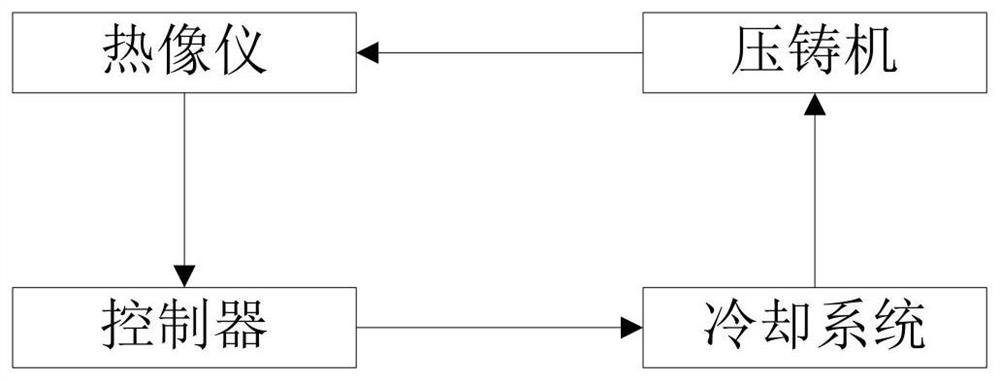

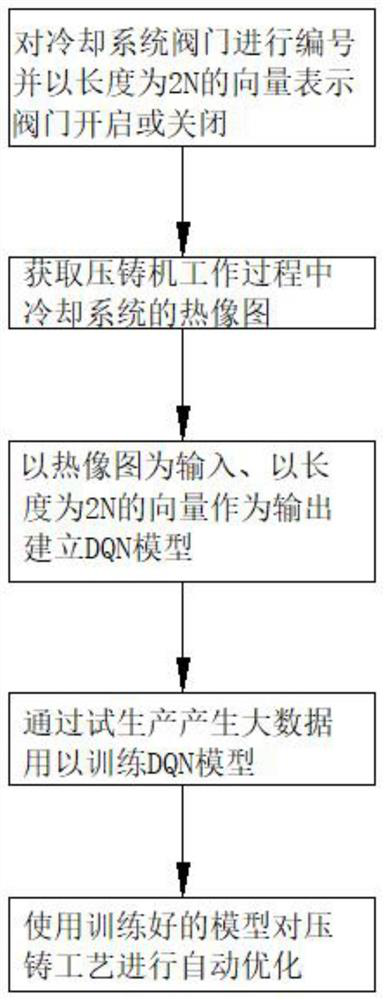

DQN-based die-casting process automatic optimization method

An automatic optimization and die-casting technology, applied in neural learning methods, geometric CAD, biological neural network models, etc., can solve the problems of large mold temperature difference, mold failure, short mold life, etc., to achieve high product qualification rate and improve service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The invention will be described in connection with the accompanying drawings and specific examples, and the schematic embodiments and description are intended to be utilized to illustrate only the invention.

[0031] It should be noted that the features of the present application and the features in the embodiments in the present application can be combined with each other in the case of an unable conflict. The present invention will be described in detail below with reference to the accompanying drawings.

[0032] It should be noted that the terms used herein are intended to describe specific embodiments, and not intended to limit the exemplary embodiments of the present application. As used herein, unless the context further explicitly indicates that the singular form is intended to include multiple forms, but it should be understood that when the term "including" and / or "includes" in this specification, it indicates There is a combination of features, steps, operations...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com