Oil well intelligent calibration self-inspection method and device

A self-inspection device and oil well technology, applied in earthwork drilling, wellbore/well components, production fluids, etc., can solve problems such as downhole flow, water cut measurement accuracy reduction, parameter drift, control failure, etc., to improve crude oil recovery efficiency, improve accuracy, and achieve production optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

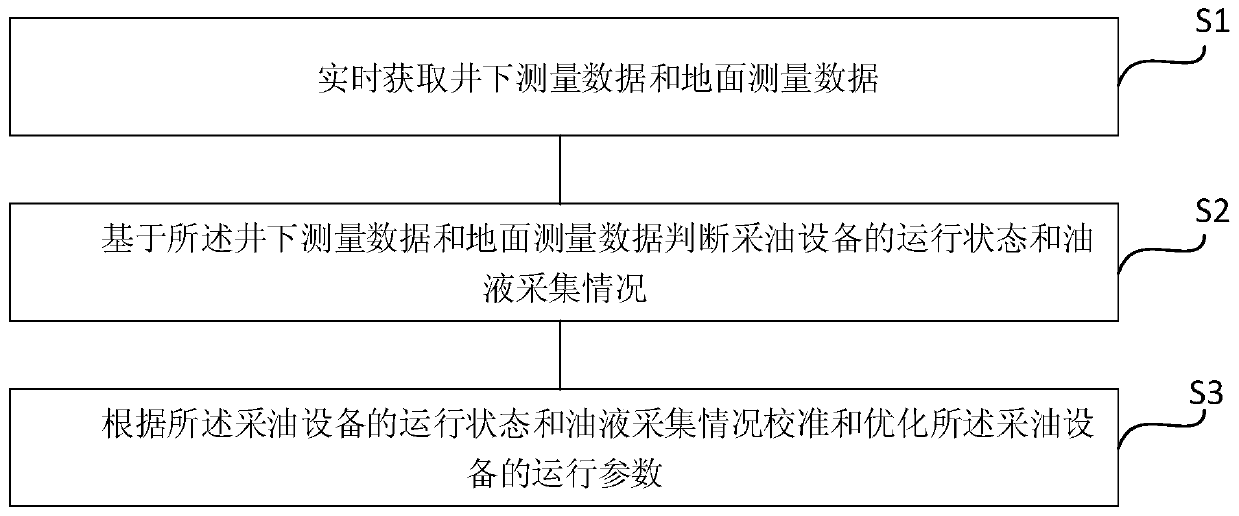

[0046] See figure 1 , figure 1 It is a flow chart of an oil well intelligent calibration self-inspection method provided by an embodiment of the present invention. The oil well intelligent calibration self-inspection method of this embodiment includes:

[0047] S1: Obtain downhole measurement data and surface measurement data in real time;

[0048] Specifically, the relevant parameters of each oil layer are collected in real time through the distribution device located in each oil layer downhole, wherein the relevant parameters of each oil layer include but are not limited to the flow rate, water content, temperature, pressure, and nozzle opening of the collected oil. , the internal pressure and external pressure of the oil pipeline, the cable head voltage, motor voltage, working current and working temperature of each oil reservoir distribution device, the power supply voltage of the instrument, and the electrical parameters of key components; the collected oil is obtained ...

Embodiment 2

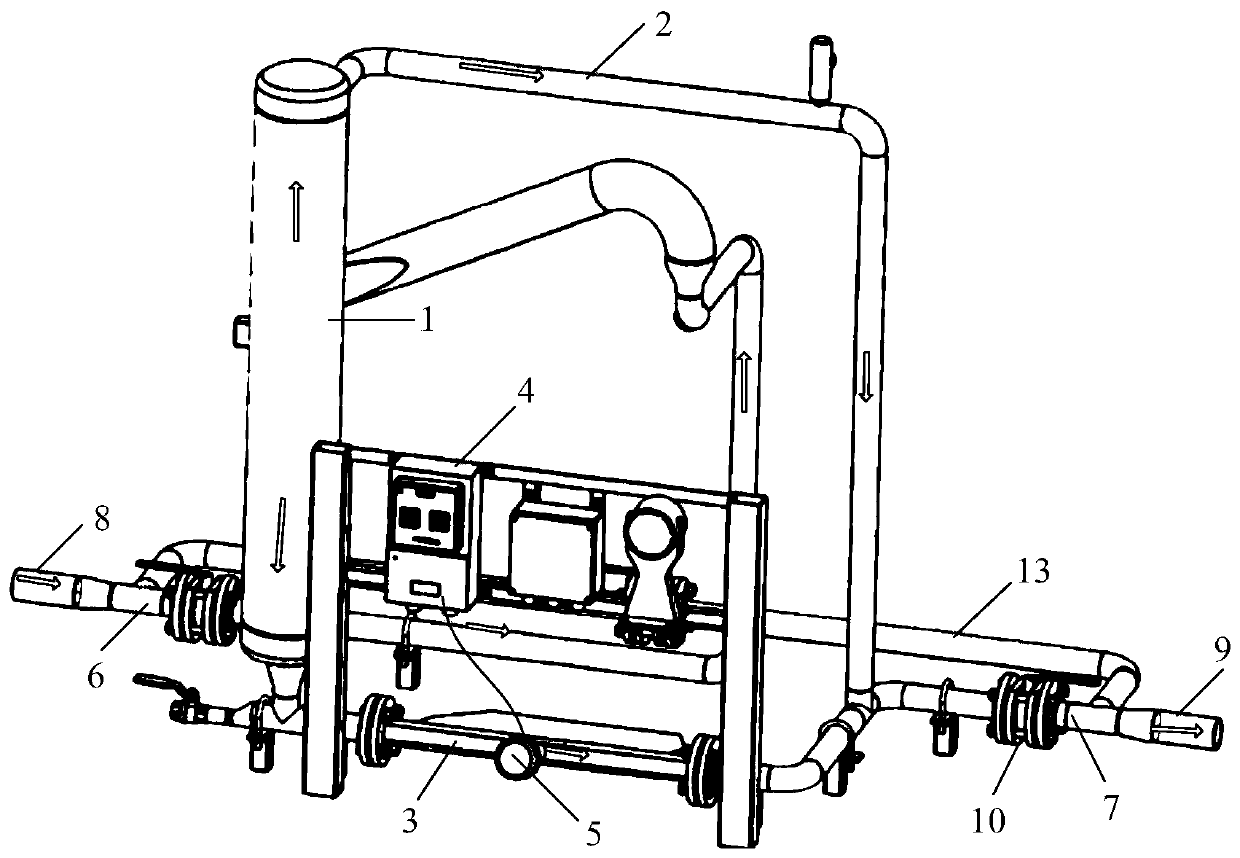

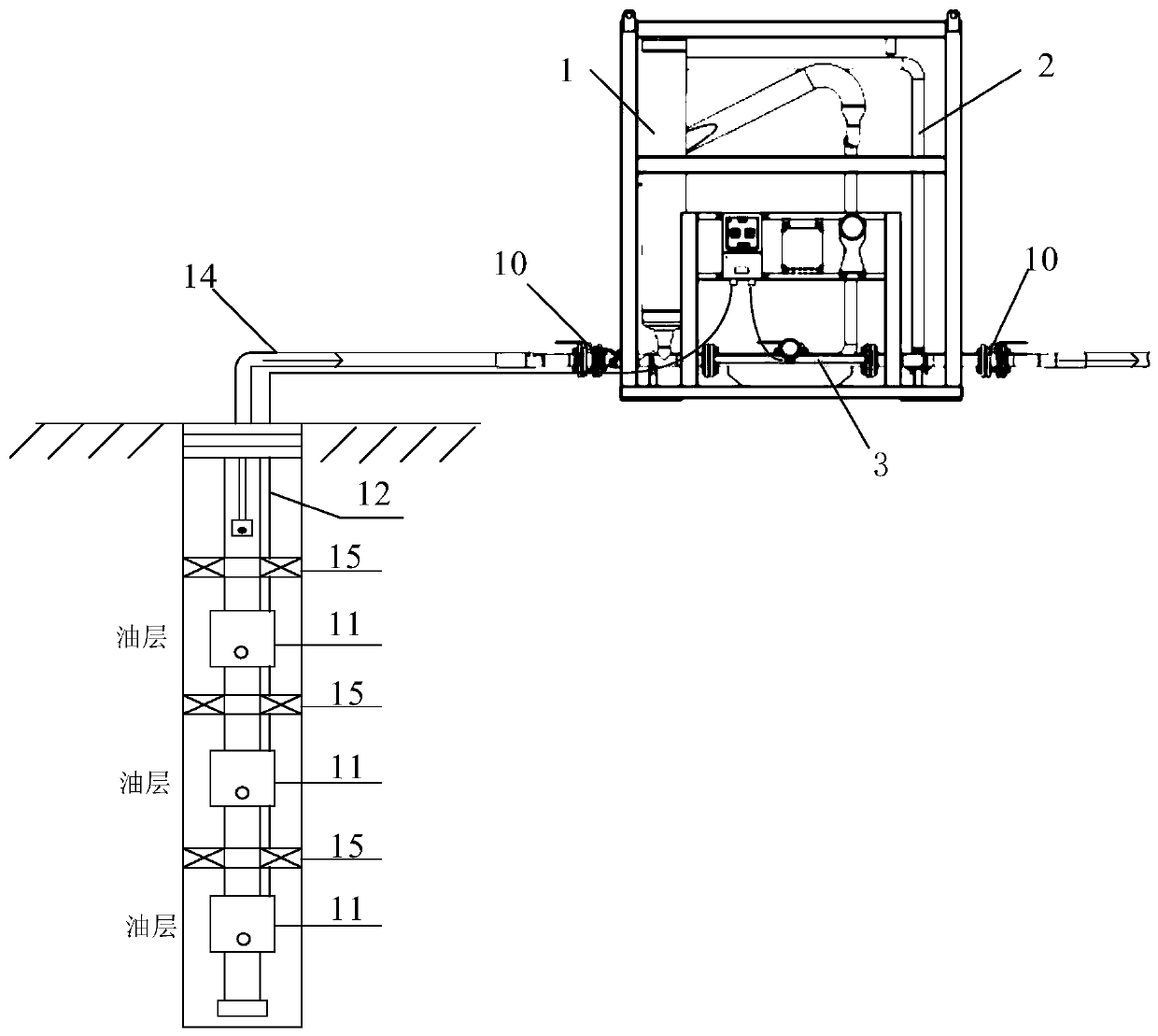

[0062] On the basis of the above embodiments, this embodiment provides an oil well intelligent calibration self-checking device. The oil well intelligent calibration device has the functions of data acquisition and analysis, self-calibration, self-test and life cycle management. The oil well intelligent calibration self-inspection device includes a ground measurement unit and a ground control unit, wherein the ground measurement unit is used to obtain the production and water content of the collected oil, and the ground control unit is connected to a plurality of downhole distribution devices and the ground measurement unit respectively. The unit is used to obtain the measurement values of the plurality of downhole distributors and the mass flow meter, and perform self-inspection and parameter optimization according to the measurement values.

[0063] Specifically, see figure 2 and image 3 , figure 2 It is a structural schematic diagram of an oil well intelligent calib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com