Method for controlling a wind power plant and corresponding wind power plant

A technology of wind energy equipment and rotor blades, which is applied to the control of mechanical equipment, wind power generation, and wind turbines, etc., and can solve problems such as increased load of wind energy equipment, adjustment algorithms that easily cause vibration, and are difficult to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

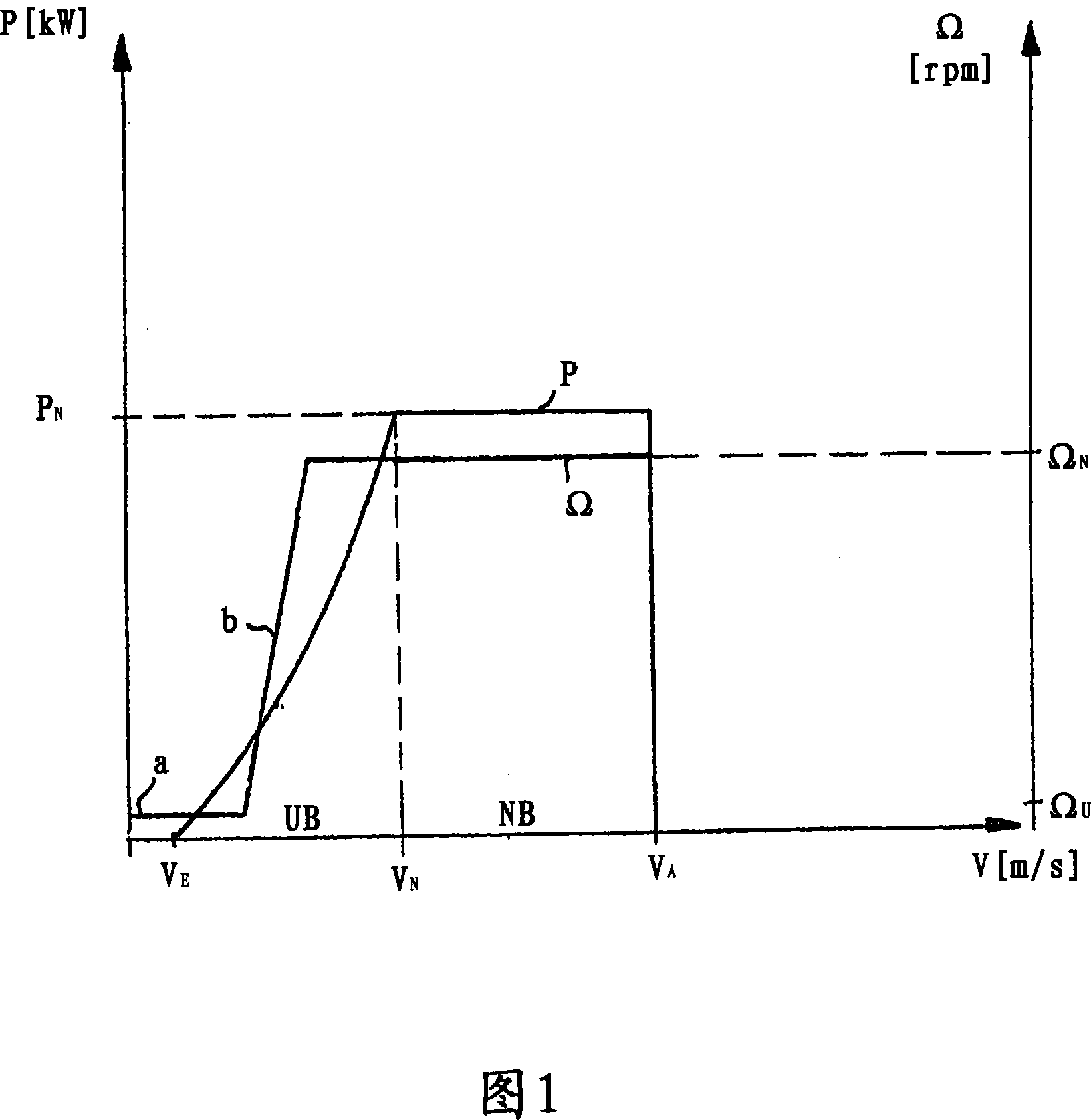

[0086] FIG. 1 has already been explained when discussing the prior art, so it should not be discussed again here.

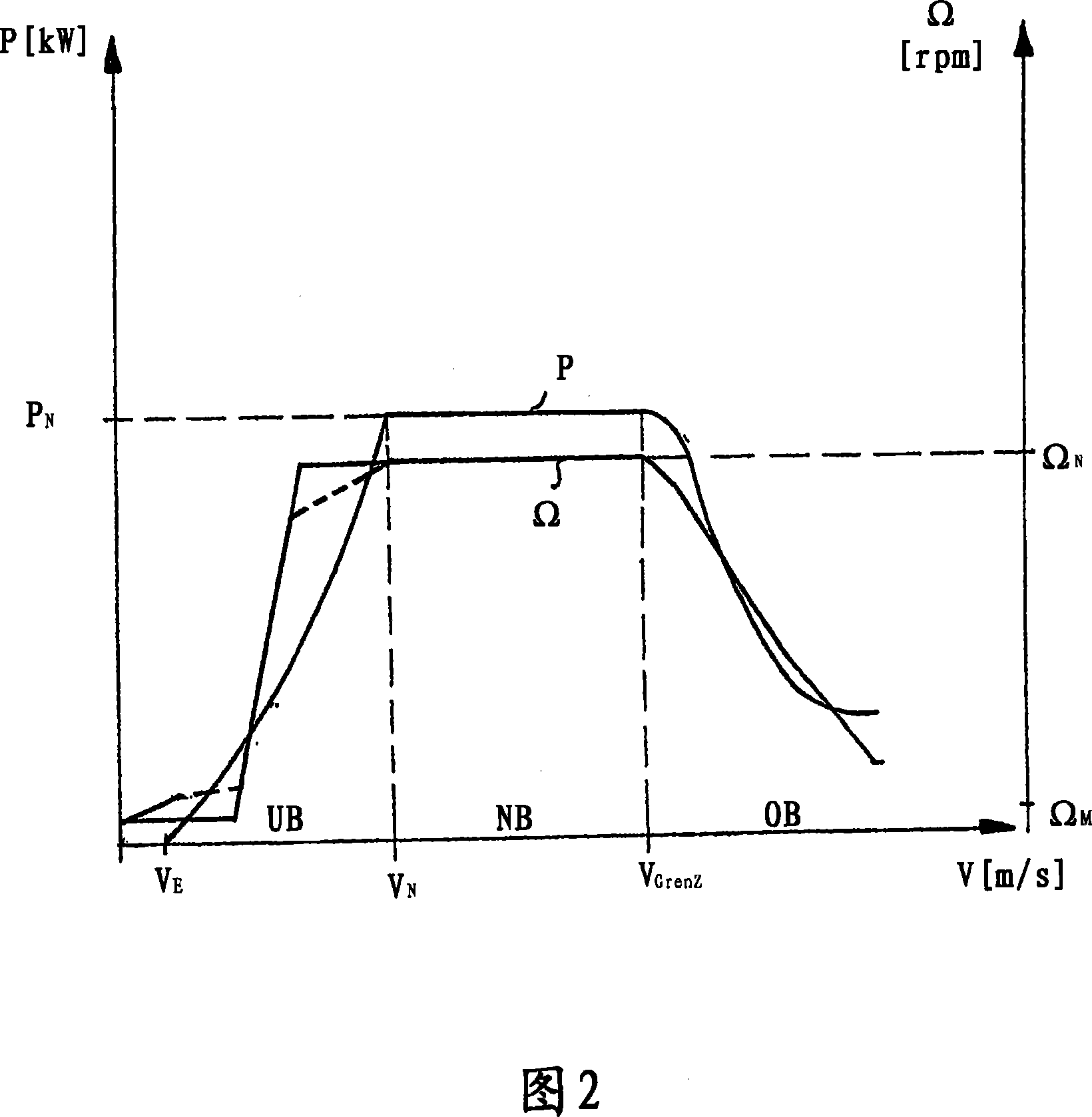

[0087] Figure 2 has also been described in the prior art, so only some additions should be made here.

[0088] Figure 2 shows a speed characteristic curve in the lower partial load region UB indicated by a thin solid line, which is specified in Ω U and Ω N Optimum energy gain in the limited speed range between them. The regulation of the rotational speed is usually carried out by means of a pair of generator torque acting PI or PID controllers, wherein the torque is limited according to the rotational speed in order to achieve a rotational speed ramp for operation at optimum fast operating speeds. Alternatively, as described above, a simple speed-torque dependence can also be determined, for example in the form of a table function, in order to implement a particularly simple control algorithm. Such a fixed speed-torque characteristic curve results, for example...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com