Method for determining machinery processing sequence and manufacturing system therewith

A technology for manufacturing systems and machines, used in semiconductor/solid-state device manufacturing, instruments, special data processing applications, etc., and can solve problems such as lost delivery time and delays

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the above and other objects, features and advantages of the present invention more comprehensible, preferred embodiments are listed below and described in detail in conjunction with the accompanying drawings.

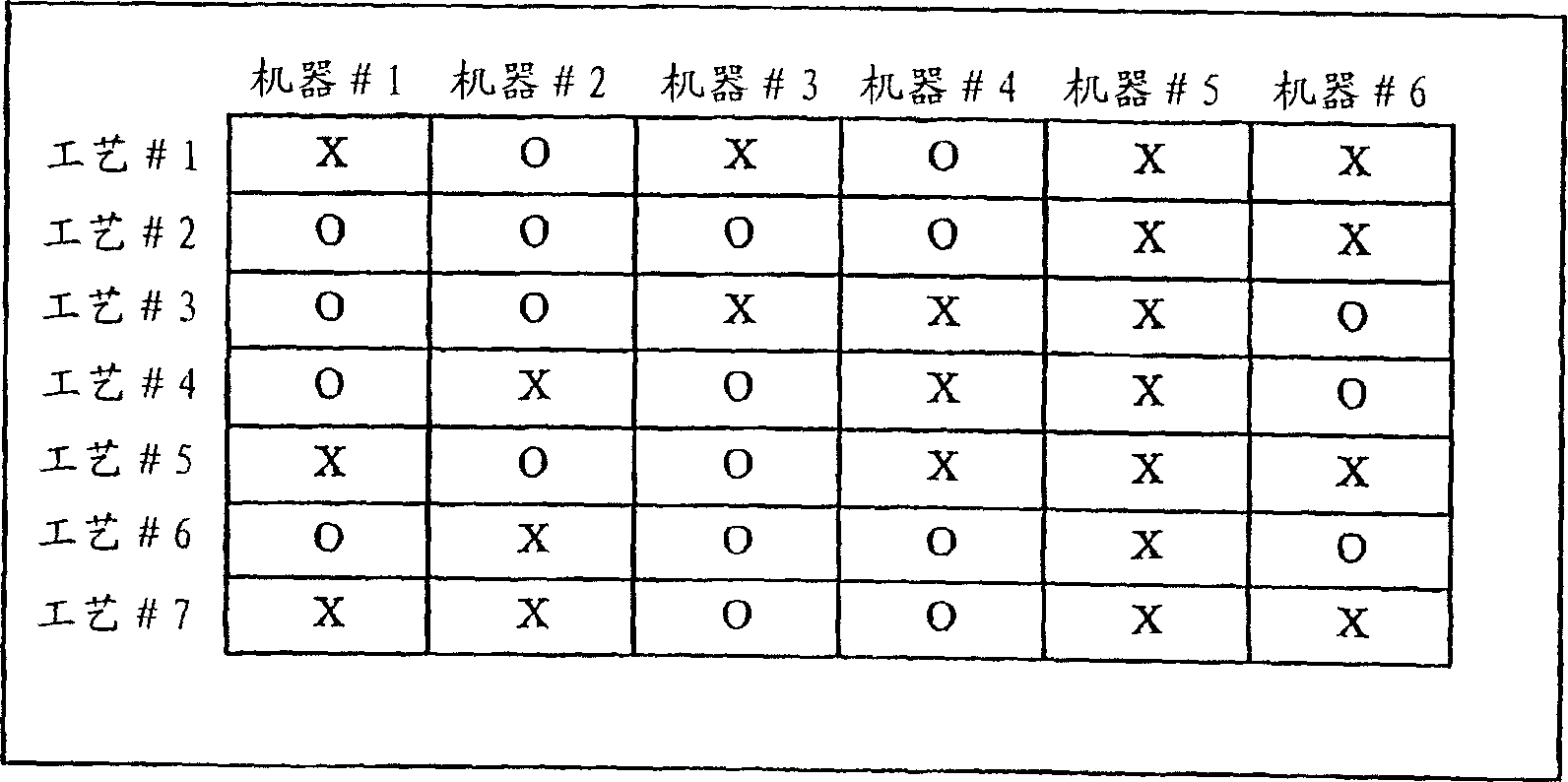

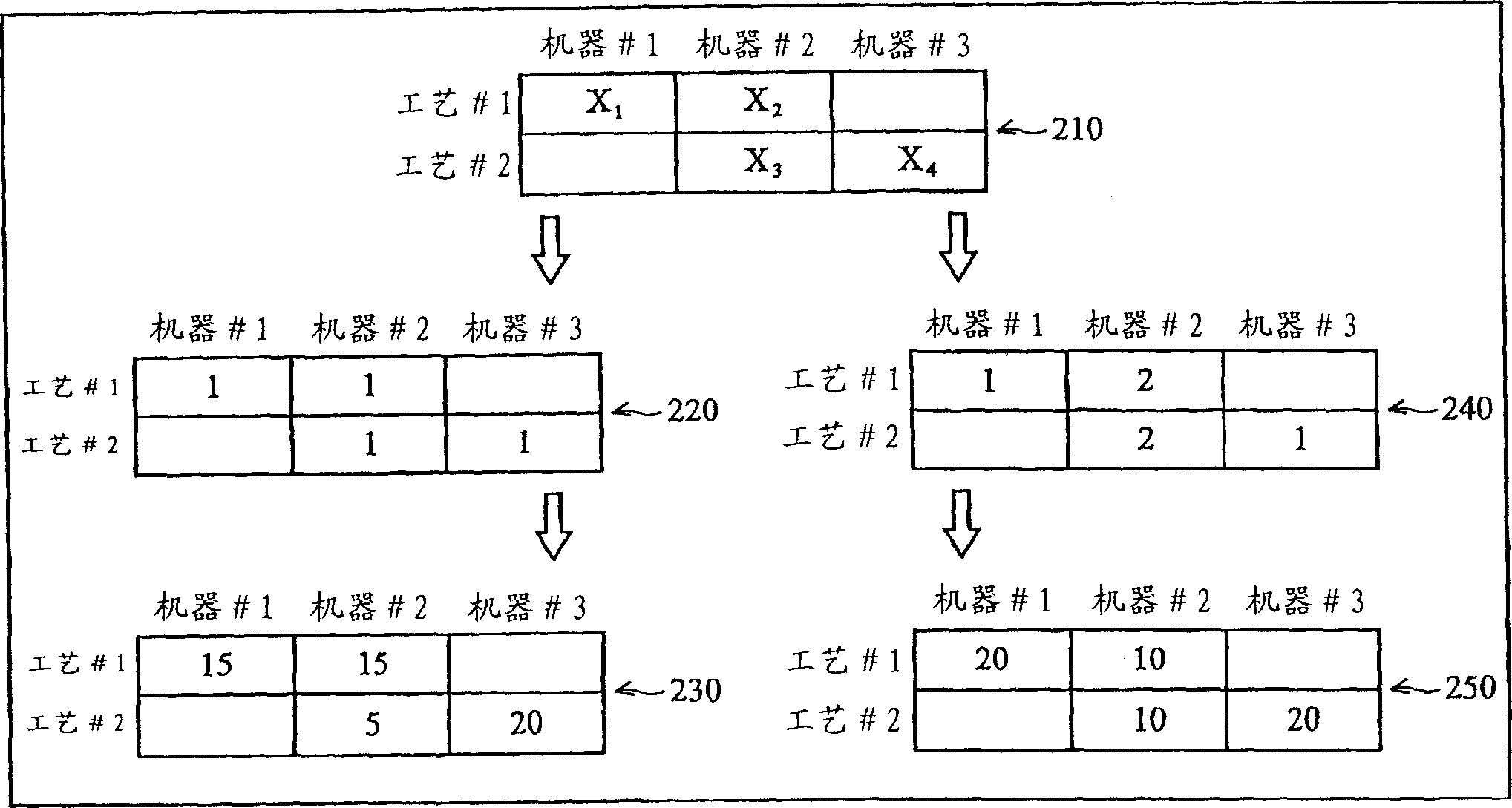

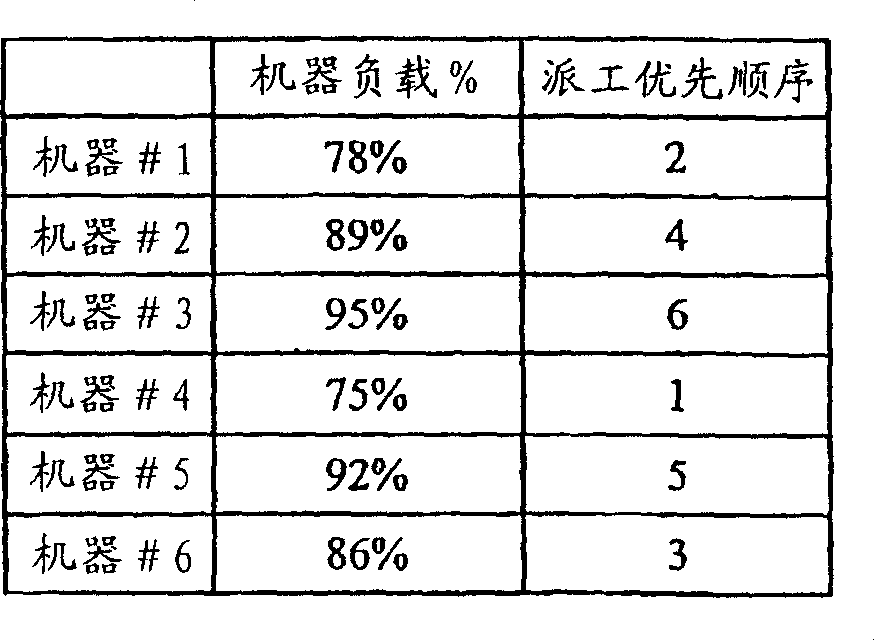

[0014] The embodiment of the present invention discloses a method and system for determining the order of machine dispatching. In solving the problem of machine dispatching, a supply chain planning tool (such as the MCP developed by ADEXA) is adopted. (Material & Capacity Planner)), which is used to estimate the output and time of each batch per day, and even determine the input and output in the production plan within half a year. As for the mixed production mode mentioned above, the production demand is divided into two parts, one is order production, and the other is stock production. Because each batch has a production deadline for order production, when the estimated production When the delivery time may exceed the deadline, it will enjoy th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com