Iron ore sinter mixture distribution method

A technology for sintering mixtures and iron ore, which is applied in furnaces, lighting and heating equipment, furnace types, etc., can solve problems such as the inability to effectively realize fuel segregation and difficult control of magnetic field strength, and achieve improved stress conditions and moving rails, Effect of Improving Magnetic Susceptibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

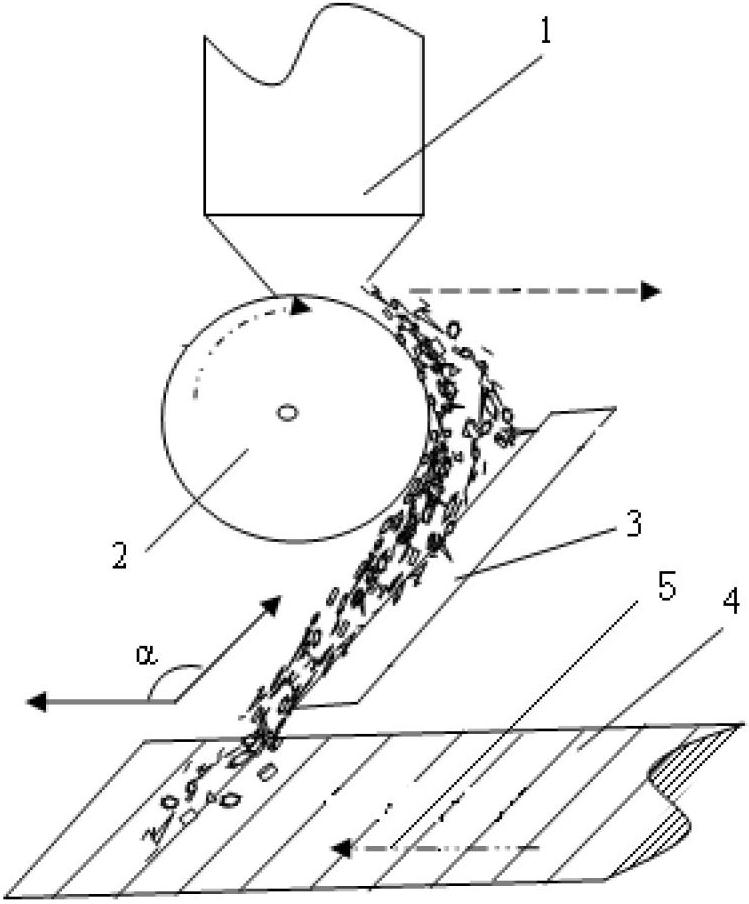

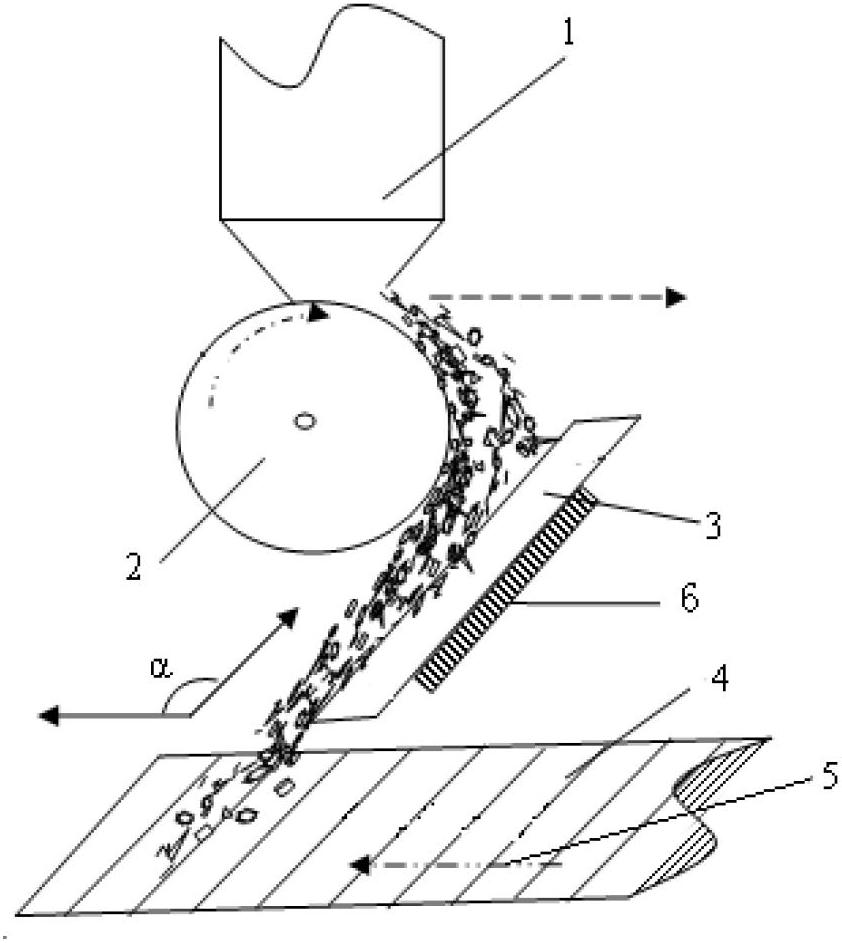

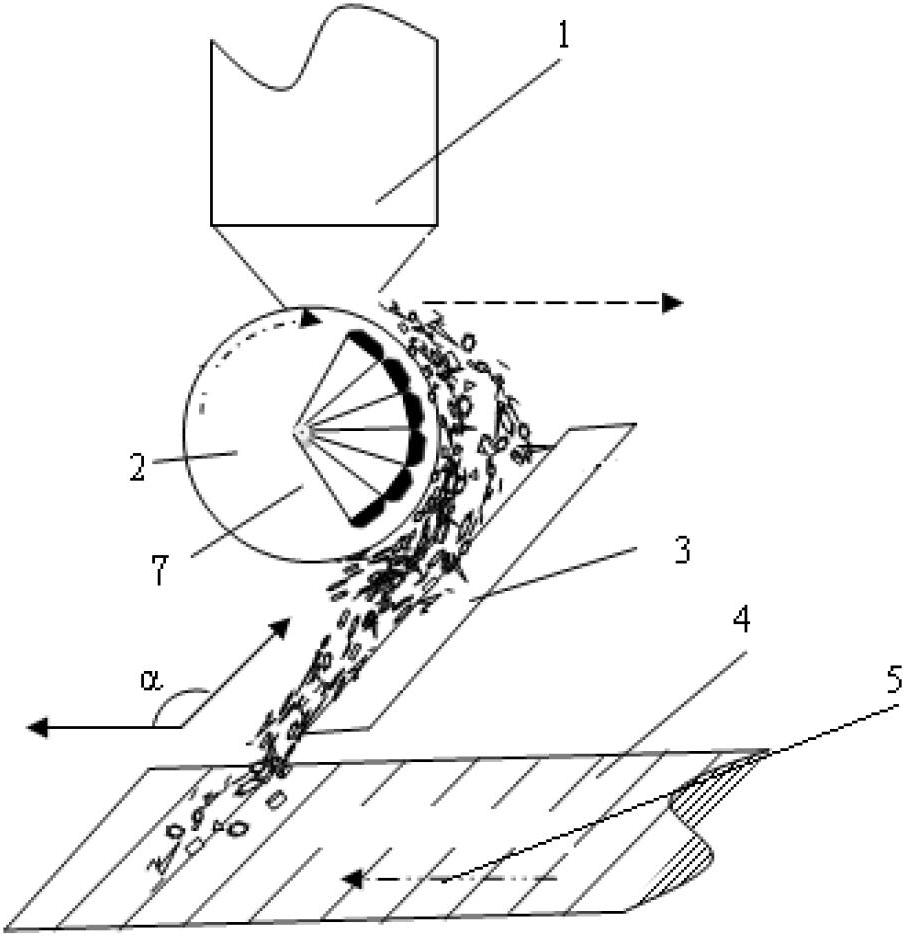

[0038] See attached Figure 4 , a distributing device for iron ore sintering mixture in the present invention, comprising a round roller feeder-reflecting plate distributor, the distributing roller in the round roller feeder is provided with a permanent magnet composed of alternating polarities Magnetic system, the reflective plate in the reflective plate distributor is below the horizontal axis of the distribution roller and parallel to the tangent line passing the circumference below the horizontal axis of the distribution roller, and the axis of the reflective plate is in line with the moving direction of the sintering machine trolley The included angle α is 45°; the magnetic system is composed of 6 NdFeB permanent magnets with alternating polarities, and the magnetic field strength formed on the circumferential surface of the distribution roller is 300Gs~2000Gs, and the distribution range on the circumferential surface of the distribution roller is The contact point betwee...

Embodiment 2

[0040] See attached Figure 4 , a distributing device for iron ore sintering mixture in the present invention, comprising a round roller feeder-reflecting plate distributor, the distributing roller in the round roller feeder is provided with a permanent magnet composed of alternating polarities Magnetic system, the reflective plate in the reflective plate distributor is below the horizontal axis of the distribution roller and parallel to the tangent line passing the circumference below the horizontal axis of the distribution roller, and the axis of the reflective plate is in line with the moving direction of the sintering machine trolley The included angle α is 45°; the magnetic system is composed of 6 NdFeB permanent magnets with alternating polarities, and the magnetic field strength formed on the circumferential surface of the distribution roller is 300Gs~2000Gs, and the distribution range on the circumferential surface of the distribution roller is The contact point betwee...

Embodiment 3

[0042] See attached Figure 4 , a distributing device for iron ore sintering mixture in the present invention, comprising a round roller feeder-reflecting plate distributor, the distributing roller in the round roller feeder is provided with a permanent magnet composed of alternating polarities Magnetic system, the reflective plate in the reflective plate distributor is below the horizontal axis of the distribution roller and parallel to the tangent line passing the circumference below the horizontal axis of the distribution roller, and the axis of the reflective plate is in line with the moving direction of the sintering machine trolley The included angle α is 45°; the magnetic system is composed of 6 NdFeB permanent magnets with alternating polarities, and the magnetic field strength formed on the circumferential surface of the distribution roller is 300Gs~2000Gs, and the distribution range on the circumferential surface of the distribution roller is The contact point betwee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Magnetic field strength | aaaaa | aaaaa |

| Magnetic field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com