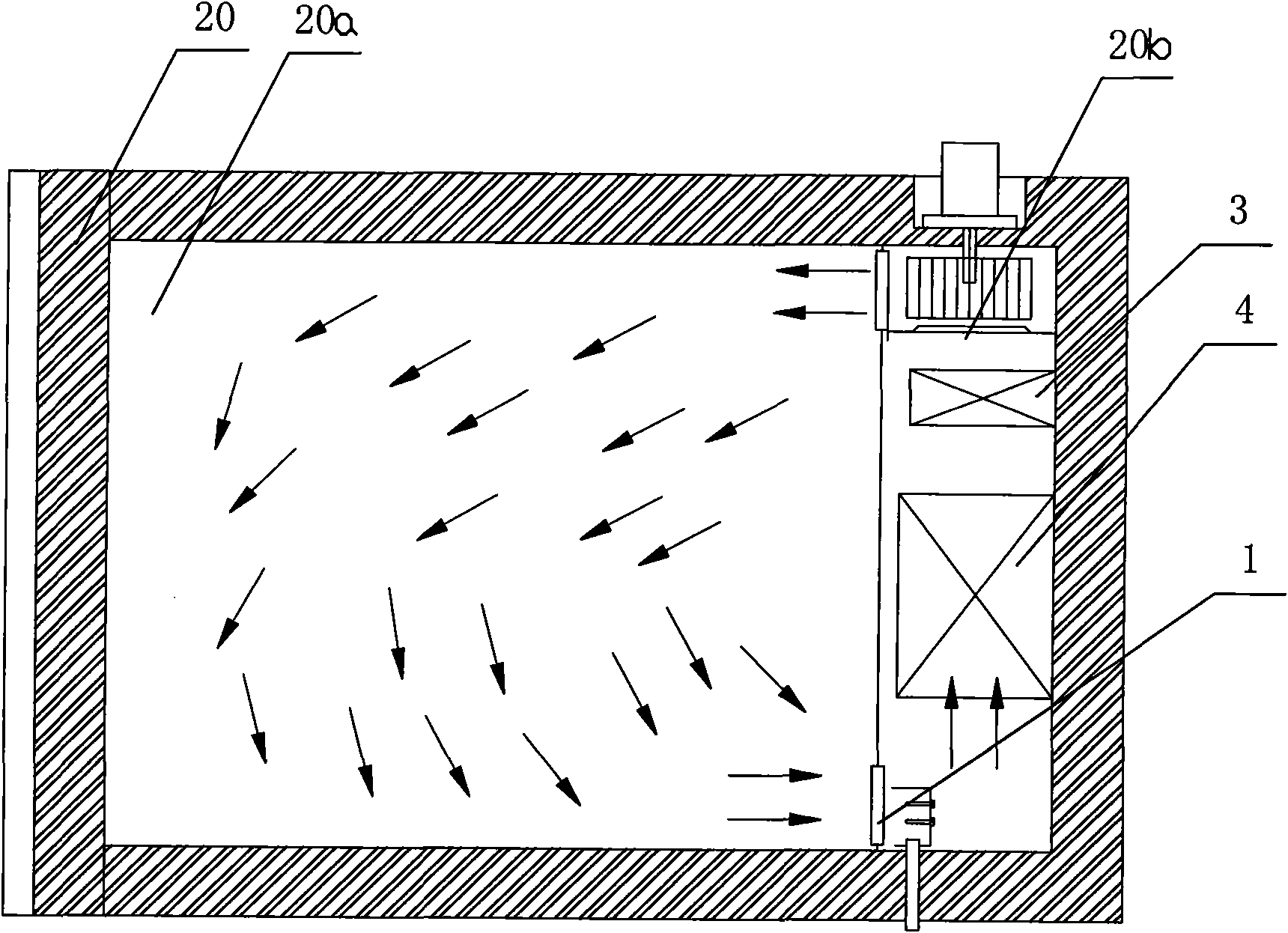

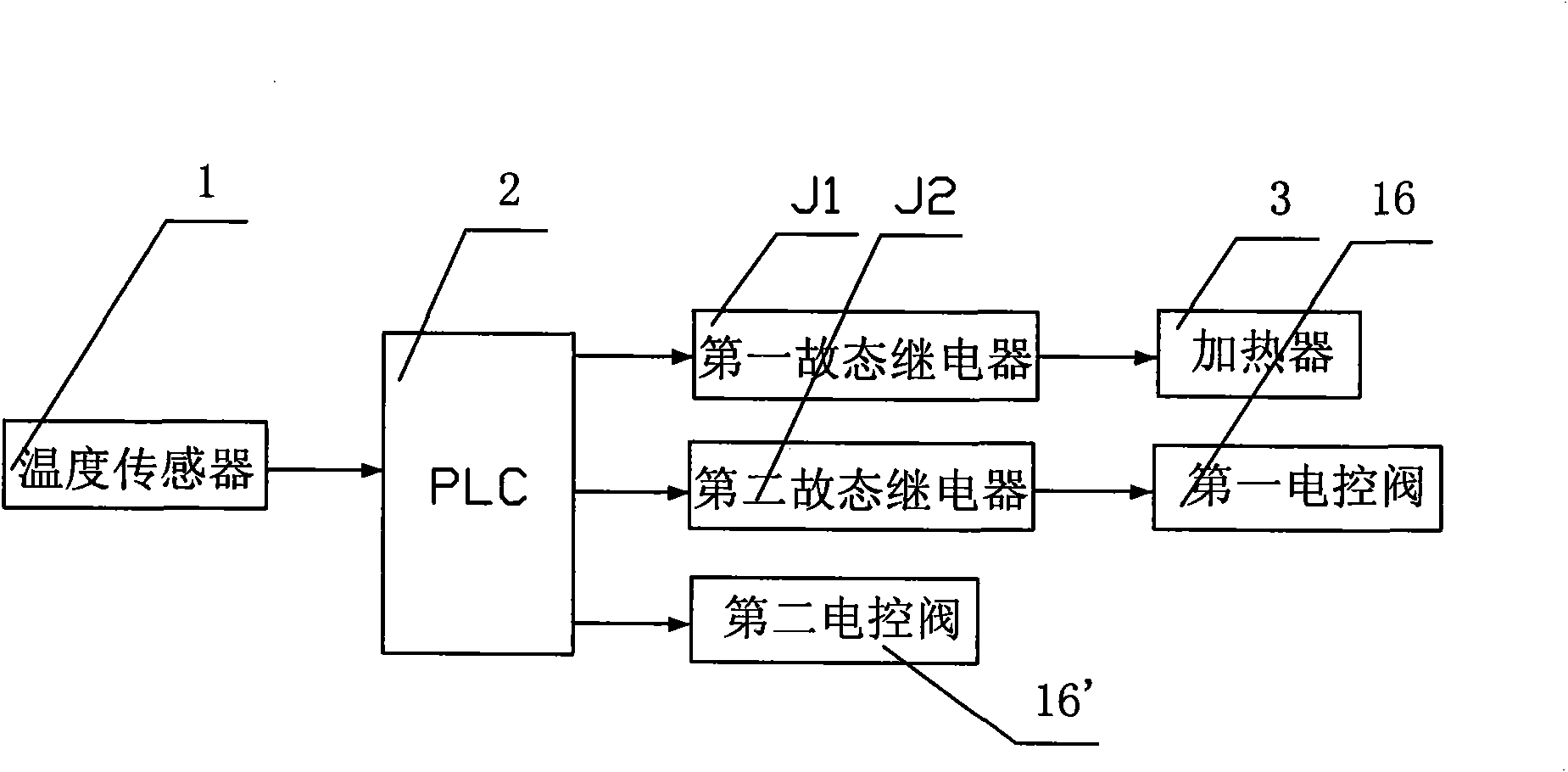

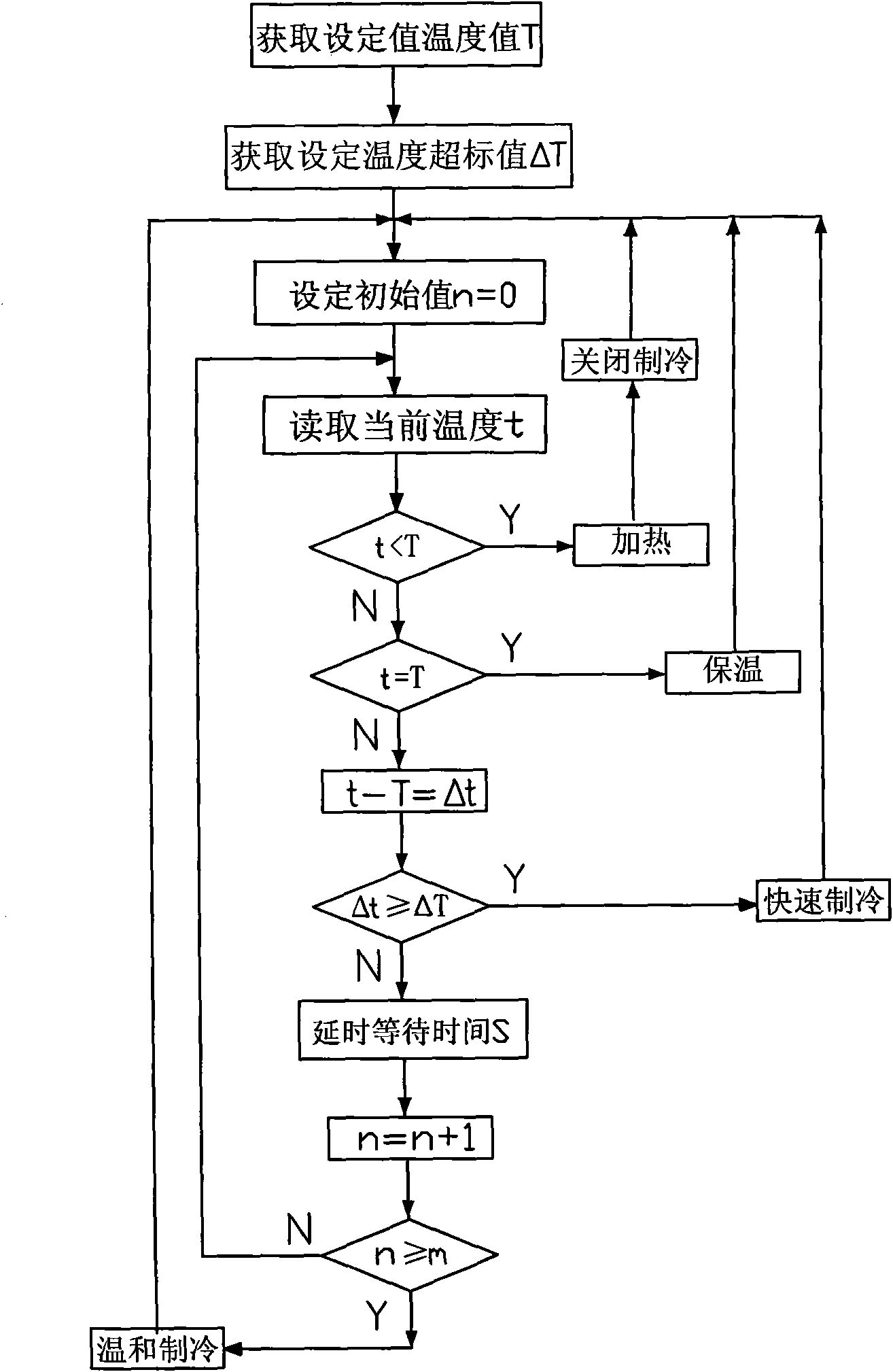

Intelligent high-low temperature test box temperature control system

ActiveCN101551682AEasy to operateReasonable useTemperatue controlCompression machines with non-reversible cycleTemperature controlMachine utilization

An intelligent high-low temperature test box temperature control system includes a temperature sensor mounted in the test box working area, the output terminal of the temperature sensor is connected to the input terminal of PLC, the refrigerating output terminal of the PLC controls a refrigeration system, and the heating output terminal of the PLC controls a heater, wherein, the heater and the refrigeration evaporator in the refrigeration system are mounted in a temperature adjustment area of the test box. The inventive intelligent high-low temperature test box temperature control system has significant effects of few system loop, simple structure, reasonable use of resources, low energy consumption, fast adjustment time, simple operation, and low machine utilization.

Owner:重庆哈丁环境试验技术股份有限公司

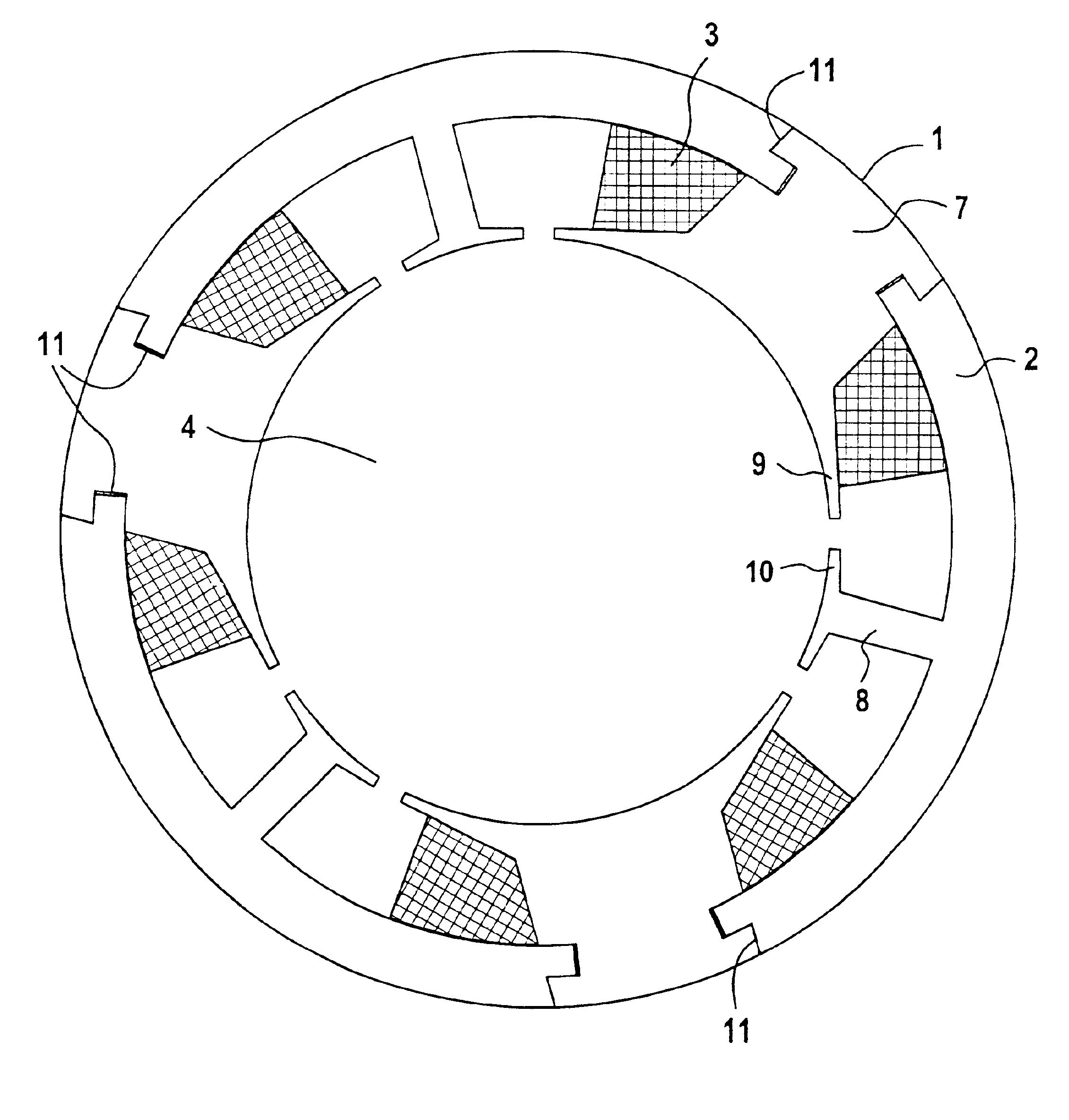

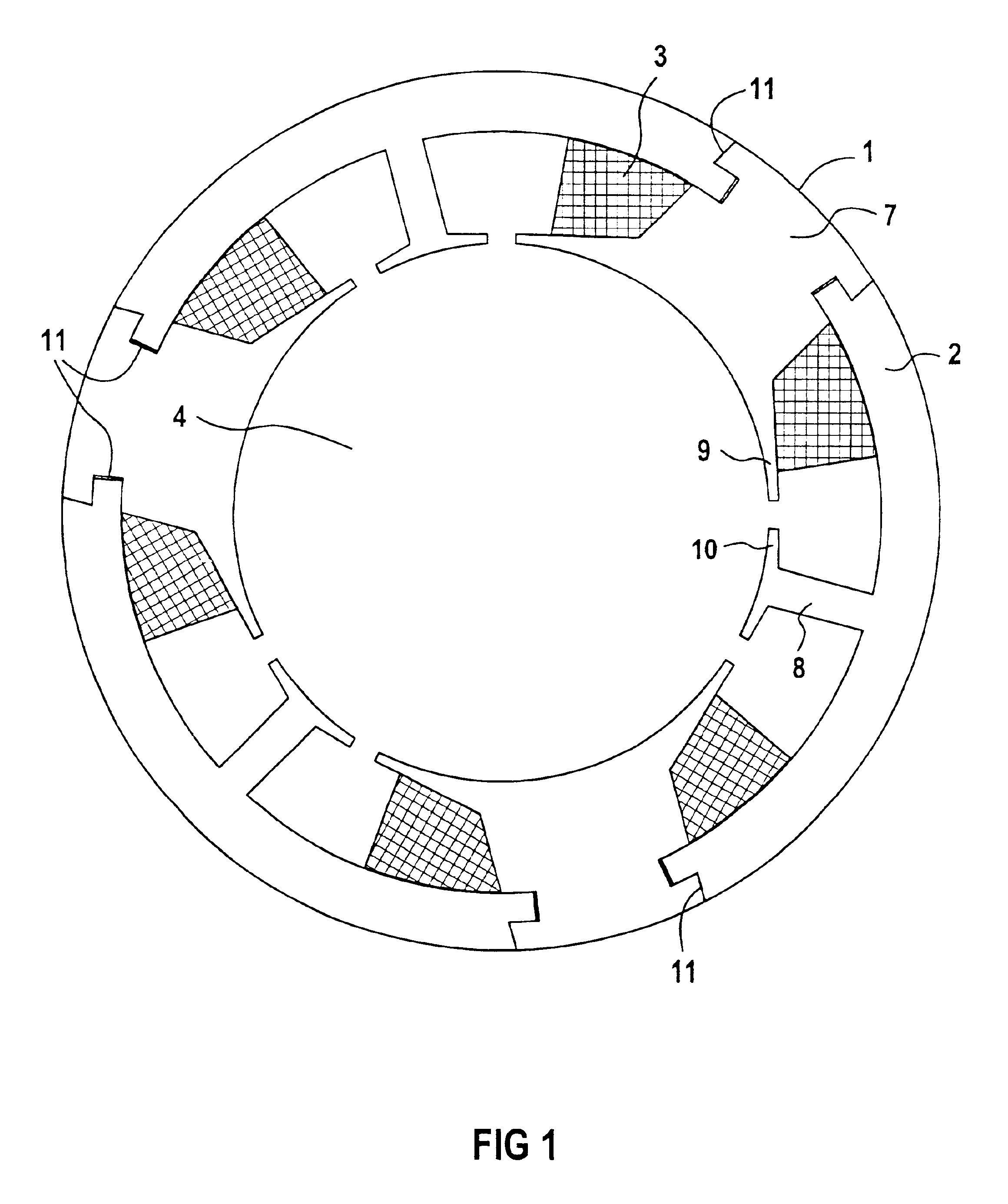

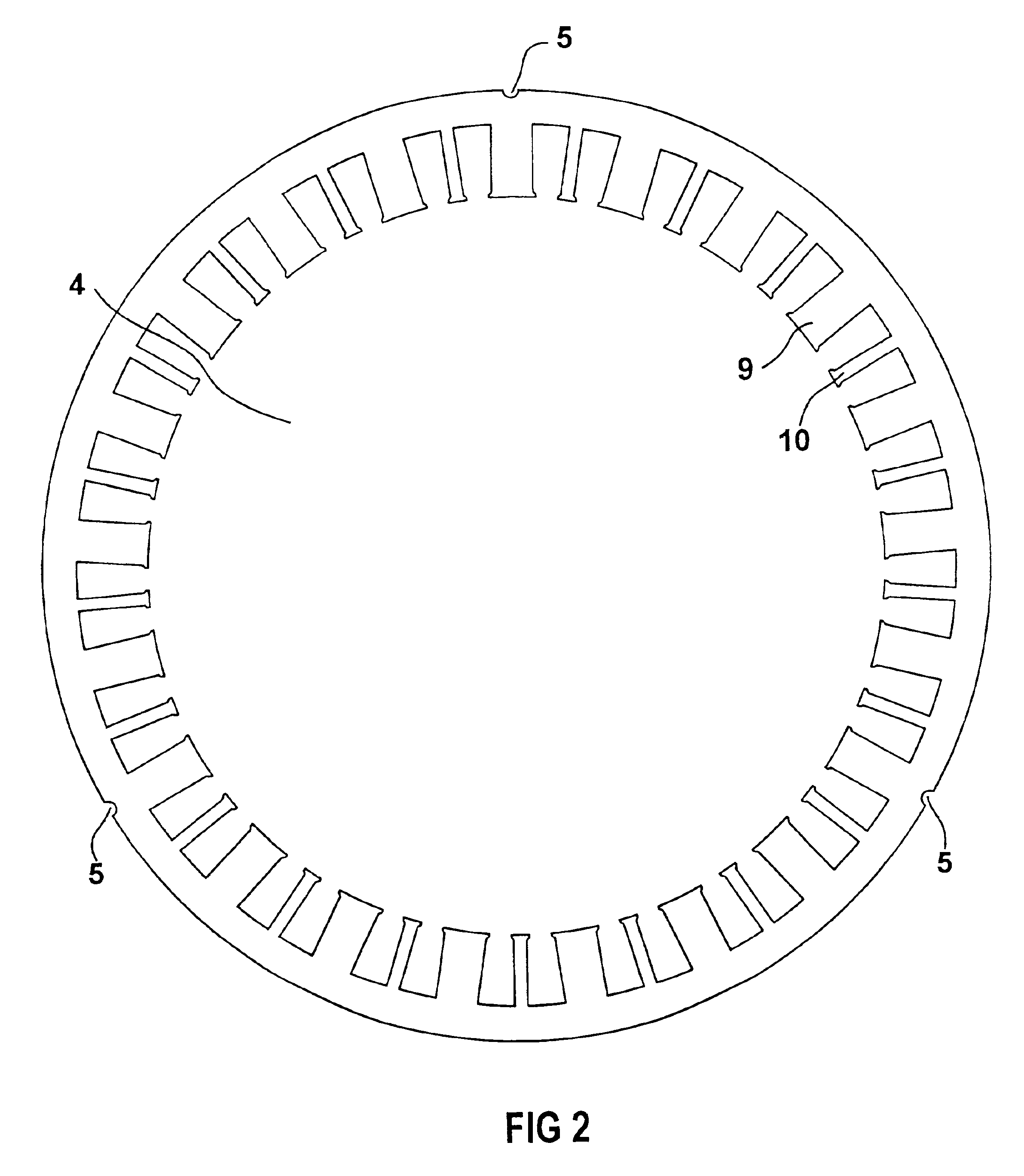

Permanent magnet rotor electrical synchronous machine with different alternatively arranged tooth pitch widths

InactiveUS6879079B2Low stator production costHigh machine utilizationSynchronous generatorsWindingsPermanent magnet rotorMachine utilization

In order to achieve high machine utilization with the magnetic fields having an approximately sinusoidal profile, an electrical synchronous machine is proposed having the following features:a stator and a rotor with the stator having a three-phase winding (3) and the rotor being fitted with permanent magnets,the three-phase winding (3) is arranged in slots in the stator,the slots in the stator are formed by essentially axially running teeth (7, 8) which have at least two different tooth pitch widths τzb and which are arranged alternately in the circumferential direction of the stator, with their number in each case being identical,only the teeth (7) with a tooth pitch width which is greater than other teeth (8) are at least partially surrounded by a winding (3).

Owner:SIEMENS AG

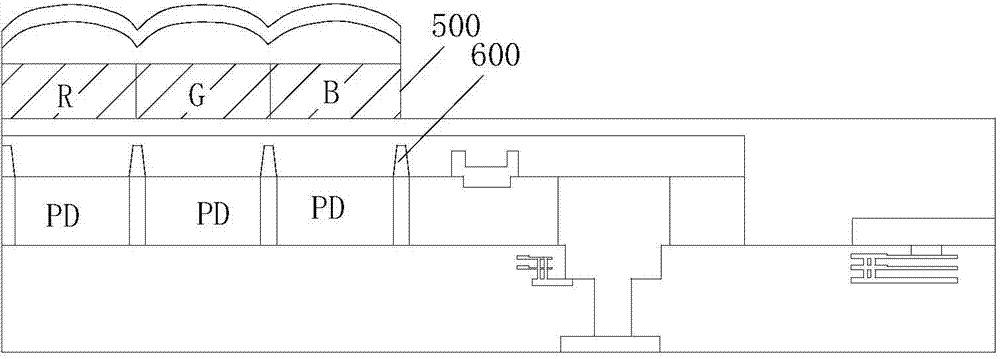

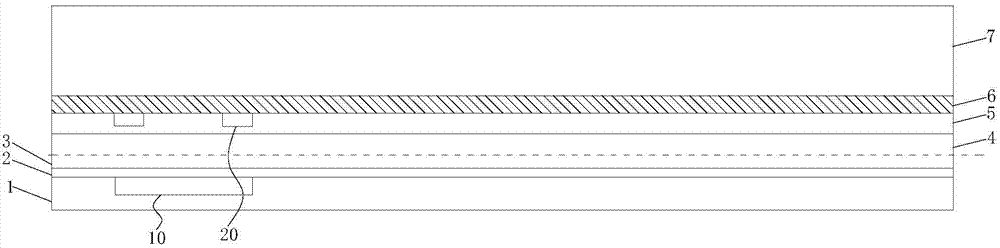

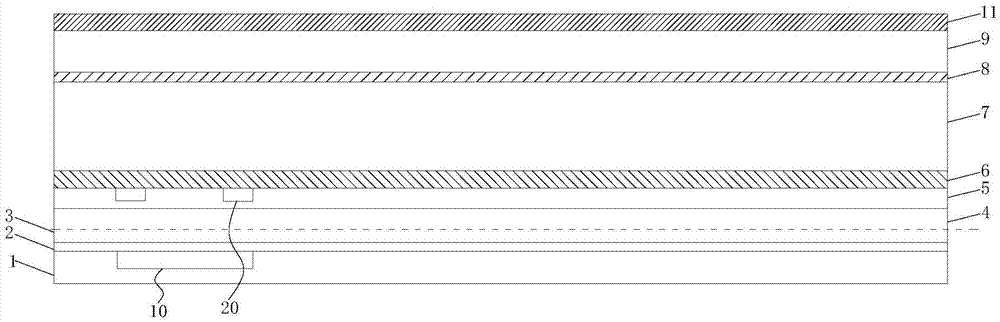

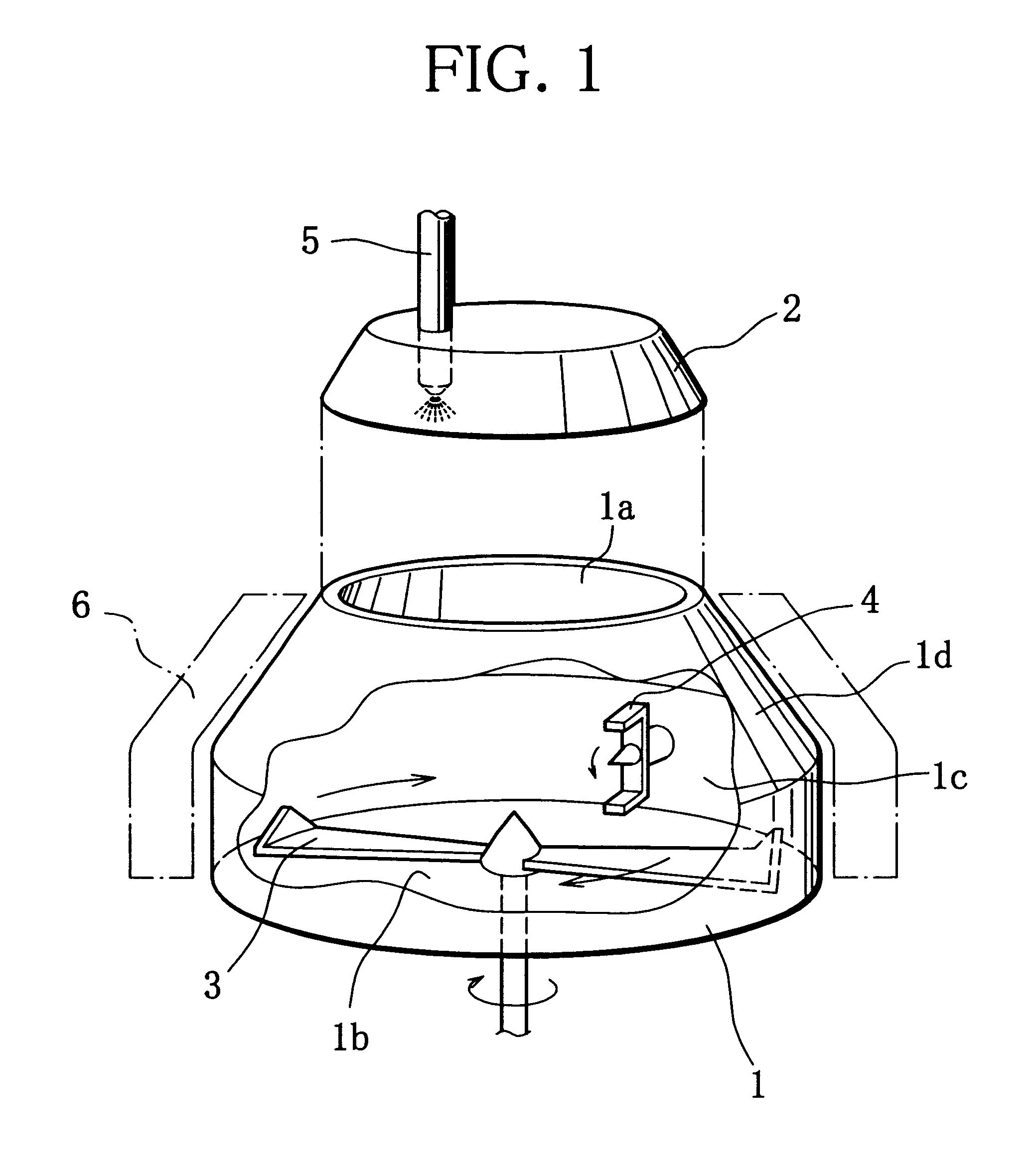

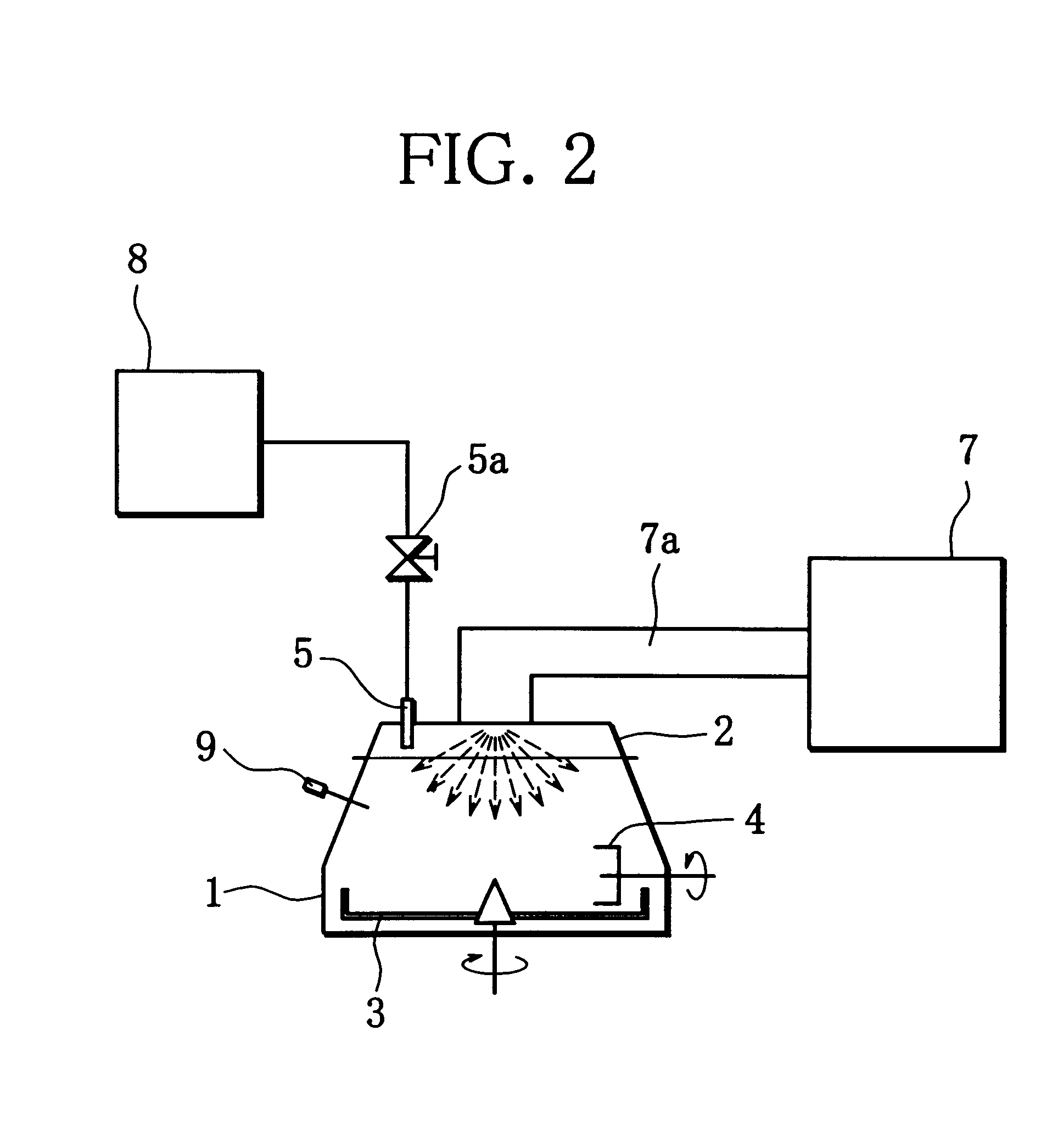

Stack type image sensor manufacturing method

ActiveCN103972257AImprove output qualityAvoid mutual interferenceRadiation controlled devicesMachine utilizationComputer science

The invention provides a stack type image sensor manufacturing method. As a filtering layer is embedded into a metal grid, when being compared with a conventional technique, in the method, a great number of unnecessary steps is omitted, the machine utilization rate is increased, and the production cost is reduced, and meanwhile, by adopting an image sensor manufactured by using the method, the influence of crosstalk to an image is effectively alleviated, and furthermore the quality of an output image is improved.

Owner:OMNIVISION TECH (SHANGHAI) CO LTD

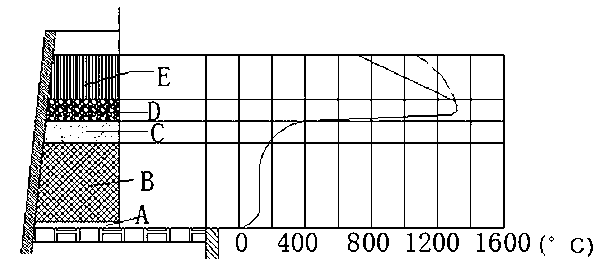

Thick-bed sintering feed surface-spraying covering agent and spraying method thereof

InactiveCN103215442ATake advantage ofPlay the role of material surface insulationCombustionSurface layer

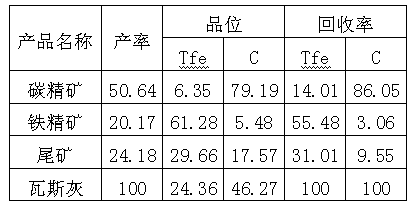

The invention discloses a thick-bed sintering feed surface-spraying covering agent and a spraying method thereof. The thick-bed sintering feed surface-spraying covering agent is mixed from the following materials: carbon concentrate, expanded slag balls and sintered return mine. The surface layer temperature of the sintering feed layer, which is sprayed with the covering agent, is higher than the surface layer temperature of the sintering feed layer not added with the covering agent, which is far higher than the ignition temperature of the fuels; the upper layer of the fuels can be continuously combusted after a combustion zone is moved downwards, so that the defect that the heat of the upper sintering feed is insufficient is overcome. The covering agent not only can be used for supplementing the upper heat of the sintering feed layer, but also can be used for achieving the effect of the material surface heat preserving agent and ensuring the good air permeability, so that thickness of the upper material layer without sufficient agglomeration strength is reduced, the yield and the strength are effectively improved, and the total carbon content is reduced, and therefore, the heat of the lower part is free of an excess and super-fusion phenomenon, the sintering machine utilization coefficient, the sinter yield and the strength under the whole thick-bed sintering condition are obviously improved. Moreover, the residual carbon resource in the carbon powder, i.e., the product obtained by gas ash beneficiation, is sufficiently utilized.

Owner:HBIS COMPANY LIMITED HANDAN BRANCH COMPANY

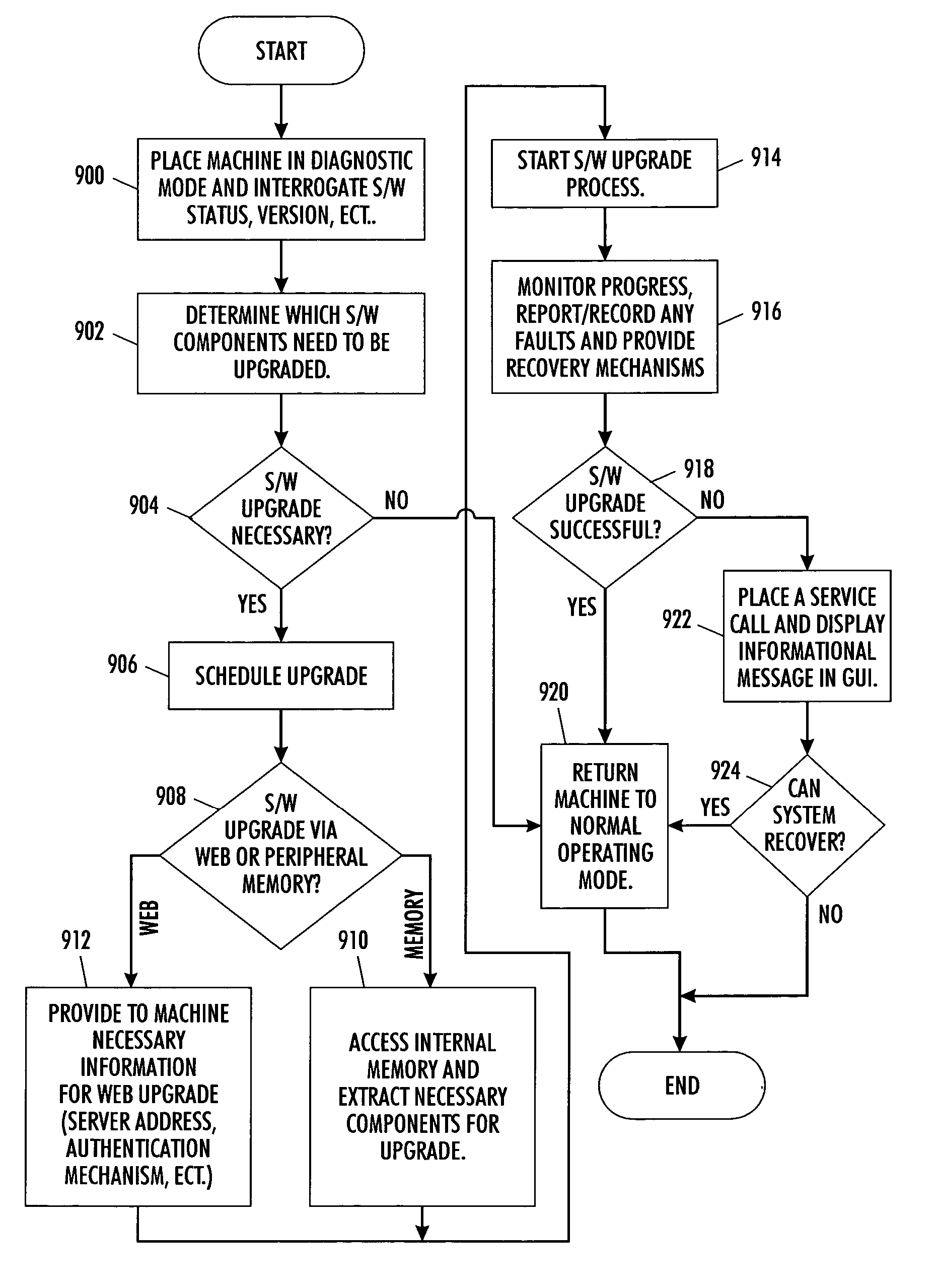

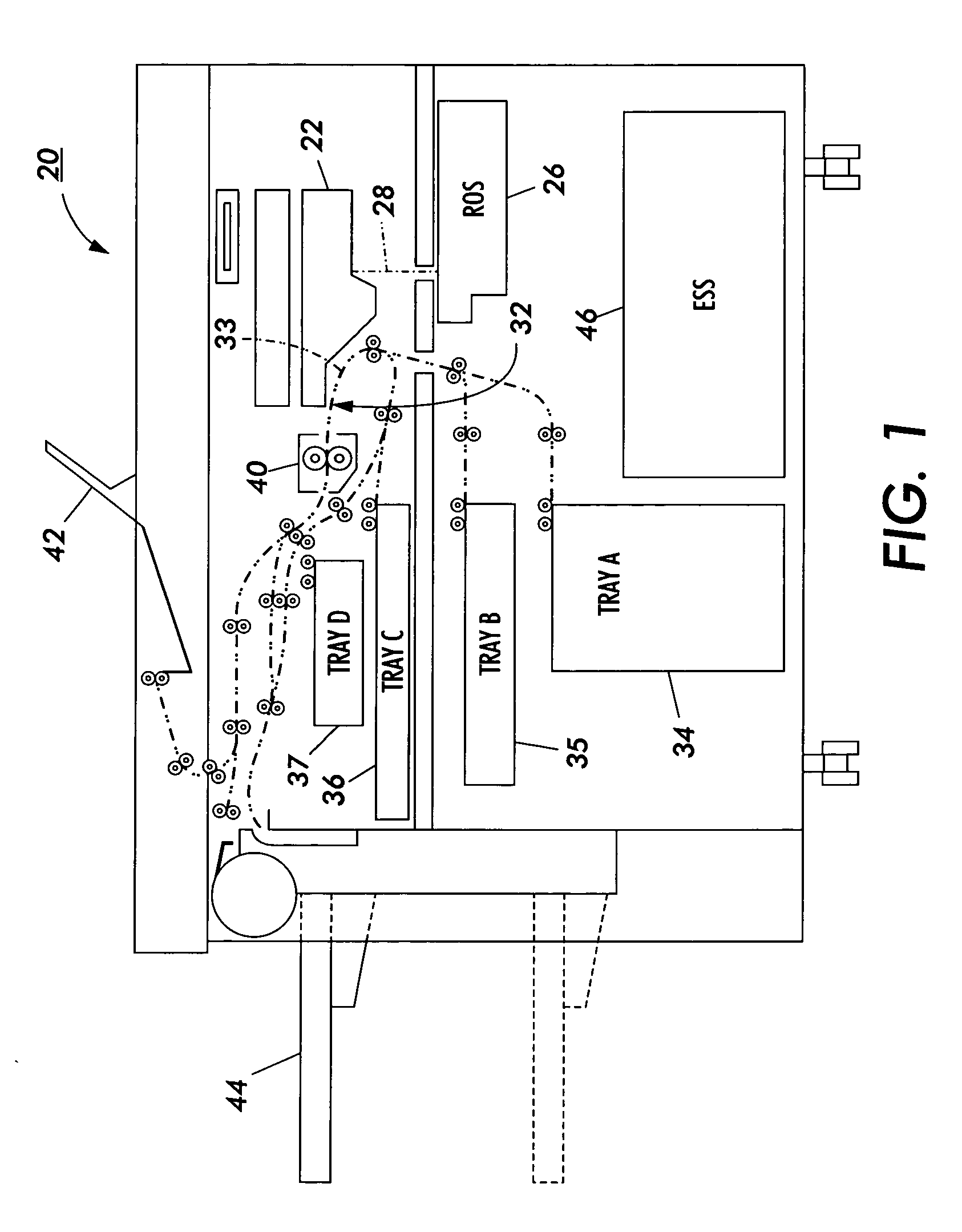

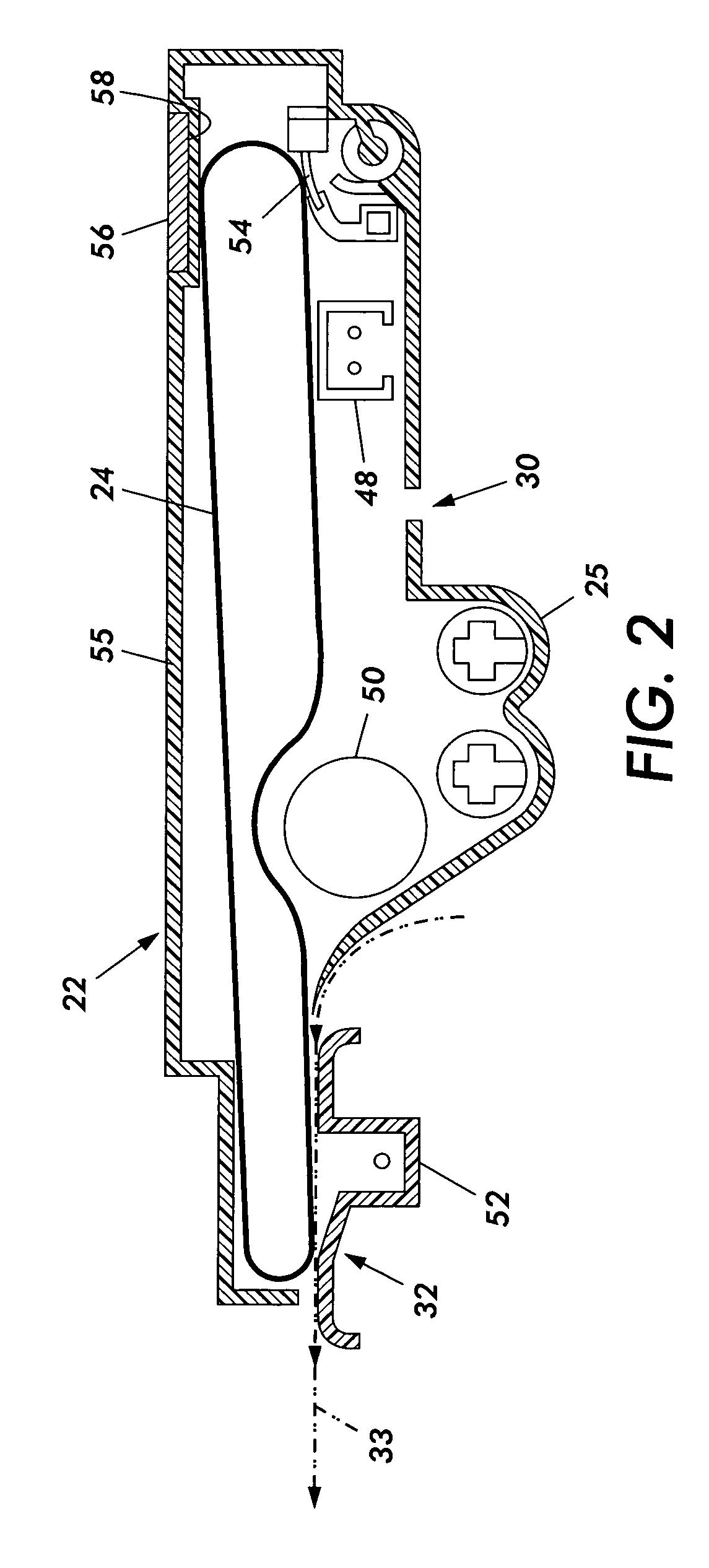

Software upgrades from a printer module with on-board intelligence

An intelligent on-board monitoring system for replaceable module for a printing apparatus includes a memory element, an input for receiving information either from sensors on the replaceable module, or from the printing apparatus concerning printing operations performed, and a microprocessor connected to the memory for performing calculations upon data stored in the memory and upon the input information. By expanding this intelligent on-board monitoring system with expanded memory, either on board the replaceable module, or by way of network access, the capability to enable software upgrades is provided. The software upgrades may relate to the performance of the replaceable module or to the machine into which it is installed. These software upgrades may be accomplished without requiring computational resources of the printing apparatus itself and by proper scheduling without impacting customer machine utilization.

Owner:XEROX CORP

Energy-saving high-efficiency servo drive paper box printing mechanism

ActiveCN102179994AIncrease profitTo achieve the purpose of energy savingRotary pressesCardboardMachine utilization

The invention discloses an energy-saving high-efficiency servo drive paper box printing mechanism. The mechanism consists of a plurality of printing units, wherein the printing transfer and transition transfer of each group of printing unit are finished by a vacuum paper feeding transmission box; a printing plate roller for transferring printing ink to a paper board and an inking anilox roller are arranged on the two sides of a frame through a linear guide rail; a speed reducing motor synchronously drives screw rods on two sides through a spiral lifter to drive the printing plate roller and the inking anilox roller to lift up and down; and the vacuum paper feeding transmission box, the printing plate roller and the inking anilox roller are driven by a servo drive motor respectively. By the mechanism, the printing plate roller and the inking anilox roller of the printing unit which does not participate in printing stop operating during printing, and the paper board is continuously transferred by the vacuum paper feeding transmission box, so that the aim of saving energy is fulfilled, and the printing unit which does not participate in printing can be subjected to plate assembling, replacing and wiping operation during printing to fulfill the aims of improving work efficiency and a machine utilization rate.

Owner:GUANGDONG DONGFANG PRECISION SCI & TECH CO LTD

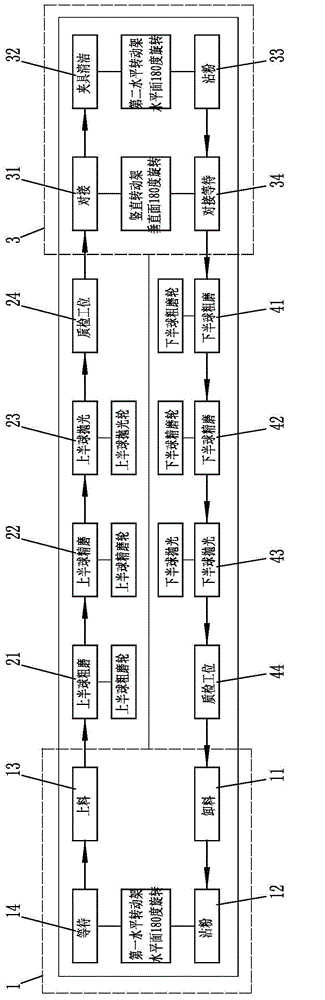

A double-layer production plan optimization control method based on an intelligent optimization algorithm

The invention relates to a double-layer production plan optimization control method based on an intelligent optimization algorithm, and effectively solves the problem of low production efficiency caused by no production plan and simple production plan in the existing factory. According to the technical scheme, the artificial leather comprises the following two layers: a first layer and a second layer, wherein the first layer is used for ordering orders, ensuring that the total penalty cost of the orders is minimum by taking delivery date priority as a principle, ordering the orders to generateproduction plans in a factory, and the second layer is used for scheduling the workshops by taking minimization of maximum completion time and maximum machine utilization rate as targets, and makingdetailed workshop production plans for the orders by taking main factors in actual production into consideration; the second layer: using a genetic algorithm to solve a workshop scheduling model withmultiple time constraints; the problems of long delivery time, long production period, low machine utilization rate, large product quantity and the like in multi-order production in a factory are solved, and good economic effects and social benefits can be achieved.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

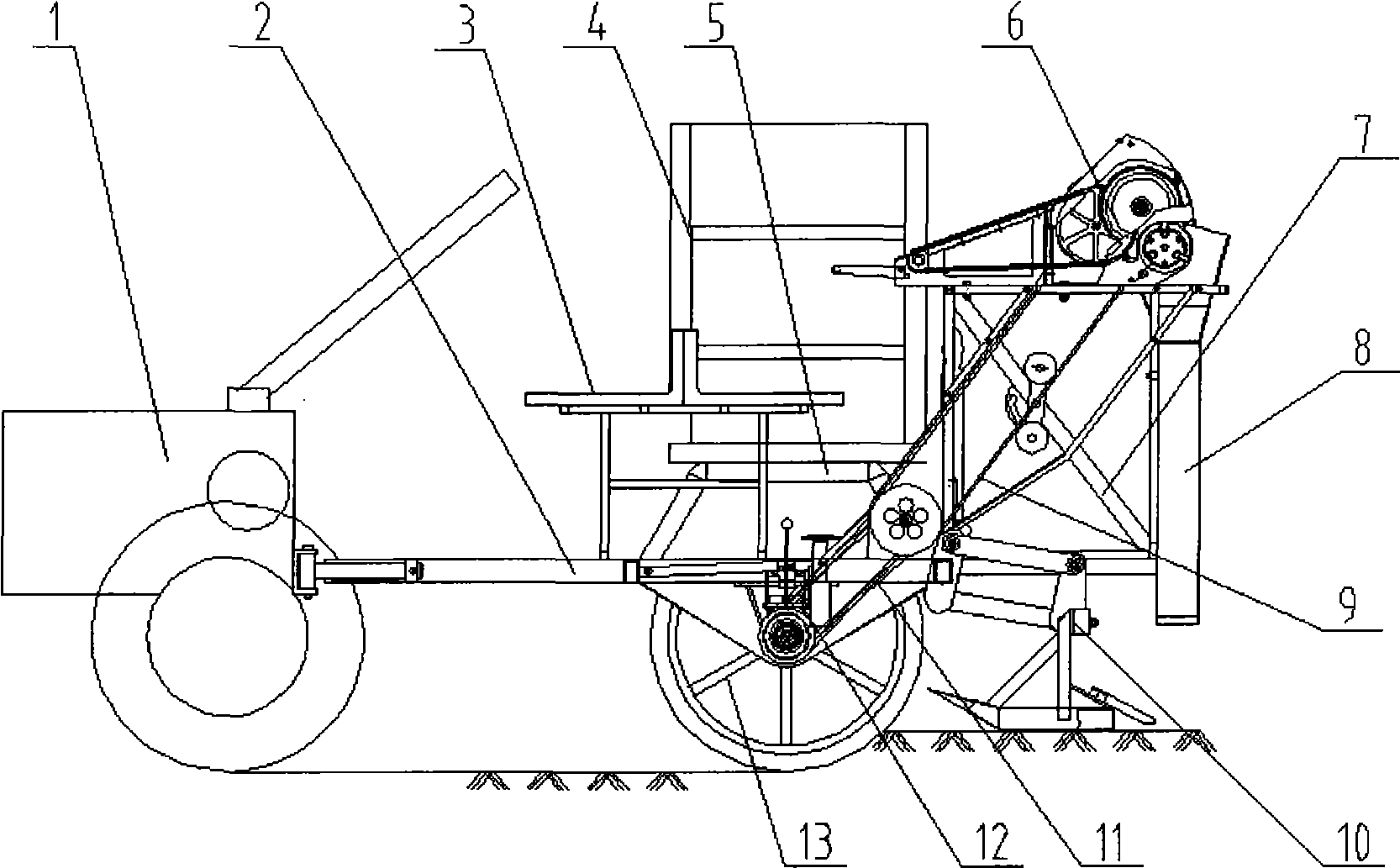

Rice pot seedling transplanter driven by trailed ground wheel

InactiveCN101530032AMeet planting technical requirementsReduce injury rateTransplantingMachine utilizationTraction frame

The invention discloses a rice pot seedling transplanter driven by a trailed ground wheel, belonging to the technical field of the rice pot seedling planting machinery for agricultural paddy field operation. The transplanter is driven by the trailed ground wheel; the front end of a traction frame is connected with a micro-cultivator head; a seat assembly and a eudipleural ground wheel cover are installed in the middle of the traction frame; a sprout rack is installed on the upper surface of the ground wheel cover; a ground wheel drive system composed of the ground wheel and a ground wheel drive control device is installed below the traction frame; a bracket is installed at the rear end of the traction frame; a transplanting part and a seedlings guide-canal are installed on the bracket; the ground wheel drive control device is connected with a lower drive system which is connected with an upper drive system; the upper drive system is connected with the transplanting part; a sliding shoe assembly is welded at the rear end of the traction frame and is in one-to-one correspondence to the seedlings guide-canal. The rice pot seedling transplanter is characterized by small damaged seedling rate, simple operation, high working efficiency, reasonable price, multiple purposes and high machine utilization.

Owner:CHINA AGRI UNIV

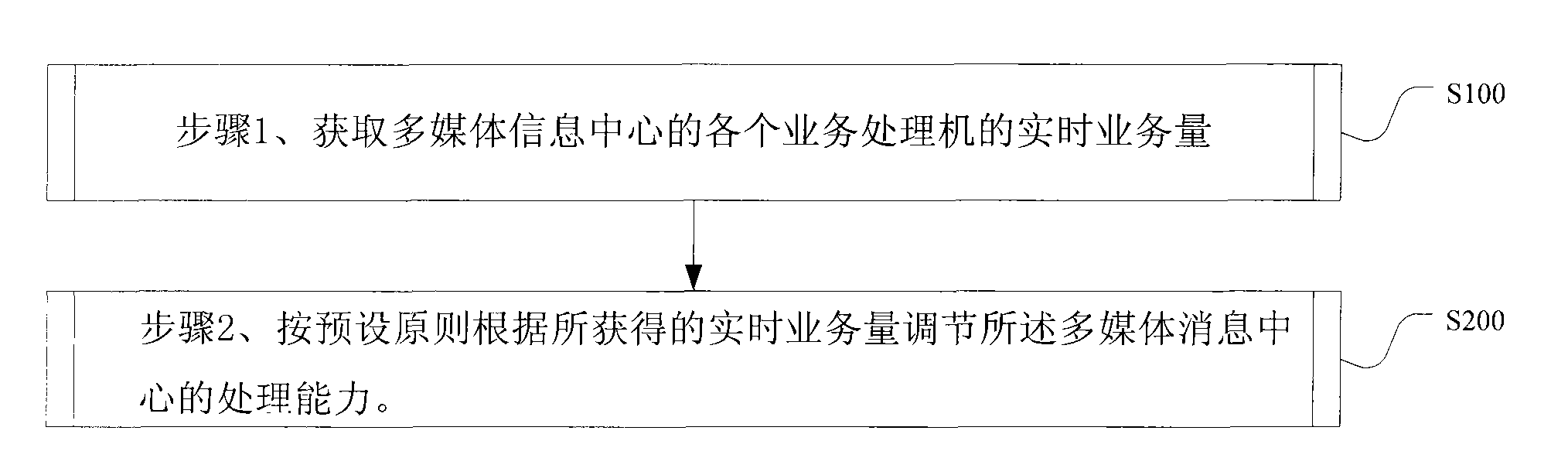

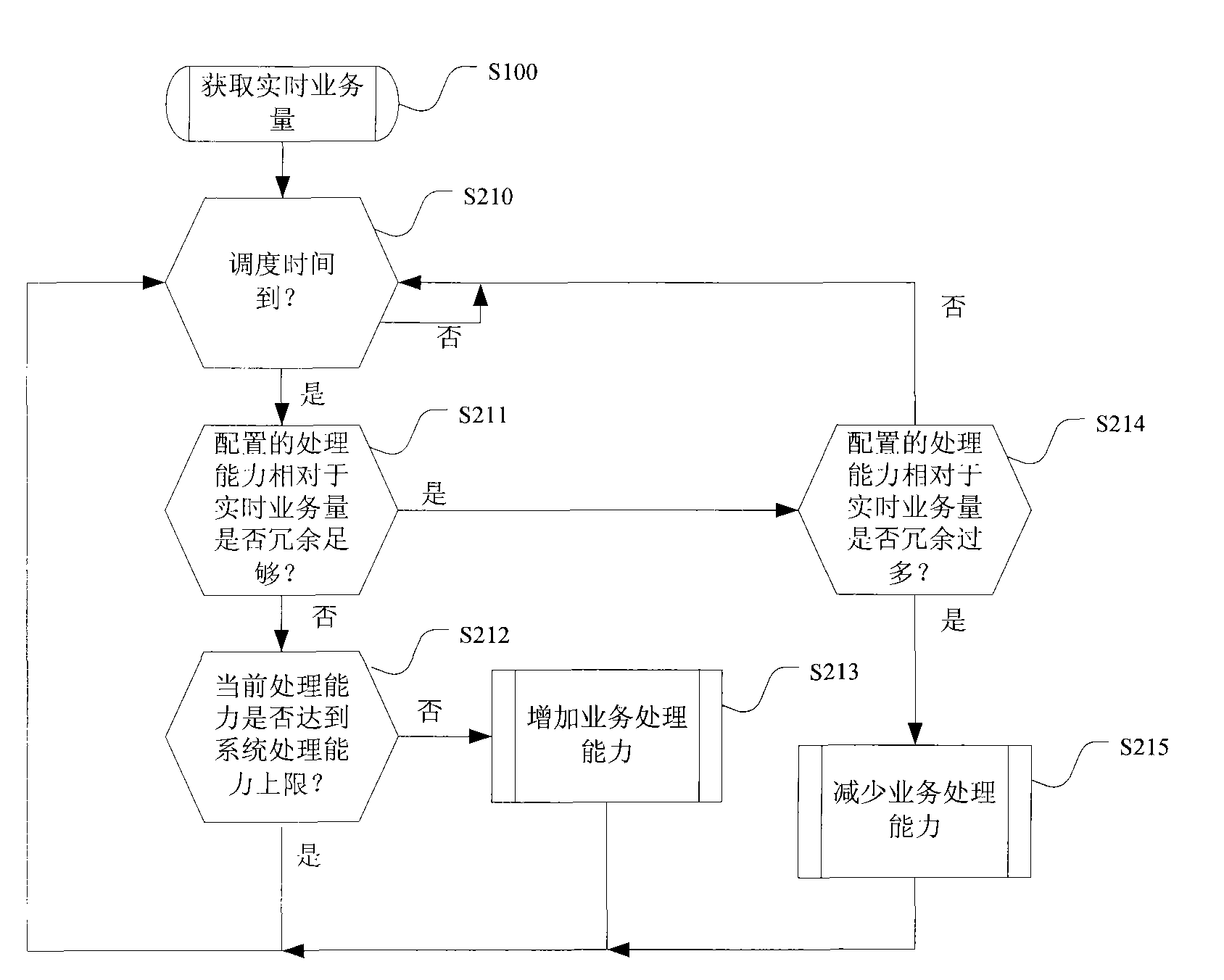

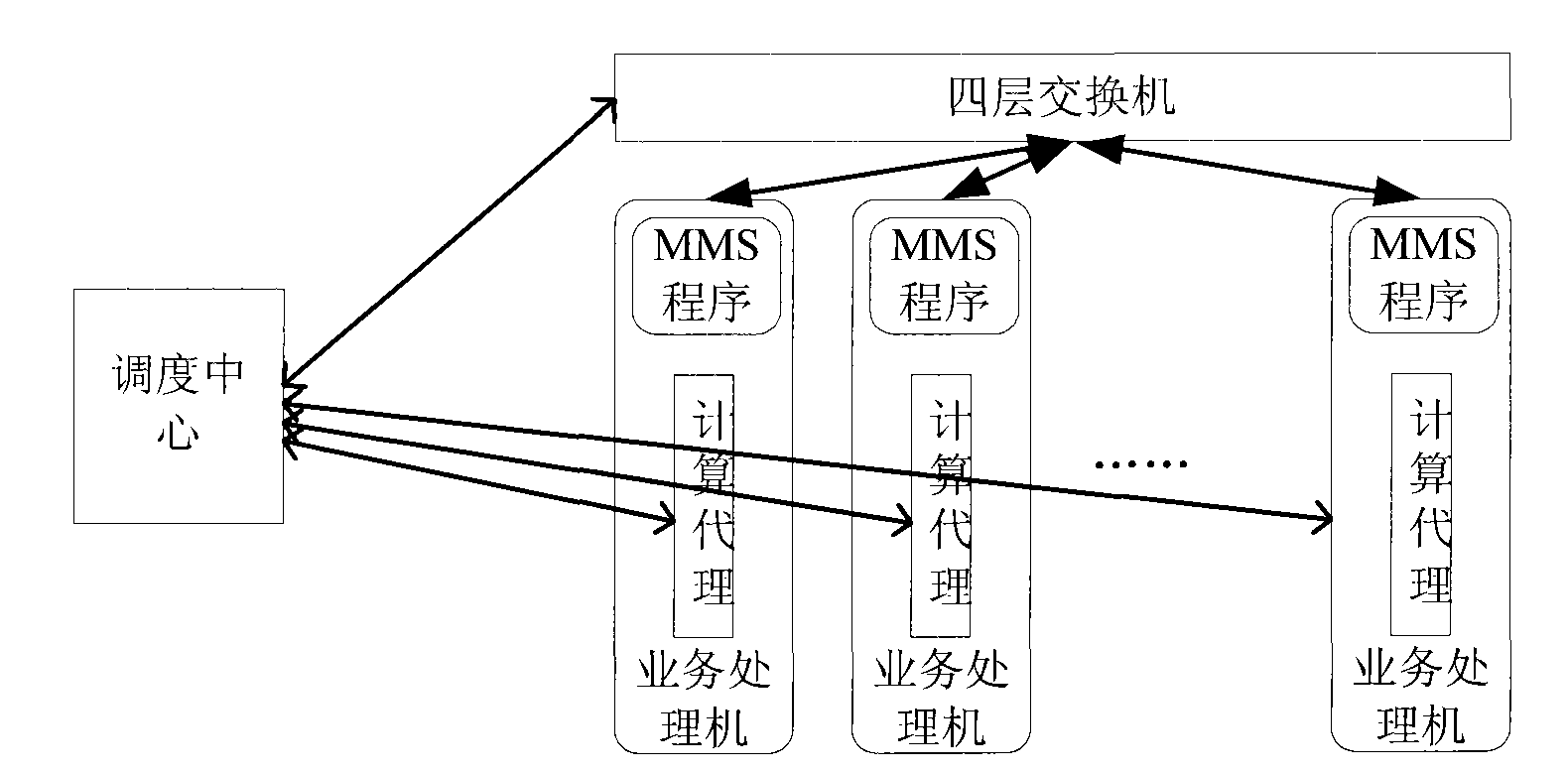

Multimedia message center and regulating method of processing capacity thereof

InactiveCN101834851AFull utilization of processing powerIncrease usageNetwork traffic/resource managementBroadcast service distributionMachine utilizationTime processing

The invention discloses a multimedia message center and a regulating method of processing capacity thereof. On the basis of the traditional multimedia message center, the multimedia message center is additionally provided with a calculation proxy module and a dispatching center module, wherein the calculation proxy module is used for collecting the real-time processing traffic volume of a traffic processor, the dispatching center module is used for receiving the transmitted real-time traffic volume of the traffic processor by the calculation proxy module and regulating the processing capacity of the multimedia message center by a predetermined rule according to the real-time traffic volume. The regulating method correspondingly is used for regulating the processing capacity of the multimedia message center according to the traffic volume condition of the multimedia message center, effectively increases the machine utilization ratio of the multimedia message center, and achieves the purposes of reducing operation and maintenance expenses of operators, saving energy and reducing emission.

Owner:深圳智慧者智能科技集团股份有限公司

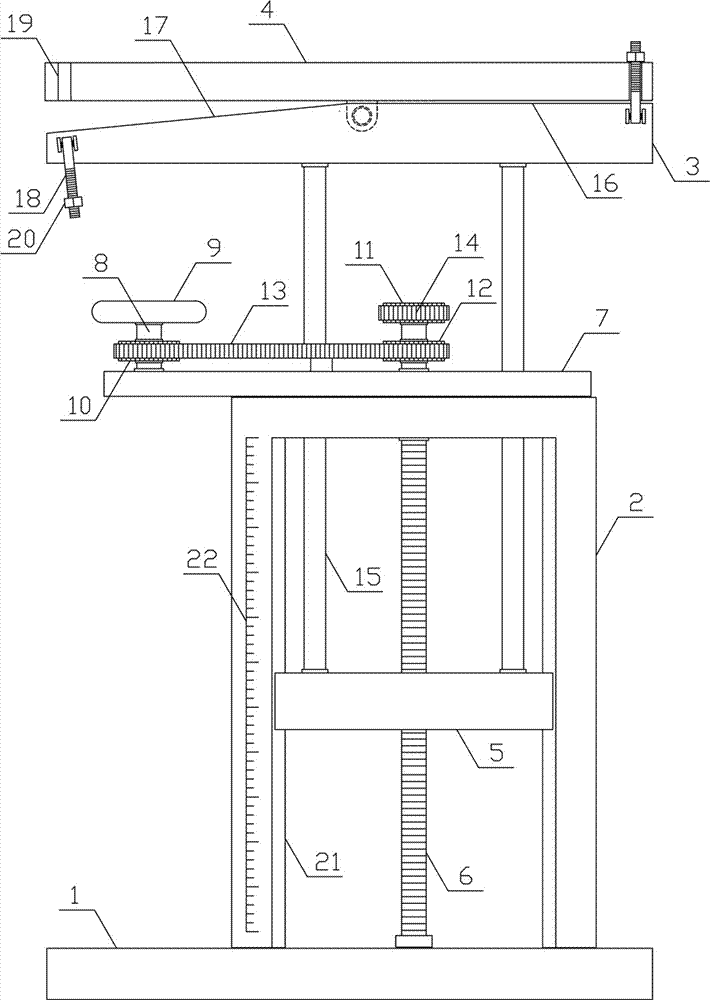

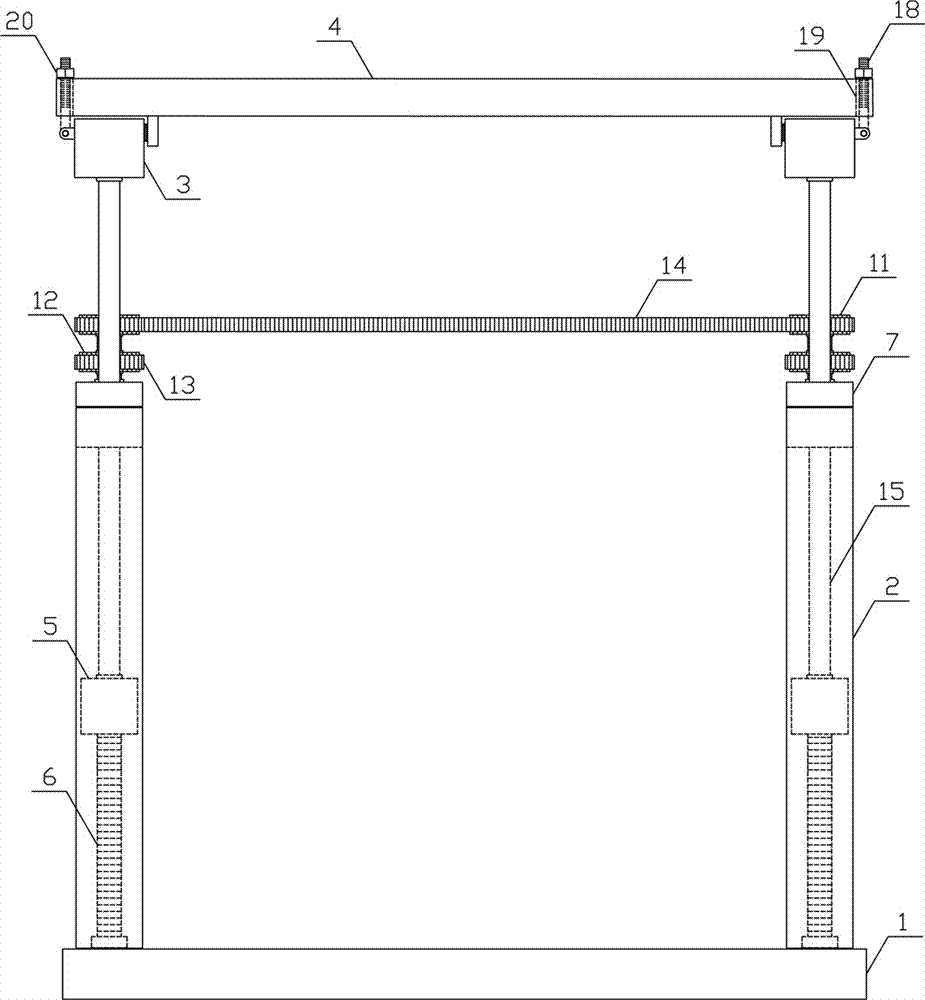

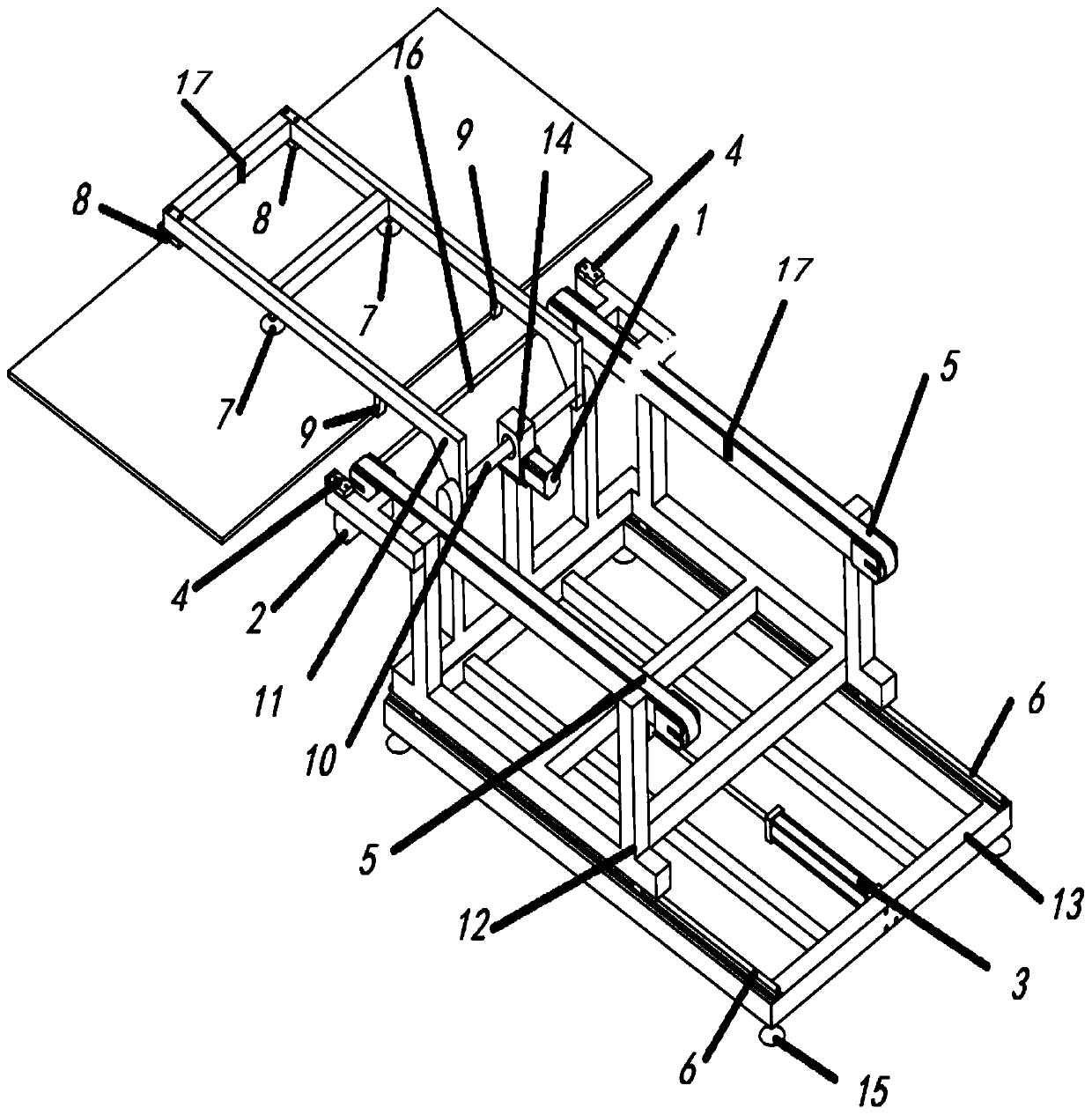

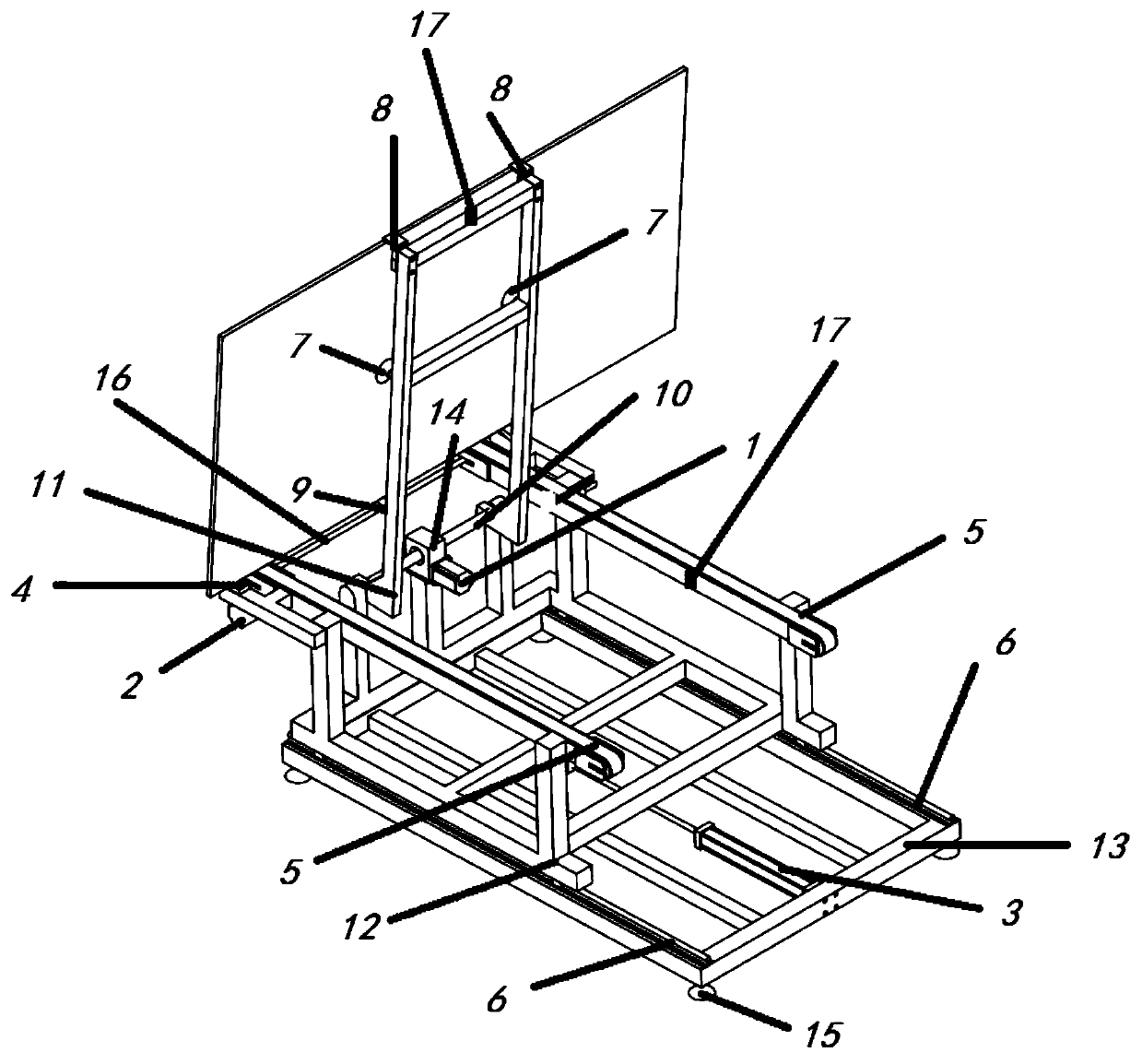

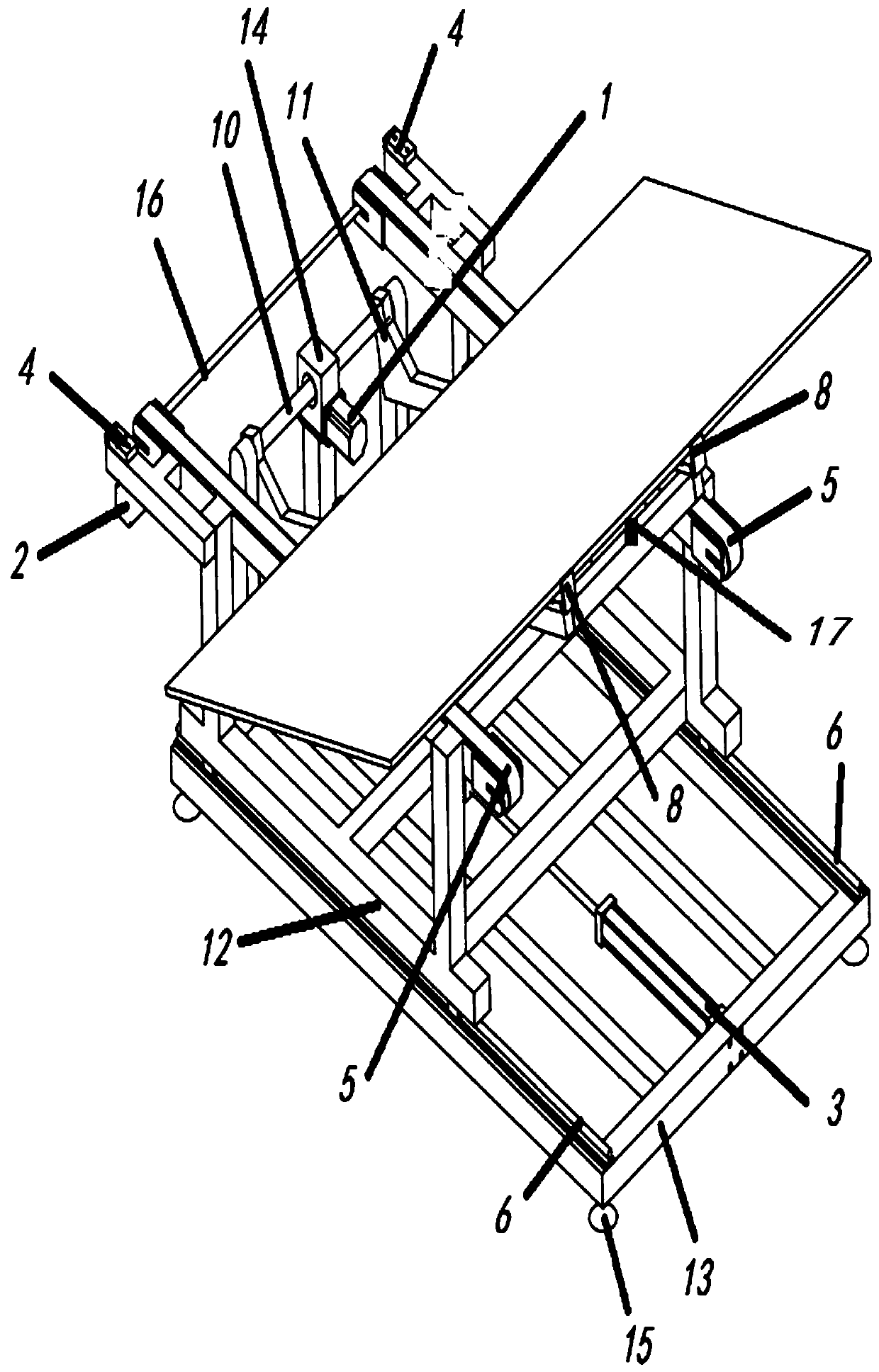

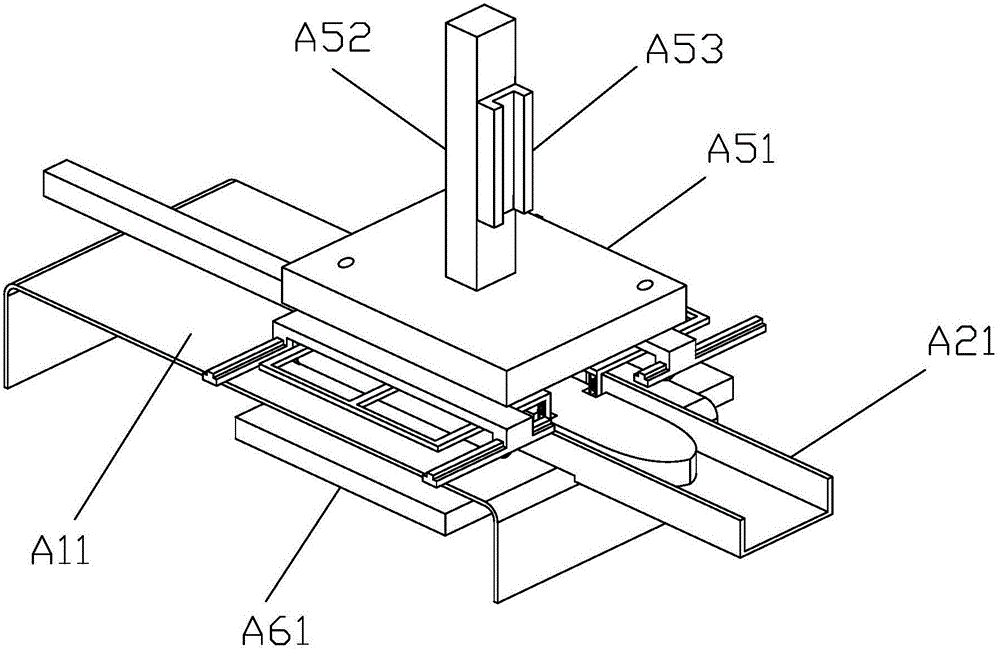

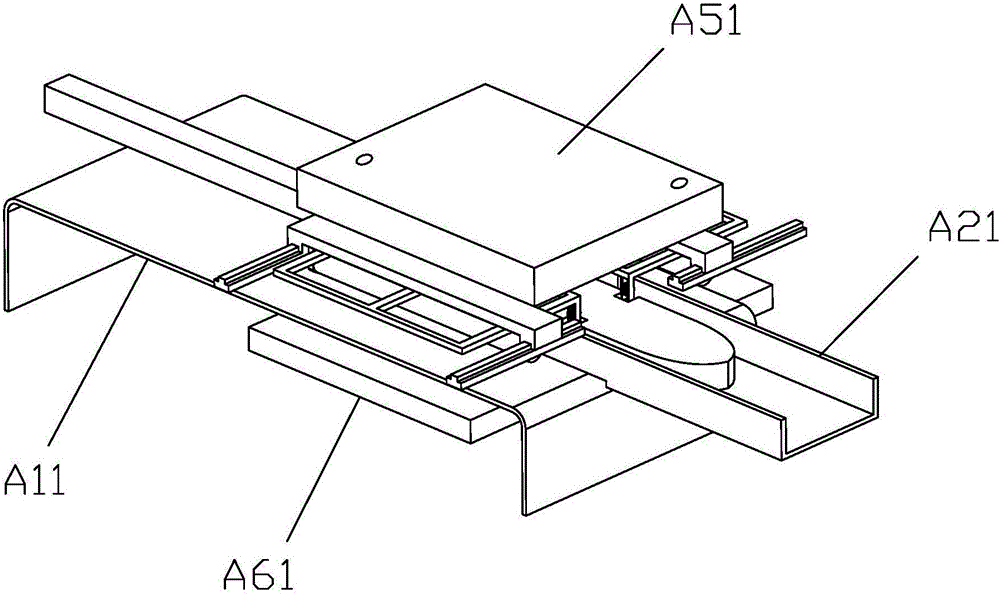

Lifting workbench

InactiveCN107081721ASmooth and accurate liftingReasonable structural designWork benchesMachine utilizationMechanical equipment

The invention provides a lifting workbench, and belongs to the field of machining auxiliary mechanical equipment. The lifting workbench comprises a fixed base, adjusting supports, bearing plate supports and a working platform. The adjusting supports are vertically and symmetrically arranged on the two sides of the top of the fixed base, and a lifting plate is arranged on the adjusting supports in a sliding mode in the vertical direction. Two synchronous chain wheels on the two sides of the top of the fixed base are connected in a transmission mode through a synchronous chain. The bearing plate supports are horizontally arranged at the upper ends of lifting guide rods, the working platform is horizontally arranged on the upper sides of the bearing plate supports, and the middle portions of the two sides of the bottom of the working platform are hinged to the middle portions of the bearing plate supports on the two sides of the top of the fixed base respectively. Locking lead screws are arranged on one side of one bearing plate support and the other side of the other bearing plate support, and locking clamping grooves which are matched with the locking lead screws are formed in the outer side of the working platform. The lifting workbench is reasonable in structural design, can rapidly and stably conduct horizontal ascent and descent on the working platform, can conduct rotating adjustment and fixing on the working platform as required, and meets the requirement of machining utilization.

Owner:钟彩凤

Catalyst for producing benzenediol by oxygenizing phenyl hydrate with hydrogen peroxide at room temperature and preparation method thereof

ActiveCN101480613AHigh selectivityHigh activityOrganic chemistryOrganic compound preparationTetramethylammonium hydroxideHigh energy

The invention relates to a catalyst for oxidizing phenol by hydrogen peroxide at room temperature to prepare benzenediol, and the preparation method of the benzenediol. The structural formula of the catalyst is AmBnFexSiOy, wherein A is one of the elements of the III main group in the periodic table, and B is one of the transition metal elements. A certain amount of inorganic metallic ferric salt and a precursor containing A and / or B are dissolved in a water solution, the solution is added to a water solution containing a surface active agent and a silicon source; after the solution is stirred, water solution of tetramethyl ammonium hydroxide is added, and then, sol is obtained by regulating the pH value; and the sol is centrifugated, washed and dried after being aged at room temperature or under the hydrothermal condition, and then, the surface active agent is removed to obtain the catalyst. The invention also relates to the preparation method of the benzenediol, which is characterized in that the catalyst is adopted, and the phenol is directly oxidized by the hydrogen peroxide at room temperature to prepare the benzenediol. The invention overcomes the disadvantages of high energy consumption, heavy machine utilization and the like under the conditions of high temperature and high pressure in the prior art of synthesizing benzenediol.

Owner:NANJING UNIV OF TECH

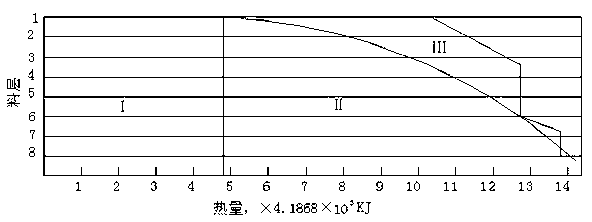

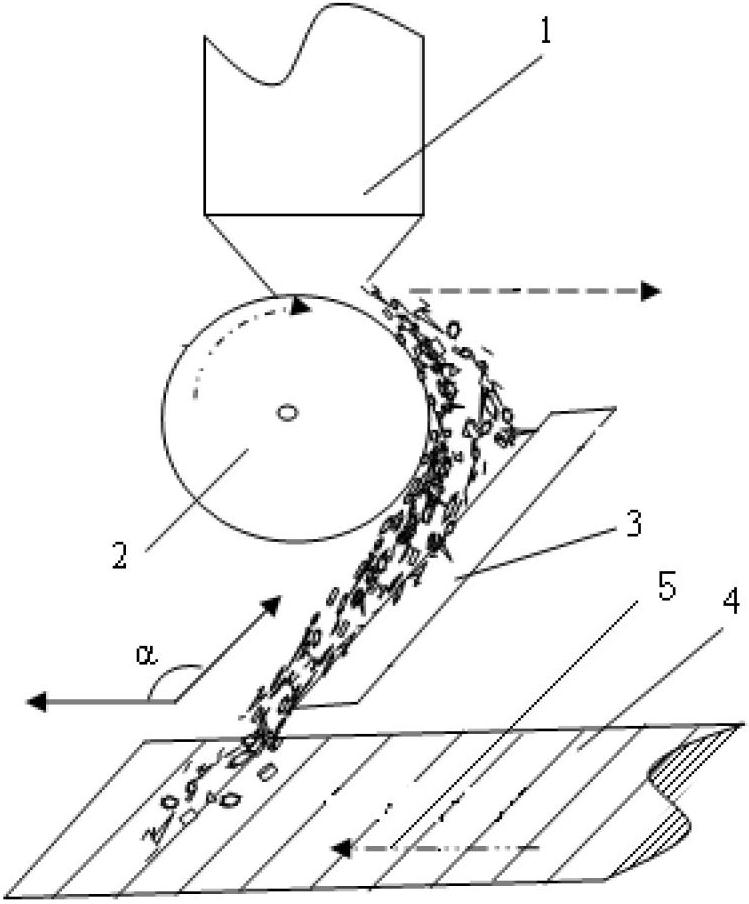

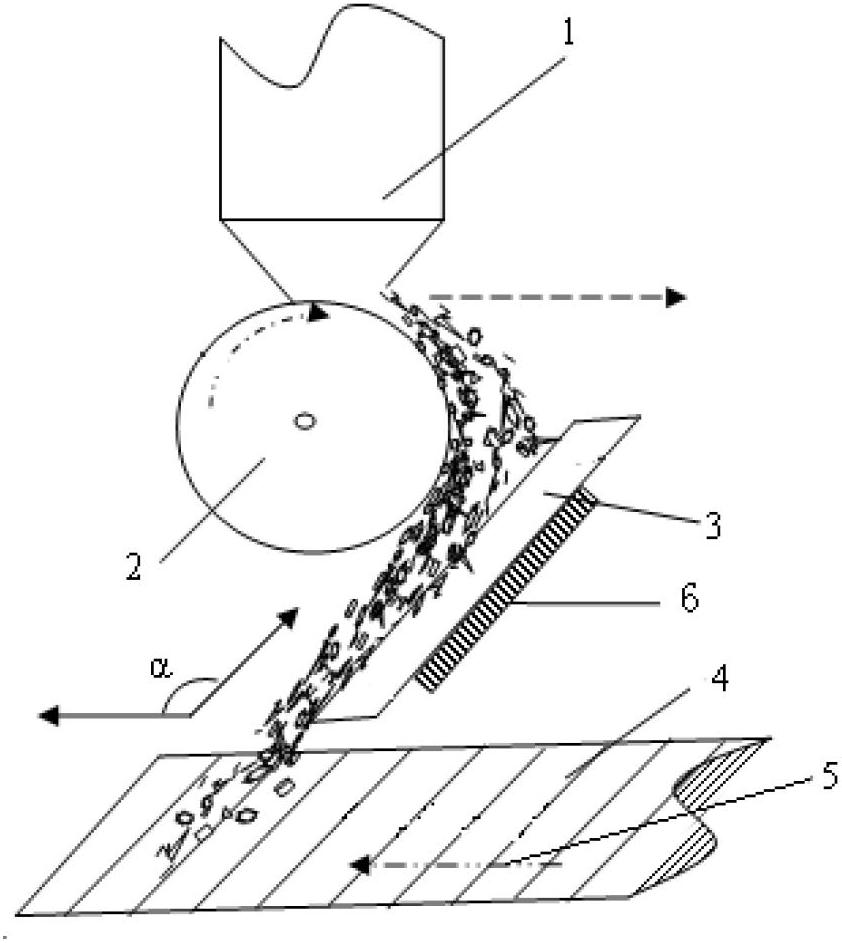

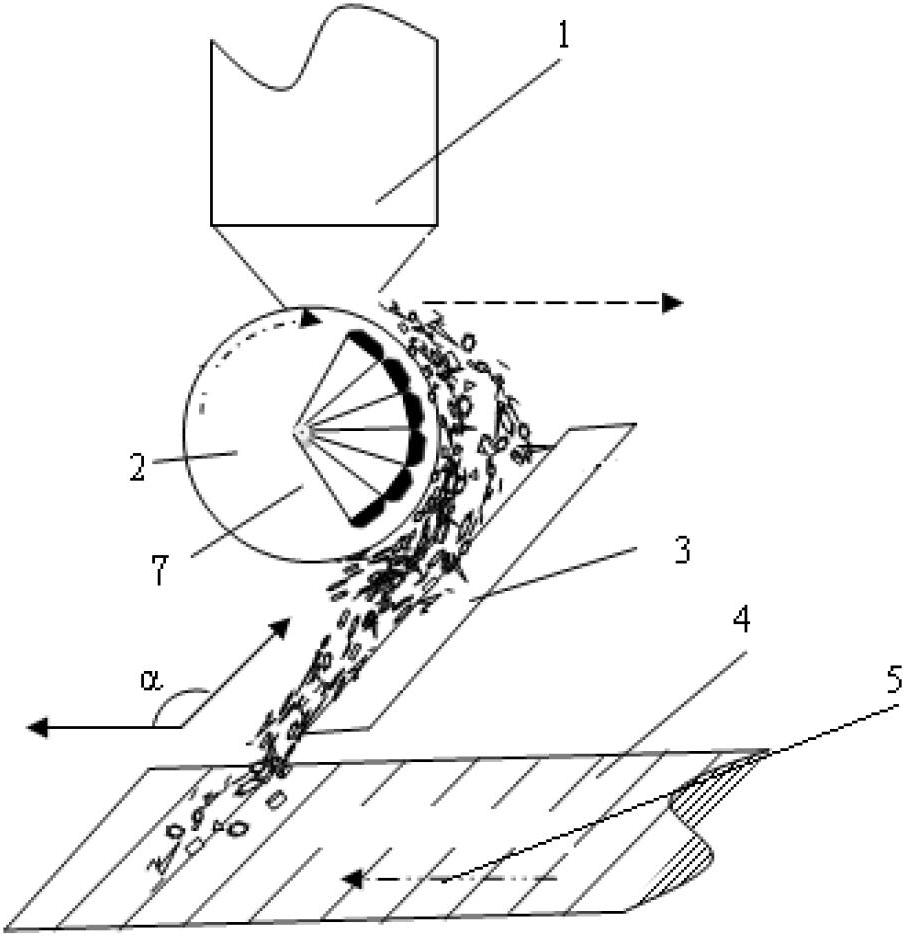

Iron ore sinter mixture distribution method

ActiveCN102676797AImprove magnetic susceptibilityImprove stressFurnace typesIronstoneMachine utilization

The invention discloses an iron ore sinter mixture distribution method. By adopting a mixture preparation technology of pre-mixing magnetite concentrate and coke powder and a matched mounting mode with a round roller, a magnetic system and a reflecting plate, the particle size segregation, the fuel segregation and the segregation of materials such as the magnetite concentrate and the like in the mixture distribution can be enhanced; the air permeability of a sinter bed can be further improved by enhancing the particle size segregation; through the enhancement of the fuel segregation, the heatdistribution is more reasonable, the uniform-heat sintering is realized, and the fuel usage is reduced; and through the segregation of the magnetite concentrate, the oxidation of the magnetite is sufficiently utilized to release heat, so that the heat accumulation effect is enhanced, and the fuel usage is further reduced. The method disclosed by the invention can comprehensively improve the air permeability, the heat distribution and the heat transfer condition of the sinter bed, reduce the fuel usage and obviously improve the yield and quality indexes of sinter; and the indexes such as the vertical sintering speed, the sintering machine utilization coefficient, the finished sintering product rate, the sinter tumbler strength, the reducing degree and the like can be improved to different degrees.

Owner:CENT SOUTH UNIV

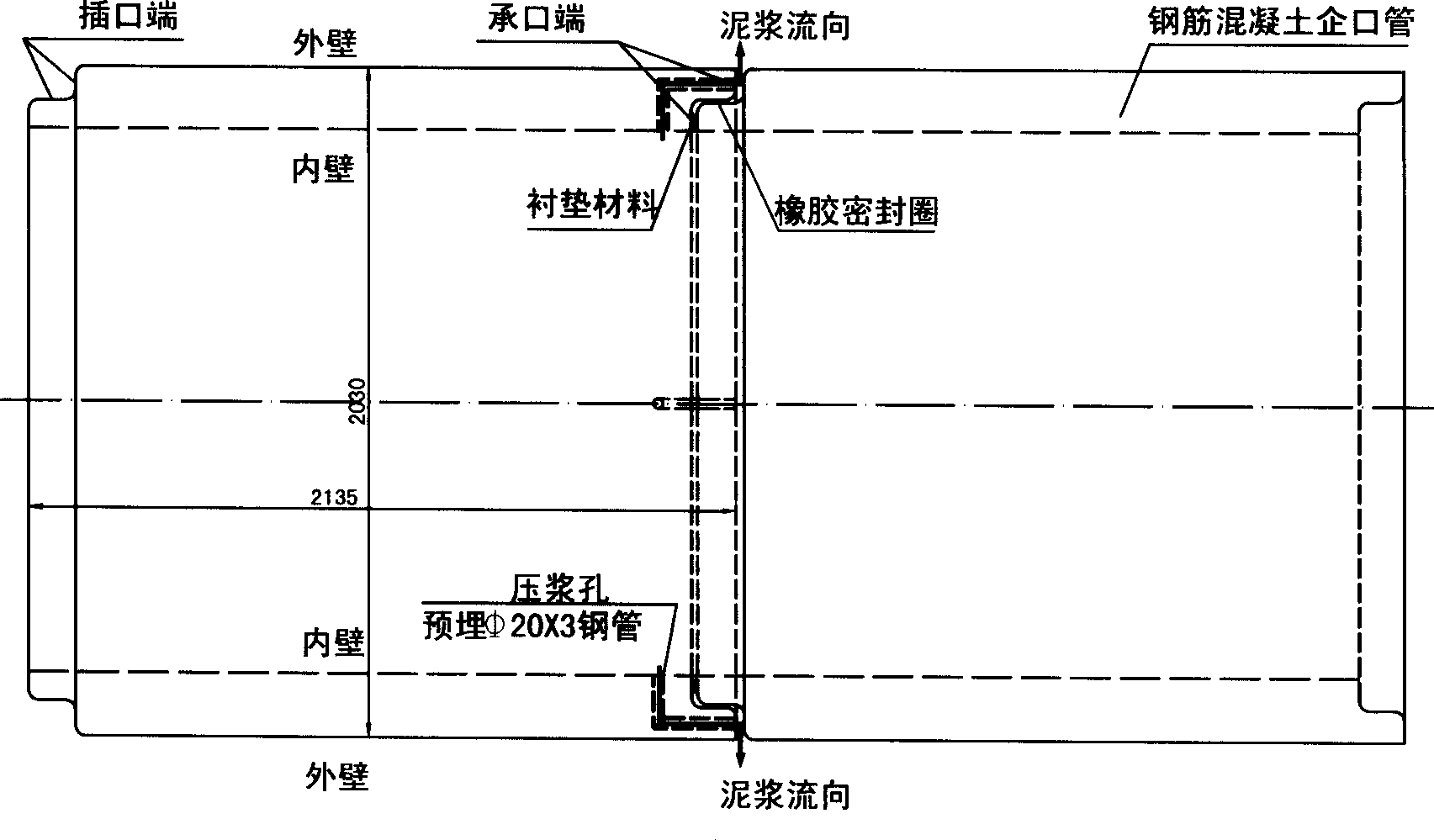

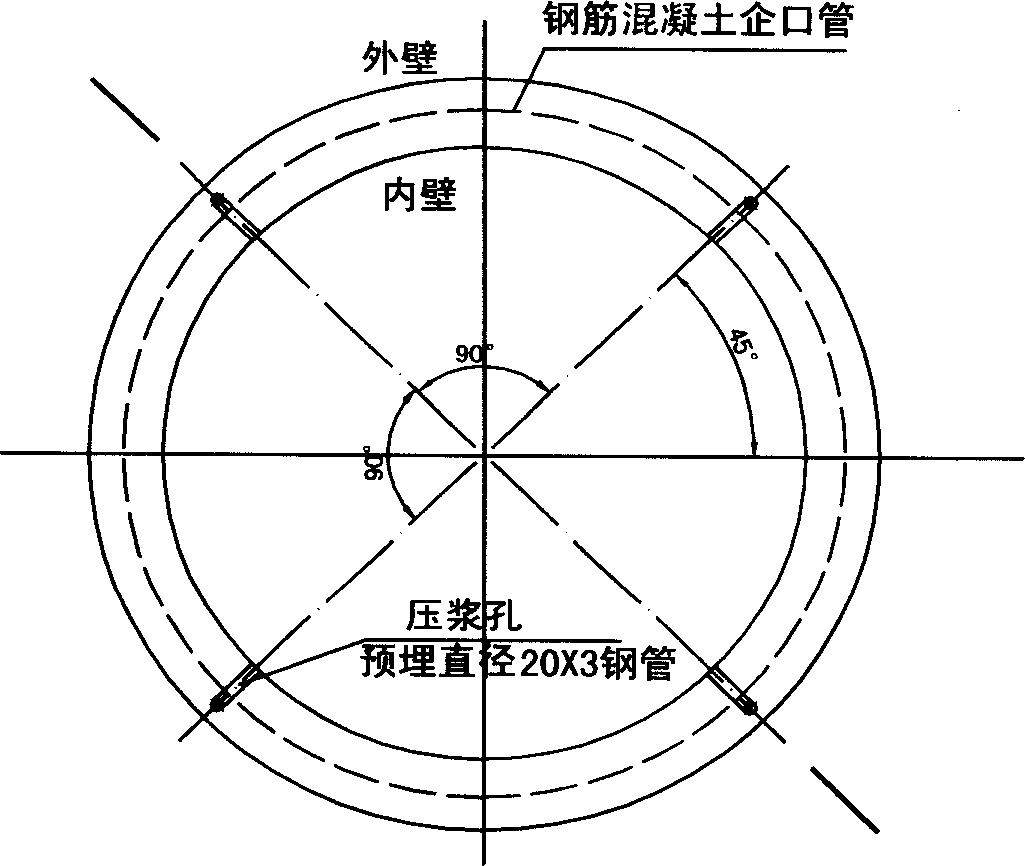

Method for reducing prop force with ring-shape mud sheath in pipe-jacking construction

InactiveCN1773151AReduce jacking forceReduce frictionPipe laying and repairSodium BentoniteReinforced concrete

The present invention relates to a method for reducing jacking force by using ring slurry guard cover in pipe-jacking construction of building engineering technology field. Said method includes the following several procedures: (1), reinforced concrete pipe-jacking machine utilization procedure; (2), gap utilization procedure; (3), using slurry-pressing equipment to feed the bentonite slurry into slurry-pressing hole; and (4) making the bentonite slurry be diffused into earth body. Said invention also provides the concrete steps of the above-mentioned every procedure.

Owner:SHANGHAI JIAO TONG UNIV

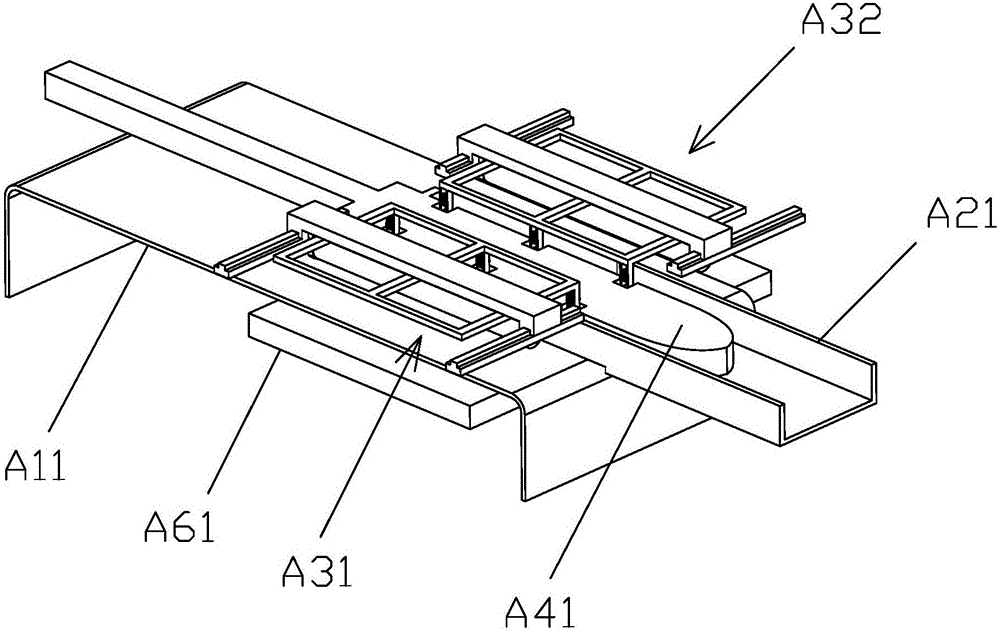

Crystal blank grinding system

ActiveCN104959892AReduce volumeIncrease profitGrinding carriagesSpherical surface grinding machinesMachine utilizationEngineering

The invention discloses a crystal blank grinding system. The crystal blank grinding system comprises a feeding station, a discharging station, a plurality of upper half ball grinding stations and an abutting station which are sequentially arranged from right to left along a first left-right transferring mechanism, and further comprises an abutting position, a plurality of lower half ball grinding stations, a feeding station and a discharging station which are sequentially arranged from left to right along a second left-right transferring mechanism. A grinding machine comprises an upper half ball grinding tool sequence and a lower half hall grinding sequence, a plurality of upper half ball grinding mechanisms are arranged left and right to form an upper half ball machining sequence, and circulation of clamps is achieved between the adjacent grinding mechanisms in the upper half ball machining sequence through the first left-right transferring mechanism; a plurality of lower half ball grinding mechanisms are arranged left and right to form a lower half ball machining sequence, and circulation of the clamps is achieved between the adjacent grinding mechanisms in the lower half ball machining sequence through the second left-right transferring mechanism. The upper half ball grinding tool sequence is located on the front side of the lower half ball grinding tool sequence. According to the crystal blank grinding system, the transition waiting vacancy is reduced, the size of a machine is small, and the machine utilization rate is high.

Owner:虞雅仙

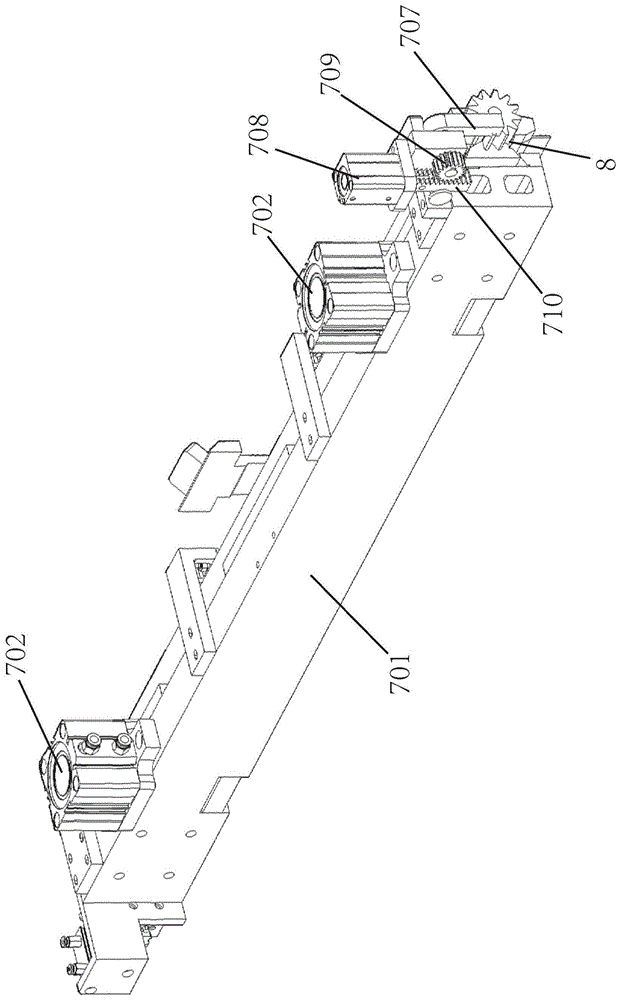

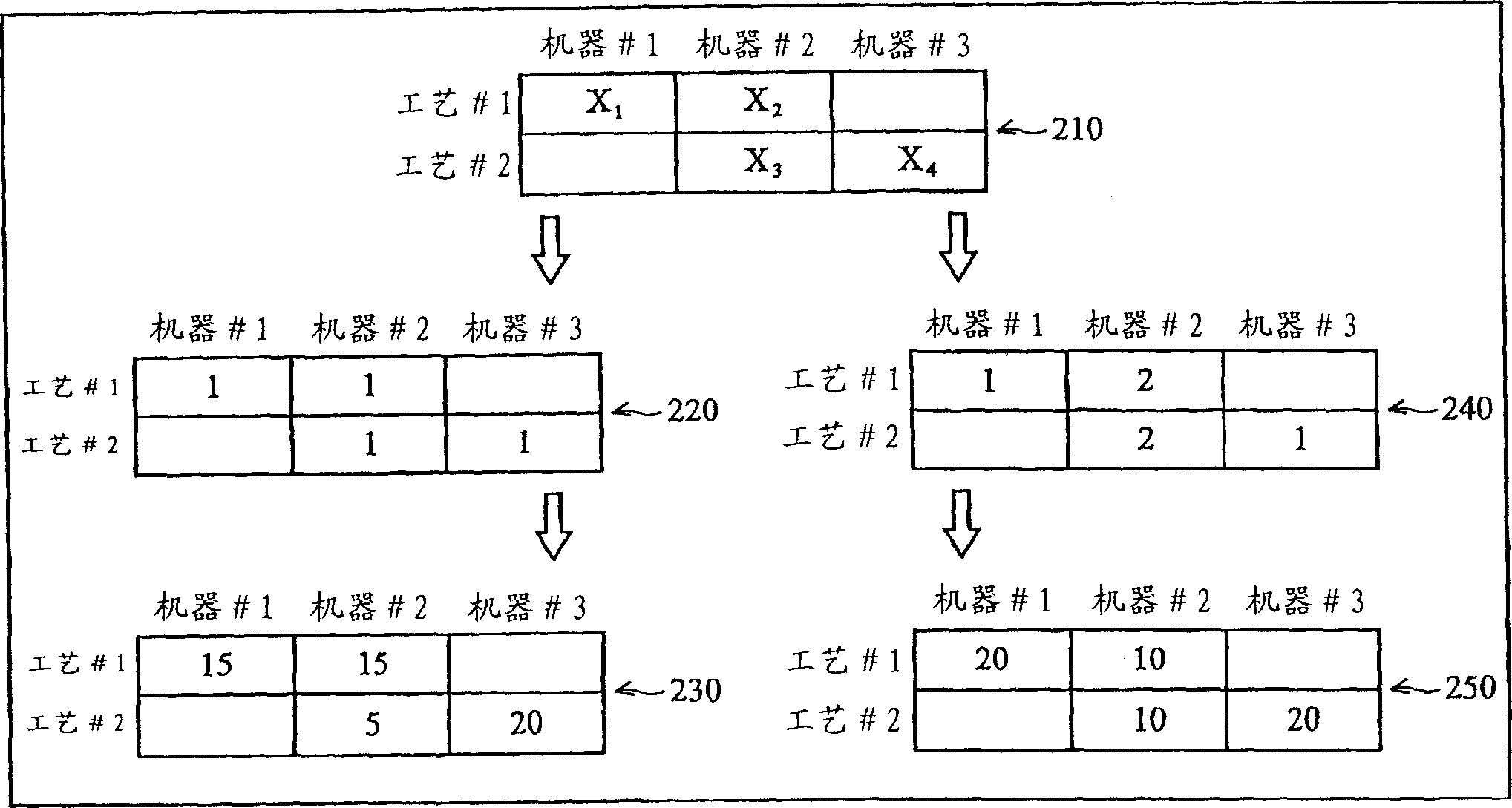

Method for determining machinery processing sequence and manufacturing system therewith

InactiveCN1855359AAchieve production optimizationSemiconductor/solid-state device manufacturingSpecial data processing applicationsElectrical conductorMachine utilization

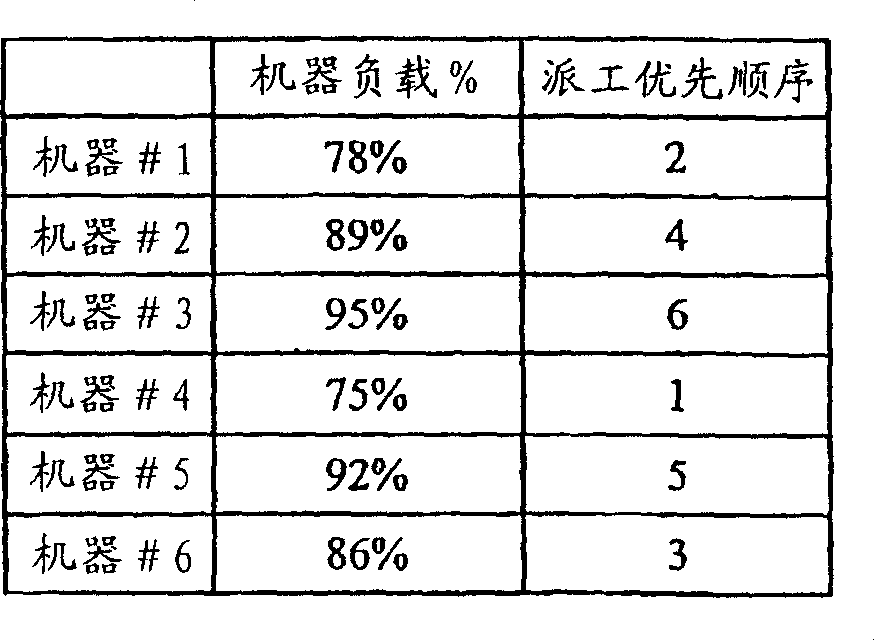

The invention is for use in a semiconductor fabrication system and provides a first machine and a second machine, and a first semiconductor technology and a second semiconductor technology capable of being executed by said machines. The quantity of output required by first and second semiconductor technology is calculated. The tasking priority of first and second machine is determined by using a statistical method, wherein the said statistic method is a two stages data feedback method. The execution process comprises the following steps: in the first stage, the machine tasking sequence where the priority is not set is executed to get the machine utilization rate; in the second stage, the result obtained from the first stage is used; wherein, if the first machine has a lowest utilization rate, then the tasking priority of the first machine is set into the first tasking priority, and meanwhile the tasking priority of the second machine is set into the second tasking priority.

Owner:POWERCHIP SEMICON CORP

Automatic woodworking board overturning machine and control method thereof

PendingCN110978154AEasy to punchEasy to carveMulti-purpose machinesMachine utilizationControl engineering

The invention belongs to the technical field of board processing equipment and supporting equipment, and provides an automatic woodworking board overturning machine and a control method thereof. Two ends of the upper side of an overturning board support are fixedly provided with sliding rails through bolts, the upper ends of the sliding rails are slidably connected with a sliding support, conveying belts are fixed to the upper end of the sliding support through fixing shafts, and the outer sides of the fixing shafts at the left ends of the conveying belts are connected with output shafts of conveying motors; and a rotating speed reducer is fixed to the middle of the sliding support through a supporting rod, a rotating shaft is arranged in the middle of the rotating speed reducer in a penetrating mode, two ends of the rotating shaft are connected with the sliding support through bearings, a board overturning motor is connected to the outer side of the rotating speed reducer through bolts, a rotating platform is fixedly connected to the two ends of the outer side of the rotating shaft, and a board fixing device is fixed to the outer side of the rotating platform through bolts. According to the automatic woodworking board overturning machine, the utilization rate of the machine is improved, and the working efficiency of about 30% is improved. According to the automatic woodworkingboard overturning machine, the overturning processing of a woodworking board is realized, the utilization rate is high, the working efficiency is improved, the safety coefficient is increased, the operation is simple, and the time is saved.

Owner:济南贝因数控机械有限公司

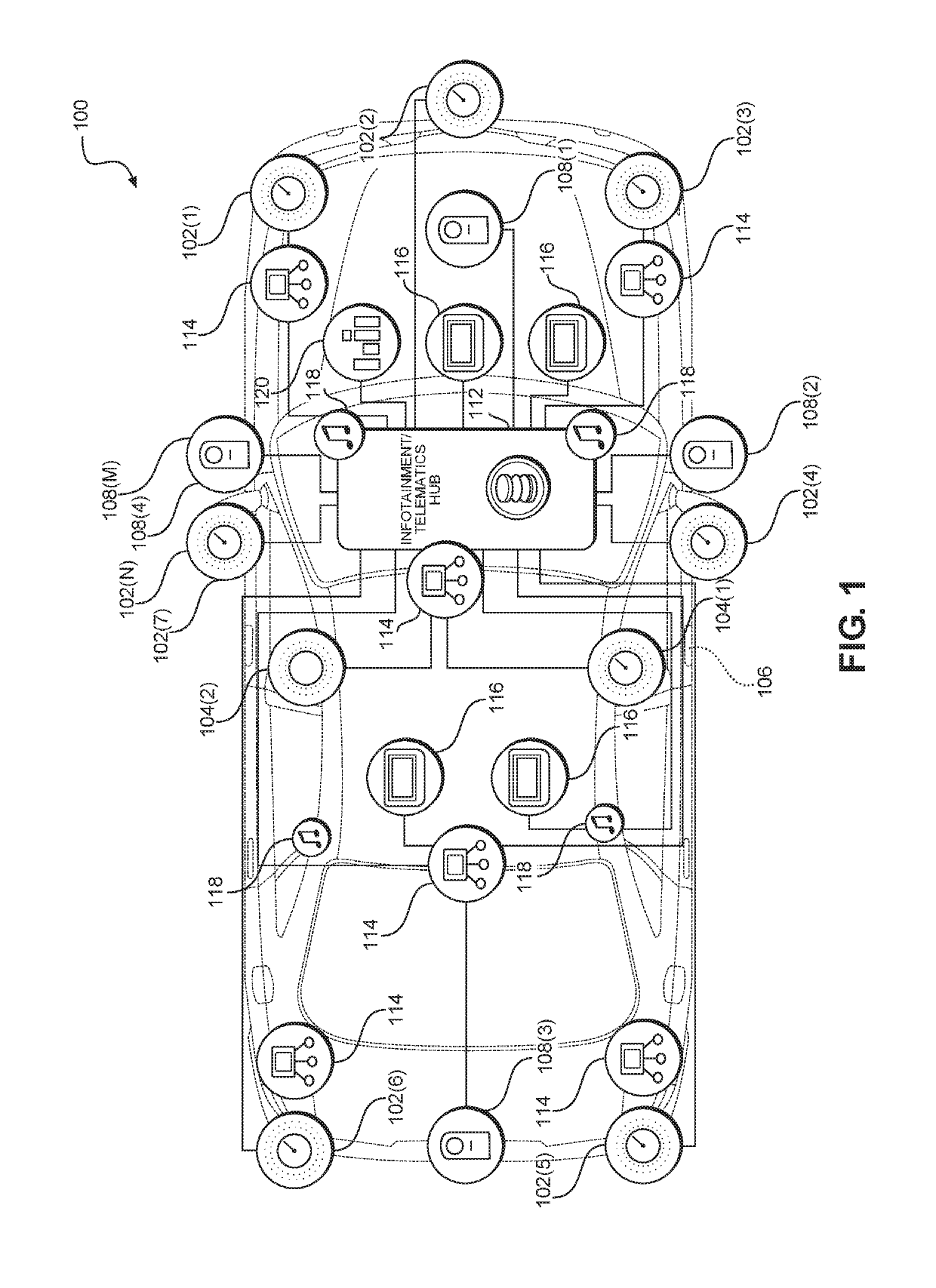

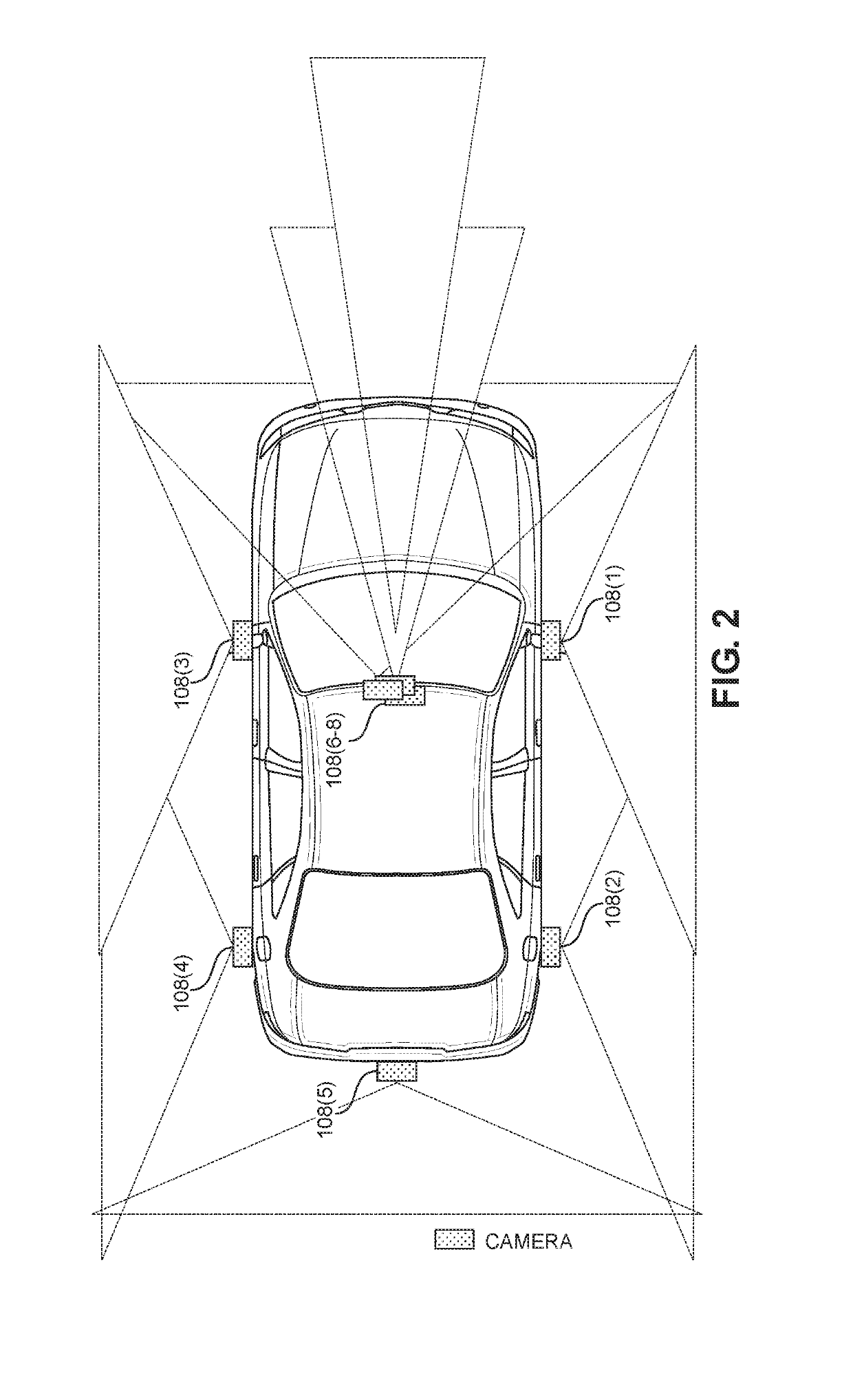

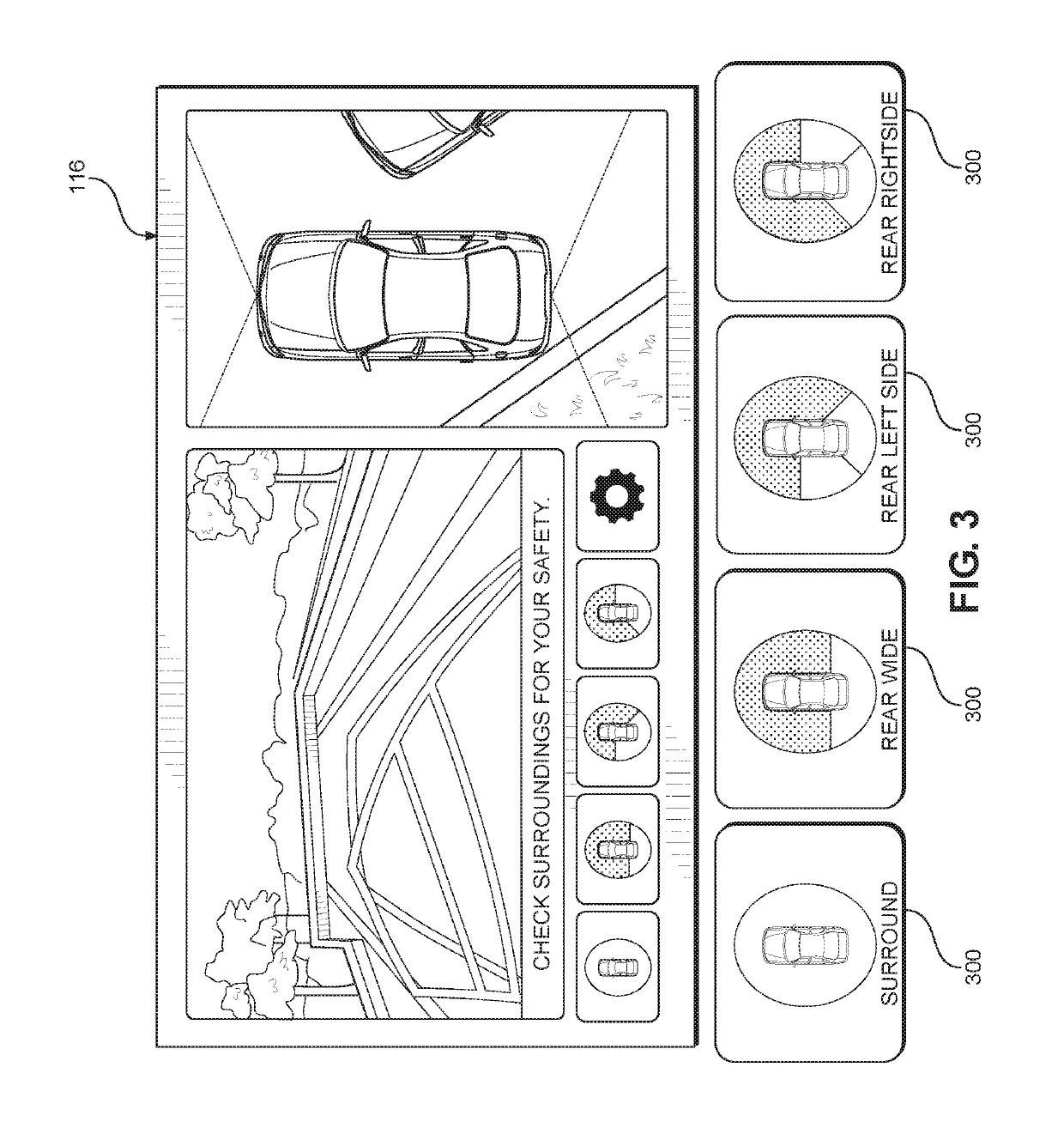

Methods and systems to broadcast sensor outputs in an automotive environment

InactiveUS20190132555A1Good flexibilityWithout imposing undue latencyClosed circuit television systemsElectromagnetic wave reradiationHuman useMachine utilization

Methods and systems to broadcast sensor outputs in an automotive environment allow sensors such as cameras to output relatively unprocessed (raw) data to two or more different processing circuits where the processing circuits are located in separate and distinct embedded control units (ECUs). A first one of the two or more different processing circuits processes the raw data for human consumption. A second one of the two or more different processing circuits processes the raw data for machine utilization such as for autonomous driving functions. Such an arrangement allows for greater flexibility in utilization of the data from the sensors without imposing undue latency in the processing stream and without compromising key performance indices for human use and machine use.

Owner:QUALCOMM INC

Method for pretreating bamboo shell through tomentum removing device

InactiveCN106078958AEffective flatteningReliable supportWood treatment detailsCane mechanical workingMachine utilizationEngineering

The invention relates to a method for pretreating a bamboo shell through a tomentum removing device. The method comprises the steps that in the S2, tomentum removing is carried out in the tomentum removing device, the tomentum removing device comprises a rack B and a tomentum removing roller which is arranged on the rack B in an inclined manner, a feeding opening and a discharging opening are formed in the two ends of the tomentum removing roller, convex ribs are arranged on the inner wall face of the tomentum removing roller, the length direction of the convex ribs is consistent with the length direction of the tomentum removing roller, the convex ribs are arranged on the inner wall of the tomentum removing roller in a layered manner in the length direction of the tomentum removing roller, convex ribs on the adjacent layers are arranged in an alternatively-staggered manner, and the tomentum removing roller is connected with a drive mechanism E. According to the technical scheme, the bamboo shell can be effectively leveled, and reliable supporting is provided for machining utilization of the bamboo shell.

Owner:王寿南

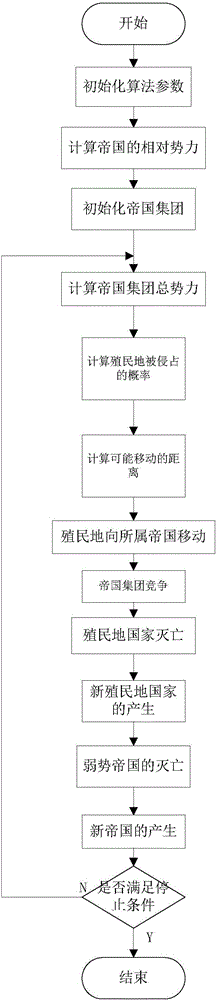

Improved imperialist competitive algorithm for solving job-shop scheduling problem

InactiveCN106611380AReduce computational complexityReduce running timeData processing applicationsManufacturing computing systemsAlgorithmBird flight

The invention provides an improved imperialist competitive algorithm for solving a job-shop scheduling problem. According to the algorithm, the empire relative power is described by machine handling operation capability; a machine is directly defined as an empire while an operation is directly defined as a colony, so that uncertainty caused by random generation of an initial solution is avoided, and algorithm operating time is reduced; machine utilization rate is described by empire survival rate, so that the algorithm is simple and easy to understand; by converting movement from the colony to the imperialist into a viewing angle of movement from the imperialist country to the colony country in the imperialist competitive algorithm, so that the algorithm is closer to the actual condition; meanwhile, a cost function is described by a distance between the colony and the empire, so that the algorithm is simple and practical, and detailed and efficient; in addition, an approaching way from the empire to the colony is simulated by Levy flight executed by a bird flight Mantegna algorithm, so that the convergence speed of the algorithm is properly reduced; by setting probability of one empire in colony embezzlement, and by performing random selection by 0-1 planning, the algorithm is more flexible, and the calculation result is more accurate.

Owner:SICHUAN YONGLIAN INFORMATION TECH CO LTD

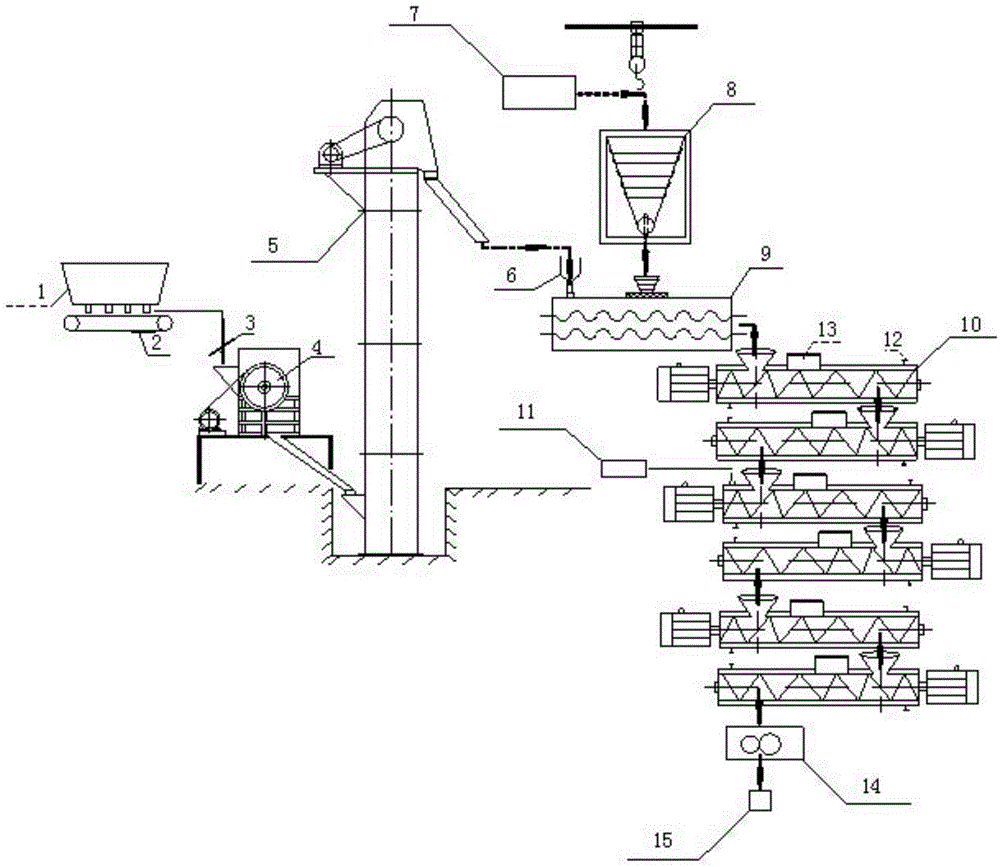

Tar slag machining process and system

InactiveCN104531182ANo secondary pollutionSimple crafting systemWorking-up pitch/asphalt/bitumen by distillationLiquid hydrocarbon mixture productionDistillationSlag

The invention provides a tar slag machining process and system, and belongs to a tar slag cleaning machining utilization process and system. According to the process, after tar slag is added to crushed coal according to proportion, the tar slag and the crushed coal are fully mixed in a double-spiral mixer and then sent to multi-stage spiral dry distillation and conveying integrated machines to be subjected to dry distillation devolatilization, pitch prepared by coal tar in a distillation mode is added into a one-level spiral dry distillation and conveying machine of the multi-stage spiral dry distillation and conveying integrated machines, three materials are fully distillated and mixed through the dry distillation and conveying machines, and a product model block formed by final mixed materials for gas making of a gas station is obtained. The system includes the four steps that 1, binder pitch is obtained through tar machining; 2, fine coal is crushed to be power coal; 3, tar slag fine coal is mixed and subjected to distillation devolatilization; 4, the binder pitch and the tar slag coal generated after dry distillation is conducted are mixed to form and manufacture the gasified model block.

Owner:CHINA UNIV OF MINING & TECH

Catalyst for producing benzenediol by oxygenizing phenyl hydrate with hydrogen peroxide at room temperature and preparation method thereof

ActiveCN101480613BHigh selectivityHigh activityOrganic chemistryOrganic compound preparationTetramethylammonium hydroxideHigh energy

The invention relates to a catalyst for oxidizing phenol by hydrogen peroxide at room temperature to prepare benzenediol, and the preparation method of the benzenediol. The structural formula of the catalyst is AmBnFexSiOy, wherein A is one of the elements of the III main group in the periodic table, and B is one of the transition metal elements. A certain amount of inorganic metallic ferric saltand a precursor containing A and / or B are dissolved in a water solution, the solution is added to a water solution containing a surface active agent and a silicon source; after the solution is stirred, water solution of tetramethyl ammonium hydroxide is added, and then, sol is obtained by regulating the pH value; and the sol is centrifugated, washed and dried after being aged at room temperature or under the hydrothermal condition, and then, the surface active agent is removed to obtain the catalyst. The invention also relates to the preparation method of the benzenediol, which is characterized in that the catalyst is adopted, and the phenol is directly oxidized by the hydrogen peroxide at room temperature to prepare the benzenediol. The invention overcomes the disadvantages of high energy consumption, heavy machine utilization and the like under the conditions of high temperature and high pressure in the prior art of synthesizing benzenediol.

Owner:NANJING TECH UNIV

Production method of active material for positive electrode of alkaline secondary battery, positive electrode using the active material and production method of alkaline secondary battery using the positive electrode

InactiveUS6268082B1Improve overall utilizationWithout riskAlkaline accumulatorsFinal product manufactureElectrical batteryNickel oxide hydroxide

The present invention is to provide a production method of an active material for an alkaline secondary battery comprising: a step of mixing particles comprising particles mainly containing nickel hydroxide and particles of a metal cobalt or a cobalt compound in a mixer with a sealed structure comprising a heating means in the presence of oxygen and an alkaline aqueous solution while heating. An active material produced by the method allows a high utilization. And a battery assembled with a positive electrode using the active material has an excellent high ratio discharge characteristic, and hardly causes the capacity decline even at the time of recharging after leaving in the over discharge state for a long time.

Owner:TOSHIBA BATTERY

Mobile monitoring image recognition system and method

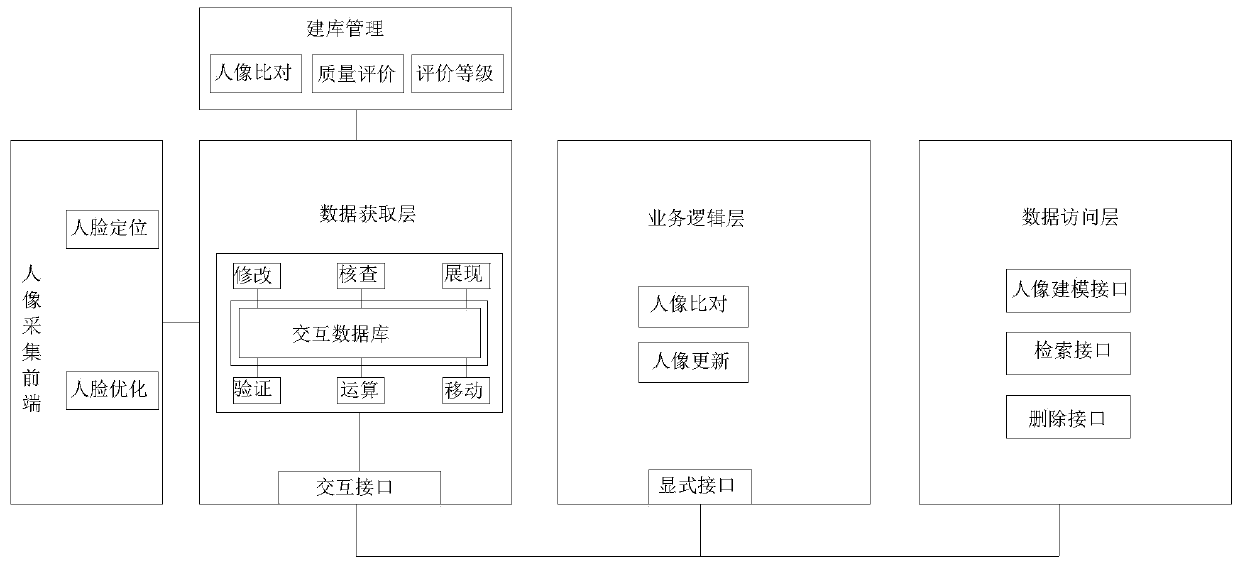

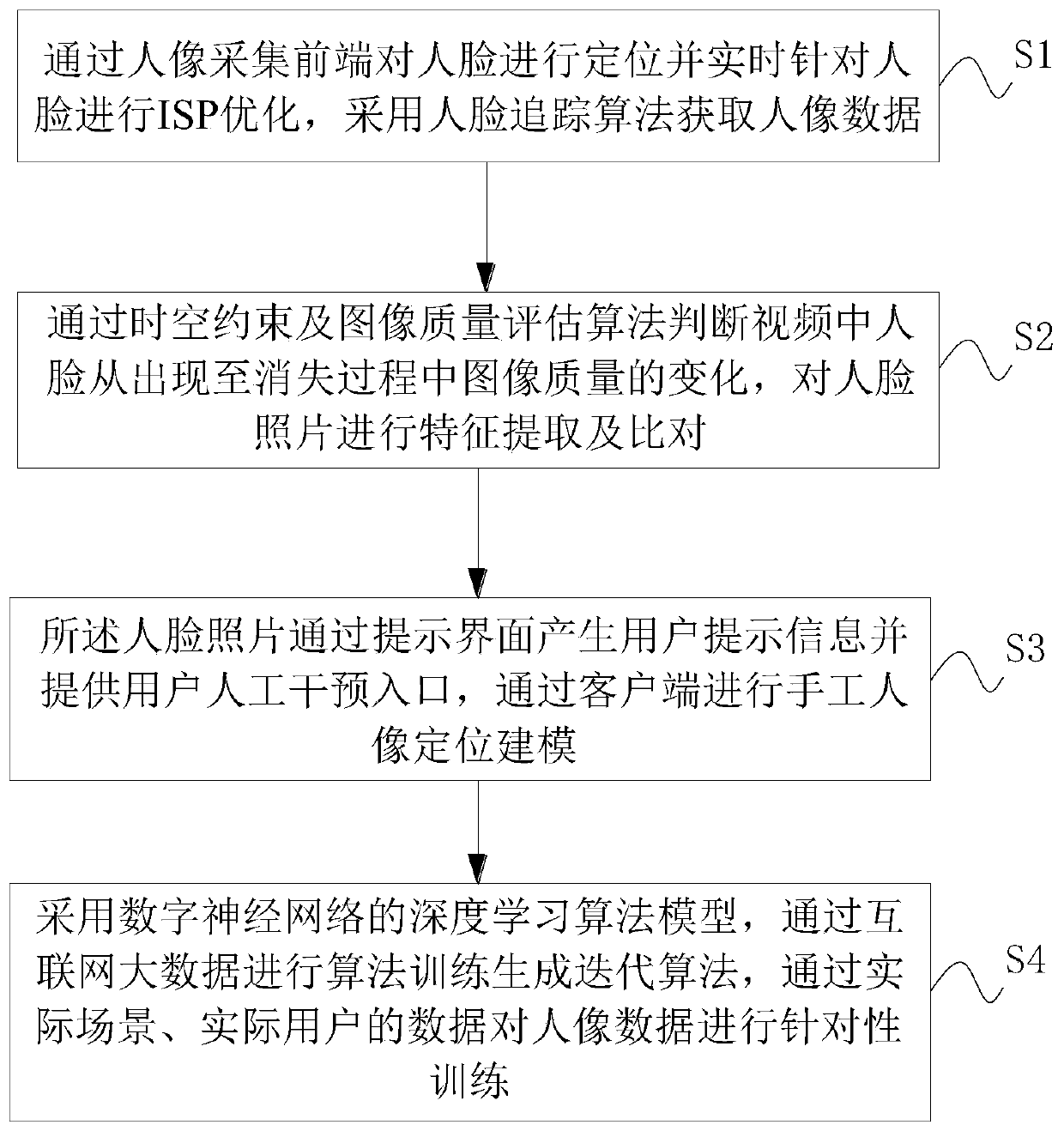

InactiveCN110321378AImprove utilization efficiencyImprove stabilityImage enhancementImage analysisImaging qualityData acquisition

The embodiment of the invention discloses a mobile monitoring image recognition system and method, and the method comprises the steps that a data obtaining layer carries out the portrait data interaction with a user, and provides a data operation interaction interface for the user; and the data acquisition layer performs calling and service driving on the data operation action through a display interface; positioning a human face through a human face acquisition front end, performing ISP optimization on the human face in real time, and obtaining human face data by adopting a human face tracking algorithm; judging the change of the image quality of the face in the video from appearance to disappearance through space-time constraint and an image quality evaluation algorithm, and carrying outthe feature extraction and comparison of a face picture; adopting a deep learning algorithm model of a digital neural network, and performing targeted training on portrait data through an actual scene and actual user data. The processing capacity can be linearly expanded according to needs, single-point limitation is avoided, load balancing can be carried out between comparison examples, the machine utilization efficiency and the system service stability are improved, and hardware resources are fully utilized.

Owner:梁勇

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com