A double-layer production plan optimization control method based on an intelligent optimization algorithm

An intelligent optimization algorithm and production planning technology, applied in computing, manufacturing computing systems, instruments, etc., can solve the problems of no production plan, simple production plan, and low production efficiency in factories, and achieve good economic and social benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

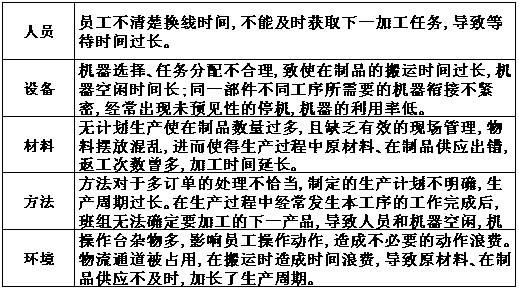

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0098] Embodiment 1, the present invention is a two-tiered production planning optimization control method based on an intelligent optimization algorithm, characterized in that the two-tiered production planning optimization control method based on an intelligent optimization algorithm includes the following two layers:

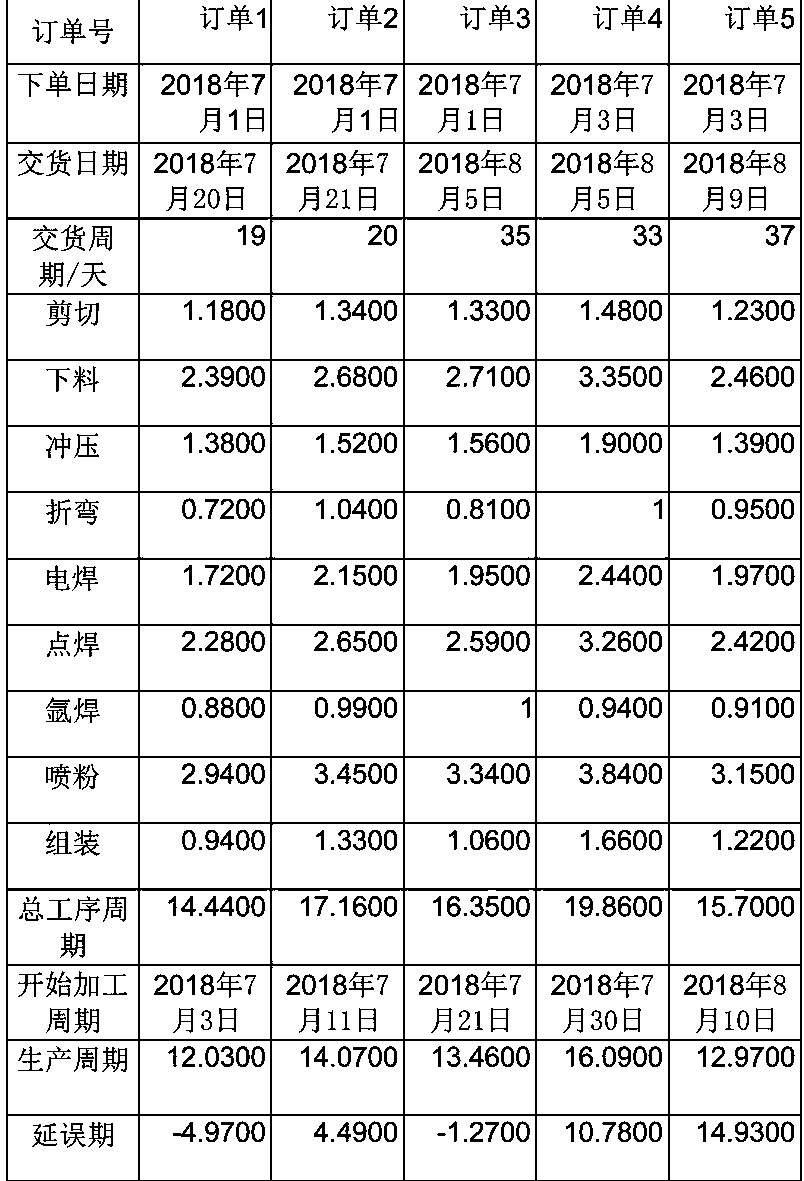

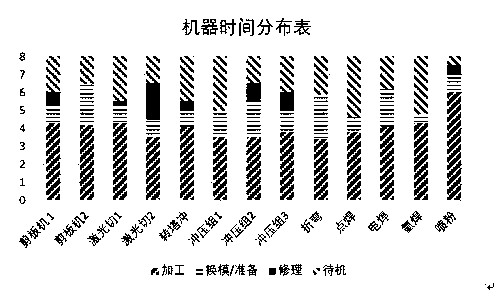

[0099] The first layer: Order sorting, based on the principle of delivery time priority, to ensure that the total penalty of the order is the smallest, sort the orders, and generate the production plan in the factory. The second layer is workshop scheduling, and minimize the maximum completion time with the machine. The maximum utilization rate is the goal, and the main factors in actual production are considered, and a detailed workshop production plan is made for the order. However, only the first-level order sorting lists the current order order, but some orders are still postponed, and the order The production plan of the company is not detailed, and it is...

Embodiment 2

[0111] Embodiment 2, on the basis of Embodiment 1, the problem modeling of the order sorting of the first layer is as follows:

[0112] There are N orders to be processed in the factory, each order has only one product, the quantity is Mi, the individual processing time of each product decreases with the increase of the number of products in the order, and the processing time of the i-th order is T i . The delivery date of the i-th order is W i ;K i Indicates the start processing time of the i-th order; Ei represents the end processing time of the i-th order; the parallelism between orders is 30%. Taking delivery date as the priority principle, order delivery ahead of schedule or late delivery will result in fines. According to the actual production in the factory, it is more inclined to produce ahead of schedule, so the weight of early or late delivery is set as 1:2, with the minimum penalty C min is the objective function:

[0113] K i-1 +T i-1 *70%=K i (4-1)

[0...

Embodiment 3

[0127] Embodiment 3, on the basis of Embodiment 2, in order to further strengthen the global search capability of the particles, the pseudo code of the hybrid variable neighborhood particle swarm optimization algorithm is as follows:

[0128] Input: Accepted Orders

[0129] Output: order sorted

[0130] 1 Generate initial population

[0131] 2 for i=1: NIND*NINIA

[0132] 3 a: Randomly mix and generate initial particles according to the delivery date

[0133] 4 end

[0134] 5 for i=NIND*NINIA+1: NIND

[0135] 6 b: Randomly generate initial particles

[0136] 7 end

[0137] 8 Calculation of fitness

[0138] 9 Particle inertia W weight update

[0139] 10 Particle learning factor C1, C2 update

[0140] 11 Particle Neighborhood Search Range NS Update

[0141] 12 for i=1: maxgen

[0142] 13 particle speed update;

[0143] 14 Particle position update

[0144] 15 particles for adaptive variable neighborhood search

[0145] 16 Calculating fitness

[0146] 17 Particle in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com