Patents

Literature

276 results about "Correlation database" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A correlation database is a database management system (DBMS) that is data-model-independent and designed to efficiently handle unplanned, ad hoc queries in an analytical system environment. Unlike row-oriented relational database management systems, which use a records-based storage approach, or column-oriented databases which use a column-based storage method, a correlation database uses a value-based storage (VBS) architecture in which each unique data value is stored only once and an auto-generated indexing system maintains the context for all values.

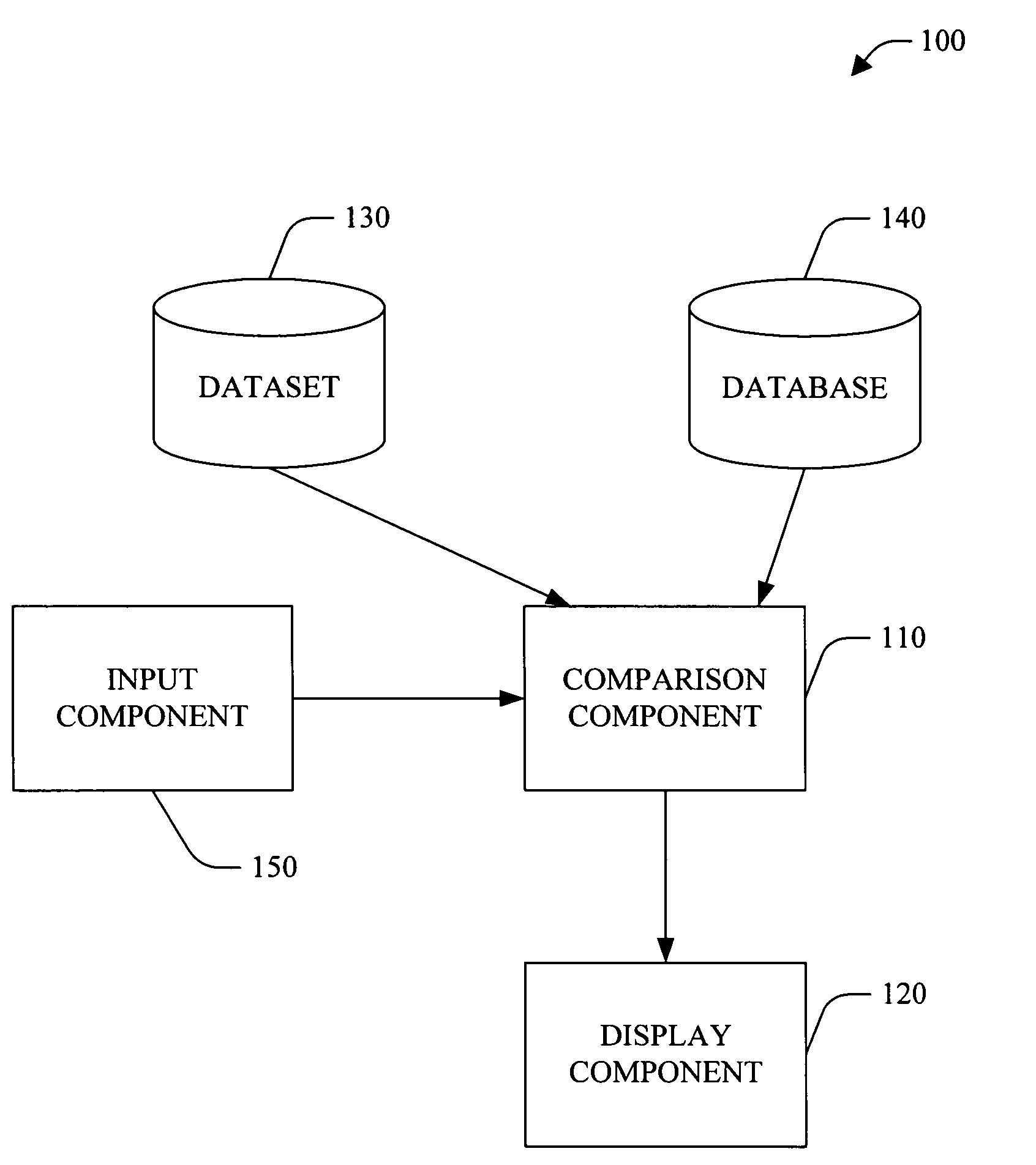

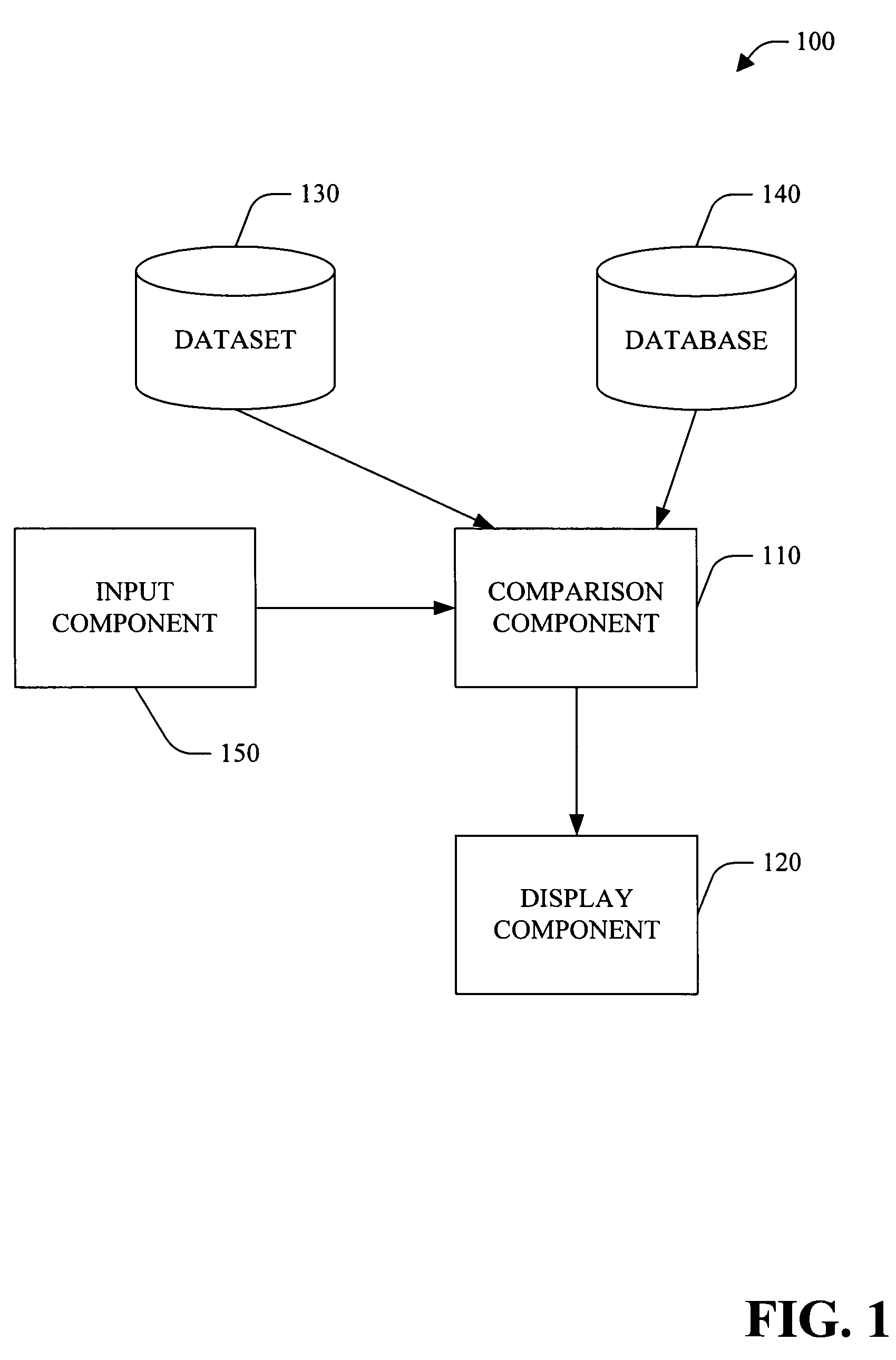

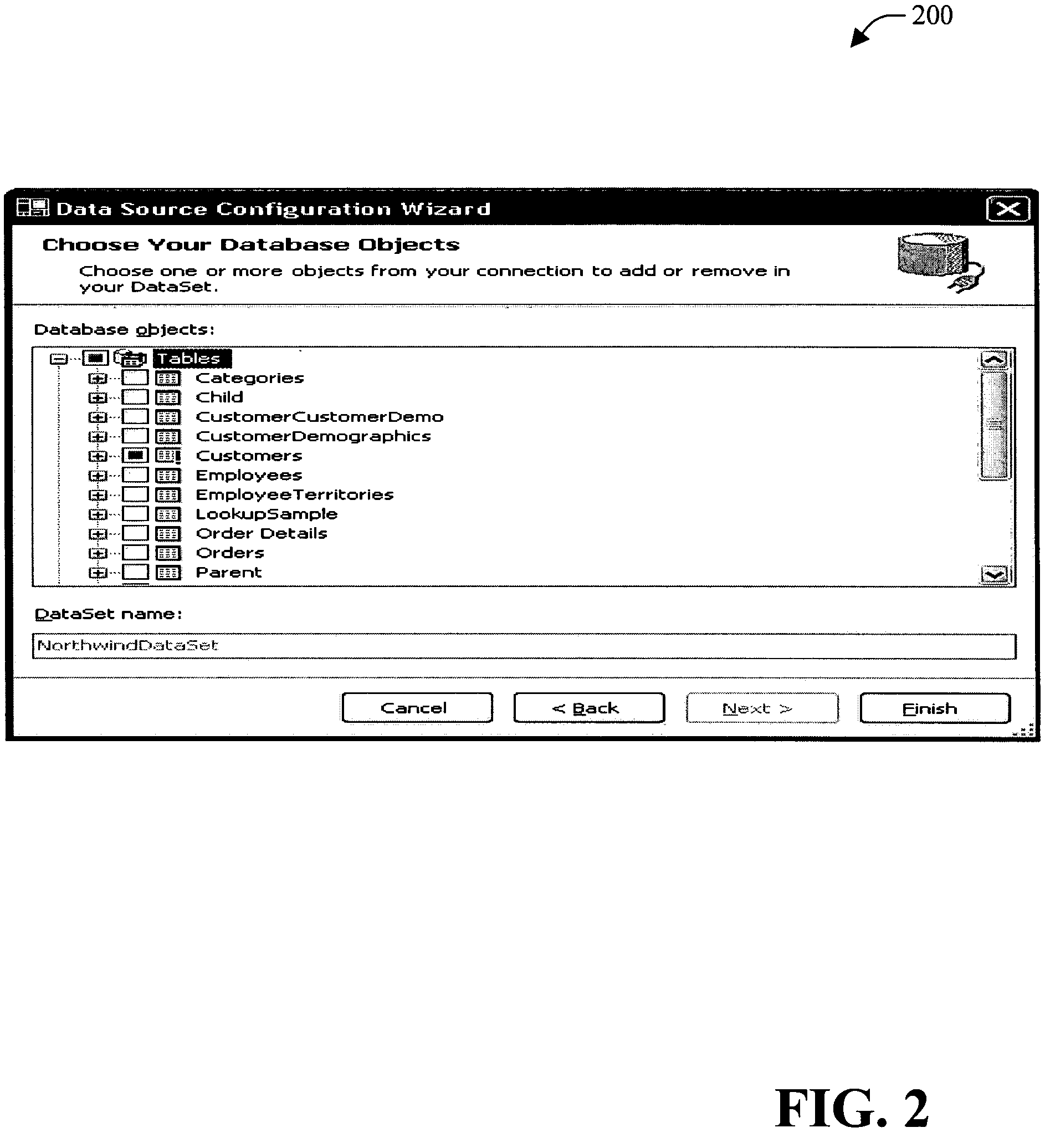

Reentrant database object wizard

InactiveUS7620644B2Data processing applicationsDigital data processing detailsData setApplication software

A system and method for a reentrant database object wizard is provided. The system provides the ability to compare a currently generated dataset to the objects of the underlying database. Columns and tables that are not common between both the dataset and the database are visually displayed for the user to make a decision on inclusion or exclusion. The system includes a comparison that provides comparison information based upon a comparison of a dataset to an associated database and a display component that displays the comparison information. The system further includes an input component which provides information associated with the user's decision on inclusion and / or exclusion of column(s) and / or table(s) to the system. The system is reentrant thus providing long-term value to the developer over the application development cycle.

Owner:MICROSOFT TECH LICENSING LLC

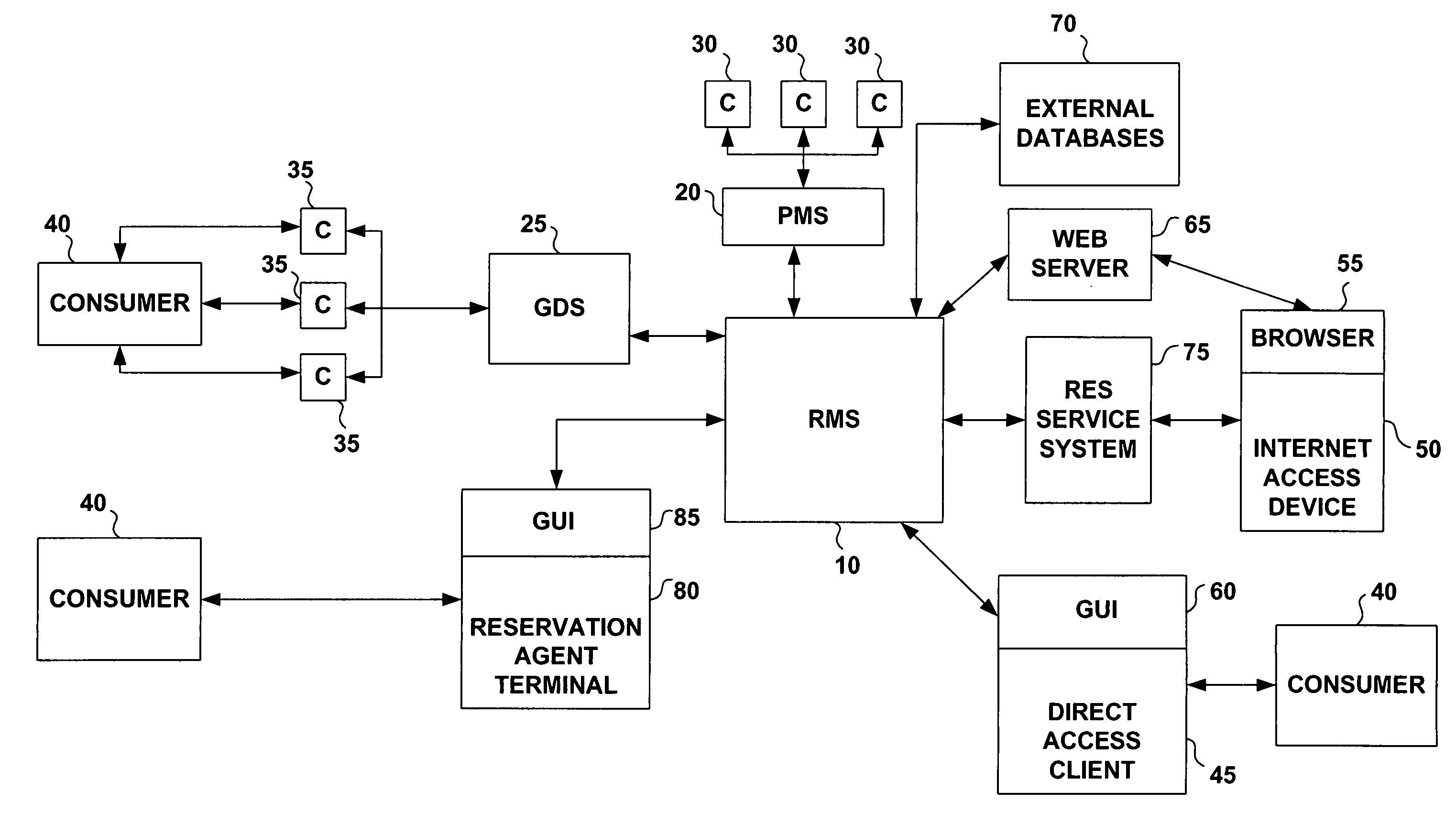

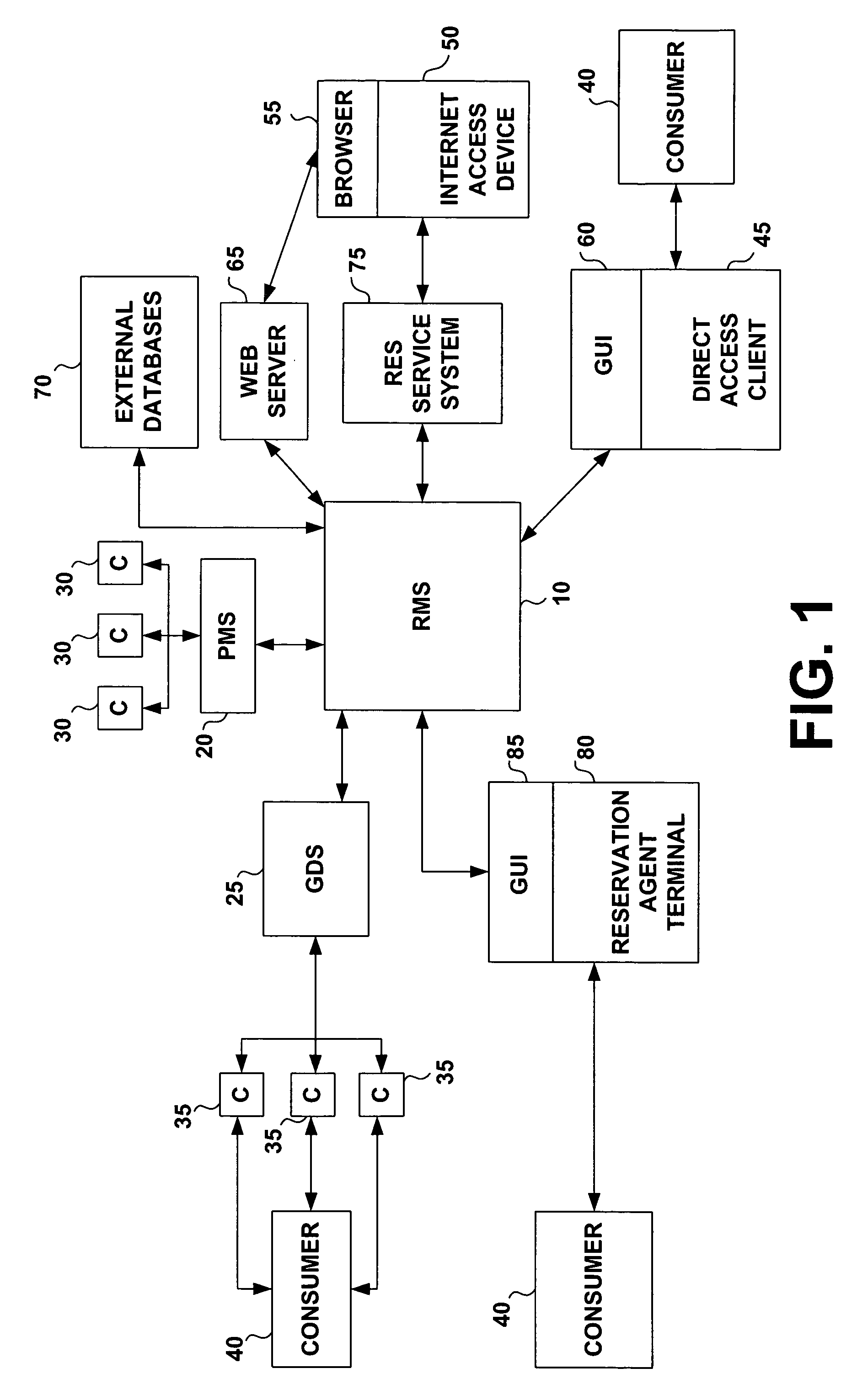

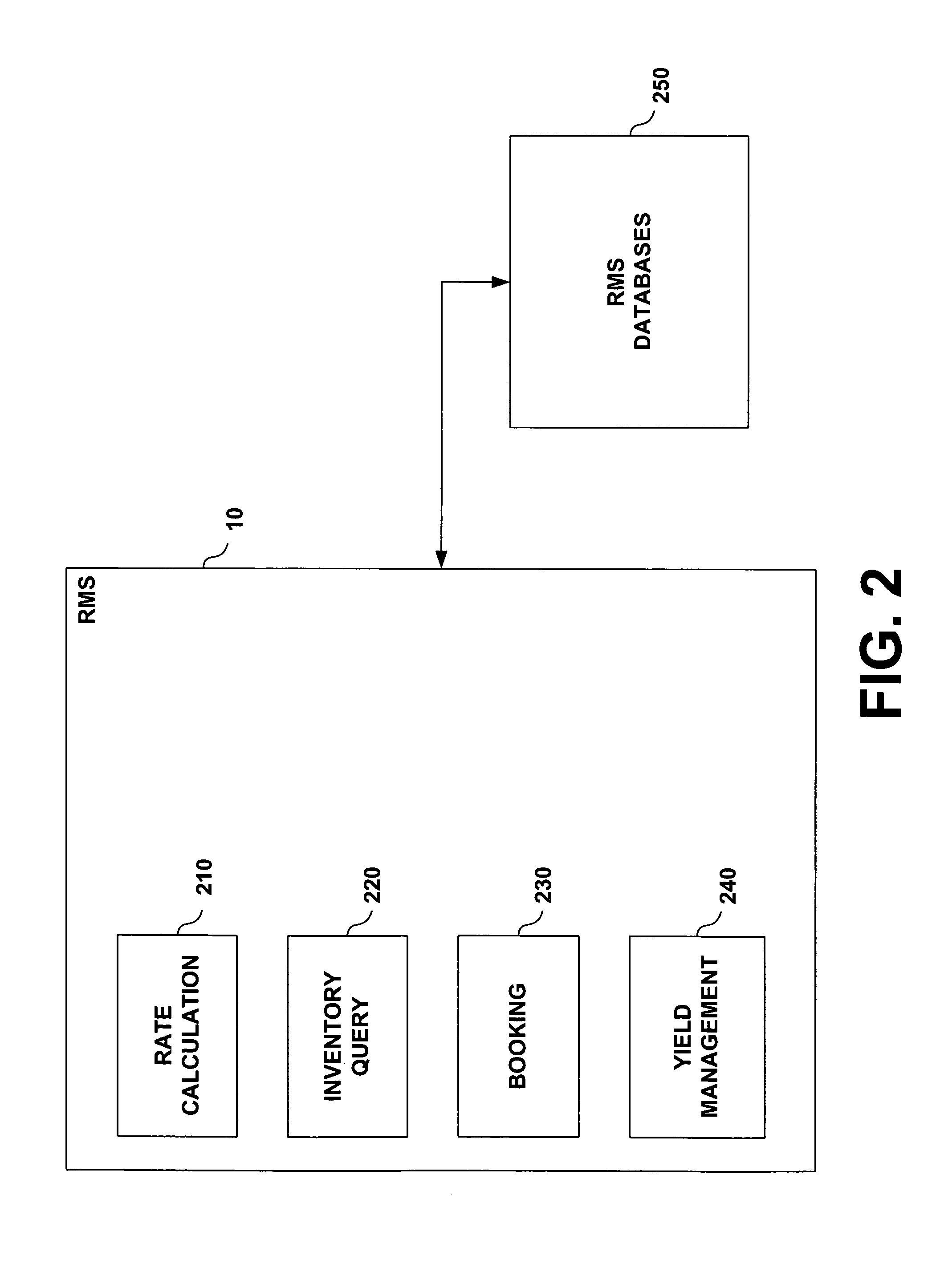

Global reservations transaction management system and method

InactiveUS7328166B1Increase incomeReal-time accessDigital data processing detailsReservationsThe InternetCentral database

A reservation system and methodology ensures that all changes to a database in a federation are reliably and immediately communicated to all of the other databases in the federation. The system communicates information concerning hotel reservation transactions. The system comprises multiple applications each associated with one or more databases including hotel reservation data. The databases in the federation reflect transactions that are communicated to other databases and they also employ information received from other databases in determining the transactions that their associated local applications permit and the way in which they are processed. In one embodiment of the invention, communication among databases occurs through the Internet and data storage devices via secure packetized messages addressed to objects that represent the relevant databases. The system of the present invention also preferably includes a central database that functions as the primary source for verifying reservations and hotel data. Additionally, the system of the present invention also includes a yield subsystem that allows hotels to increase revenues. The yield subsystem calculates rates and availability based upon forecasted changes in supply and customer segment demand.

Owner:SYNXIX

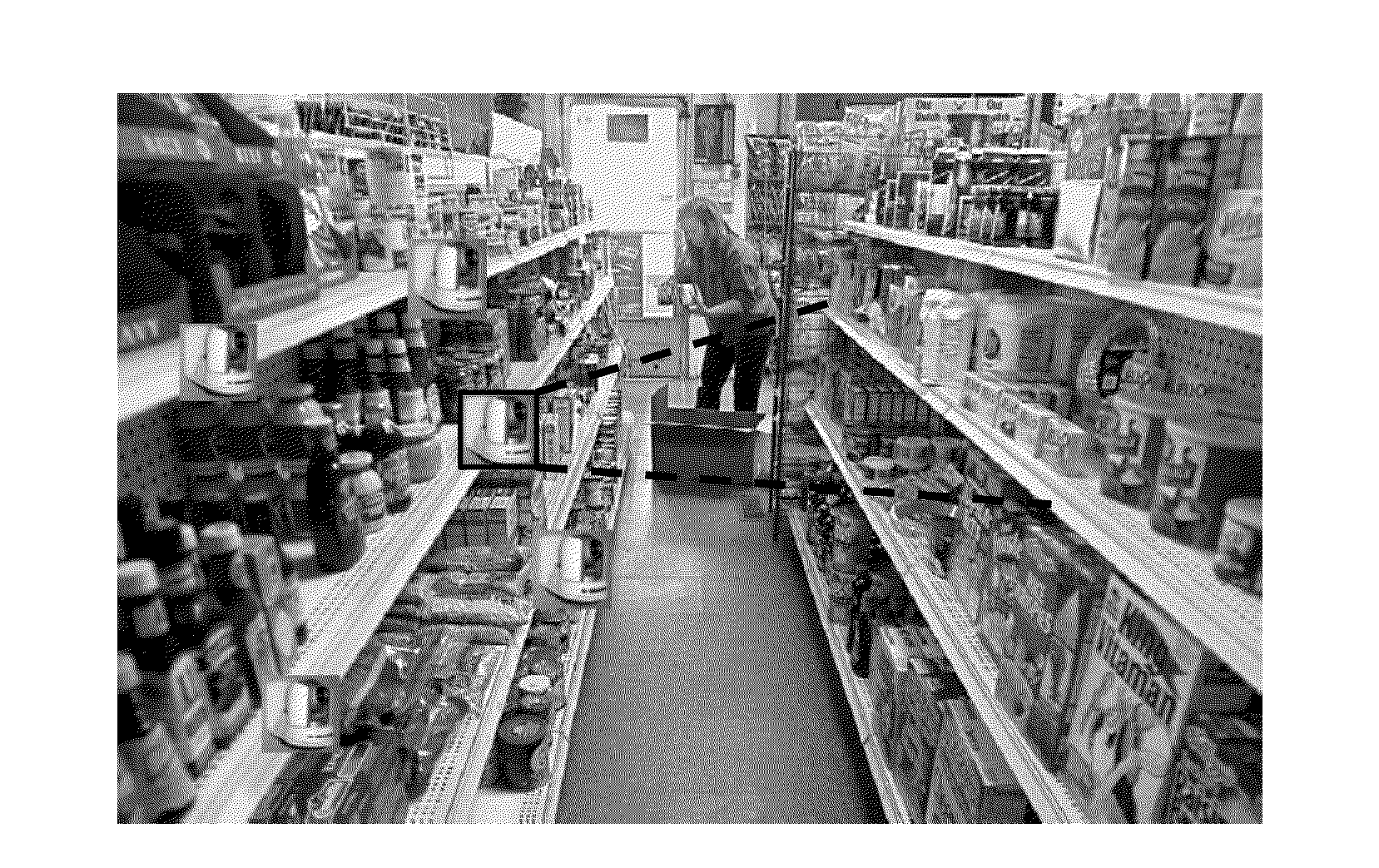

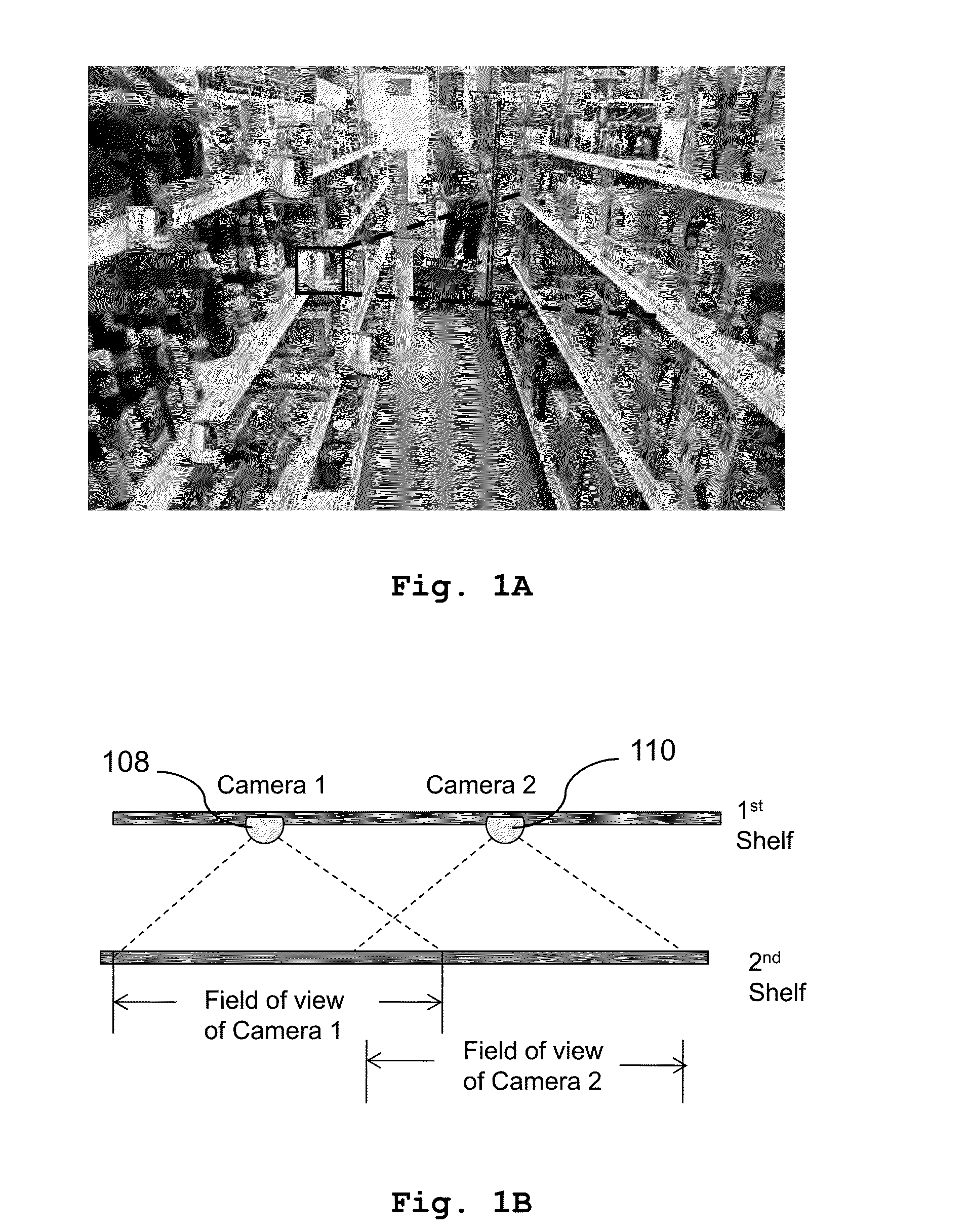

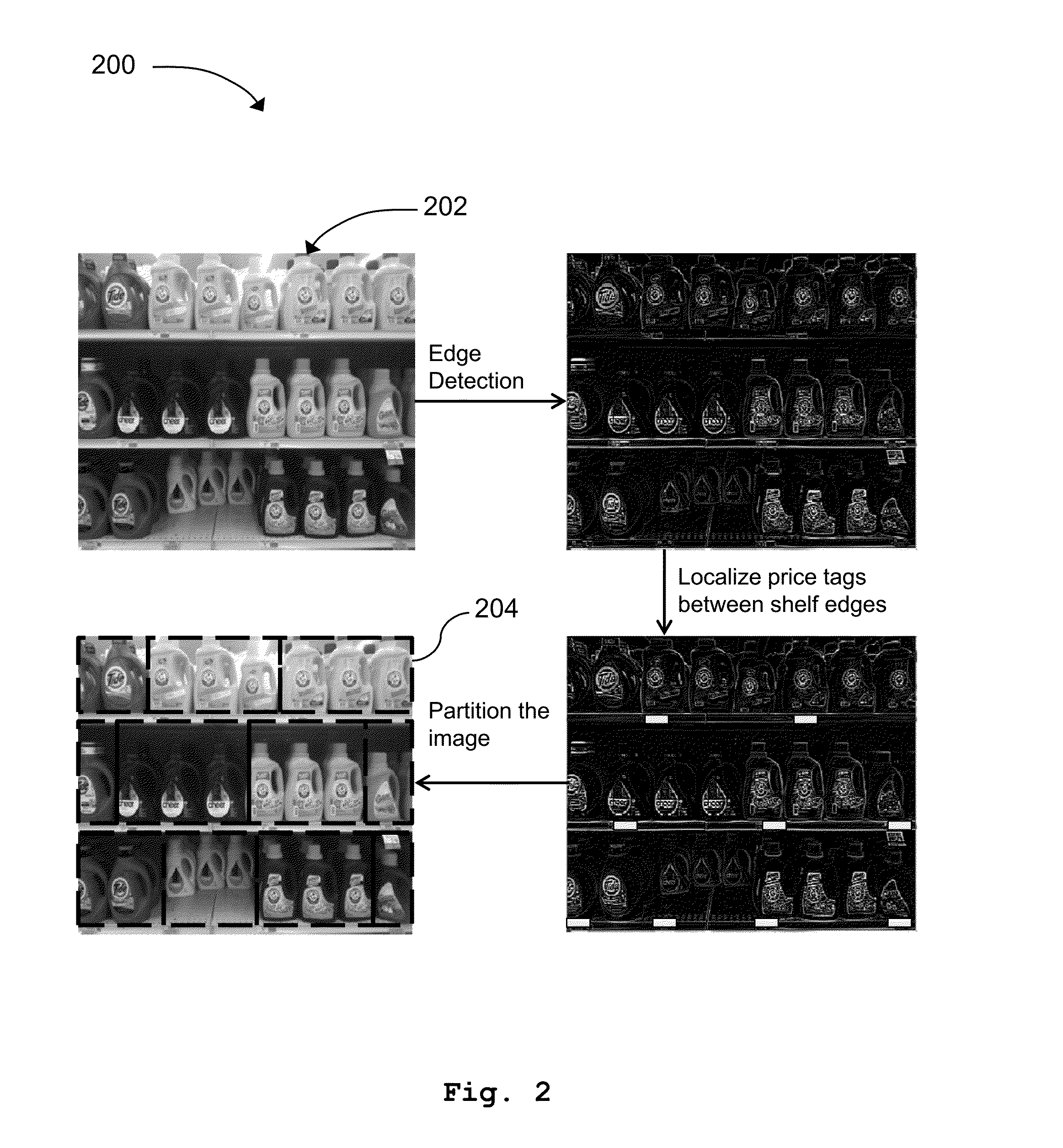

Machine vision technology for shelf inventory management

InactiveUS20150262116A1Character and pattern recognitionService system furnitureMachine visionBarcode

A system, method and computer program product for maintaining shelf inventory data on a shelf. The system includes a camera for capturing shelf images of items on the shelf. An inventory database stores a product name, type, barcode, image and inventory data. An image-count correlation database stores historical product inventory images and product shelf inventory counts associated with the products in the historical images which are read from the product inventory database. A computer processor segments the shelf images into product inventory images, matches the inventory images with the historical images, and updates the shelf inventory data in the inventory database based on the product shelf inventory counts associated with the matched historical images in the image-count correlation database.

Owner:IBM CORP

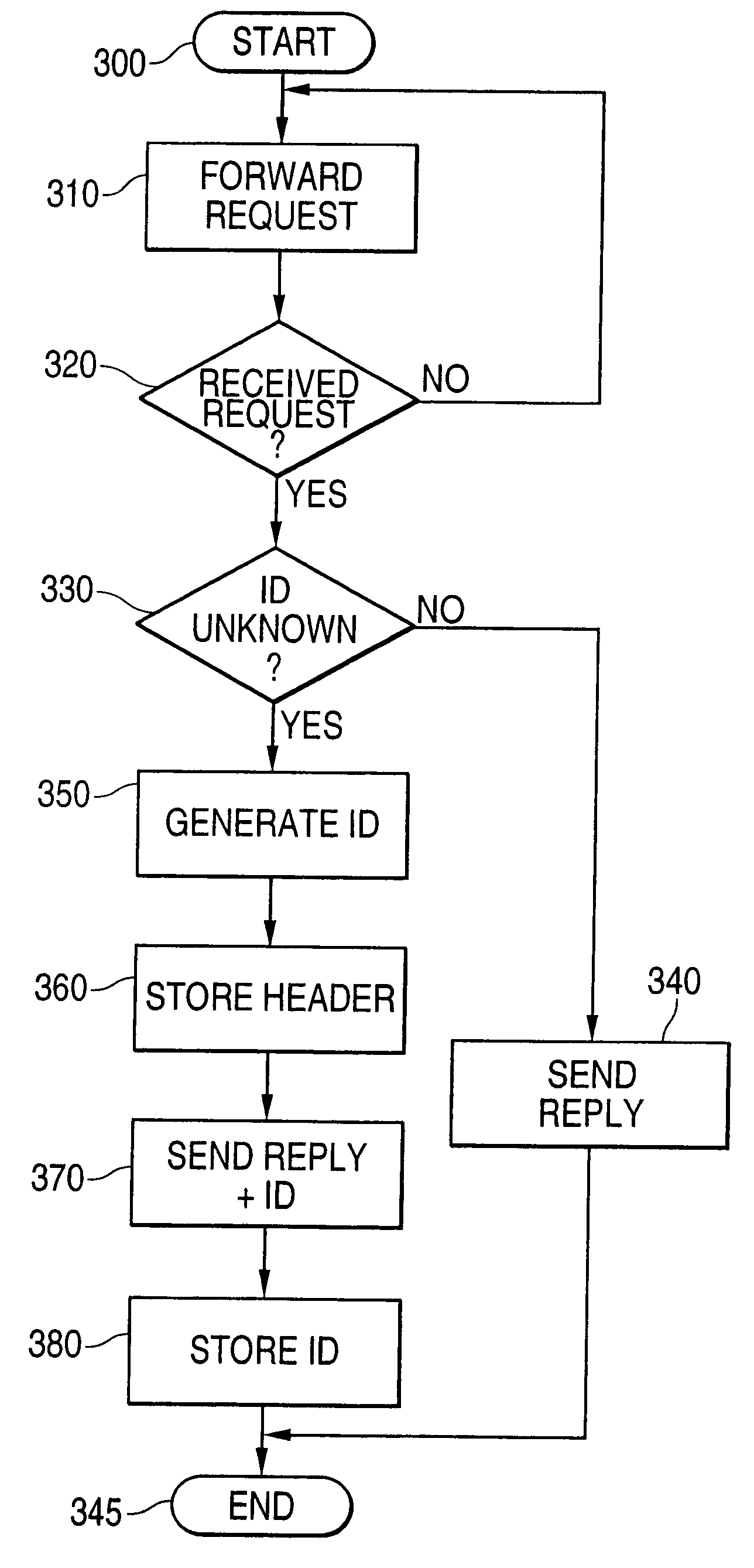

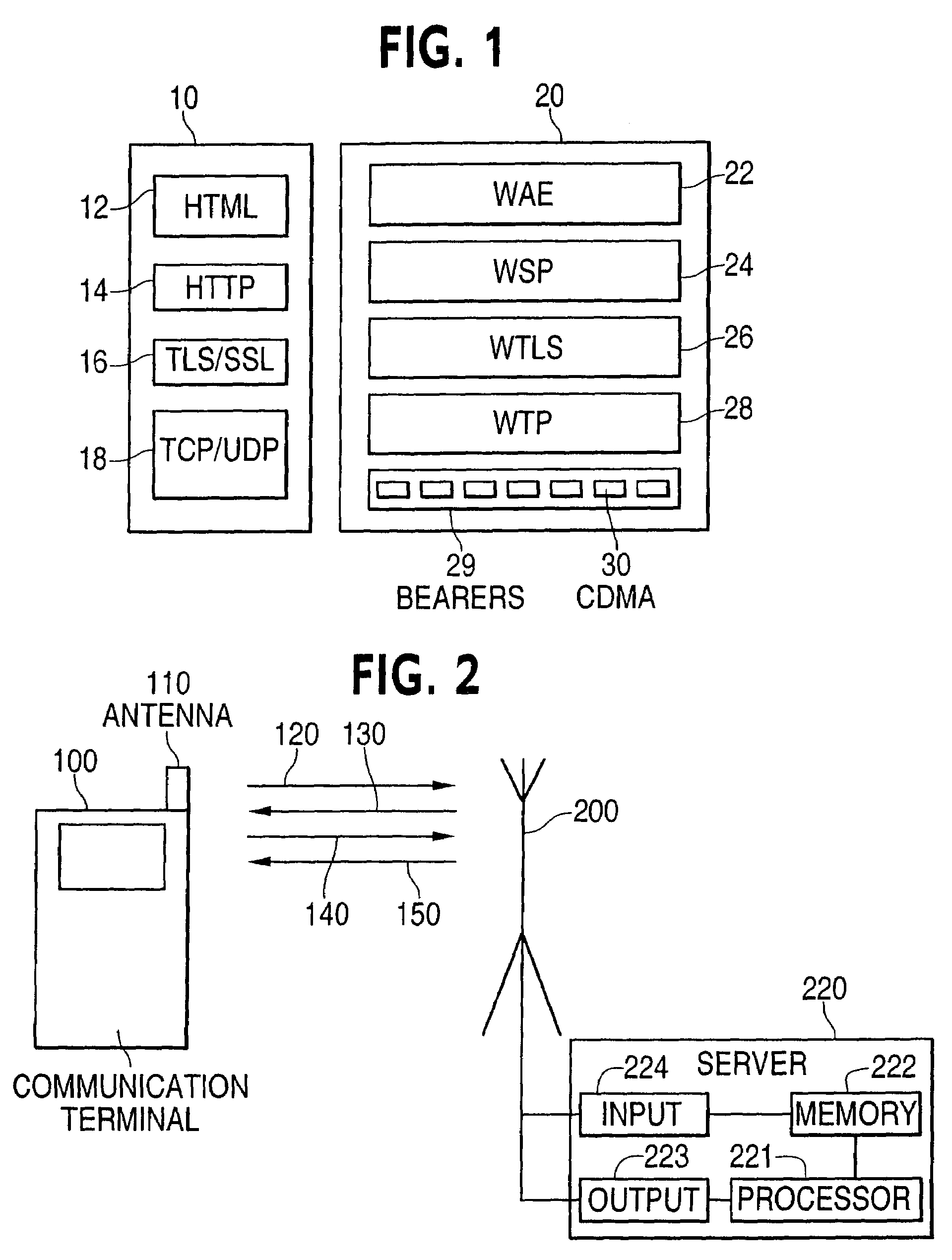

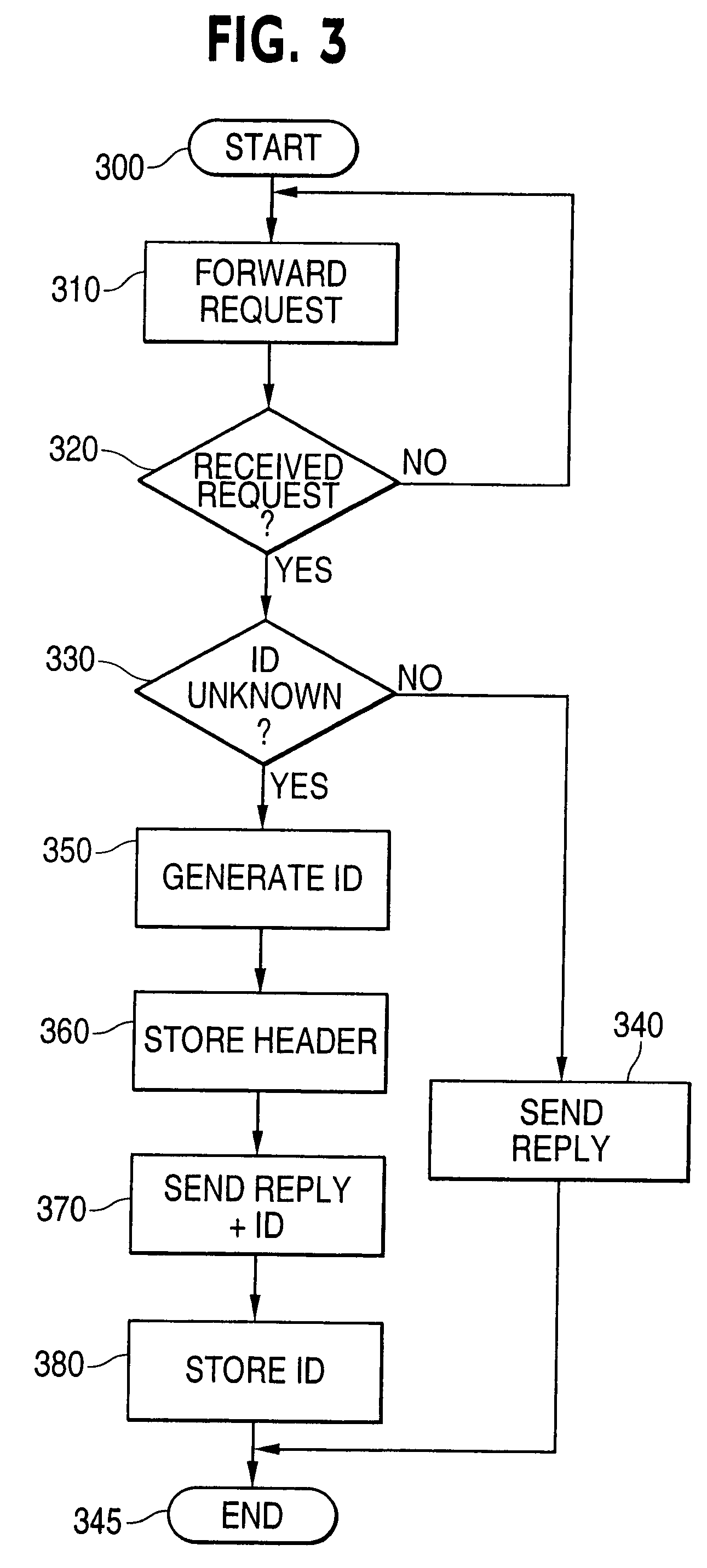

Method of and a network for handling wireless session protocol (WSP) sessions

InactiveUS7103018B1Reduce the amount requiredUnacceptable overheadNetwork traffic/resource managementConnection managementComputer terminalUser profile

A communication terminal initiates a Wireless Session Protocol (WSP) session by forwarding a request of data to a server. The request comprises an identification of the requested data and a communication terminal identification number provided by the server. The server. when receiving a request containing a communication terminal identification number, recalls user profile information from an associated database memory corresponding to said communication terminal identification number. The user profile information indicates a data format which will be handled by the communication terminal. Then the server replies to the request by forwarding the requested data in the format defined by the user profile information.

Owner:NOKIA TECHNOLOGLES OY

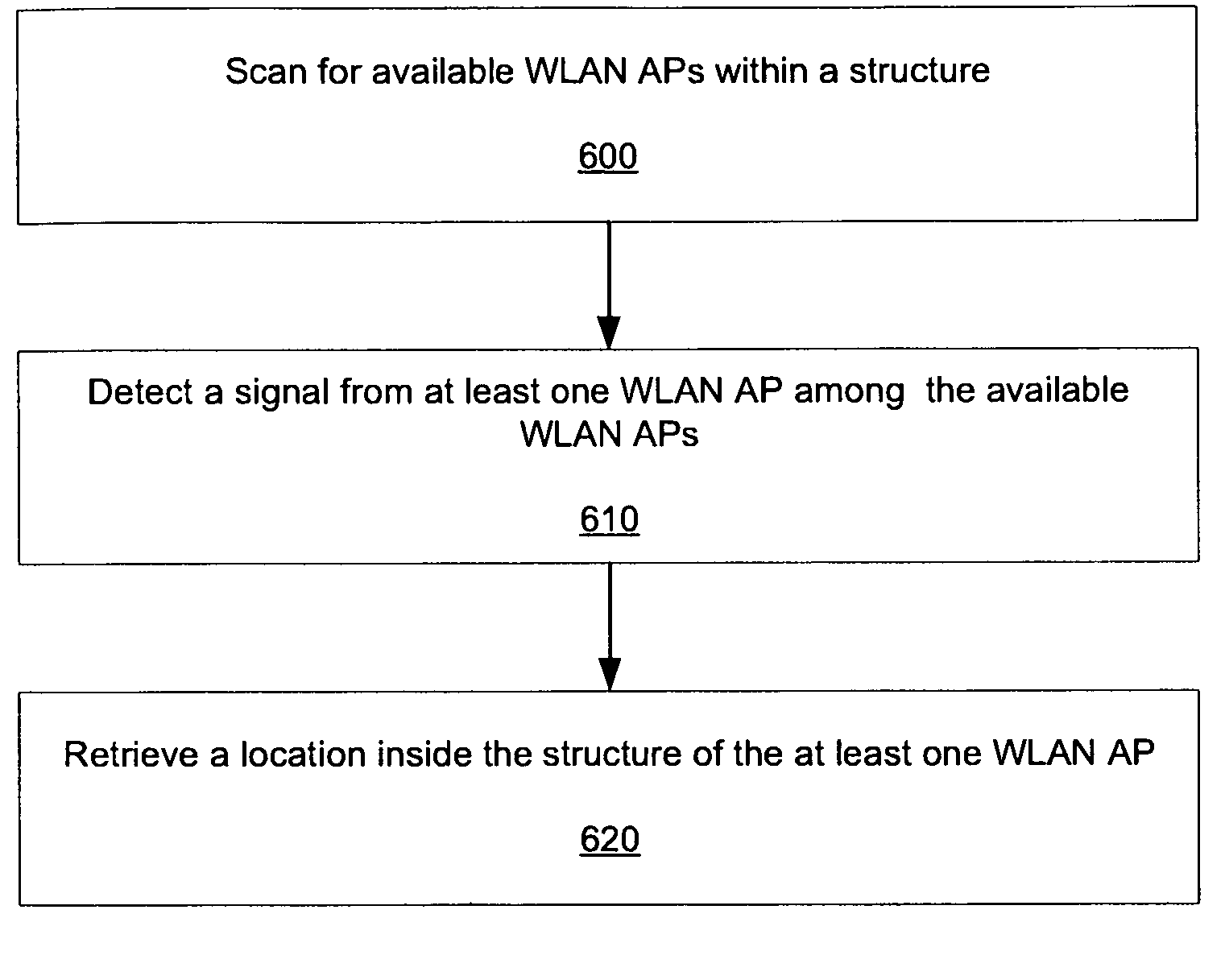

Method providing positioning and navigation inside large buildings

Owner:NOKIA TECH OY

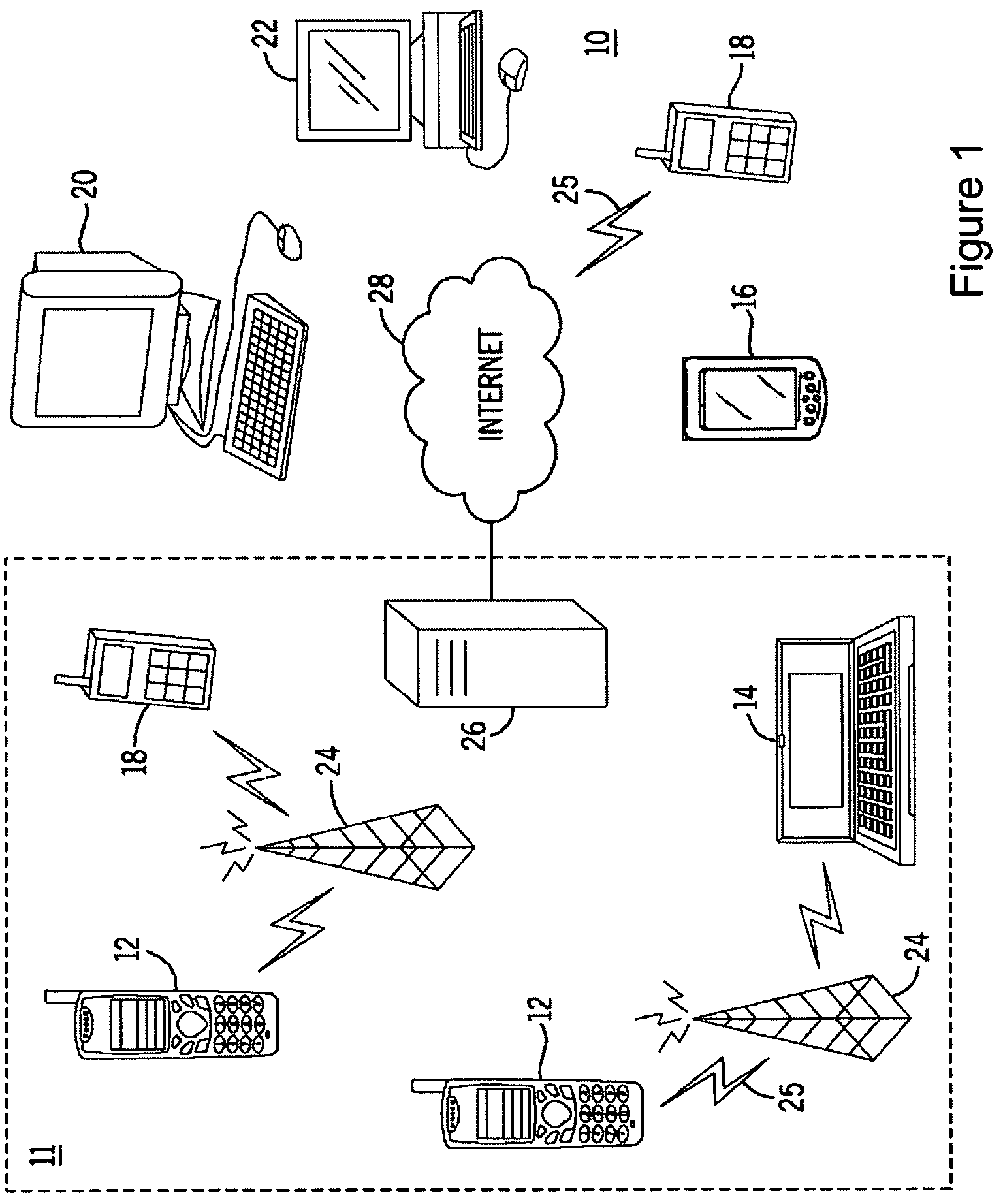

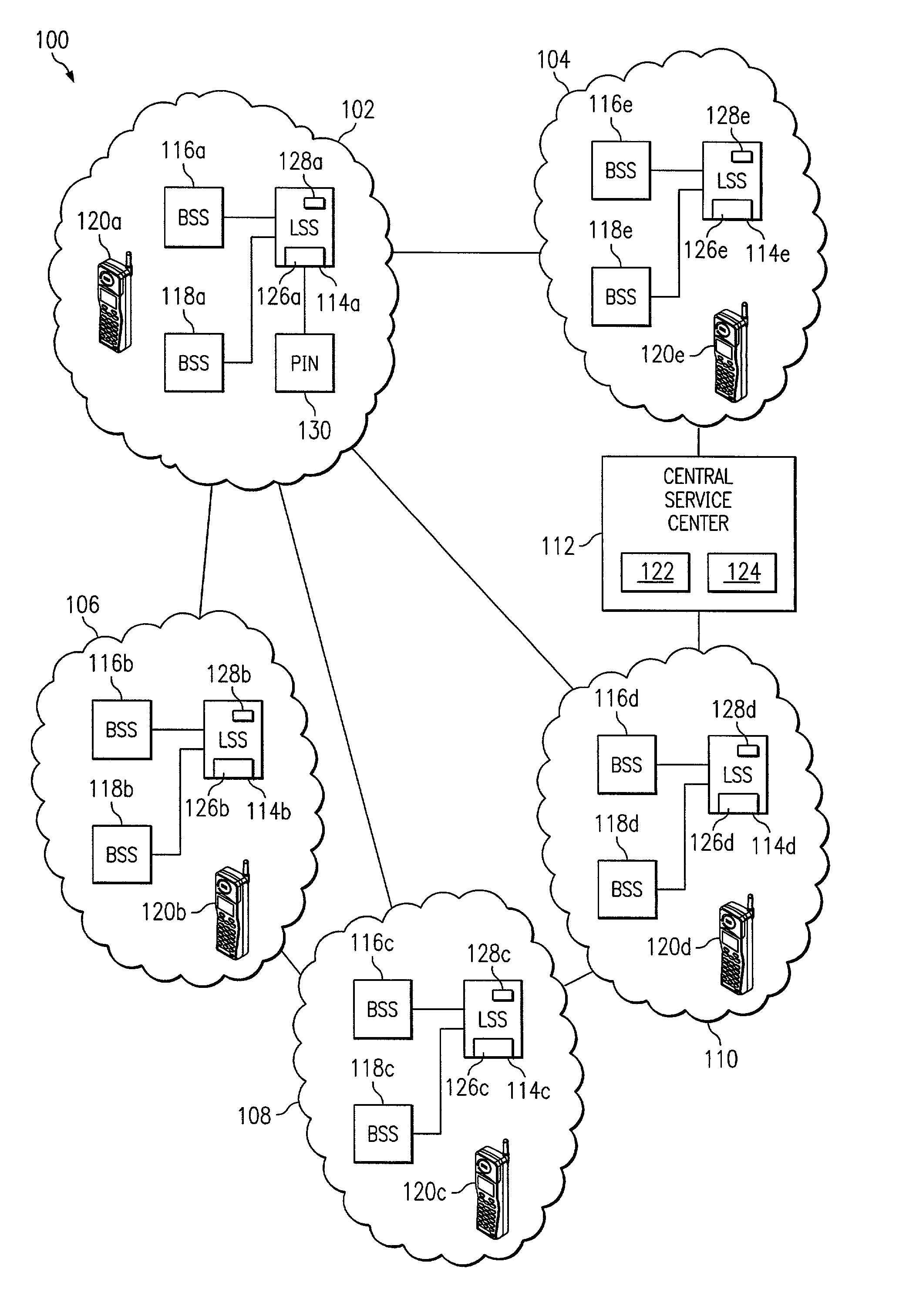

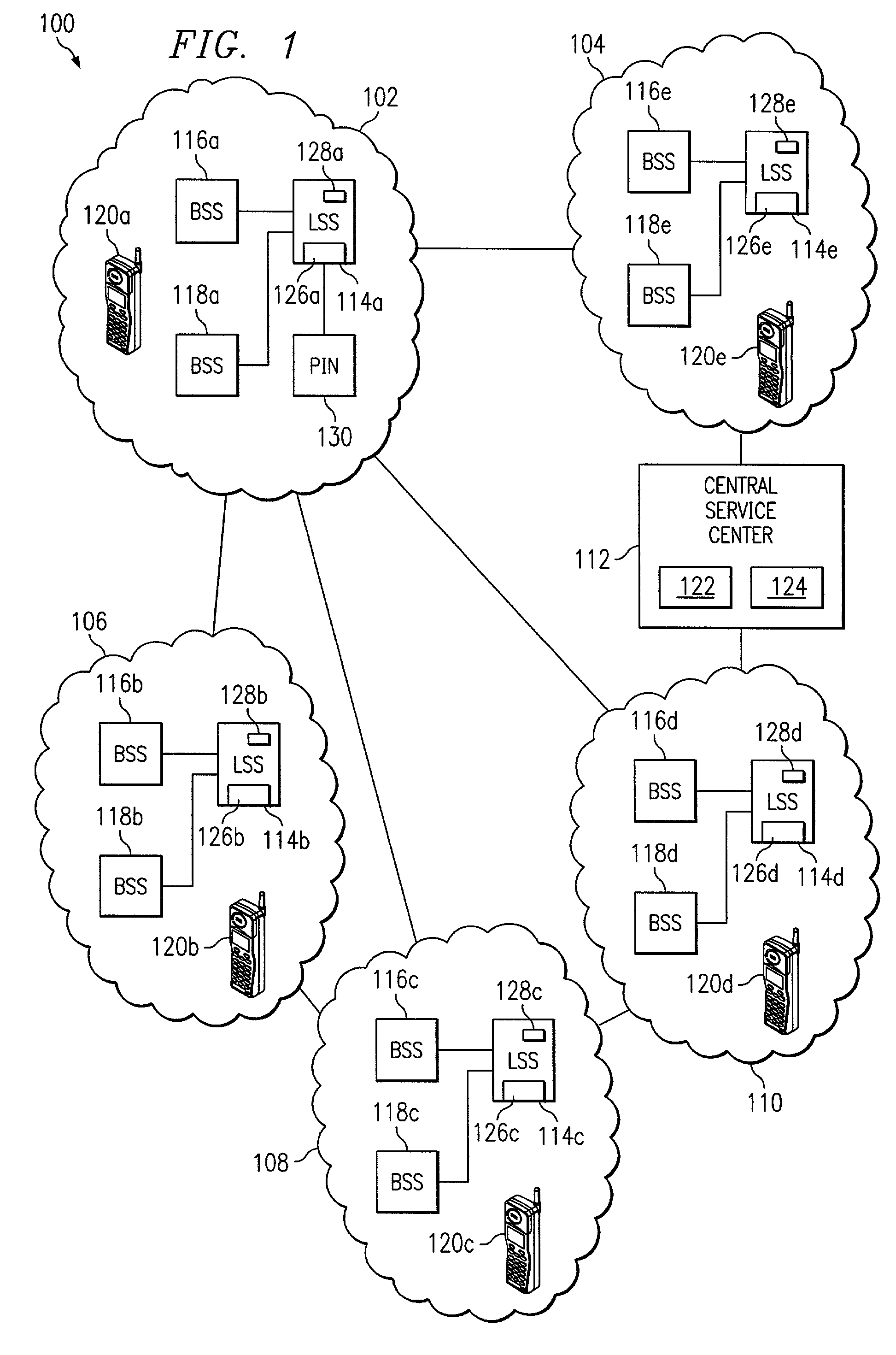

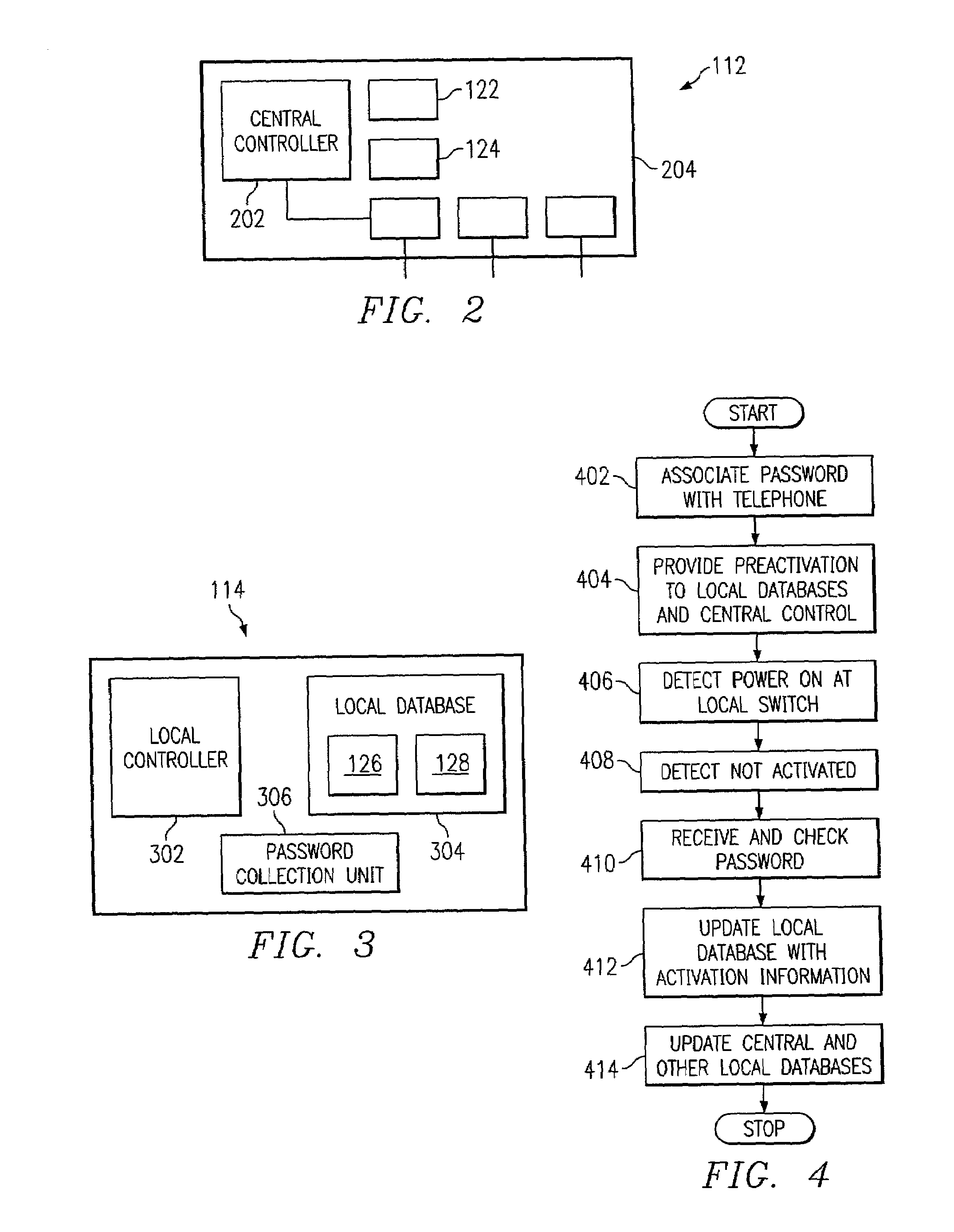

System and method for automatic mobile device activation

ActiveUS7133695B2Substation equipmentAutomatic exchangesTelecommunications networkBiological activation

A telecommunications network includes a central service center (112) for maintaining a master system database (122, 124) and propagating to switch databases preactivation information. Local switches (114) include or are operably coupled to switch databases (126, 128) and PIN collection units (130). The central service center (112) is adapted to receive a PIN and preactivation information, and then propagate this information to the local switch databases (128). The local switches (114), associated databases and PIN collection units, are adapted to detect a power on of a cellular telephone, receive and check and PIN, and activate to allow service to the telephone. The local switches (114) are further adapted to transmit the activation information to either the central master database (122, 124) (which will then transmit to other switches) or to propagate the activation information to other switch databases itself.

Owner:UNIFY PATENTE GMBH & CO KG +1

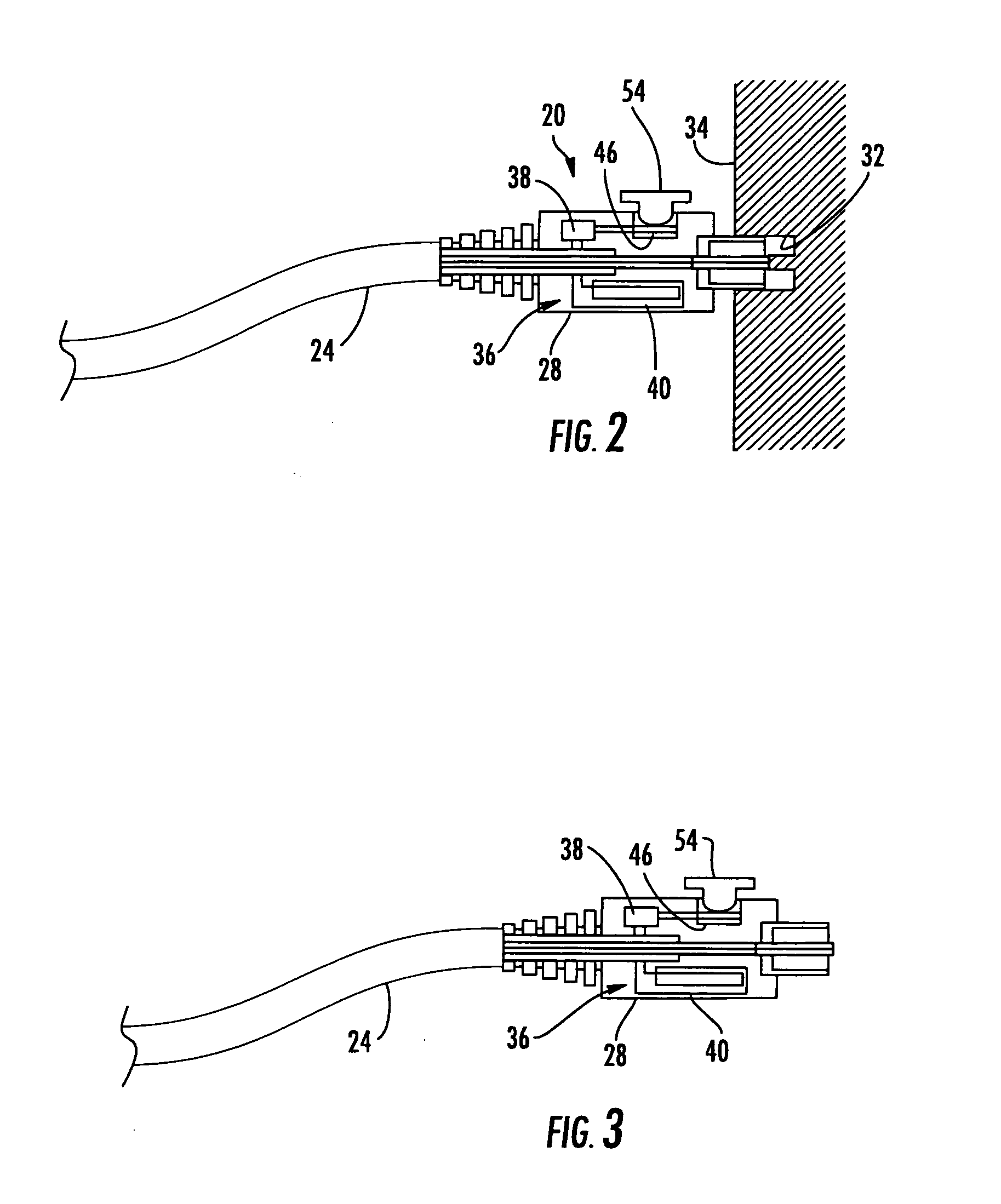

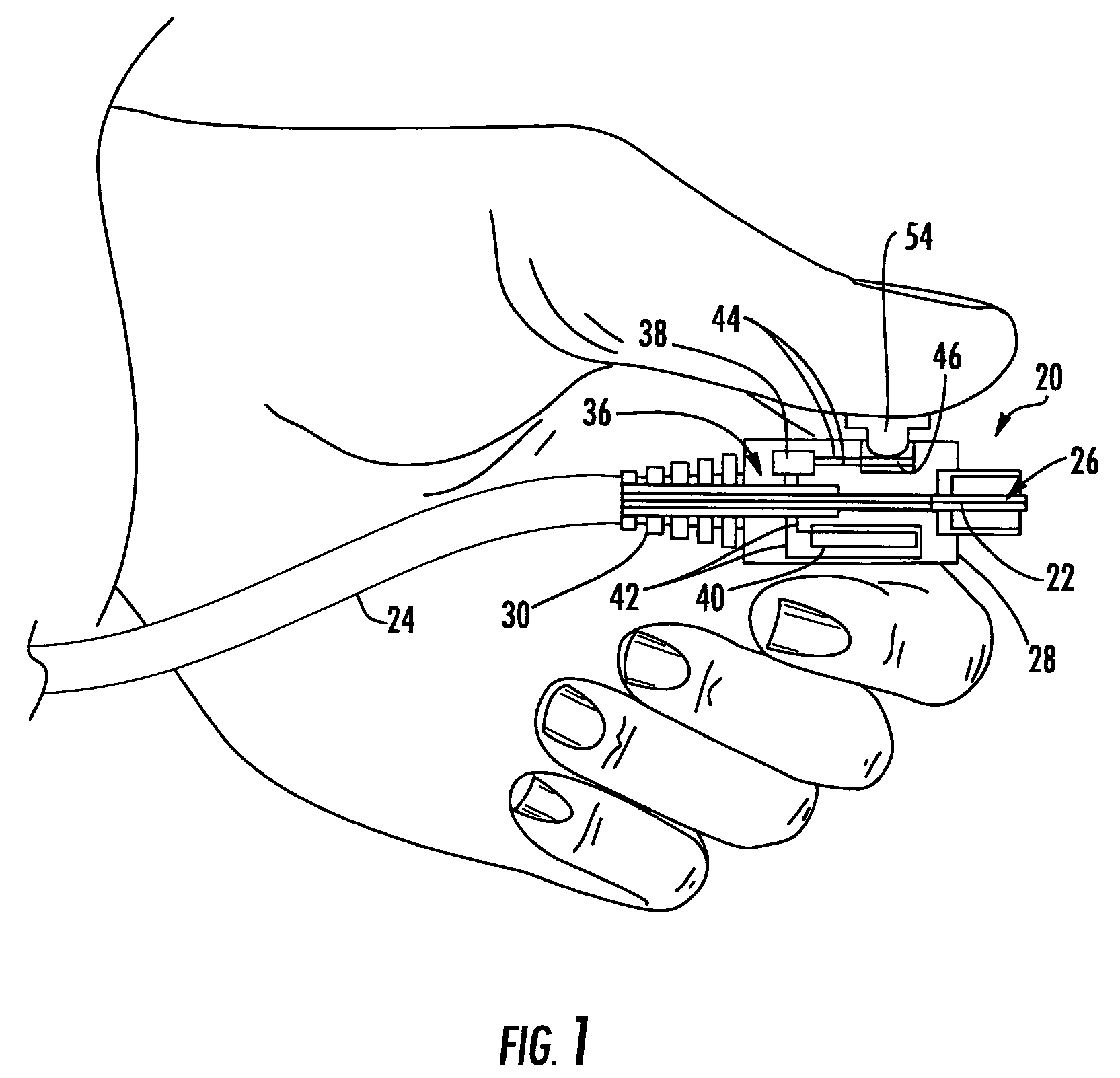

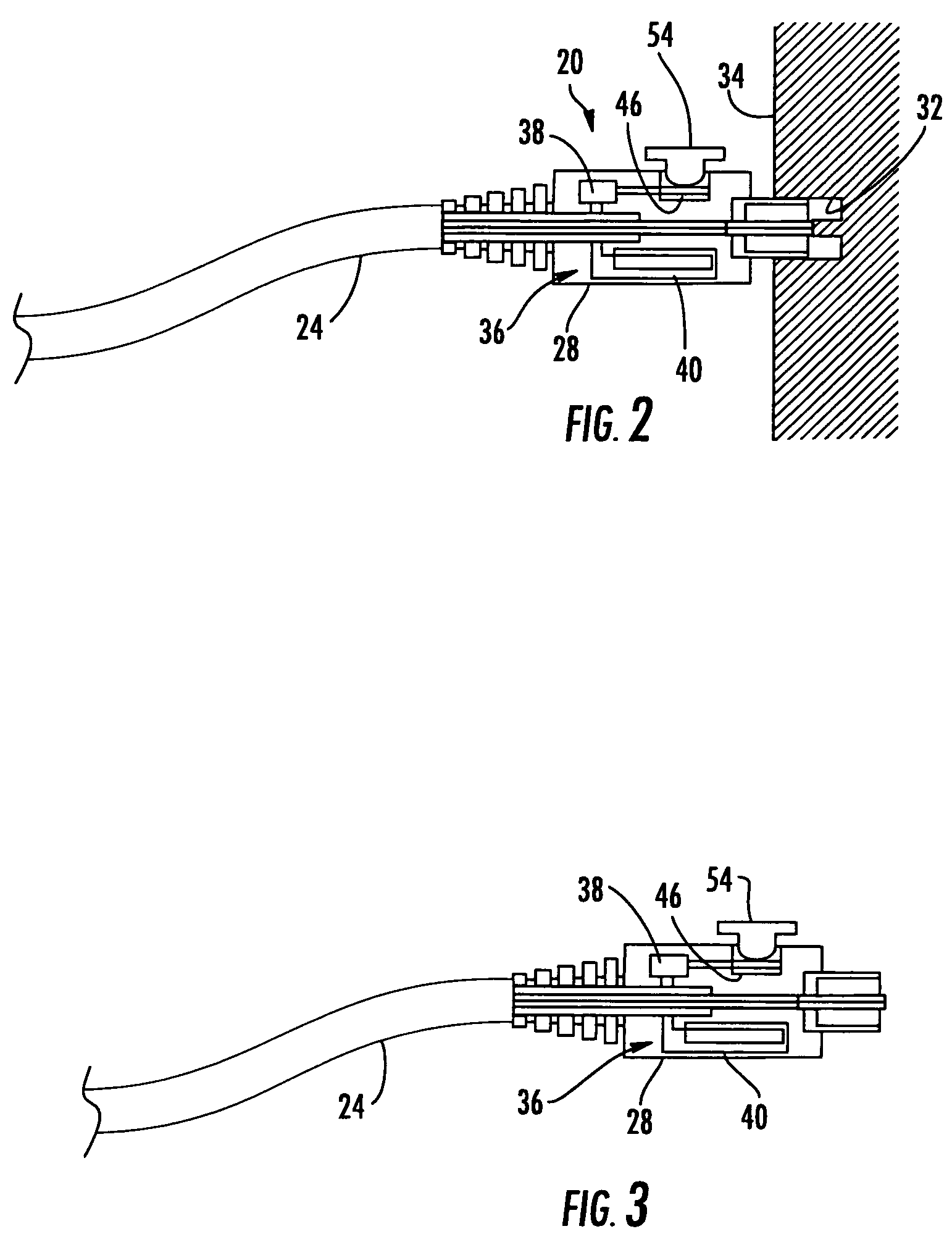

System for mapping connections using RFID function

ActiveUS20080100456A1Subscribers indirect connectionRecord carriers used with machinesProcessing elementEmbedded system

There is provided a system for identifying a plurality of components via an RFID reader with an associated database and processing element. The system includes a first component with an associated first RFID transponder and a second component with an associated second RFID transponder. A third RFID transponder may be associated with the first component, wherein either the first or third RFID transponder includes stored information relating to both transponders. The first and second RFID transponders are adapted to communicate with the RFID reader to enable identification of the connection of the first component to the second component. One of the RFID transponders may be adapted to identify the other RFID transponder and store the identification information for subsequent communication to the RFID reader of identification information for both RFID transponders and the associated components. The system is adapted to create a map of the two or more components, such as components of telecommunications equipment.

Owner:FIBER MOUNTAIN INC

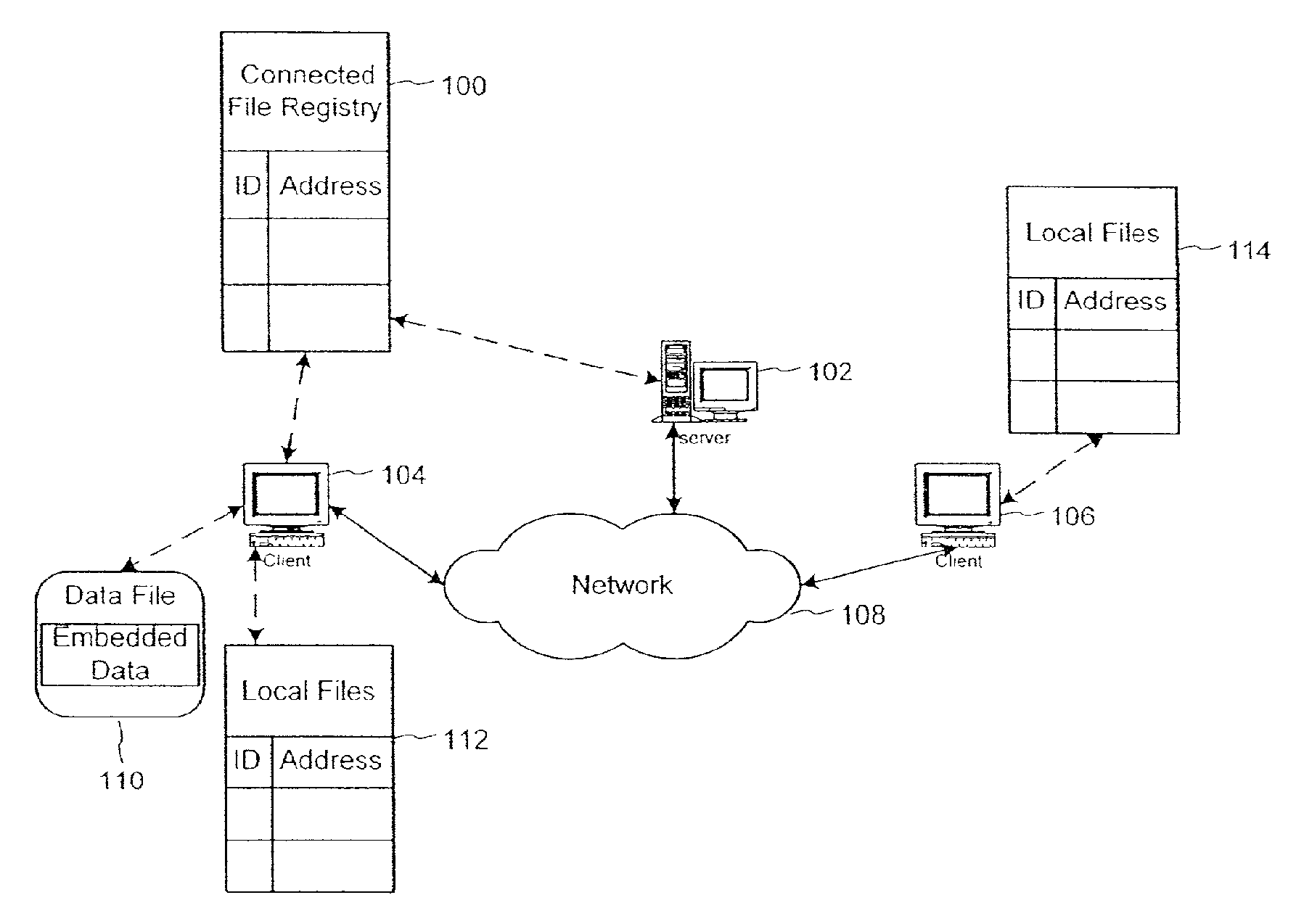

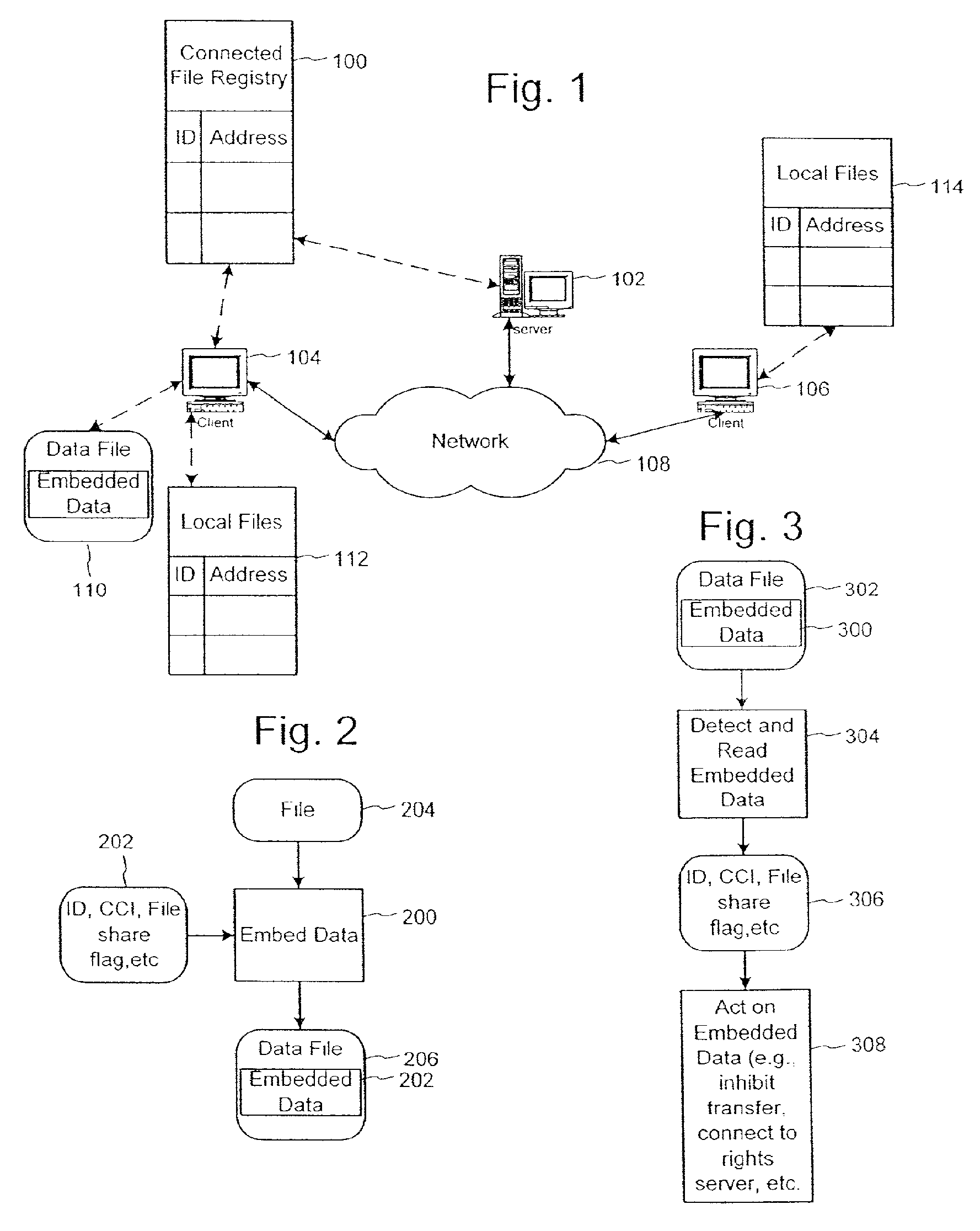

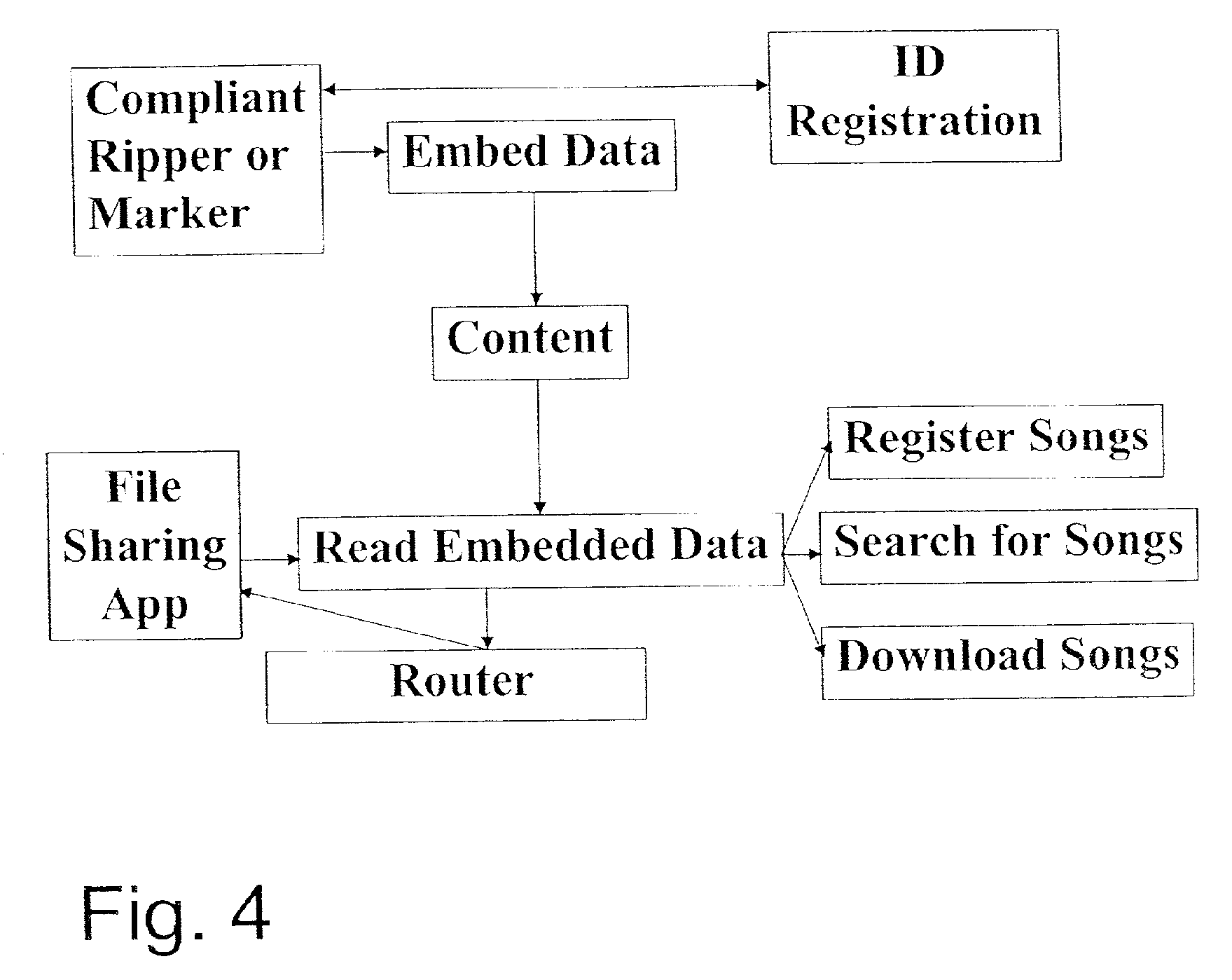

Using object identifiers with content distribution

InactiveUS20080052783A1Easy to liftFacilitates and enhances authorized file sharingDigital data processing detailsAnalogue secracy/subscription systemsContent distributionComputer science

Object identifiers are used in a variety of content distribution arrangements, including—but not limited to—peer to peer networks. The object identifiers may be of different forms, including digital watermarks, fingerprint identifiers, etc. Through use of such identifiers, sometimes in conjunction with related databases, a number of functions and services can be readily implemented. These include governing content uploading / downloading in order to inhibit piracy, and to enable subscription models. A variety of other features and arrangements are also detailed.

Owner:DIGIMARC CORP

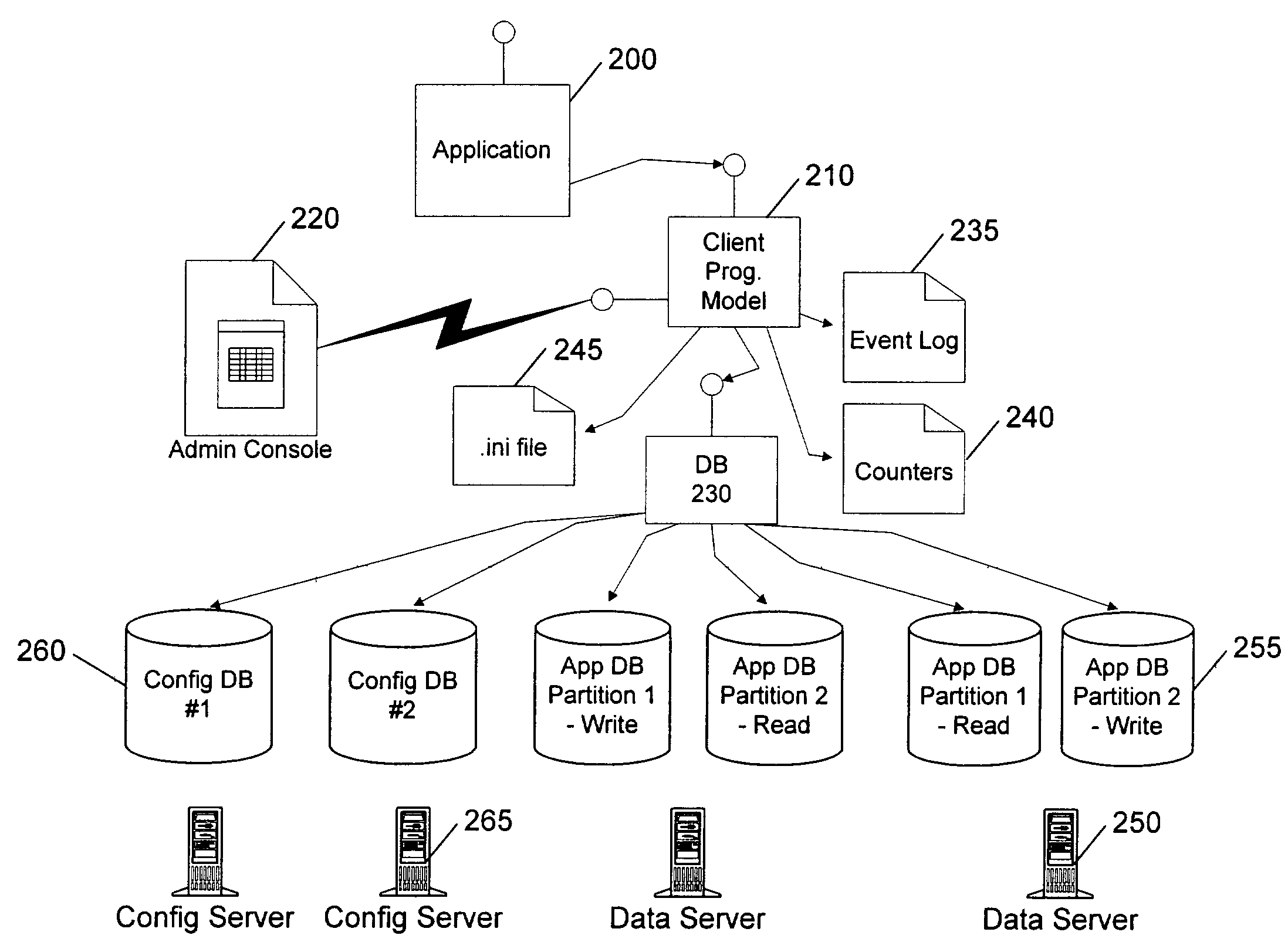

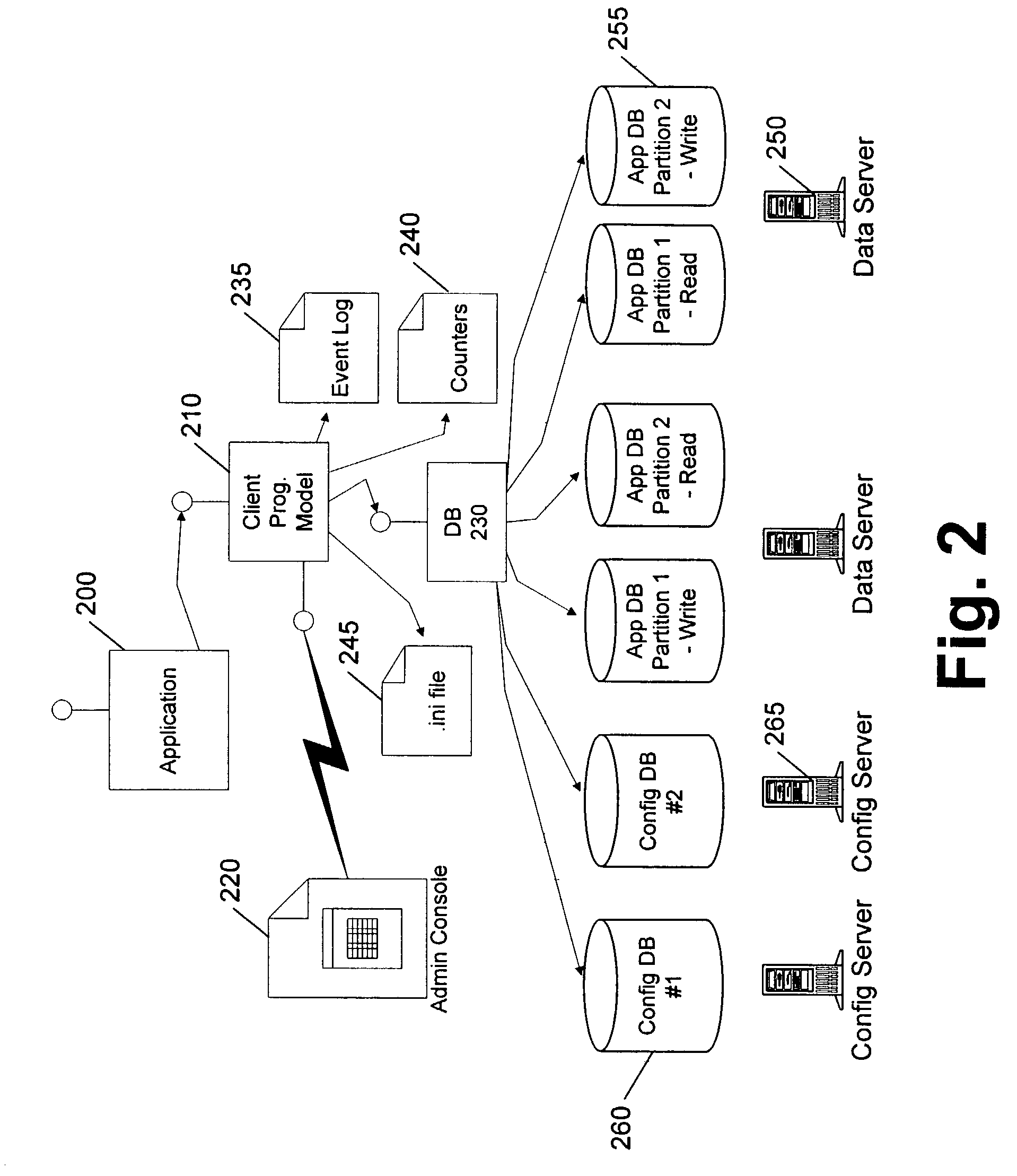

Client programming model with abstraction

InactiveUS7058958B1Digital data information retrievalData processing applicationsFailoverParallel programming model

A client programming model with abstraction hides from an underlying client application or application program interface (API) the details of where each element of data is located, and which copy of the data is resident on an available server and associated databases. The model wraps a database, such as a virtual database, and provides data-dependent and application-dependent routing, failover, and operational administration.

Owner:MICROSOFT TECH LICENSING LLC

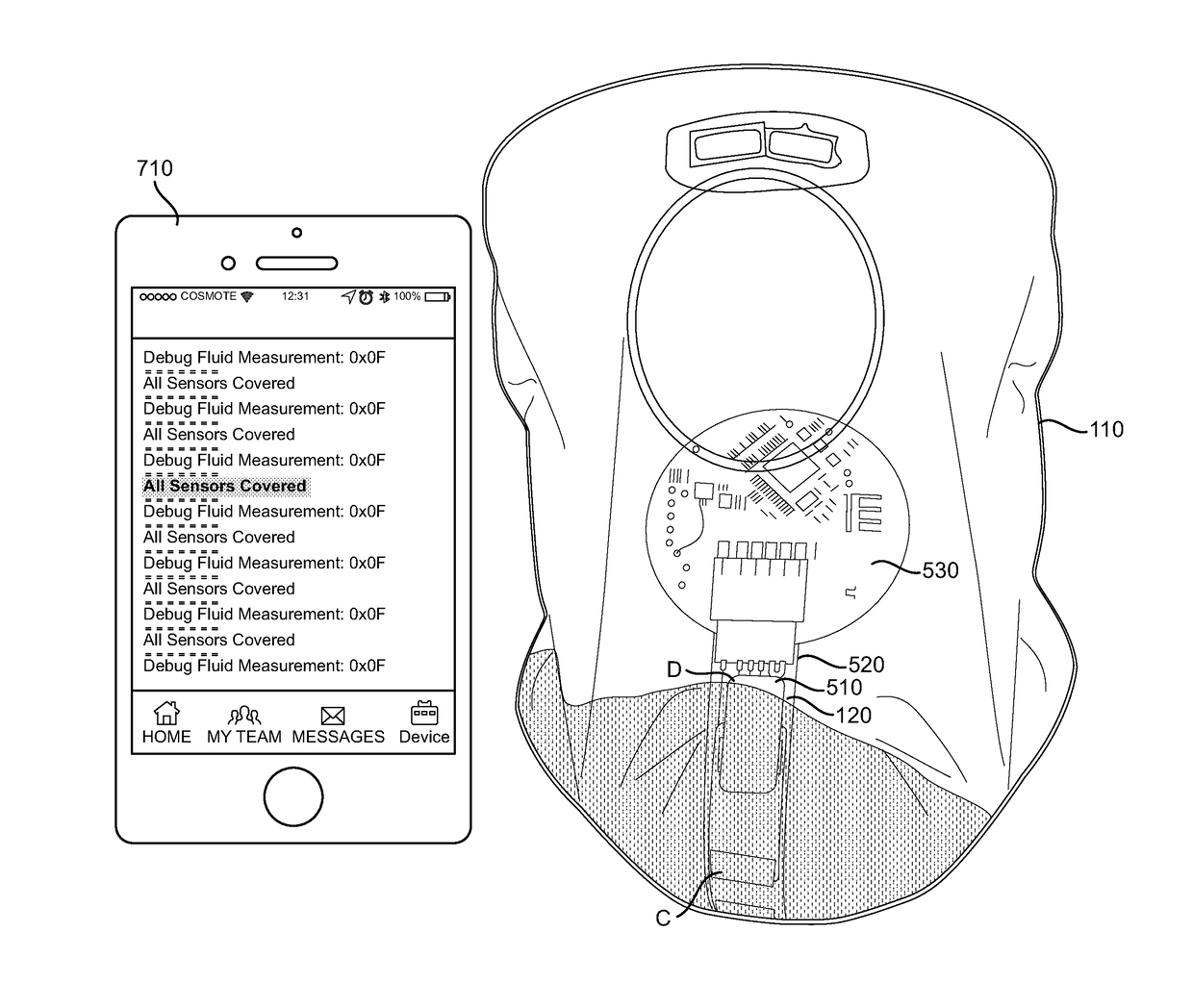

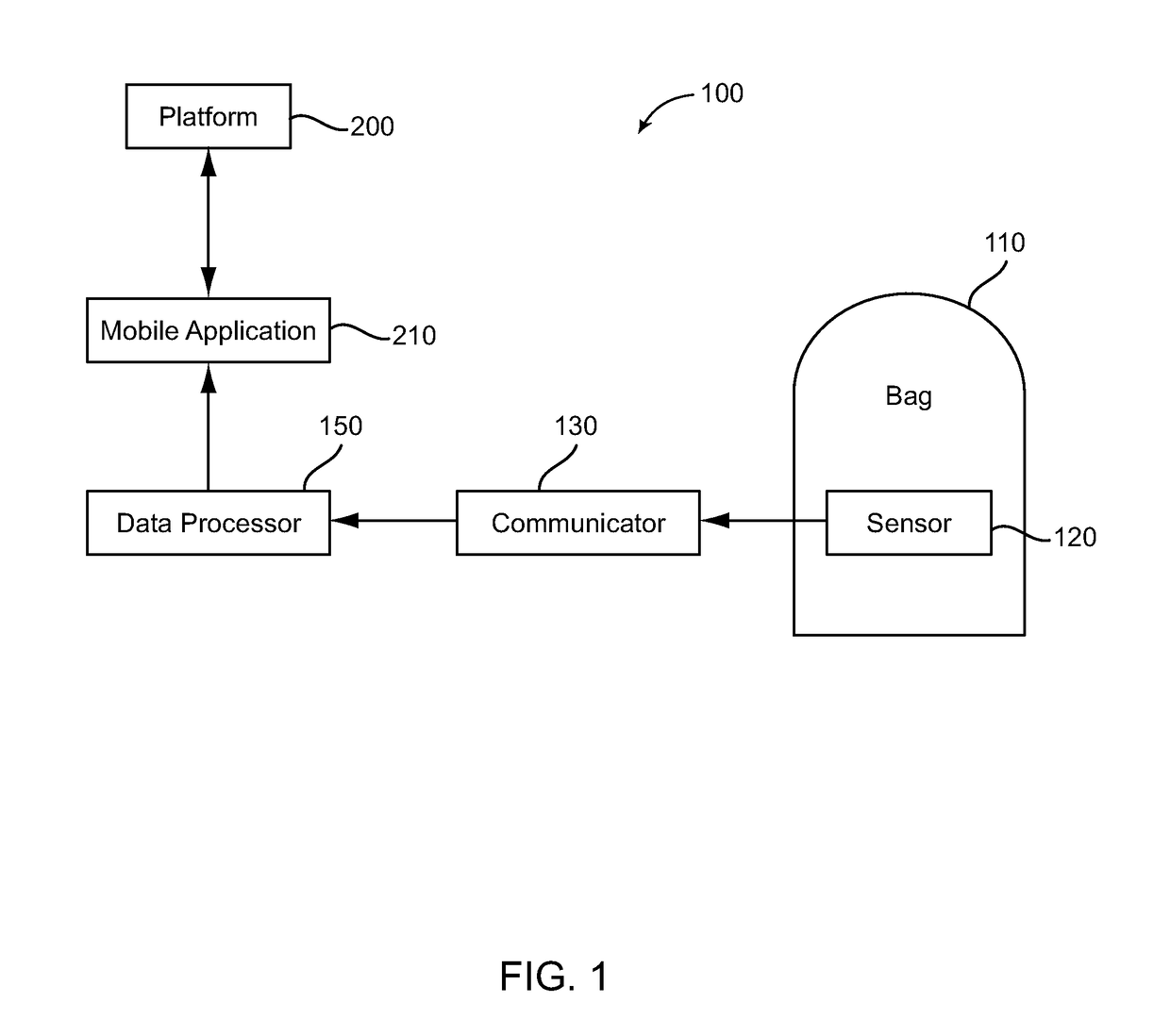

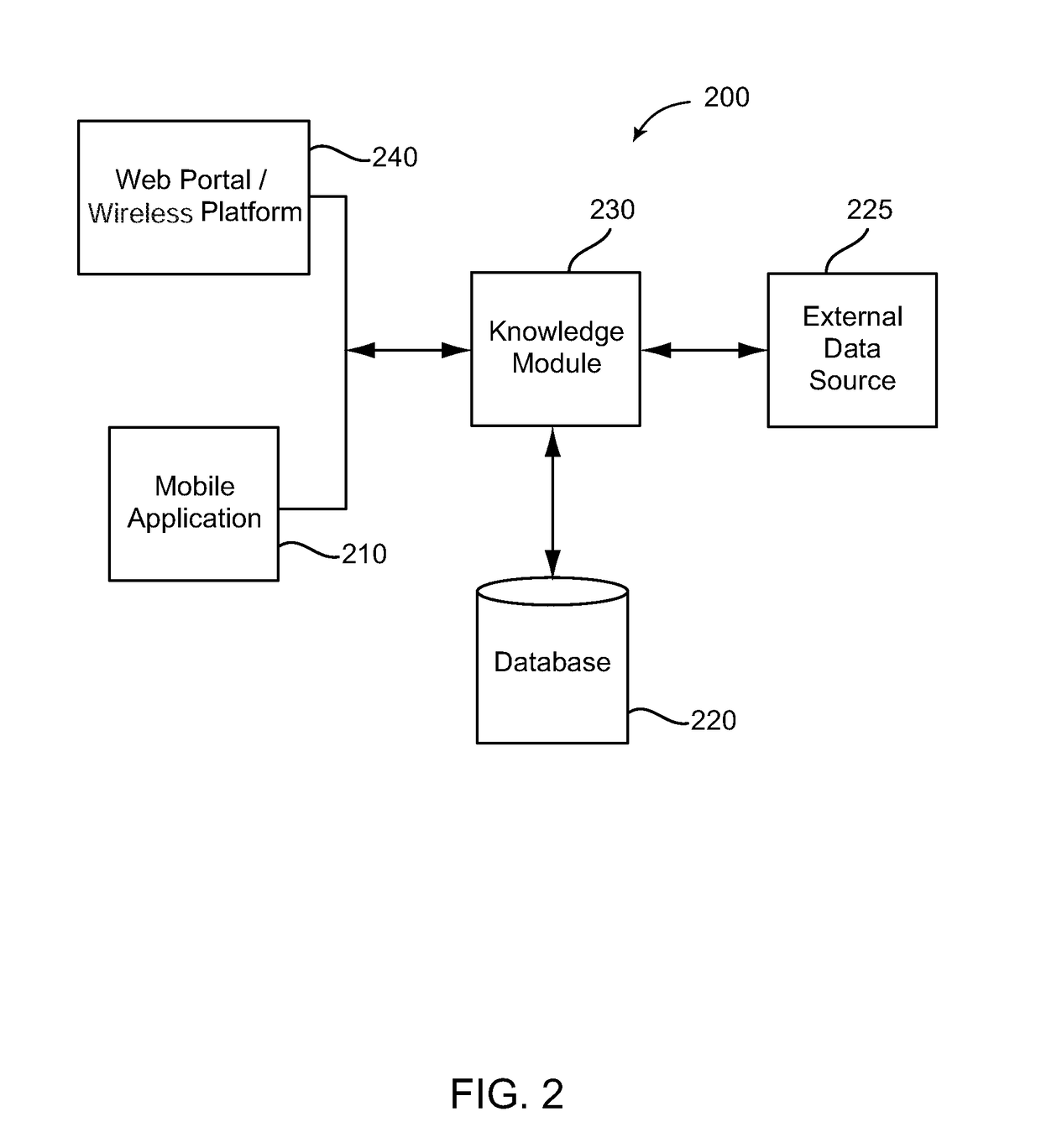

Systems and methods for providing comprehensive care for stoma patients

Embodiments of the invention include systems and methods for providing comprehensive care for stoma patients. According to one embodiment, a system for providing comprehensive care for a stoma patient includes: a sensor device for detecting a fill level of an ostomy bag fitted over and around a stoma, wherein the sensor device is configured to sense one or more parameters of an effluent received in the bag; communicating the measurements to a stoma care management software application for formatting and visualization on a patient mobile device; and transferring the formatted data to an interactive wireless stoma care management platform, wherein the platform is configured to maintain a patient related database and to periodically advise the patient of needed actions as well as to provide reminders, advice and coaching.

Owner:VIVANTE HEALTH INC

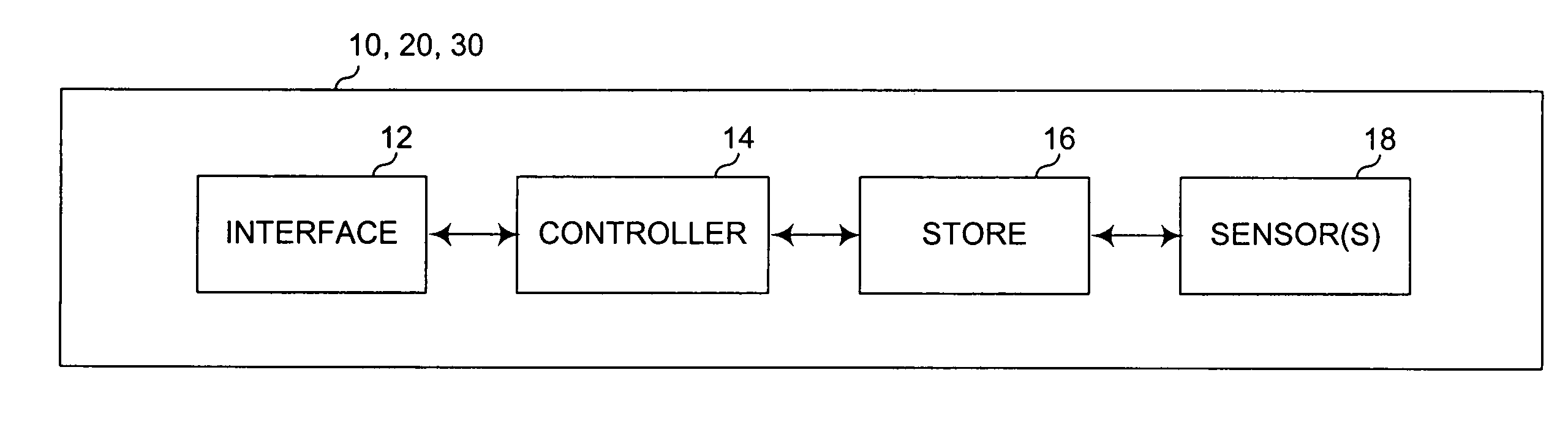

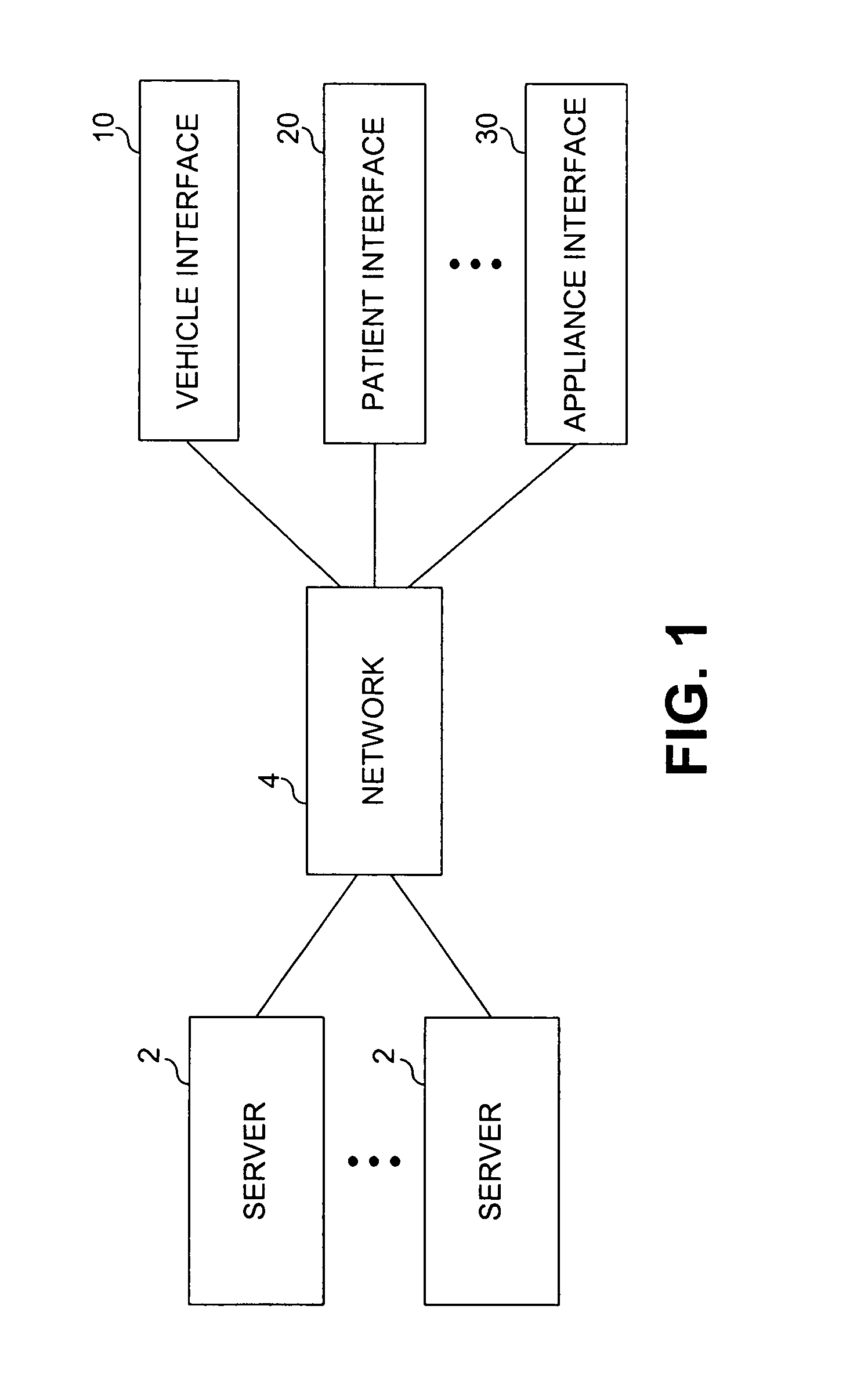

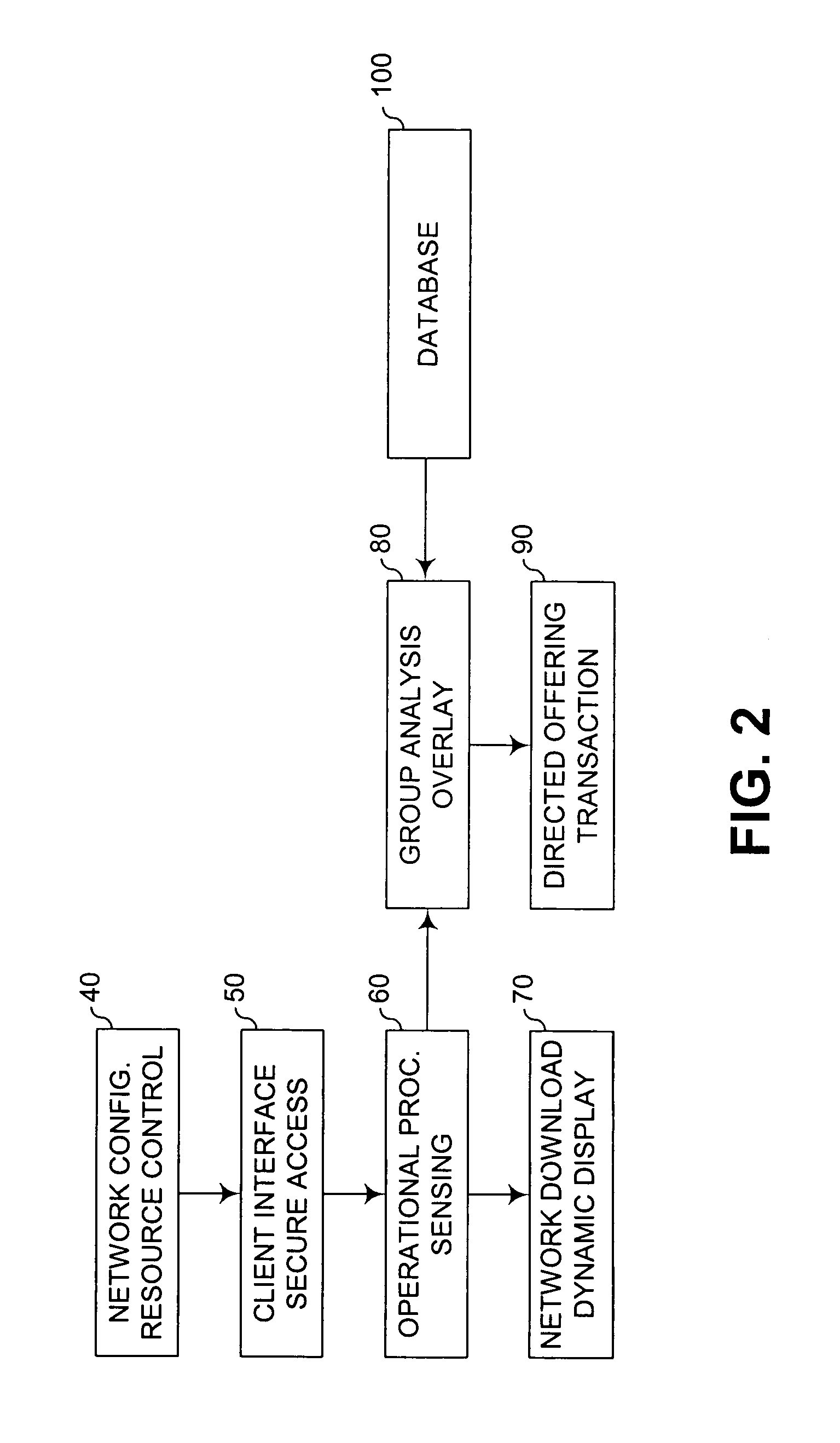

Adaptive direct transaction for network client group

Internet-based software and associated database provide group analysis overlay to monitor client-server web traffic and provide direct marketing to client group. Client car, patient, office or school sensor and interface provides overlay attribute for database comparison to classify usage pattern, location, timing, or family for targeted messaging for enhanced service from server source. Database group registry tracks client classification and provides adaptive context mapping according to set attribute relative to targeted on-line transaction.

Owner:FERNANDEZ & ASSOCS +1

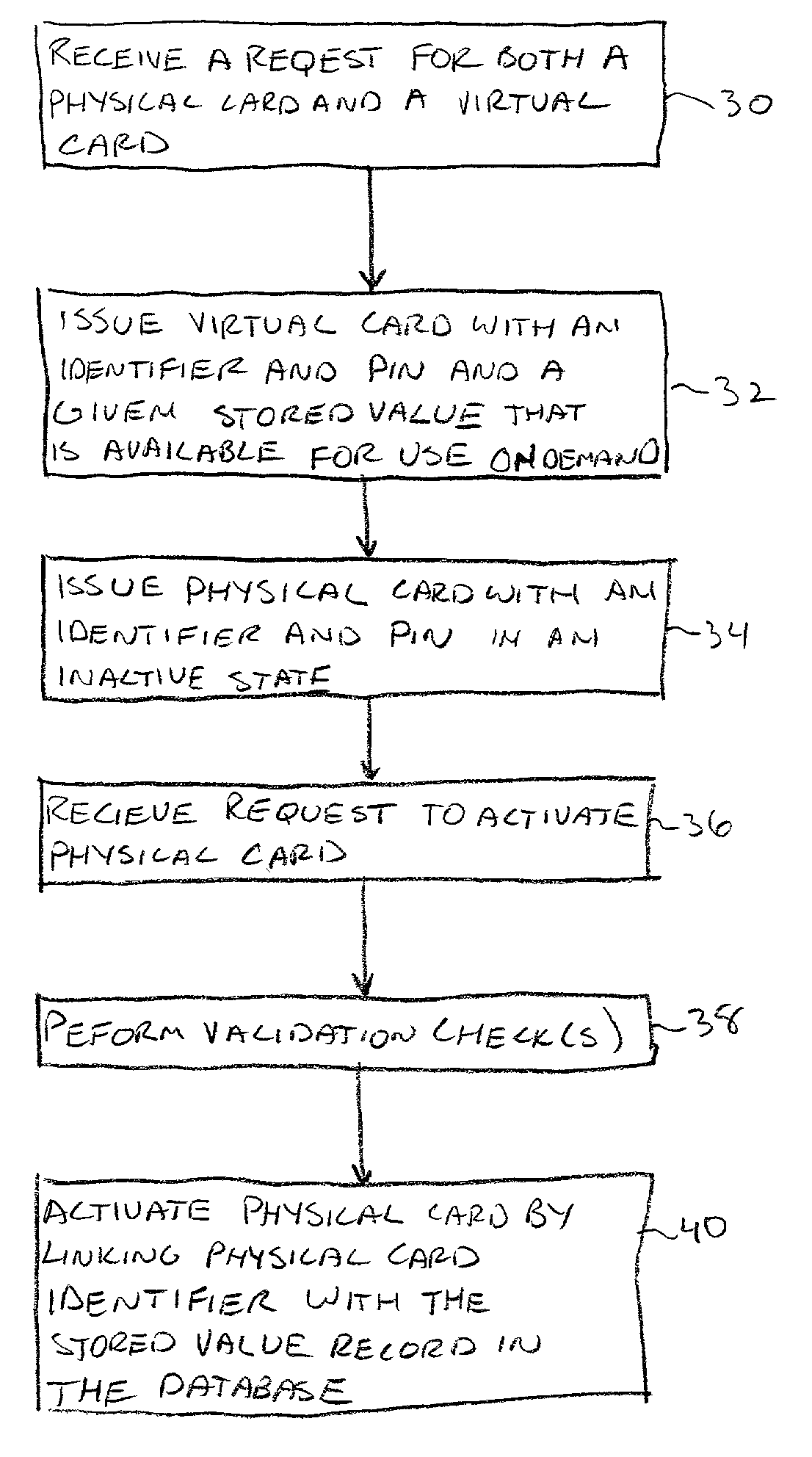

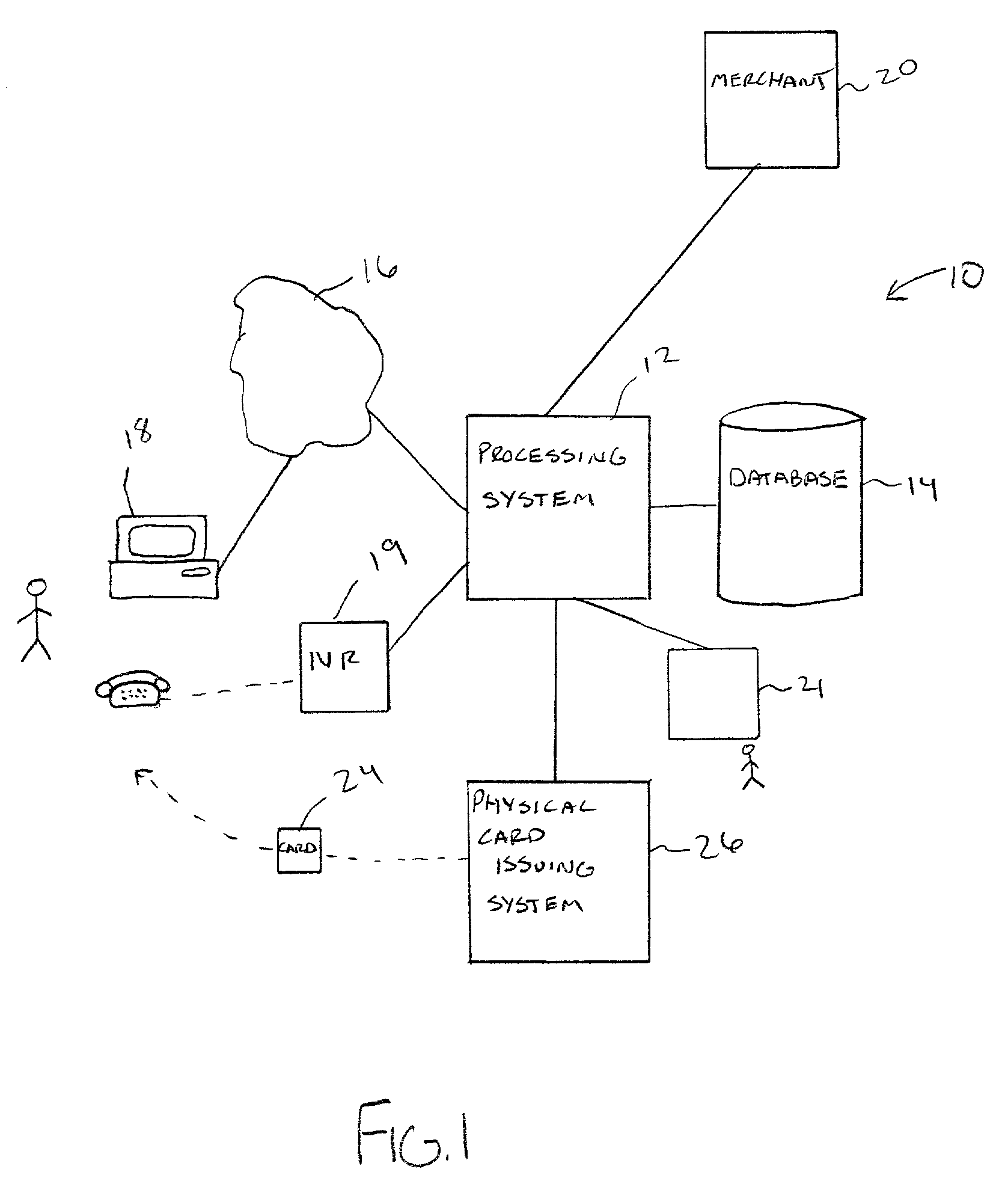

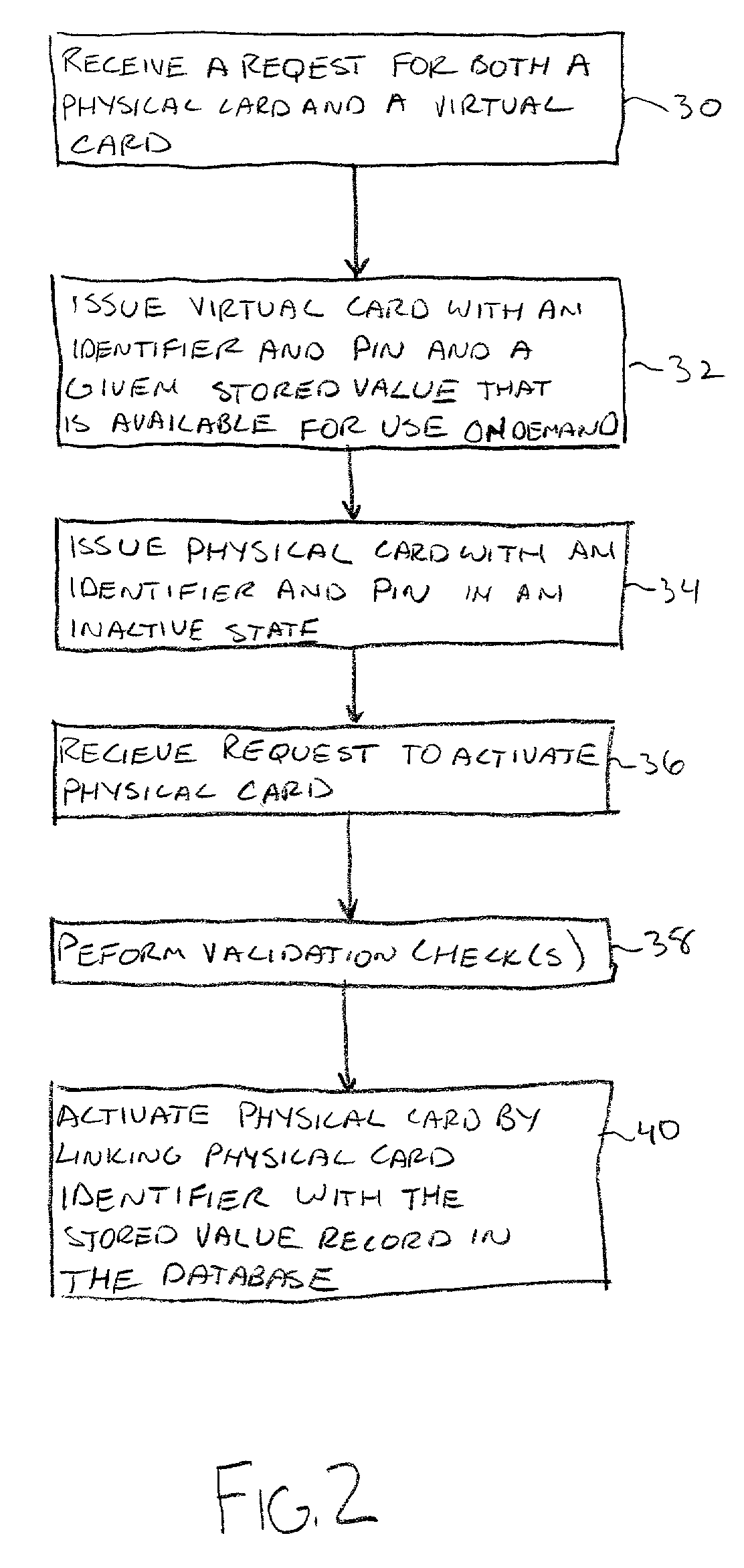

Stored value cards and methods for their issuance

InactiveUS7054842B2Low costCredit registering devices actuationFinanceComputer hardwareStored-value card

A method for issuing both a virtual card and a physical card to a cardholder comprises issuing a virl card to a cardholder, with the virtual card comprising an identifier and an associated database record of a stored value. A physical card is also issued to the cardholder. The physical card includes an identifier that is different from the virtual card identifier, and the physical card is in an inactive state until the physical card is activated by linking of the physical card identifier to the database record of the stored value.

Owner:FIRST DATA +1

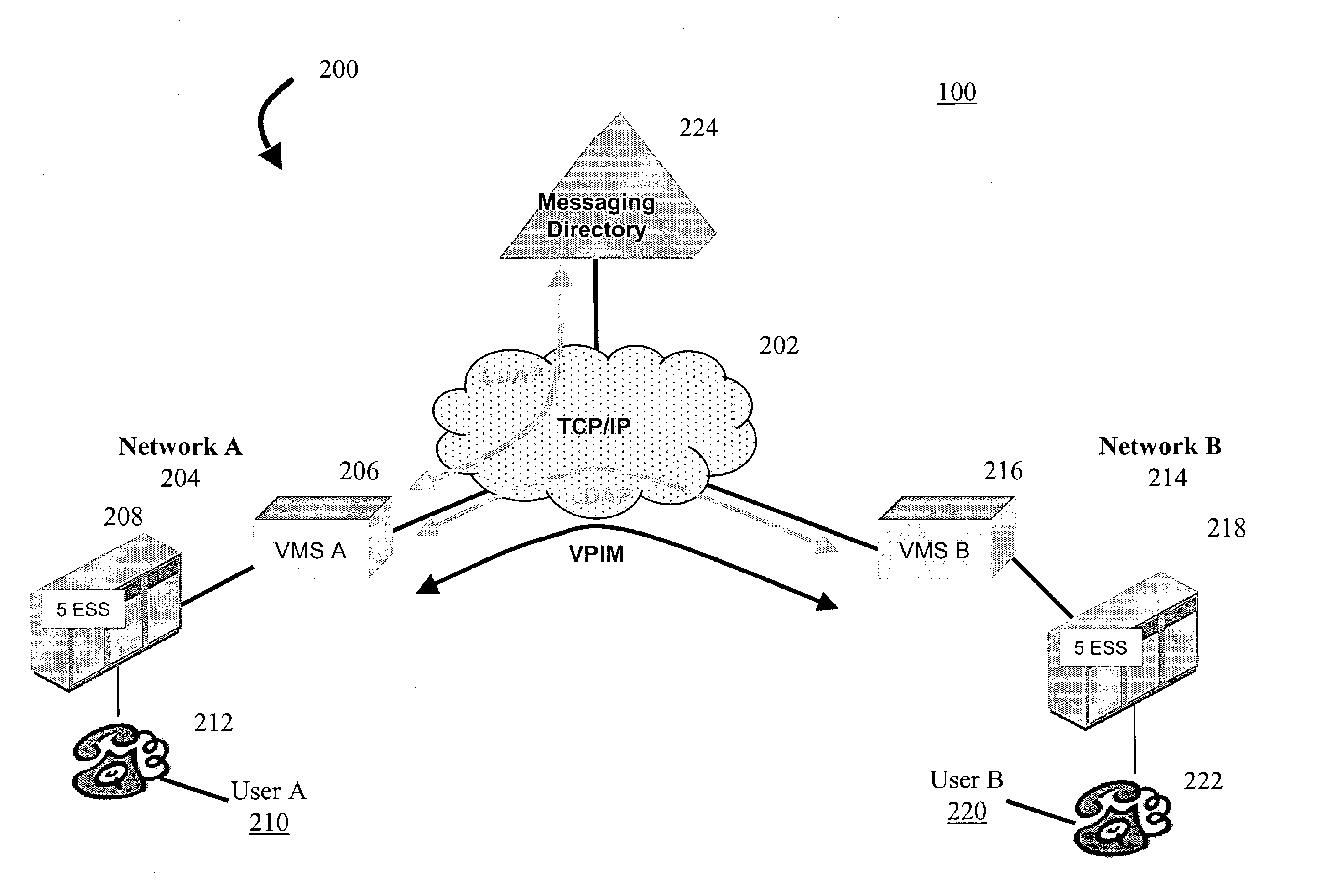

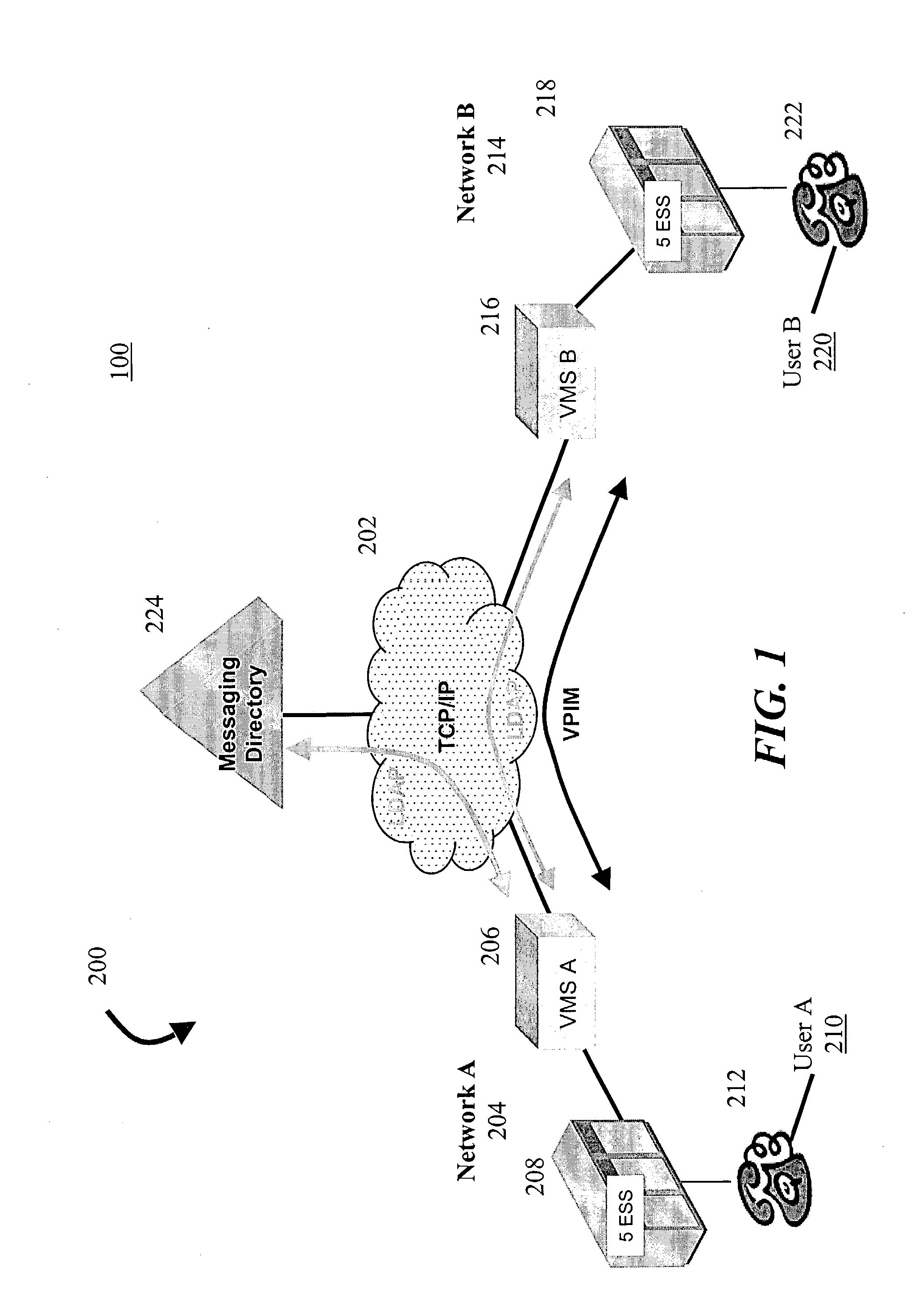

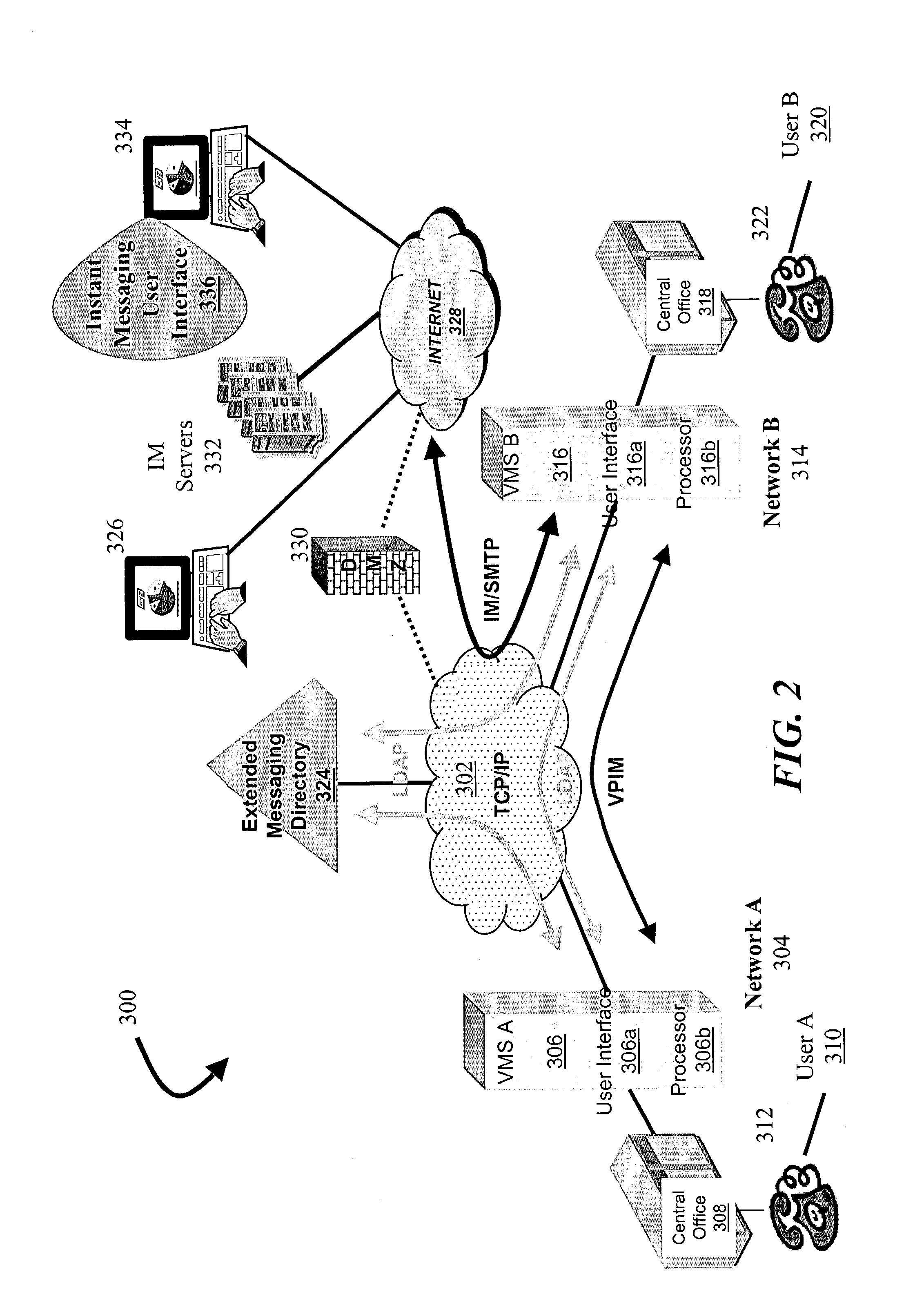

Systems and methods for originating and sending a voice mail message to an instant messaging platform

InactiveUS7283620B2Automatic call-answering/message-recording/conversation-recordingAutomatic exchangesMessage passingSpeech sound

Systems and methods for originating and sending a voice mail message to an instant messaging platform. One particular system includes a voice mail service adapted to receive a voice mail message and information associated with a recipient subscriber, request an instant messaging address associated with the recipient subscriber's information, and encode the voice mail message for transmission to an instant messaging platform. The system also includes an associated database adapted to provide the voice mail service with an instant messaging address associated with the recipient subscriber's information. Further, the system includes an instant messaging platform adapted to receive the encoded voice mail message from the voice mail service. Also, the system includes a network in communication with the voice mail platform and the instant messaging platform, wherein the voice mail platform transmits the encoded voice mail message to the instant messaging address, and the network routes the encoded voice mail message to the instant messaging platform.

Owner:BELLSOUTH INTPROP COR

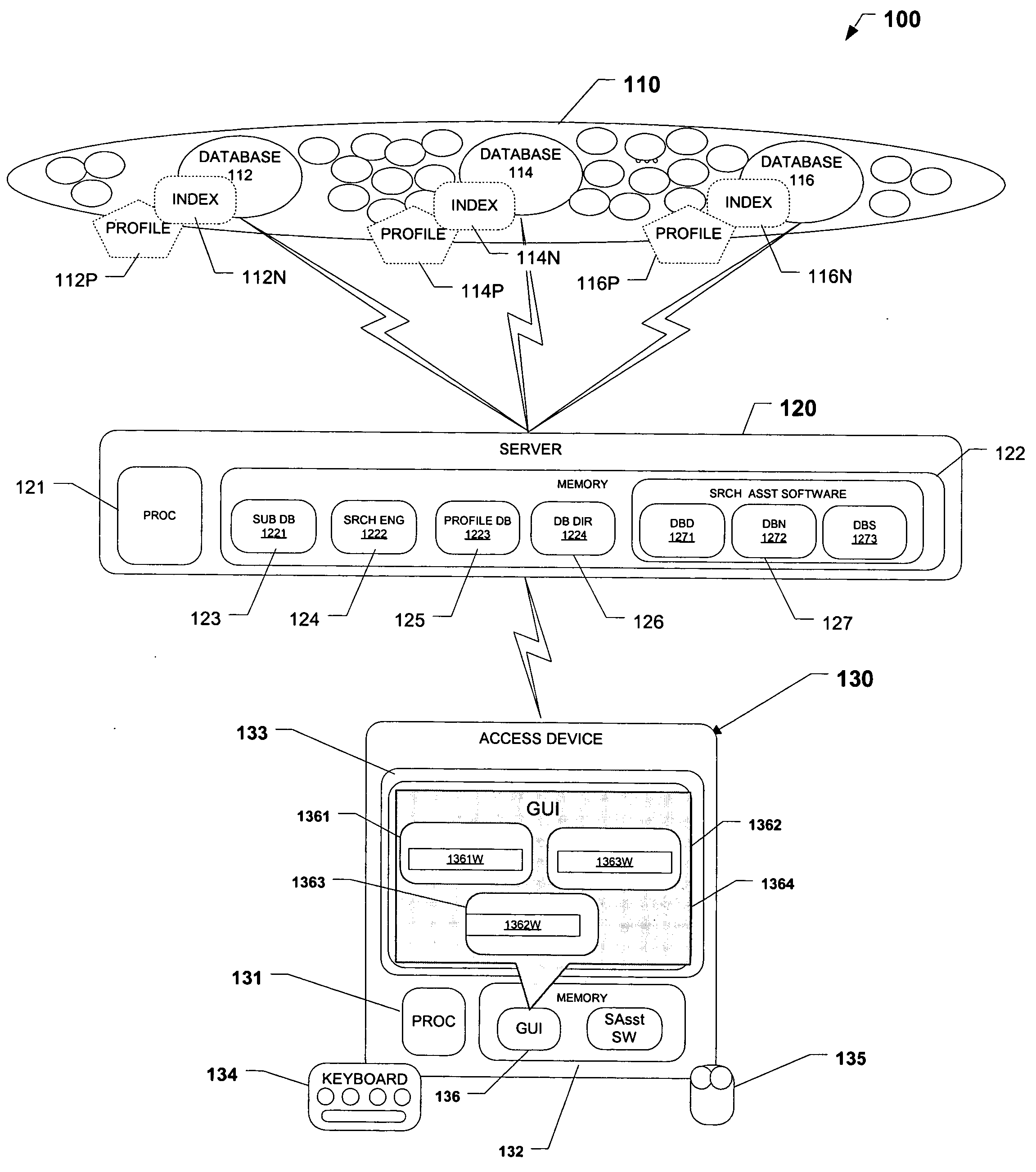

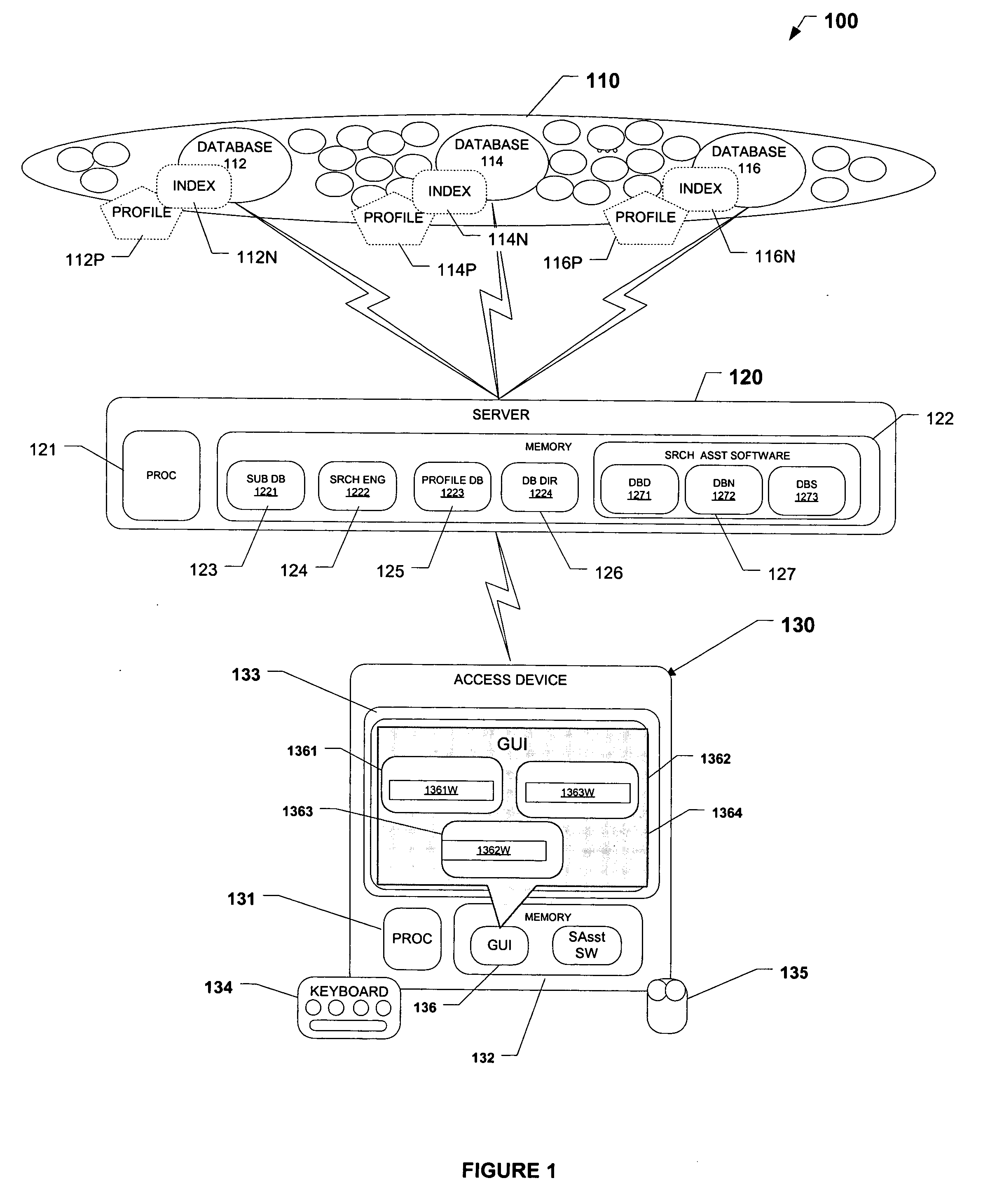

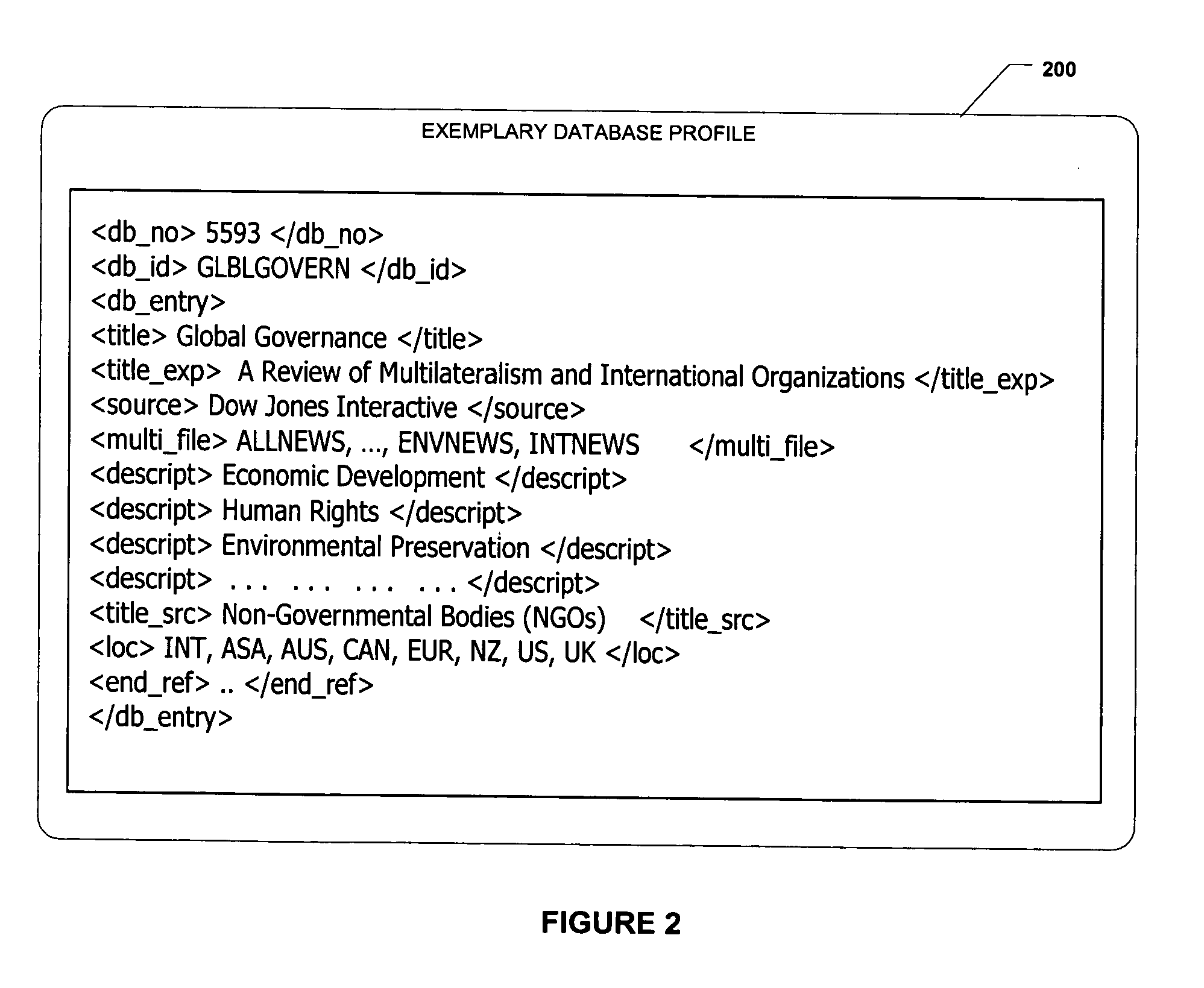

Information retrieval systems with database-selection aids

ActiveUS20050010605A1Effectively and efficiently targetingLighten the computational burdenWeb data indexingDigital data processing detailsComputer scienceOnline database

Owner:THOMSON REUTERS ENTERPRISE CENT GMBH

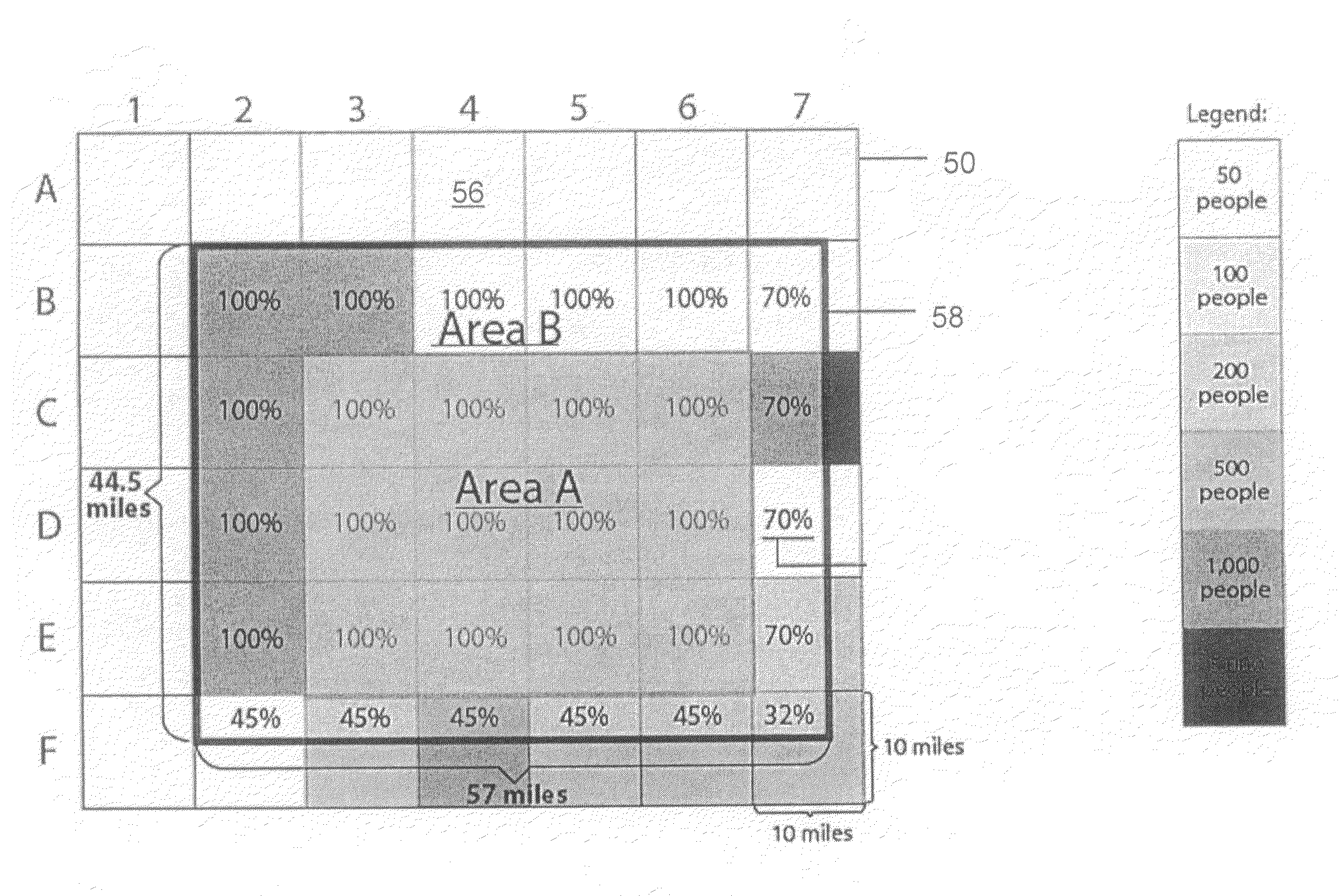

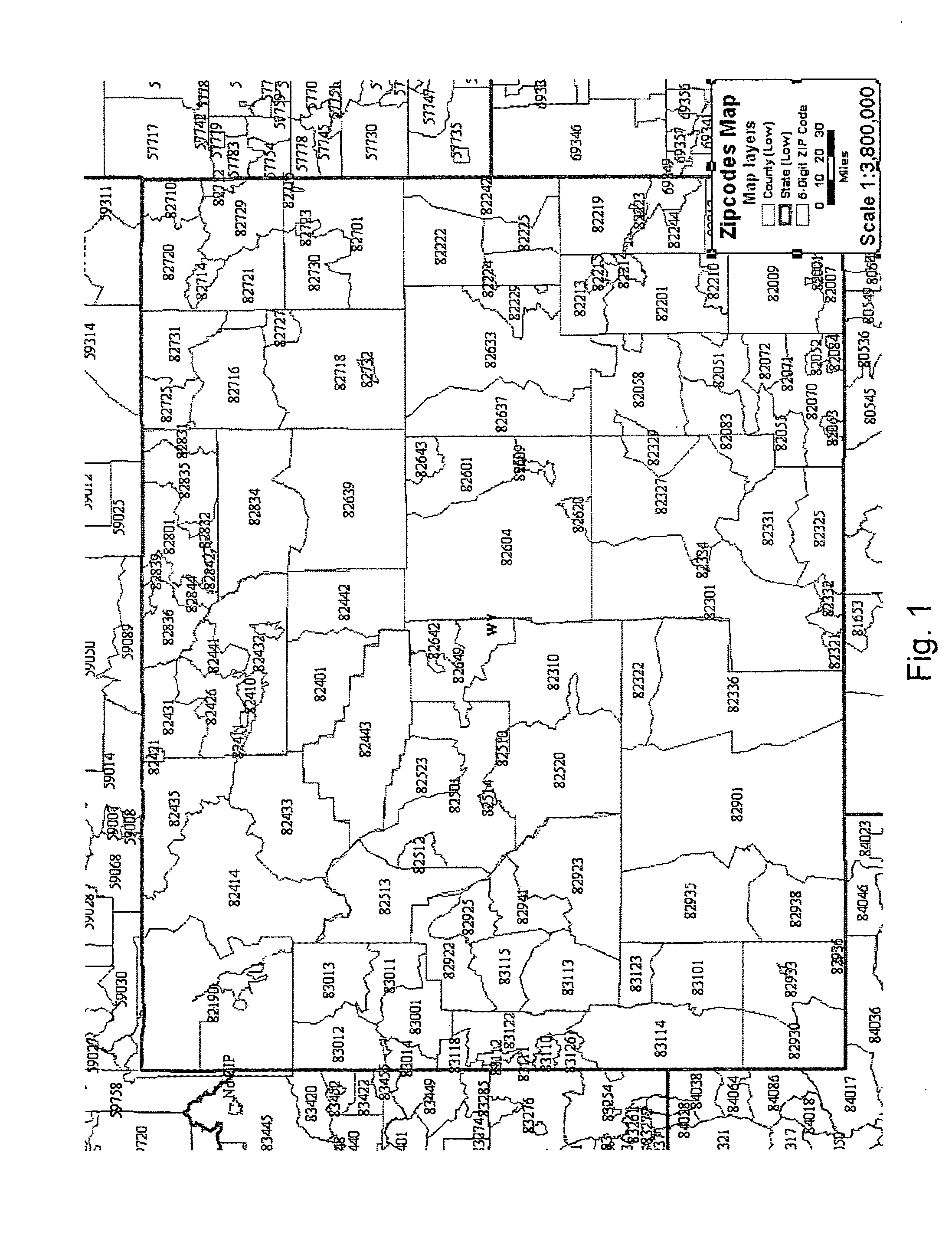

Adaptive map layer visibility control

InactiveUS20090158185A1Improve visibilityMaps/plans/chartsDigital output to display deviceVisibilityComputer science

The instant application provides a method and related system that adaptively turns layers on and off based upon a visibility value extracted from a respective layer or related database. Map data is first portioned by a grid and the visibility value for a layer is computed for each grid element. For a given map view, the visibility value of all grid elements within the view is used to compute an overall average visibility value for the layer in the current map view. The layer is then activated based upon the average visibility value as compared to a table of optimal scales.

Owner:SOCIAL EXPLORER

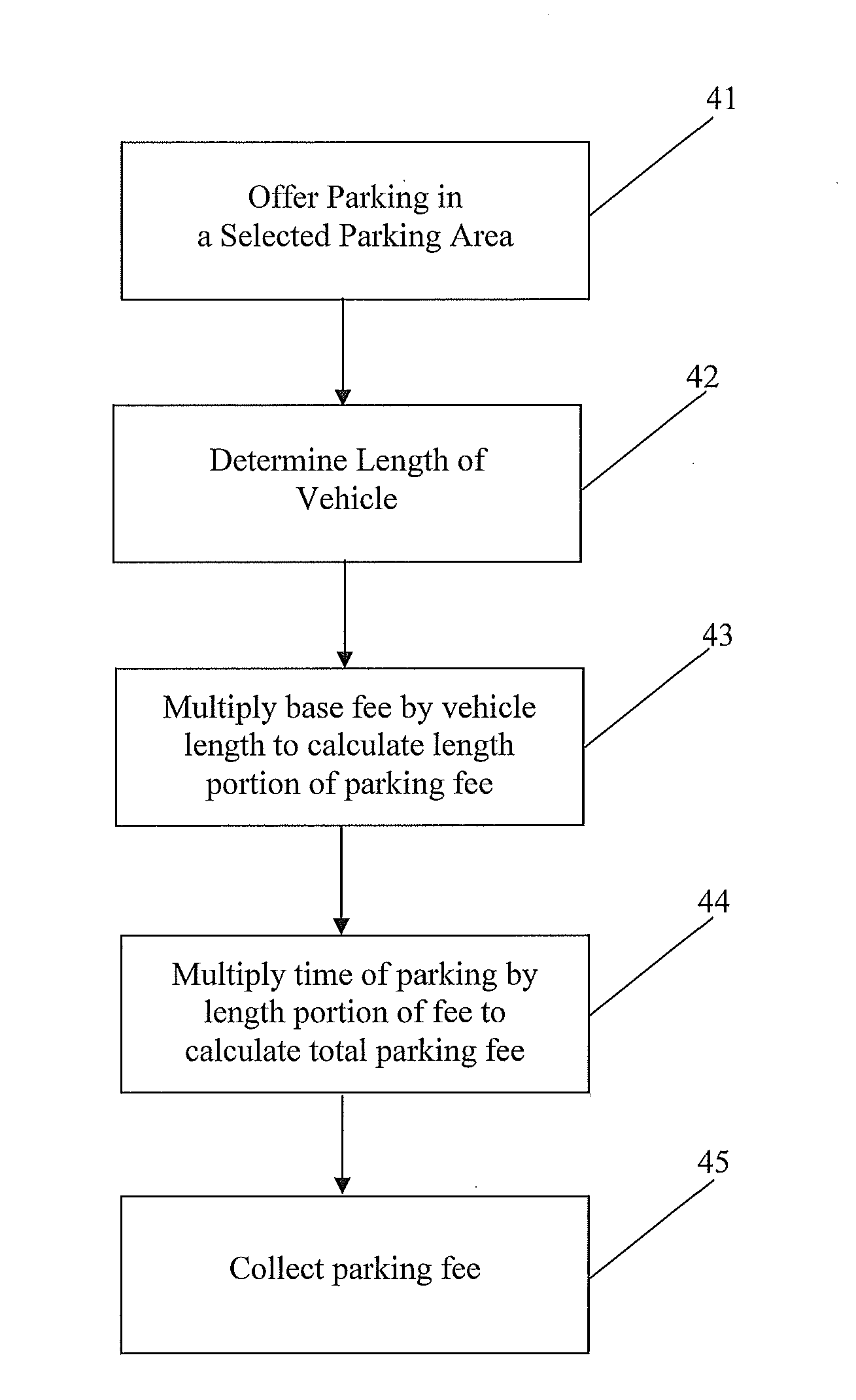

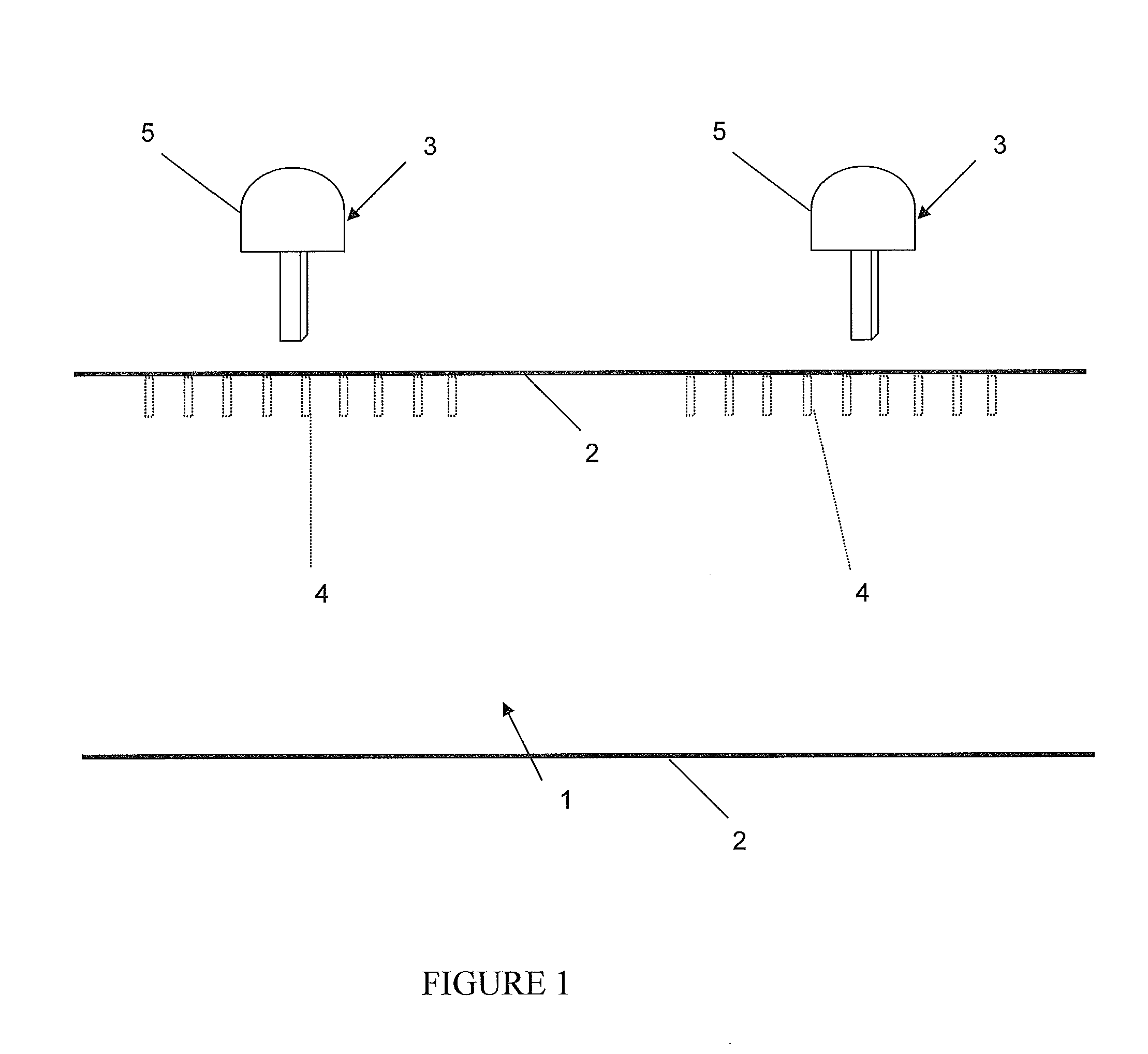

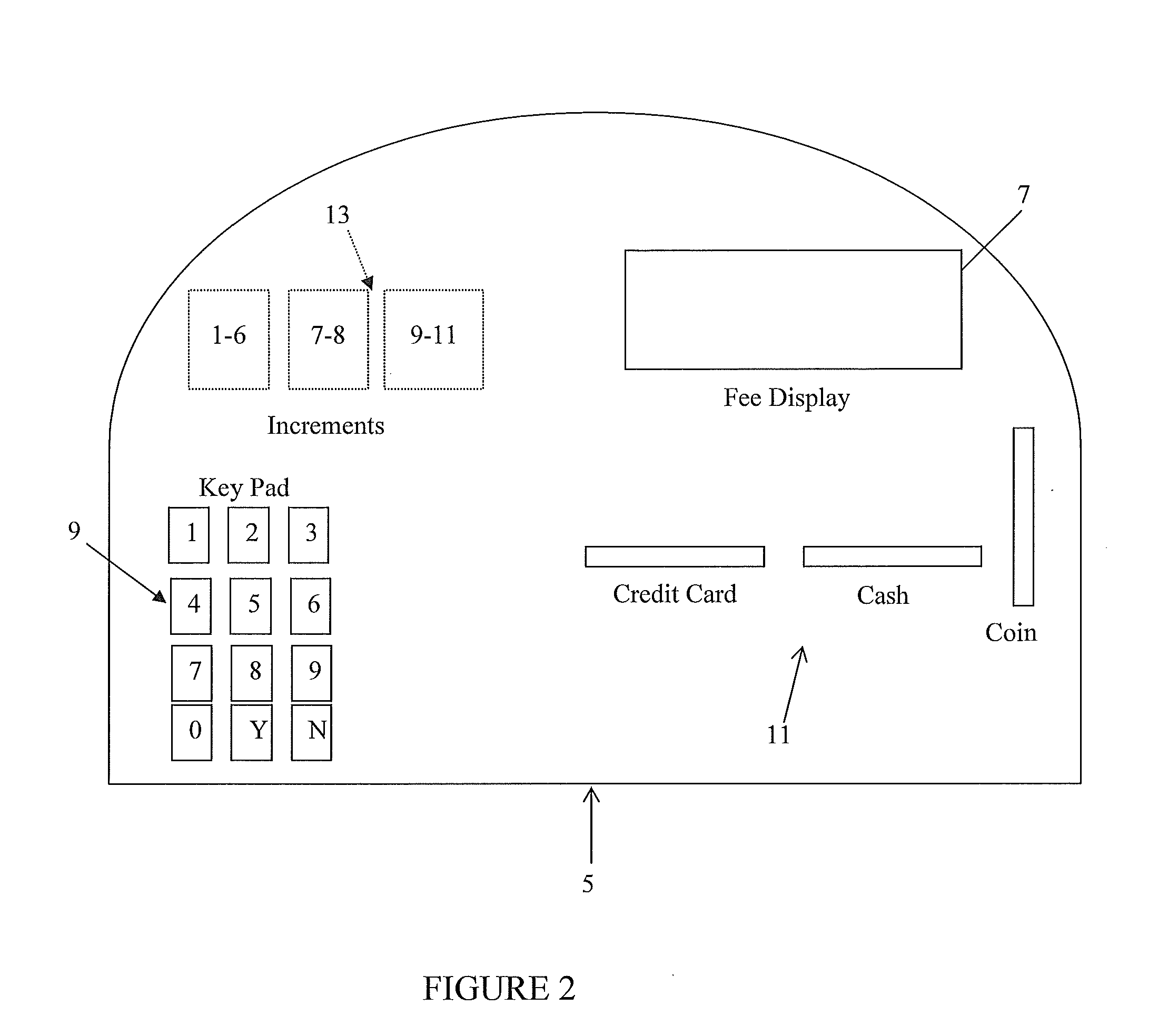

Method of Assessing Parking Fees Based Upon Vehicle Length

A method for assessing fees for parking is disclosed. The method includes providing vehicle length or information about a vehicle which is associated with the vehicles length to a parking meter or other fee collection device. The parking fee collection device communicates with an associated database containing a parking fee charged for vehicle based upon vehicle length. A vehicle operator enters into the parking fee collection device a vehicle length or information about the vehicle which is associated with vehicle length for a selected vehicle and a parking fee is assessed based upon the vehicle length. The database may also contain information about unpaid parking tickets associated with vehicles, a list of stolen vehicles and / or outstanding warrants for vehicle owners. An appropriate notice is provided when a match is found.

Owner:BURDICK JOSHUA

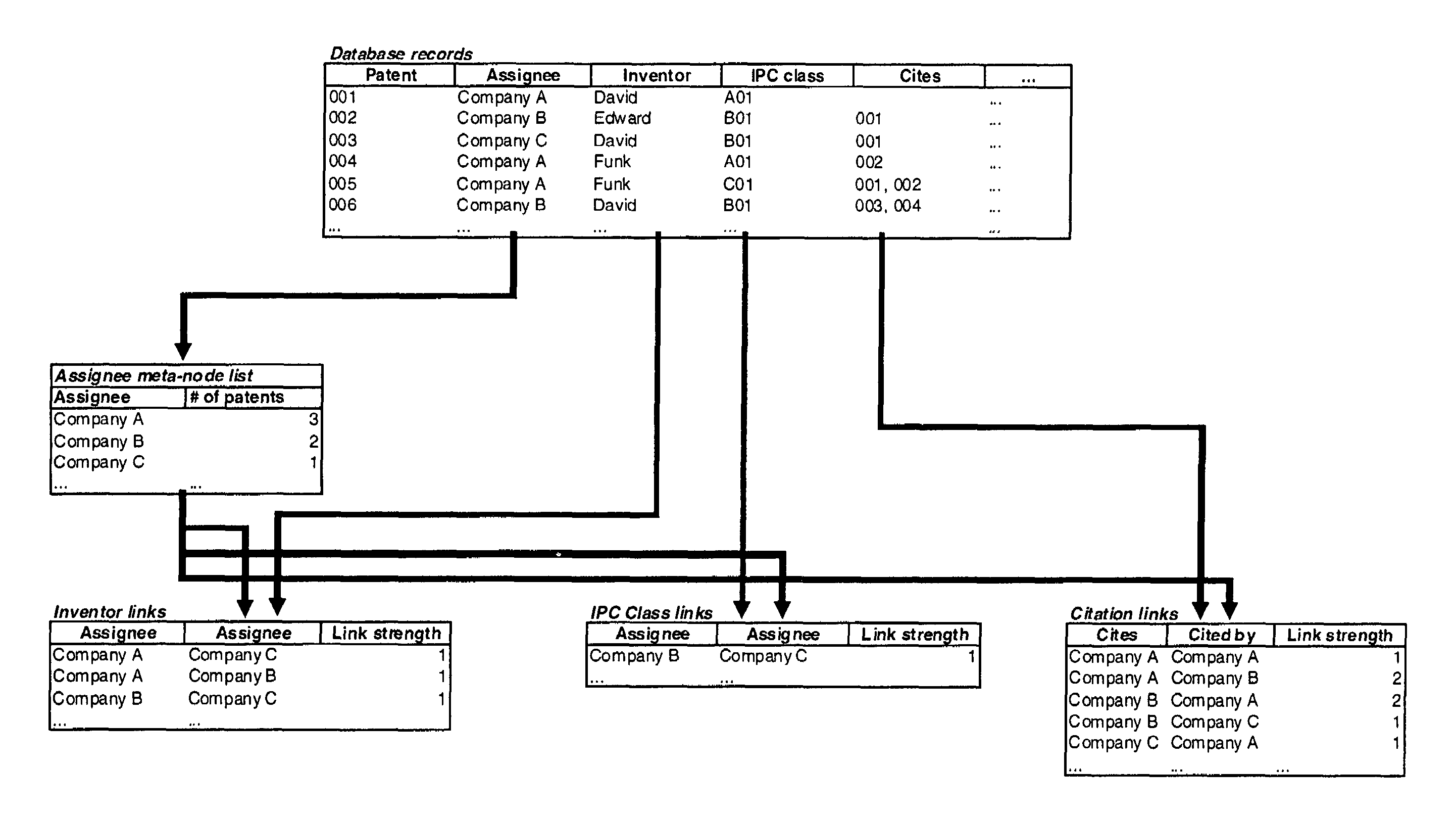

Method and apparatus for selecting, analyzing, and visualizing related database records as a network

A method and apparatus for selecting and converting database records or sets of related documents into network data and presenting that data in a network visualization system that enables users to select among, and move between various network displays by selecting one or more attributes of the data to be represented as the nodes and links of the network.

Owner:BOSTON CONSULTING GRP INC

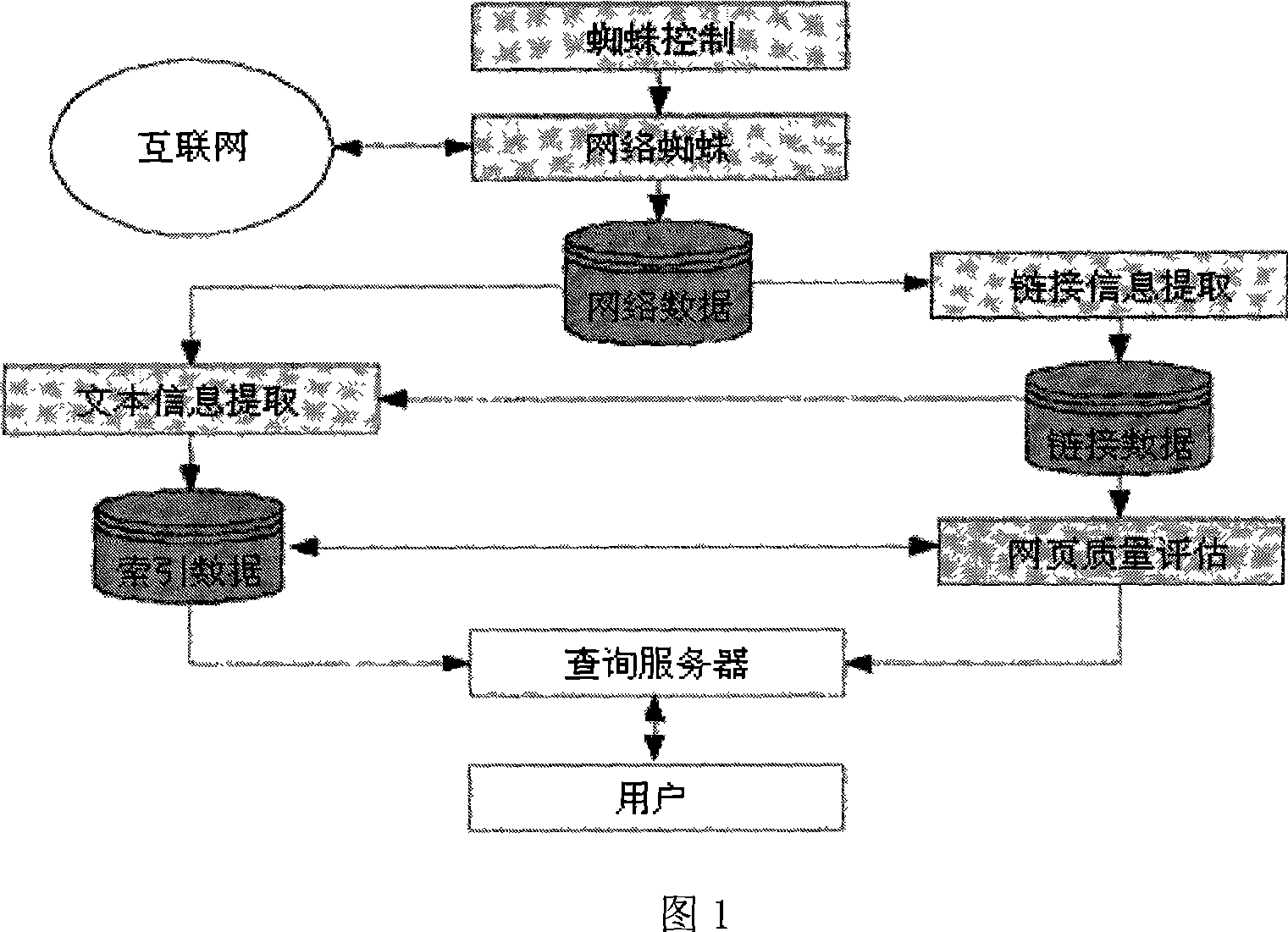

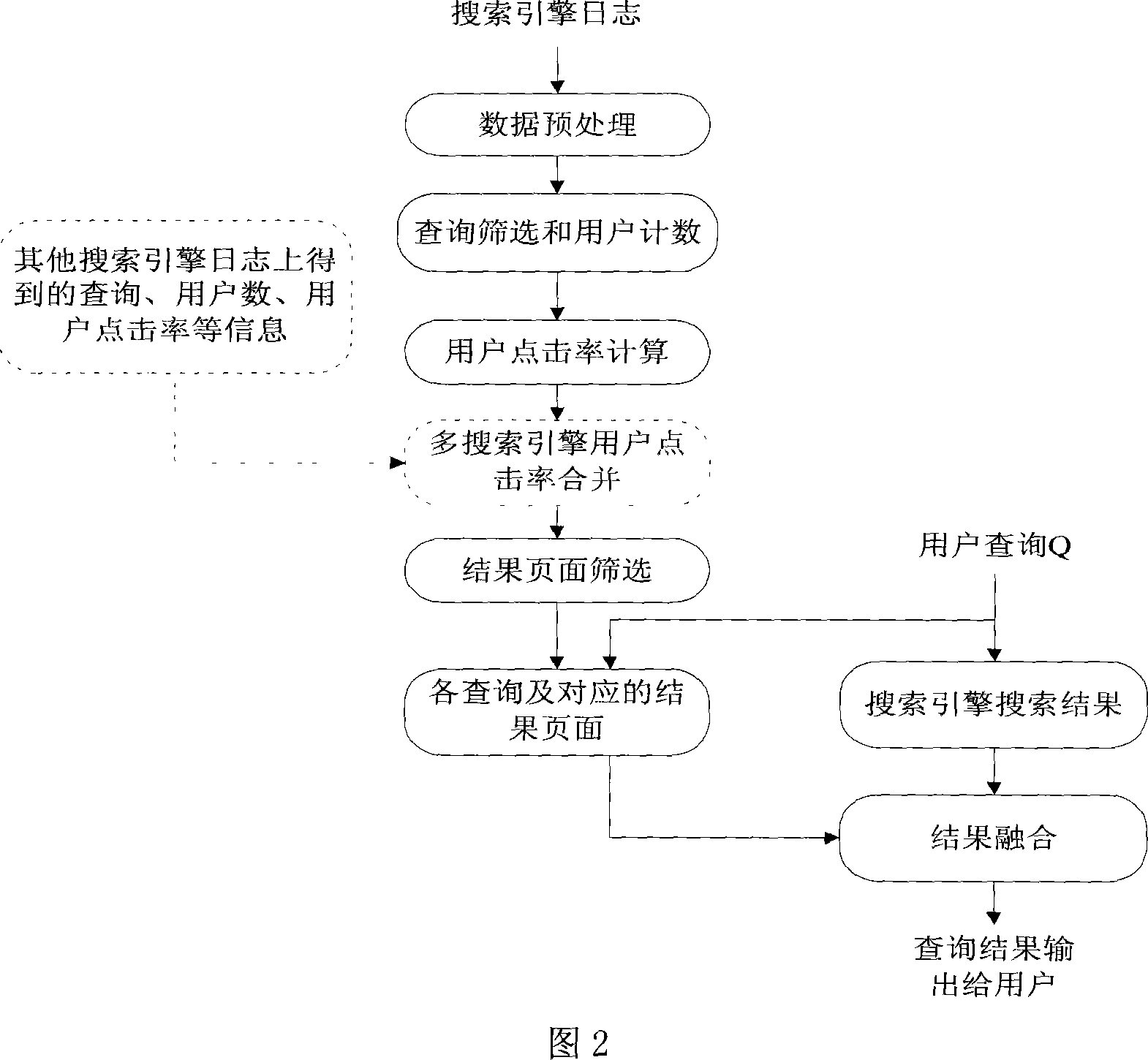

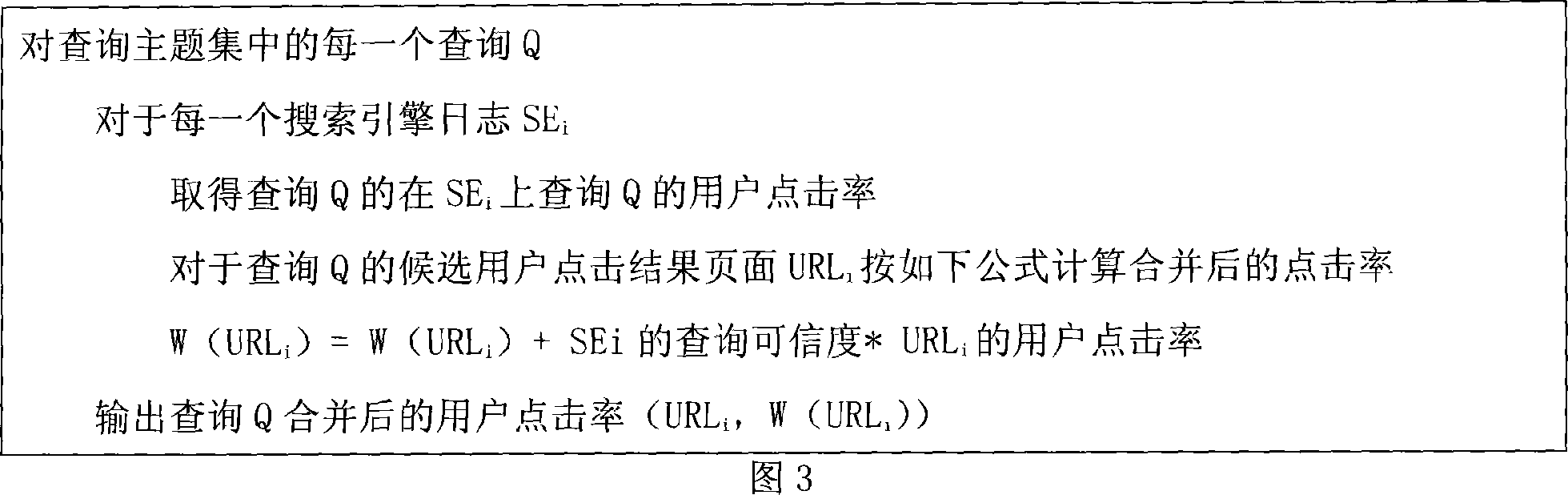

Search engine retrieving result reordering method based on user behavior information

ActiveCN101055587AOptimize search resultsReduce complexitySpecial data processing applicationsHuman search engineMassage

The invention belongs to internet massage processing field, characterized in that: common inquiry set which is cared by user, according to one ore more search engine logs, is screened out firstly using the inquiry of corresponding information of user number; then calculating user touching ratio corresponding to user touching page of inquiry in common inquiry set, if multi-search engine logs is used, user touching ratio are united; user touching pages are effectively screened out based on user touching ratio, the ralated inquiry and corresponding result page address are stored related database; at last, the result from user information and the result by searching by search engine are united effectively when user puts in the demand of inquiry, and are reordered to return to user. The method has the advantage that computer is completed automatically and efficiently submits search engine performance in real time and objectively.

Owner:TSINGHUA UNIV +1

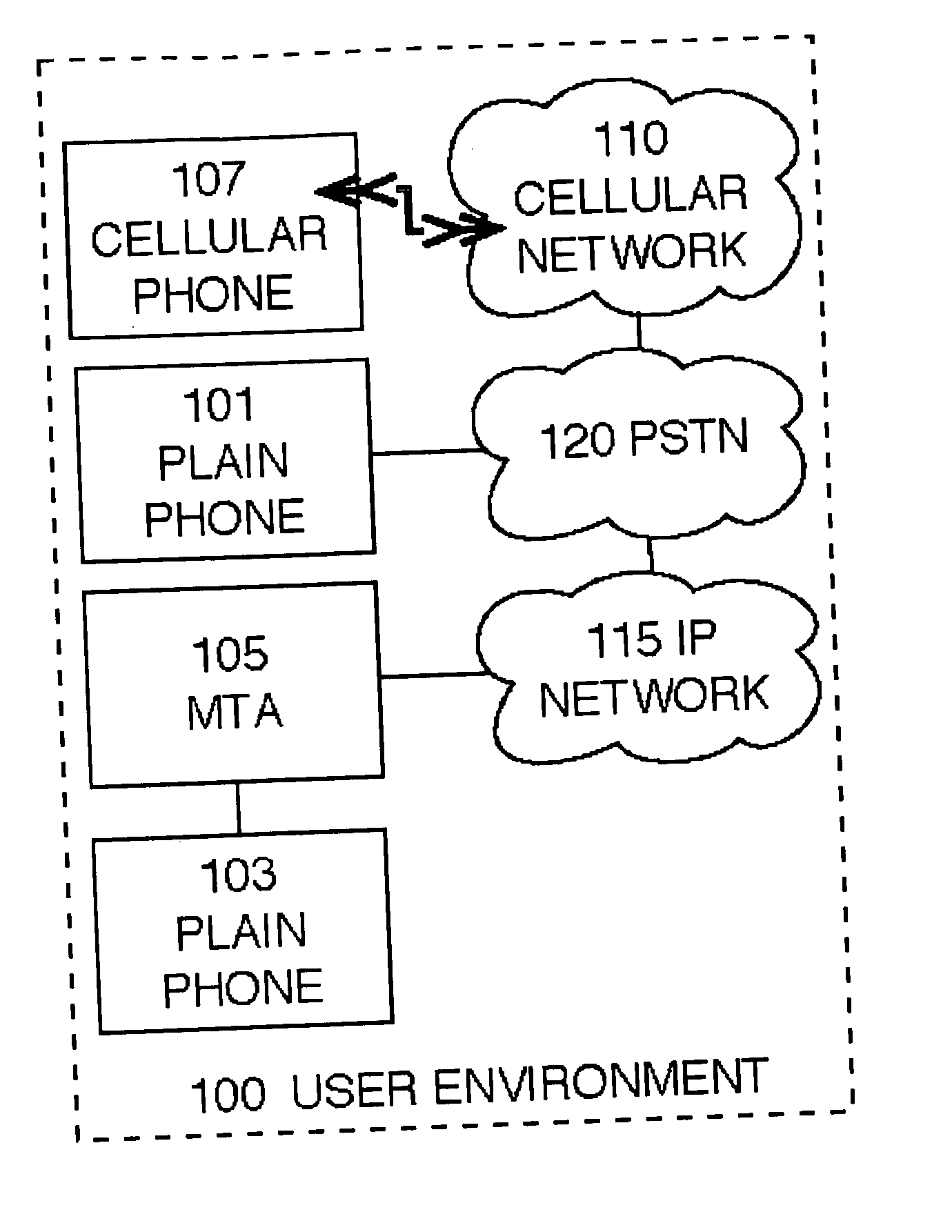

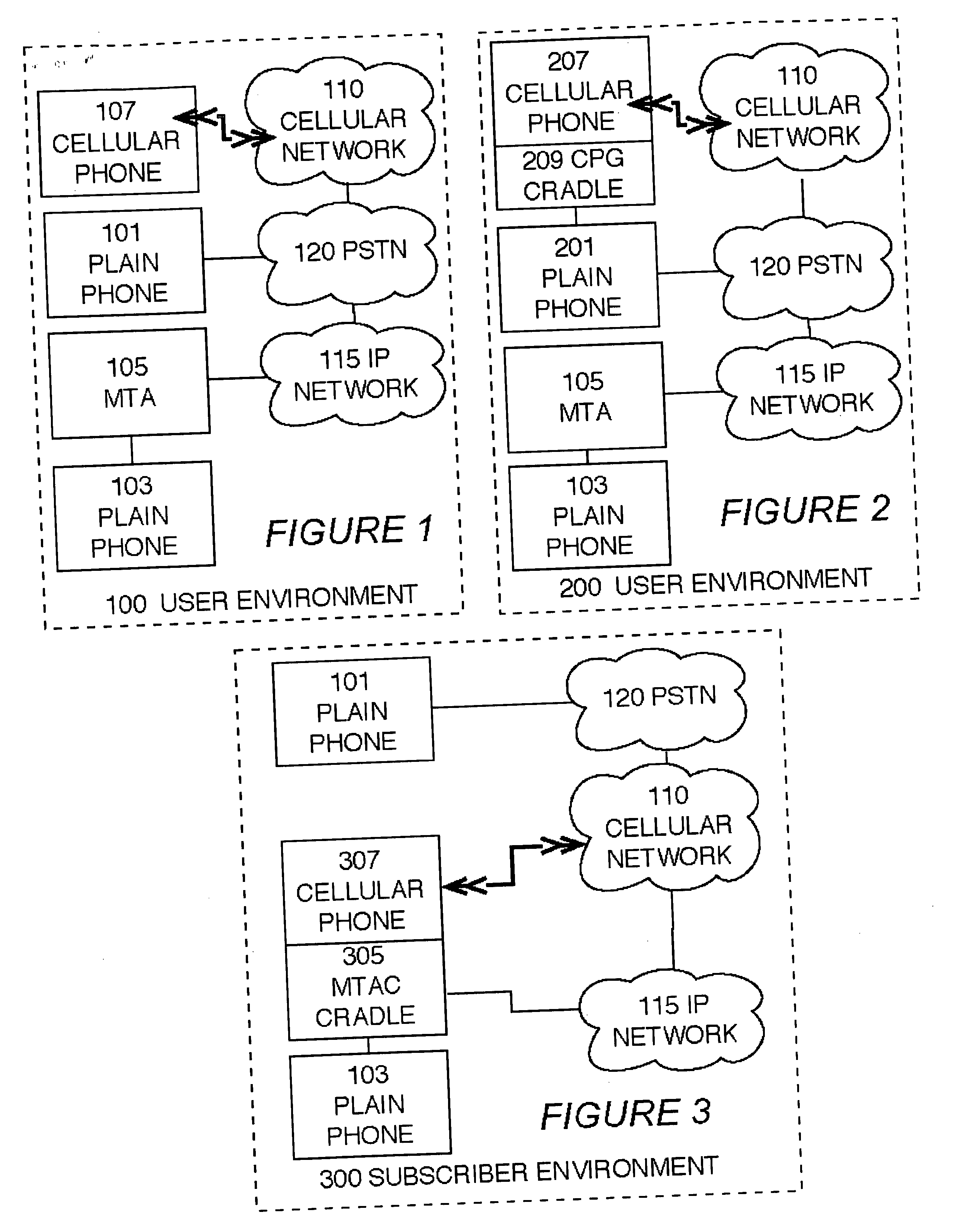

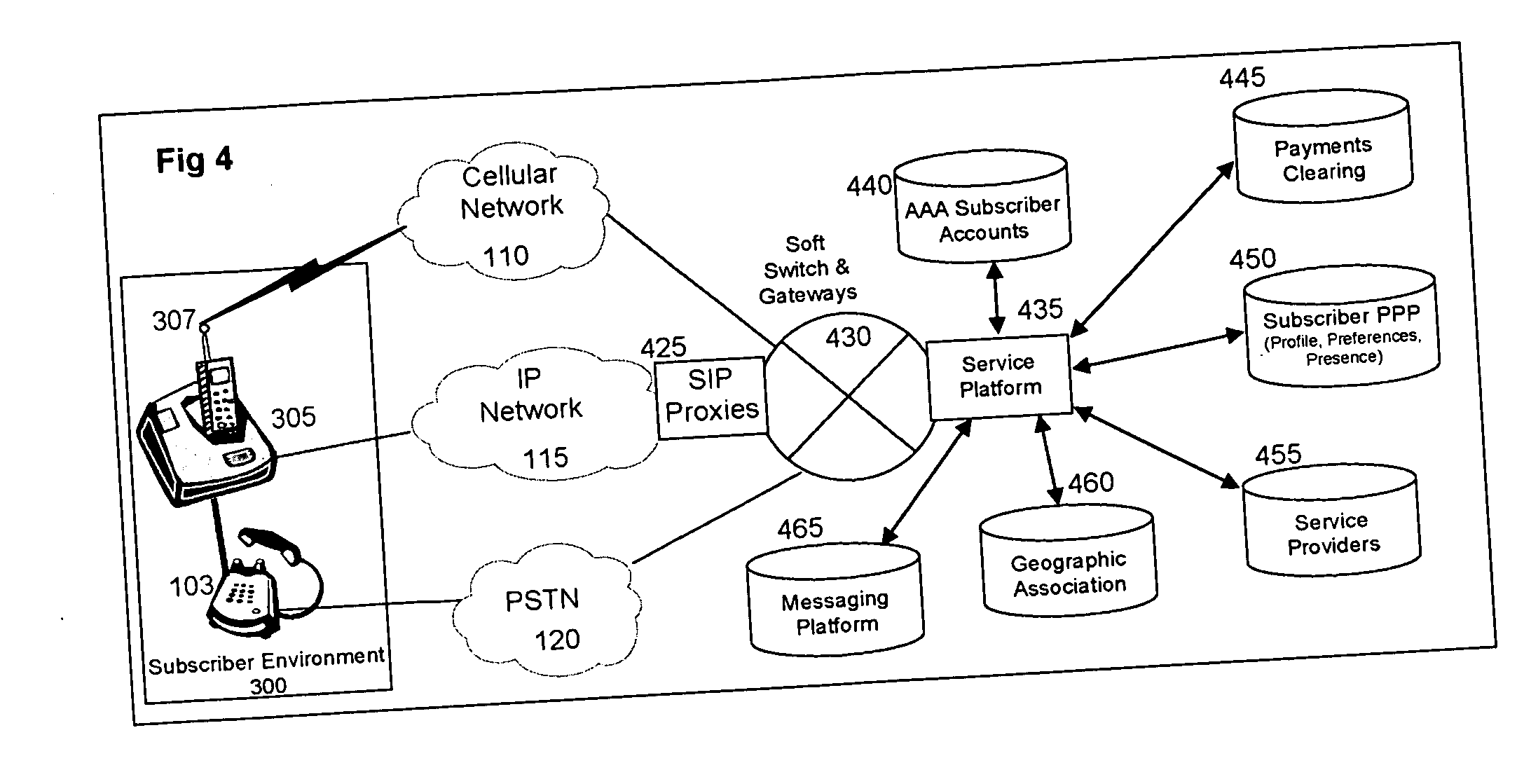

IP-enhanced cellular services

InactiveUS20070047707A1Accelerates telephony service convergenceGood serviceTelephonic communicationTranscodingMediaFLO

A federation of multinational PSTN, IP and cellular service providers coordinate their accounting by: populating a subscriber database of subscribers to one number services, a service providers database and a payments clearing database having amounts owed across the service providers based on the individual service provider's portion of pre-agreed payments for services; collecting accounting data from the service providers; updating the relevant databases with the data collected; and providing accounting data to the service providers and subscribers. Voice over IP service is applied to a cellular phone by selecting a compatible codec at peripheral gateways of IP network paths, thereby avoiding transcoding by a connecting multimedia terminal adapter. A portable module, multimedia terminal adapter cellular internet protocol gateway for media communications over an IP network (MTAC IPG) bridges a cellular network, an IP network and a PSTN so that a user may locally dial a cellular phone that is then used to enter the IP network and dial the called party. The MTAC IPG provides gateway functionality and packetizing.

Owner:NET2PHONE

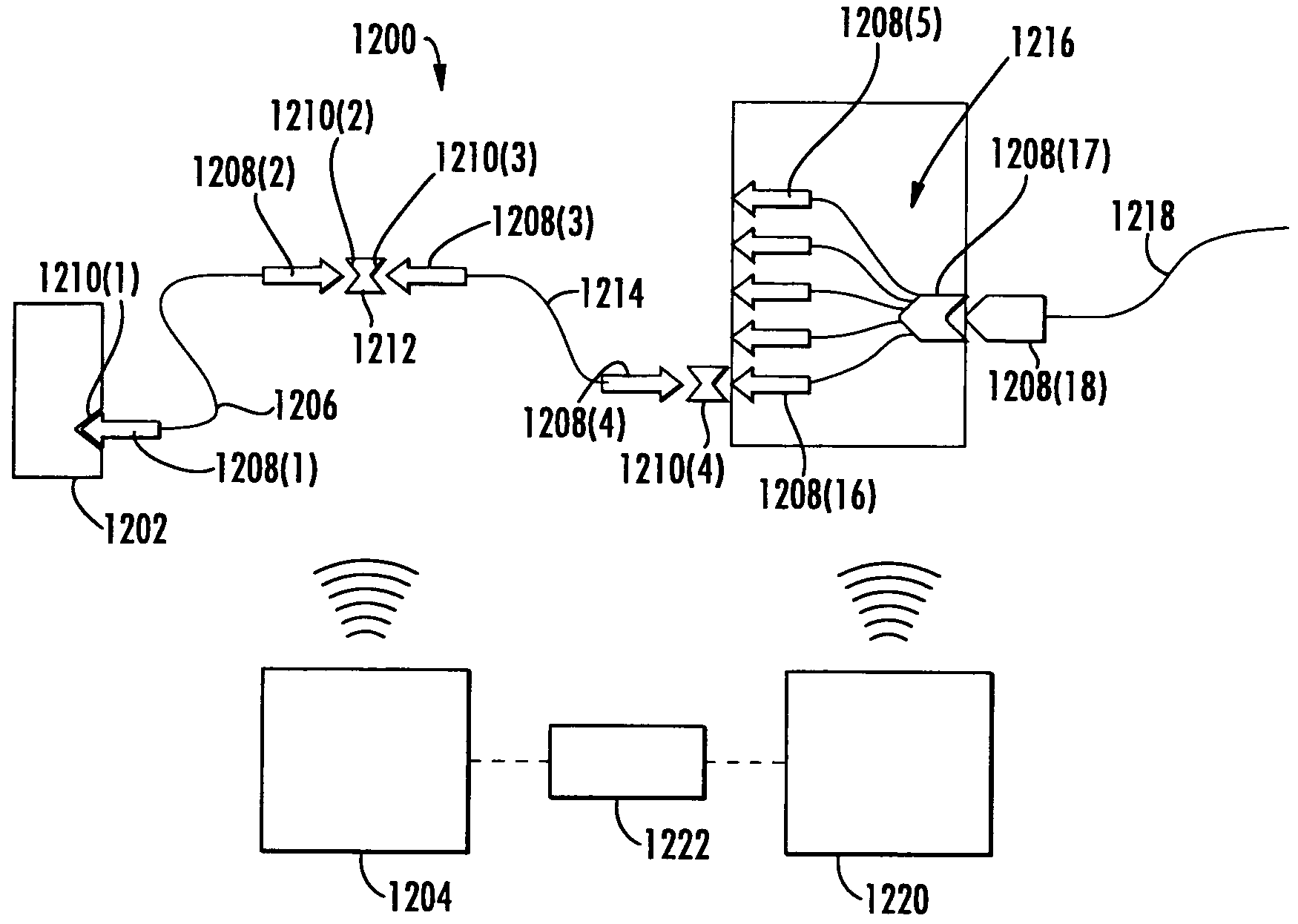

System for mapping connections using RFID function

ActiveUS7772975B2Subscribers indirect connectionRecord carriers used with machinesProcessing elementEmbedded system

There is provided a system for identifying a plurality of components via an RFID reader with an associated database and processing element. The system includes a first component with an associated first RFID transponder and a second component with an associated second RFID transponder. A third RFID transponder may be associated with the first component, wherein either the first or third RFID transponder includes stored information relating to both transponders. The first and second RFID transponders are adapted to communicate with the RFID reader to enable identification of the connection of the first component to the second component. One of the RFID transponders may be adapted to identify the other RFID transponder and store the identification information for subsequent communication to the RFID reader of identification information for both RFID transponders and the associated components. The system is adapted to create a map of the two or more components, such as components of telecommunications equipment.

Owner:FIBER MOUNTAIN INC

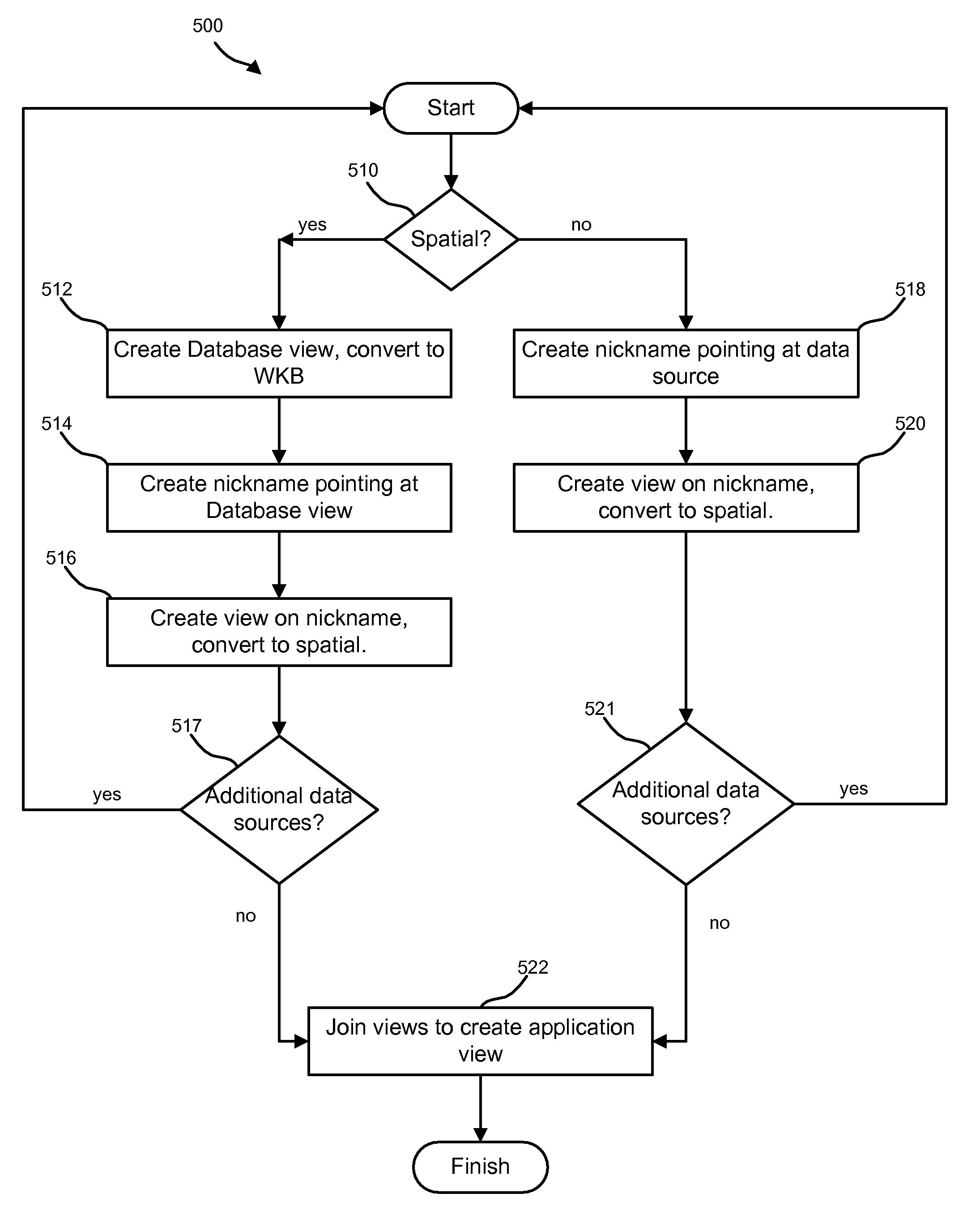

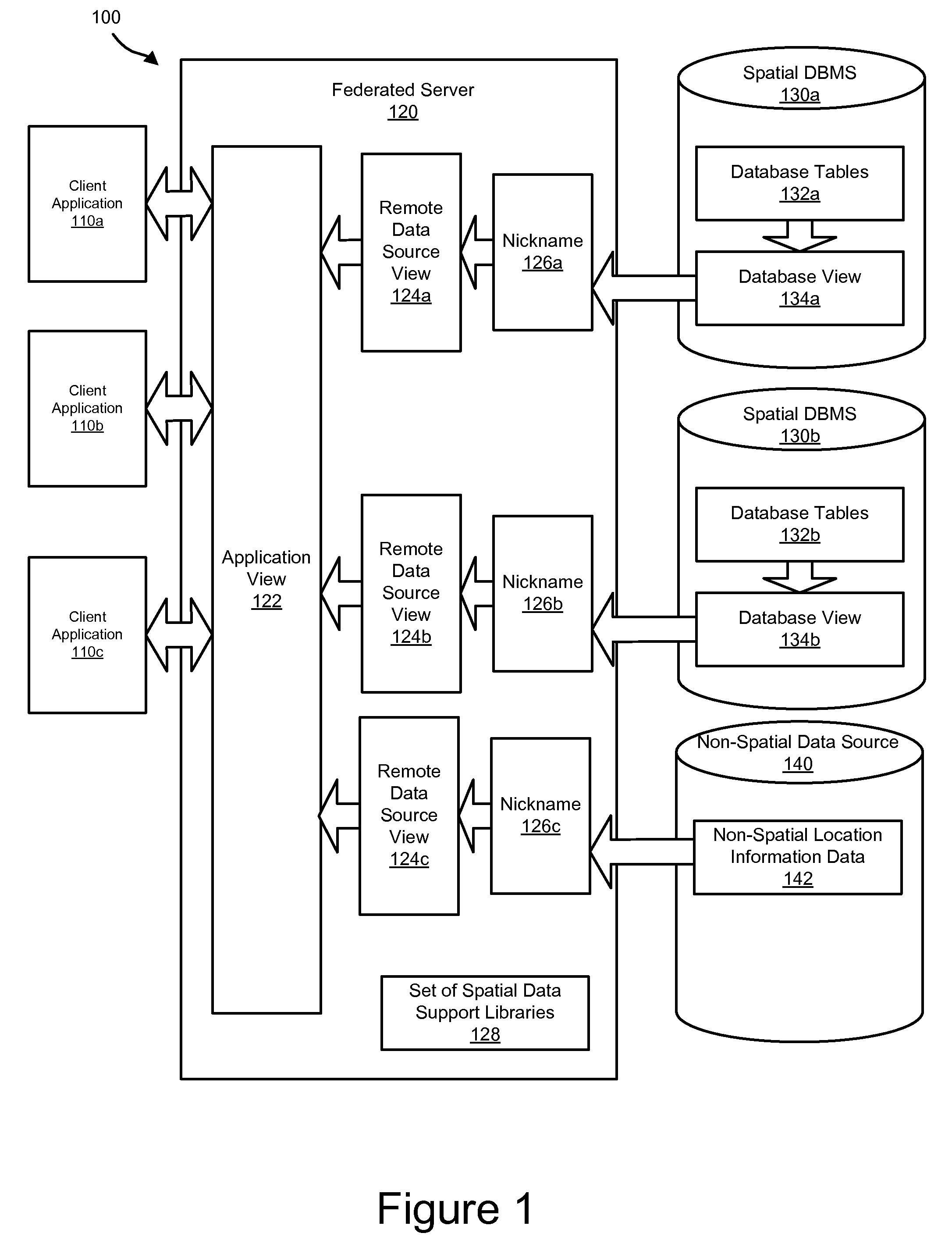

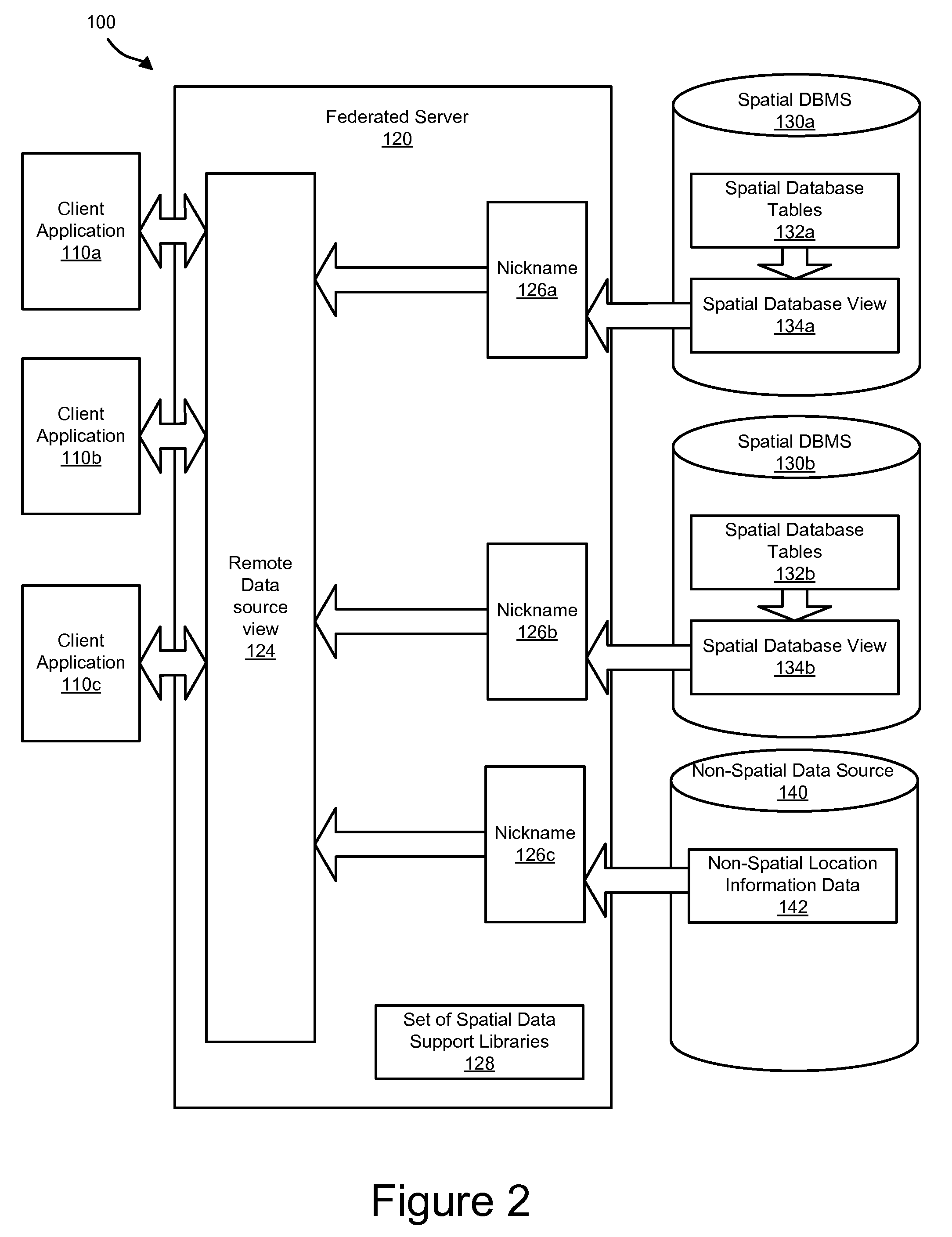

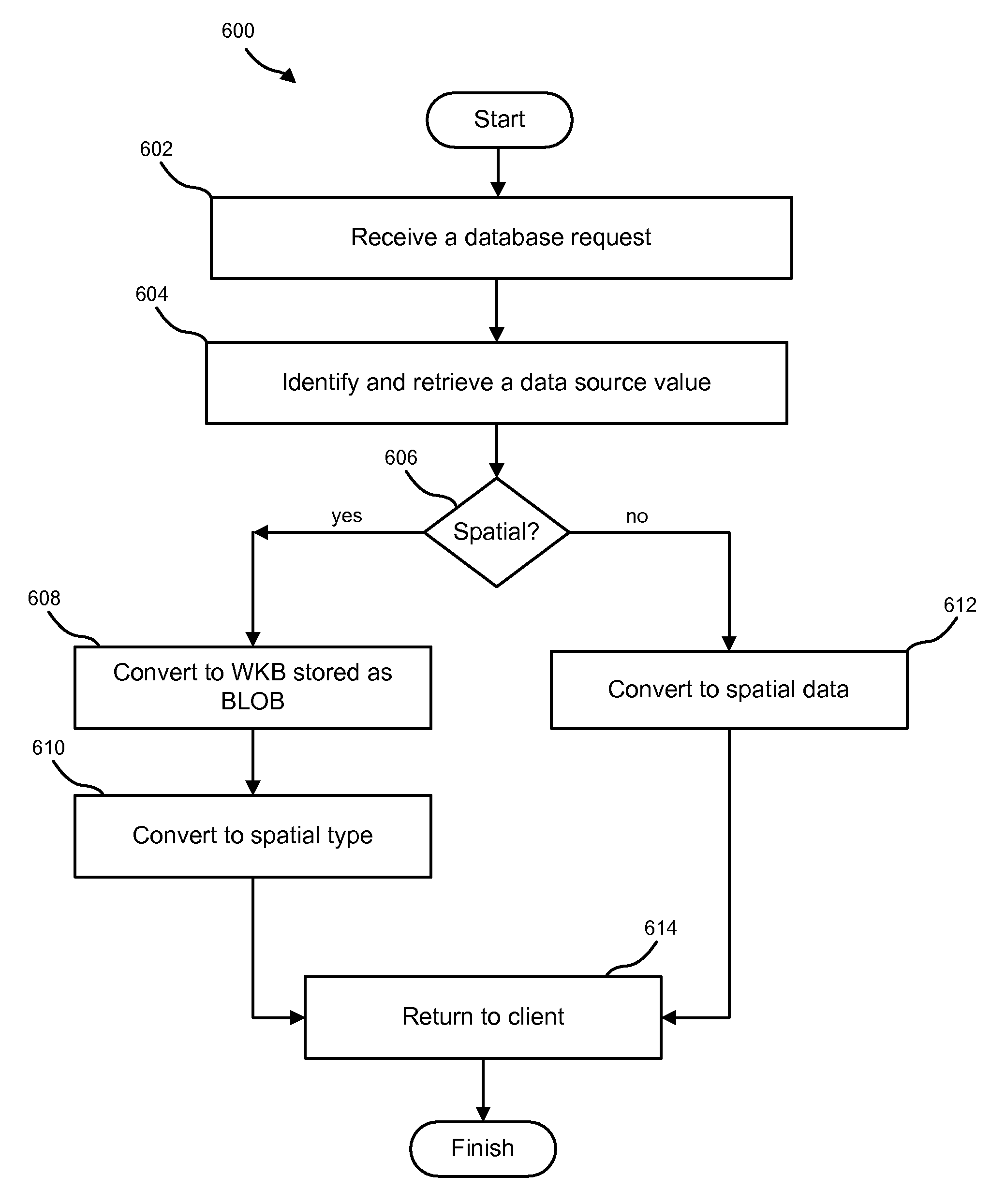

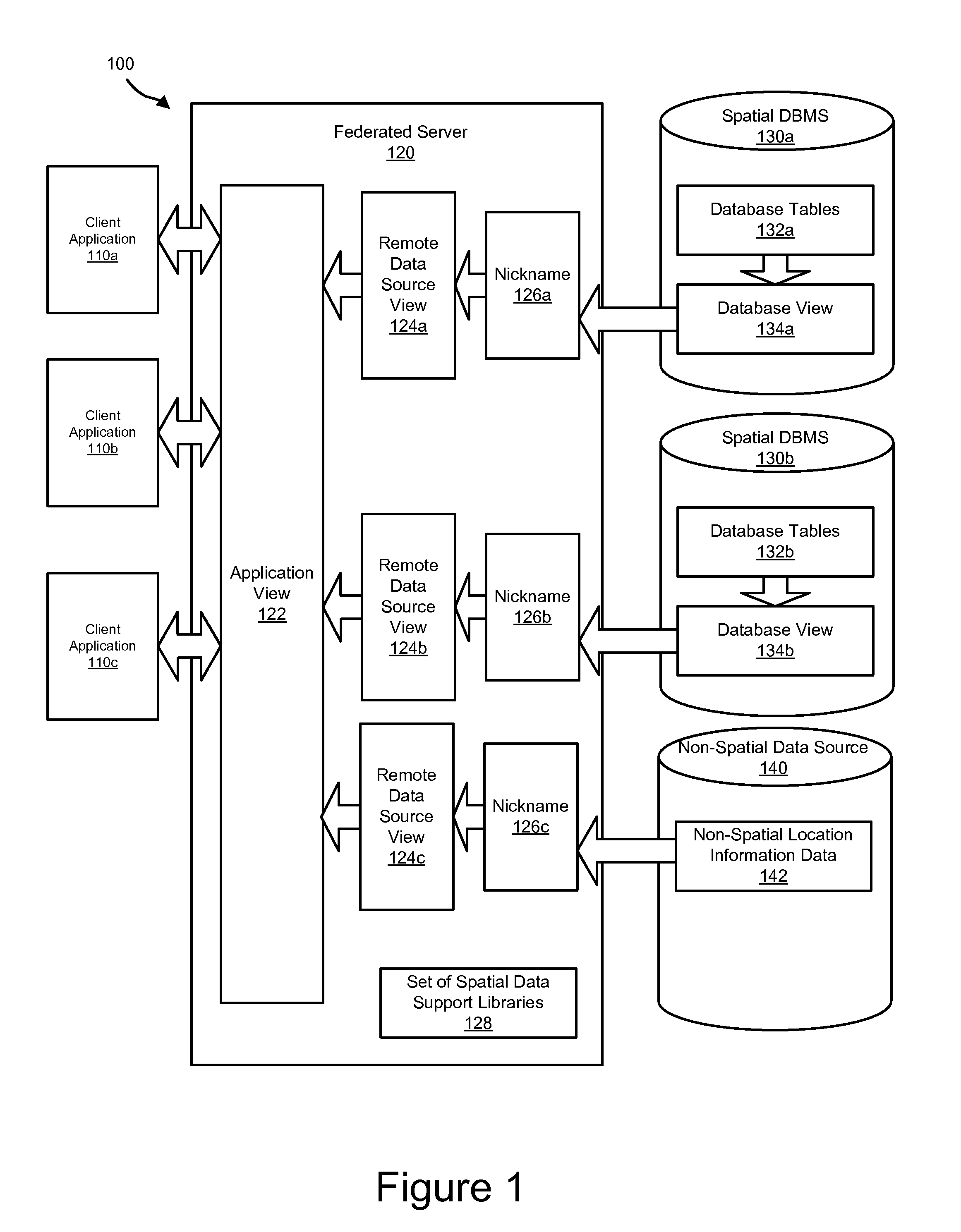

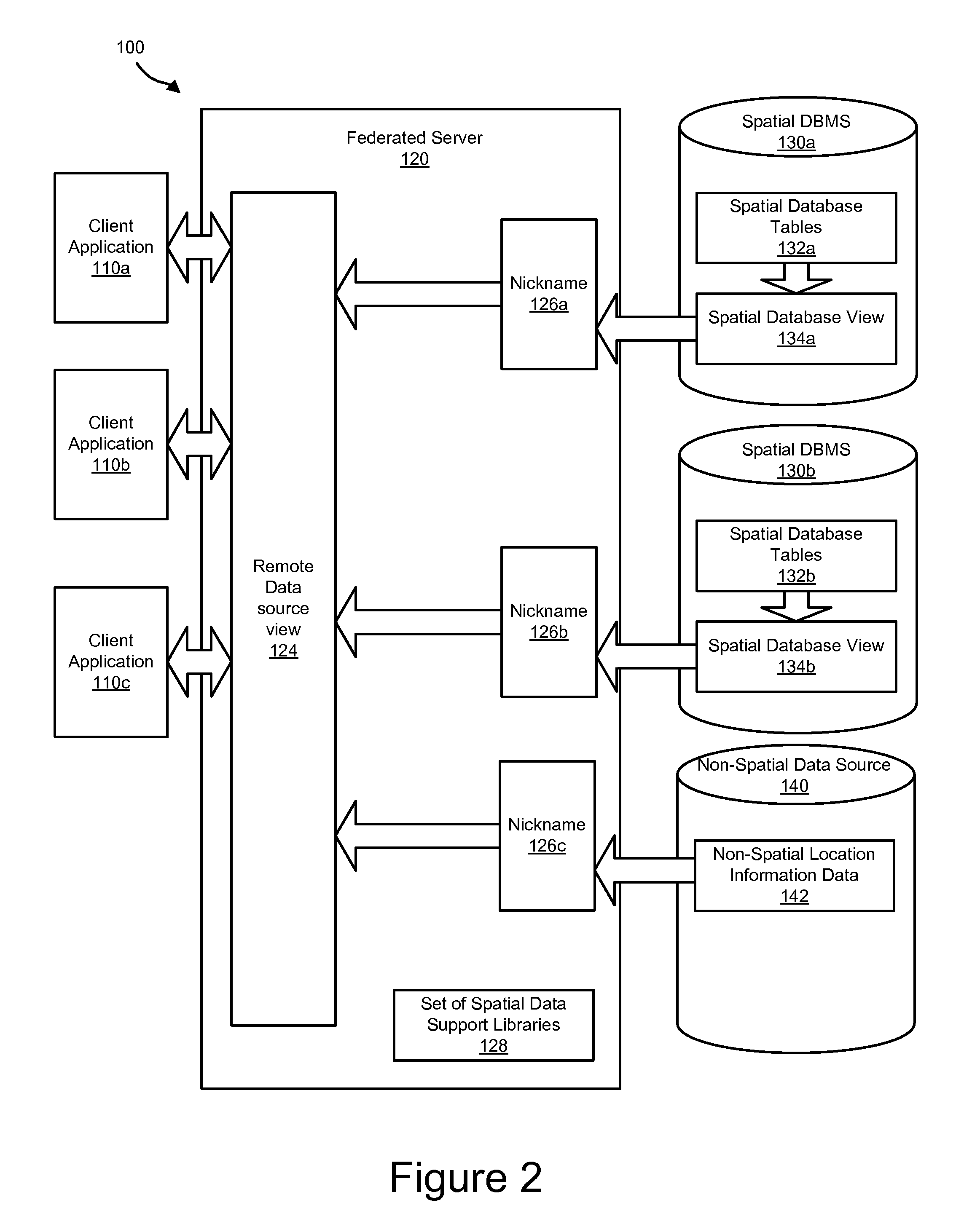

Apparatus, system, and method for executing a distributed spatial data query

InactiveUS20090063524A1Digital data processing detailsGeographical information databasesData sourceClient-side

A method for executing a distributed spatial data query. The present invention allows a client to perform spatial queries against spatial data stored in a various formats in various separate databases. A view of the data is created in the relevant databases, wherein the spatial data is converted to WKB and stored as a BLOB. A federated server contains nicknames for the various database views, and also contains views of the data where the BLOB is converted back to a spatial data type. The federated server presents to clients an application view of the distributed heterogeneous spatial data such that the clients can treat the data as if it were a homogenous data source. Also taught is incorporating distributed non-spatial data into the application view by creating a nickname and a view on top of the nickname which derives spatial information from the non-spatial location information.

Owner:IBM CORP

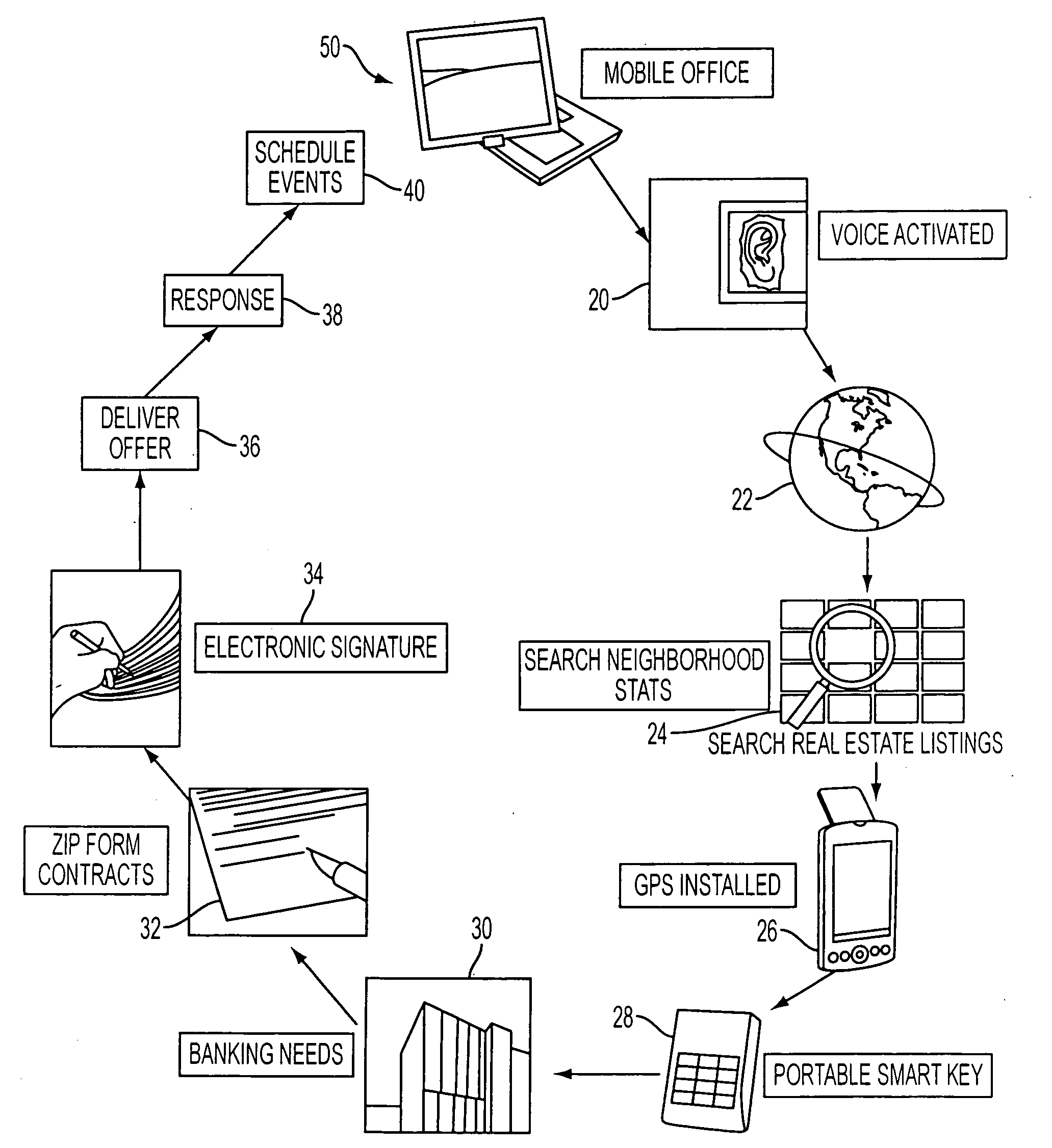

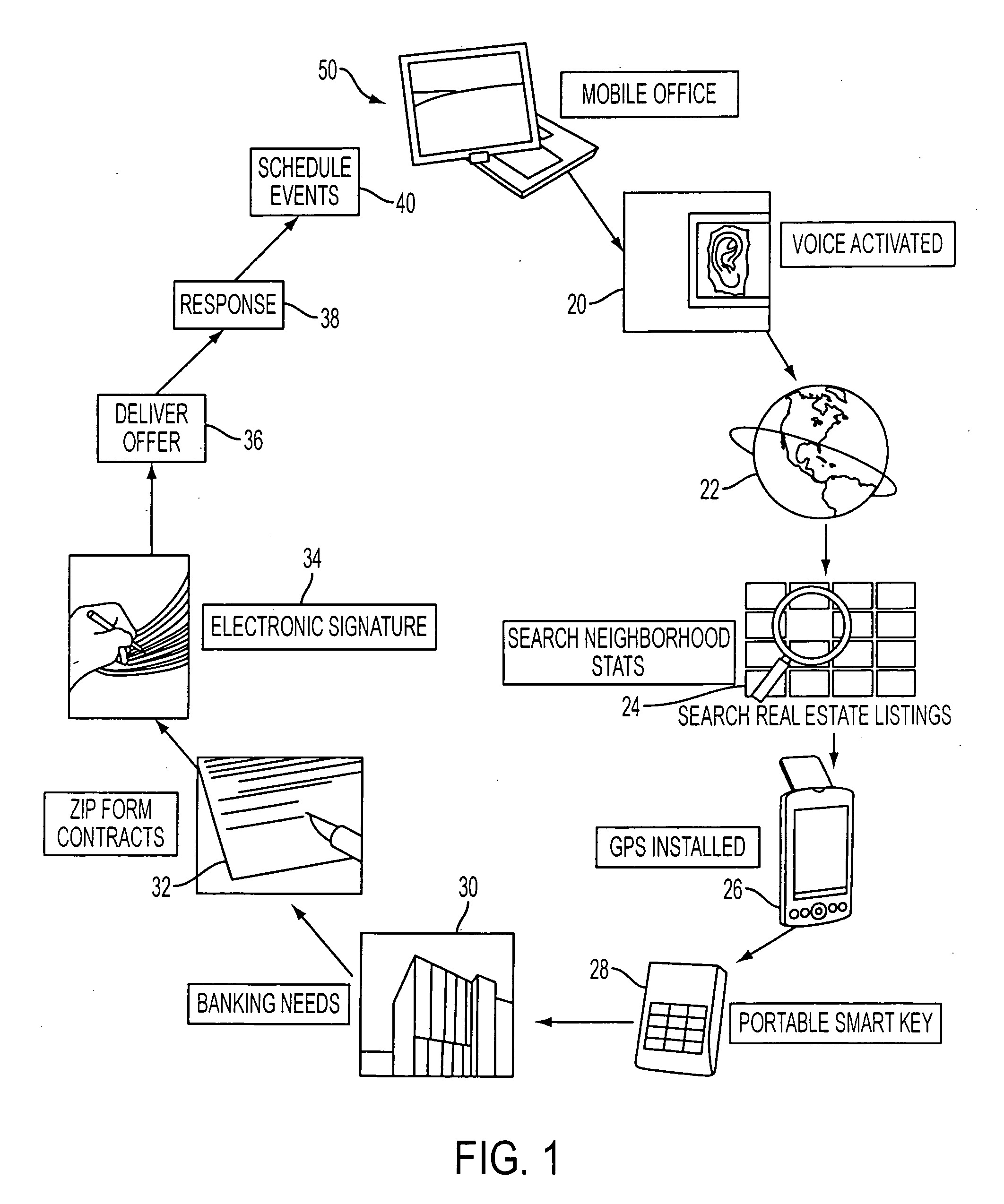

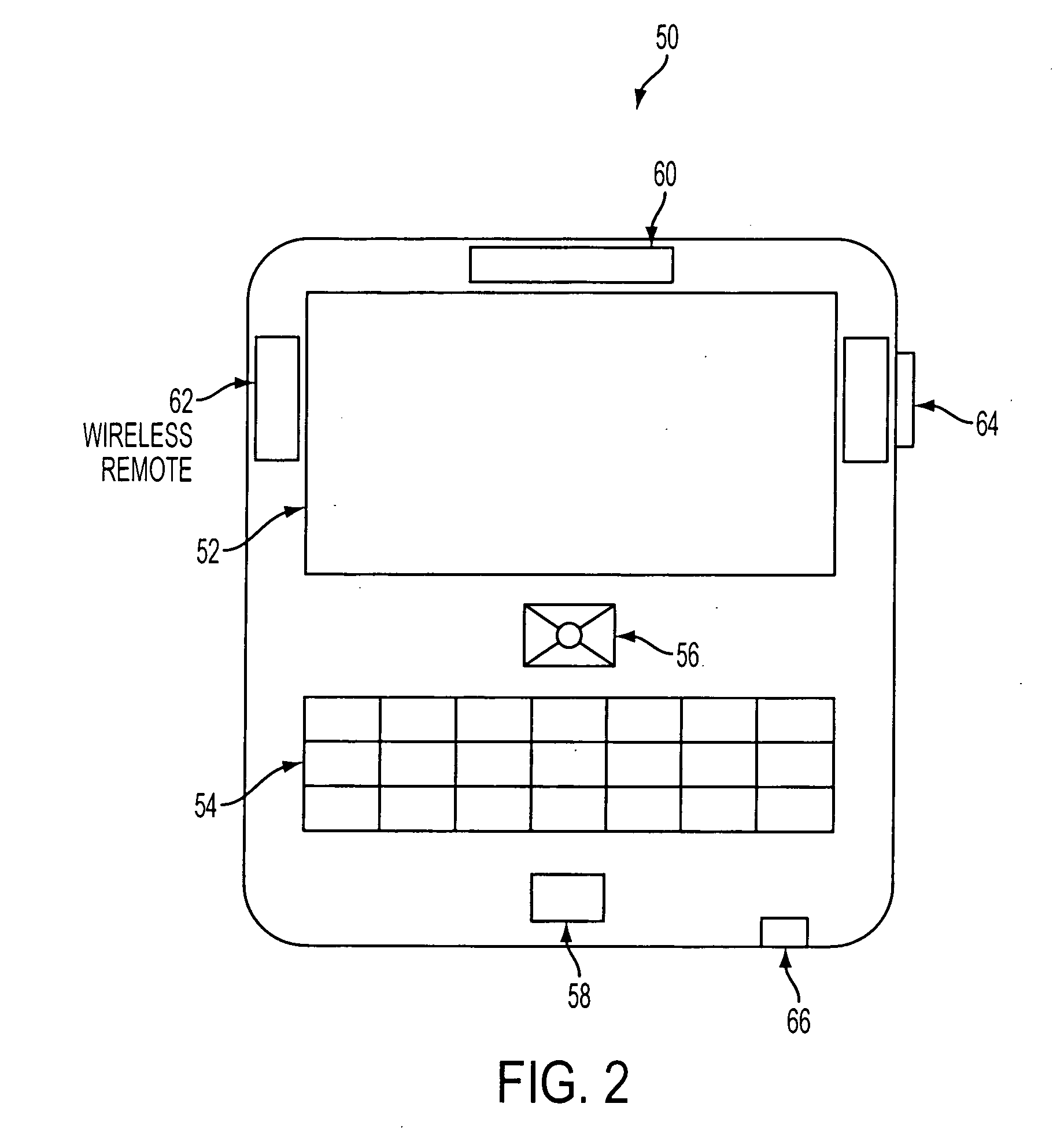

Interactive remote wireless system and method to assist in real estate transactions, and the like

InactiveUS20090182748A1Buying/selling/leasing transactionsSpecial data processing applicationsSystem combinationComputer science

A system and apparatus to provide remote interactive access to multiple databases and, specifically, related to a system and apparatus to provide remote interactive access to real estate information related databases using a portable, voice interactive computing device with GPS capabilities and “smart” computer features. The system combines access to search engines configured to retrieve real estate listings, publicly available statistics about a specific geographic area, and retrieval of stored forms specific to completing an offer for real estate. The device can have several components in various combinations including a touch sensitive screen, a keyboard, a processor, GPS circuitry, a microphone, an audio device, wireless circuitry, cellular circuitry, a data jack, a wireless remote, and a camera. Software utilizing those components maximizes efficiency for a real estate agent in the field.

Owner:WALKER TIMOTHY

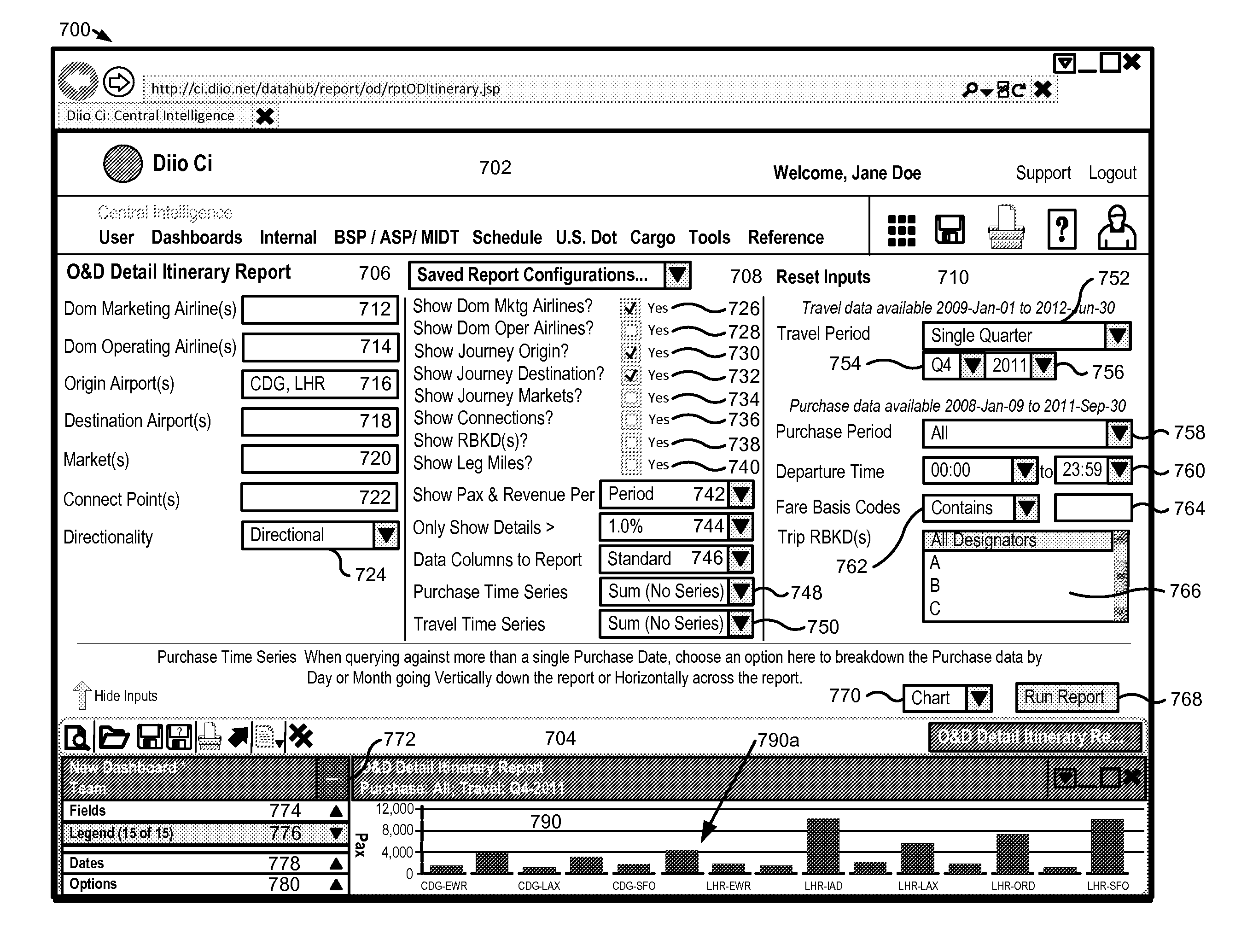

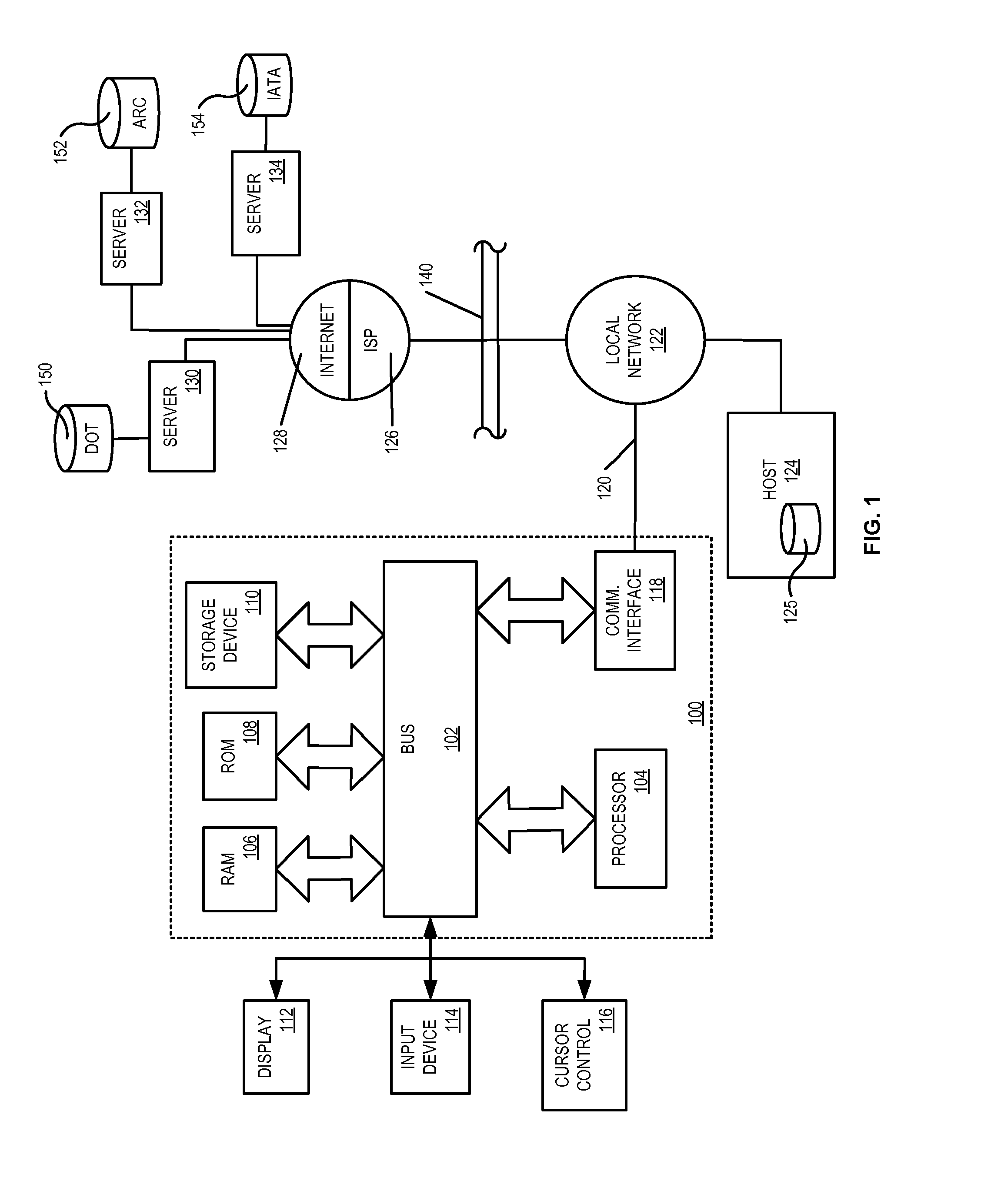

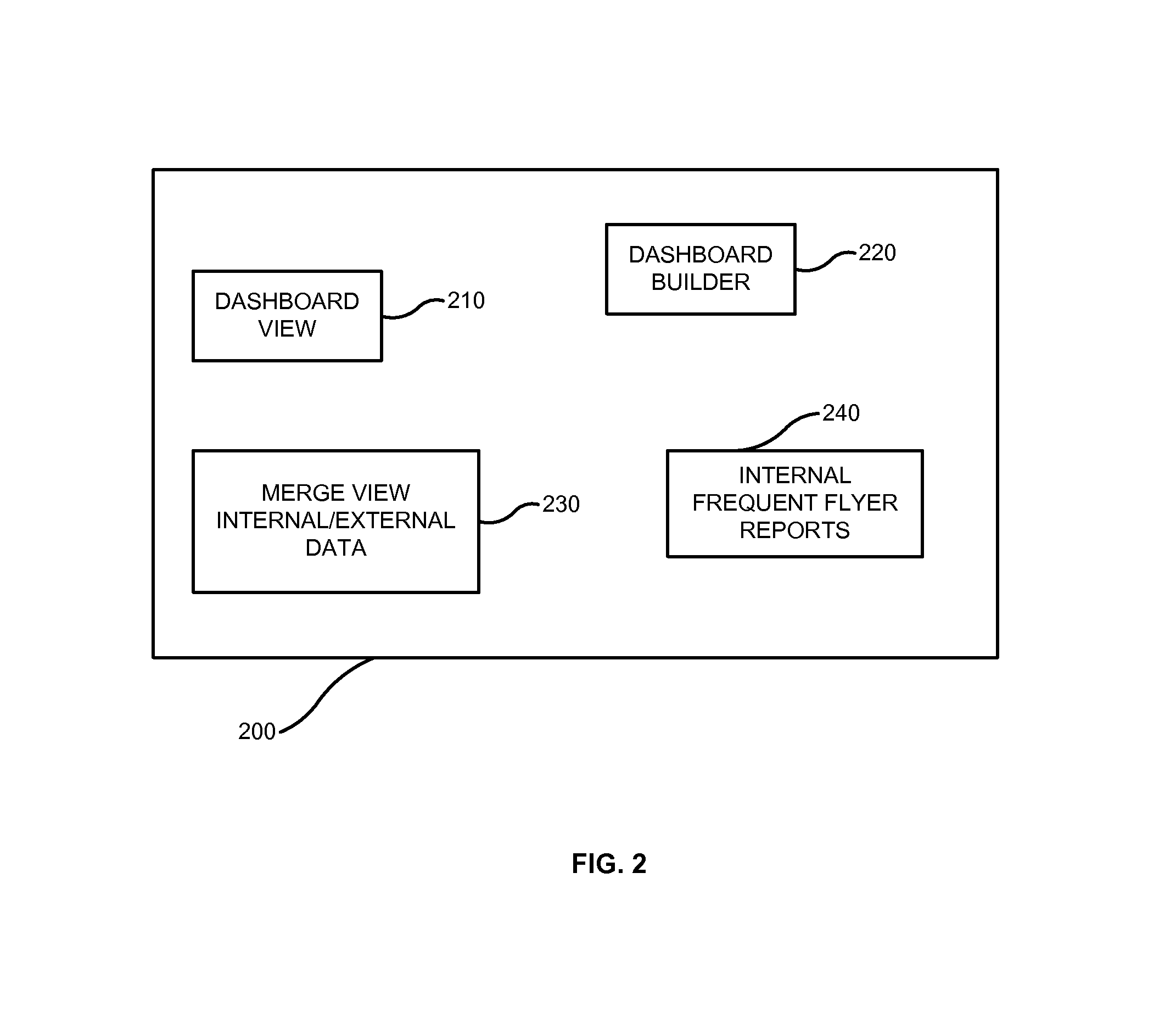

System and methods for presenting market analyses using intuitive information presentation

Methods and apparatus for conducting market analyses on data drawn from various one or more sources for conducting airline travel and cargo market analyses and the presentation of analysis results using intuitive graphical user interfaces. Data is displayed in a visual dashboard having plural dashboard panes for interfacing an associated user with a plurality of associated databases. Data is presented to an associated user from at least one associated database in drill down enabled hierarchical levels. A user is presented with data from associated firewall protected and non-firewall protected databases in selectable merged visual formats.

Owner:DIIO LLC

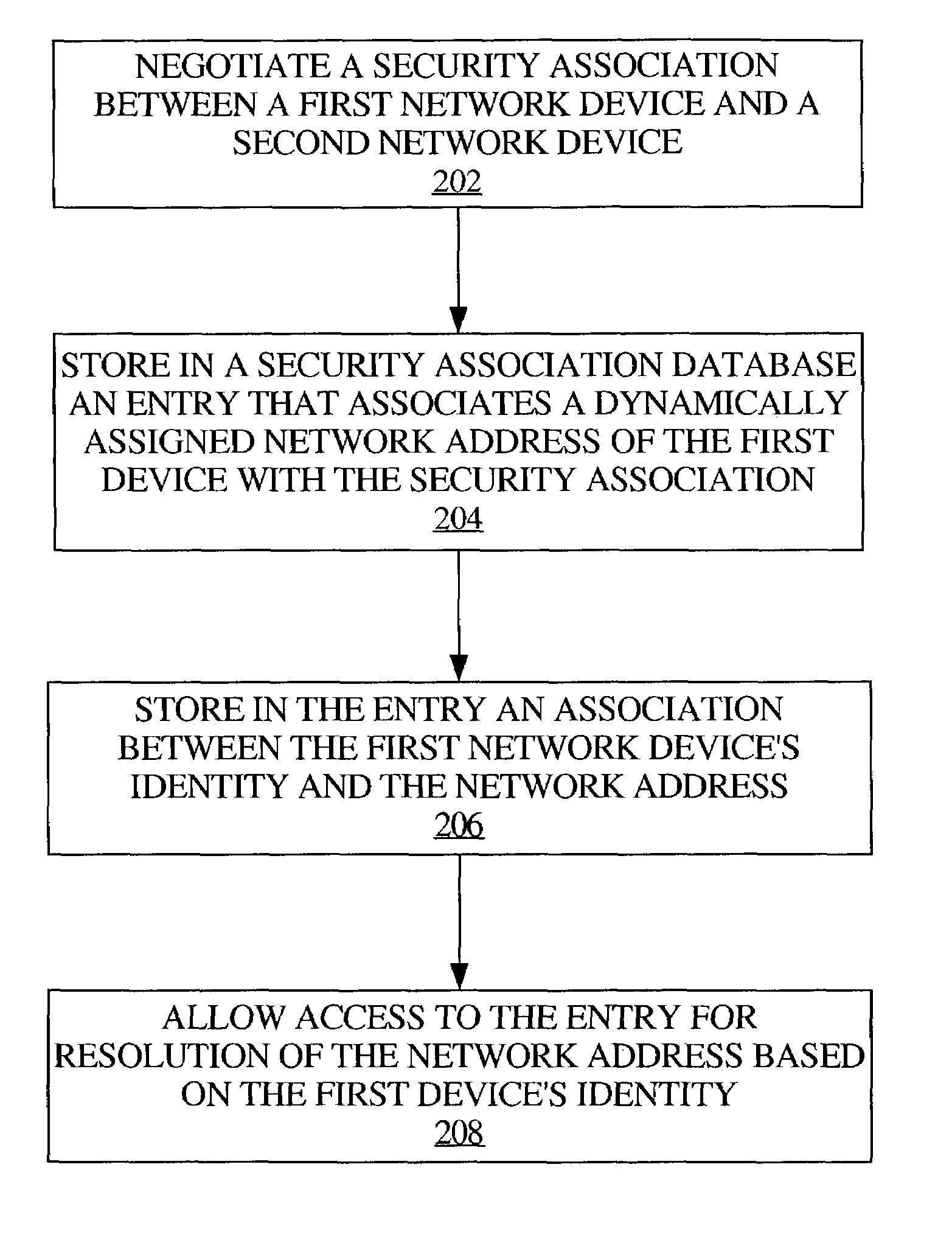

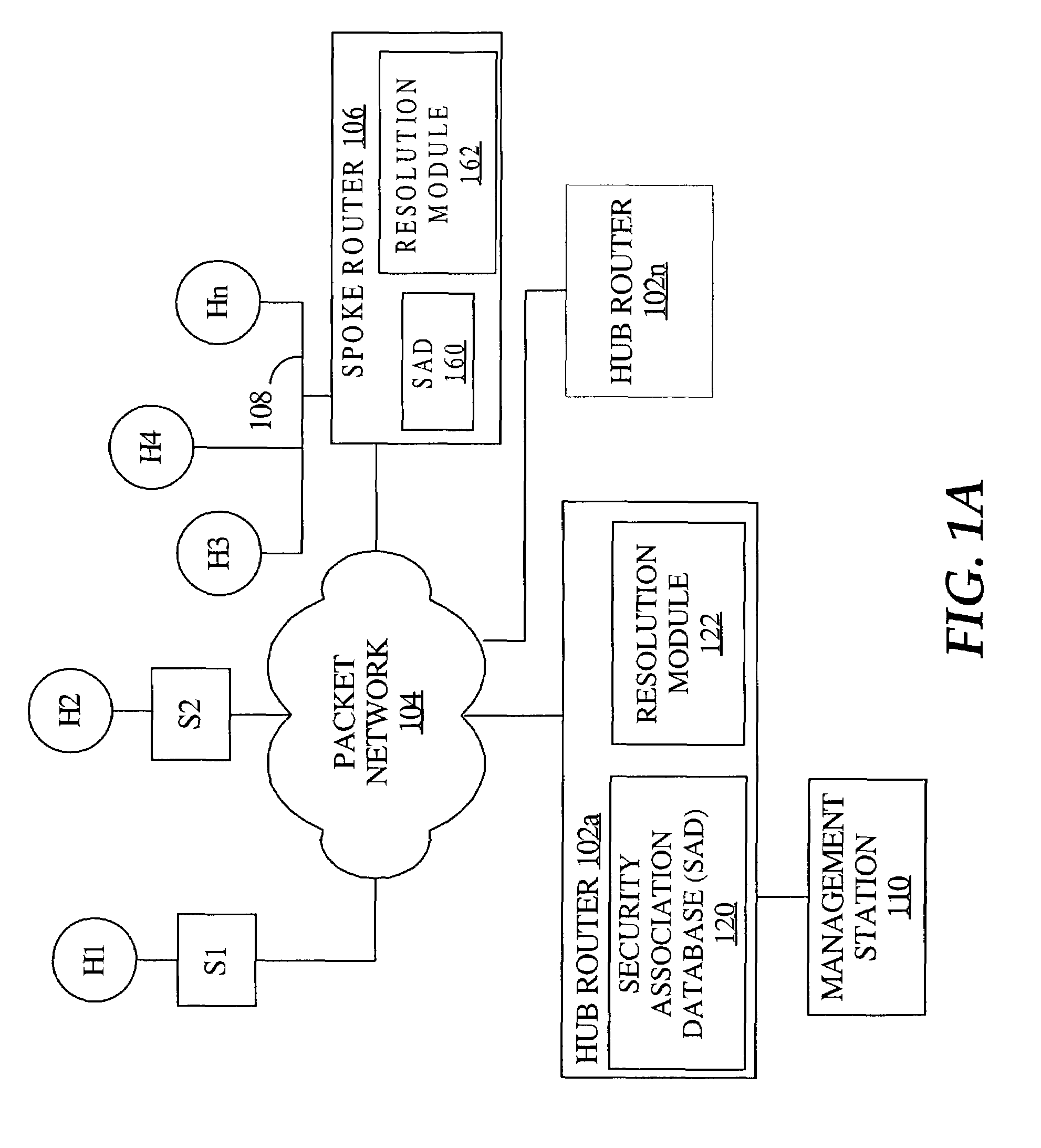

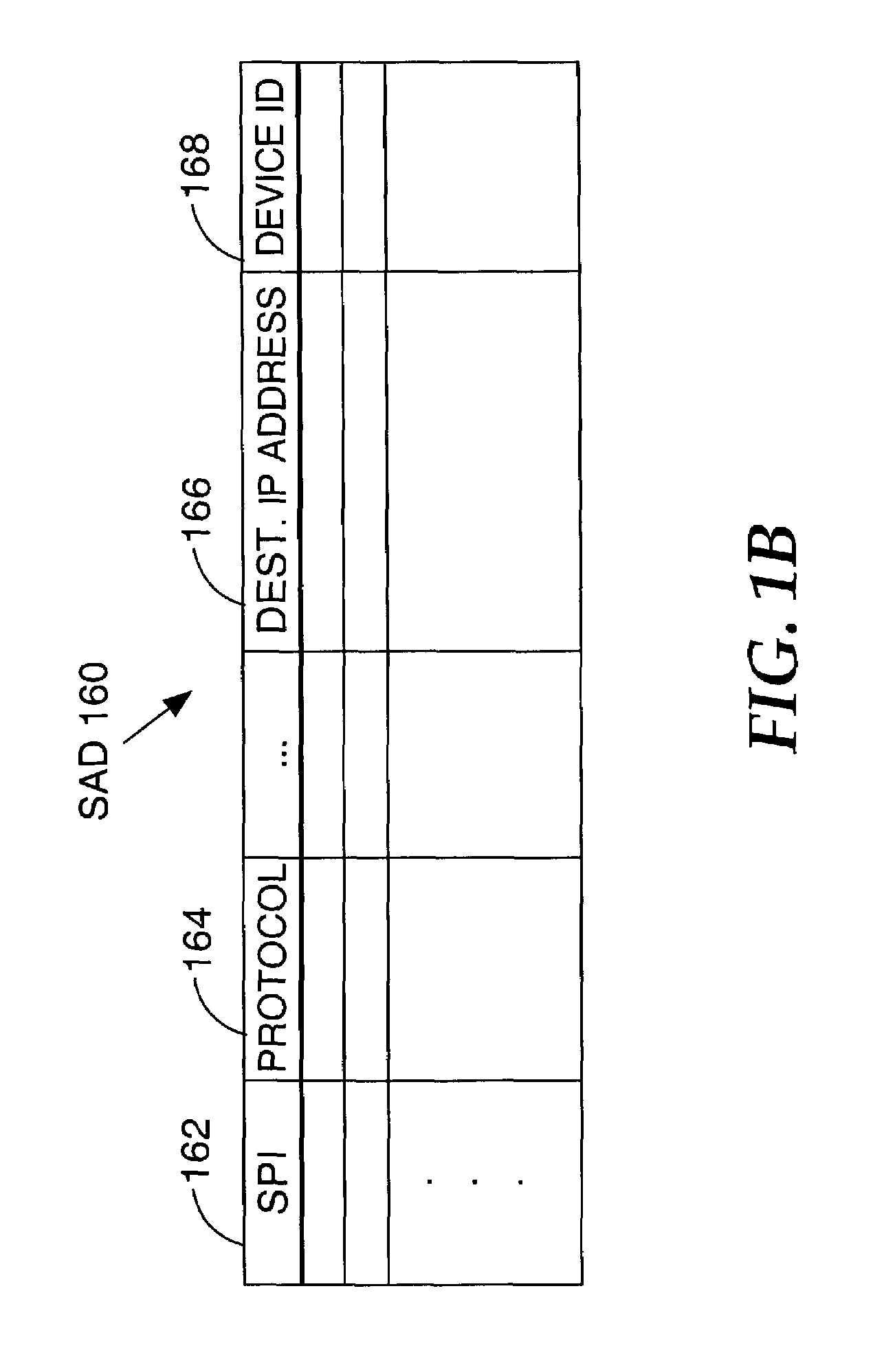

Method and apparatus for providing a secure name resolution service for network devices

InactiveUS7562384B1Digital data processing detailsUser identity/authority verificationSecurity associationNetwork addressing

Resolving information associated with a network device includes receiving a request for first information associated with the network device. The request includes second information associated with the device, such as identification information. Based on the second information, an entry that includes the first information in association with the second information is located in a security association database. For example, an entry that includes the information association is located in a Security Association Database (SAD) of an IPsec endpoint device. The first information is read from the entry and a response to the request is based on this first information. The association between the first and the second information that is stored in the relevant database may be based on an identification authentication mechanism. Thus, for example, a management station is able to obtain the dynamically assigned network address of an interesting IPsec endpoint device by providing identity information associated with the device.

Owner:CISCO TECH INC

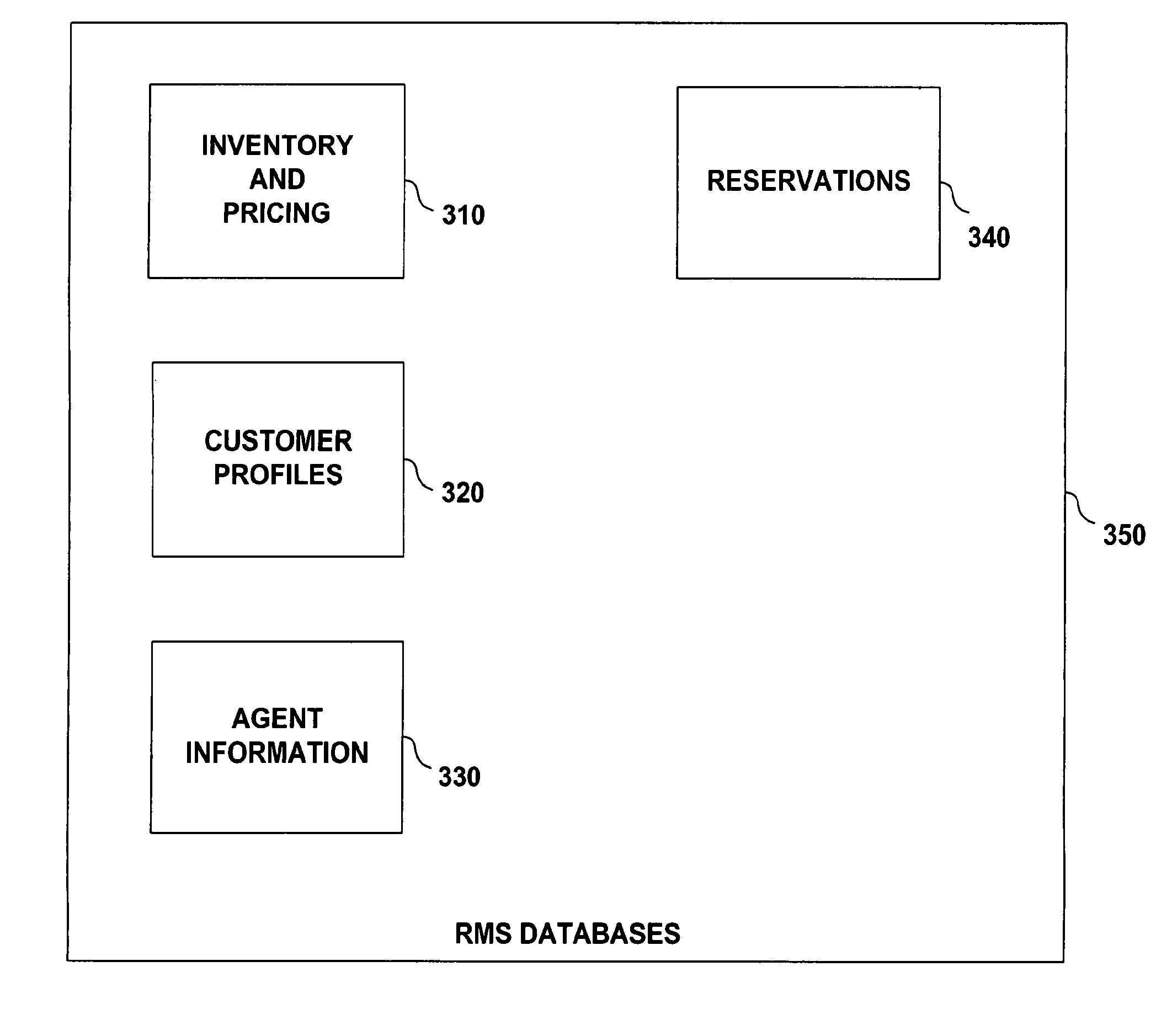

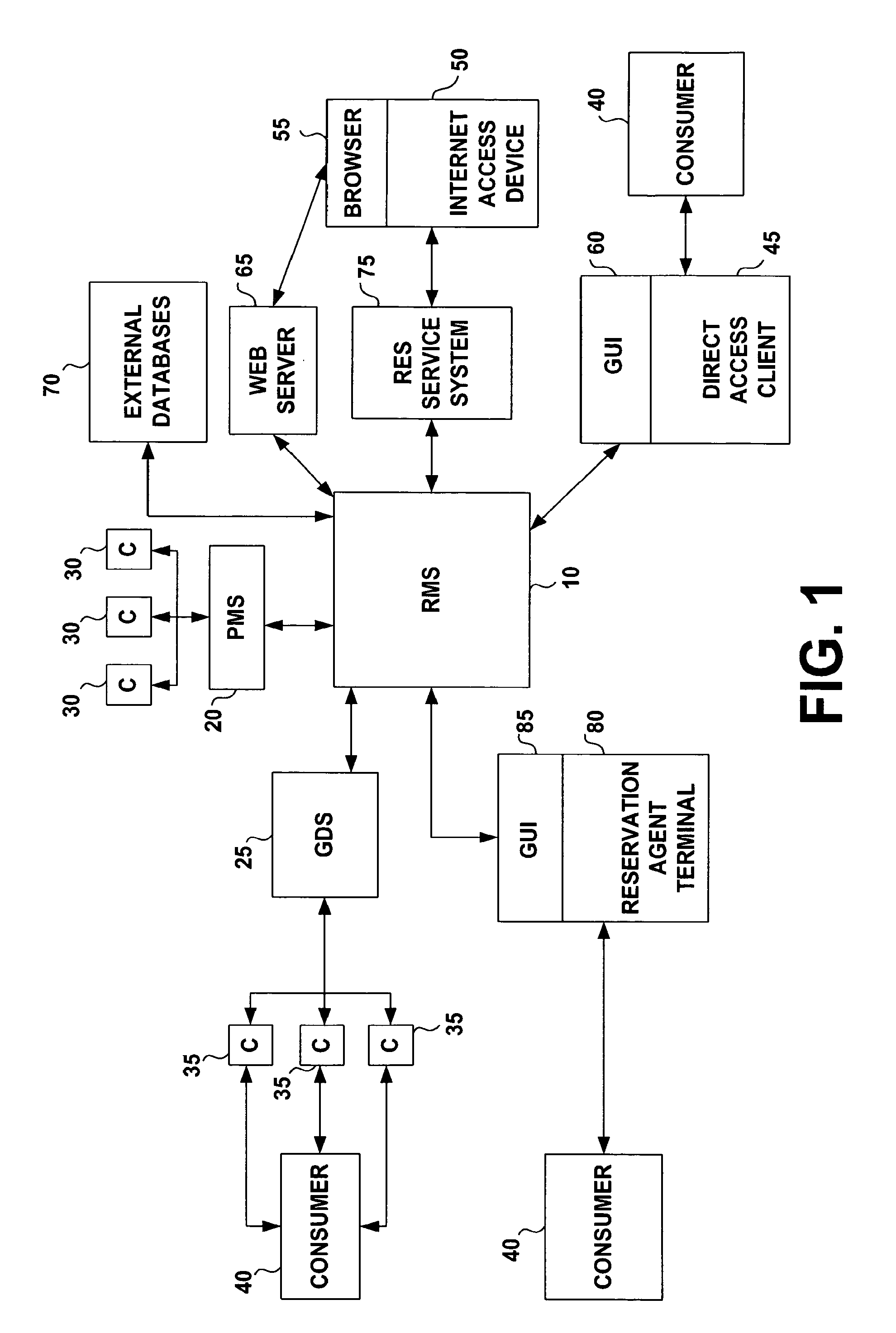

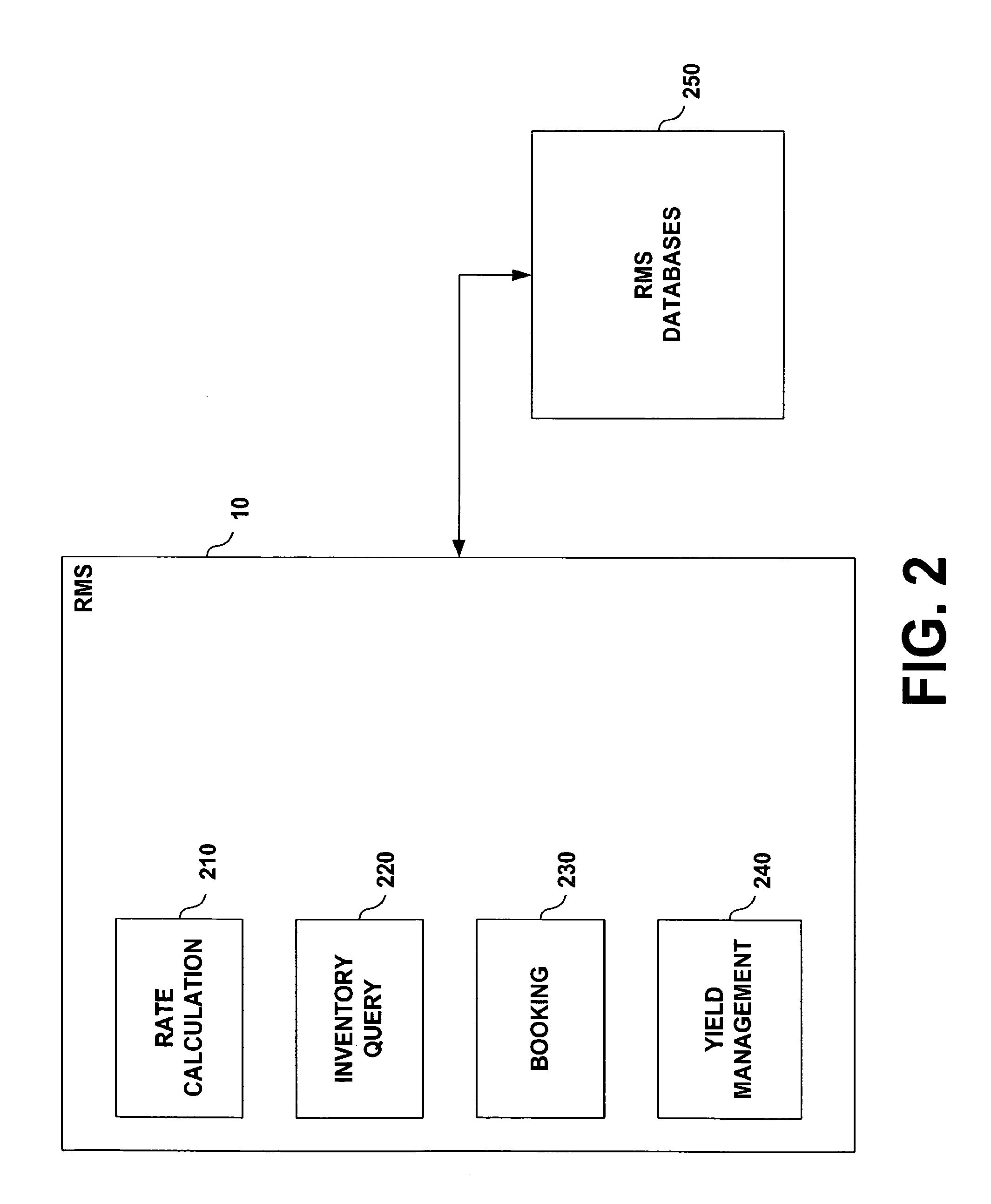

Global reservation transaction management system and method

A reservation system and methodology ensures that all changes to a database in a federation are reliably and immediately communicated to all of the other databases in the federation. The system communicates information concerning hotel reservation transactions. The system comprises multiple applications each associated with one or more databases including hotel reservation data. The databases in the federation reflect transactions that are communicated to other databases and they also employ information received from other databases in determining the transactions that their associated local applications permit and the way in which they are processed. In one embodiment of the invention, communication among databases occurs through the Internet and data storage devices via secure packetized messages addressed to objects that represent the relevant databases. The system of the present invention also preferably includes a central database that functions as the primary source for verifying reservations and hotel data. Additionally, the system of the present invention also includes a yield subsystem that allows hotels to increase revenues. The yield subsystem calculates rates and availability based upon forecasted changes in supply and customer segment demand.

Owner:SABRE

Apparatus, system, and method for executing a distributed spatial data query

InactiveUS20090063453A1Facilitate faster data transactionQuick searchDigital data processing detailsGeographical information databasesData sourceApplication software

An apparatus, system, and method for executing a distributed spatial data query. The present invention allows a client to perform spatial queries against spatial data stored in a various formats in various separate databases. A view of the data is created in the relevant databases, wherein the spatial data is converted to WKB and stored as a BLOB. A federated server contains nicknames for the various database views, and also contains views of the data where the BLOB is converted back to a spatial data type. The federated server presents to clients an application view of the distributed heterogeneous spatial data such that the clients can treat the data as if it were a homogenous data source. Also taught is incorporating distributed non-spatial data into the application view by creating a nickname and a view on top of the nickname which derives spatial information from the non-spatial location information.

Owner:IBM CORP

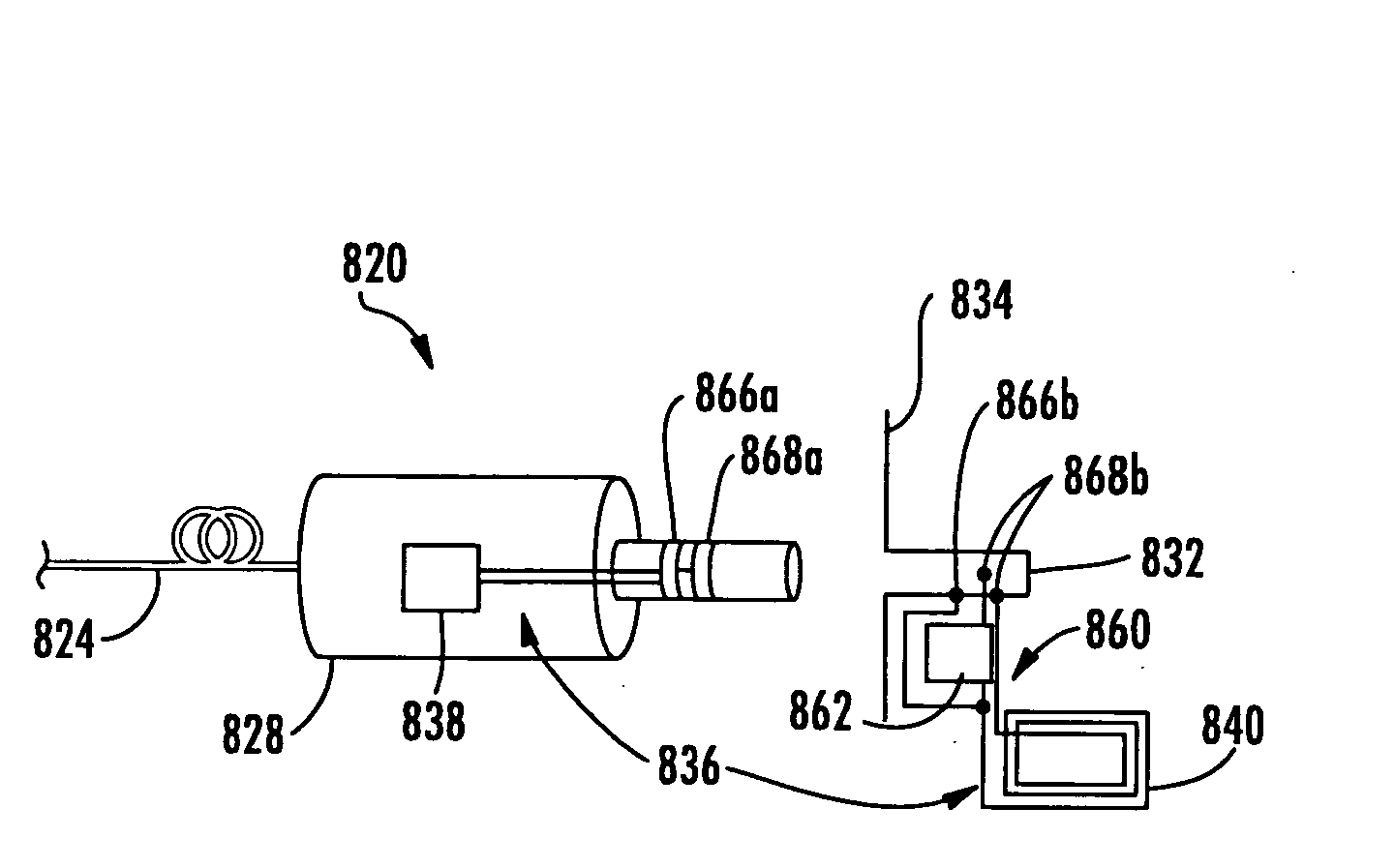

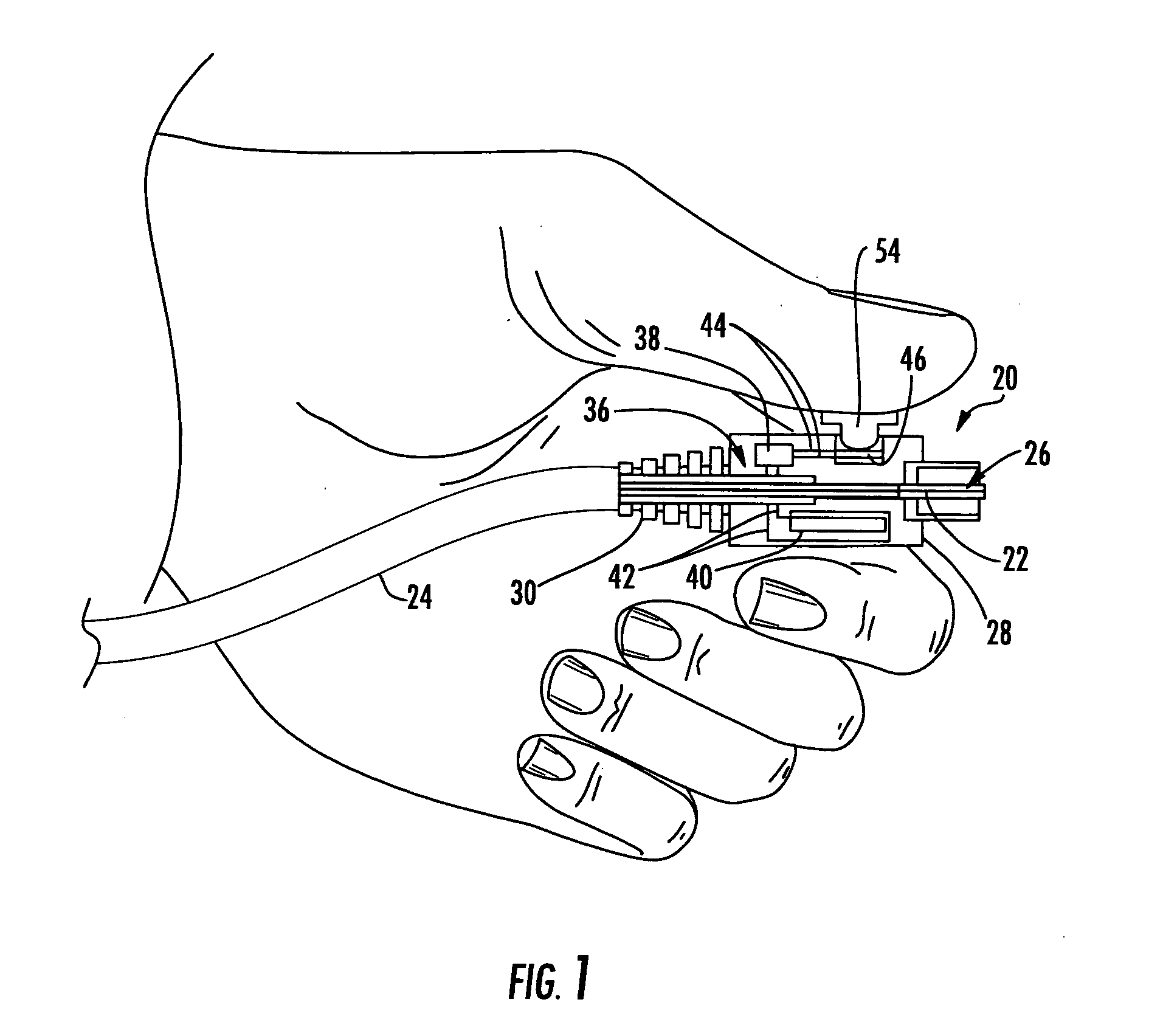

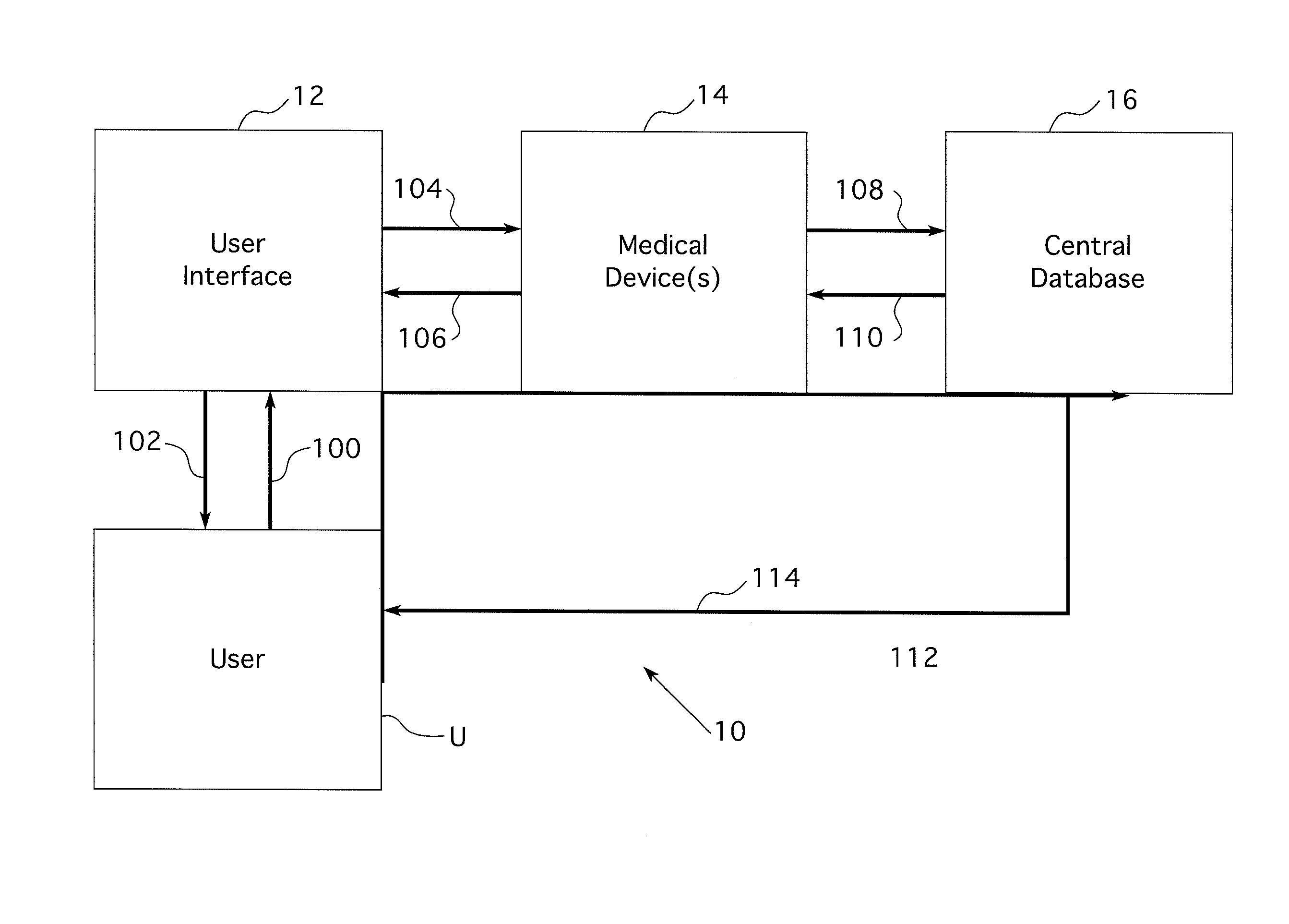

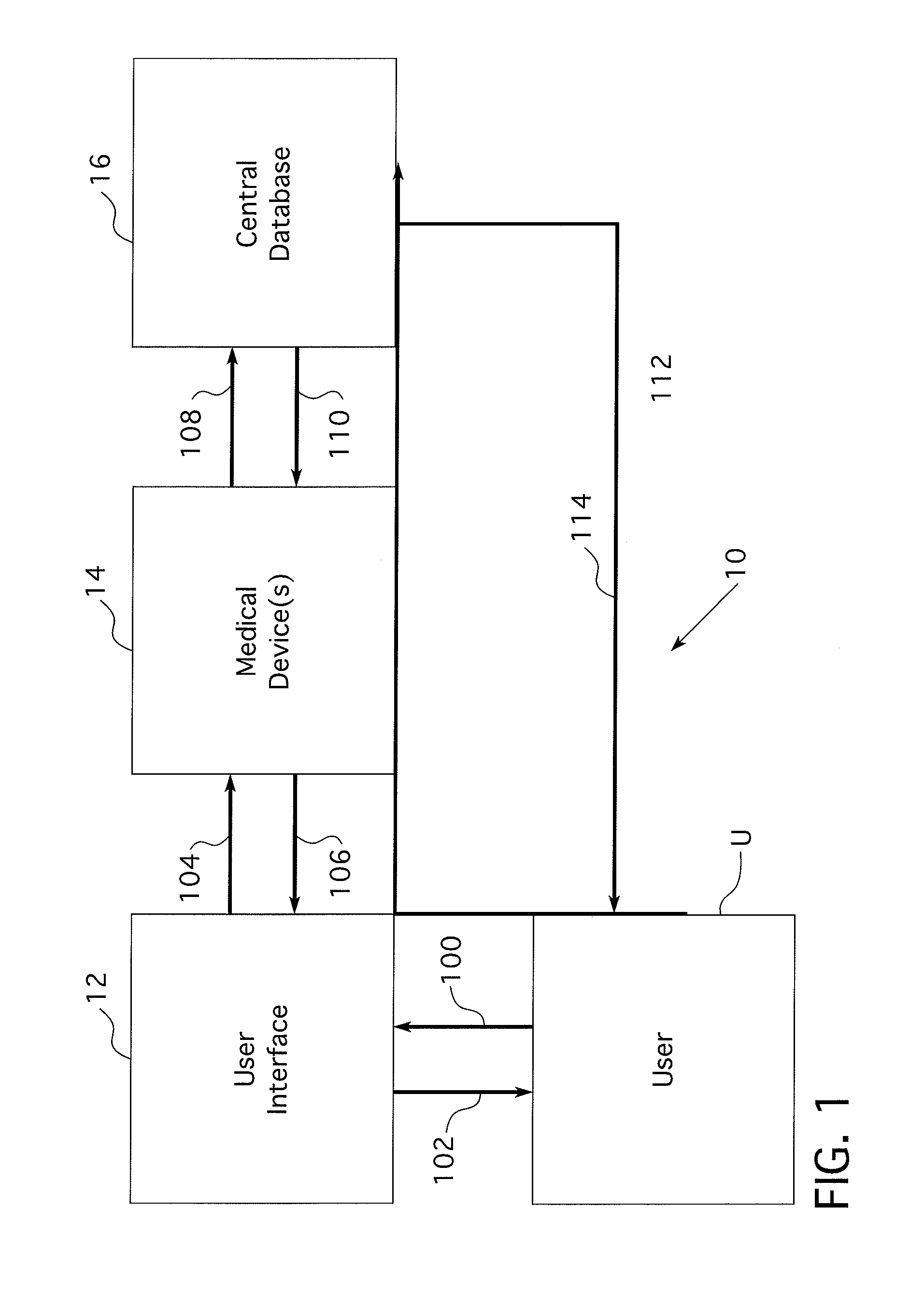

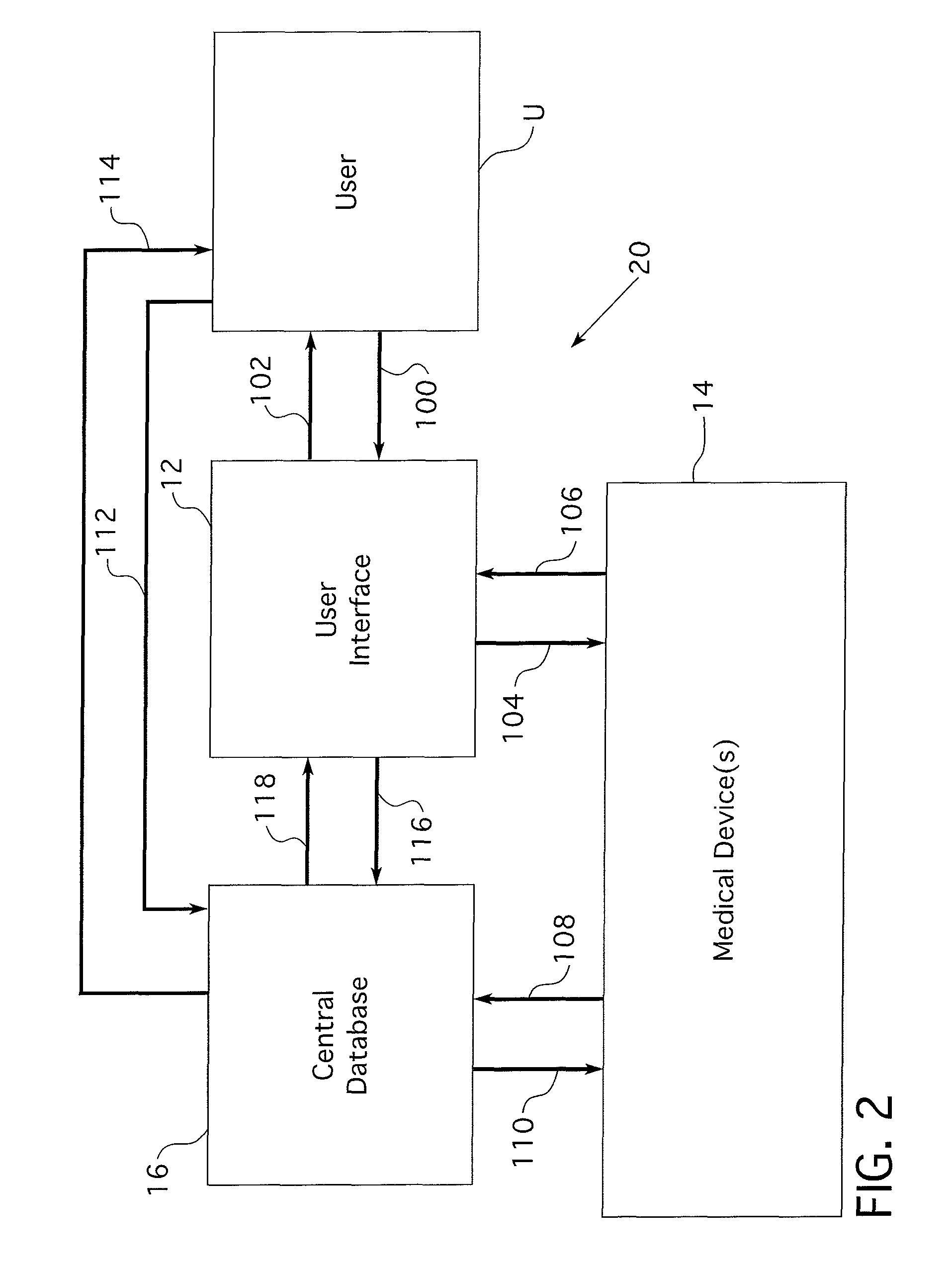

System and method for automated benchmarking for the recognition of best medical practices and products and for establishing standards for medical procedures

InactiveUS7996381B2Reduce gapLow costDigital data processing detailsDrug and medicationsTechnical standardUser interface

A system for collecting, managing and disseminating information relating to medical procedures includes a central computer and a plurality of medical devices each in communication with an injector, a scanner, a hospital system and / or at least one other device. Each medical device receives (I) before a procedure is performed, patient identification information from a user interface, the scanner and / or the hospital system and (II) during and / or after the procedure, injection information from the injector and imaging study information from the scanner. Each medical device has an associated database for storing as a record therein the patient identification information, the injection information and the imaging study information for each procedure performed on each patient. The central computer remotely links to each medical device for accessing, collecting and storing in a related database the records transmitted therefrom and for analyzing the records and creating therefrom at least one related entry based thereon.

Owner:BAYER HEALTHCARE LLC

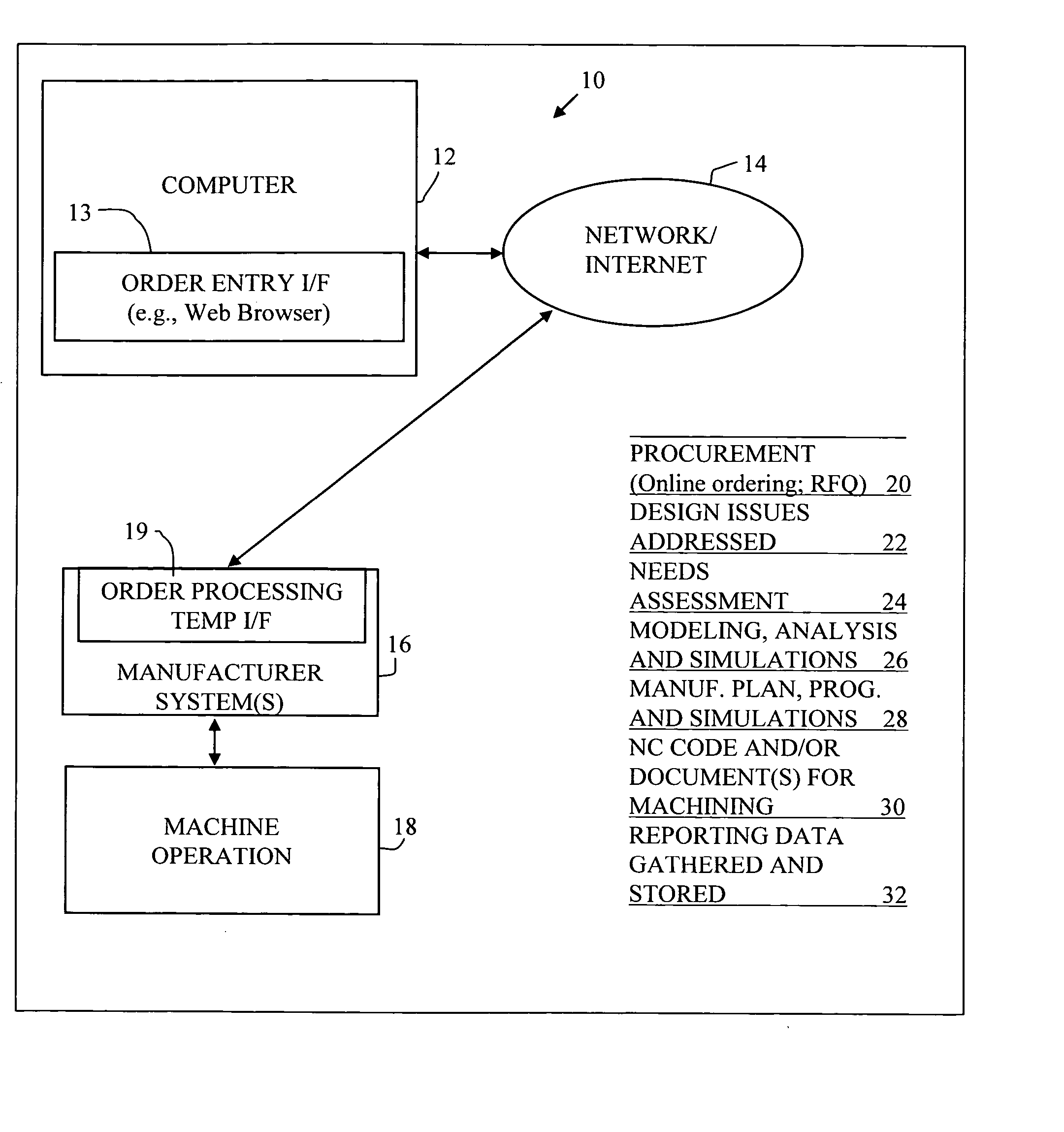

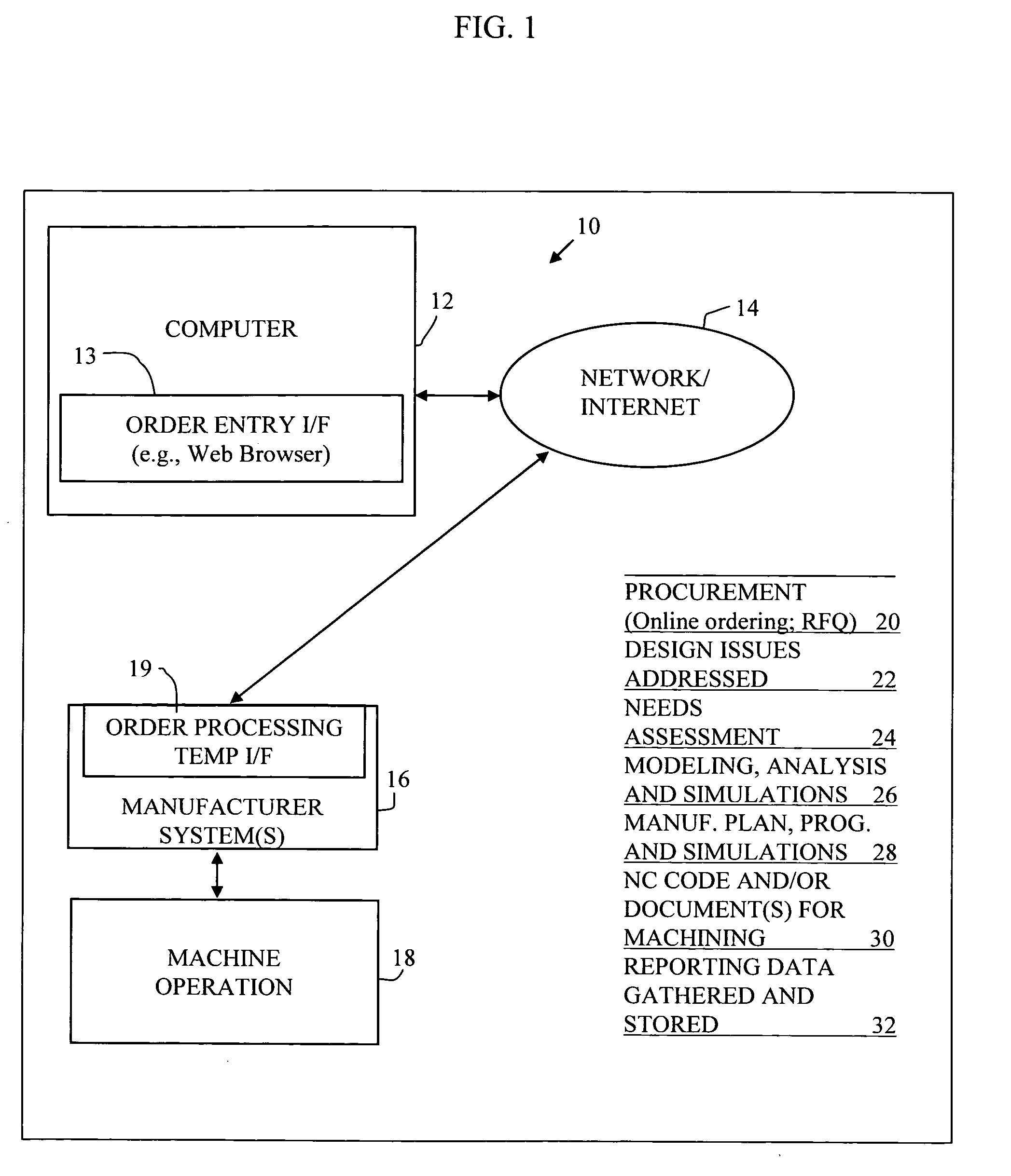

Automated planning and manufacturing systems

InactiveUS20060129462A1Increased riskImprove product qualityBuying/selling/leasing transactionsOrder formOrder processing

A system is provided for part ordering, design, and manufacturing. A manufacturer computer system is provided which comprises a parametric design mechanism to specify geometries of the part with parameters, an intelligent geometry portion, a 3D solid modeling function, and one or more simulation components. The intelligent geometry portion determines machining cycles to manufacture the part. Part-related databases are provided, and order processing components are provided. Such part-related databases and order processing components may form part of one or both of an ERP and PLM computer system. An order processing template is provided to facilitate sales and order processing, tool planning, CA parametric modeling, computer simulation, and the generation of a factory machine program. The order processing template comprises financial and manufacturing engineering planning fields and technical fields. An order template interface, or a set of order template interfaces, is provided. This interface or set of interfaces provides, for a given ordered part, from the order template, CA-specific information to the manufacturer computer system before the manufacturer computer system performs any CAD modeling or CAE calculation of the part. The interface or set of interfaces further provides, for the given ordered part, from the order template, ERP-specific information to the ERP system before the ERP system performs any scheduling of machines and resources, material reservation, or RFQ calculations.

Owner:PANKL GEROLD +1

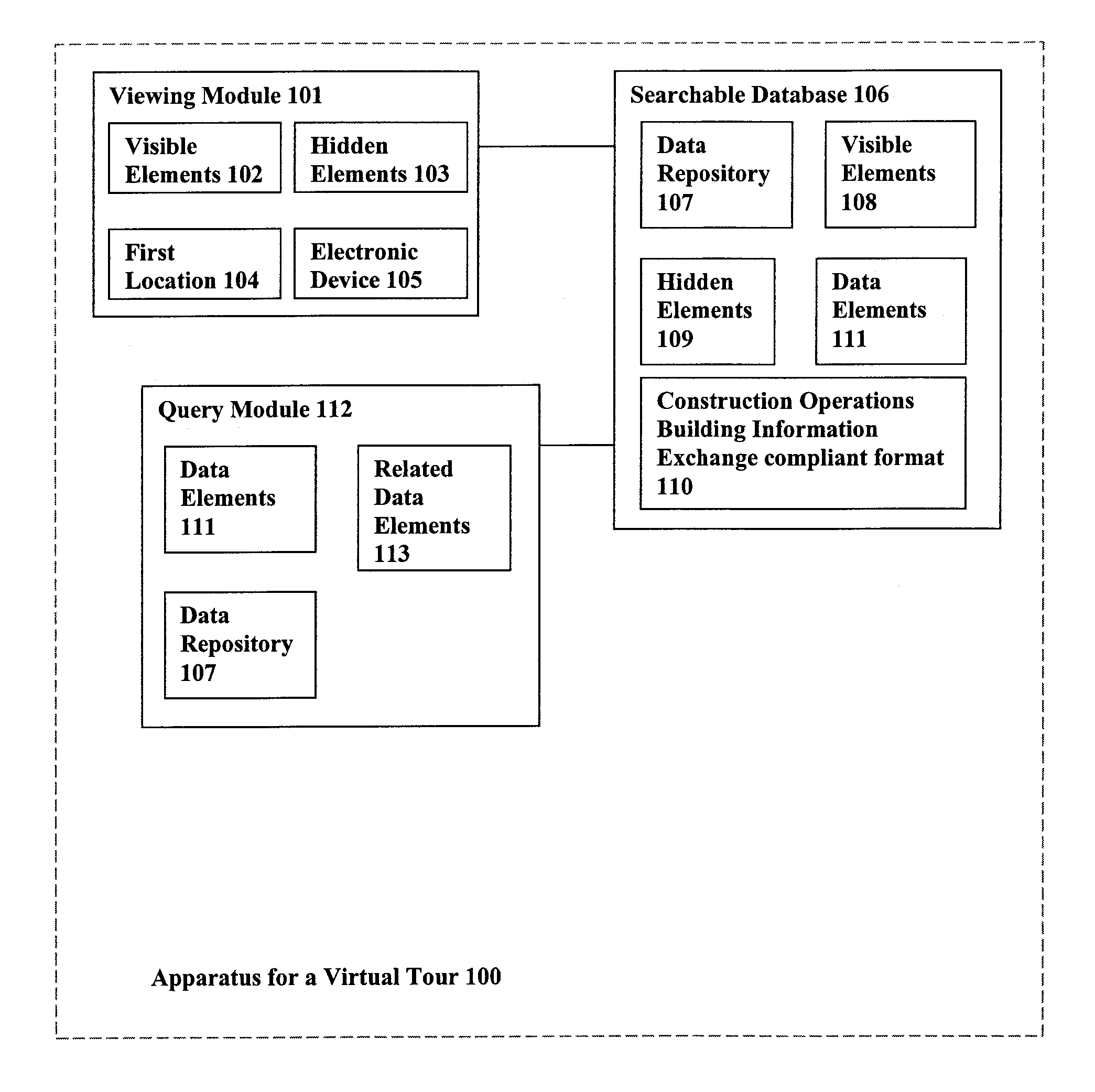

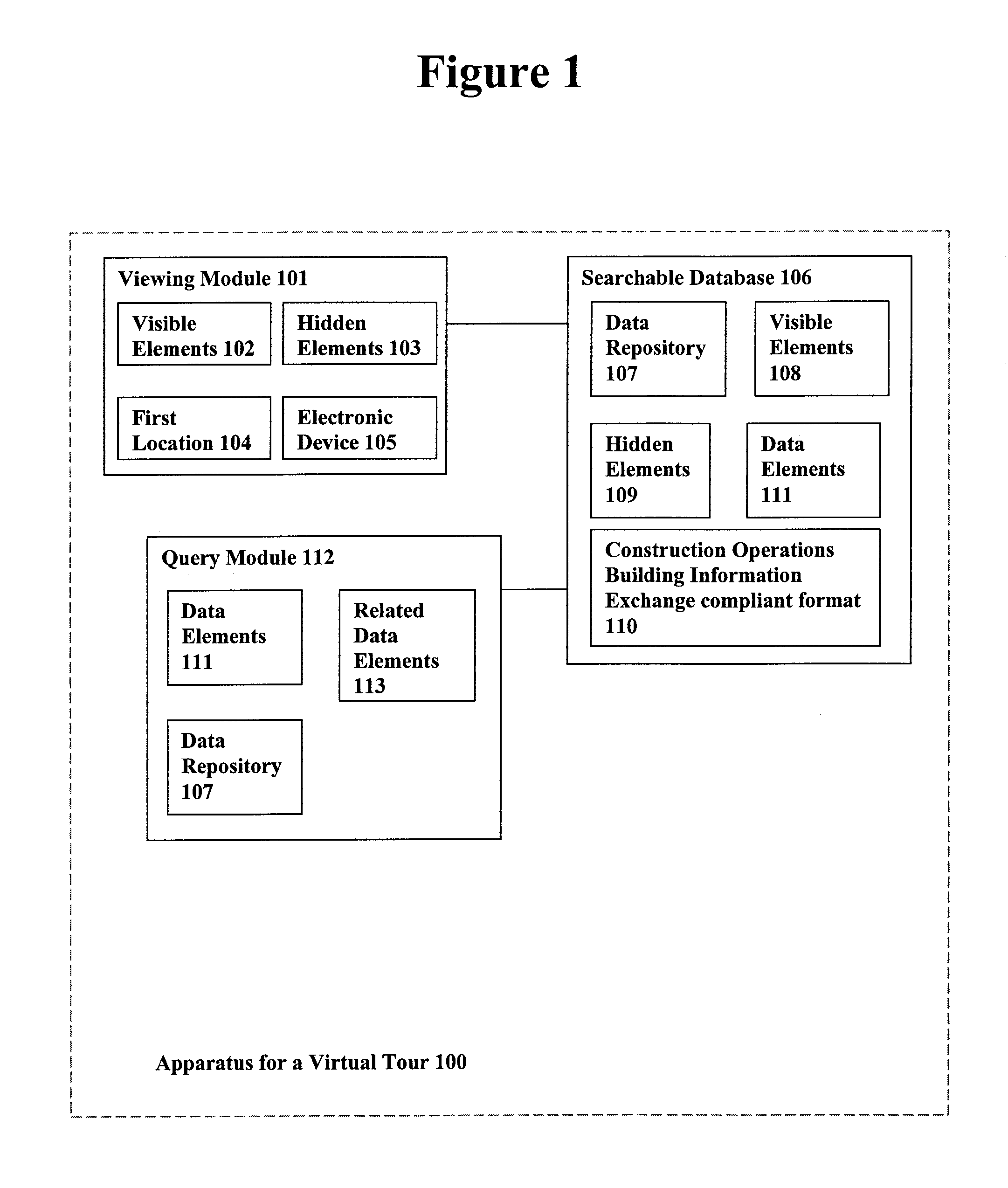

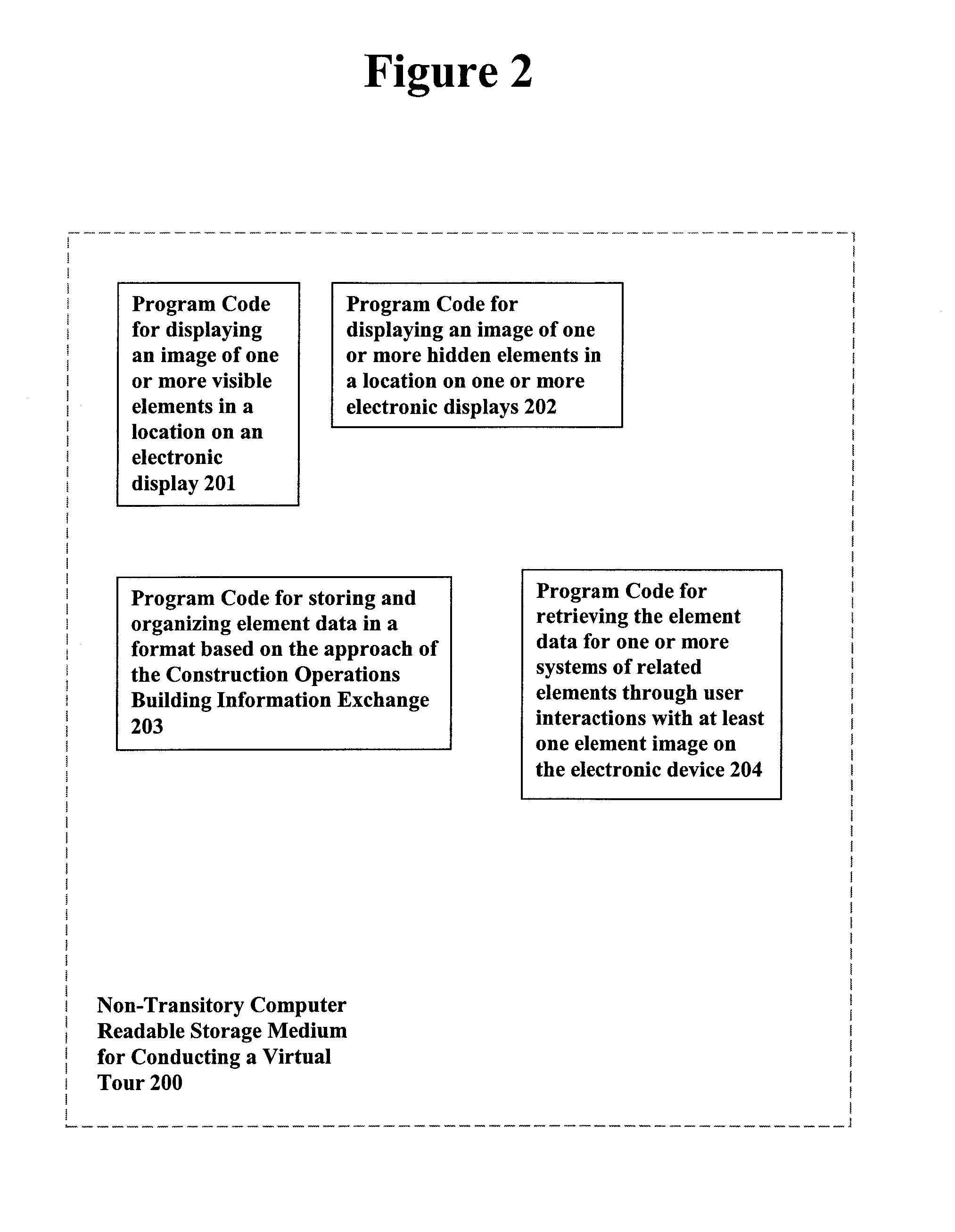

Virtual Building Browser Systems and Methods

Systems and methods are provided for a virtual building browser with a viewing module displaying images of visible elements and hidden elements, a searchable, relational database configured in a (COBie) compliant format, a query module, and an interface tool for accessing building information management (BIM) data in real-time, monitoring systems to manage facility assets, integration applications linking the searchable database with associated databases, peripheral devices, and user devices. In one embodiment, user devices are iPad® tablet devices with GPS. A computer implemented apparatus for a virtual tour system is also included. Steps for providing a virtual building browser, a virtual tour, and for linking LEED data to a virtual location are included plus computer-implemented methods with computer-usable readable storage medium having computer-readable program code embodied therein for causing a computer system to perform steps for a virtual tour, displaying building information management images of locations are included.

Owner:WALTER MARK +1

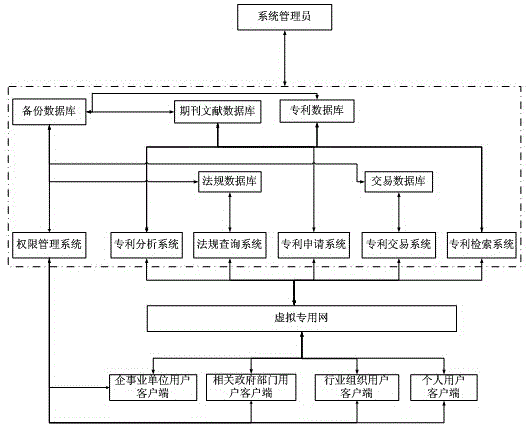

Intellectual property service system based on Internet of things

InactiveCN105608652AReal-time detection operationImprove securityData processing applicationsPrivate networkIntellectual property

The invention discloses an intellectual property service system based on Internet of things, and relates to the technical field of Internet of things. The system comprises a client, a virtual private network and a server. Different users have exclusive clients. The virtual private network is used for guaranteeing the security of data transmission. The server comprises an authority management system, a patent analysis system, a law query system, a patent application system, a patent transaction system, a patent retrieval system and relevant databases. The authority management system is used for managing the authority of each user in the system; the patent analysis system is used for providing a patent analysis service for users; the law query system is used for providing law and regulation query for the users; the patent application system is used for providing a patent application service for the users; the patent transaction system is used for providing a patent transaction platform; the patent retrieval system is used for providing a patent retrieval service for the users; and the relevant databases are used for providing a database support for each system.

Owner:SICHUAN JIUDINGZHIYUAN INTPROP OPERATIONS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com