Patents

Literature

78results about "Comparison table algorithms" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

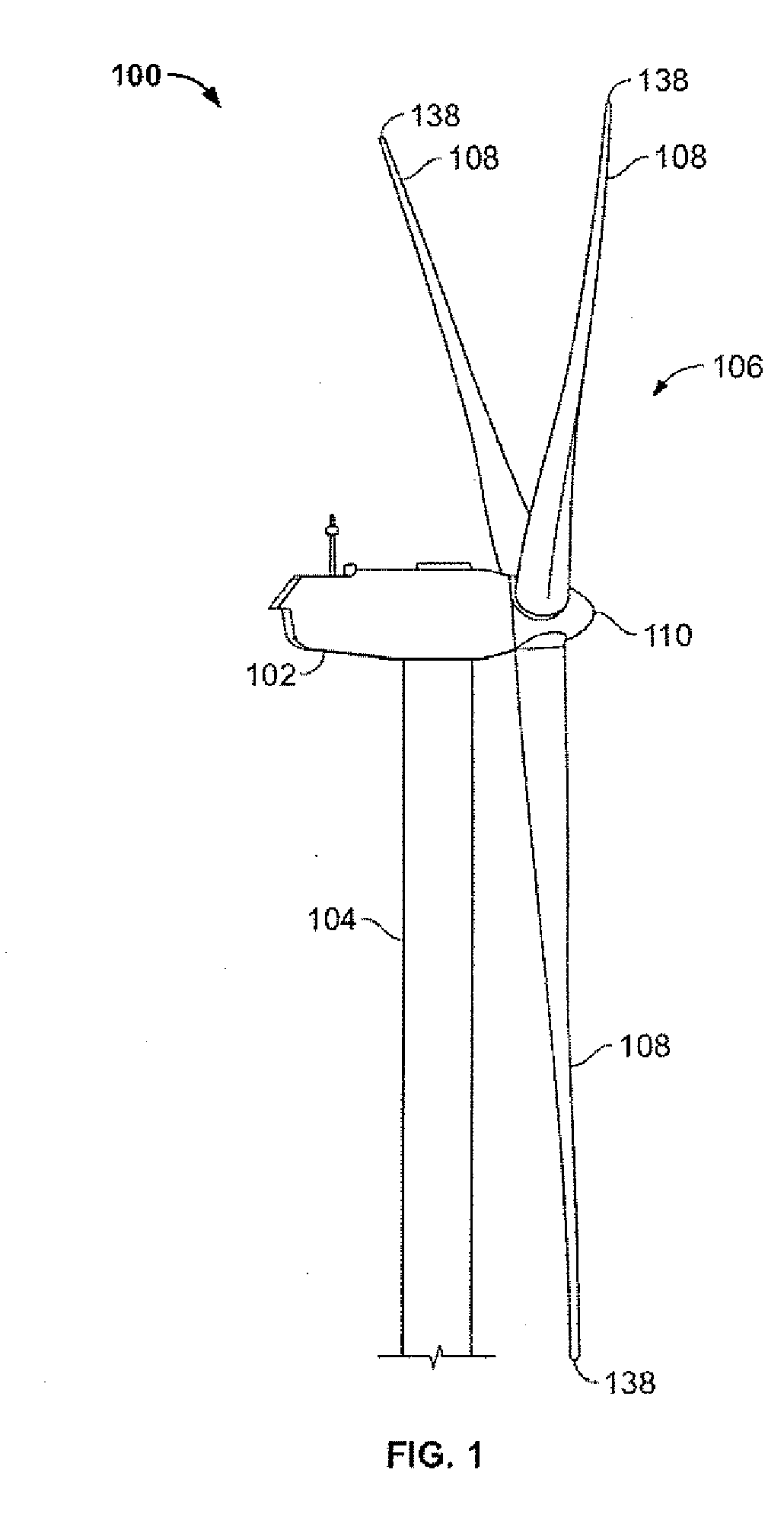

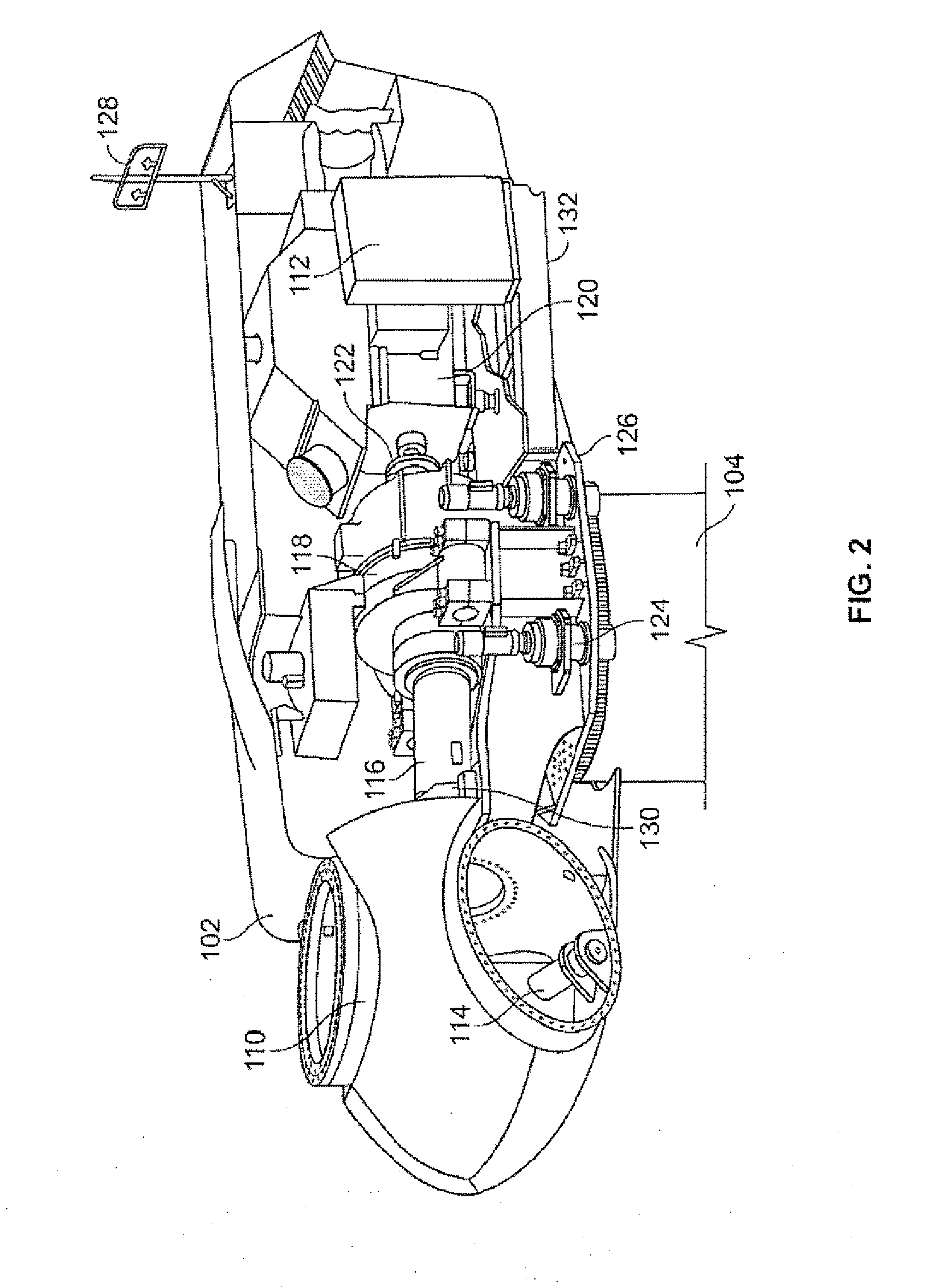

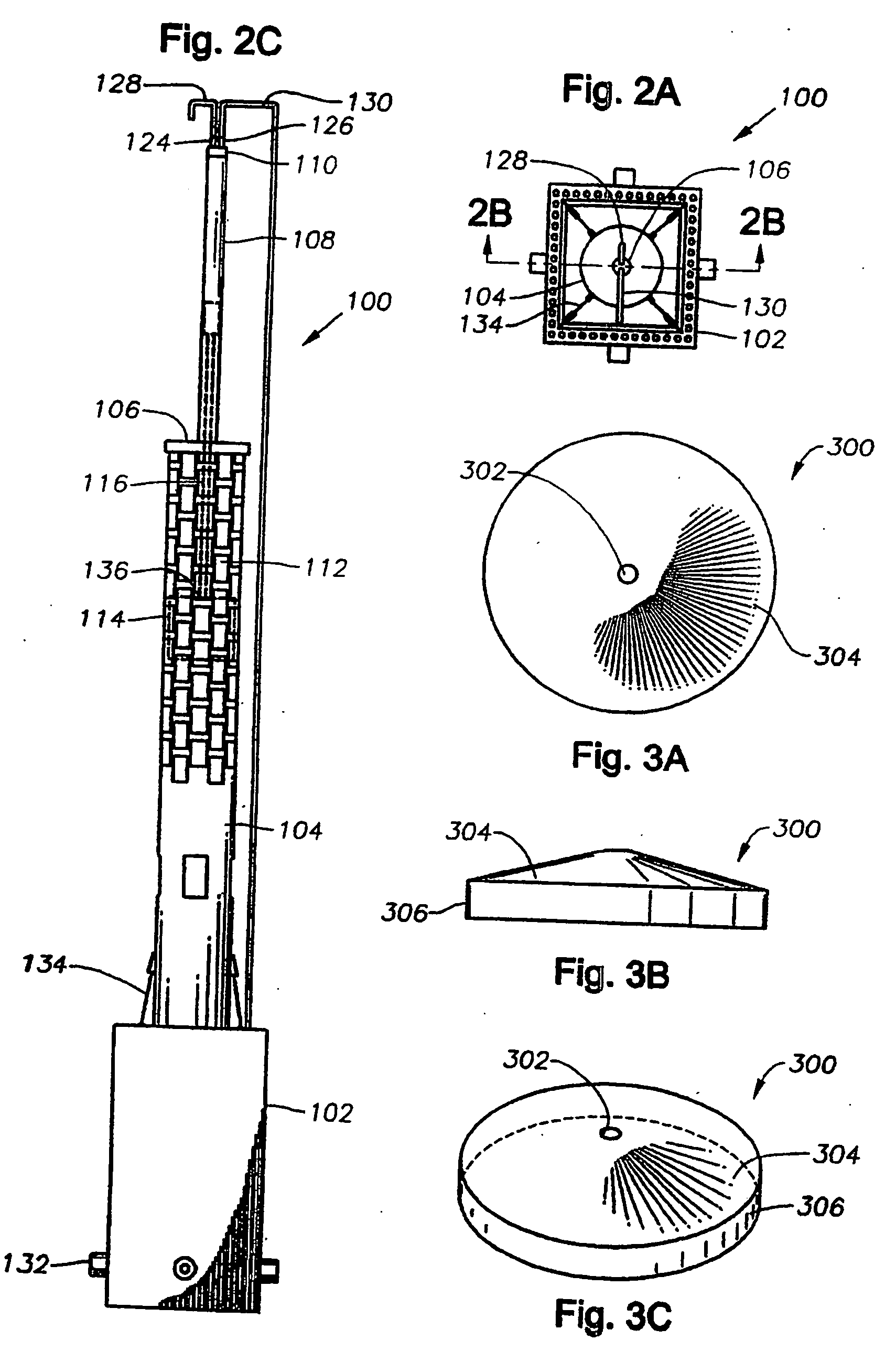

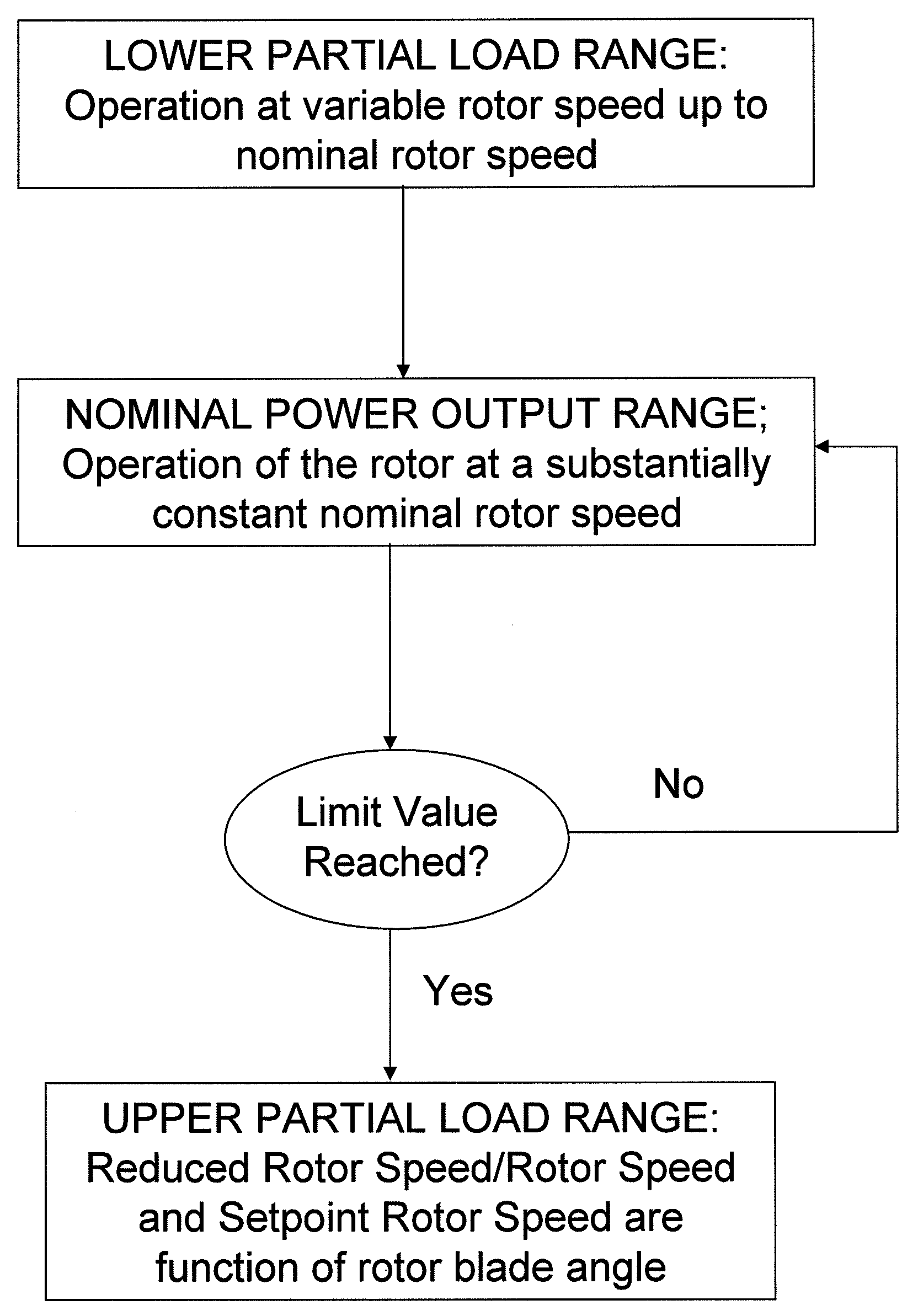

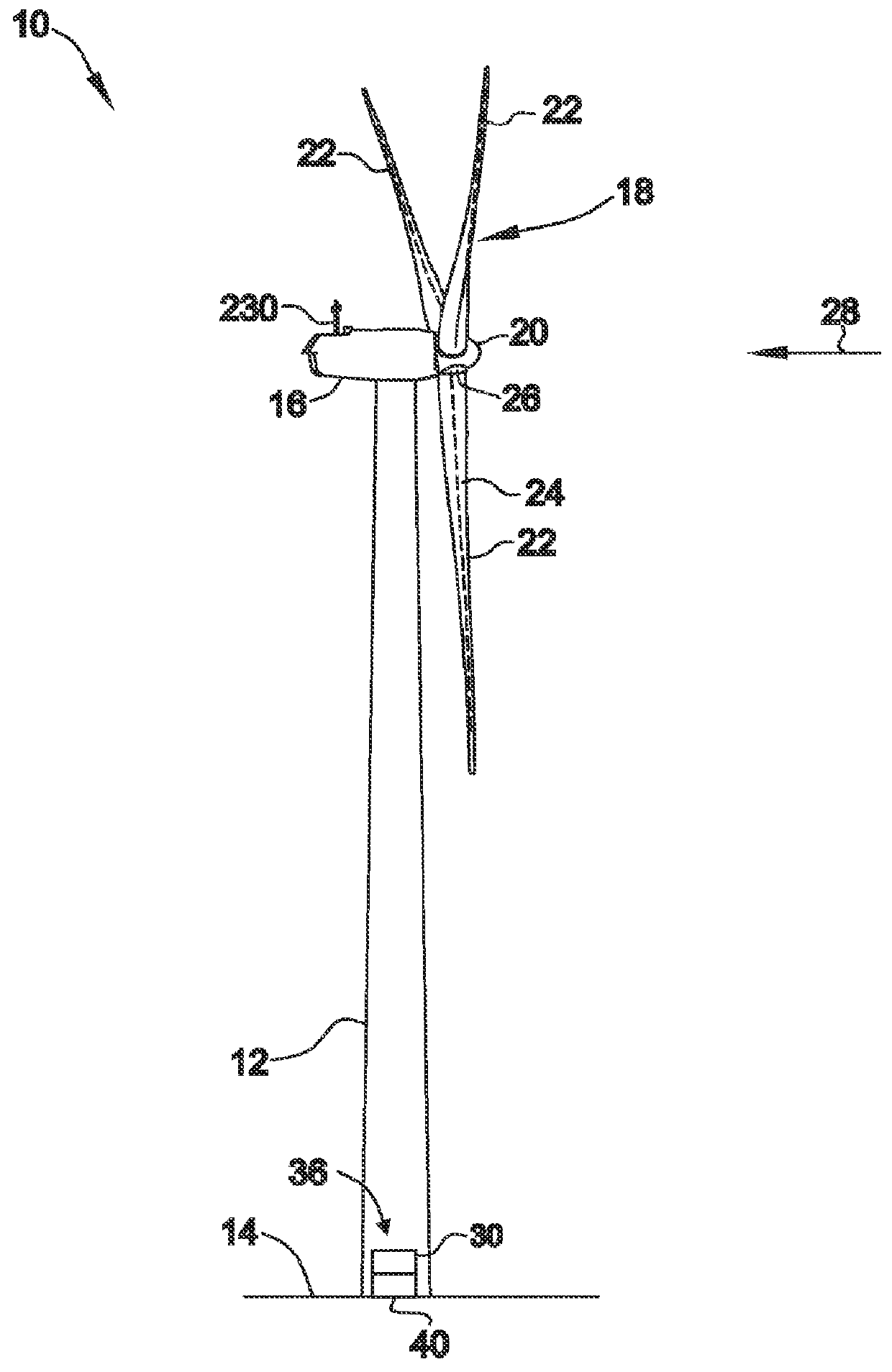

Method for controlling a wind power plant and corresponding wind power plant

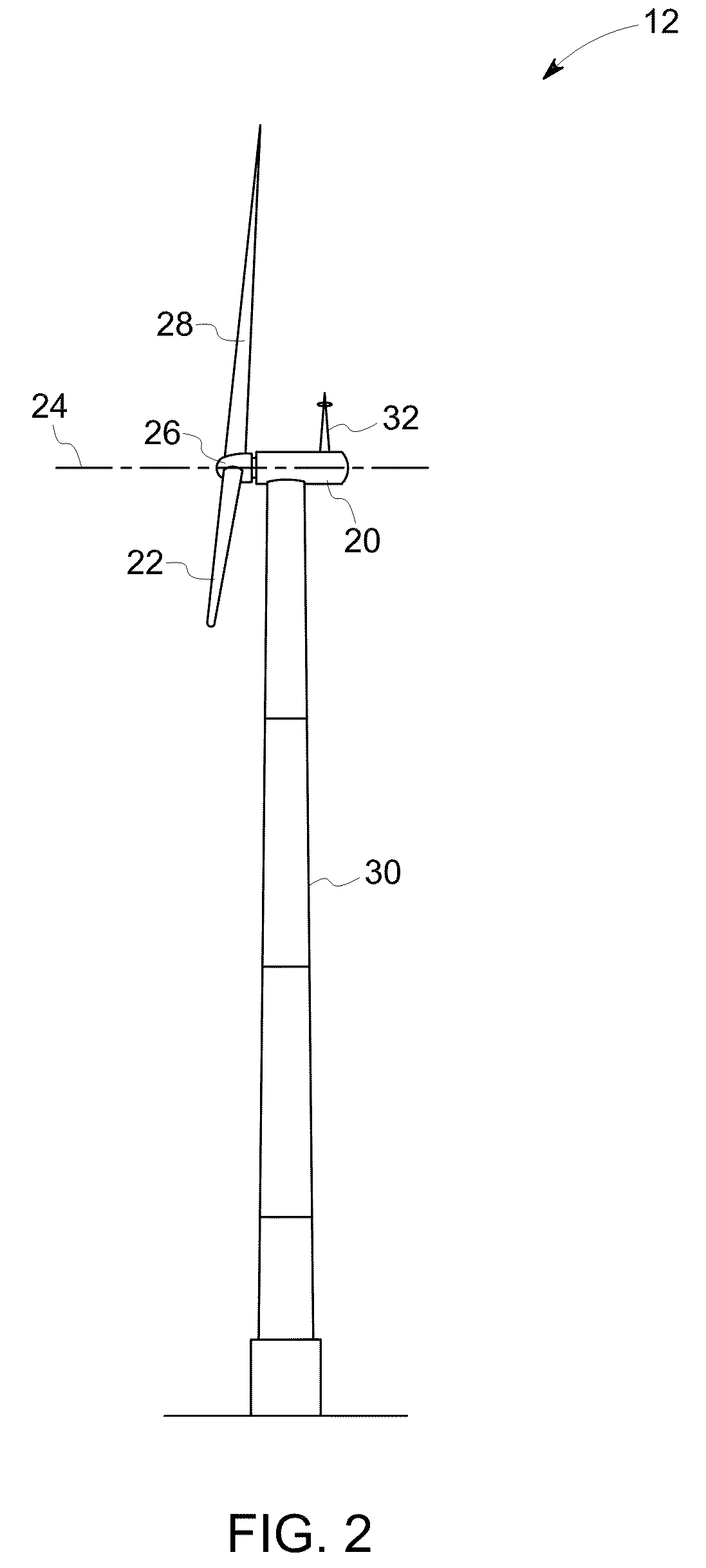

InactiveUS20070216166A1Improved and reliableImprove compatibilityWind motor controlComparison table algorithmsPower stationEngineering

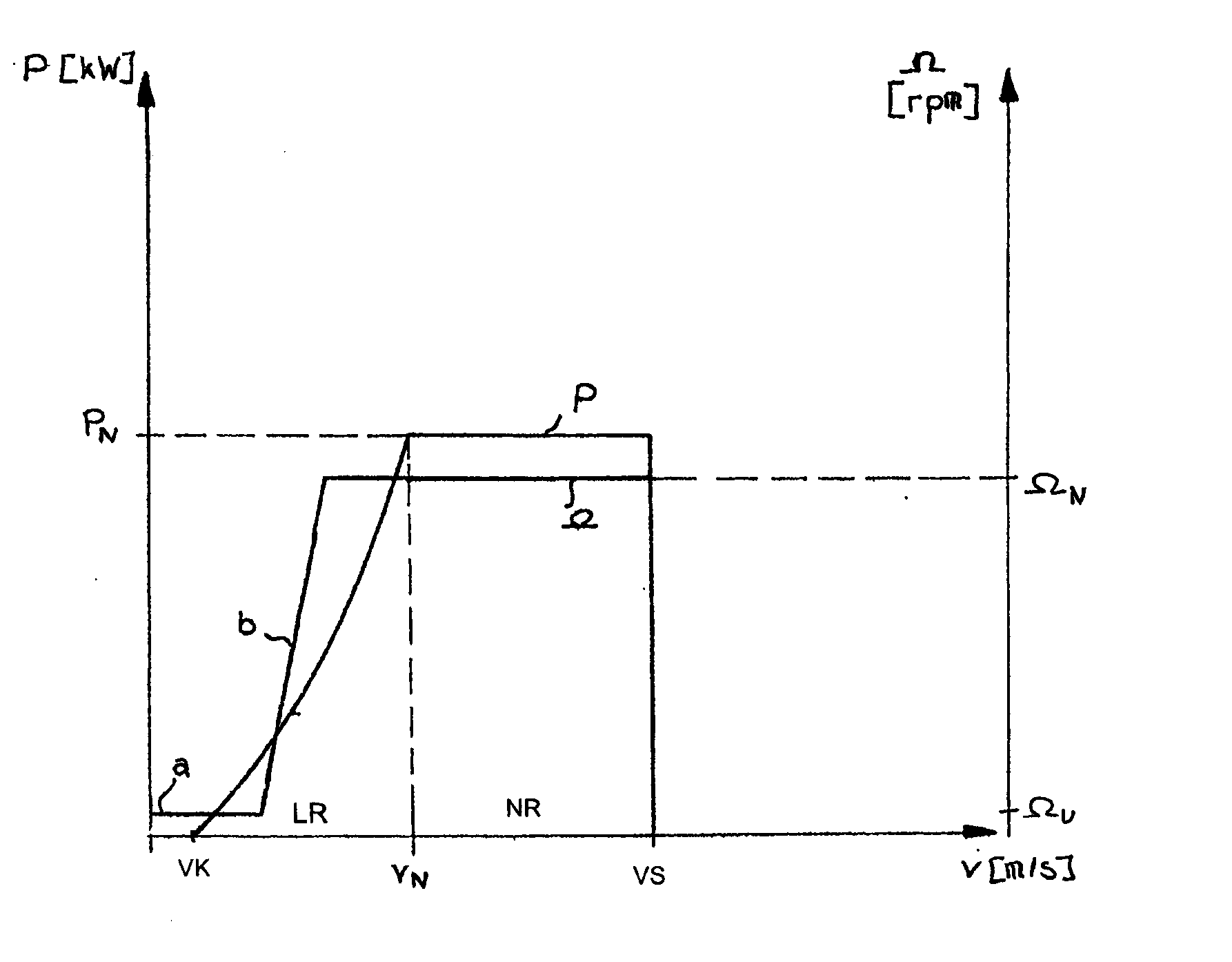

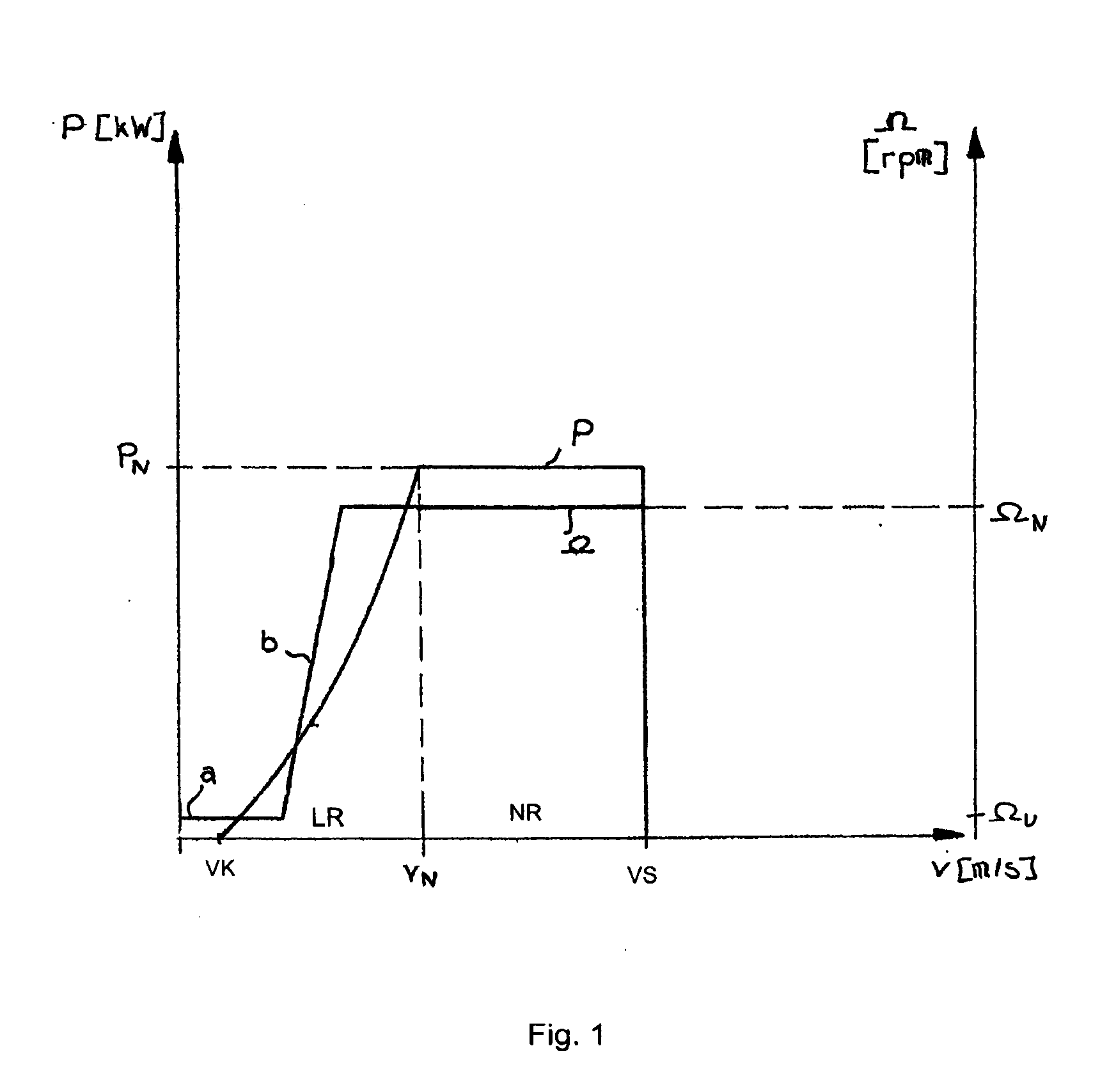

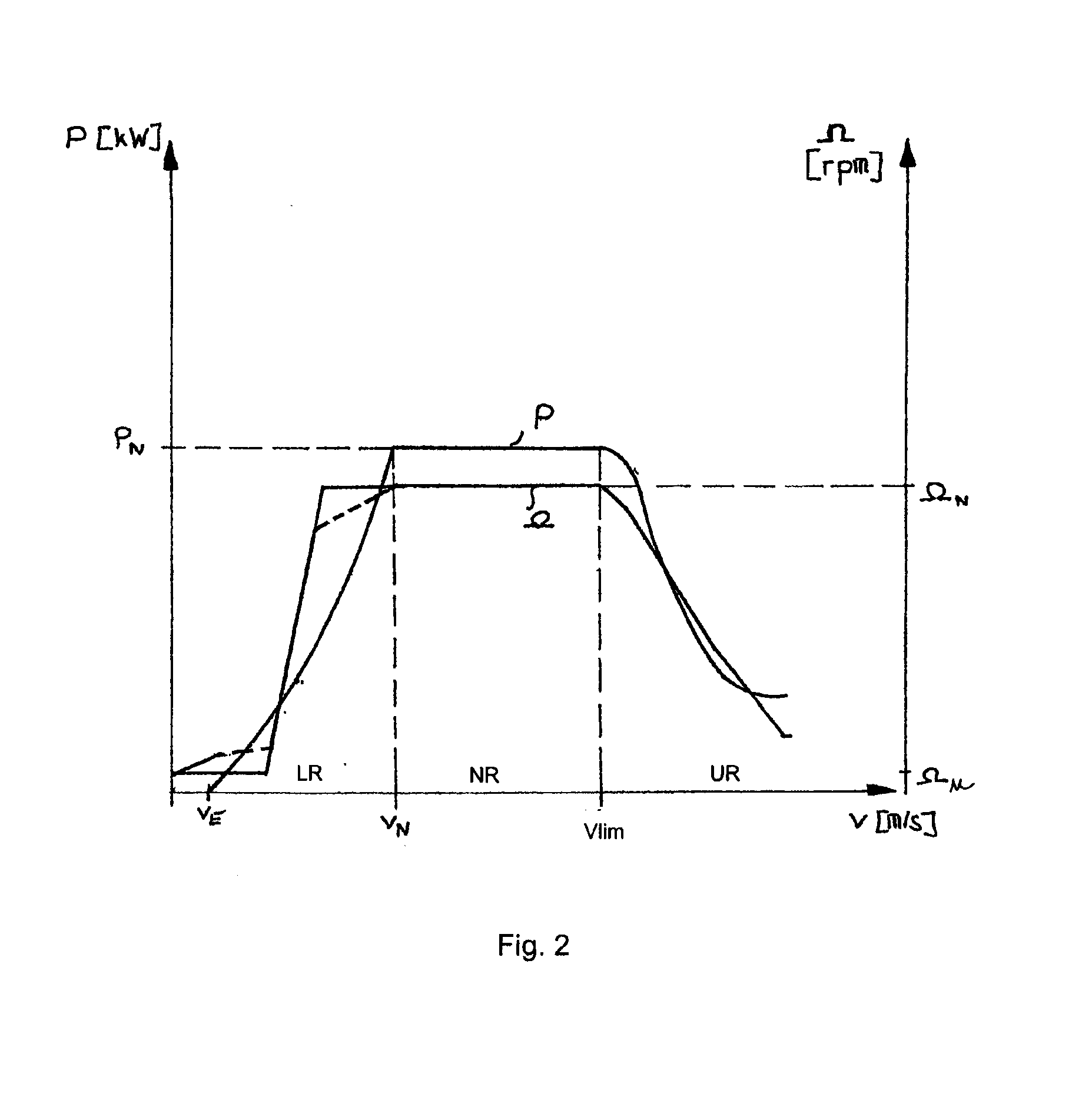

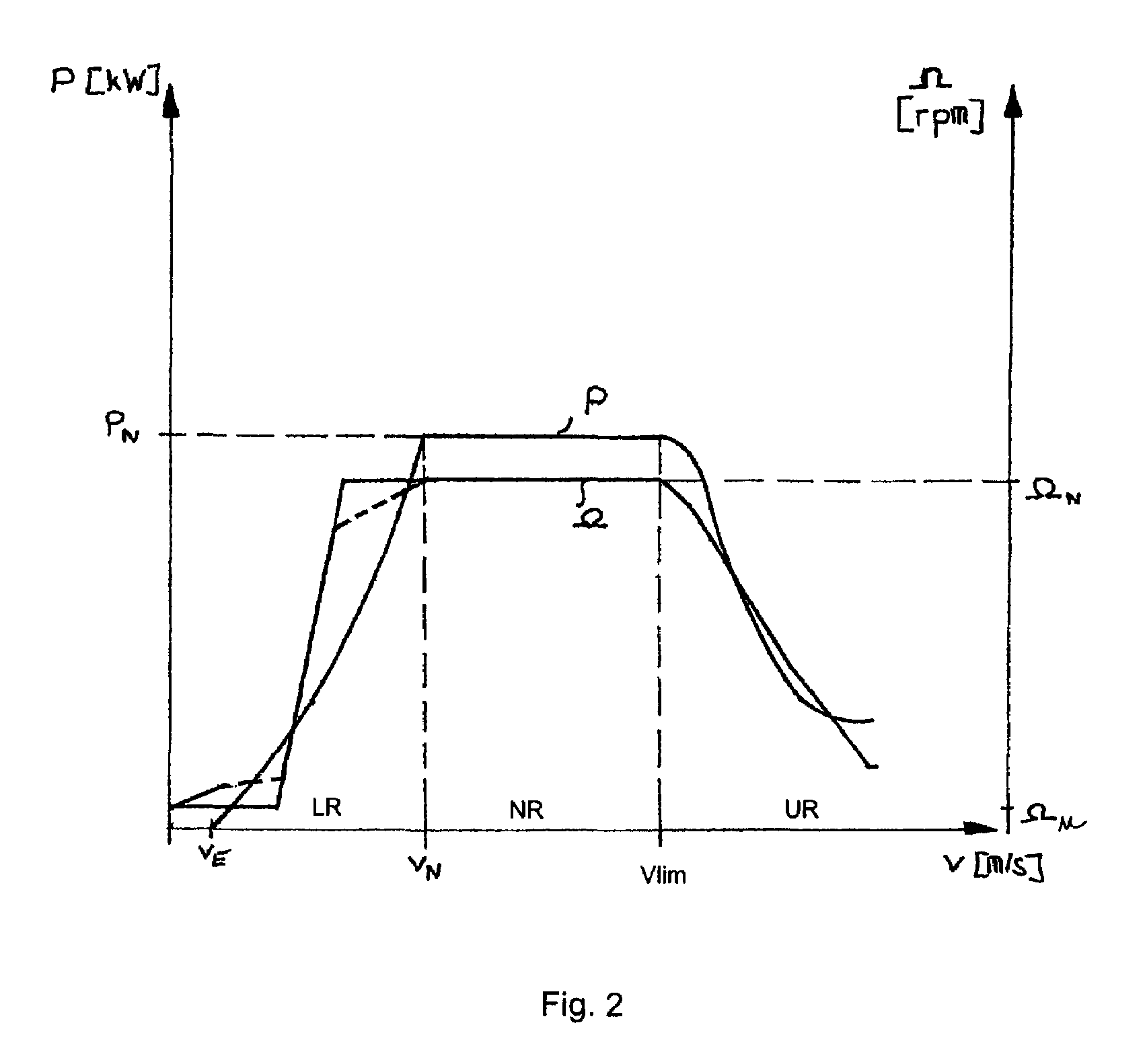

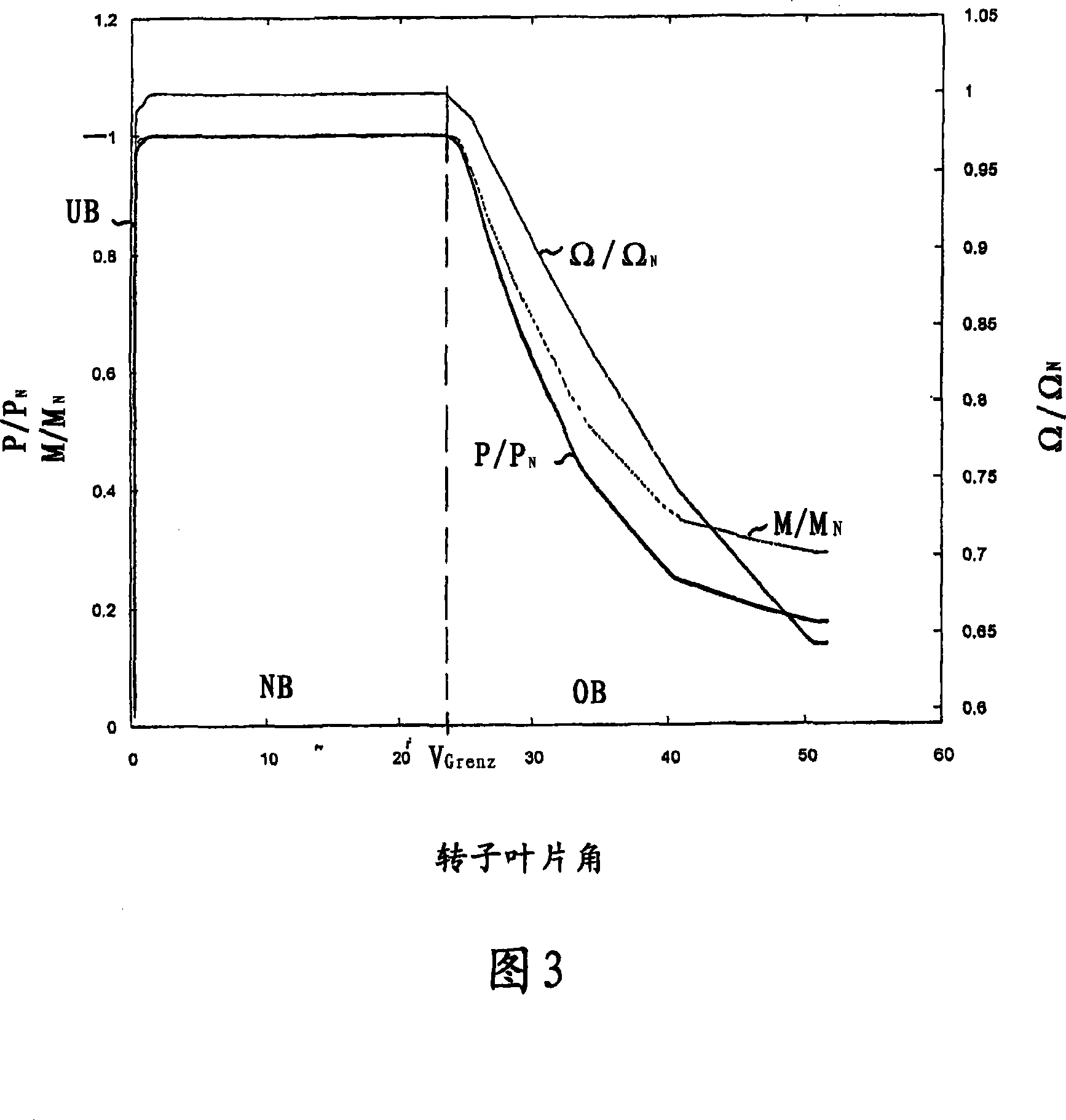

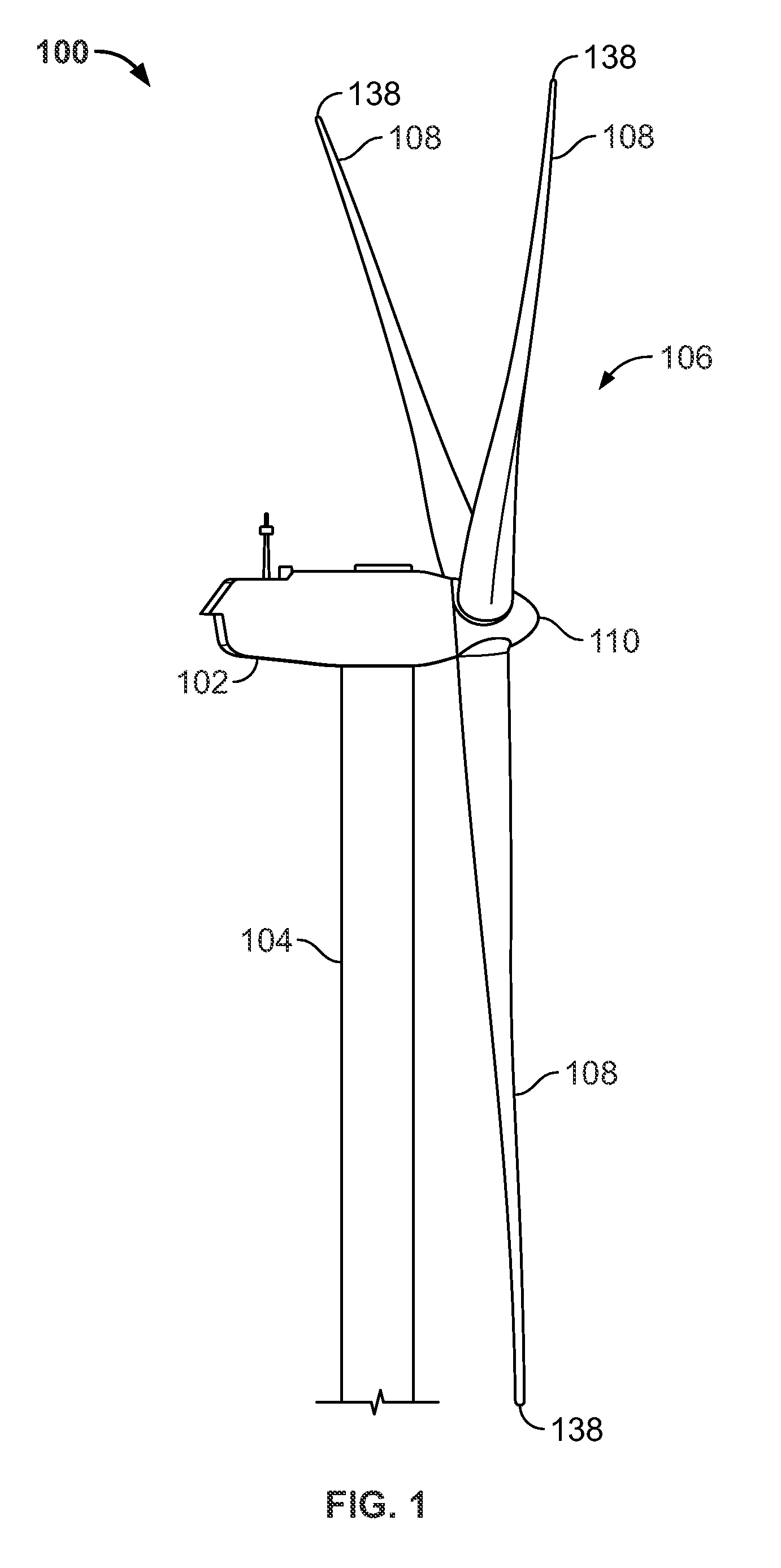

Reduction in power output or rotor speed of a wind turbine above a defined limit value, the reduction not being implemented based on the measured wind speed, but on an input value which on one hand is easily detected physically and by control technology and on the other hand is a good indicator of mechanical stresses on the wind turbine. The invention uses the rotor-blade angle as the input value in a manner that starting at the limit value, the reduction in power output or in rotor speed is adjusted as a function of the rotor-blade angle.

Owner:SENVION GMBH

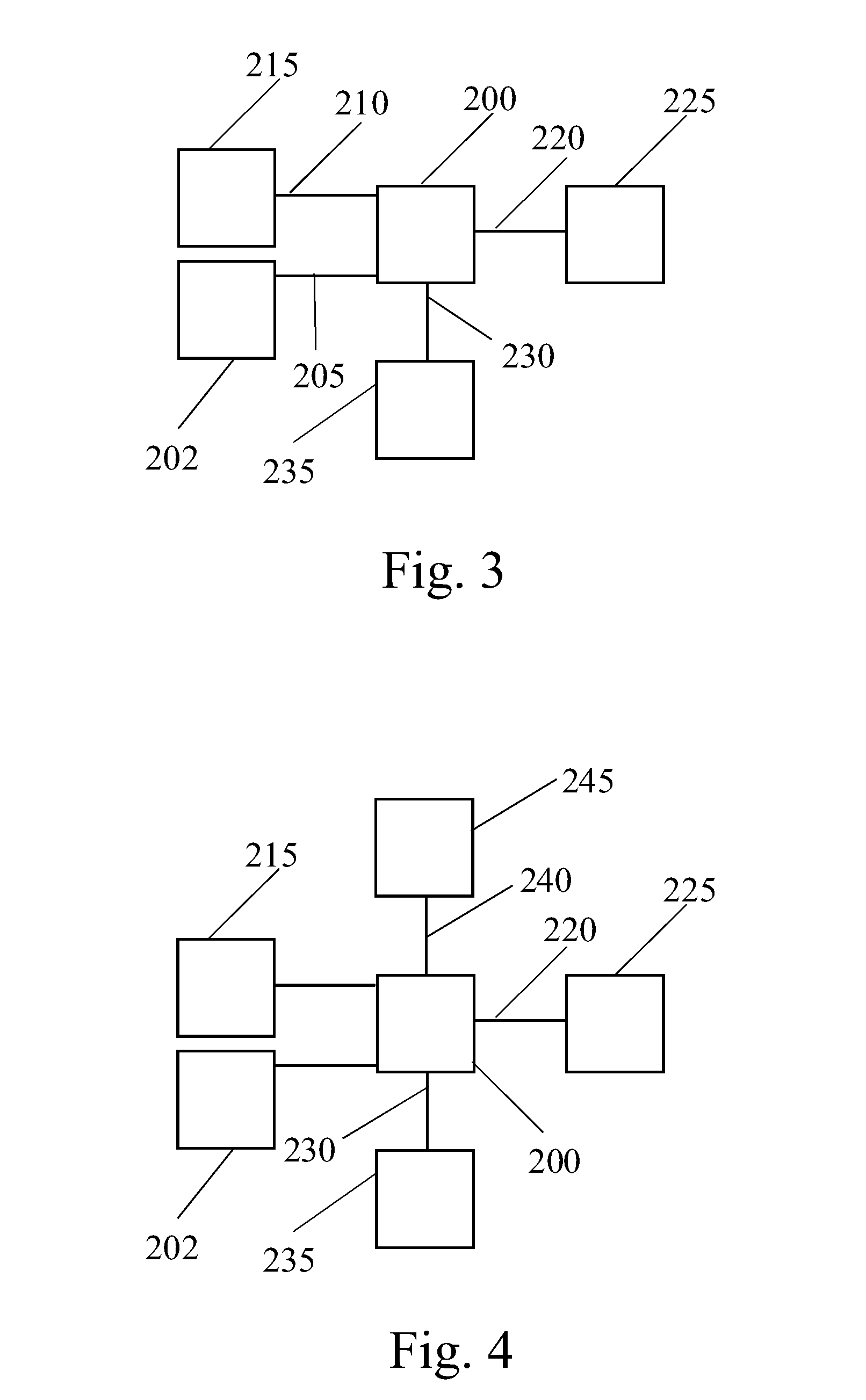

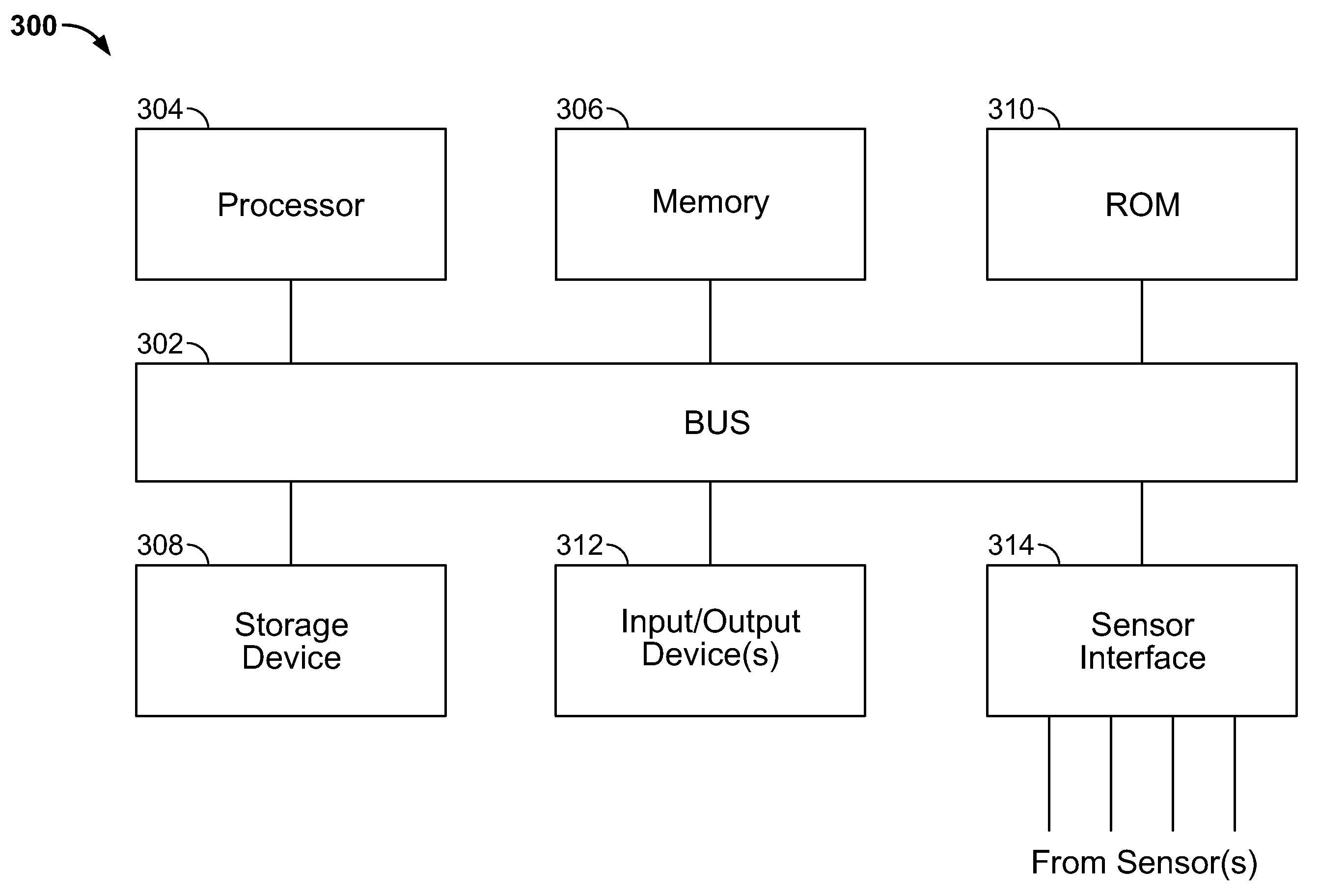

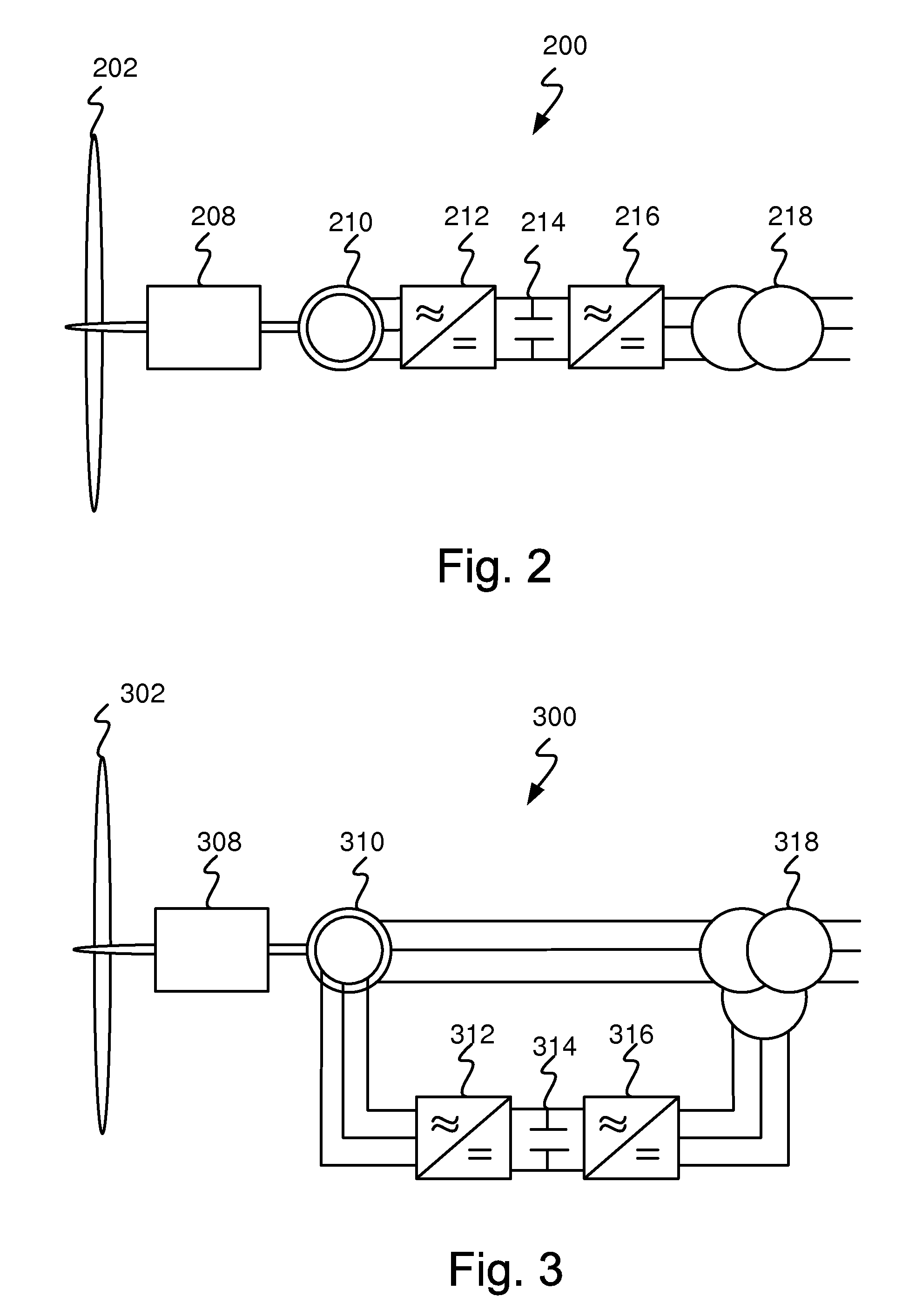

Wind energy system and method of operation thereof

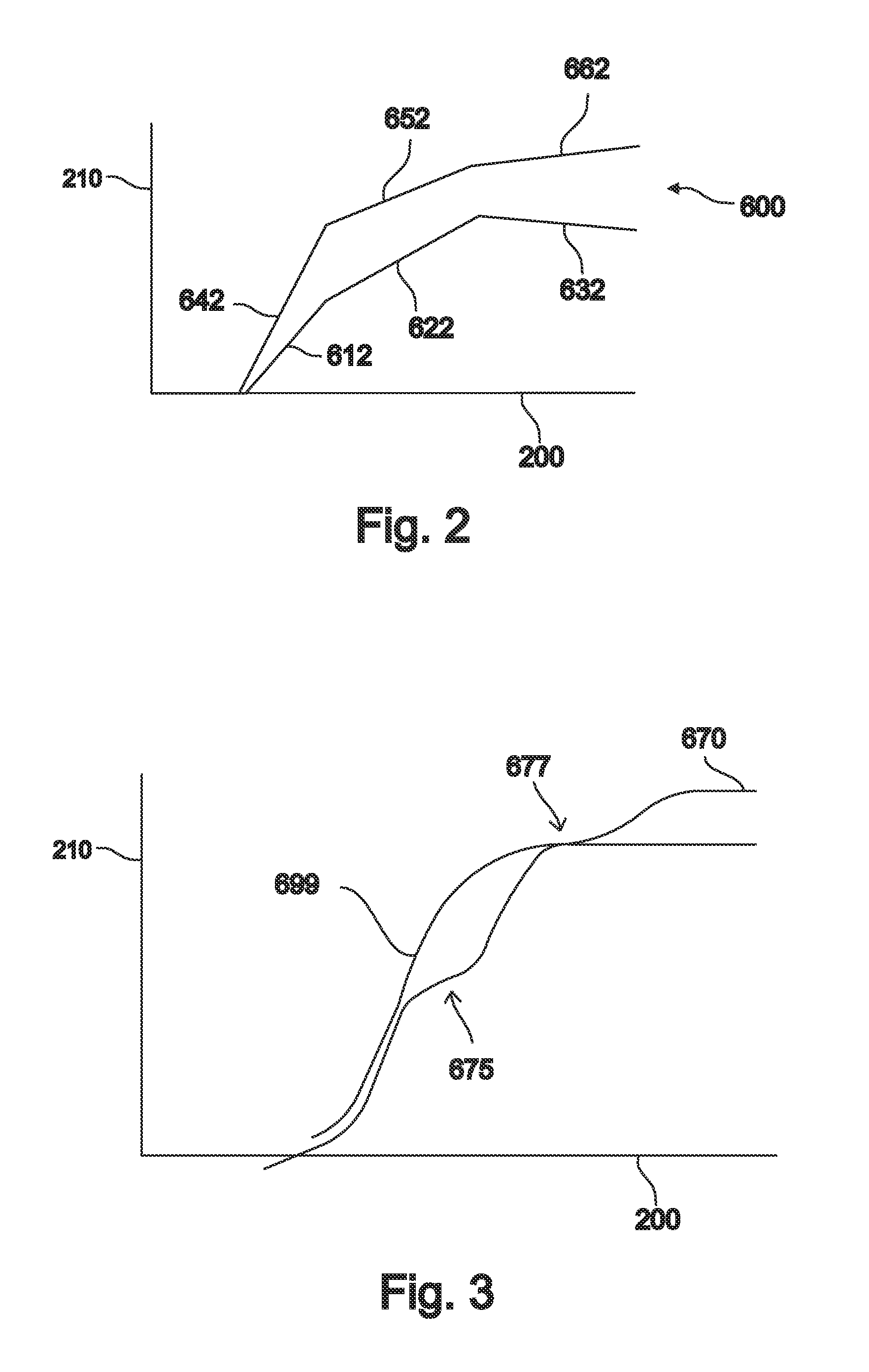

ActiveUS20080001409A1High yieldImprove performanceOptimise machine performanceWind motor controlLearning controllerEngineering

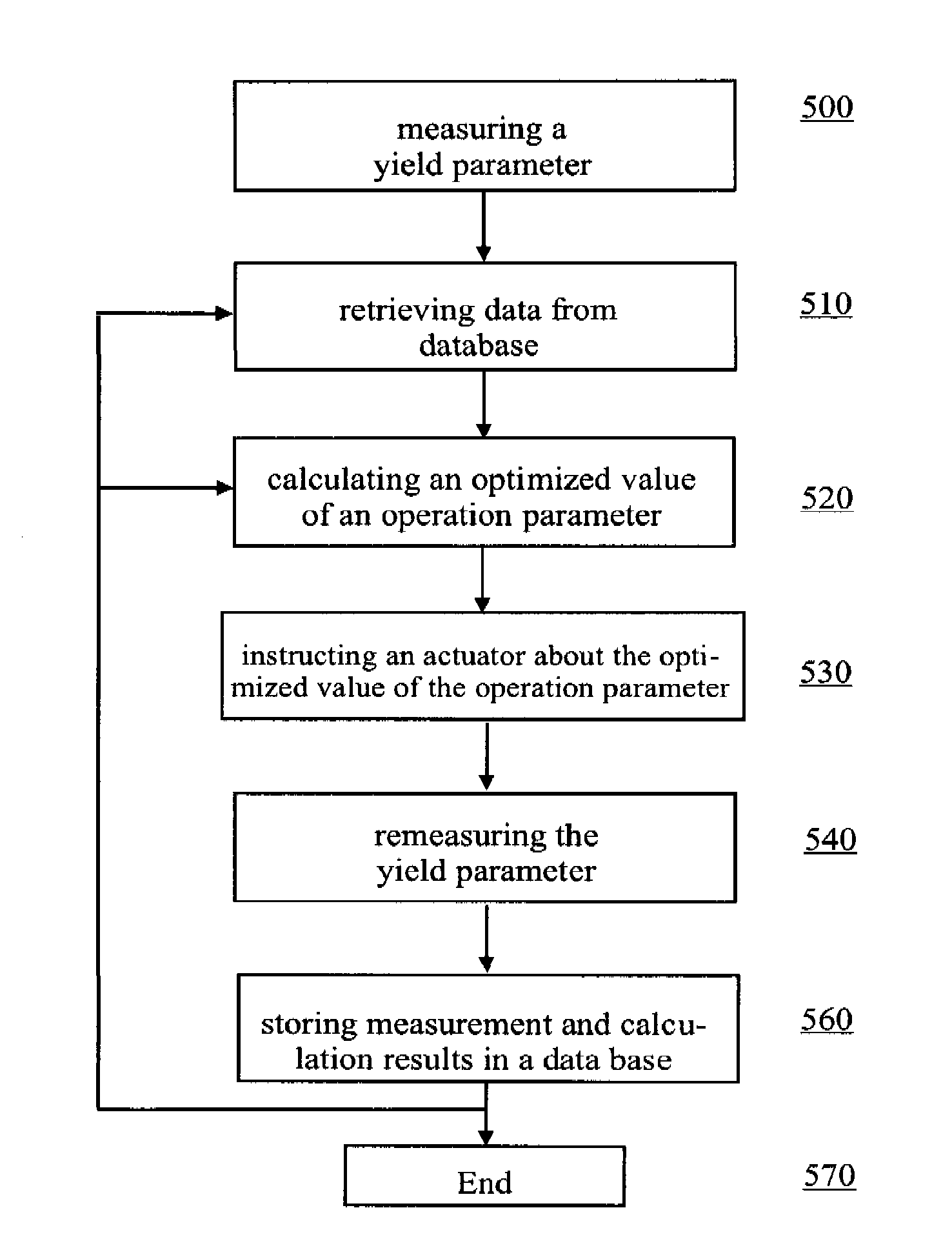

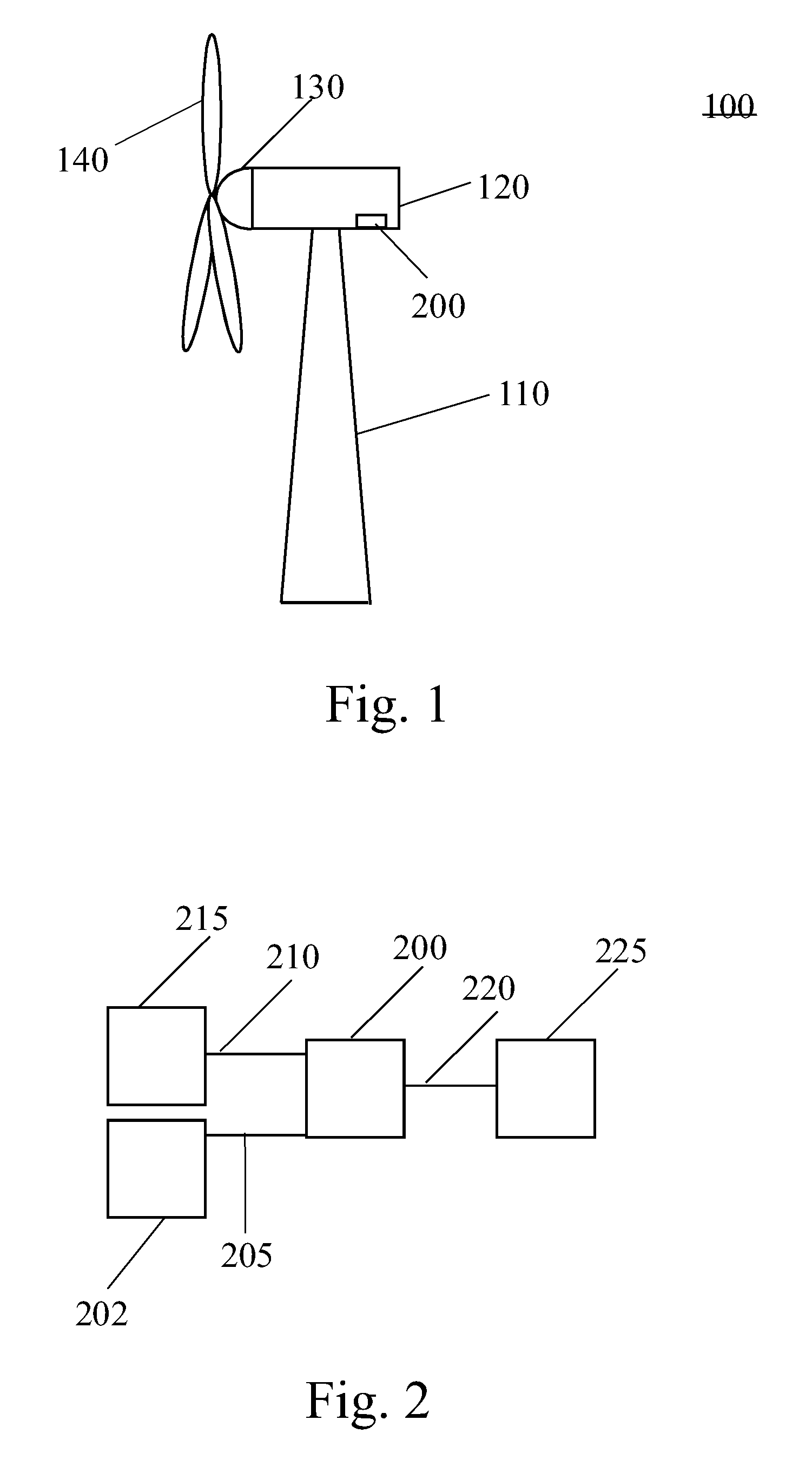

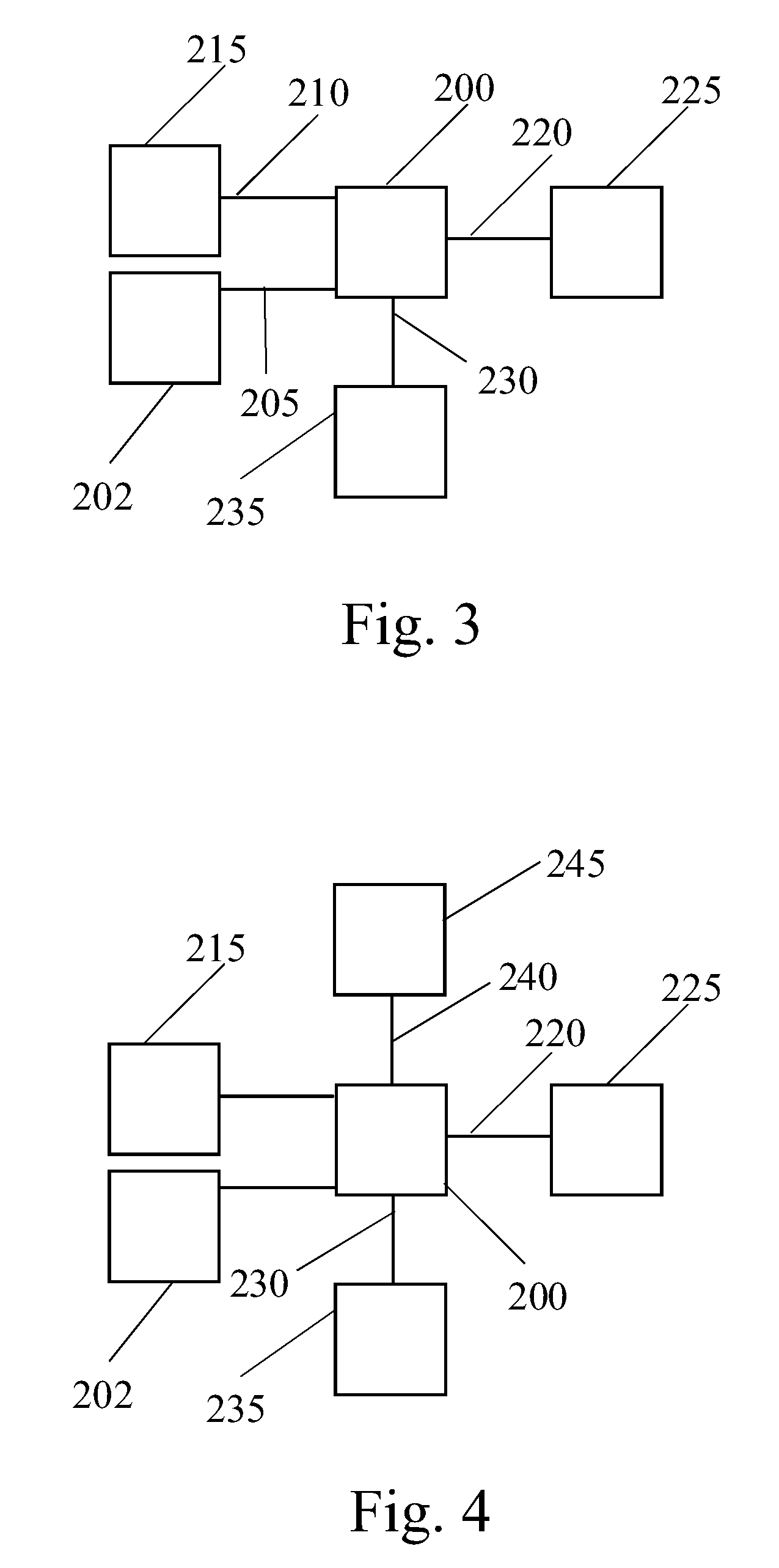

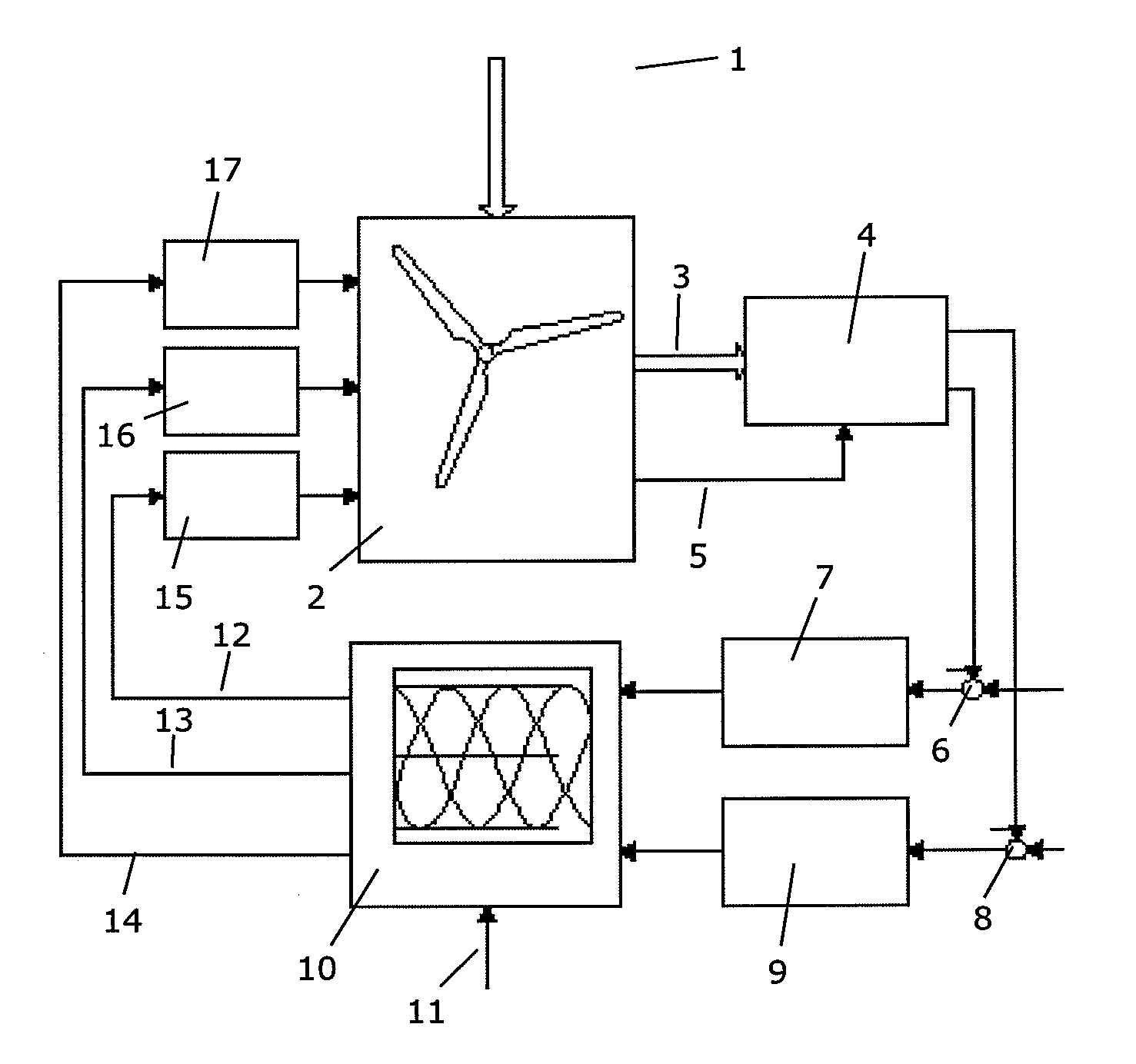

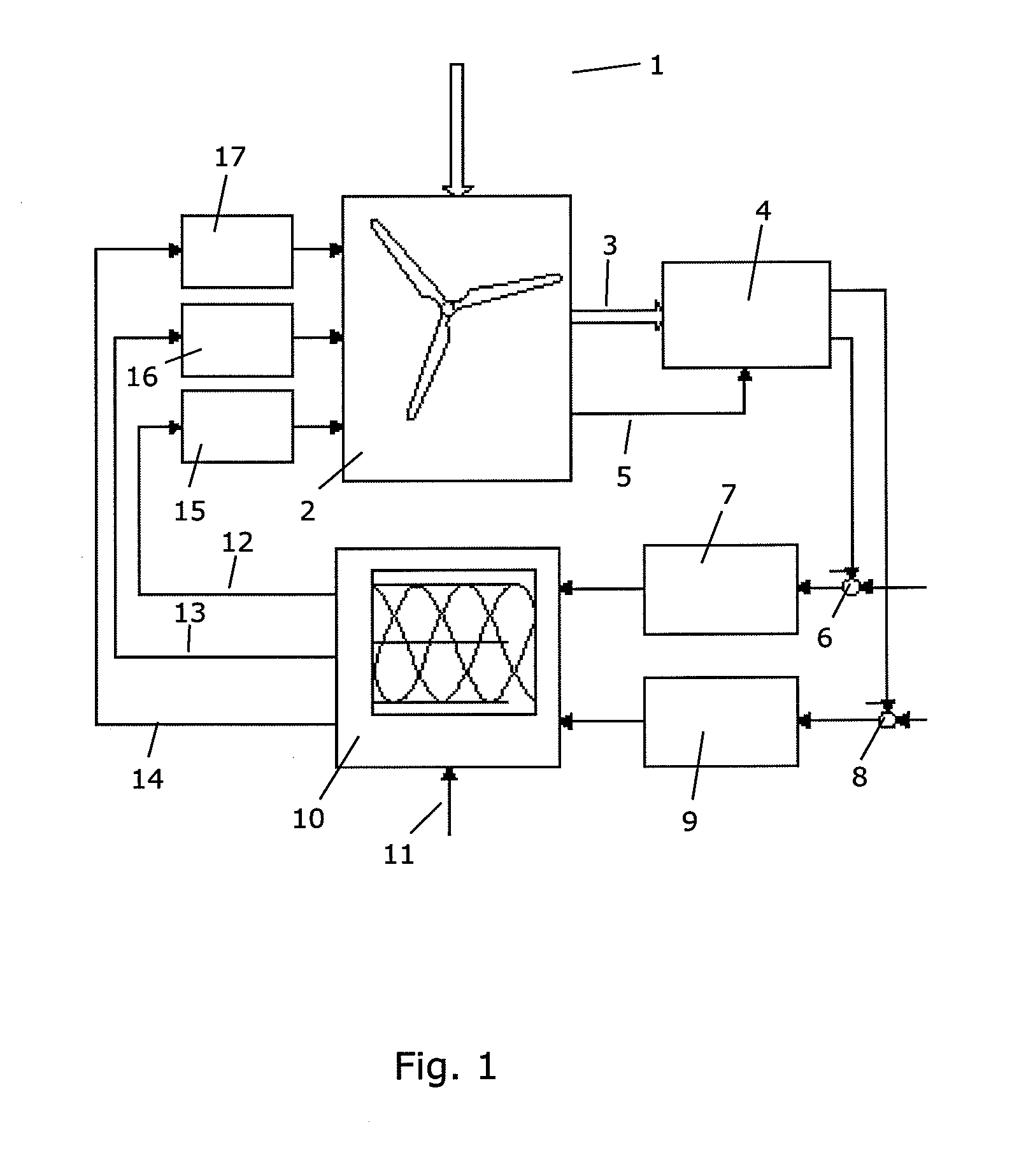

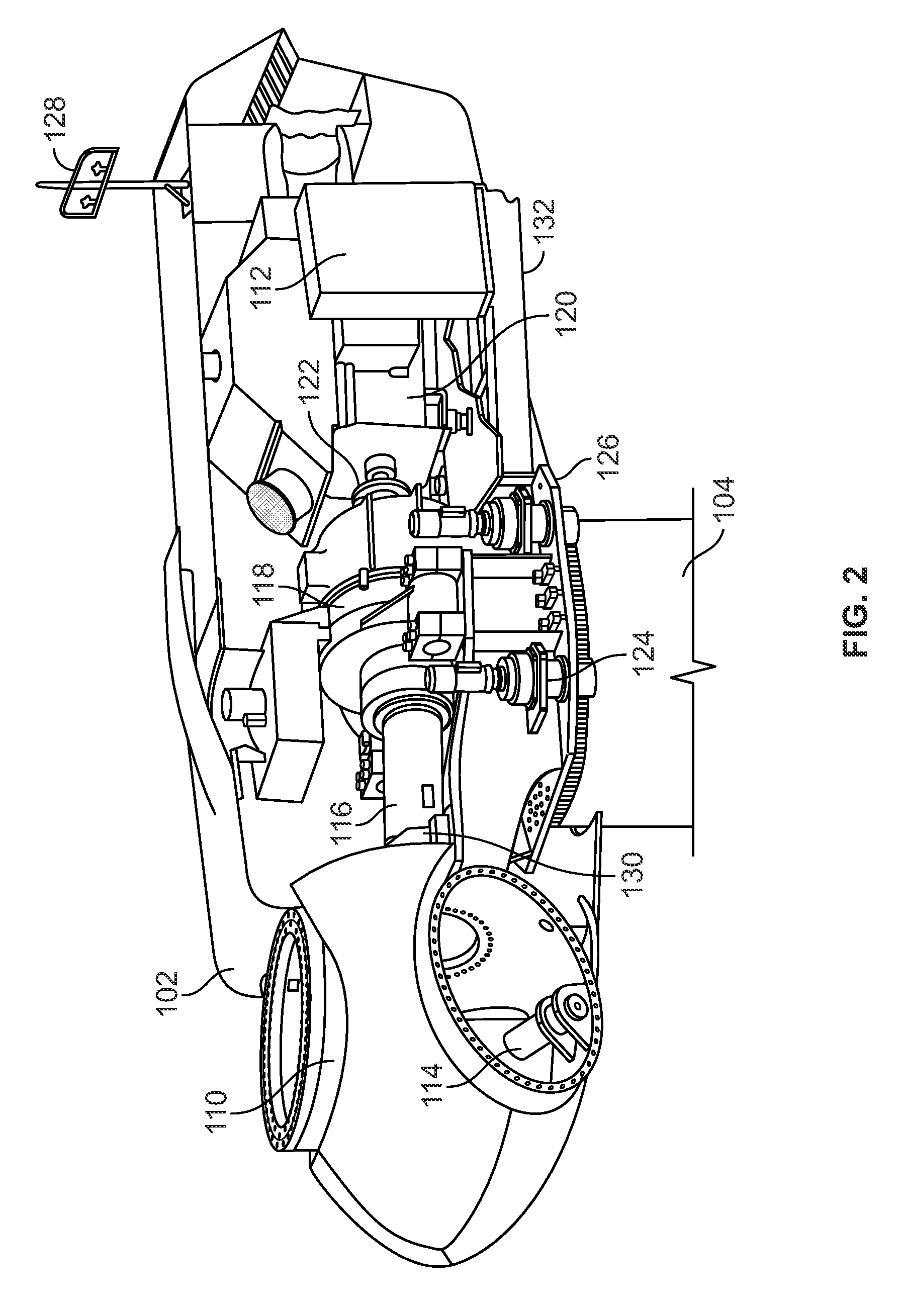

A method for operating a wind energy system is provided comprising the steps of setting the value of an operational parameter of the wind energy system, measuring a yield parameter of the wind energy system and measuring a condition parameter. Further, the method comprises the step of calculating an optimized value of the operational parameter based on historical data and the outcome of the measurements. The method further comprises the step of resetting the operational parameter to the optimized value of the operational parameter wherein the resetting is such that the yield parameter is optimized. Further, a wind energy system is provided having a sensor unit for measuring a yield parameter of the wind energy system, a sensor for measuring a condition parameter, an actuator for adjustment of at least one adjustable part of the wind energy system, and a self-learning controller. The self-learning controller is connected to the sensor unit and the actuator and receives measurement data from the sensor unit. The self-learning controller performs optimization calculations based on the measurement data and sends instruction signals to the actuator based on the outcome of the optimization calculations for the adjustment of the adjustable part of the wind energy system. The instruction signals are such that the yield parameter is optimized.

Owner:GENERAL ELECTRIC CO

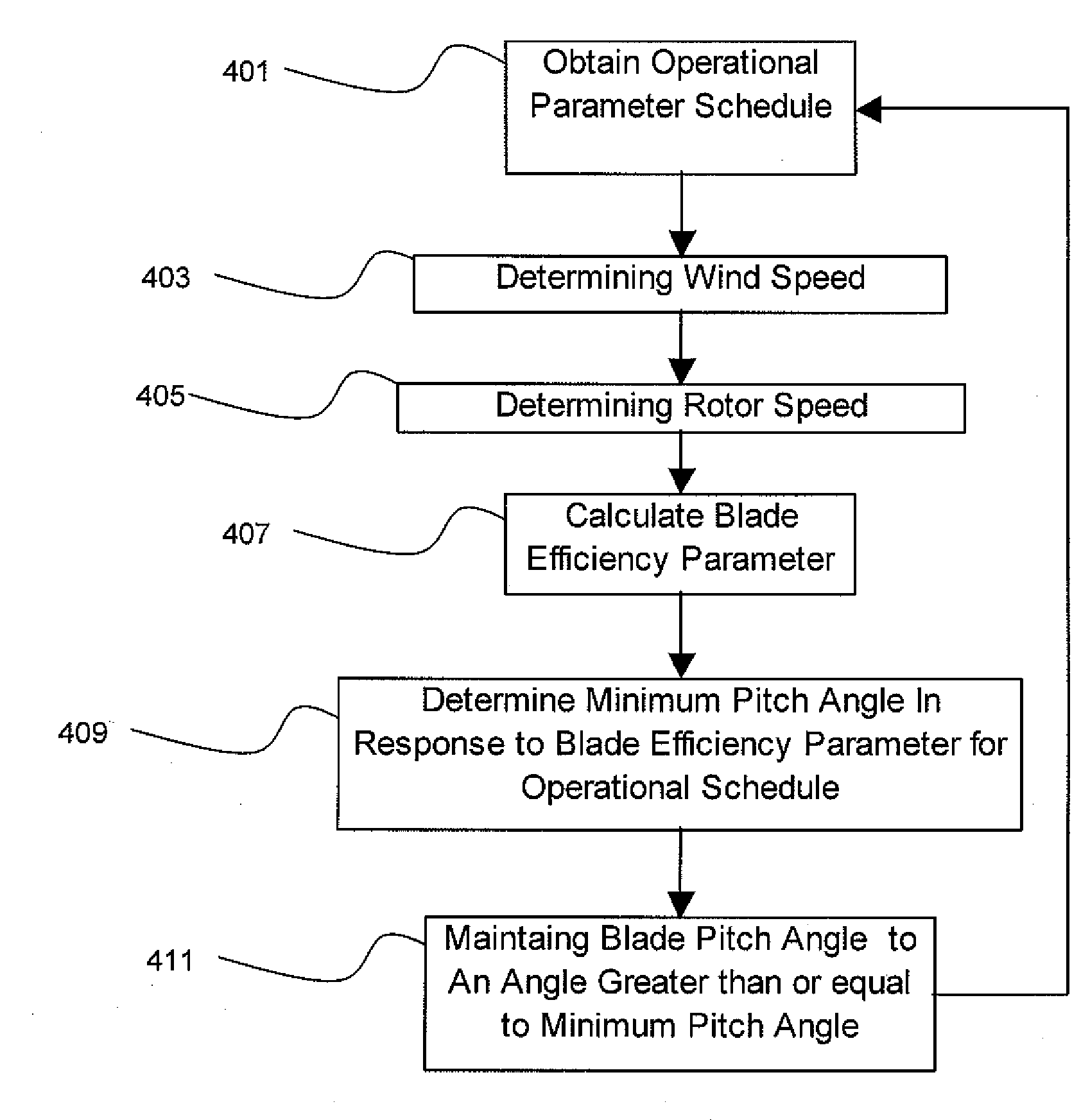

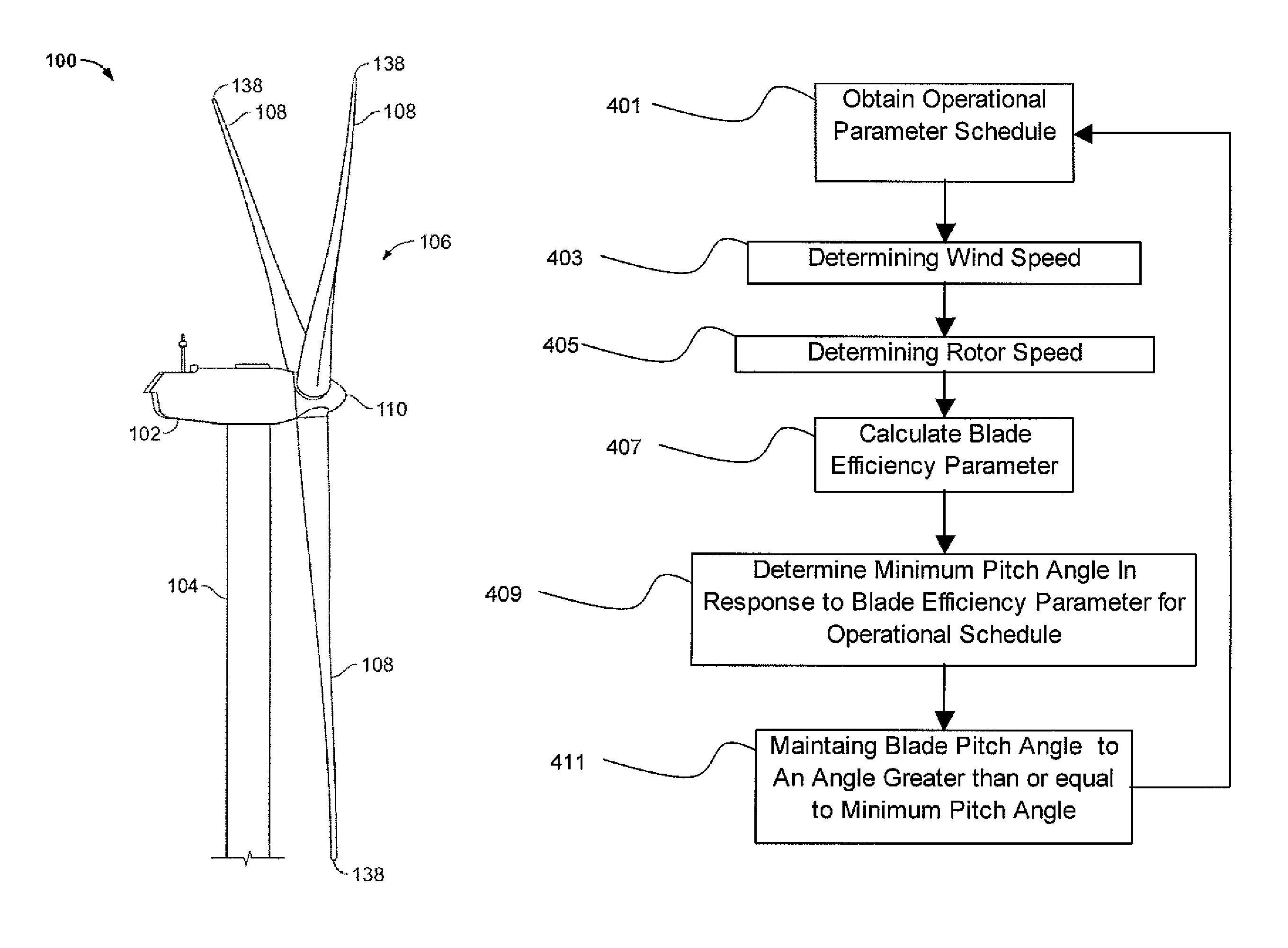

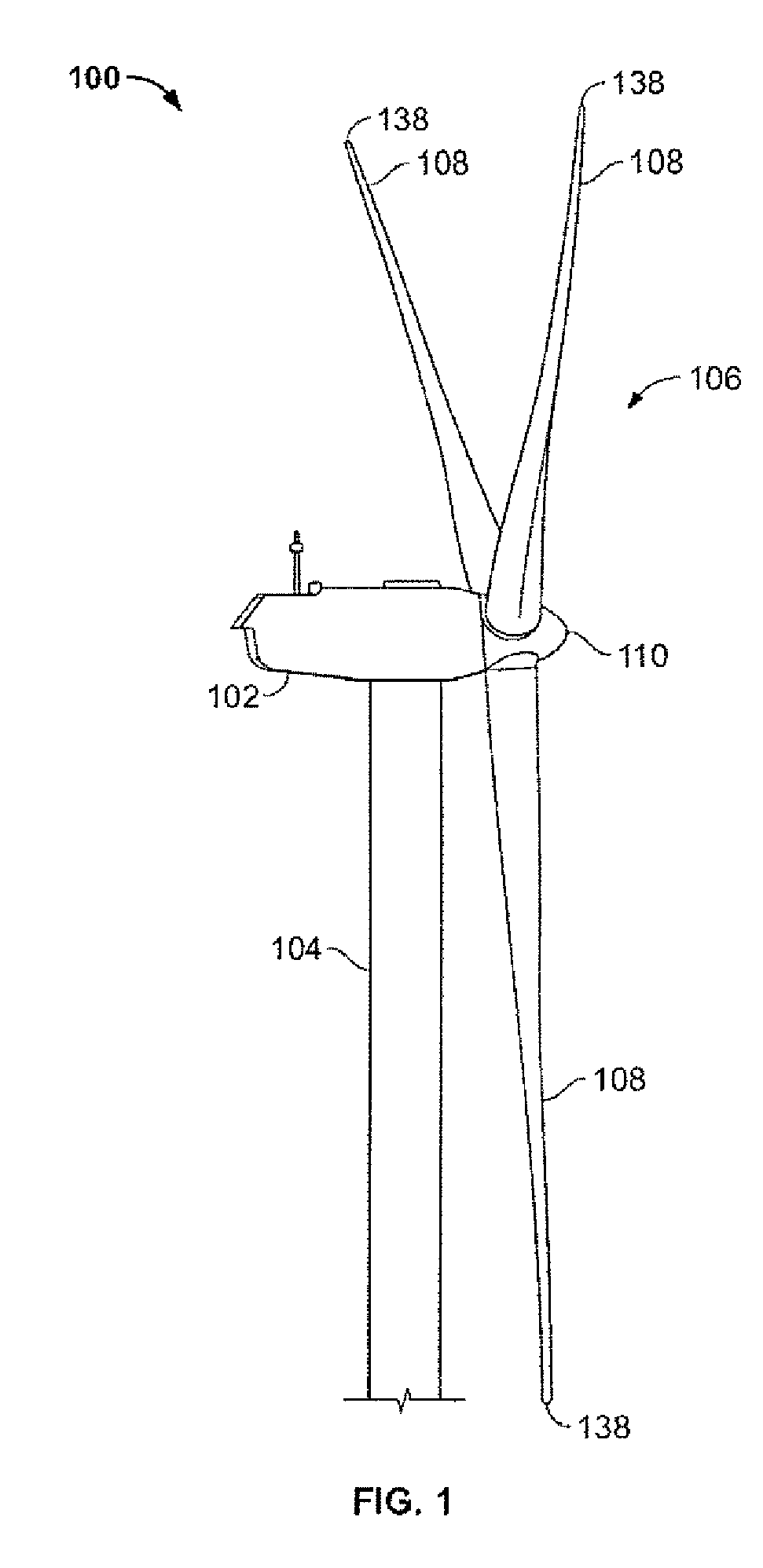

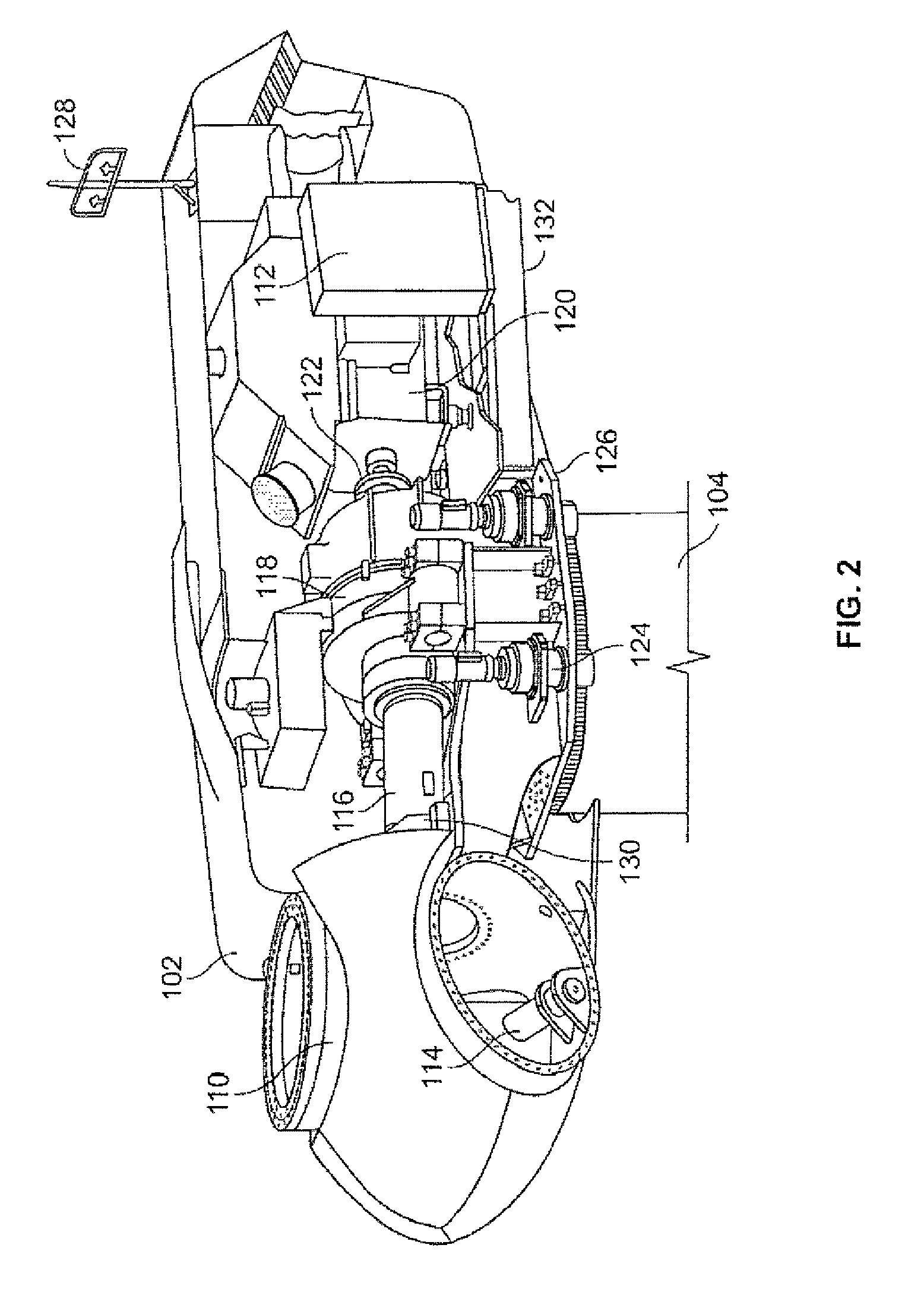

Blade pitch management method and system

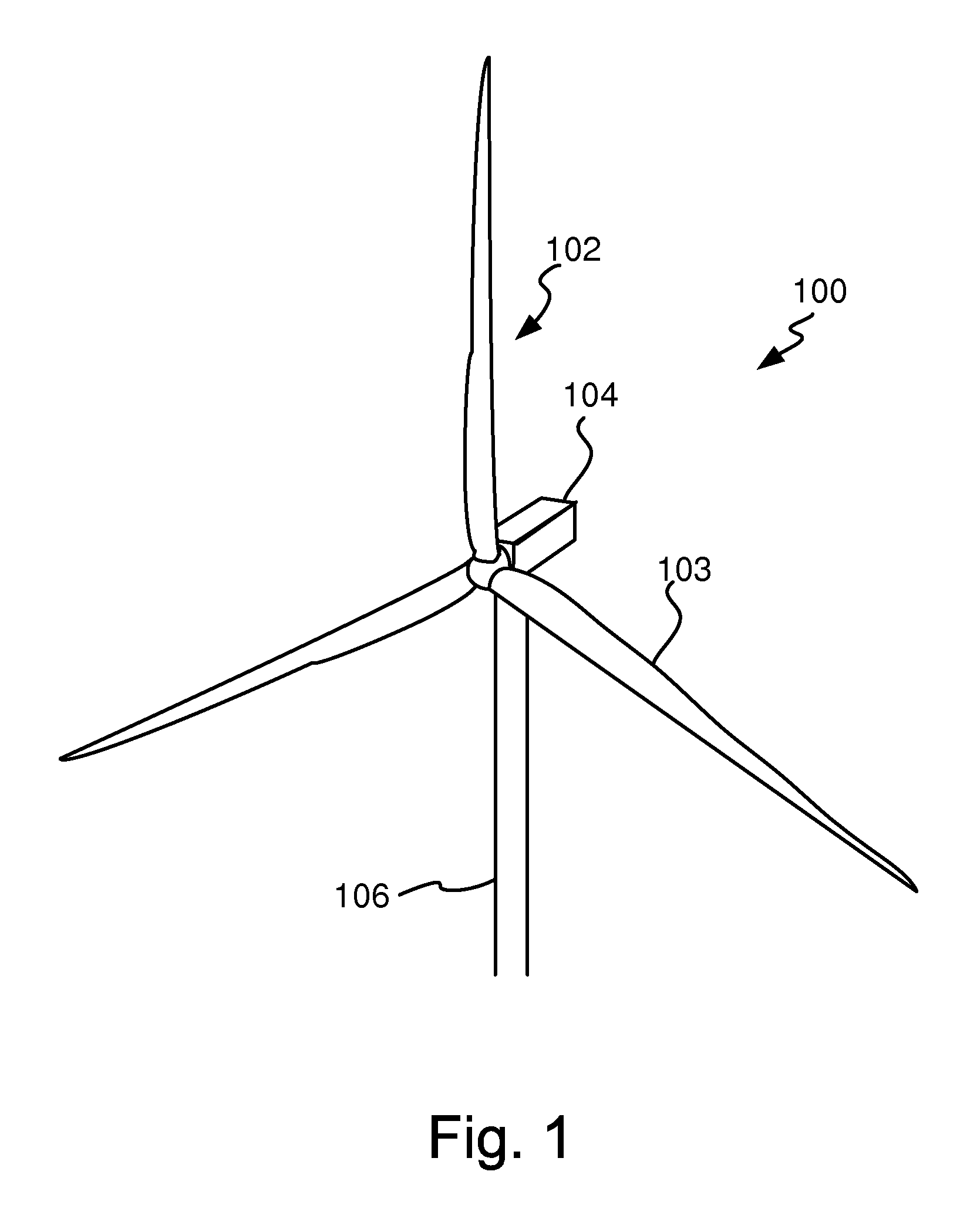

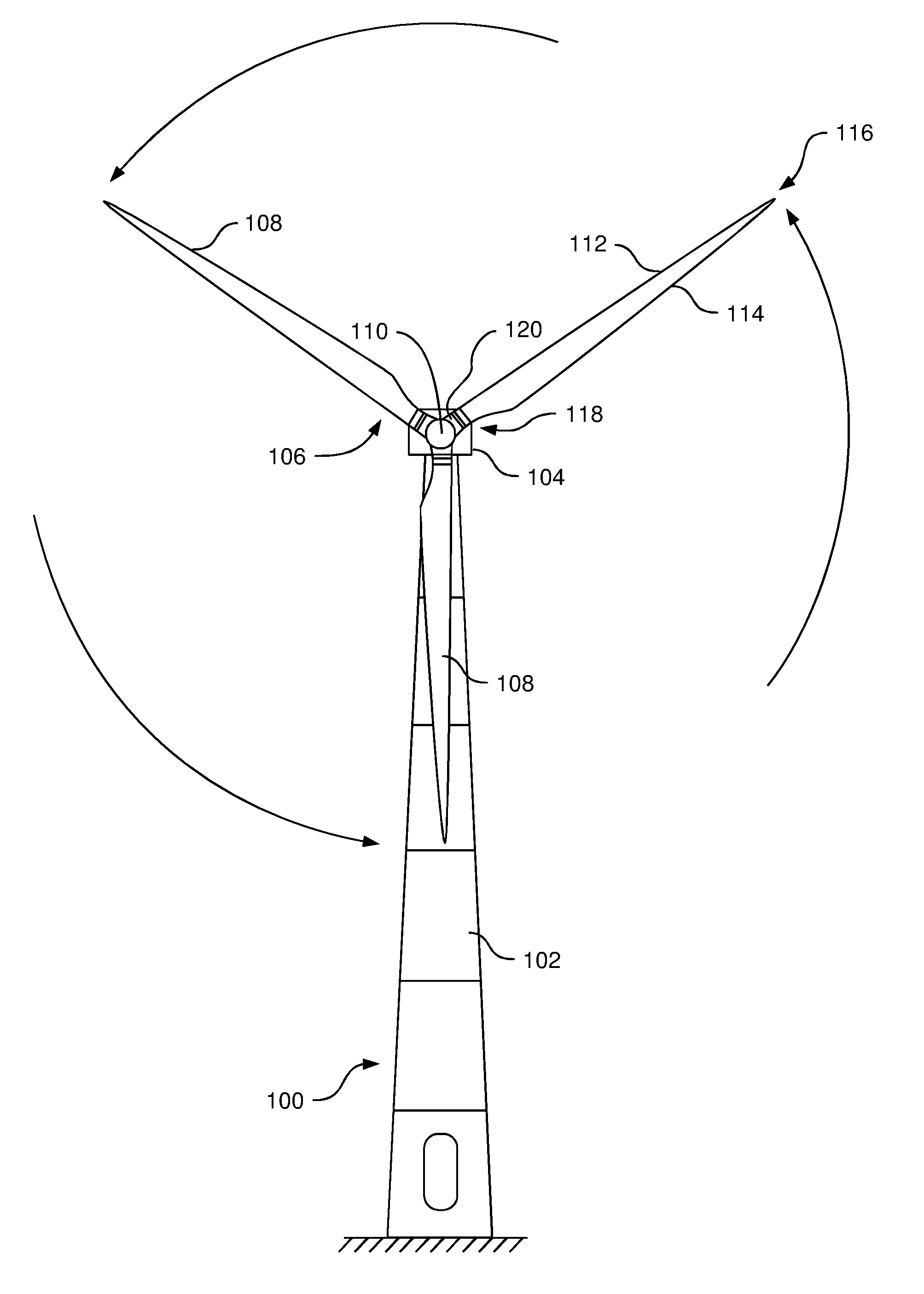

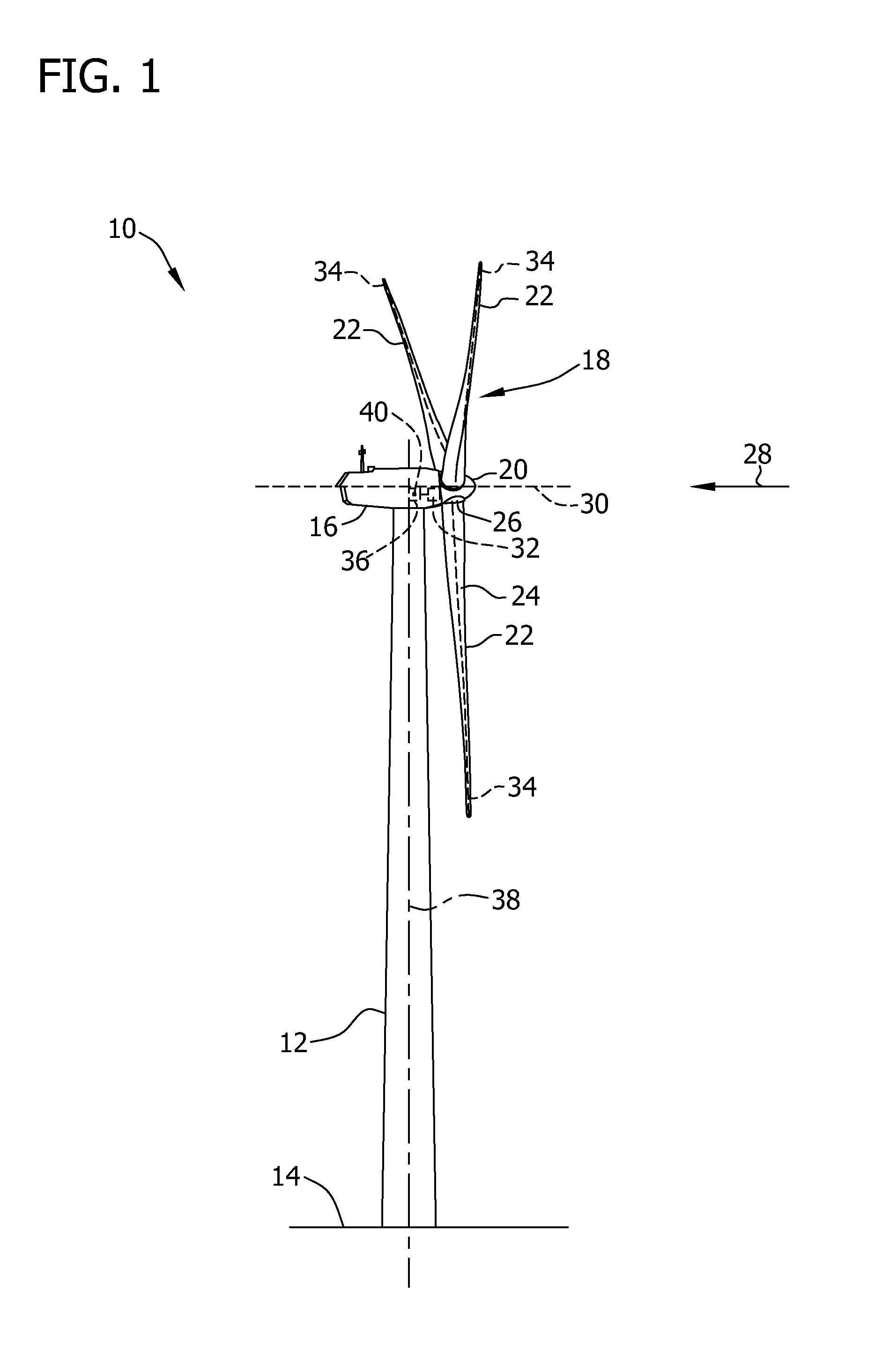

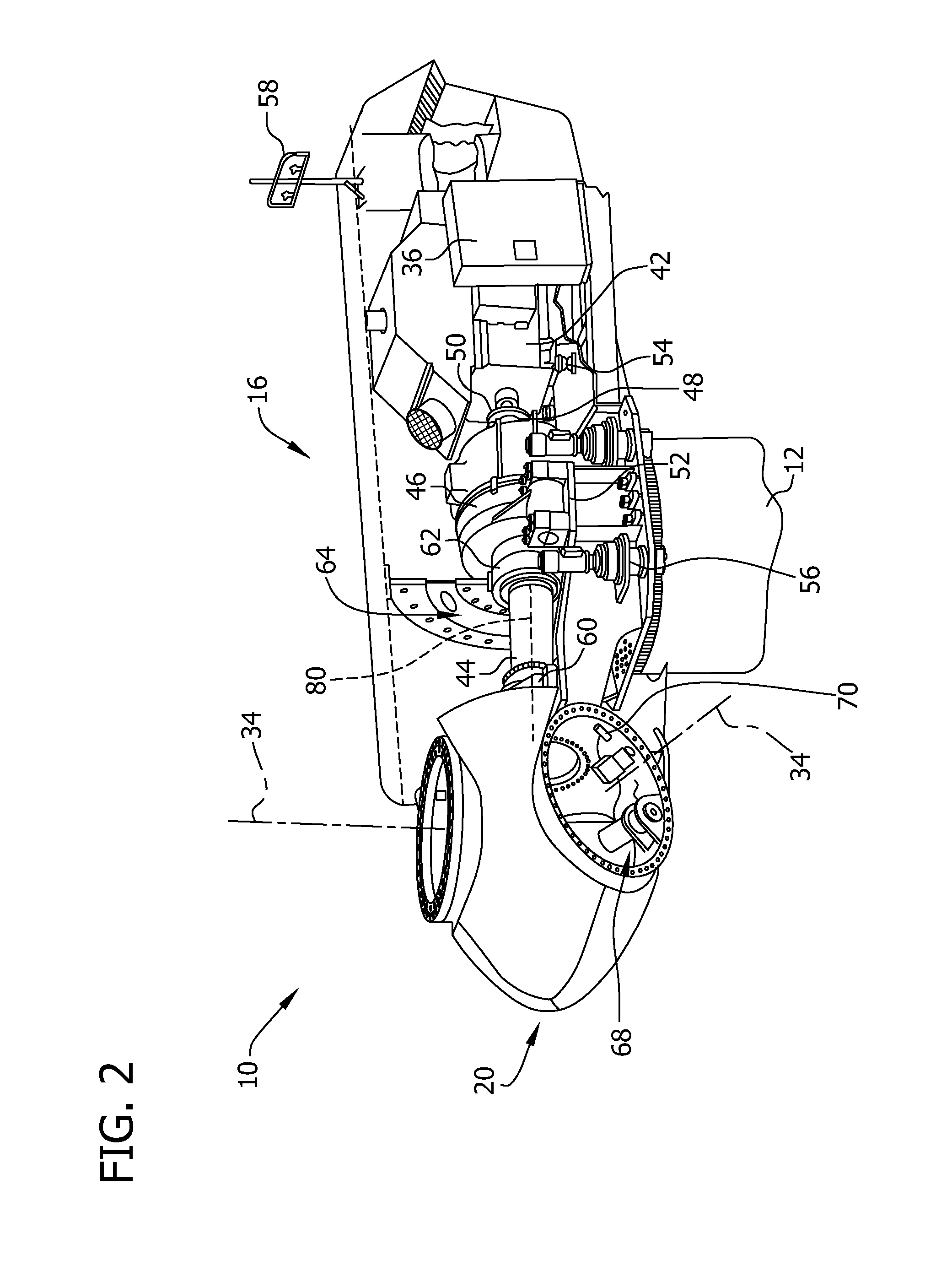

ActiveUS20100098540A1Reduce eliminateLow densityPropellersComparison table algorithmsEngineeringBlade pitch

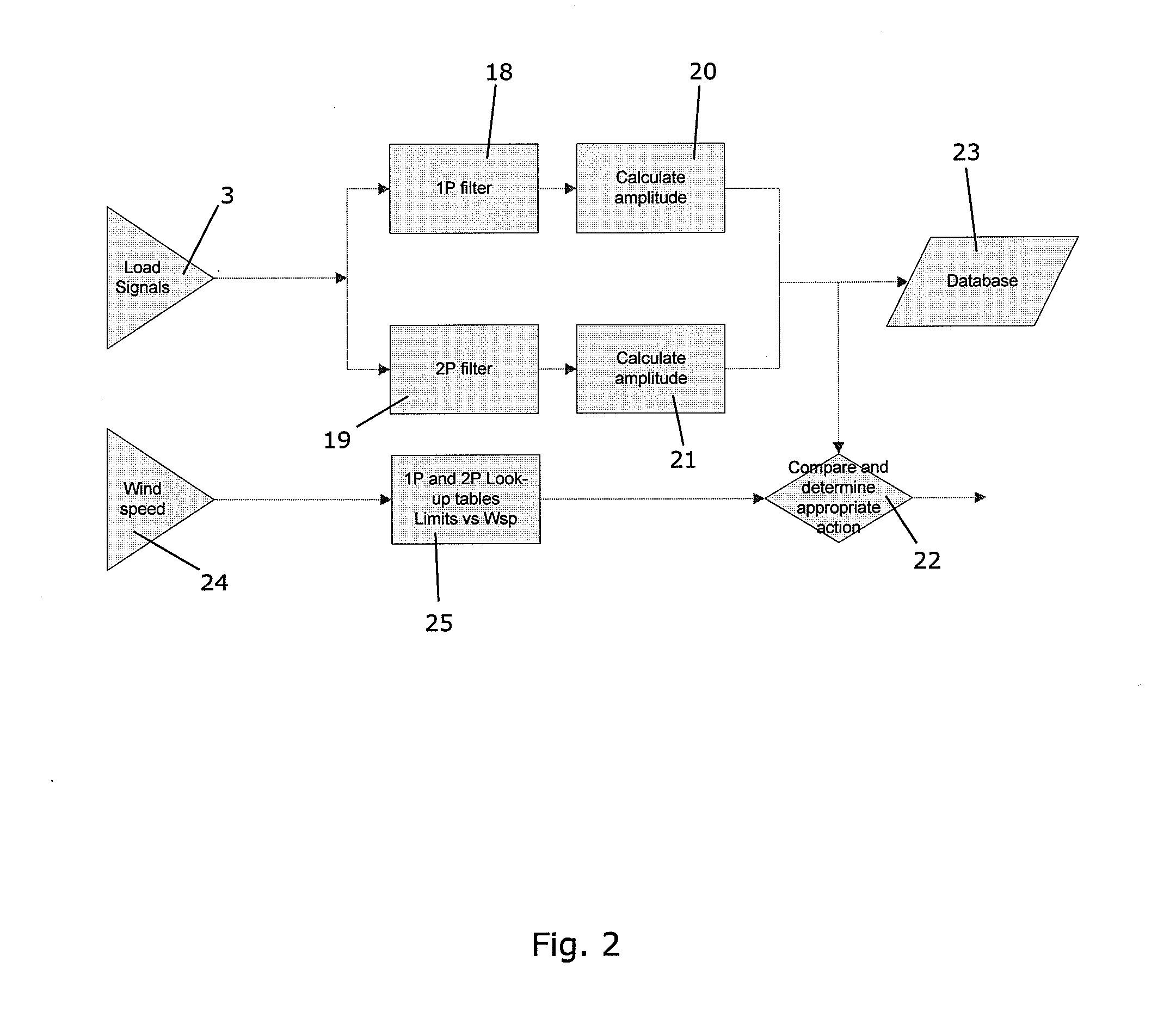

A method for operating a wind turbine. The method includes providing a wind turbine having at least one blade having adjustable pitch angle that is adjusted according to an operational parameter schedule. A blade efficiency parameter is determined in response to a wind speed and a rotor speed. A minimum pitch angle is determined in response to the blade efficiency parameter and the pitch angle of the at least one blade in response to the blade efficiency parameter is maintained to an angle equal to or greater than the minimum pitch angle independent of the operational parameter schedule. A wind turbine plant and a method for servicing a wind turbine are also disclosed.

Owner:GENERAL ELECTRIC CO

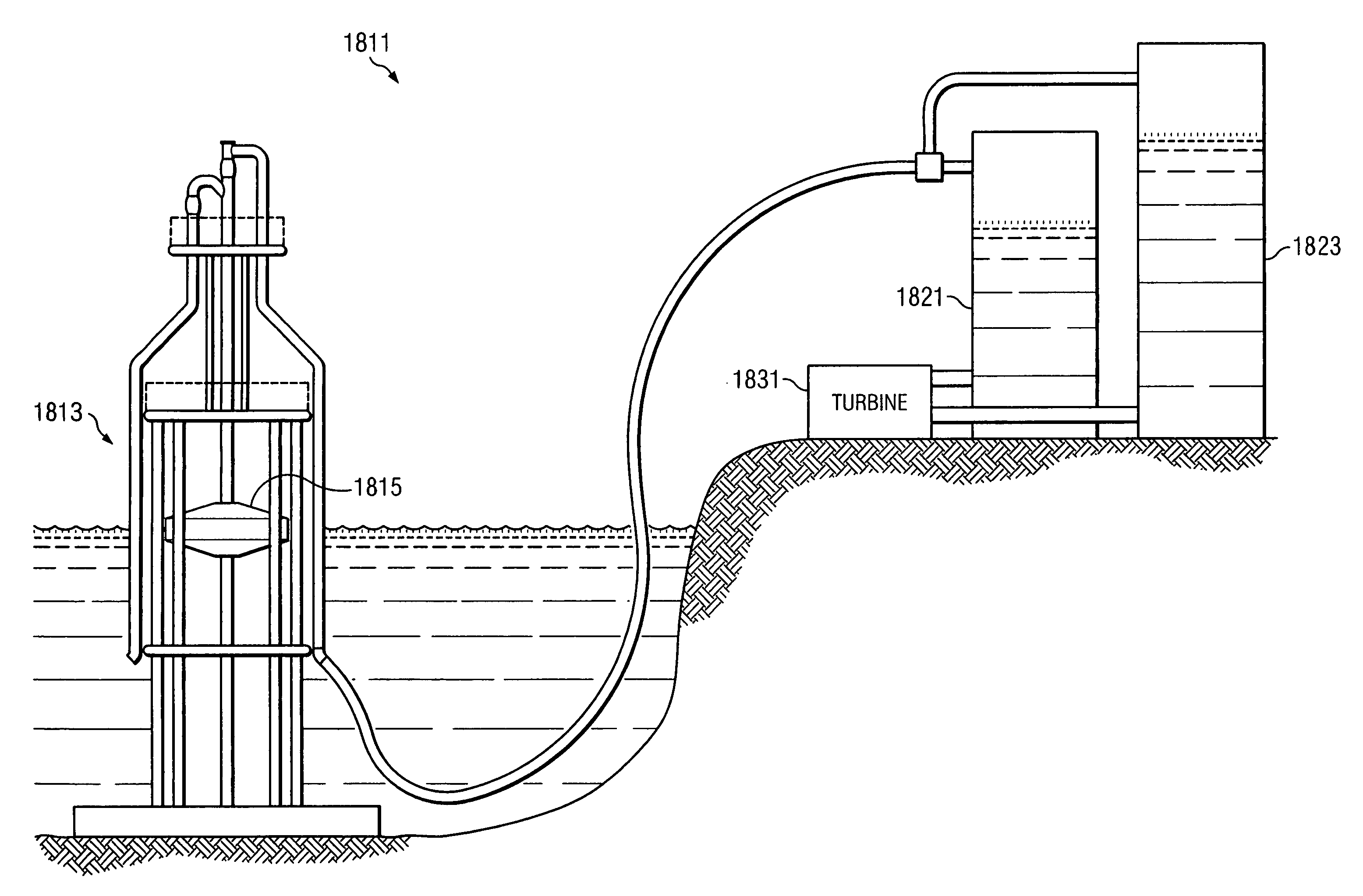

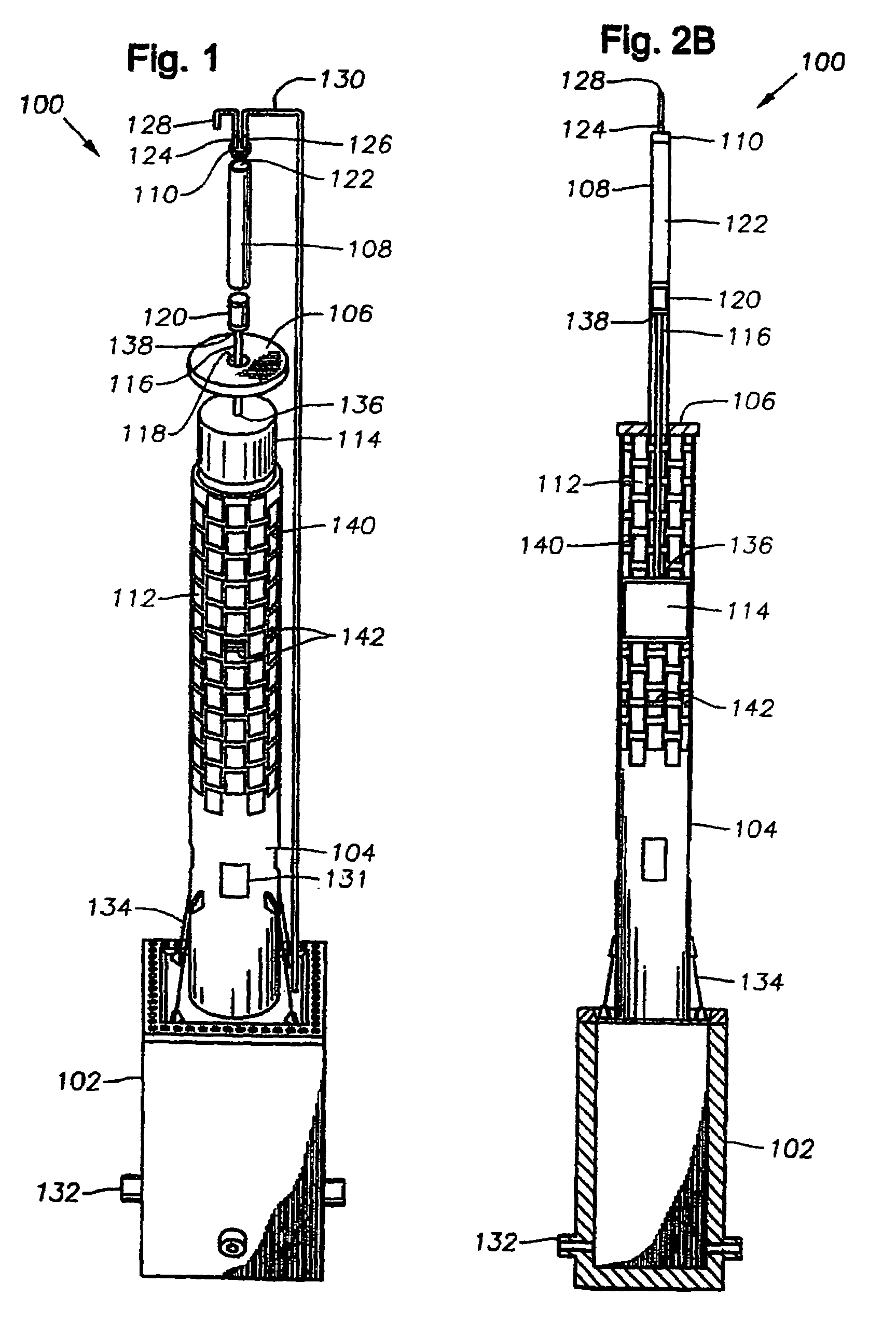

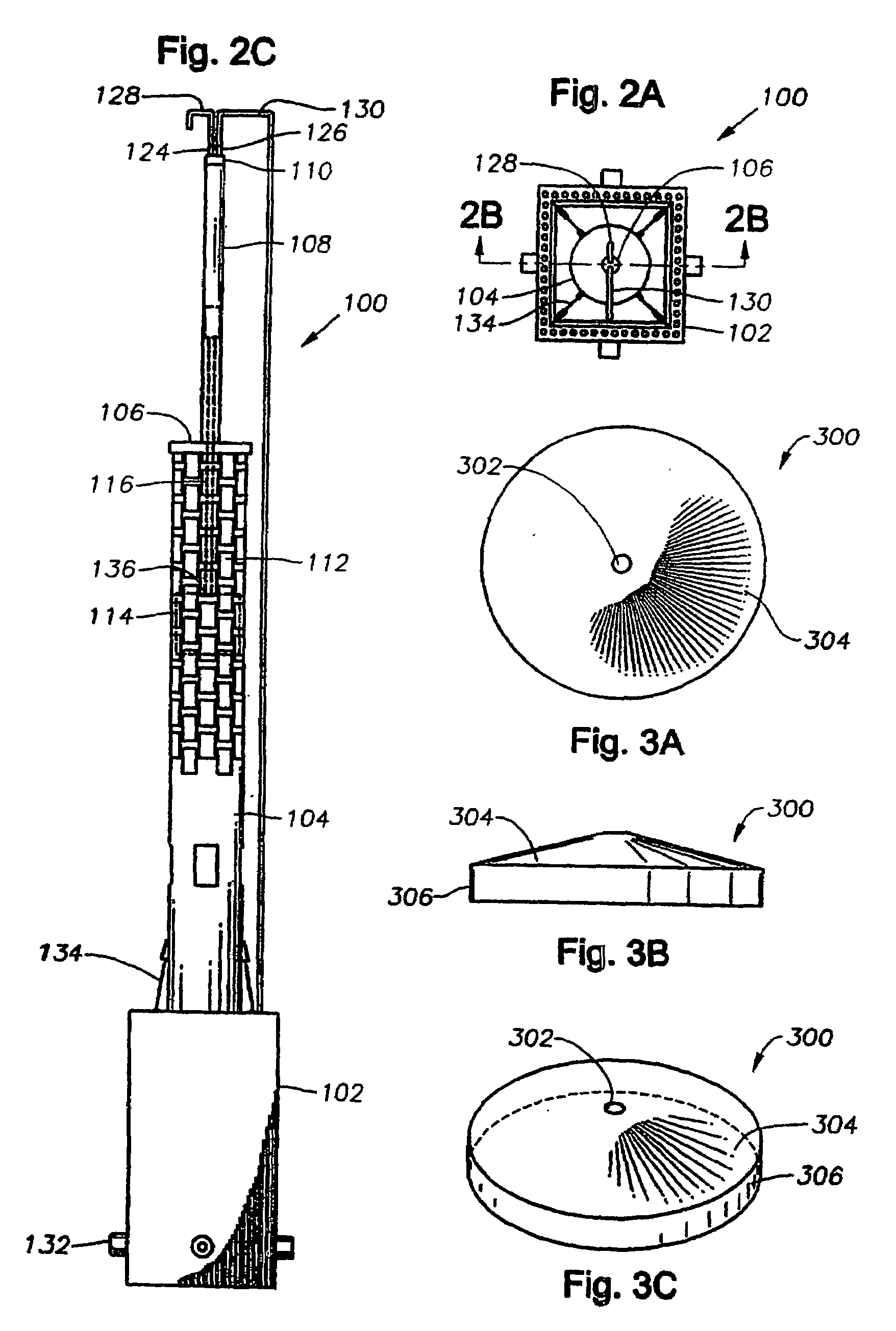

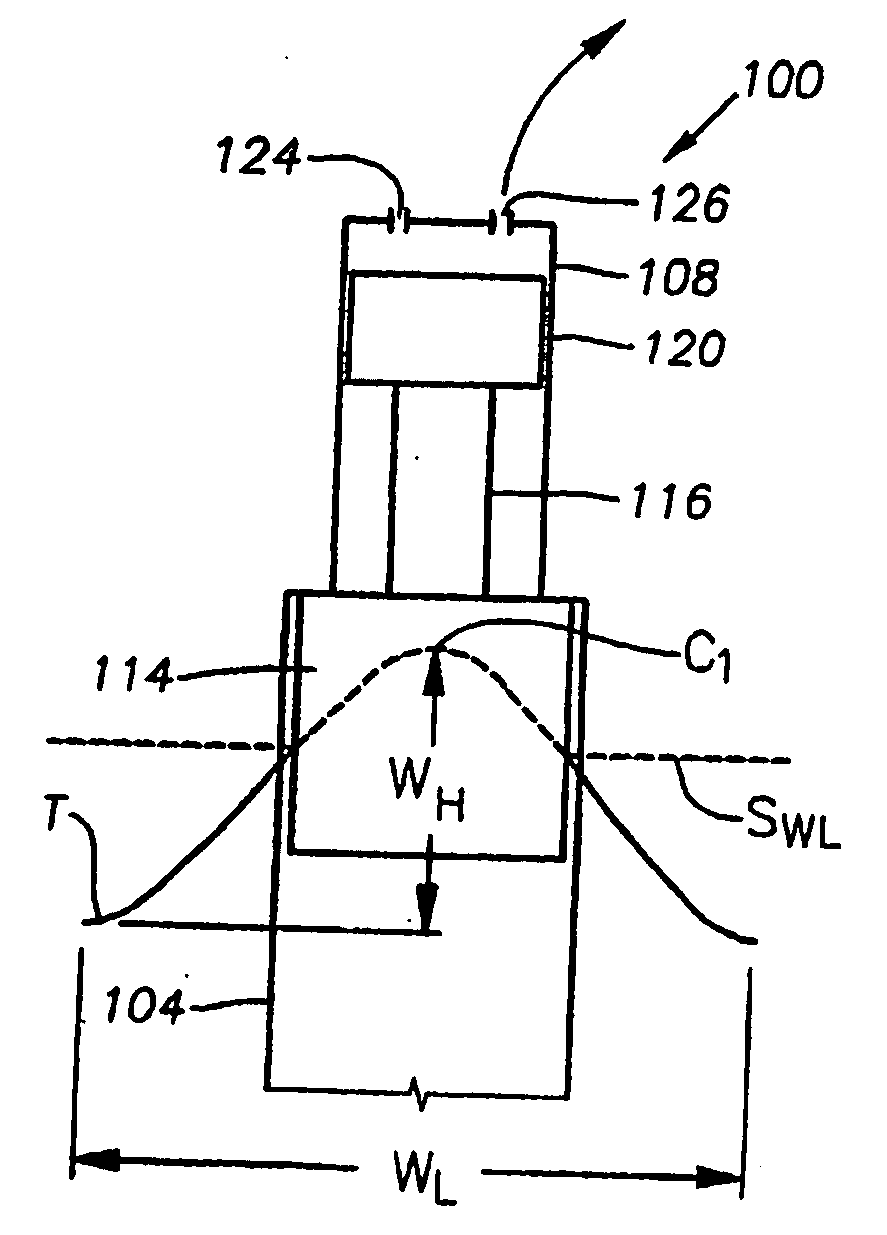

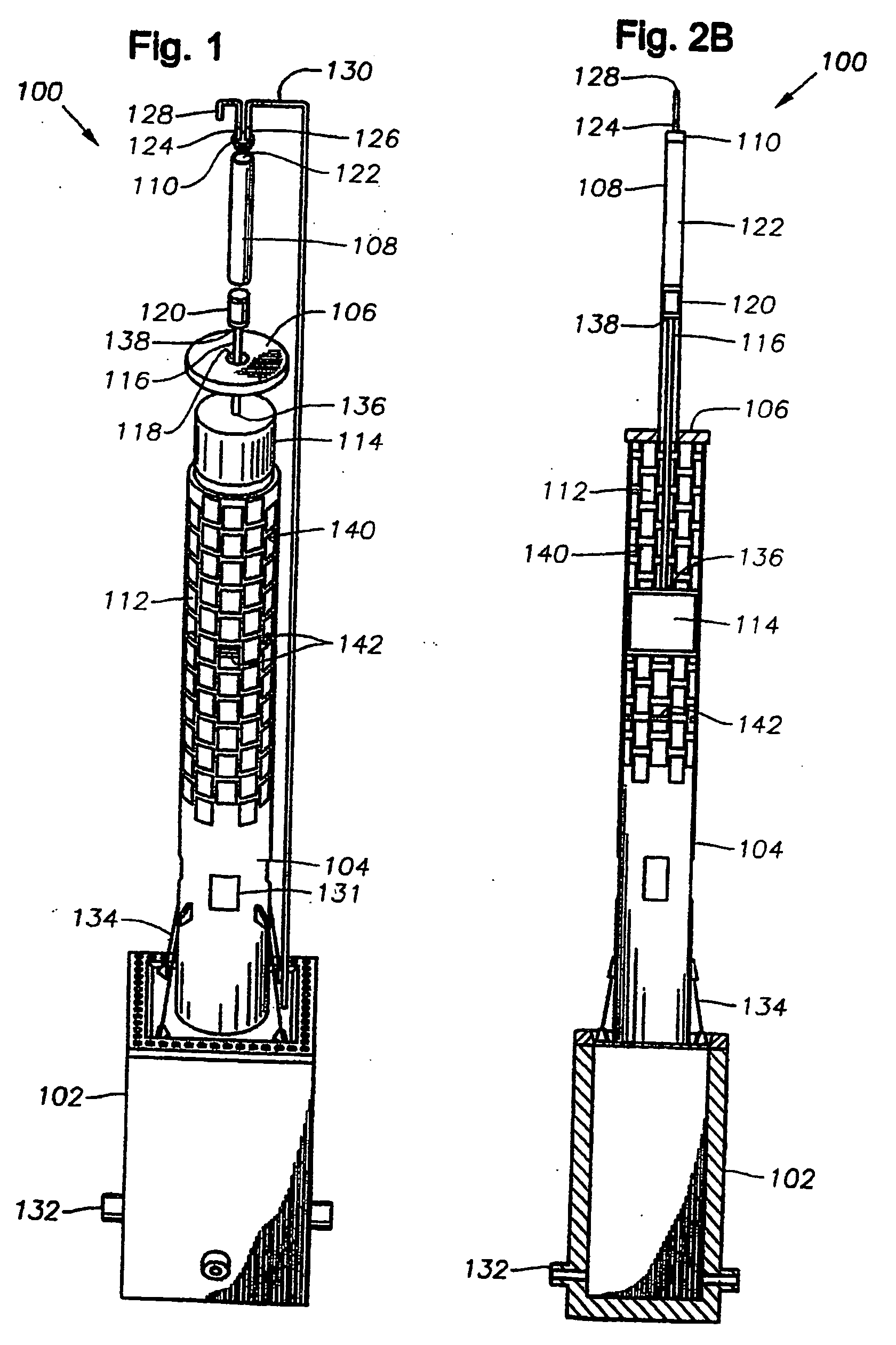

Buoyancy pump power system

A system for generating electricity includes a pump operable to convert wave motion from a body of water into mechanical energy. The pump includes an input port through which an operating fluid can enter the pump and an output port through which the operating fluid can exit the pump. A first outlet line and a second outlet line are fluidly coupled to the output port of the pump. A first reservoir is fluidly connected to the first outlet line, and a second reservoir is fluidly connected to the second outlet line, both reservoirs being selectively capable of receiving operating fluid driven through the output port.

Owner:INDEPENDENT NATURAL RESOURCES

Buoyancy pump power system

A system for generating electricity includes a pump operable to convert wave motion from a body of water into mechanical energy. The pump includes an input port through which an operating fluid can enter the pump and an output port through which the operating fluid can exit the pump. A first outlet line and a second outlet line are fluidly coupled to the output port of the pump. A first reservoir is fluidly connected to the first outlet line, and a second reservoir is fluidly connected to the second outlet line, both reservoirs being selectively capable of receiving operating fluid driven through the output port.

Owner:INDEPENDENT NATURAL RESOURCES

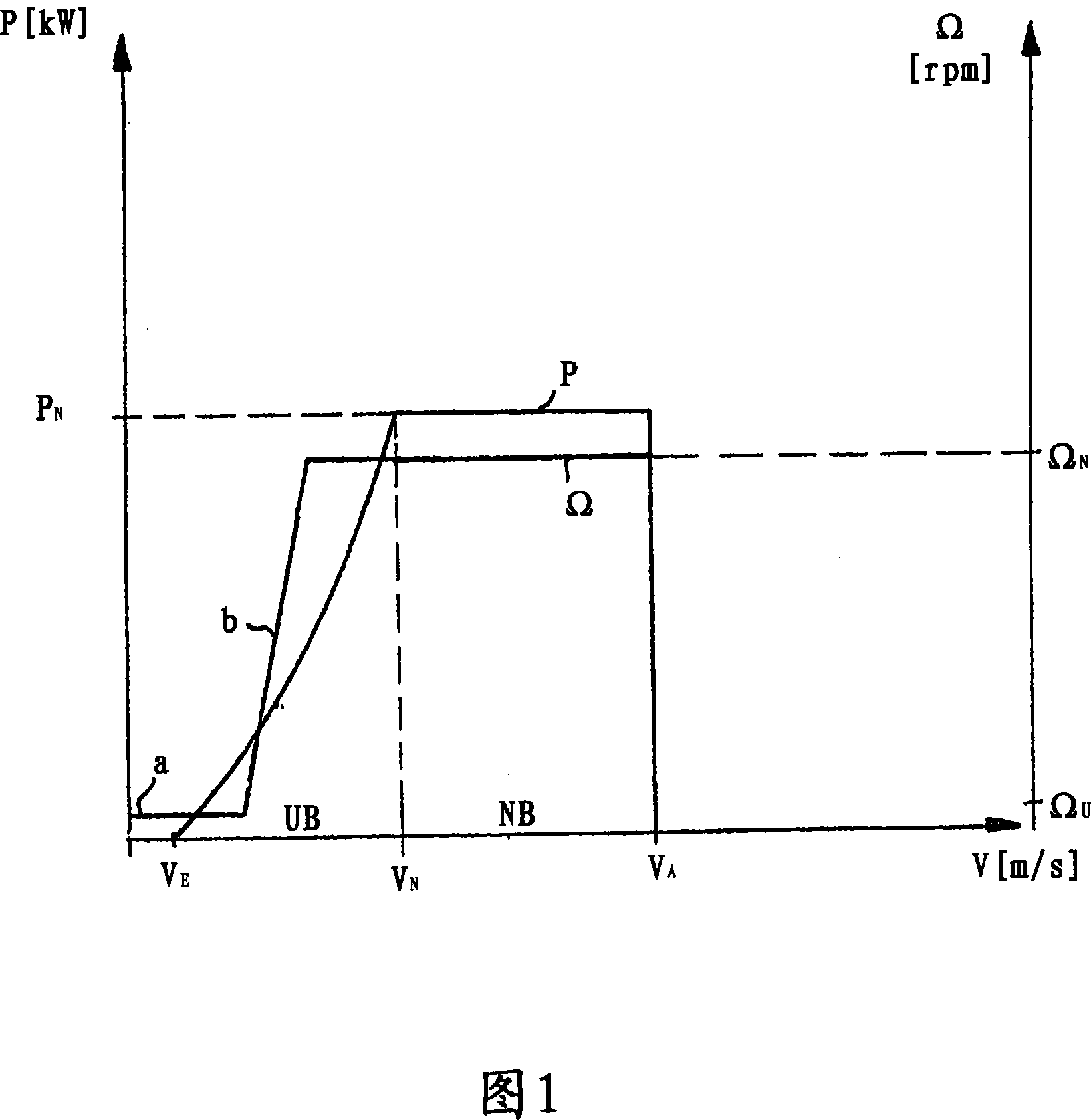

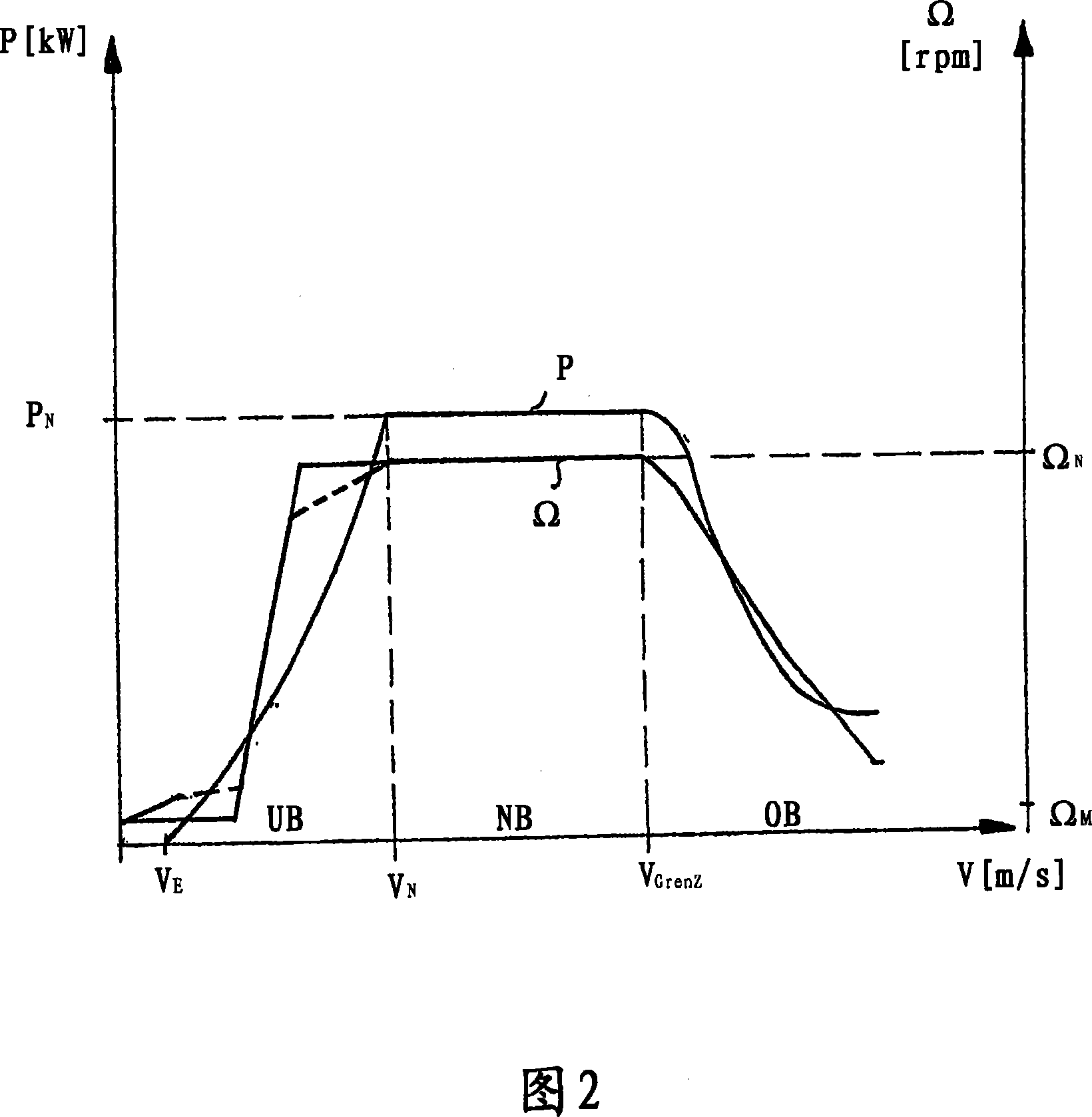

Method for controlling a wind turbine and corresponding wind turbine

InactiveUS7629702B2Improved and reliableImprove compatibilityWind motor controlComparison table algorithmsEngineeringLimit value

Reduction in power output or rotor speed of a wind turbine above a defined limit value, the reduction not being implemented based on the measured wind speed, but on an input value which on one hand is easily detected physically and by control technology and on the other hand is a good indicator of mechanical stresses on the wind turbine. The invention uses the rotor-blade angle as the input value in a manner that starting at the limit value, the reduction in power output or in rotor speed is adjusted as a function of the rotor-blade angle.

Owner:SENVION GMBH

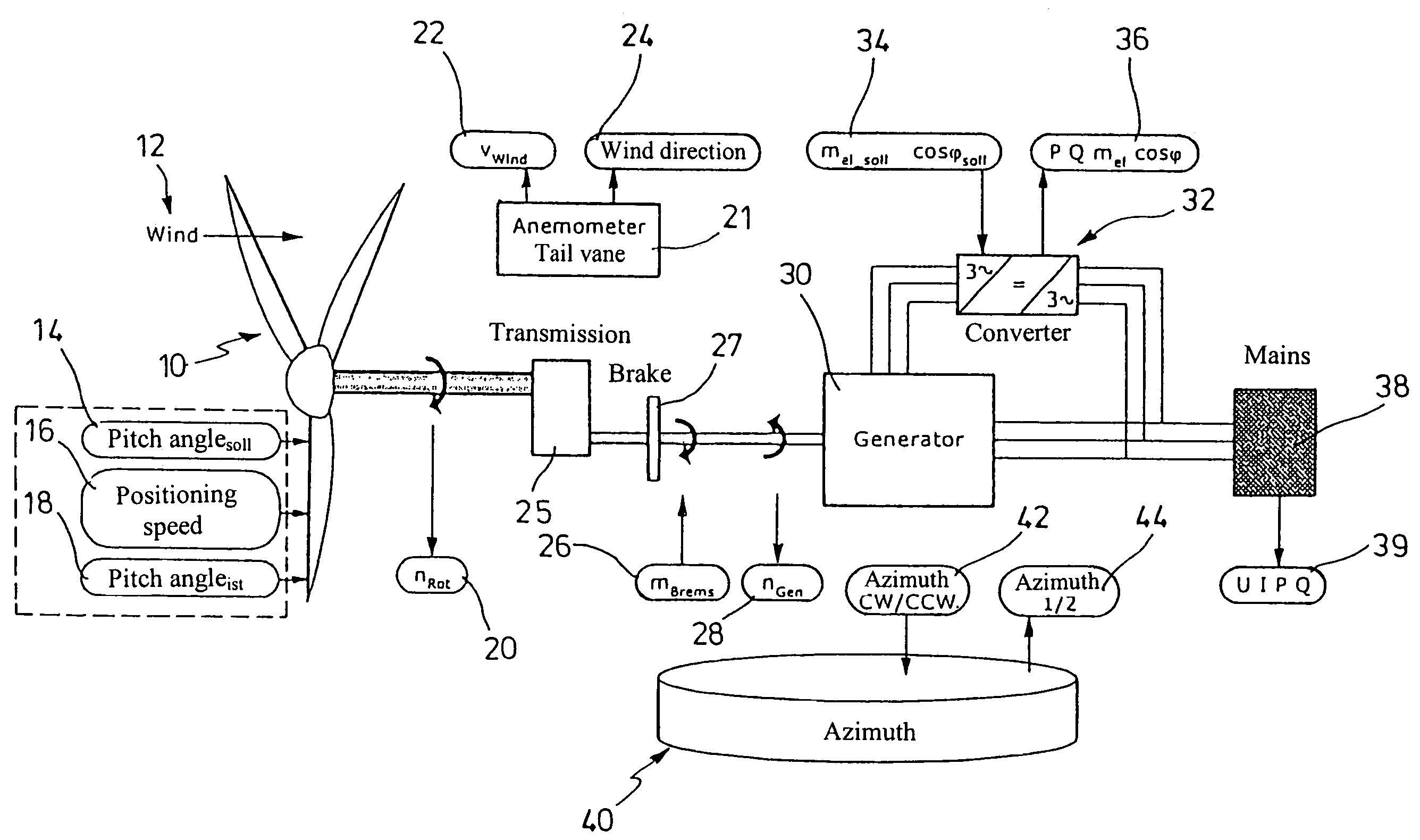

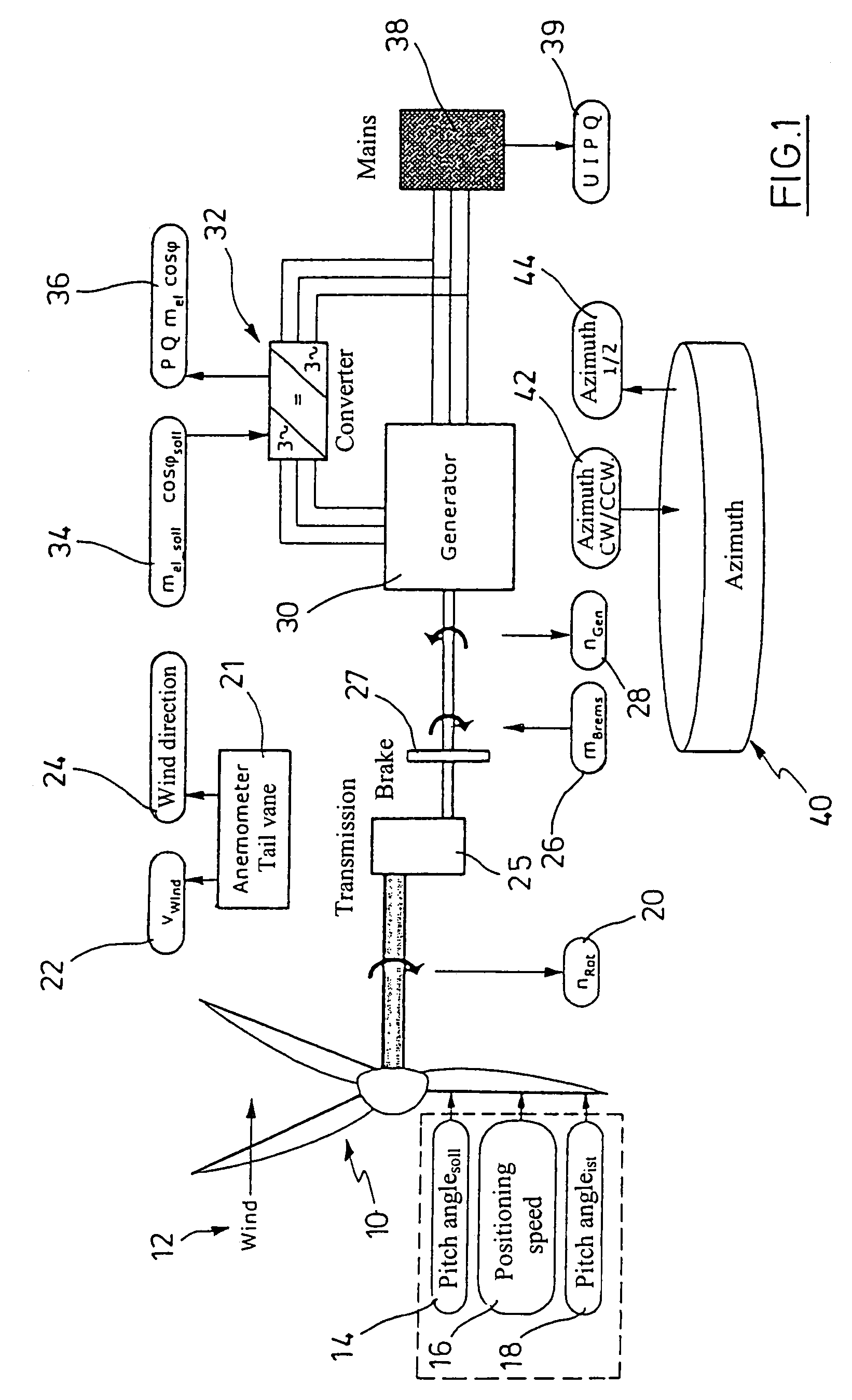

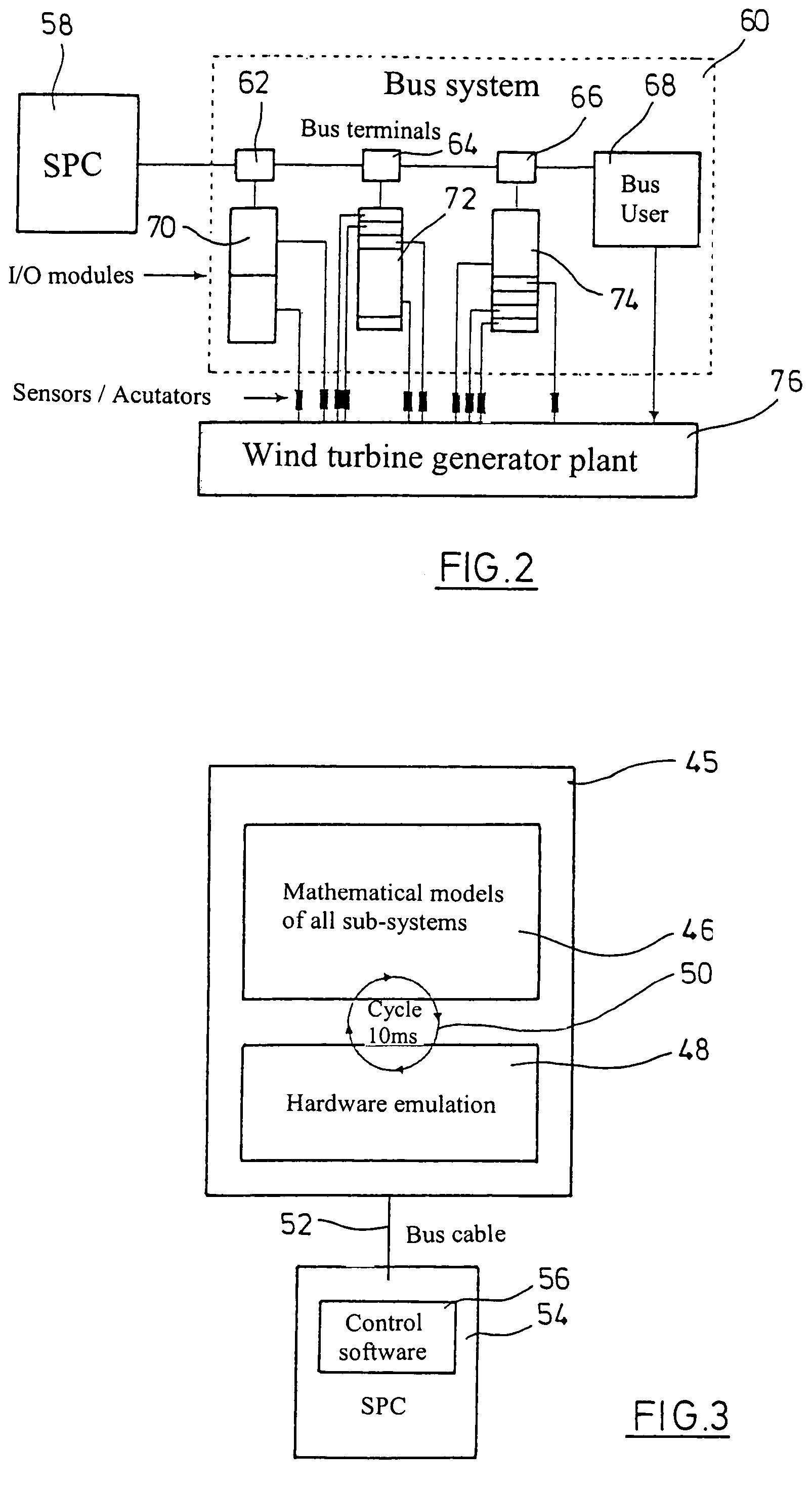

Device and method for a functional test of one wind turbine generator plant

InactiveUS20060113801A1Rapid and reliable functional testReduce amountLevel controlComparison table algorithmsMathematical modelControl signal

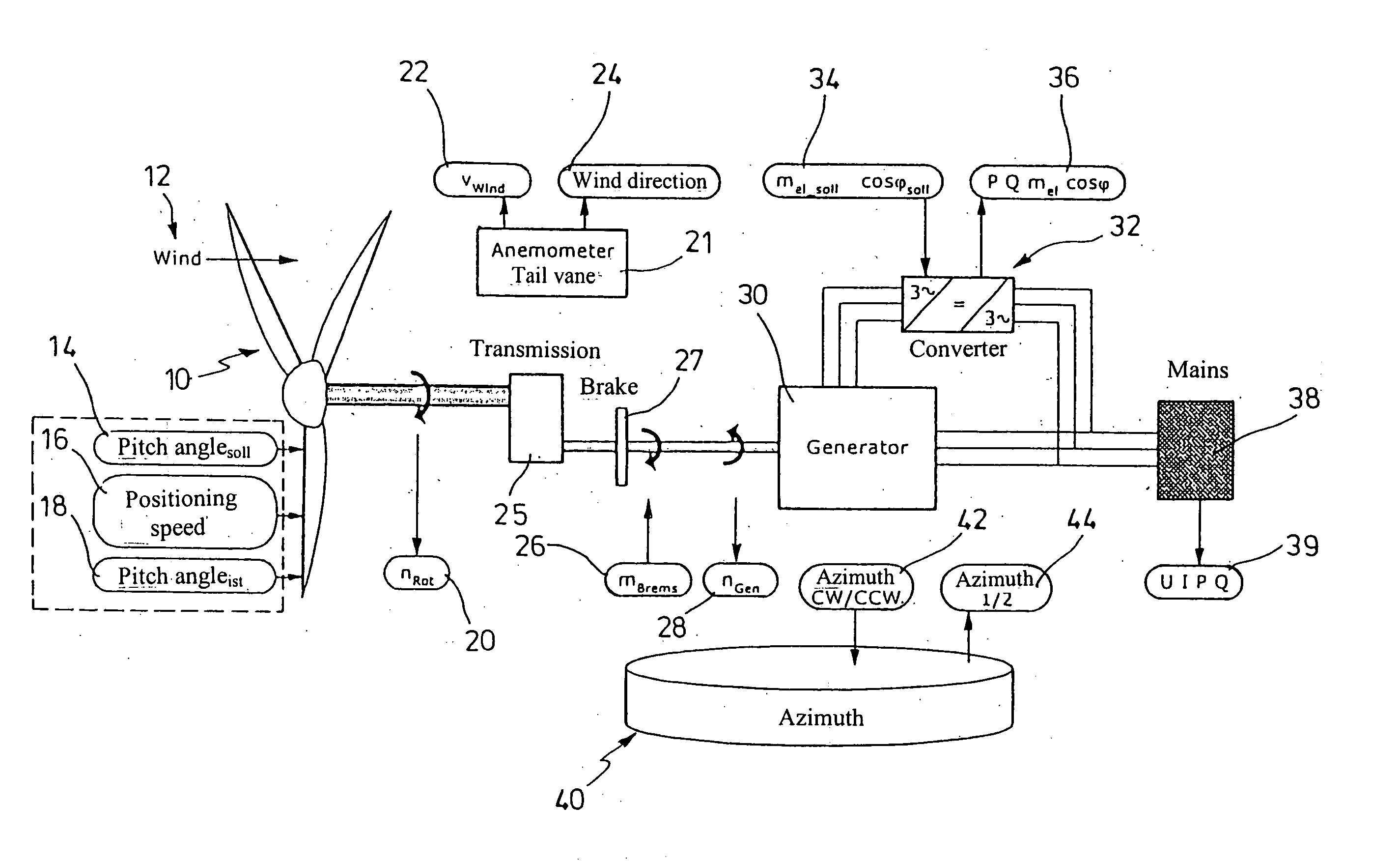

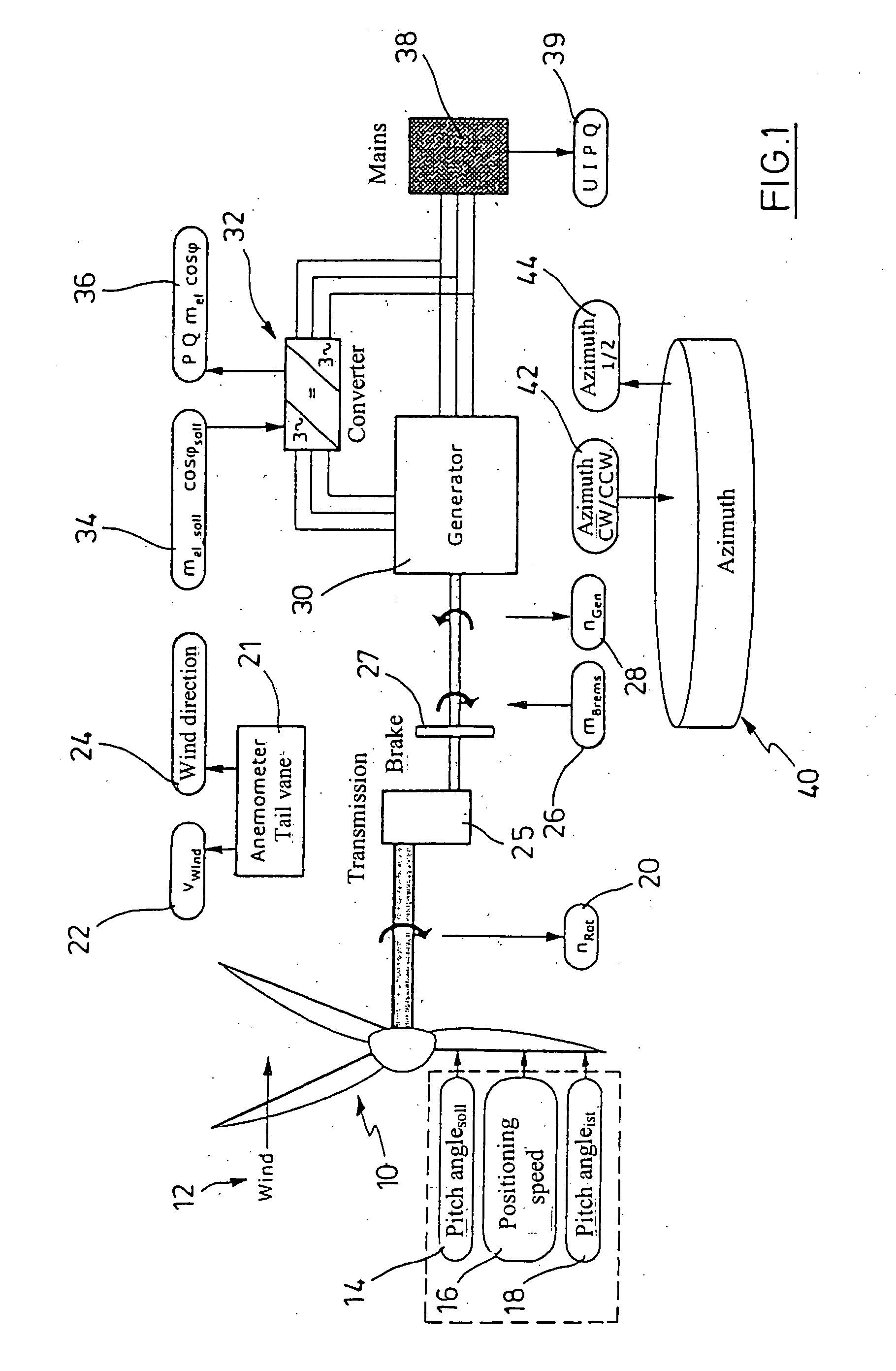

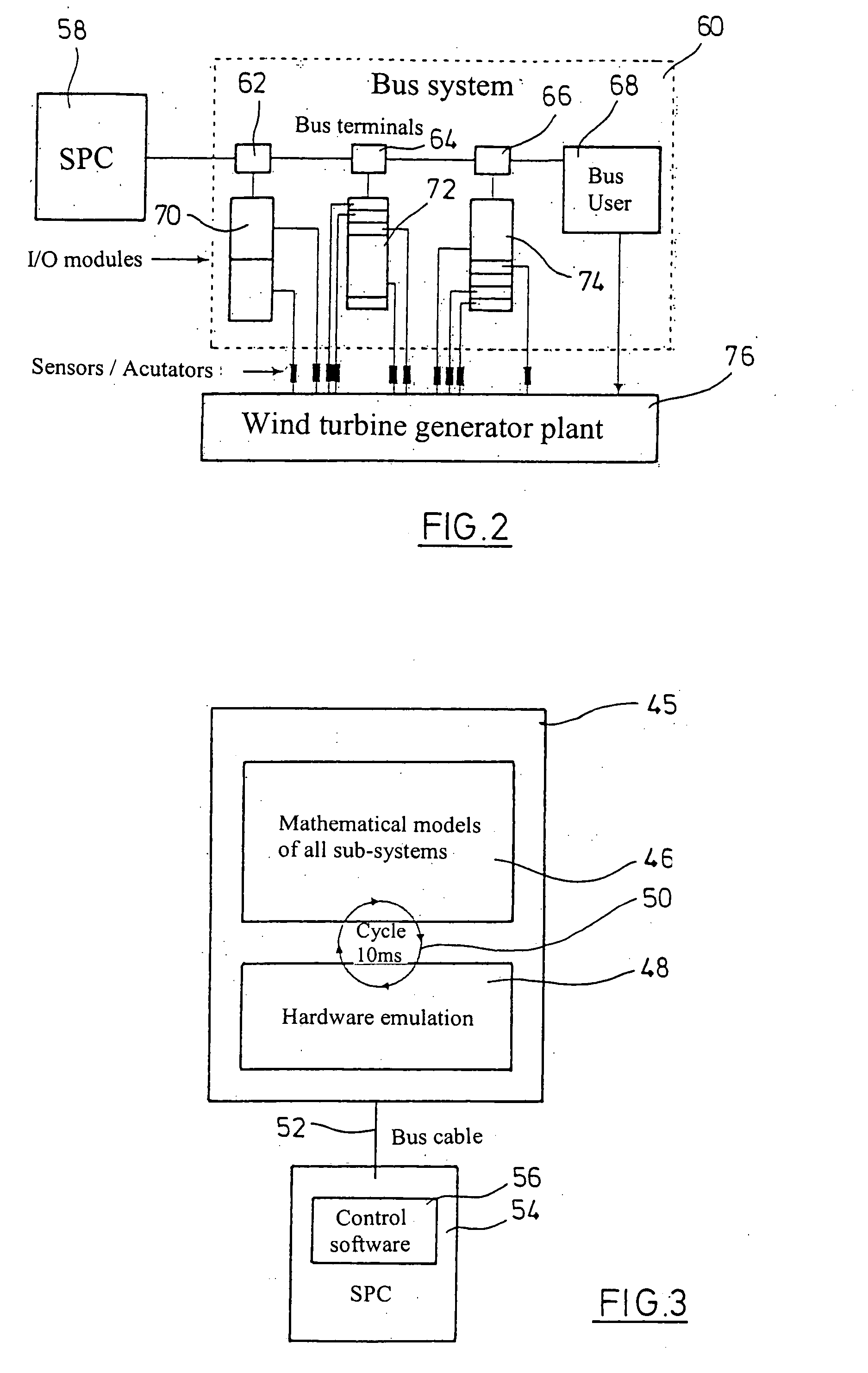

A method for a functional test of a wind turbine generator plant which comprises the following procedural steps: a control unit for the wind turbine generator plant reads in actual values from at least one structural part of the wind turbine generator plant and generates control signals for actuators of the wind turbine generator plant, a simulation unit has at least one input and at least one output as well as one or more mathematical models which depict the behaviour of one or more structural parts of the wind turbine generator plant, the control signals are applied to the input of the simulation unit and the modeled actual values of the models on the structural parts are applied to the output of the simulation unit, wherein the actual values of the simulation unit are applied to the input of the control unit and the control signals of the control unit are applied to the input of the simulation unit; the simulation unit models the actual values of the structural parts resulting for the control signals applied, for certain initial conditions.

Owner:NORDEX ENERGY

Wind energy system and method of operation thereof

ActiveUS7560823B2High yieldImprove performanceOptimise machine performanceComparison table algorithmsLearning controllerEngineering

A method for operating a wind energy system is provided comprising the steps of setting the value of an operational parameter of the wind energy system, measuring a yield parameter of the wind energy system and measuring a condition parameter. Further, the method comprises the step of calculating an optimized value of the operational parameter based on historical data and the outcome of the measurements. The method further comprises the step of resetting the operational parameter to the optimized value of the operational parameter wherein the resetting is such that the yield parameter is optimized. Further, a wind energy system is provided having a sensor unit for measuring a yield parameter of the wind energy system, a sensor for measuring a condition parameter, an actuator for adjustment of at least one adjustable part of the wind energy system, and a self-learning controller. The self-learning controller is connected to the sensor unit and the actuator and receives measurement data from the sensor unit. The self-learning controller performs optimization calculations based on the measurement data and sends instruction signals to the actuator based on the outcome of the optimization calculations for the adjustment of the adjustable part of the wind energy system. The instruction signals are such that the yield parameter is optimized.

Owner:GENERAL ELECTRIC CO

Method for controlling a wind power plant and corresponding wind power plant

InactiveCN101031720AWind motor controlComparison table algorithmsPeaking power plantMachine utilization

The power of wind energy or the revolution rate drive down to the prescribed limit value has been carried based on easily measured in physical and control technique aspect and reflect the input variable of machine utilization but not based on the metrical wind speed. For the assume of this invention, use rotor blade angle as input variable, then when arrive in the limit value adjust power and the drive down of revolution rate based on the rotor blade angle.

Owner:SENVION GMBH

Method for evaluating performance of a system for controlling pitch of a set of blades of a wind turbine

InactiveUS20110178771A1Efficient use ofOptimise machine performanceWind motor controlVariable speed wind turbineBlade pitch

Methods of controlling a variable speed wind turbine generator connected to a power grid. The method may include measuring the frequency, f, of the power grid, controlling the speed of the generator for optimizing the power delivered to the power grid, and setting limits for the generator speed. The setting of the limits for the generator speed is performed in dependency of the measured frequency of the power grid. This provides a dynamical set of limits providing improved possibilities of optimizing the power production.

Owner:VESTAS WIND SYST AS

Device and method for a functional test of one wind turbine generator plant

InactiveUS7231282B2Rapid and reliable functional testReduce amountLevel controlComparison table algorithmsMathematical modelControl signal

A method for a functional test of a wind turbine generator plant which comprises the following procedural steps: a control unit for the wind turbine generator plant reads in actual values from at least one structural part of the wind turbine generator plant and generates control signals for actuators of the wind turbine generator plant, a simulation unit has at least one input and at least one output as well as one or more mathematical models which depict the behaviour of one or more structural parts of the wind turbine generator plant, the control signals are applied to the input of the simulation unit and the modeled actual values of the models on the structural parts are applied to the output of the simulation unit, wherein the actual values of the simulation unit are applied to the input of the control unit and the control signals of the control unit are applied to the input of the simulation unit; the simulation unit models the actual values of the structural parts resulting for the control signals applied, for certain initial conditions.

Owner:NORDEX ENERGY

Variable tip speed ratio tracking control for wind turbines

ActiveUS20090220340A1Increase energy capture power coefficientPropellersComparison table algorithmsTurbine bladeAerodynamic load

The present invention relates to a method of controlling the aerodynamic load of a wind turbine blade by controlling the tip speed ratio (TSR) and / or blade pitch setting of the wind turbine blade so as to optimize power production. A wind turbine blade undergoes an aero-elastic response including deflection and twist that is a function of the blade loading. The blade loading is dependent on the wind speed, TSR, and pitch setting. The aero-elastic response requires a different TSR and / or pitch to be selected throughout the power curve in order to maintain the optimum power production and to improve energy capture.

Owner:GENERAL ELECTRIC CO

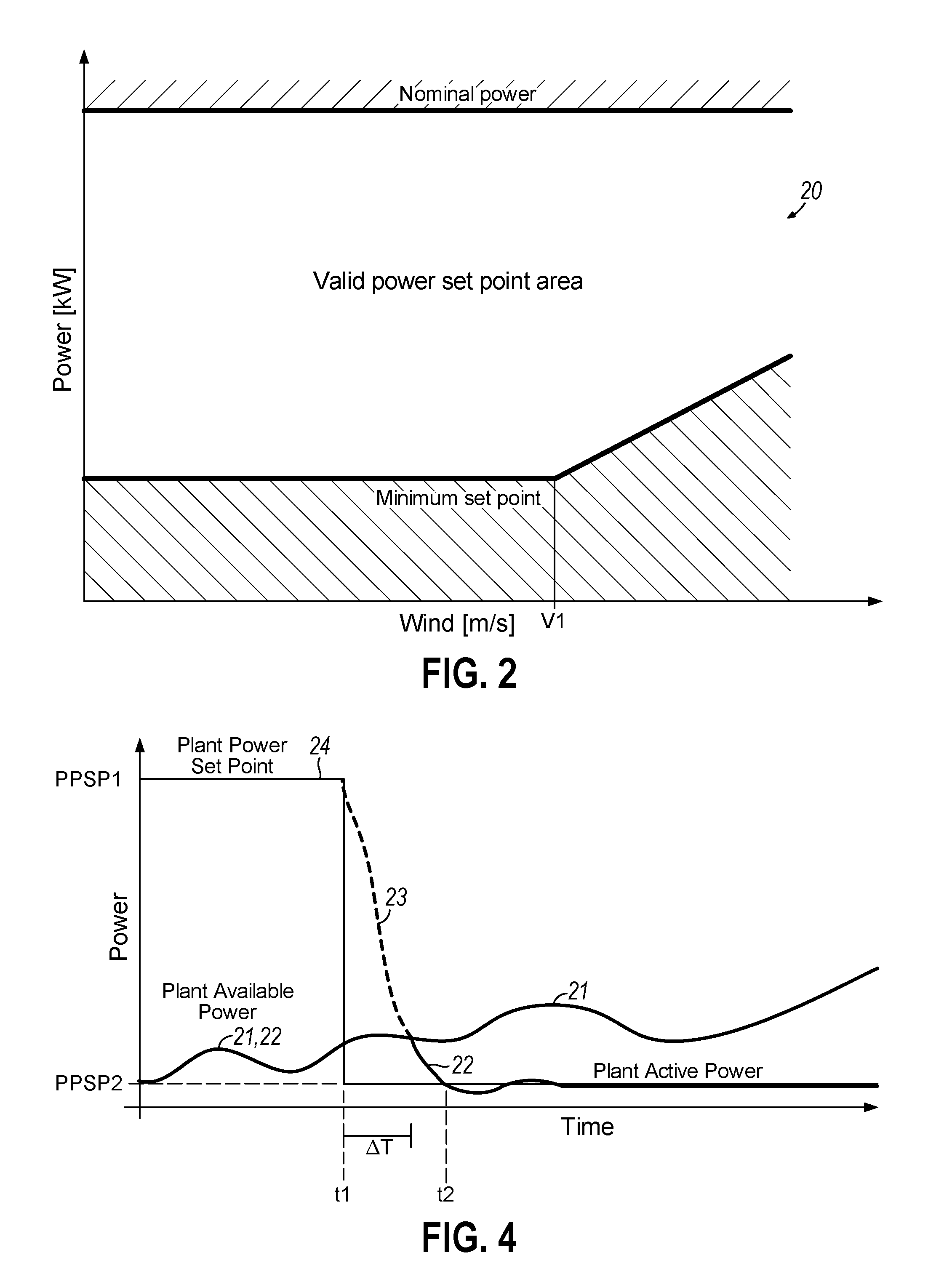

Method of controlling a wind power plant

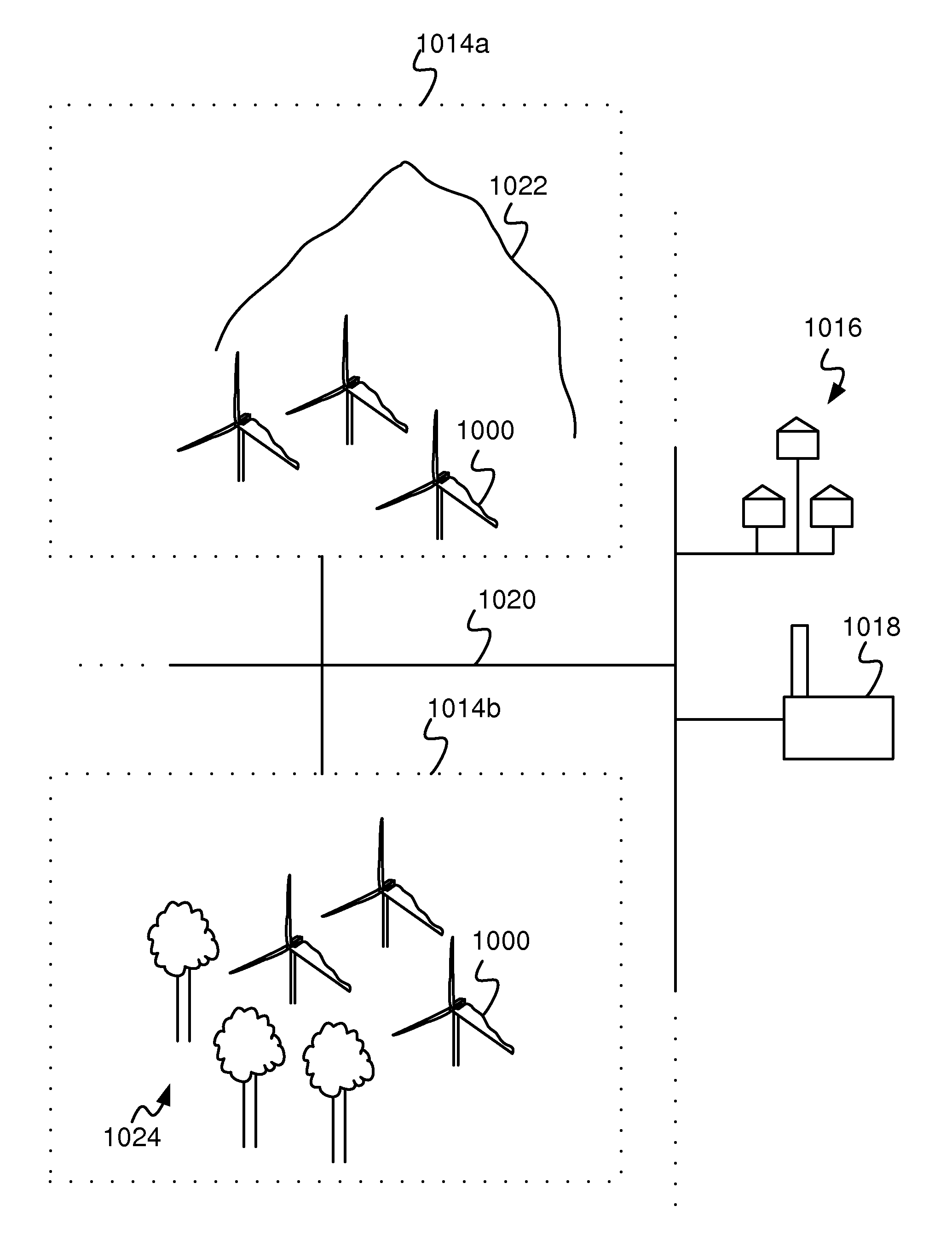

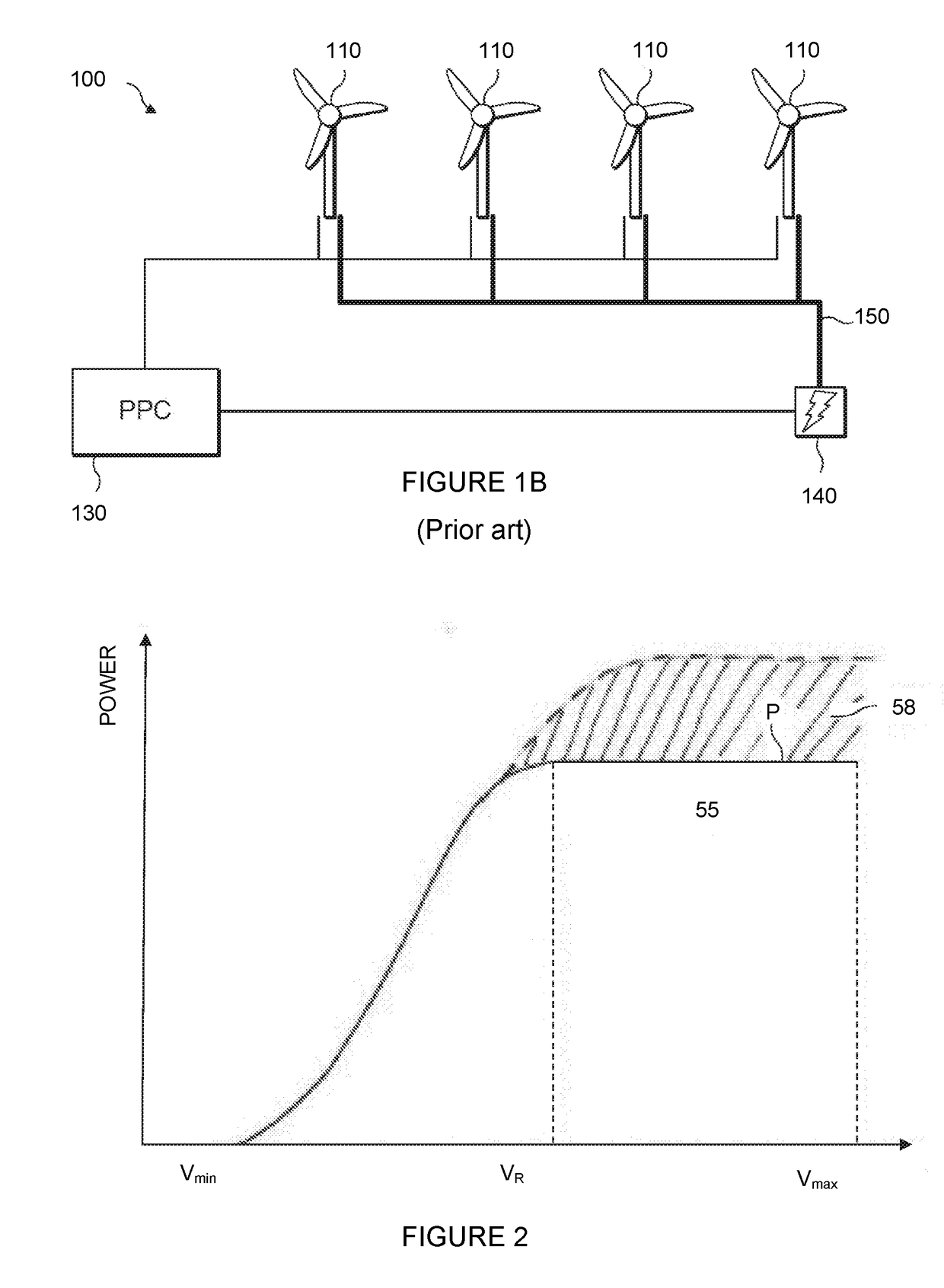

ActiveUS20110182712A1Easy to controlStable power supplyLevel controlWind motor controlPeaking power plantPower station

It is presented a method for controlling the instantaneous power output from a wind power plant. Wind speed and wind directions are determined, wherein an upper limit power output for the specific wind speed and wind direction is determined from a previously measured power output value at the same wind speed and wind direction, and wherein the power output of the wind power plant is controlled based on the determined upper limit power output. A wind power plant is also presented.

Owner:VESTAS WIND SYST AS

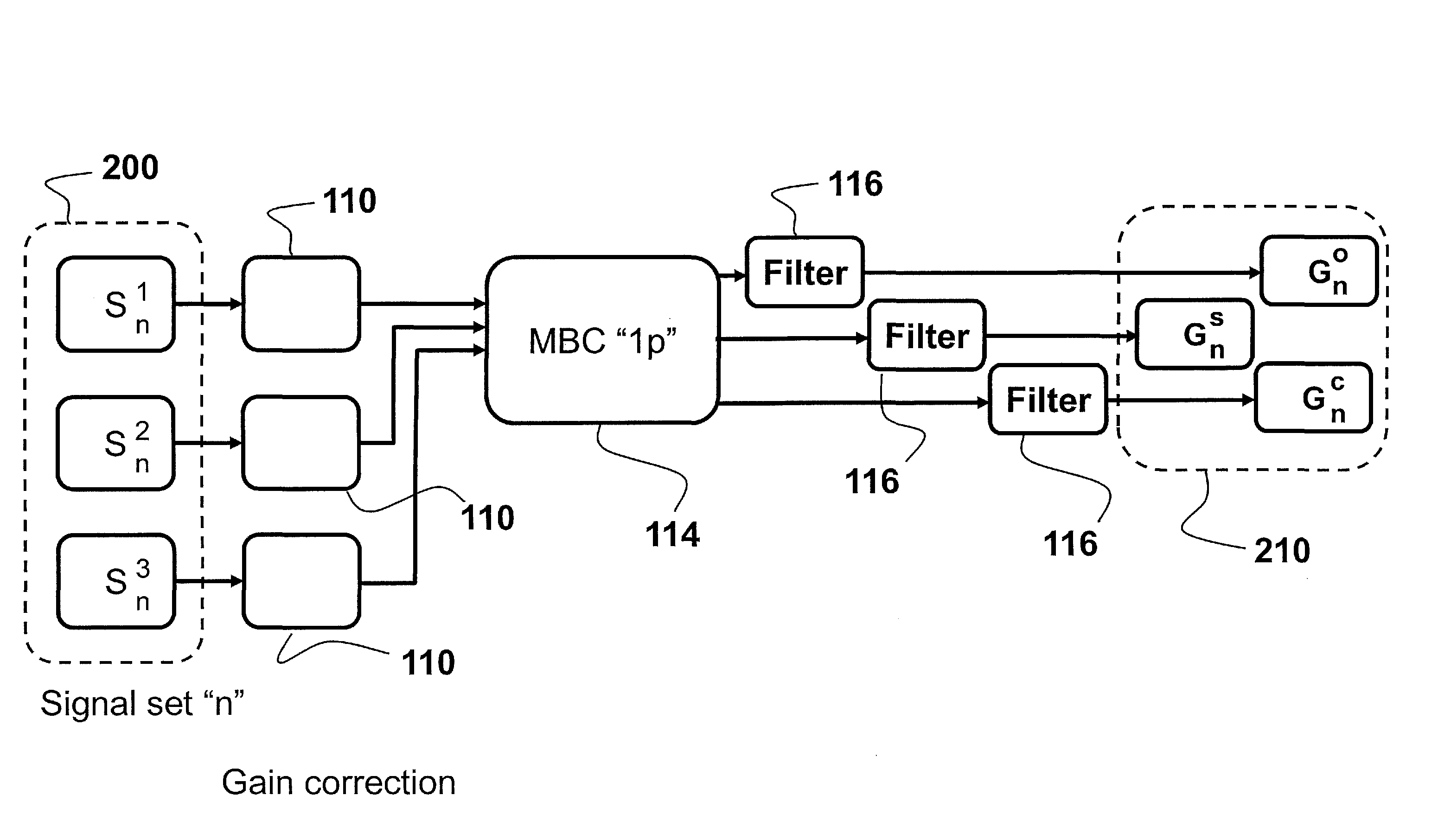

Wind sensor system using blade signals

The present invention relates to a wind-velocity-field measurement system for use in a wind turbine having a rotor with two or more blades, comprising at least one sensor-signal obtained by measuring a physical quantity on at angle least one of the blades, the physical quantity being indicative of at least one wind-velocity-field characteristic; a table (140, 142, 144) build for a plurality of wind conditions by associating values characterizing the at least one sensor-signal with values of the at least one wind-velocity-field characteristic, and; searching means (150, 152, 154) for determining from the table a value of the at least one wind-velocity-field characteristic for a current wind condition given values characterizing the at least one sensor-signal.

Owner:NIDEC SSB WIND SYST GMBH

Blade pitch management method and system

A method for operating a wind turbine. The method includes providing a wind turbine having at least one blade having adjustable pitch angle that is adjusted according to an operational parameter schedule. A blade efficiency parameter is determined in response to a wind speed and a rotor speed. A minimum pitch angle is determined in response to the blade efficiency parameter and the pitch angle of the at least one blade in response to the blade efficiency parameter is maintained to an angle equal to or greater than the minimum pitch angle independent of the operational parameter schedule. A wind turbine plant and a method for servicing a wind turbine are also disclosed.

Owner:GE INFRASTRUCTURE TECH INT LLC

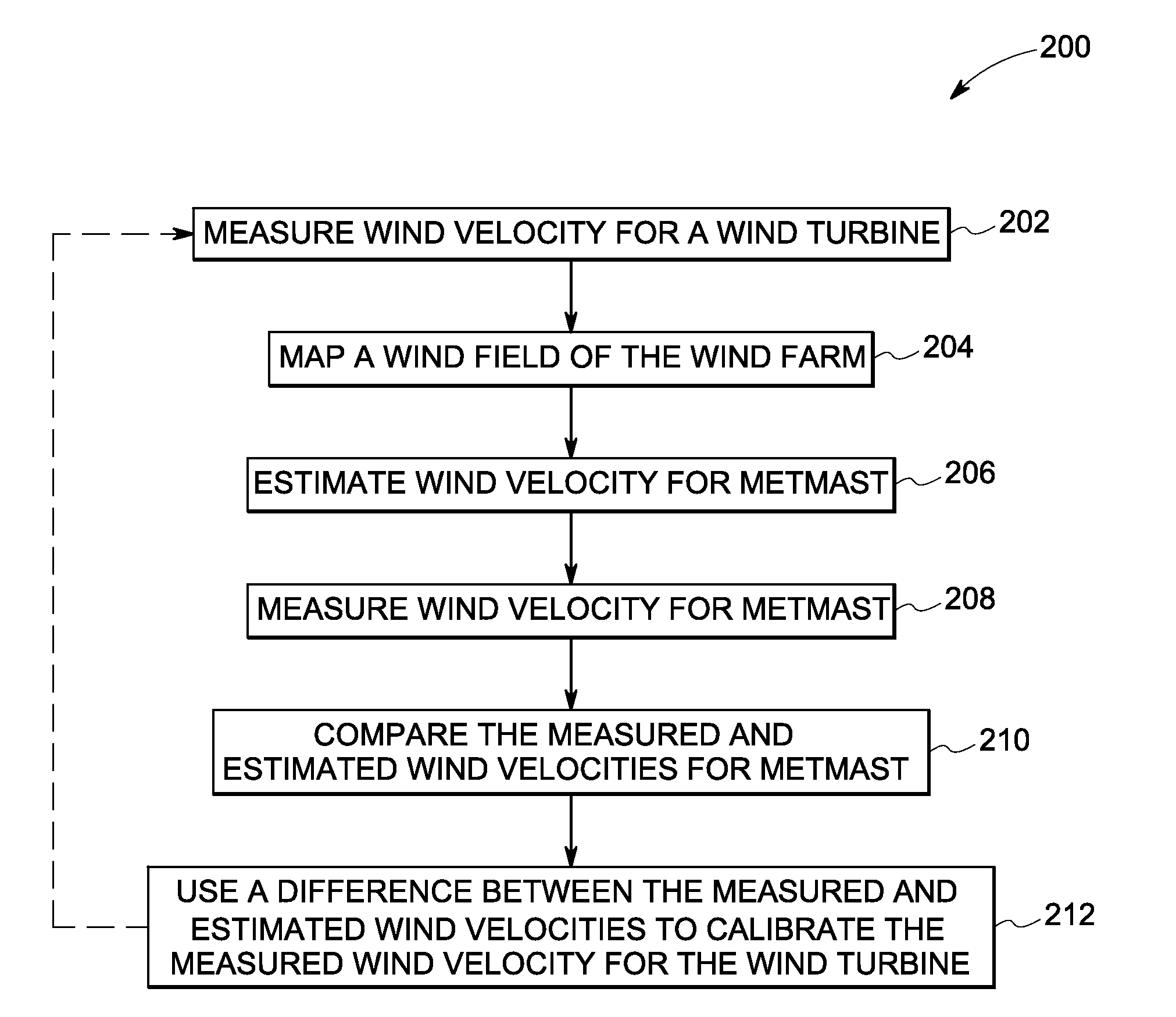

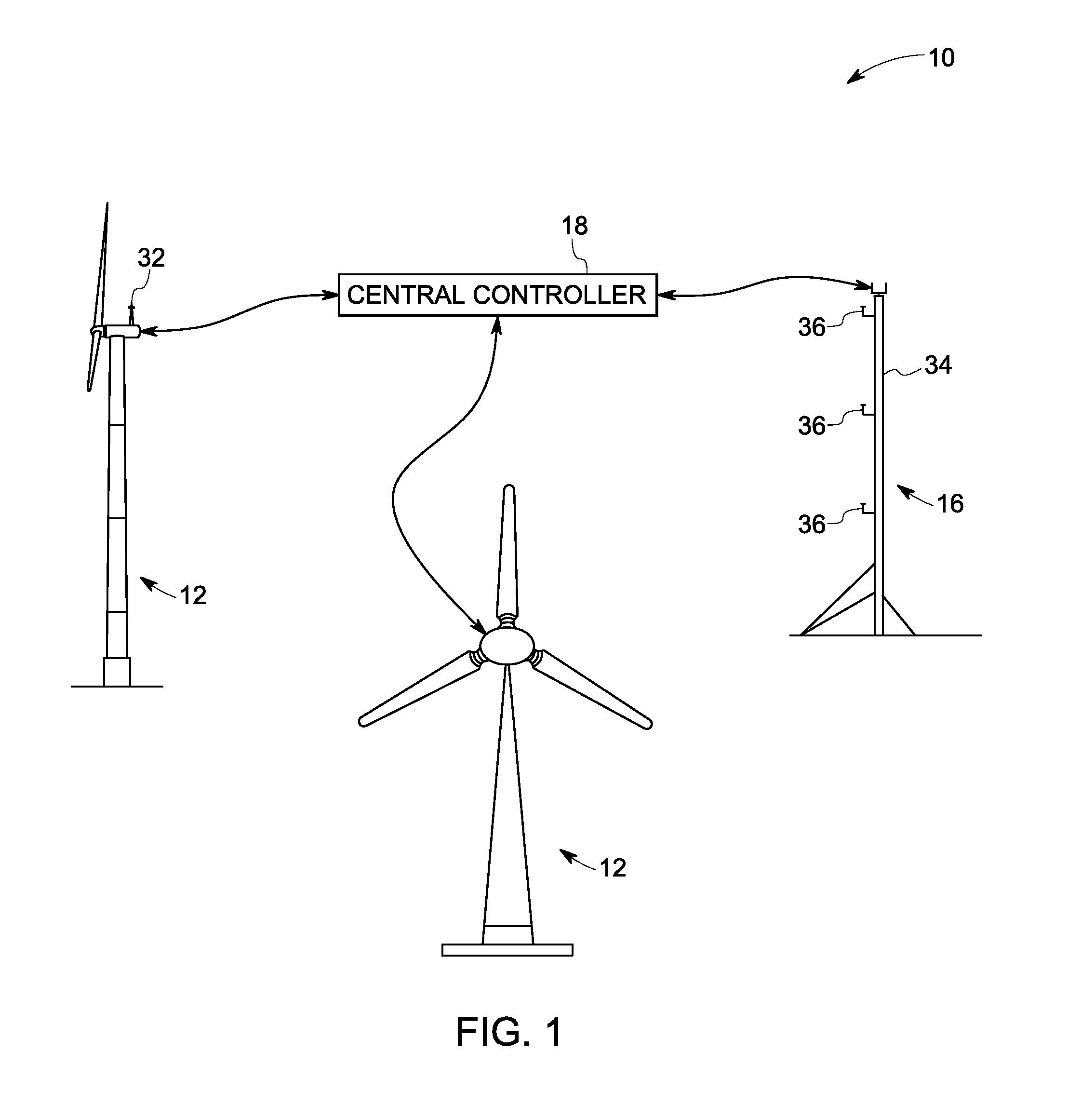

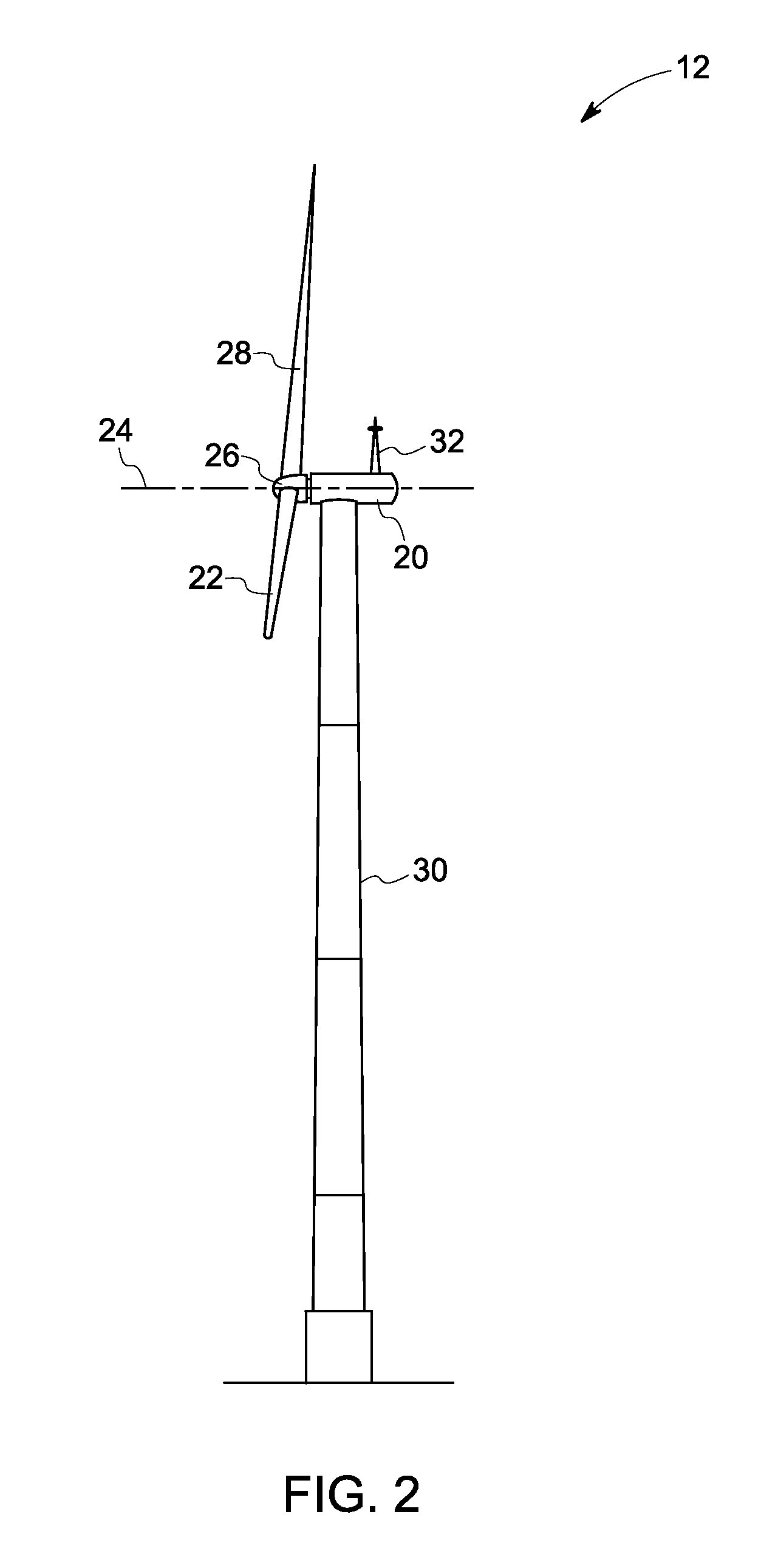

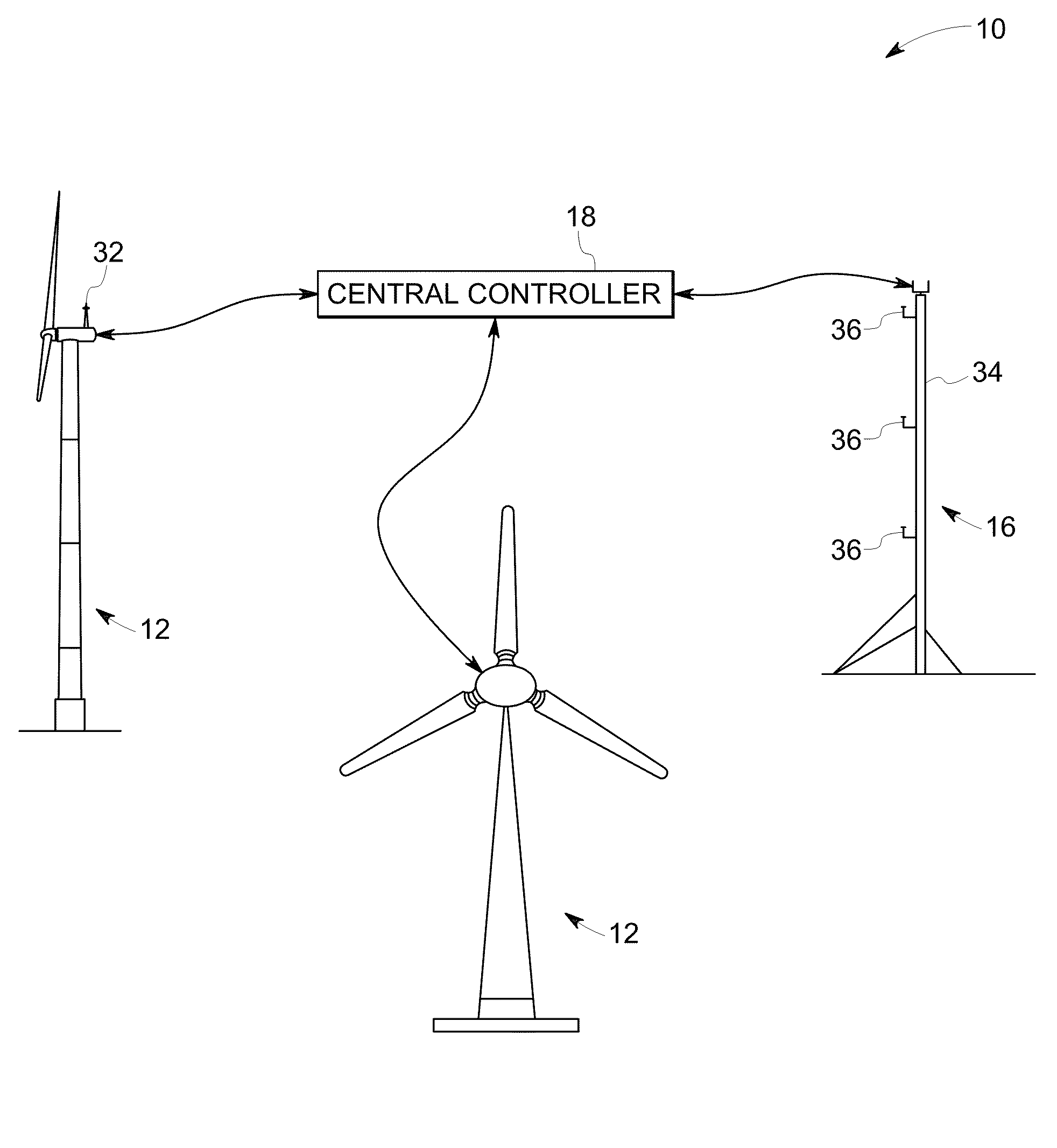

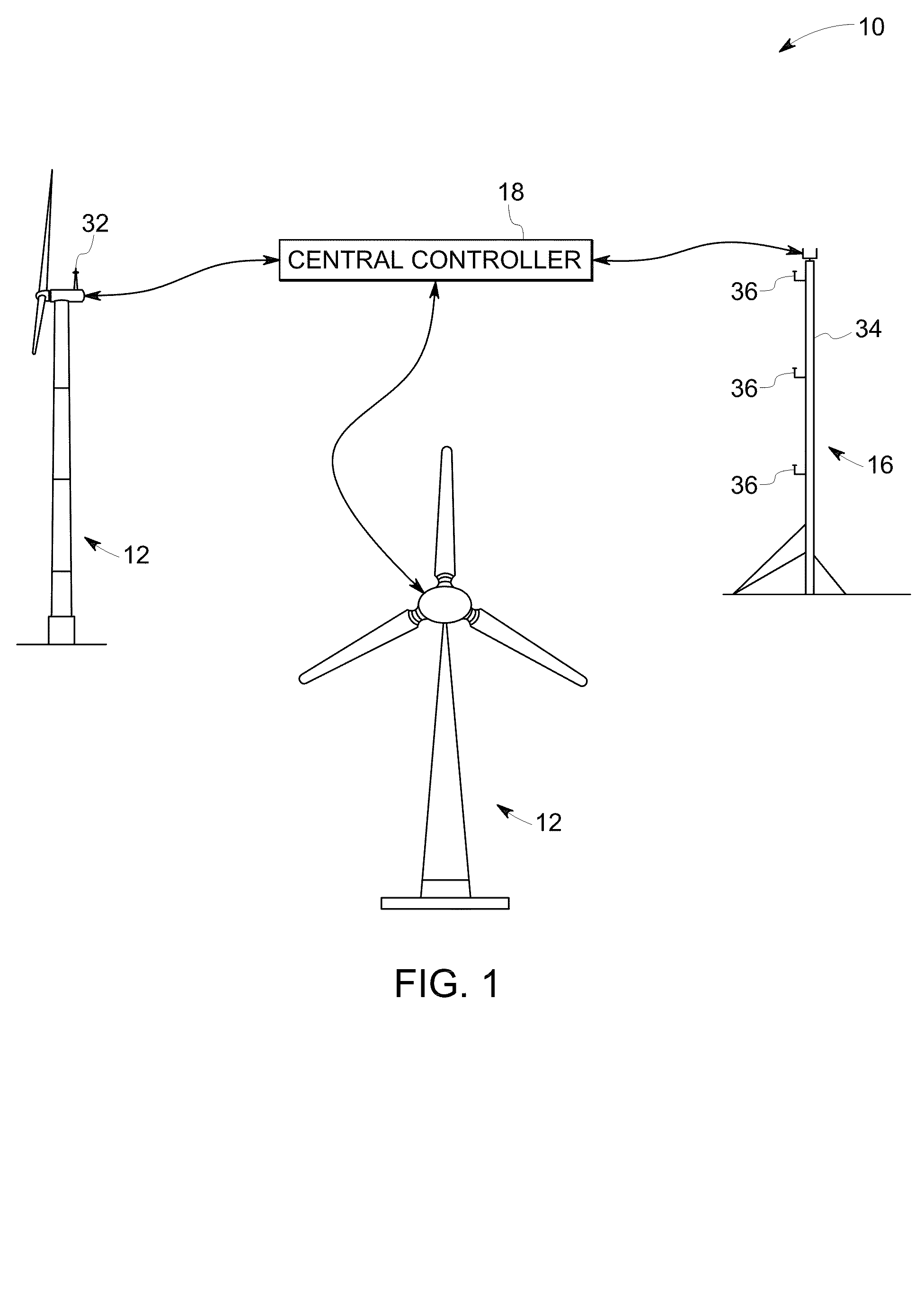

System and method for wind condition estimation

A wind power generation system includes a wind turbine at a wind turbine location, a measuring device for providing a wind condition signal at a test location, a sensor for providing a wind condition signal at the wind turbine, and a controller. The controller is configured for receiving the wind condition signals, using a wind correlation database and the wind condition signal at the test location for providing a wind condition estimation at the wind turbine location, obtaining a difference between the wind condition signal at the wind turbine location and the wind condition estimate at the wind turbine location, and using the difference for adjusting the wind condition signal at the wind turbine location.

Owner:GENERAL ELECTRIC CO

System and method for wind condition estimation

A wind power generation system includes a wind turbine at a wind turbine location, a measuring device for providing a wind condition signal at a test location, a sensor for providing a wind condition signal at the wind turbine, and a controller. The controller is configured for receiving the wind condition signals, using a wind correlation database and the wind condition signal at the test location for providing a wind condition estimation at the wind turbine location, obtaining a difference between the wind condition signal at the wind turbine location and the wind condition estimate at the wind turbine location, and using the difference for adjusting the wind condition signal at the wind turbine location.

Owner:GENERAL ELECTRIC CO

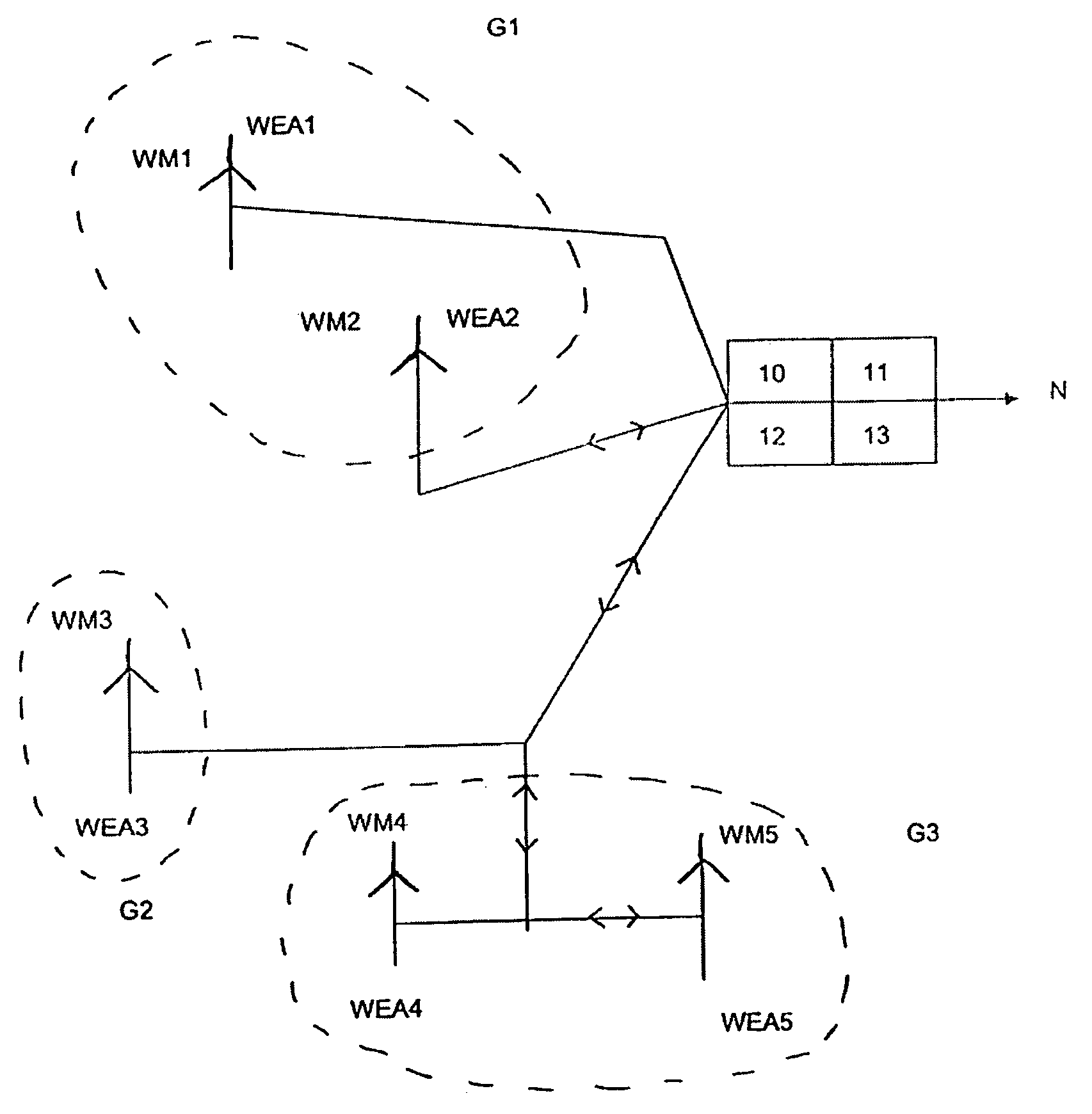

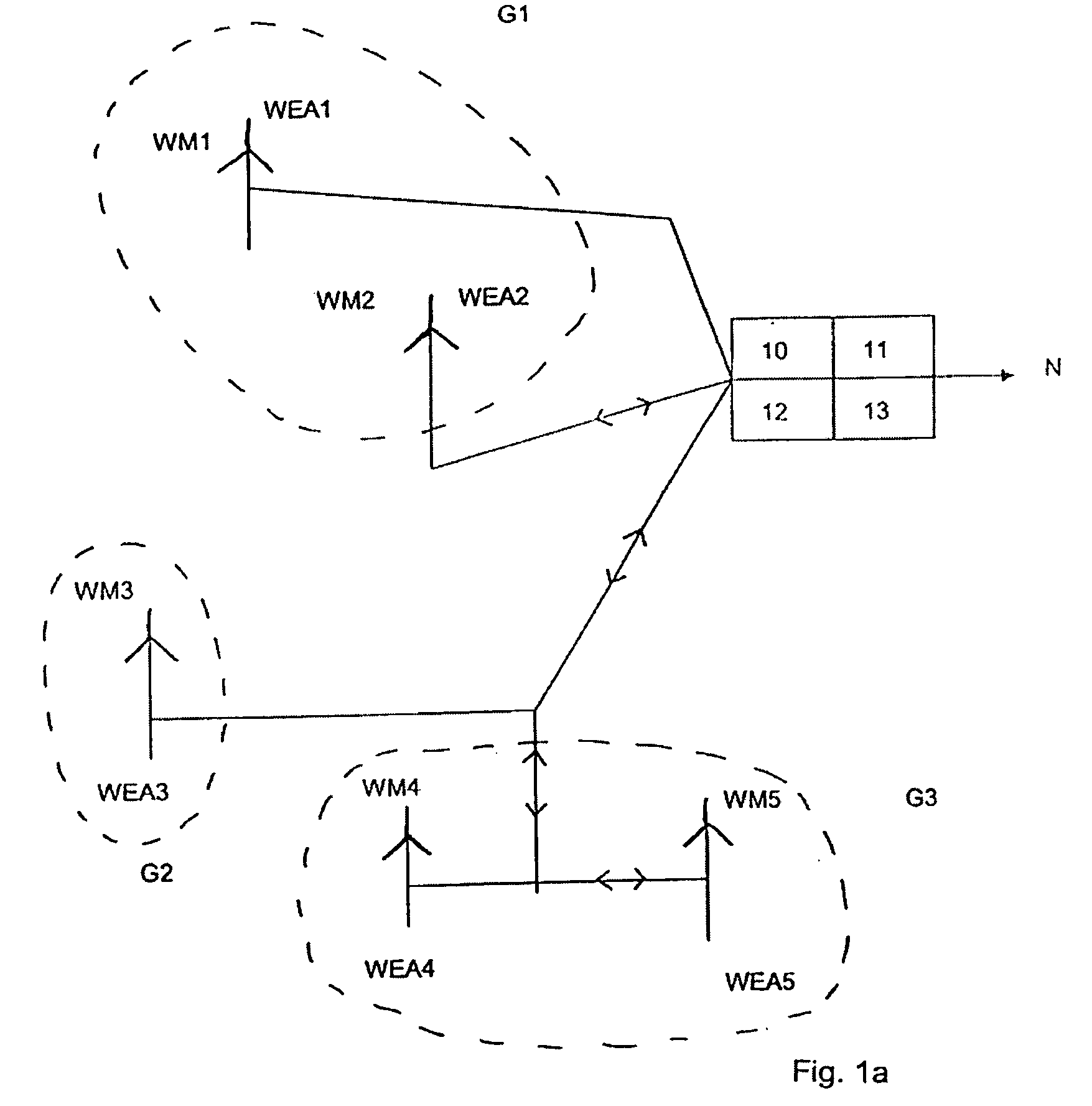

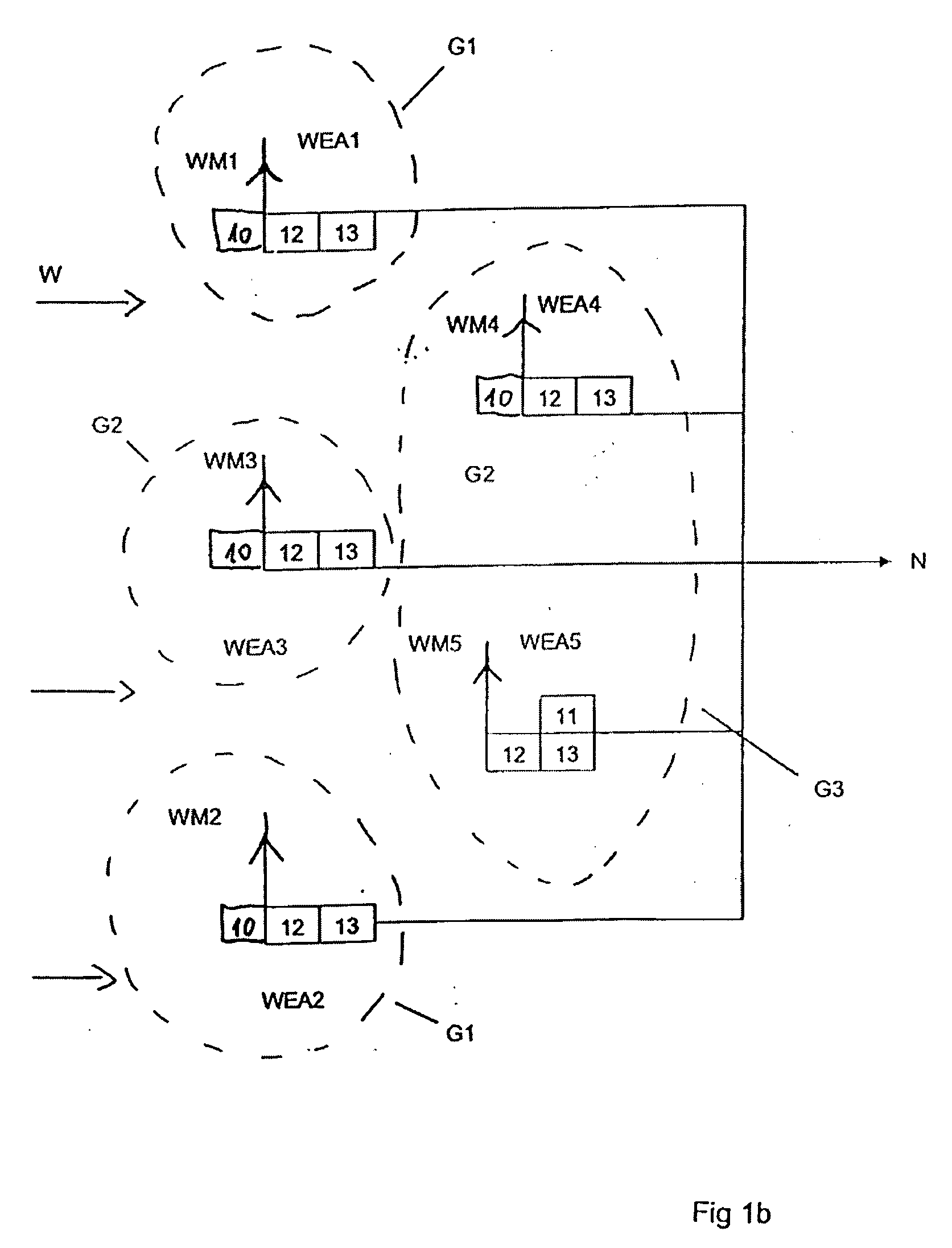

Wind Farm Capable of Staggered Disconnection

The invention relates to a method of operating a wind farm intended for connection to an electric power network, which wind farm includes at least two wind turbine generator systems (WEA1, WEA2, WEA3, WEA4, WEA5). At least one actual value (vt1(WEA1), . . . , vt3(WEA5)) for a wind speed or a parameter associated with wind speed is determined for each of the at least two wind turbine generator systems (WEA1, WEA2, . . . , WEA5), and the at least two wind turbine generator systems (WEA1, WEA2, WEA3, WEA4, WEA5) are divided at least temporarily into at least two predeterminable groups (G1, G2, G3). At least one first disconnect value (At1(G1), At2(G1), At3(G1)) is assigned to each wind turbine generator system of the first group (G1), and at least one second disconnect value (At1(G2), At2(G2), At3(G2)), which is different from the at least one first disconnect value (At1(G1), At2(G1), At3(G1)), is assigned to each wind turbine generator system of the second group (G2). The at least one actual value (vt1(WEA1), . . . , vt3(WEA5)) is assigned one of the disconnect values (At1(G1), . . . , At3(G3)), and the actual values (vt1(WEA1), . . . , vt3(WEA3)) are compared with the assigned disconnect values (At1(G1), . . . , At3(G3)), and, when a disconnect value (At1(G1), . . . , At3(G3)) is exceeded by the assigned actual value (vt1(WEA1), . . . , vt3(WEA3)), the wind turbine generator system or group of wind turbine generator systems (G1, G2, G3) which is assigned to the disconnect value (At1(G1), . . . , At3(G3)) is automatically disconnected.

Owner:SENVION GMBH

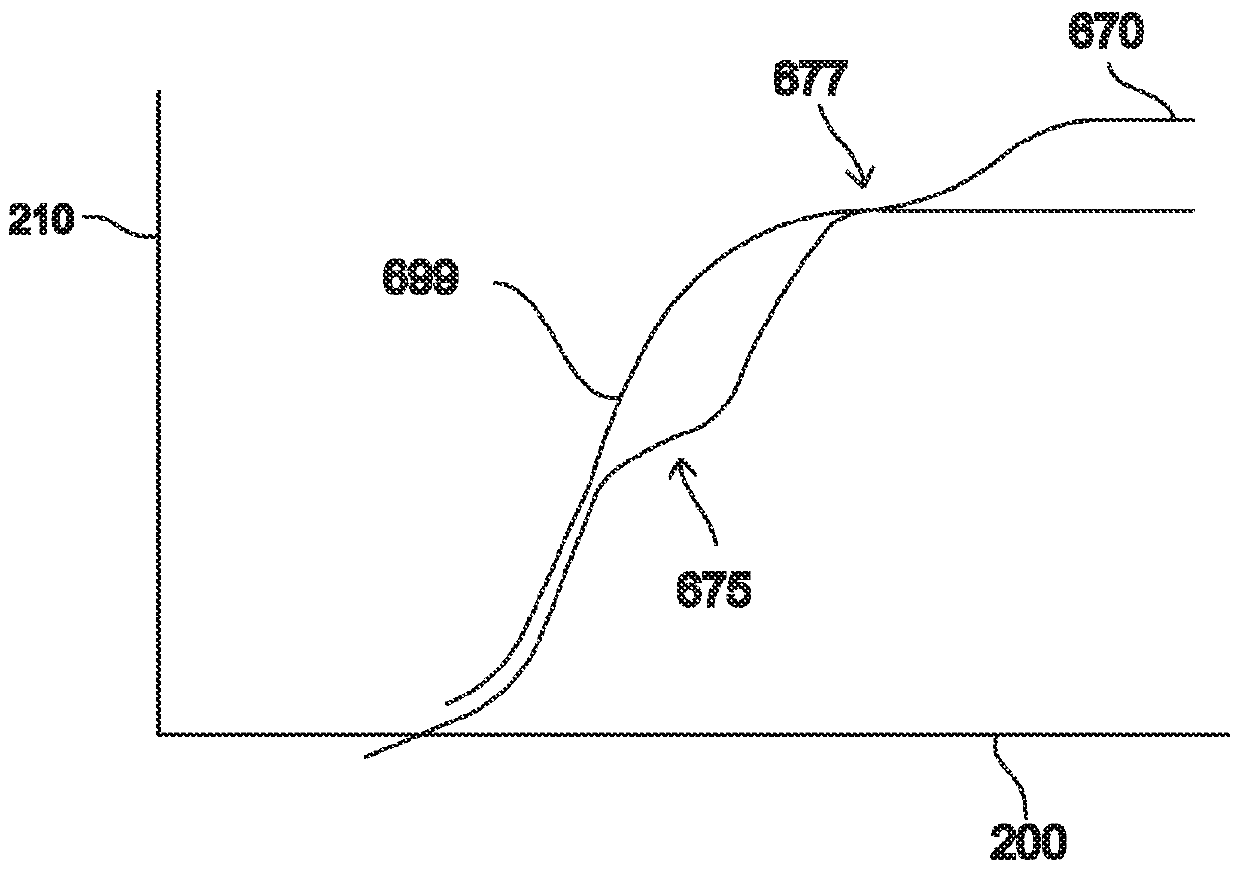

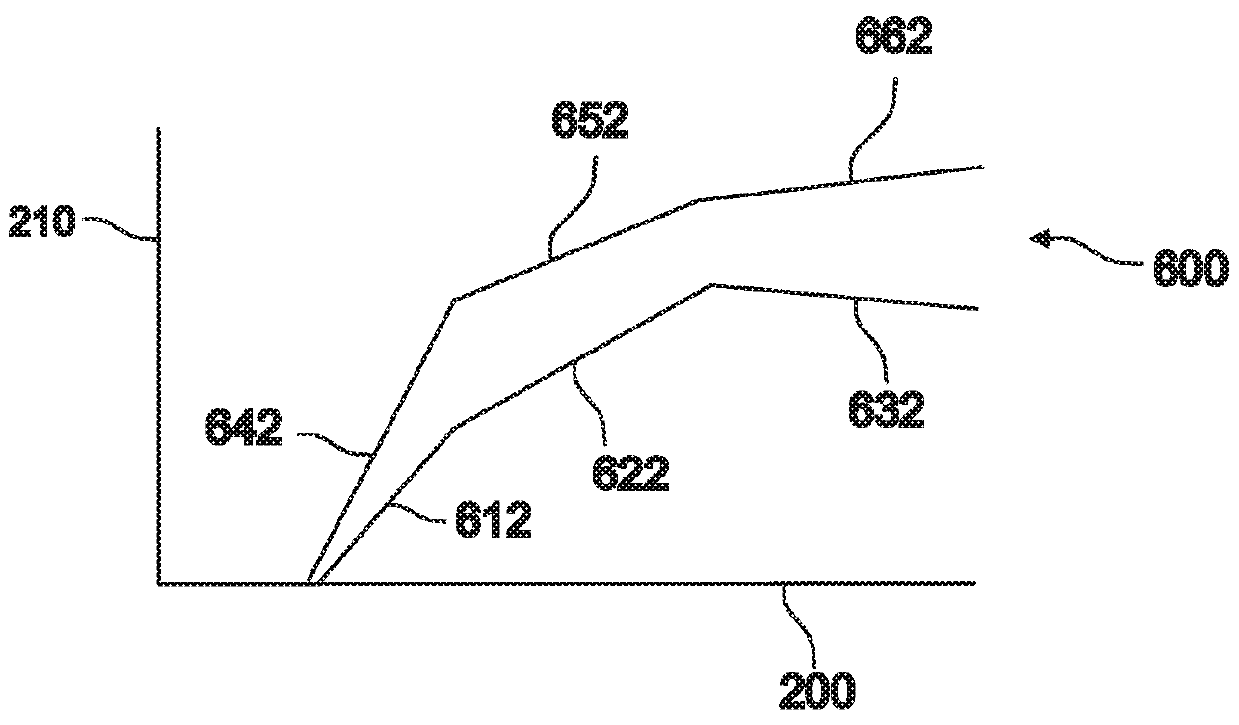

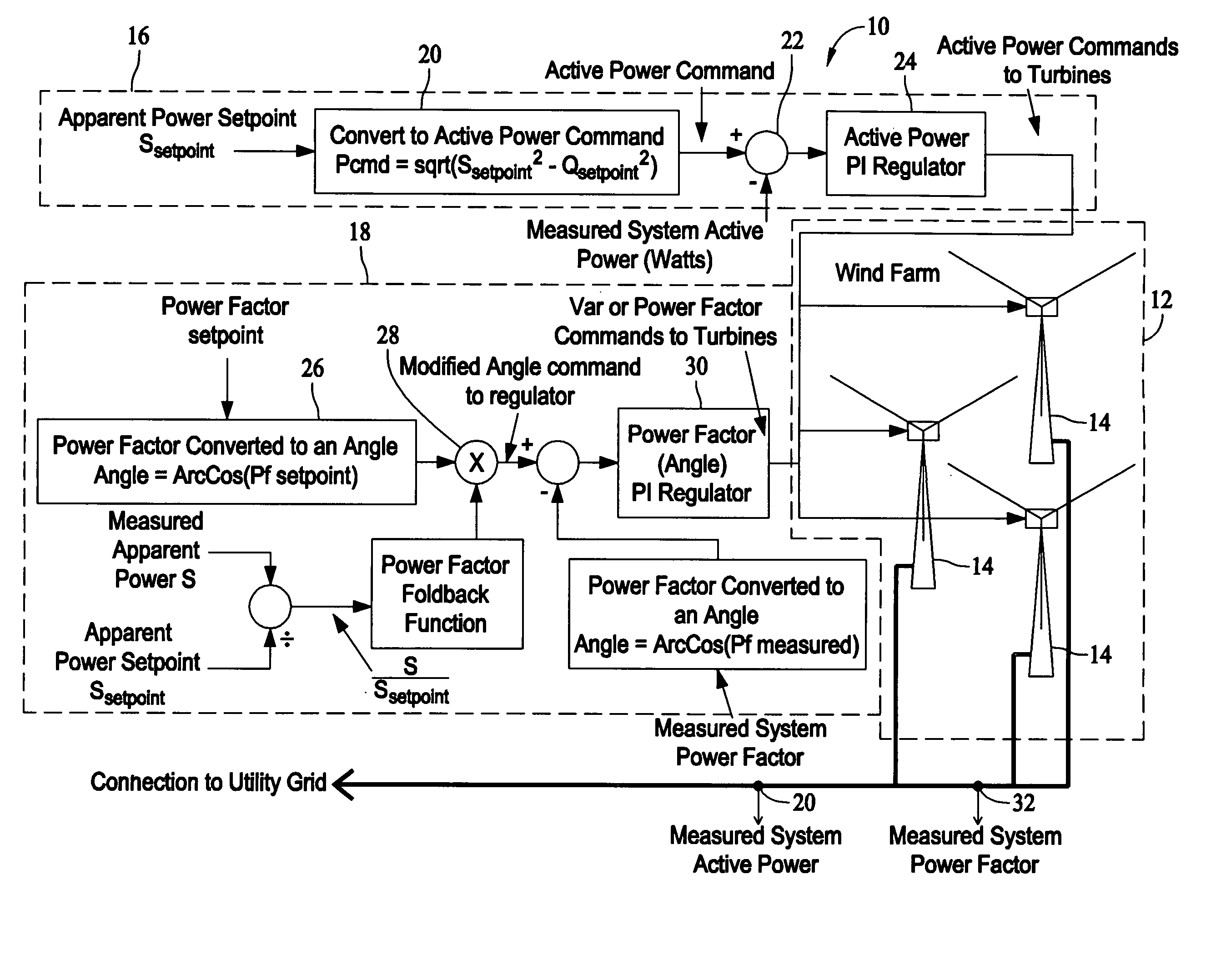

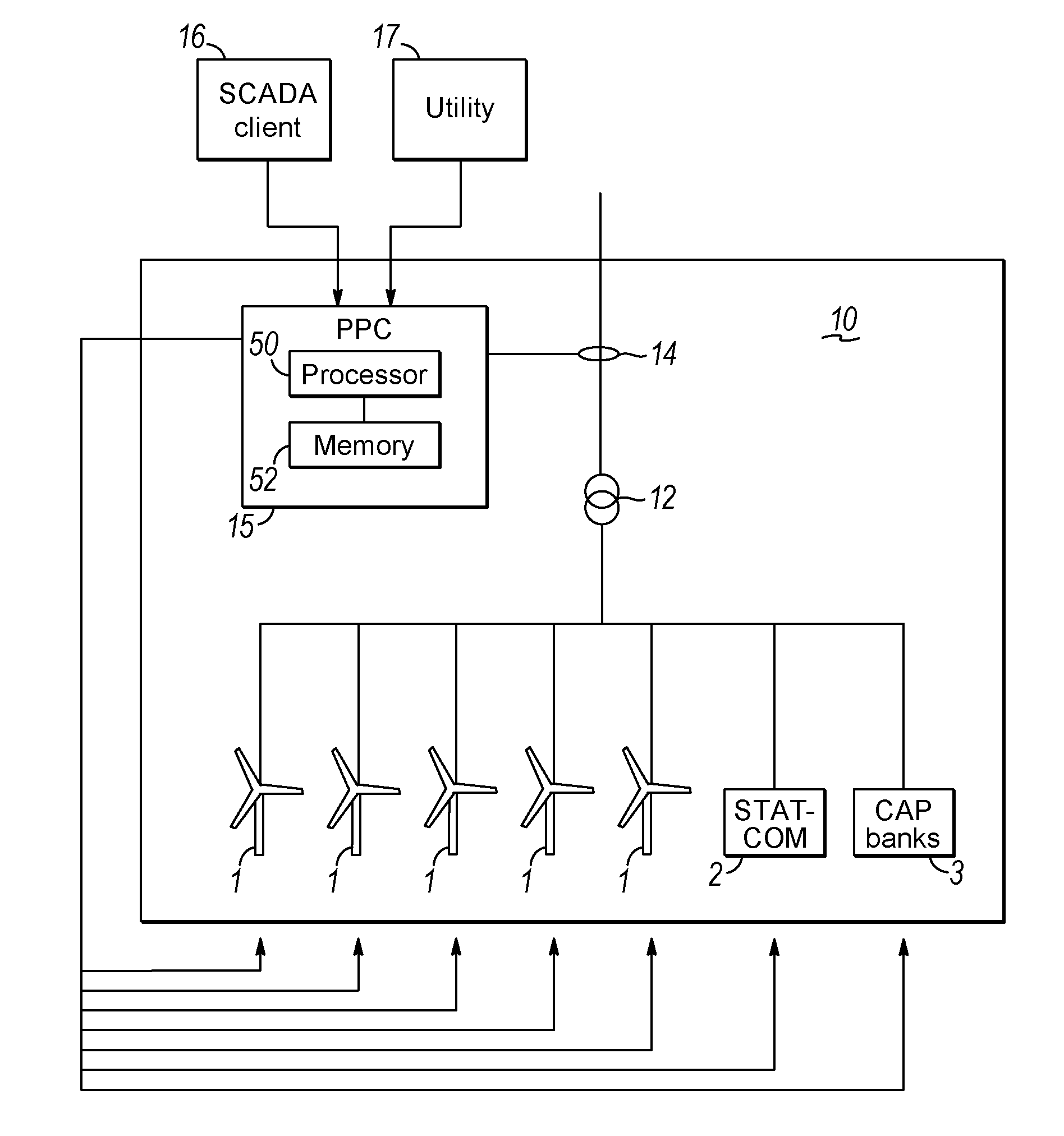

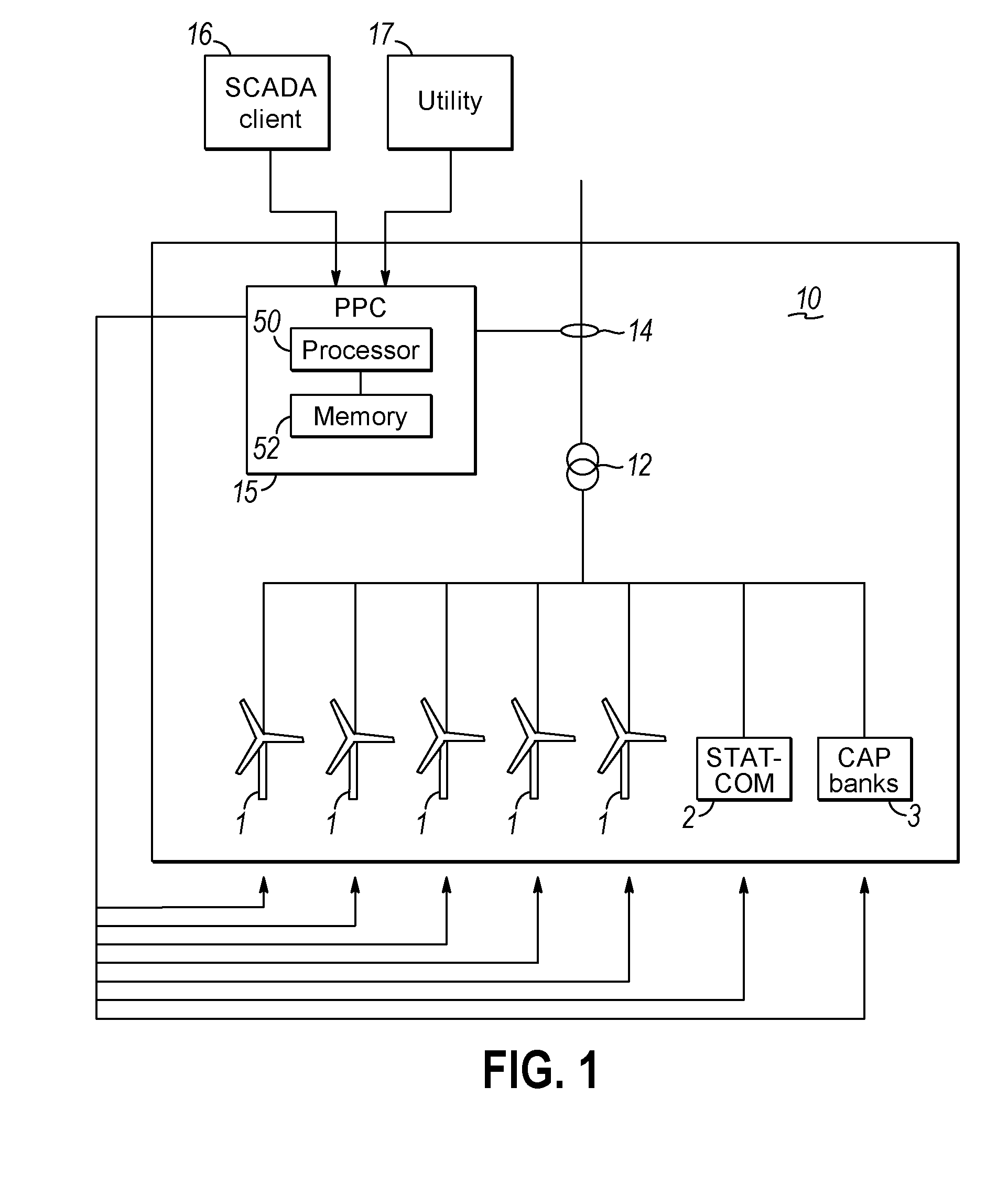

Methods and apparatus for controlling windfarms and windfarms controlled thereby

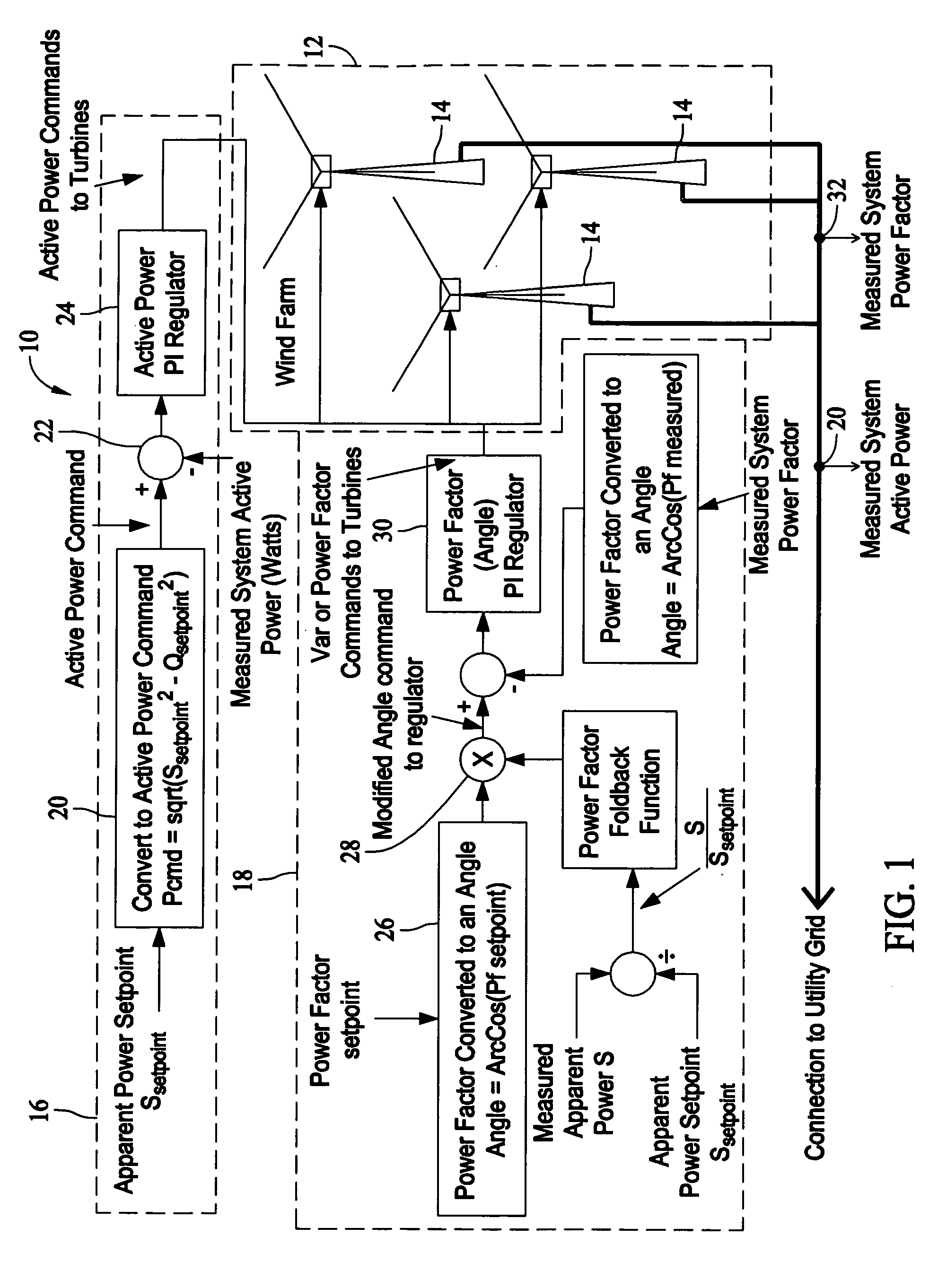

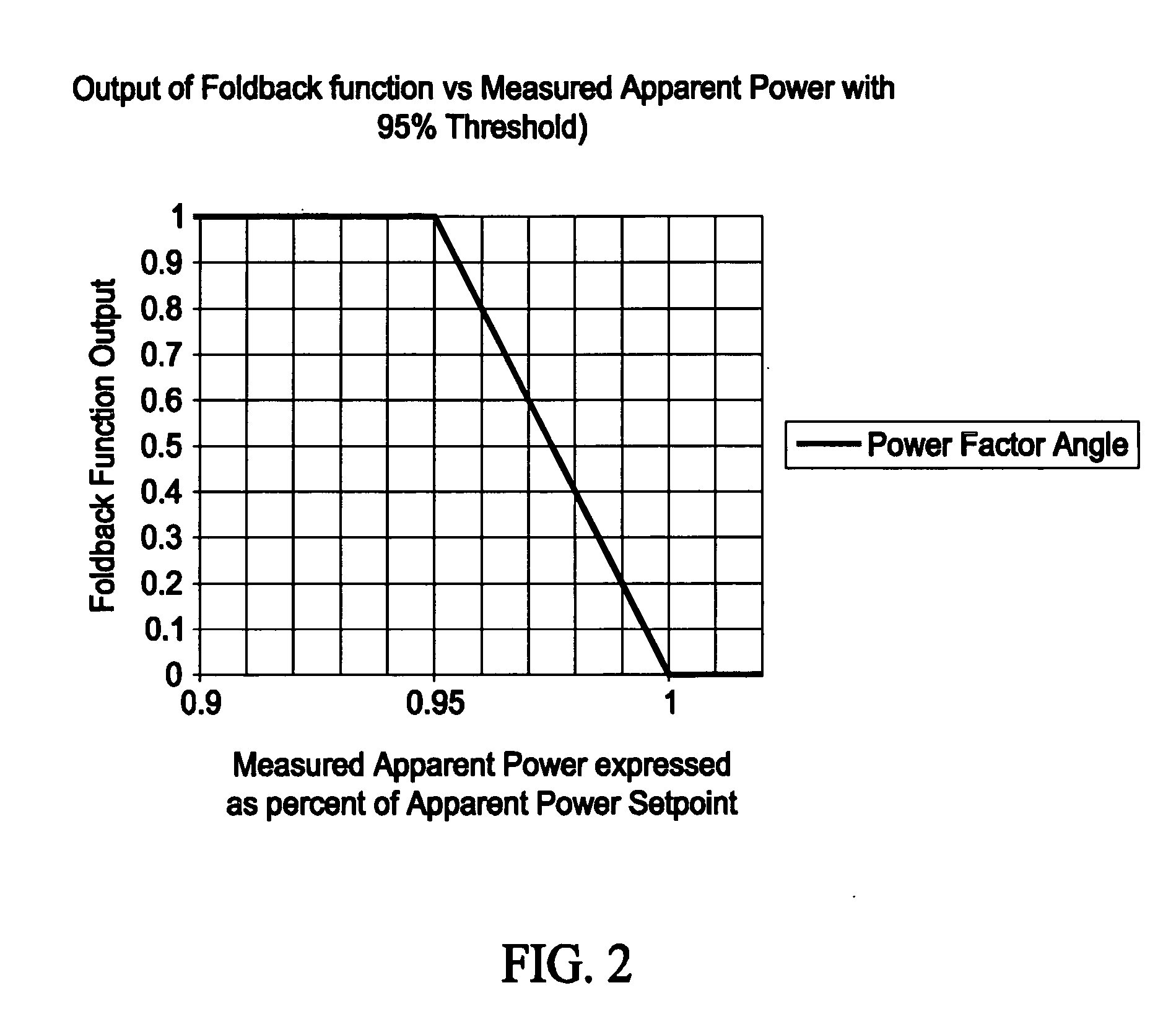

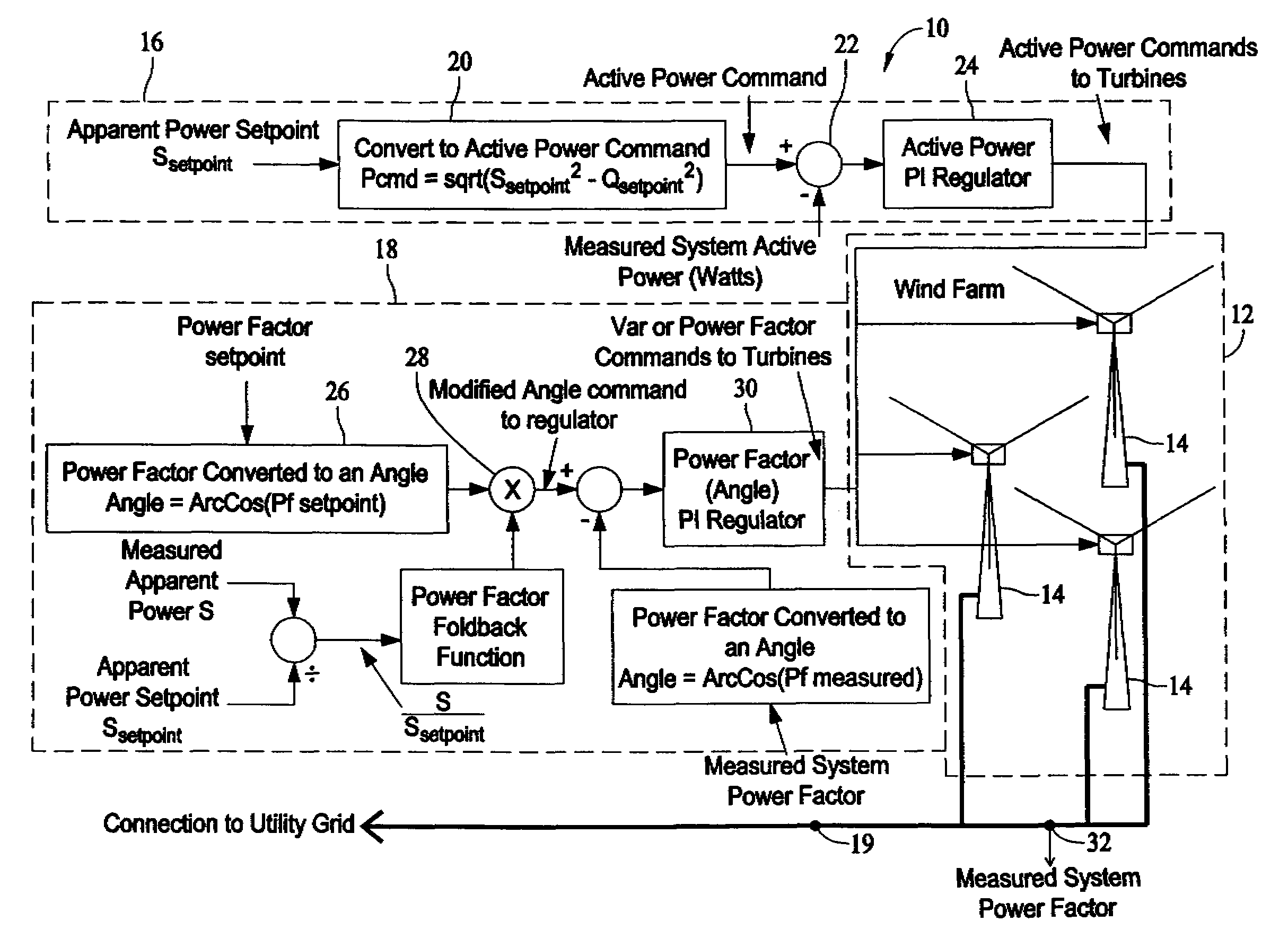

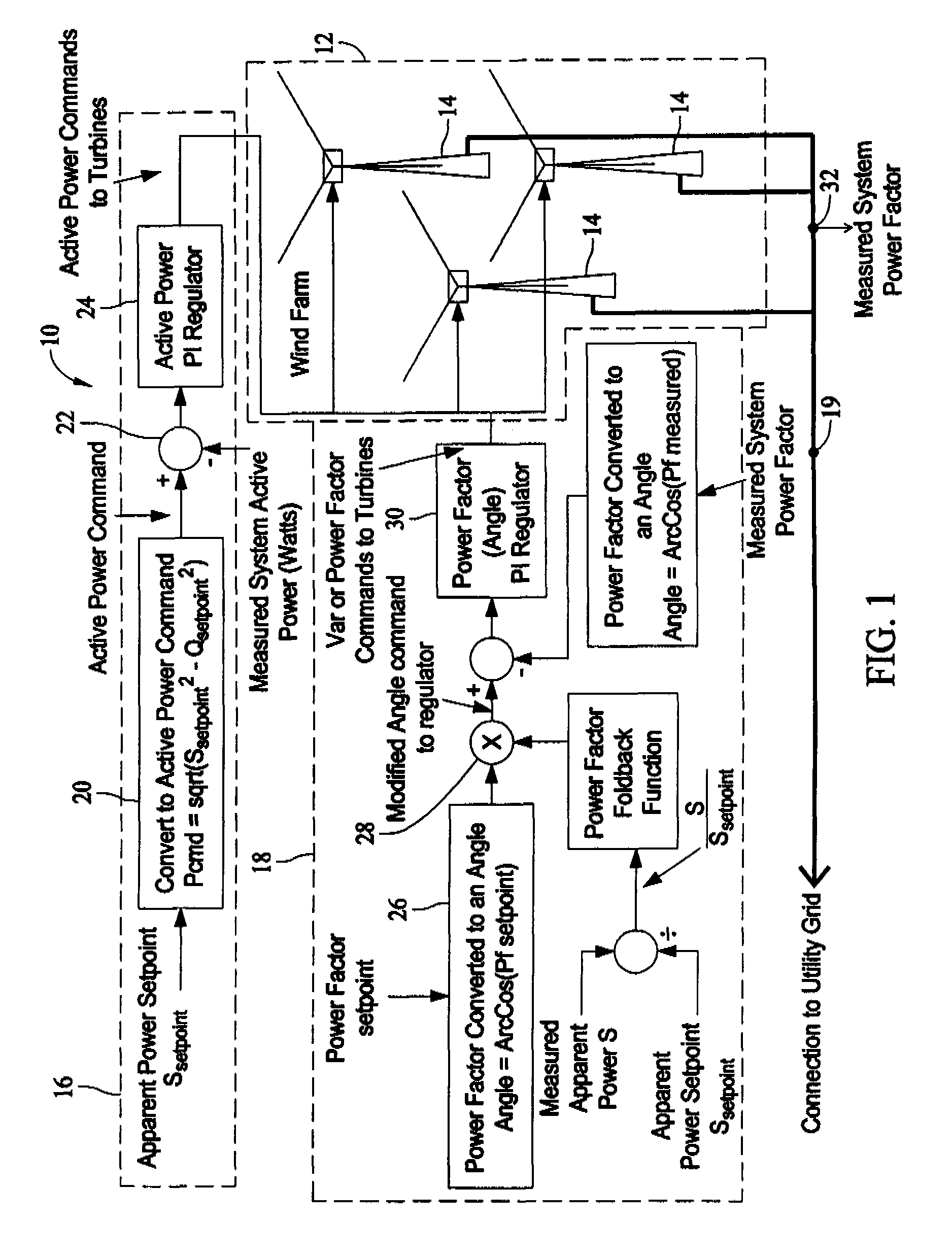

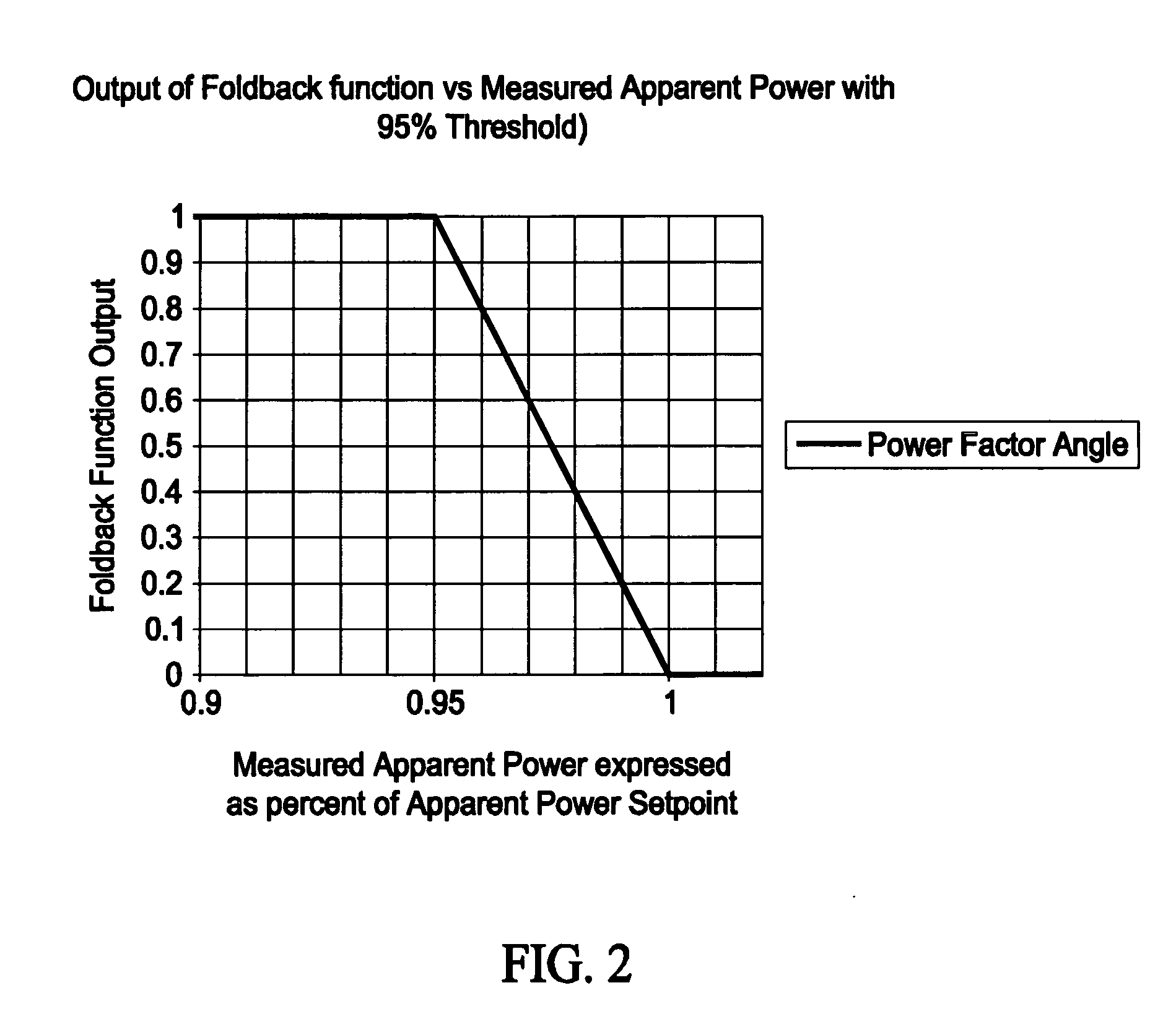

ActiveUS20070018510A1Weakening rangeWind motor controlComparison table algorithmsPower factorSet point

A method for controlling power produced by a windfarm includes regulating active power produced by the windfarm in accordance with an apparent power setpoint, and regulating a power factor of the windfarm in accordance with a power factor setpoint. However, during periods in which the apparent power setpoint is approached or exceeded, the method includes reducing a magnitude of an angle of a power factor setpoint towards zero and regulating the power factor of the windfarm in accordance with the reduced power factor setpoint angle magnitude.

Owner:GENERAL ELECTRIC CO

Detecting blade structure abnormalities

Owner:VESTAS WIND SYST AS

Extreme load control

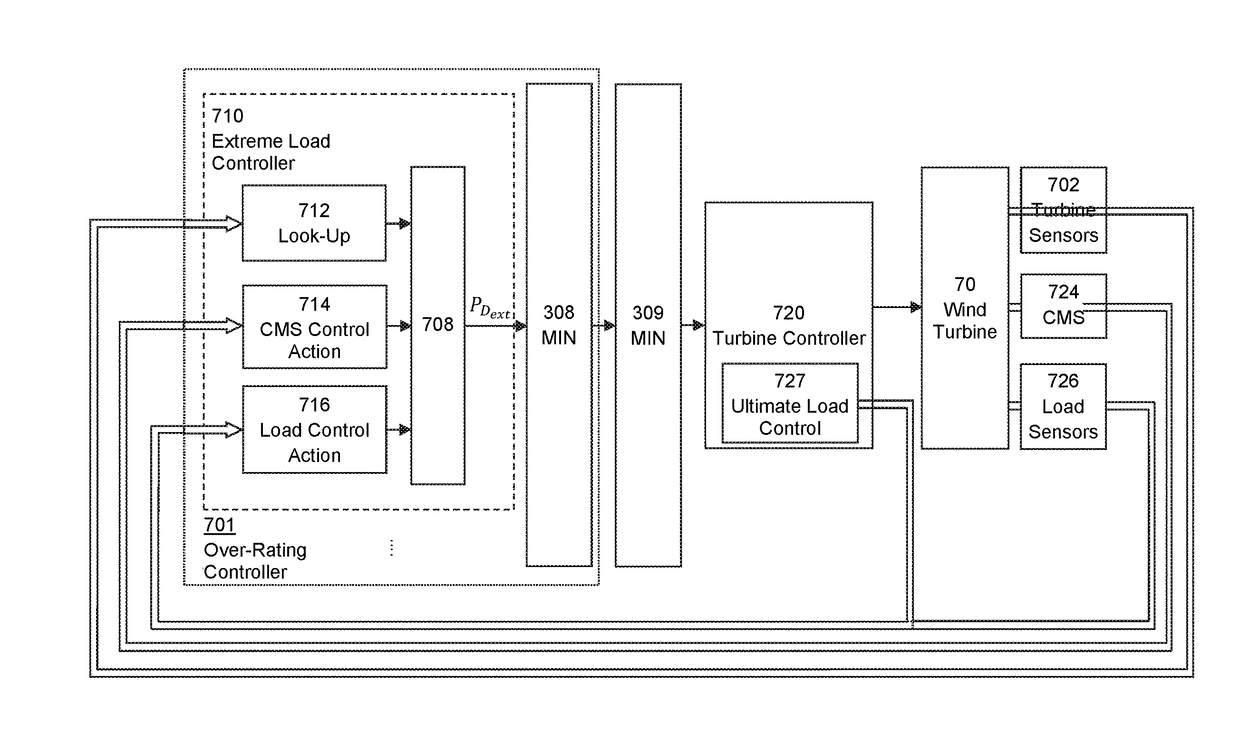

ActiveUS20180171978A1Reduce riskProduced in advanceSafety arrangmentsComparison table algorithmsPeaking power plantPower station

Methods for calculating a maximum safe over-rated power demand for a wind turbine operating in non-standard conditions include the steps of determining a value indicative of a risk of exceeding an ultimate design load during operation in a standard operating condition, and establishing a maximum over-rated power demand corresponding to a maximum power that the turbine may produce under the non-standard operating condition without incurring an increased risk of exceeding the ultimate design load, with respect to operation in the standard condition. A method of over-rating a wind turbine, a wind turbine controller, a wind turbine and a wind power plant are also claimed.

Owner:VESTAS WIND SYST AS

Methods and apparatus for controlling windfarms and windfarms controlled thereby

A method for controlling power produced by a windfarm includes regulating active power produced by the windfarm in accordance with an apparent power setpoint, and regulating a power factor of the windfarm in accordance with a power factor setpoint. However, during periods in which the apparent power setpoint is approached or exceeded, the method includes reducing a magnitude of an angle of a power factor setpoint towards zero and regulating the power factor of the windfarm in accordance with the reduced power factor setpoint angle magnitude.

Owner:GE INFRASTRUCTURE TECH INT LLC

Method and system for operating a wind turbine

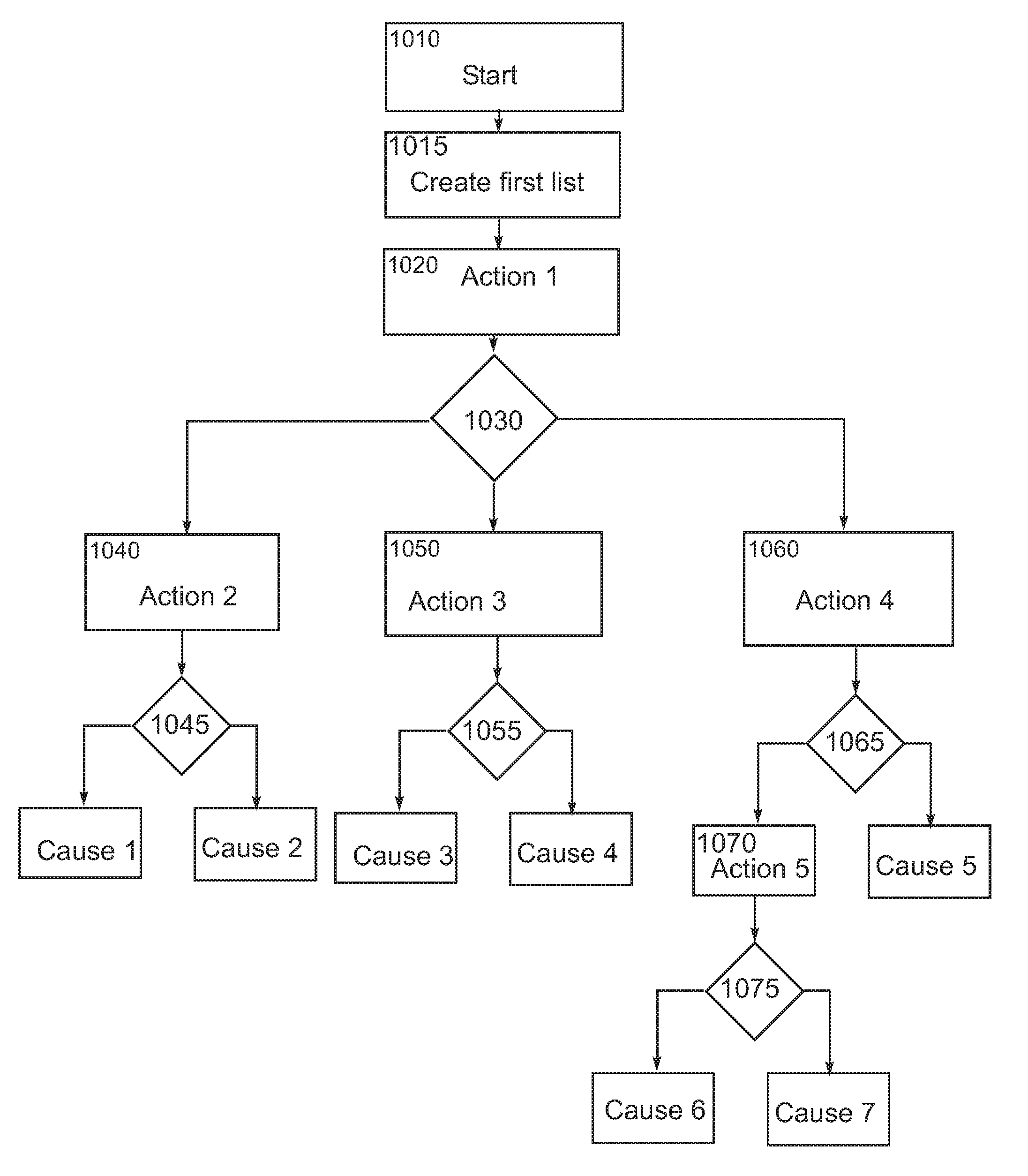

The Disclosure relates to a method for operating a wind turbine comprising: (a) monitoring a wind turbine including: receiving at least one value of at least one sensor and comparing the at least one value with at least one reference; and, determining depending on the comparison between the at least one value with at least one reference whether a malfunction of the wind turbine is present; (b) determining the cause of the malfunction of the wind turbine depending on at least one of: the sensor type of the at least one sensor or the at least one measured value, wherein the cause determination includes: automatically creating a first list comprising at least one possible cause of the malfunction depending on at least one of the sensor type of the at least one sensor or the at least one measured value; and automatically creating a second list comprising a sequence of at least two steps, wherein a first step of the second list is based on the a cause selected from the first list and a second step of the second list is automatically determined based on a result of the first step.

Owner:GENERAL ELECTRIC CO

Control of a wind power plant

ActiveUS8694173B2Lower latencyHigh power outputLevel controlWind motor controlPower stationEngineering

Methods for controlling a wind power plant that includes a plurality of wind turbines being operatively connected to a plant collector grid a power plant controller, a wind power plant, and a computer program product. The method may include generating an actual power reference signal in response to a determination of the power production of the wind power plant and comparing a desired power reference signal with the actual power reference signal. The method may include either applying a first filter characteristic as part of a generation of a wind turbine power reference if the desired power reference signal exceeds the actual power reference signal, or applying a second filter characteristic as part of the generation of the wind turbine power reference if the actual power reference signal exceeds the desired power reference signal. The first filter characteristic is different from the second filter characteristic.

Owner:VESTAS WIND SYST AS

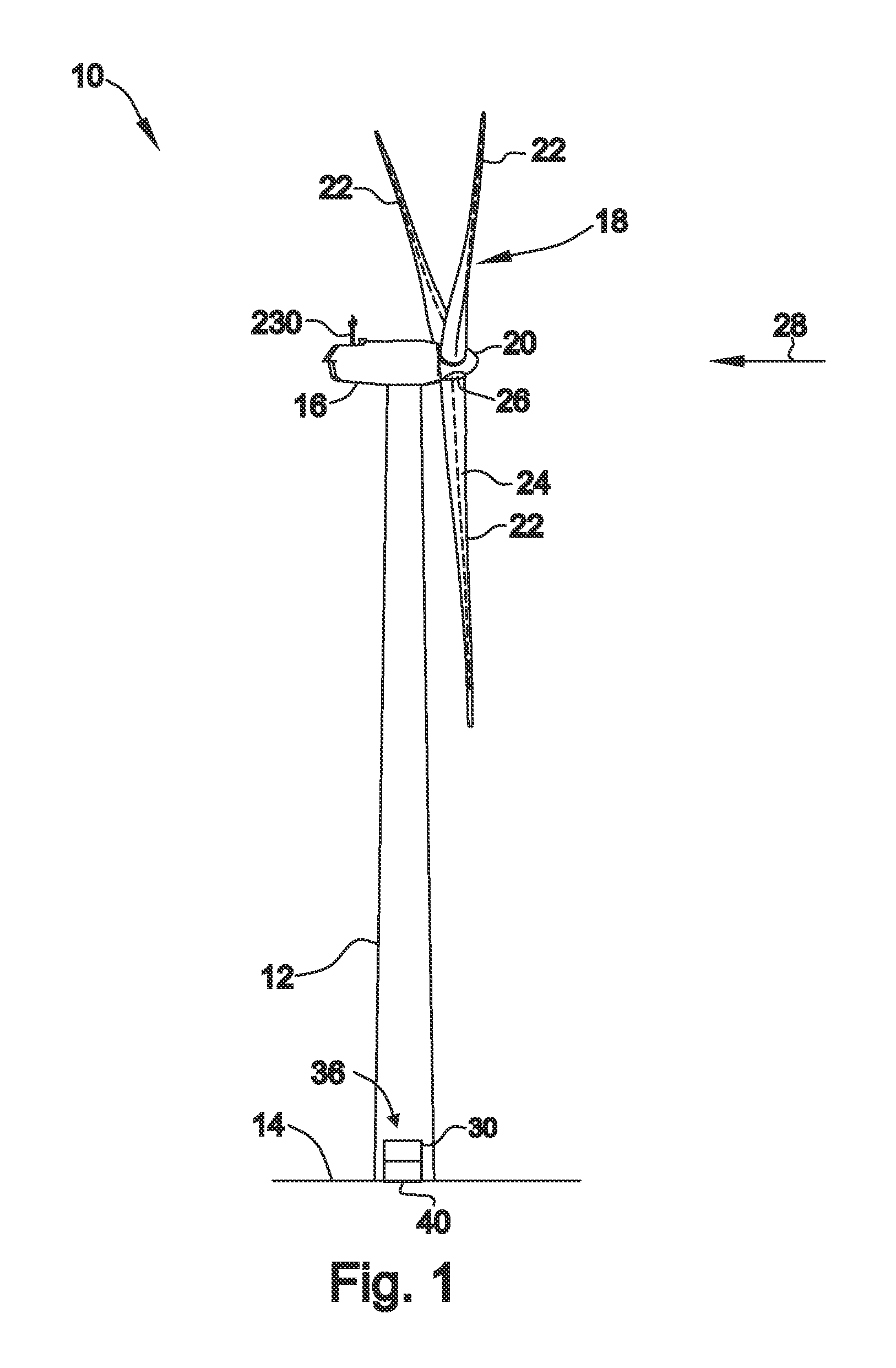

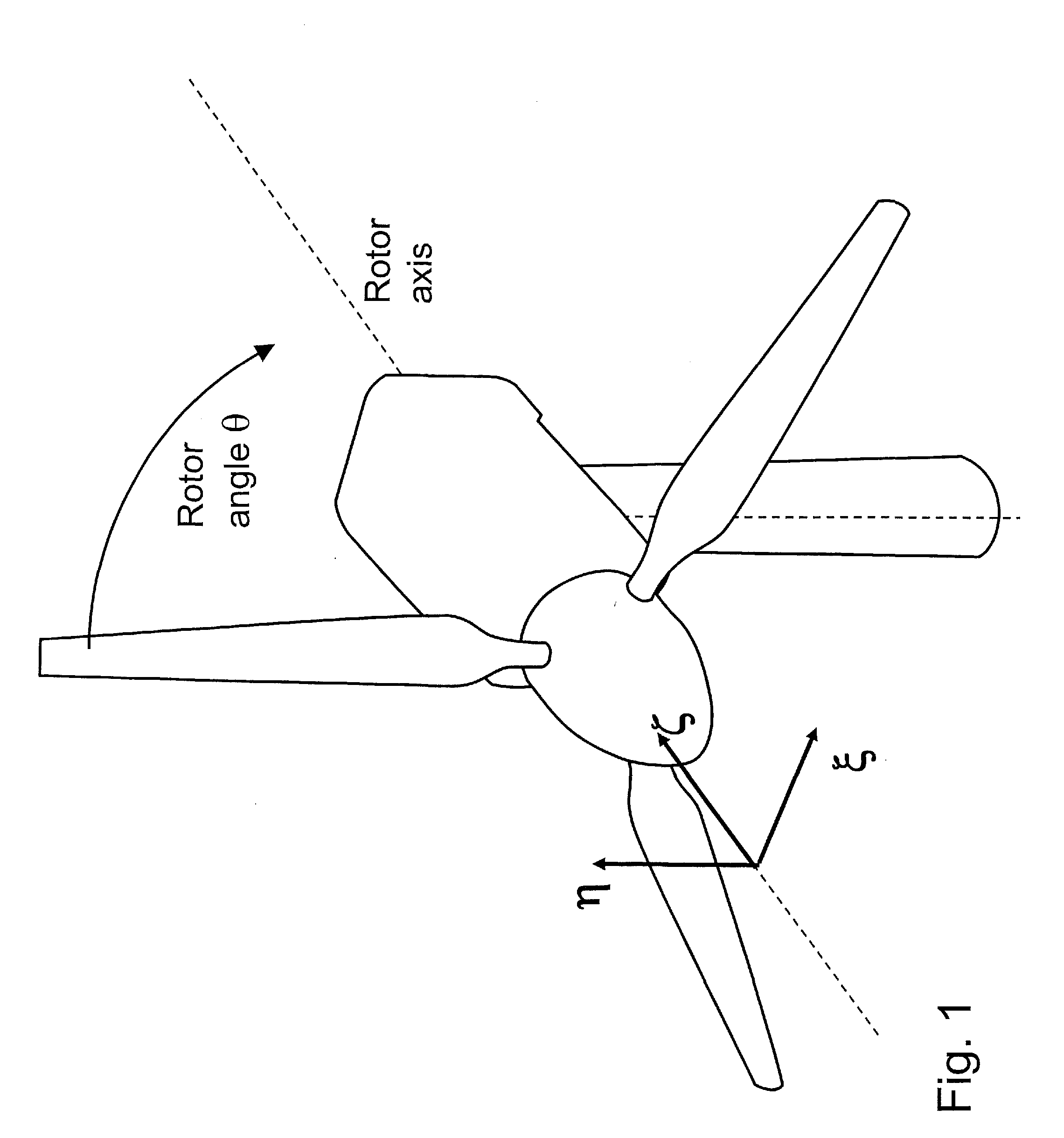

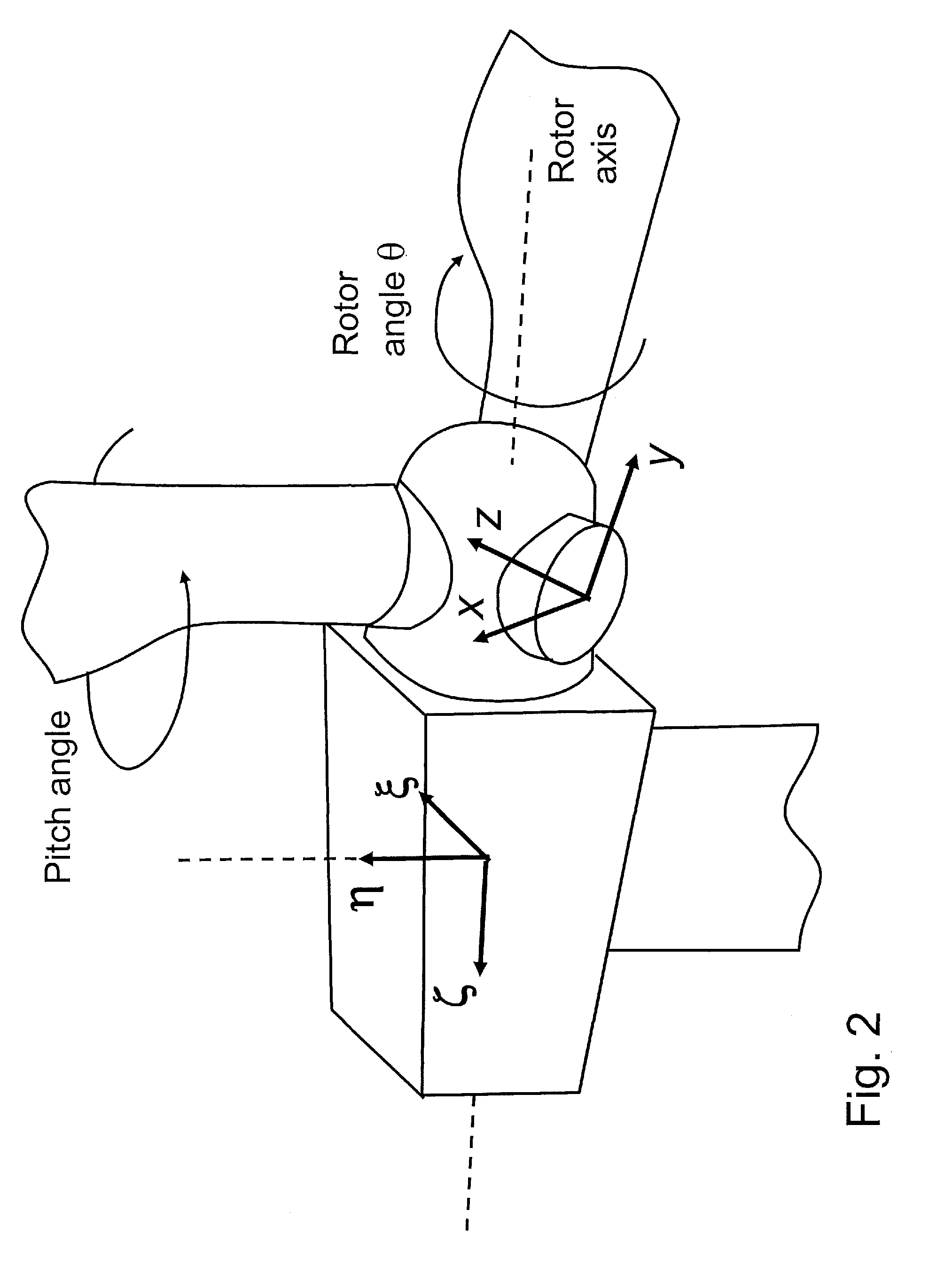

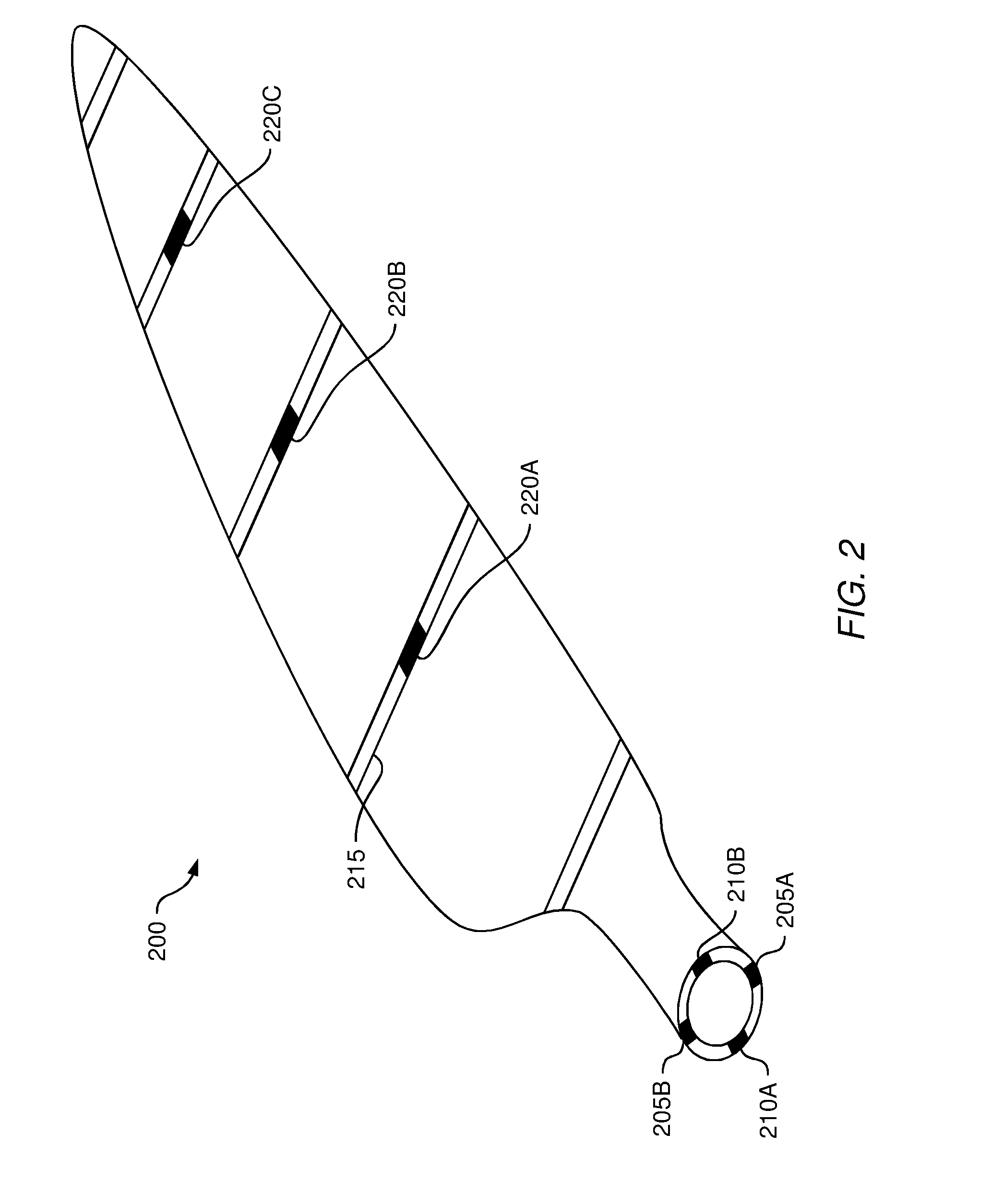

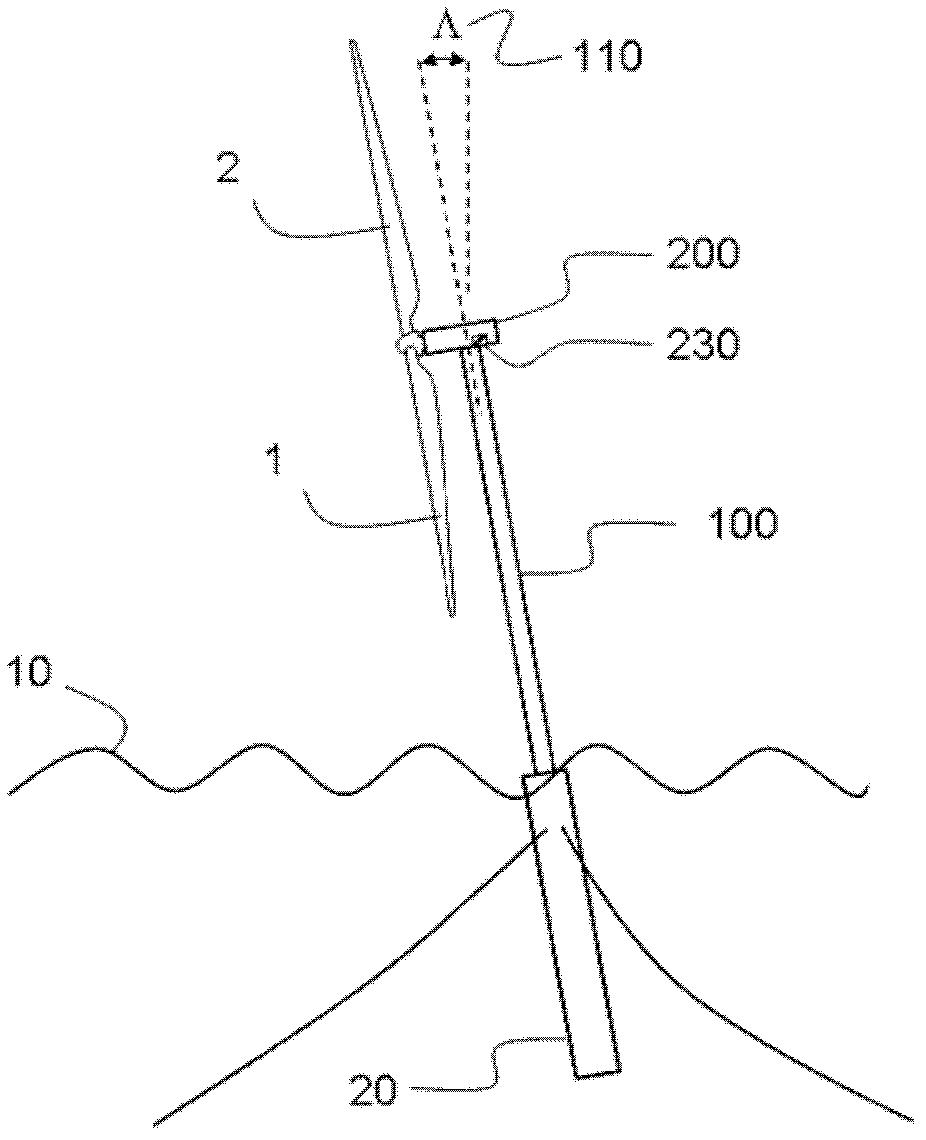

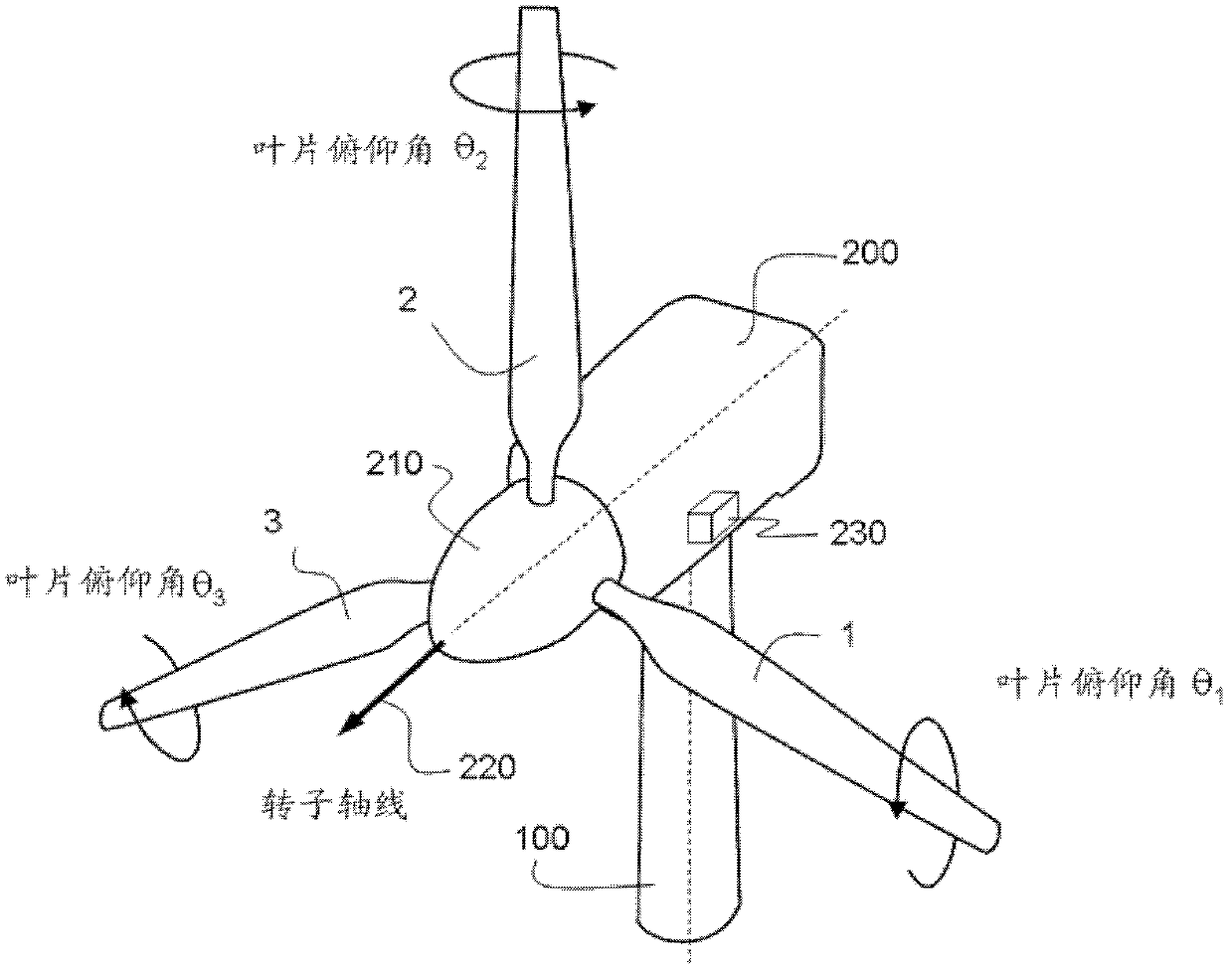

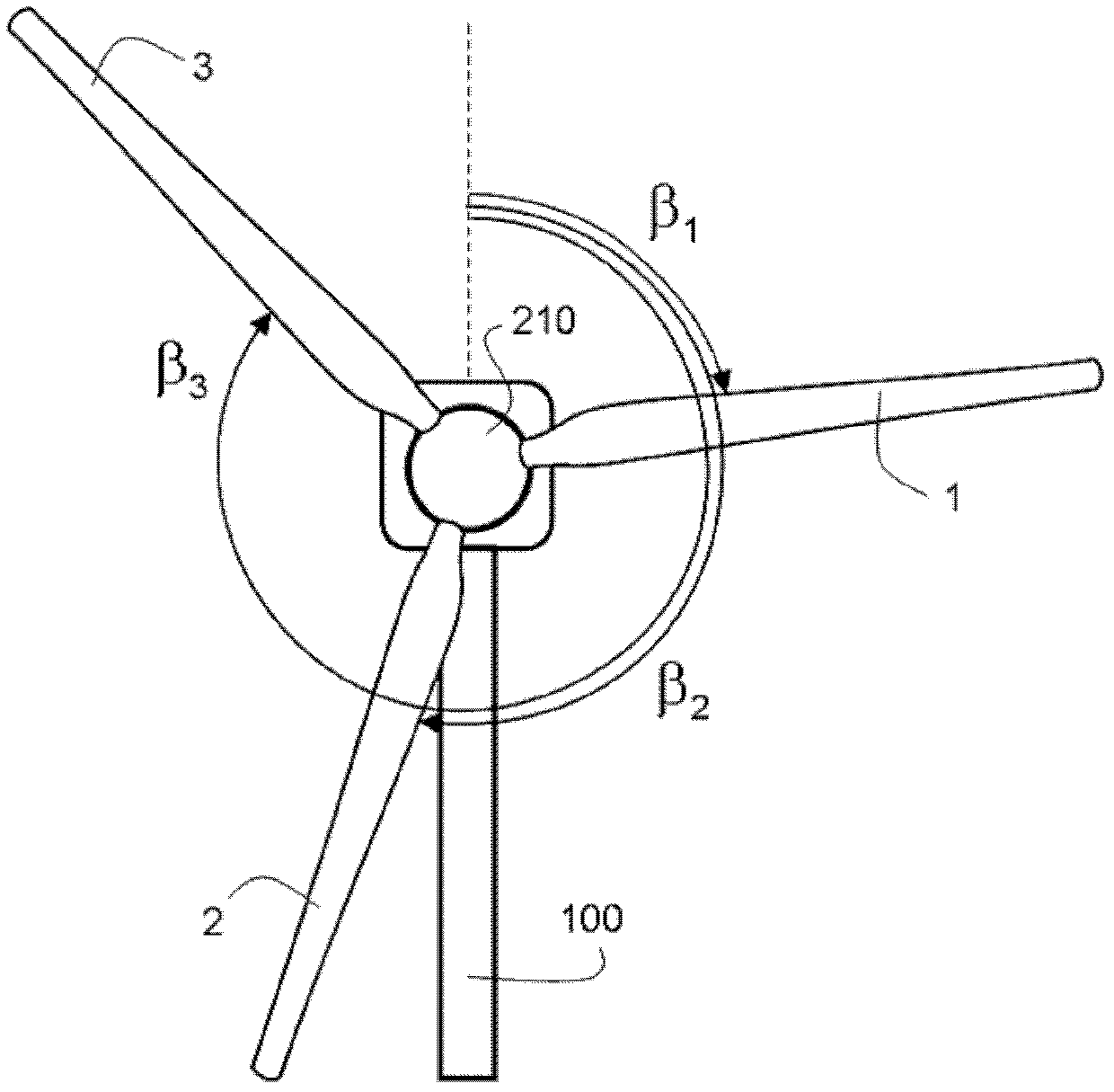

Blade load reduction for wind turbine

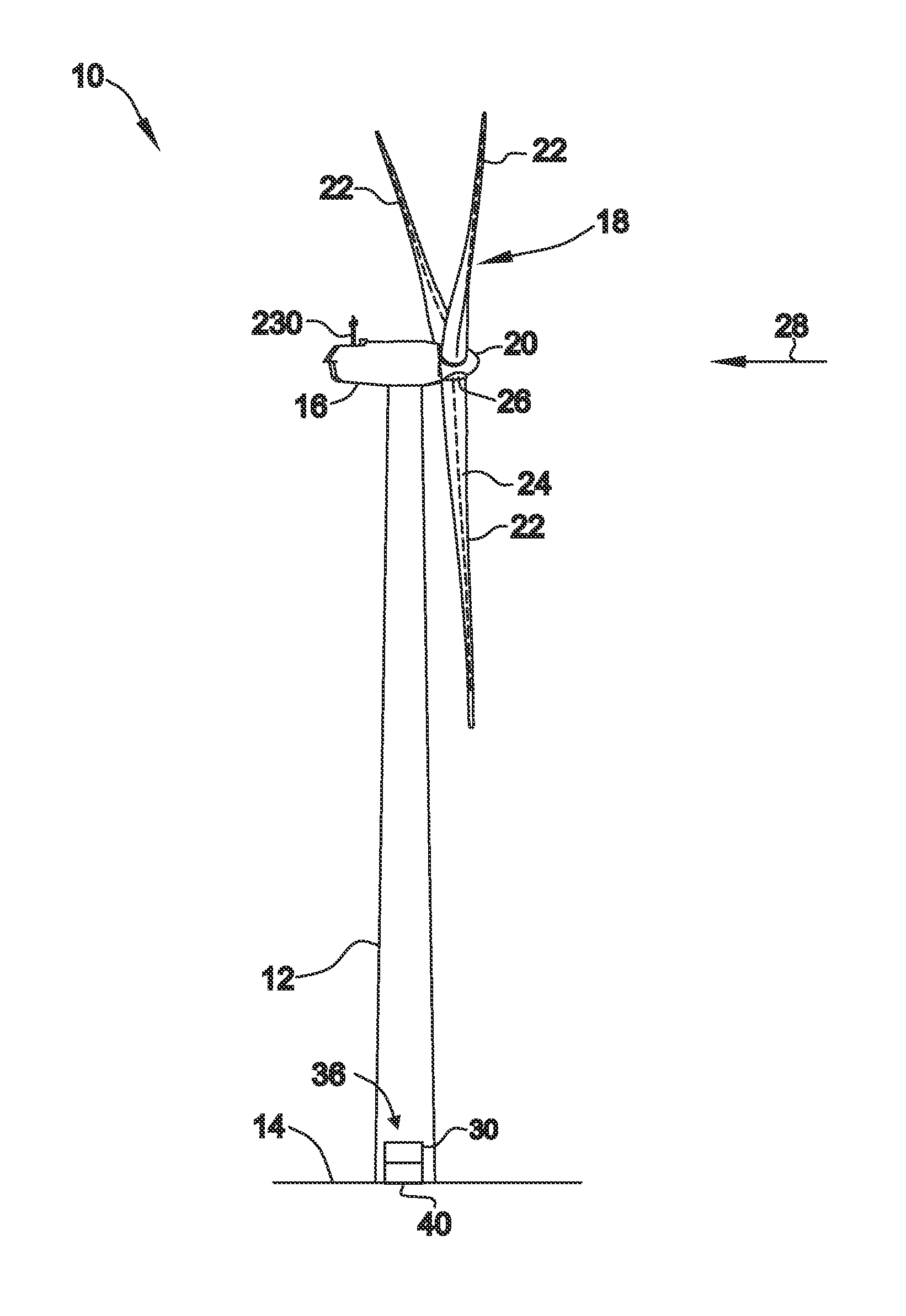

A wind turbine having a hub (210) rotably attached to a nacelle (200), at least two blades (1, 2, 3) rotationally attach to the hub (210) to allow a change in blade pitch angle ( 1 , 2 3 ) a blade-pitch system (250) for individually controlling the blade-pitch angle ( 1 , 2 3 ) of each blade, a supervisory control unit for issuing a first pitching command, a rotor position sensor (238) generating a rotor-position signal () indicative of the rotor azimuthally position, a rotor-rotational-rate sensor (236) generating a rotor-rotational-rate signal ( CR ) indicative of the rotor rotational speed, and a tower (100) supporting the nacelle (200), comprising a nautical-pitch-rate sensor (230) generating a nautical-pitch-rate signal ( ) indicative of the nautical-pitch-rate of the wind turbine and a computational unit (240, 241) receiving turbine-state signals comprising the rotor-position signal (), the rotor-rotational-rate signal ( CR ), and the nautical-pitch-rate signal ( ).

Owner:SSB WIND SYST

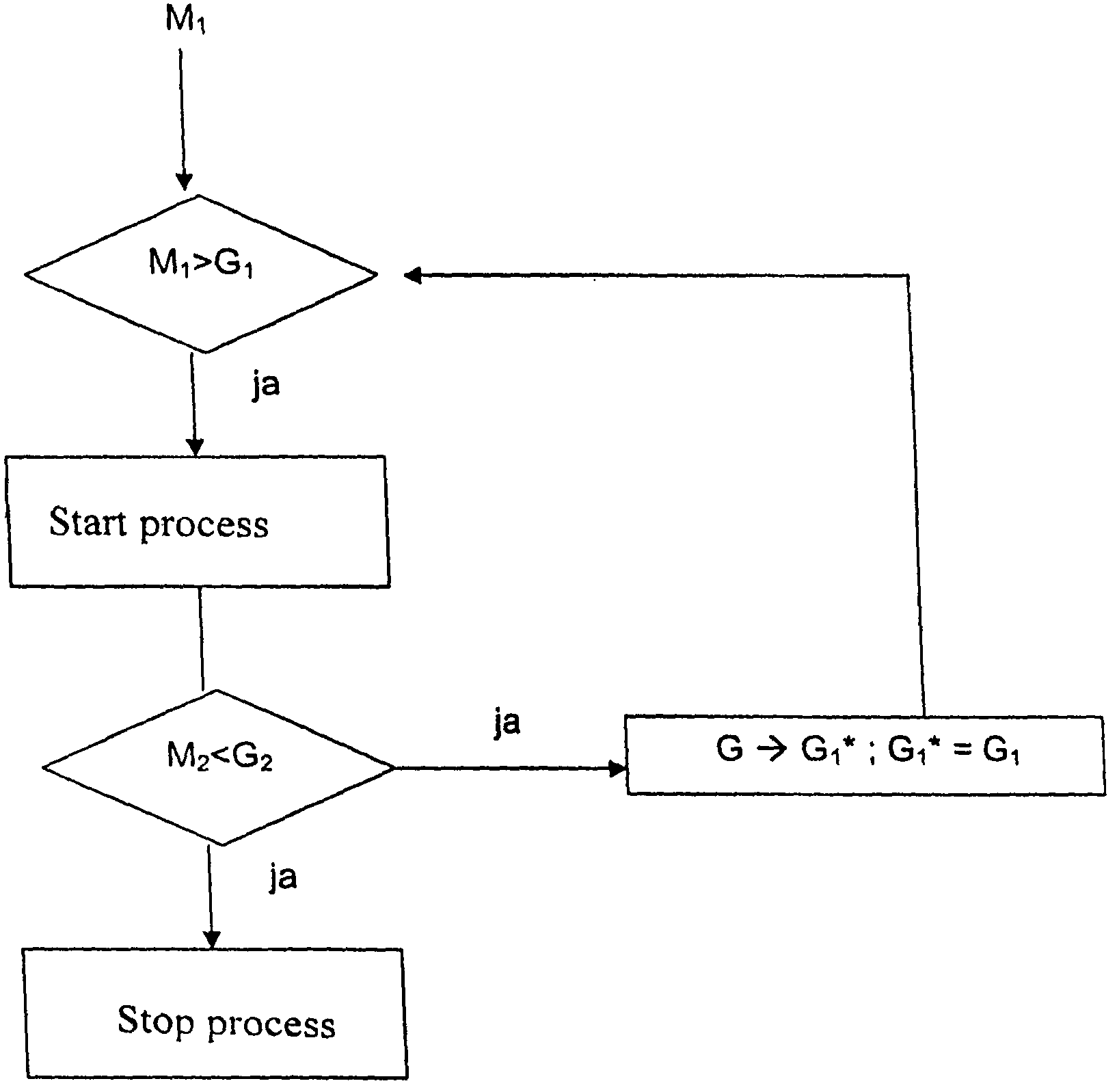

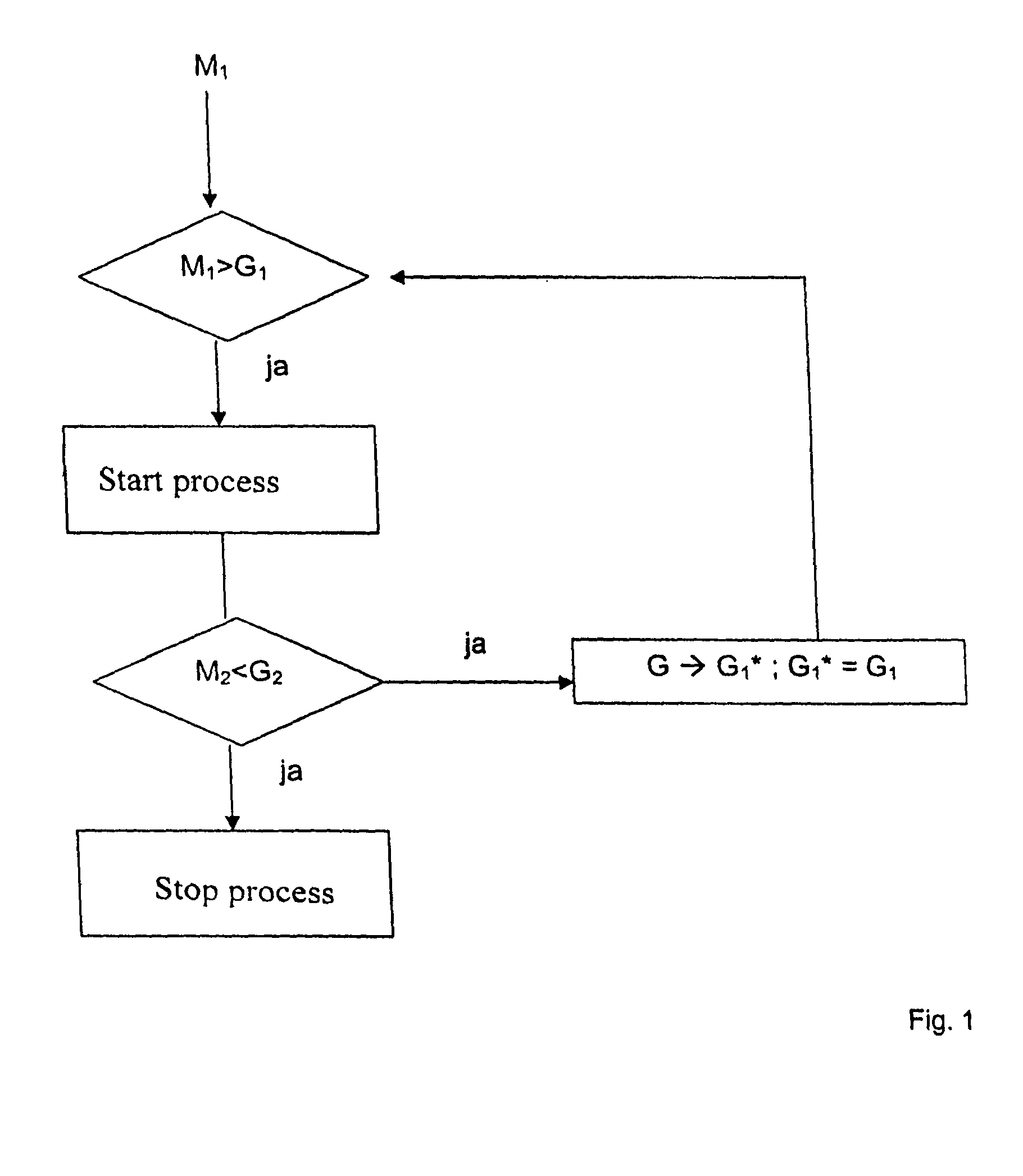

Method for operating a wind energy system

The invention relates to a method for operating a wind energy system wherein when a first settable boundary value (G1) is reached by a first parameter (M1) a process is automatically started whose course is monitored by measuring a second parameter (M2). By comparing the measured values of the second parameter (M2) with a second settable boundary value (G2), the first settable boundary value is changed upon reaching the second boundary value (G2) by the second parameter (M2).

Owner:SIEMENS GAMESA RENEWABLE ENERGY SERVICE GMBH

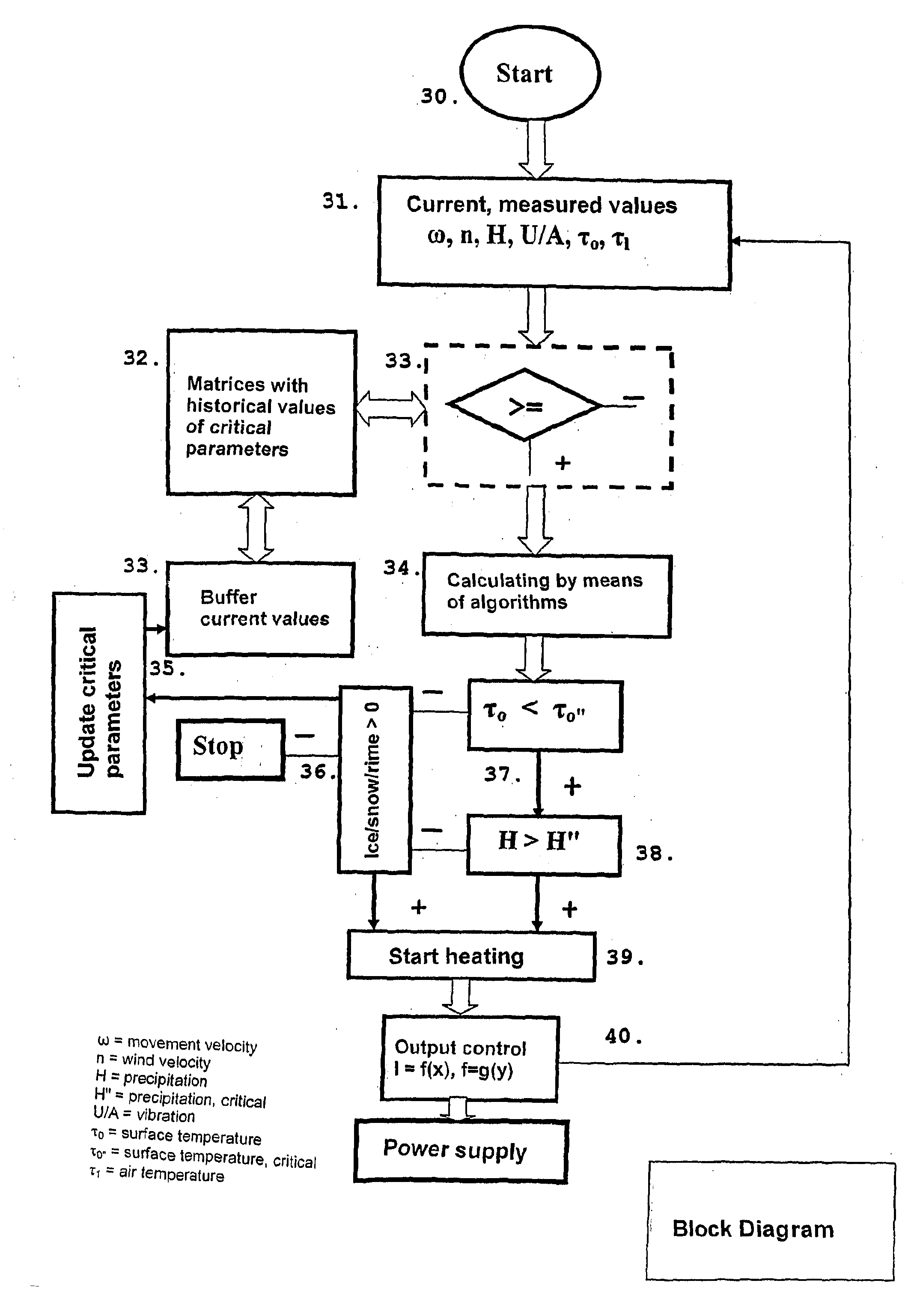

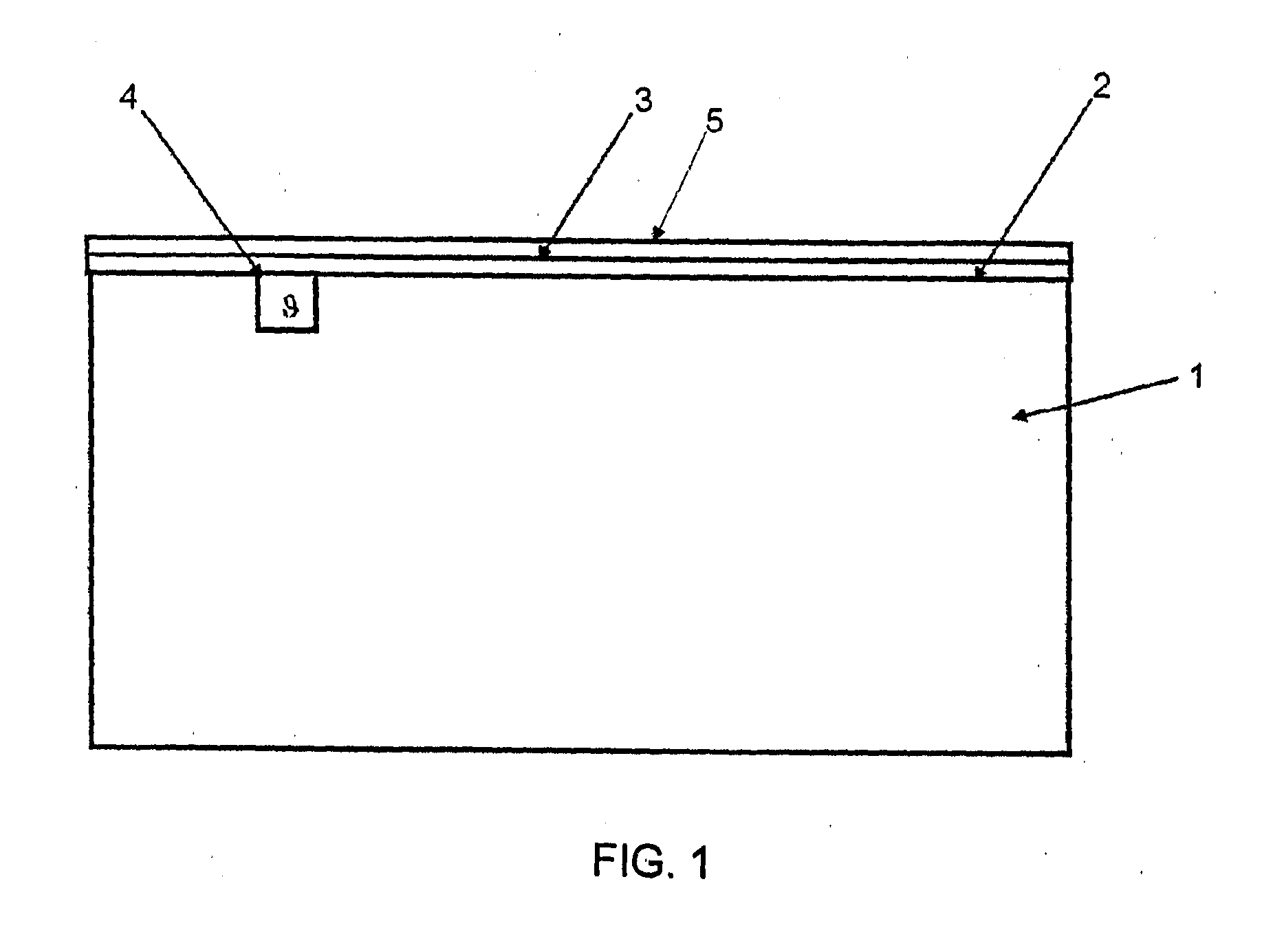

Method and Means for Controlling Power Delivery to an Equipment for Counter-Acting Formation of Ice or for Removing Snow/Ice on a Constructional Element

InactiveUS20100224621A1Improve energy efficiencyEasy to useComparison table algorithmsEngine fuctionsEffective surfaceControl signal

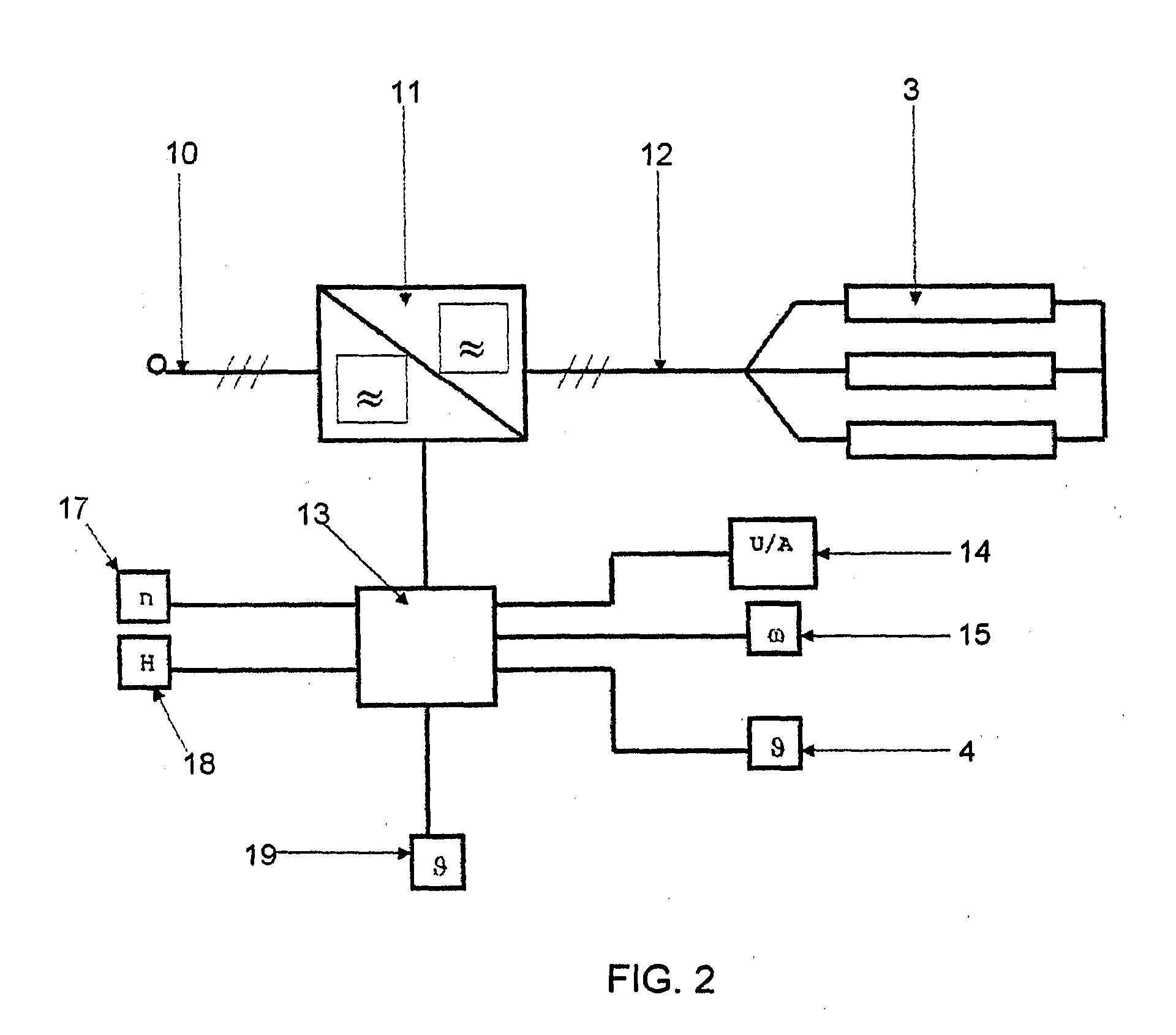

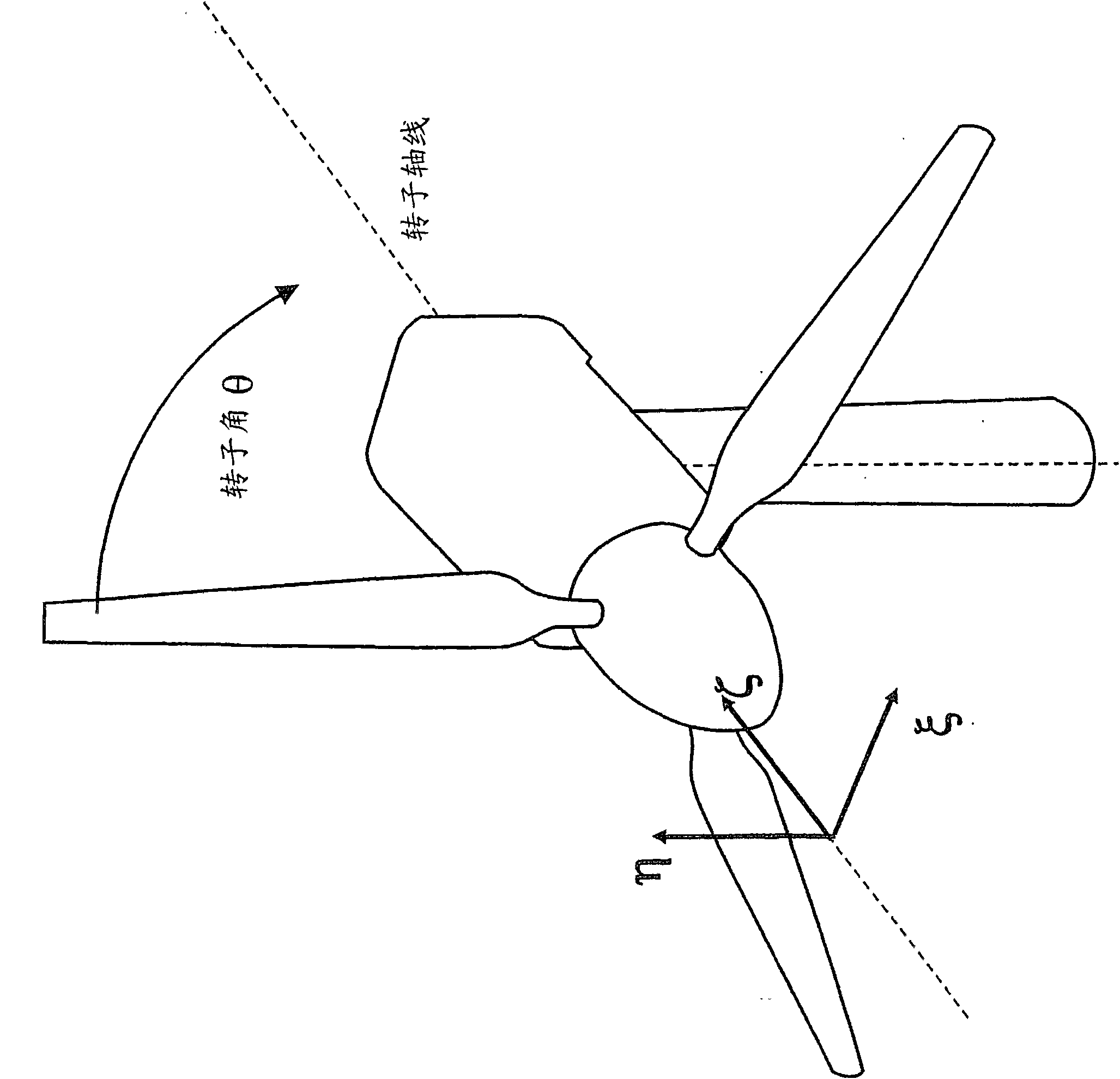

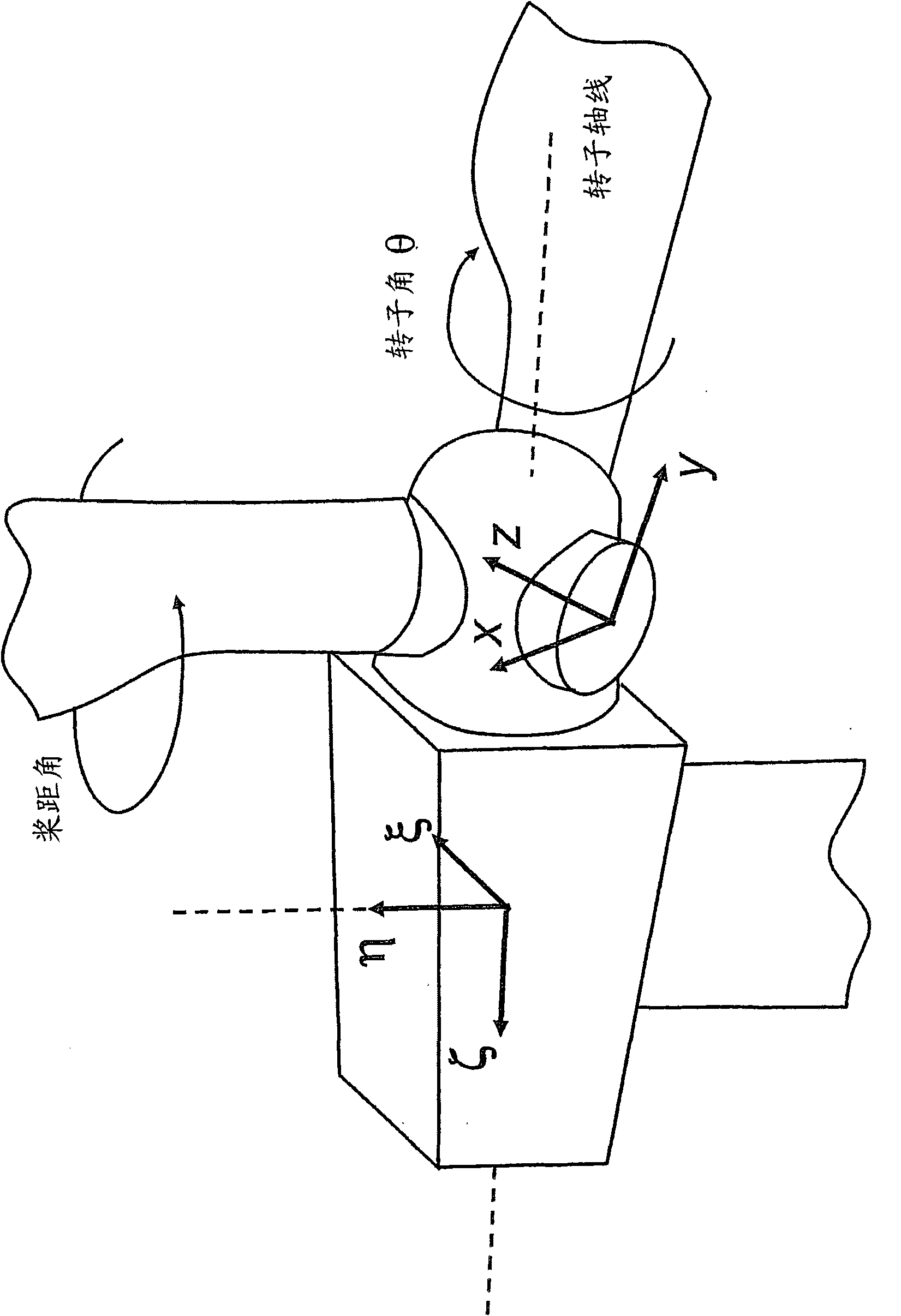

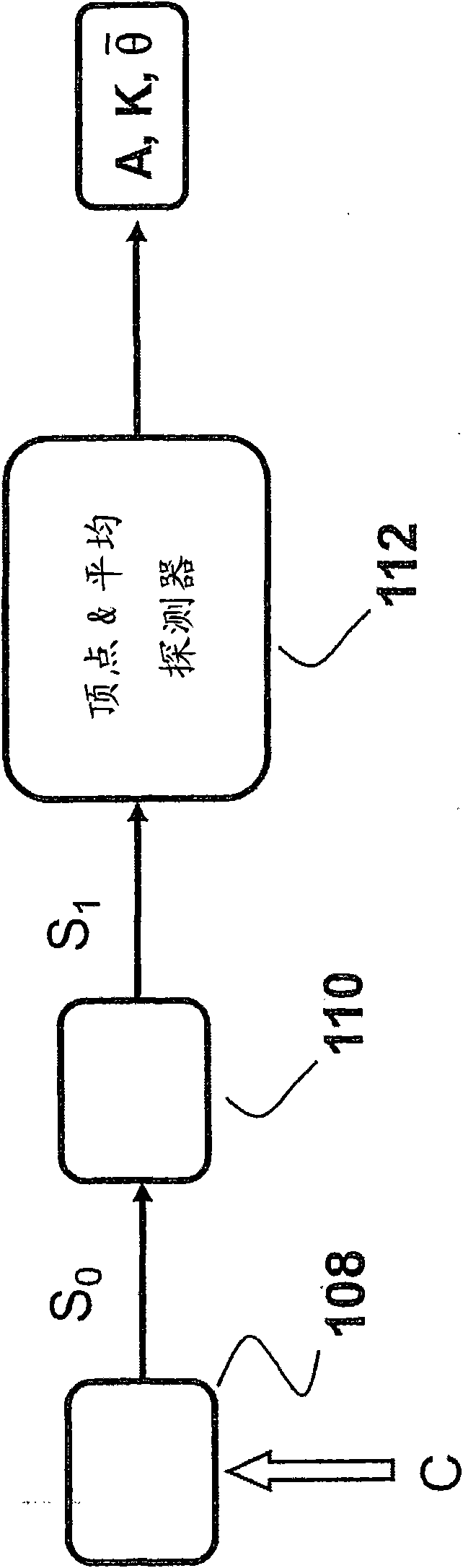

In order to remove snow or ice from an exposed constructional element (1) by means of electric current in a heat emission equipment (3), the supply of power is controlled by way of a controller (13) operating based on physical parameter values as measured by sensors (4, 14, 15, 17, 18, 19) at the constructional element (1) and based on historical data relating to snow and ice conditions. The input data are the effective surface temperature of the constructional element (1) as well as the amount of snow / ice on the constructional element (1), air temperature, wind velocity, precipitation, velocity of the constructional element (1), and vibrations thereof. These input data are compared to stored historical data in the controller (13). The controller (13) then calculates, using stored algorithms, whether the supply of power is necessary, and in that case also the necessary amperage and frequency values, the frequency affecting a time constant of change in the surface temperature of the constructional element. The controller then provides a start or stop signal as well as an output control signal to power supply equipment (11), and the controller then updates its historical data with new data. Preferably, the invention is used on the blades of a wind turbine.

Owner:NORSK MILJKRAFT FORSKNING OG UTVIKLING

Wind sensor system using blade signals

The present invention relates to a wind-velocity-field measurement system for use in a wind turbine having a rotor with' two or more blades, comprising at least one sensor-signal obtained by measuring a physical quantity on at least one of the blades, the physical quantity being indicative of at least one wind-velocity-field characteristic; a table (140, 142, 144) build for a plurality of wind conditions by associating values characterizing the at least one sensor-signal with values of the at least one wind-velocity-field characteristic, and; searching means (150, 152, 154) for determining from the table a value of the at least one wind-velocity-field characteristic for a current wind condition given values characterizing the at least one sensor-signal. Methods for measuring wind-velocity-field ina wind turbine having a rotor with' two or more blades and related wind turbines and turbine control systems are also disclosed in the invention.

Owner:SSB WIND SYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com