Patents

Literature

55results about How to "Increase magnetic susceptibility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

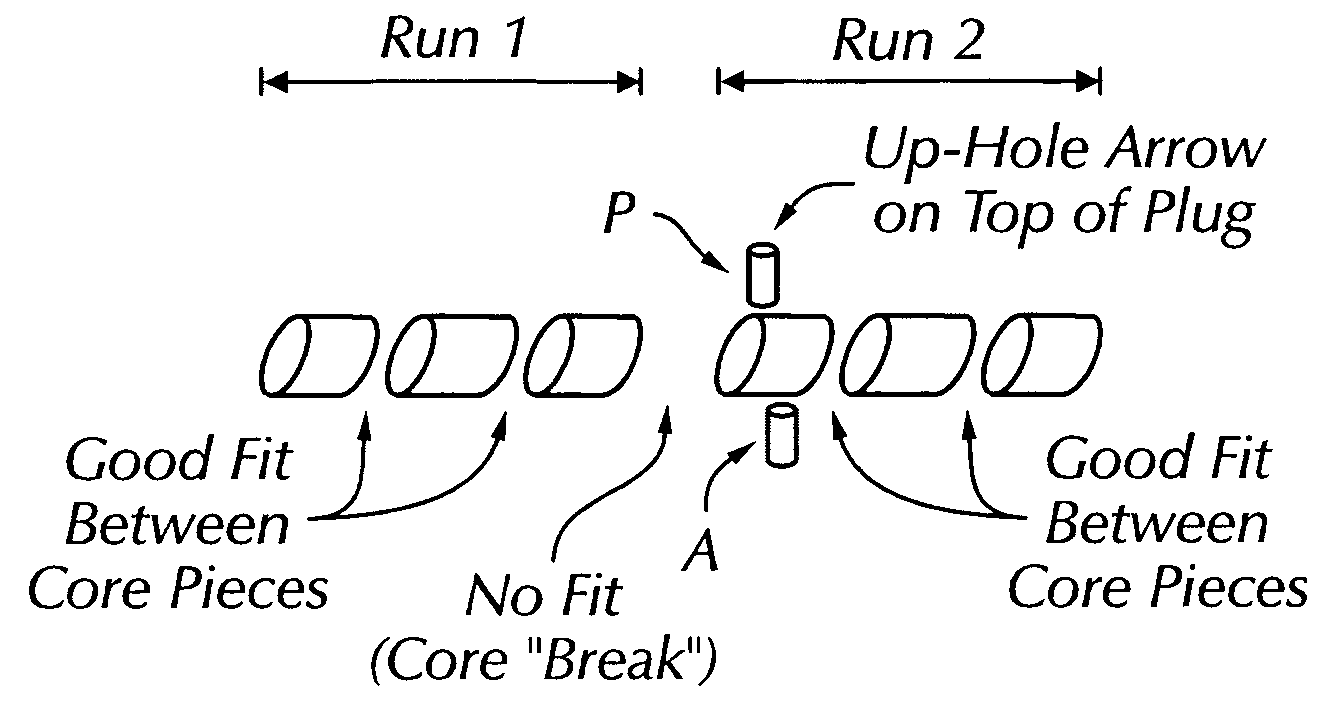

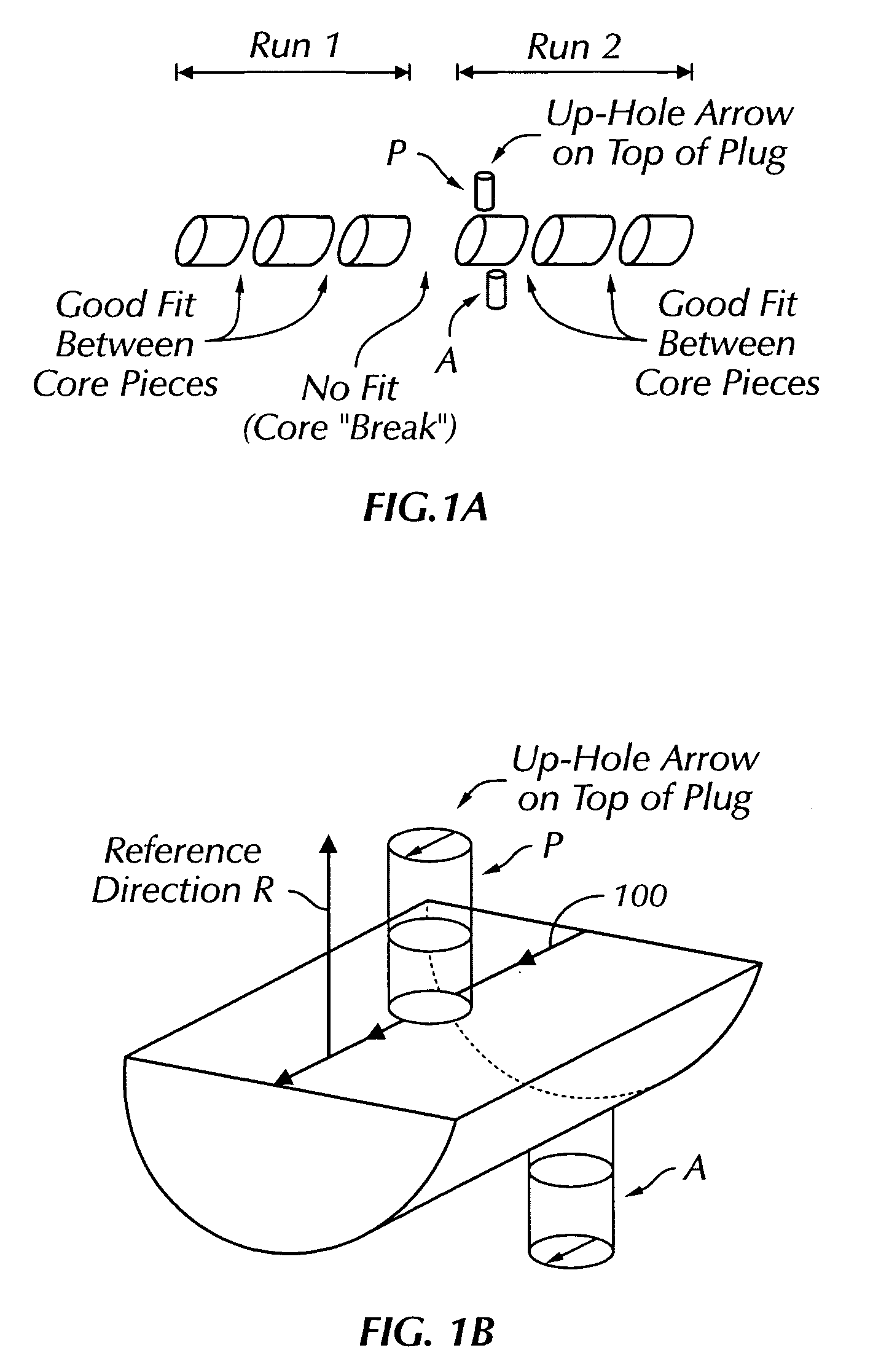

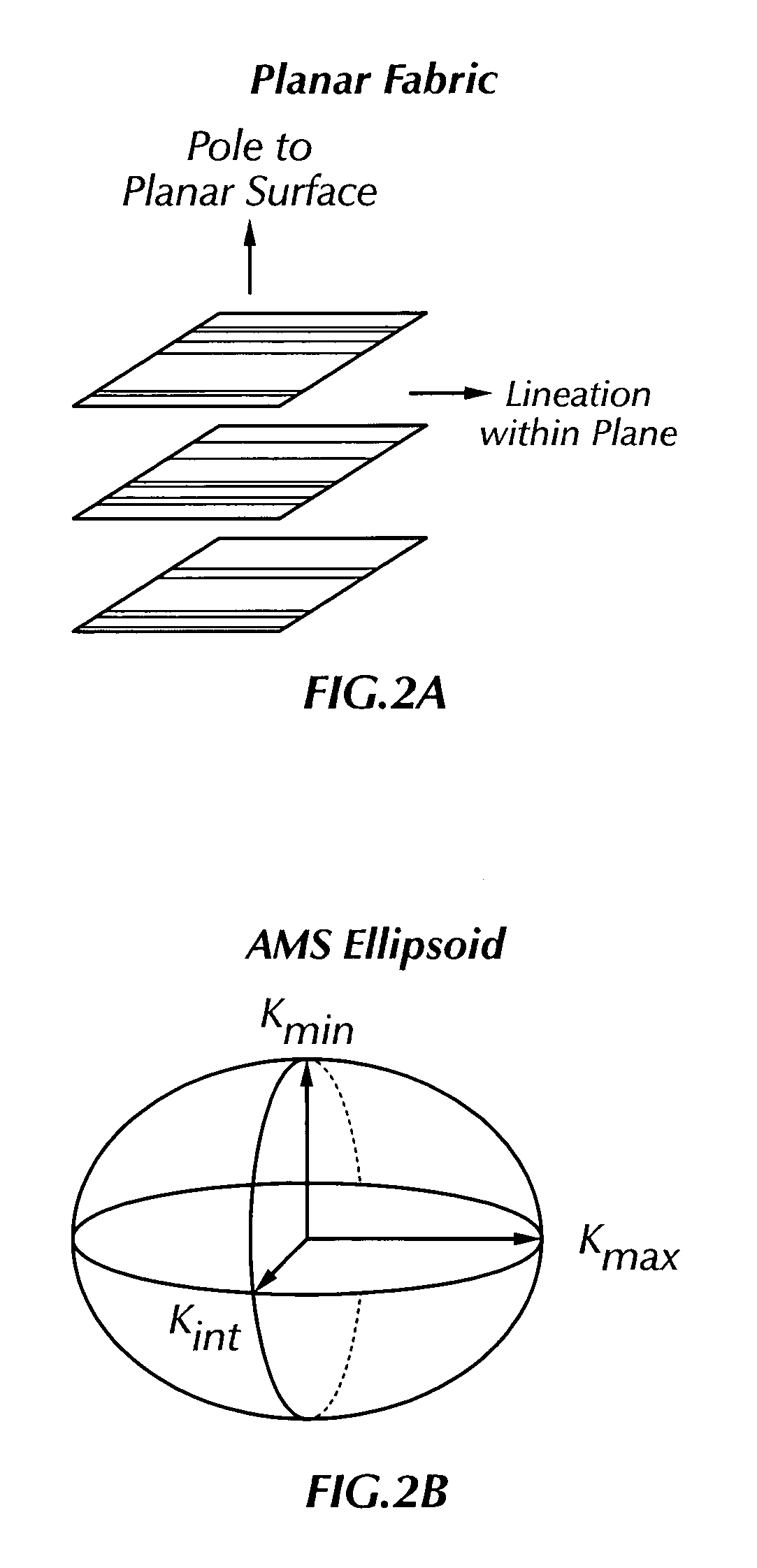

Method to characterize microfractured hydrocarbon reservoirs by artificially induced anisotropy of magnetic susceptibility

ActiveUS7126340B1Increase magnetic susceptibilityElectric/magnetic detectionAcoustic wave reradiationMagnetic susceptibilityPorosity

Subterranean hydrocarbon reservoirs are analyzed by characterizing the relative presence and character of microfractures in rock samples from the reservoirs. Core samples are saturated with a suspension of magnetite particles of known concentration. The samples are then subjected to an applied magnetic field of known strength. The anisotropy of magnetic susceptibility, or AMS, of the samples is then observed, providing a measure of grain orientation in the samples. The characteristics of the microfractures in the samples are thus available to characterize the reservoirs, and in particular the contribution of the microfractures to the porosity and permeability of formations in the reservoirs.

Owner:SAUDI ARABIAN OIL CO

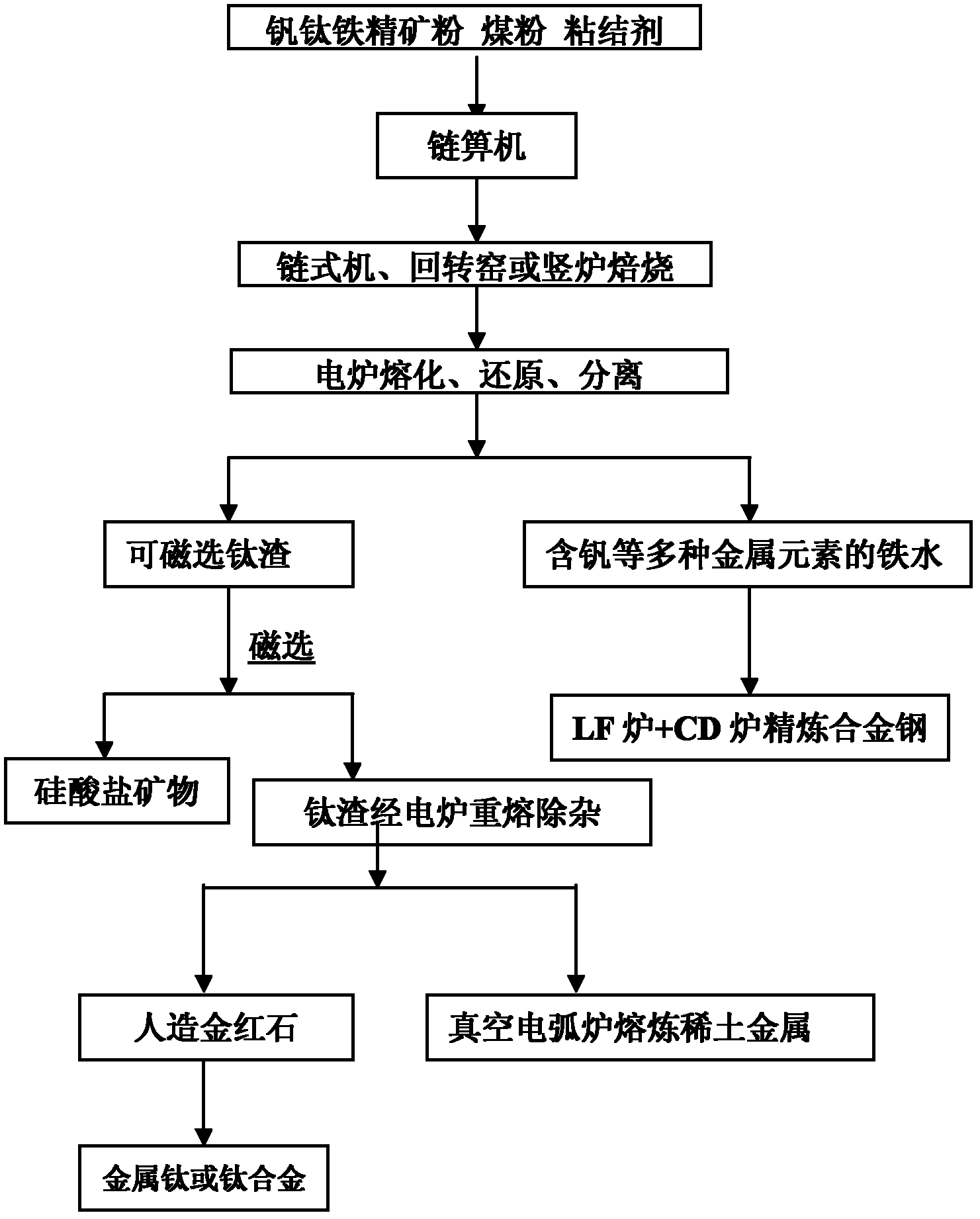

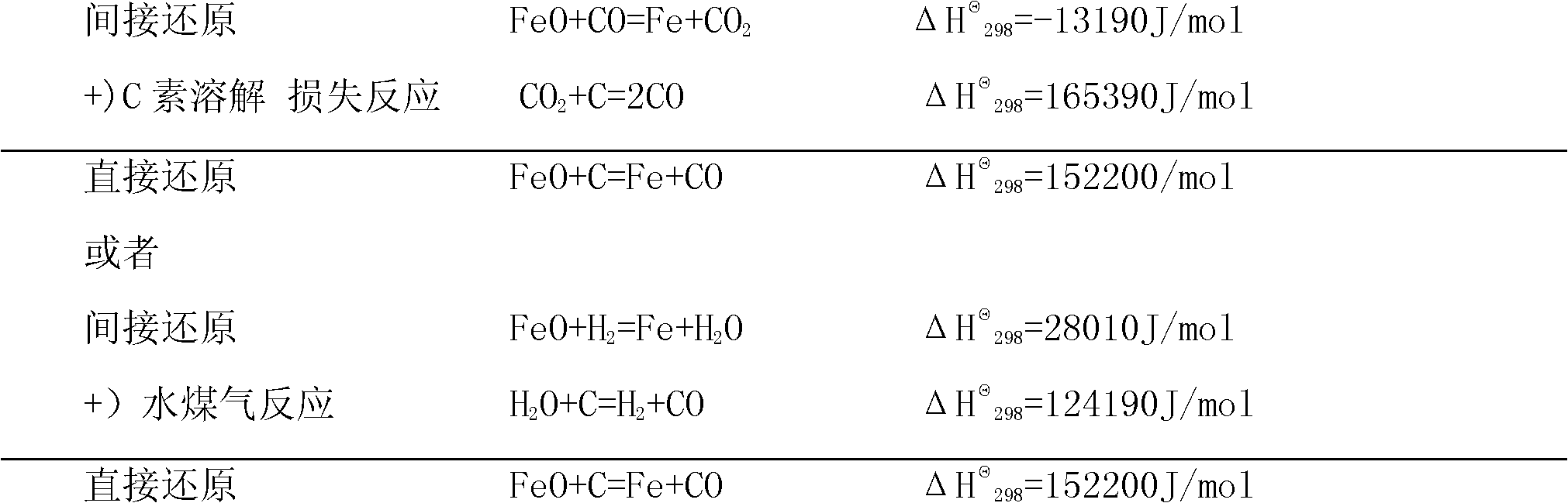

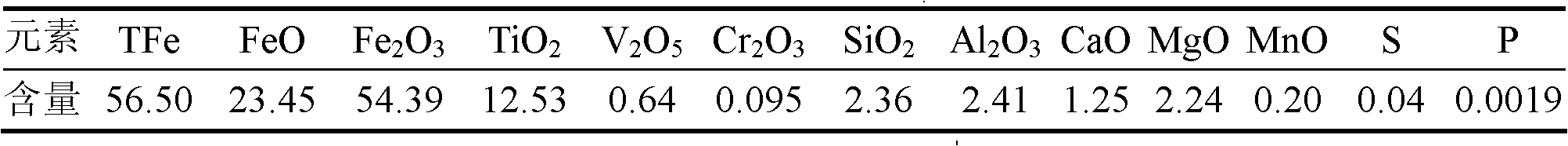

Method for selecting and smelting titanium from vanadium titanomagnetite at low temperature

InactiveCN102352423AQuick restoreIncrease magnetic susceptibilityProcess efficiency improvementElectric furnaceDc arc furnaceTitanium metal

The invention relates to a method for selecting and smelting titanium from vanadium titanomagnetite at low temperature, belonging to the technical field of metallurgy. The method comprises the following steps: 1) roasting at the low temperature of 500-1100 DEG C; 2) adding a solid reductant to the roasted product, carrying out reduction smelting at 1100-1300 DEG C, and separating slag and iron torespectively obtain molten iron and titanium slag; carrying out magnetic separation on the titanium slag to remove impurities, thereby obtaining the titanium-rich material; and 4) adding required metal oxide concentrate into a direct-current arc furnace, and directly alloying the molten iron to obtain alloy steel. The smelting method provided by the invention is a brand new smelting method, and changes the existing iron ore selection into titanium ore selection; the pellet is molten and reduced by roasting at low temperature, and the separated molten iron facilitates the addition of ores withdeficient metal elements so as to directly smelt the alloy steel; the titanium slag is subjected to magnetic separation to obtain the titanium-rich material, and the titanium-rich material is furthersmelted to obtain the titanium alloy or titanium metal; and the smelting slag can be used as the raw material for smelting rare earth metals so as to sufficiently and respectively utilize the elements in the ores in one step.

Owner:攀枝花慧泰金属新材料有限公司

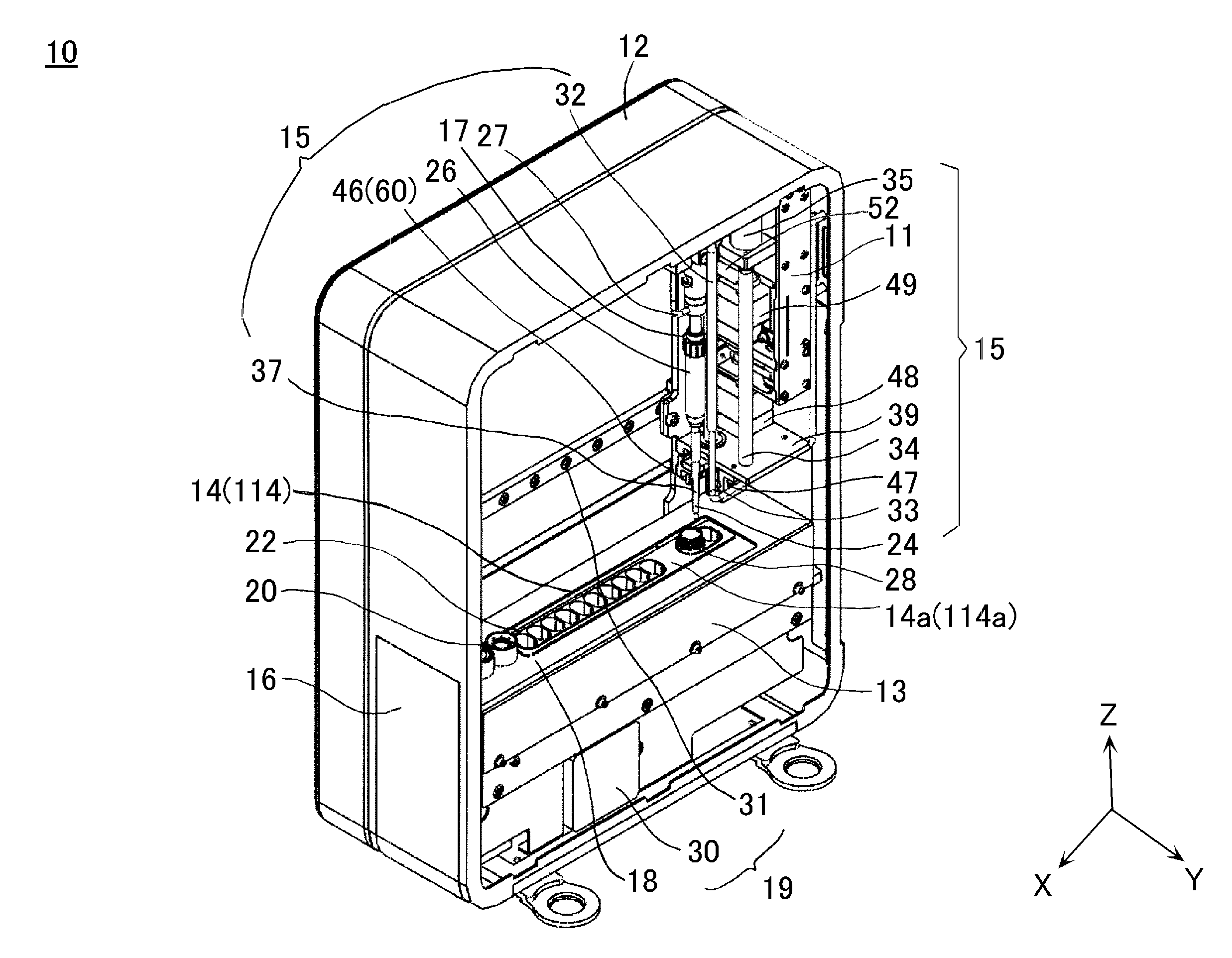

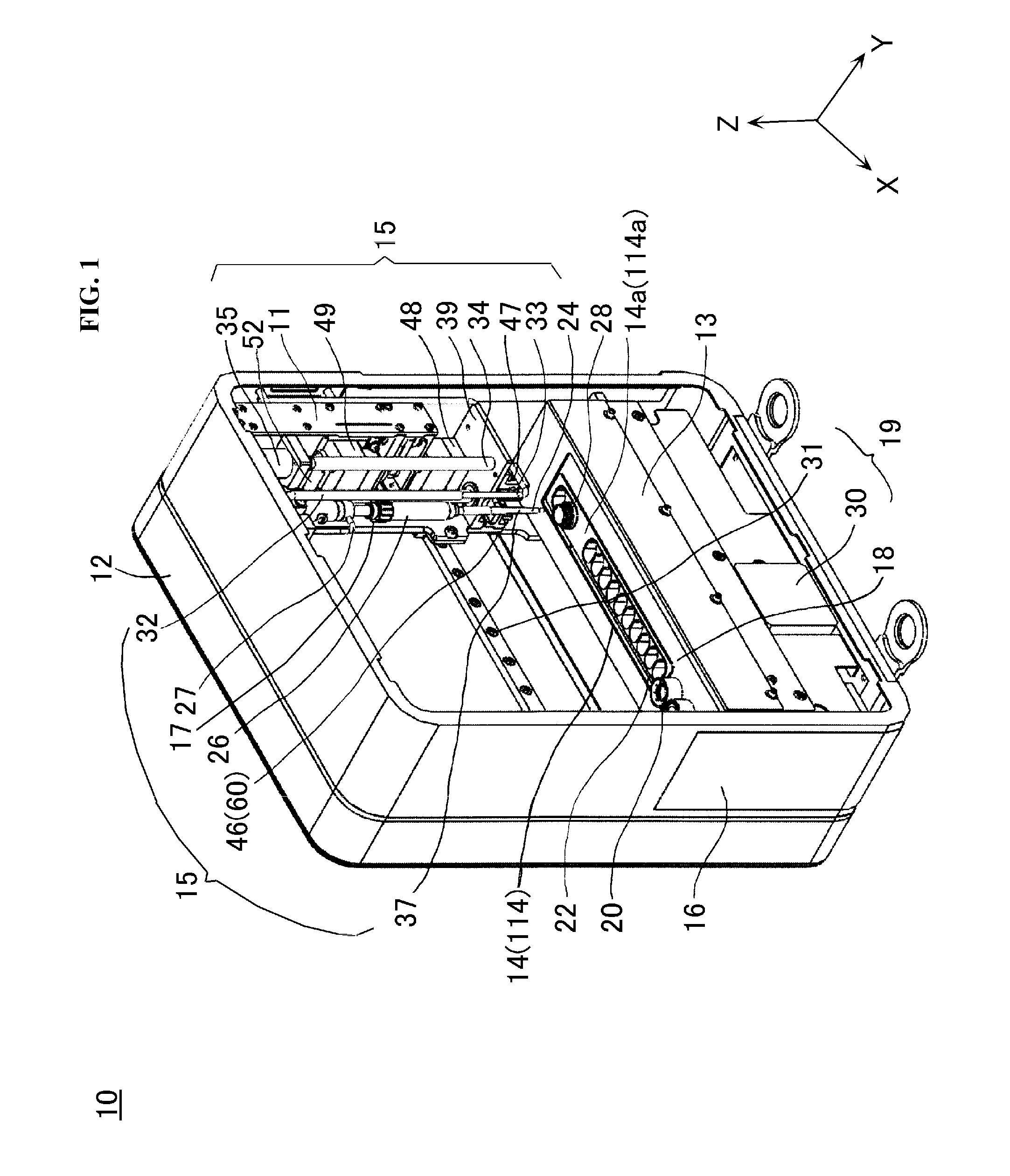

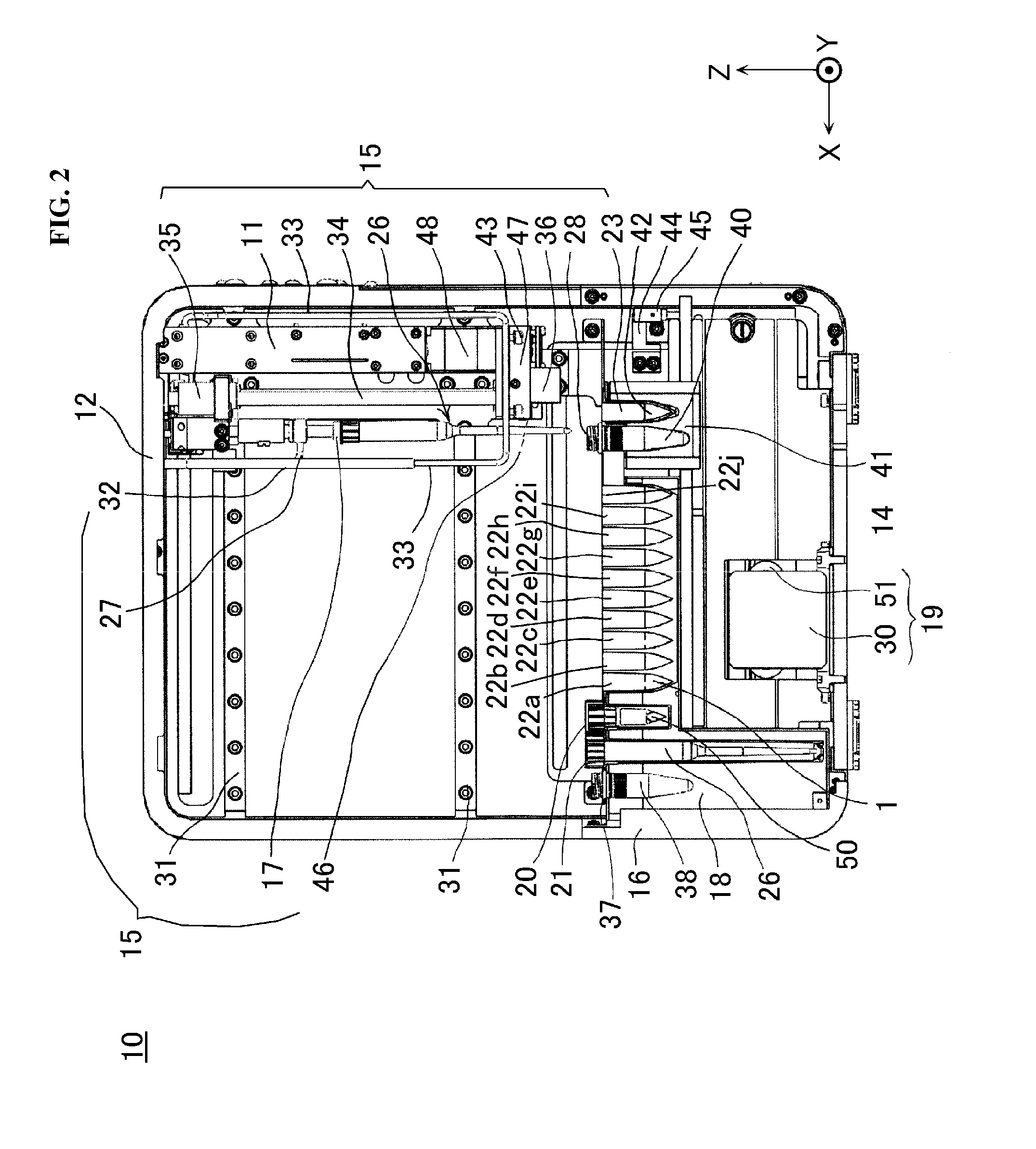

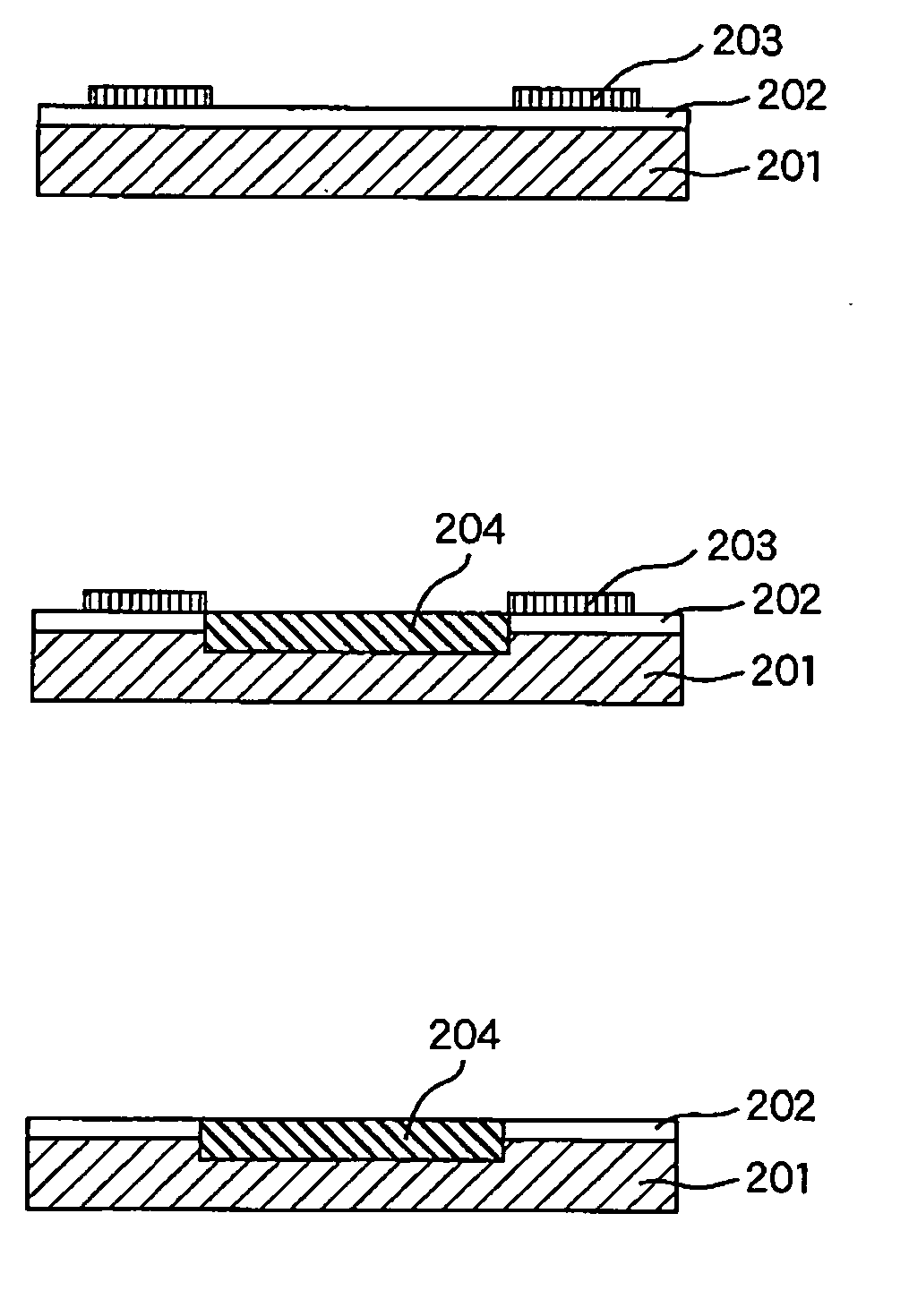

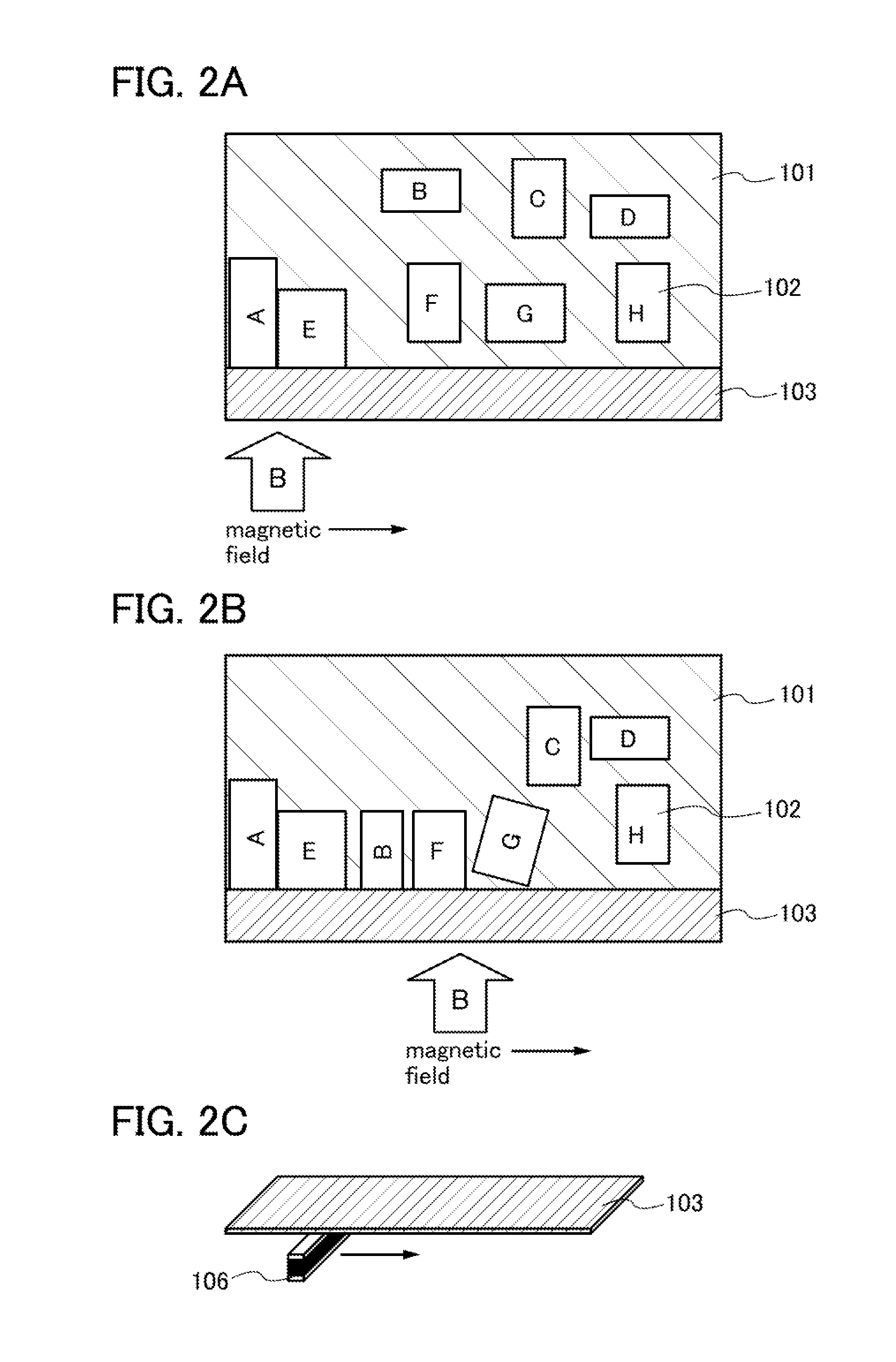

Magnetic reagent, magnetic reagent kit, method for treating magnetic carriers, and treatment device therefor

ActiveUS20120329124A1Increase surface areaQuick snapMaterial nanotechnologyMagnetic paintsMaterials scienceReagent

The present invention relates to a magnetic reagent, a magnetic reagent kit, a method for treating magnetic carriers, and a treatment device therefor, with an object of quickly and efficiently treating magnetic carriers of a micro particle diameter including nanosized magnetic carriers.The magnetic reagent or magnetic reagent kit includes: a plurality of magnetic carriers which can be magnetized by being exposed to a magnetic field, can be bonded to a predetermined chemical substance or living organism in a liquid, and that have a particle diameter that enables them to be suspended in the liquid; and a plurality of treatment promoting magnetic particles which can be magnetized by being exposed to a magnetic field and thus can have the magnetic carriers adsorbed on the surface thereof, are formed so that they can be moved within the liquid by movement of the liquid or by a magnetic field, and promote a treatment for capturing or re-suspension of the magnetic carriers.

Owner:UNIVERSAL BIO RESEARCH CO LTD

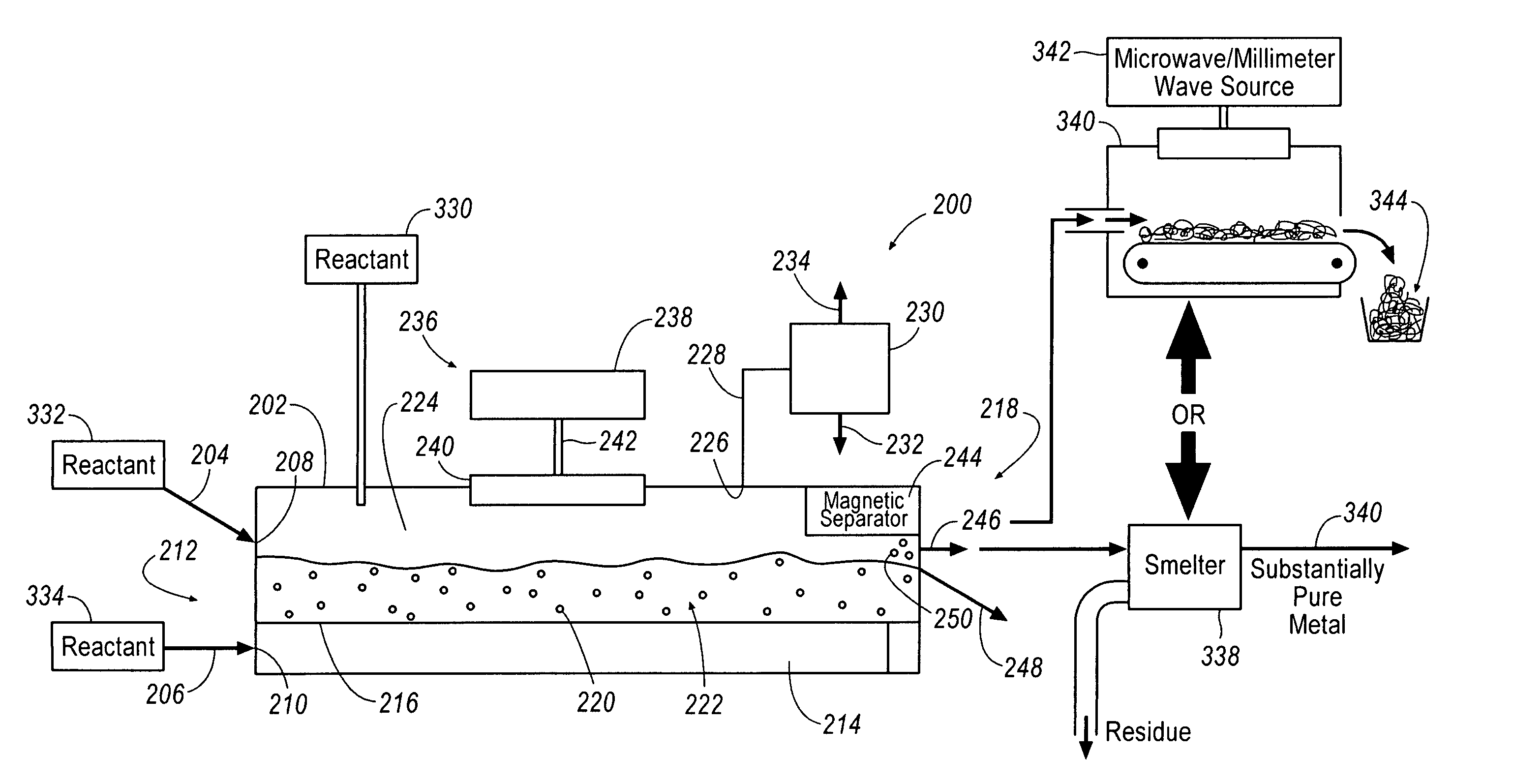

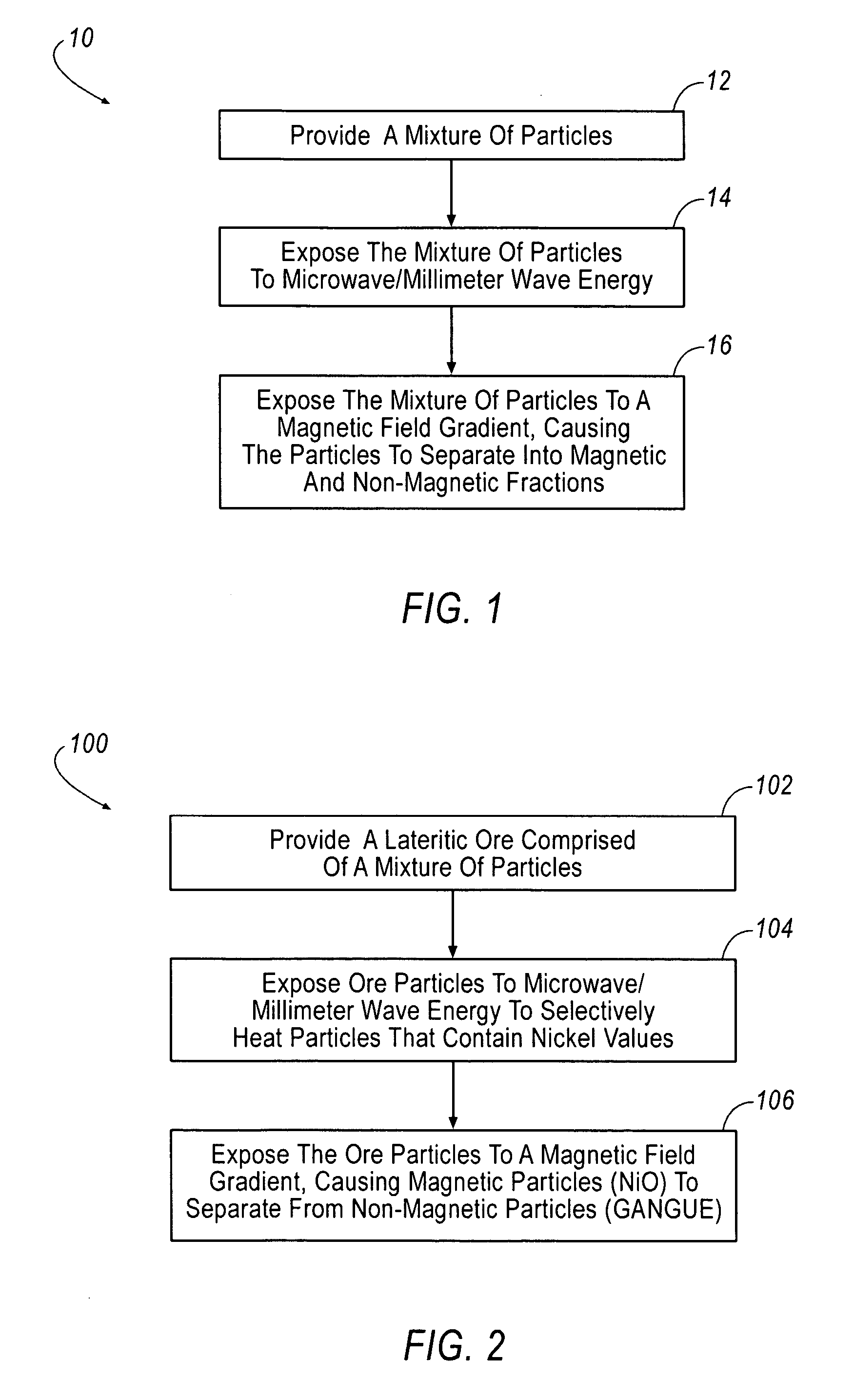

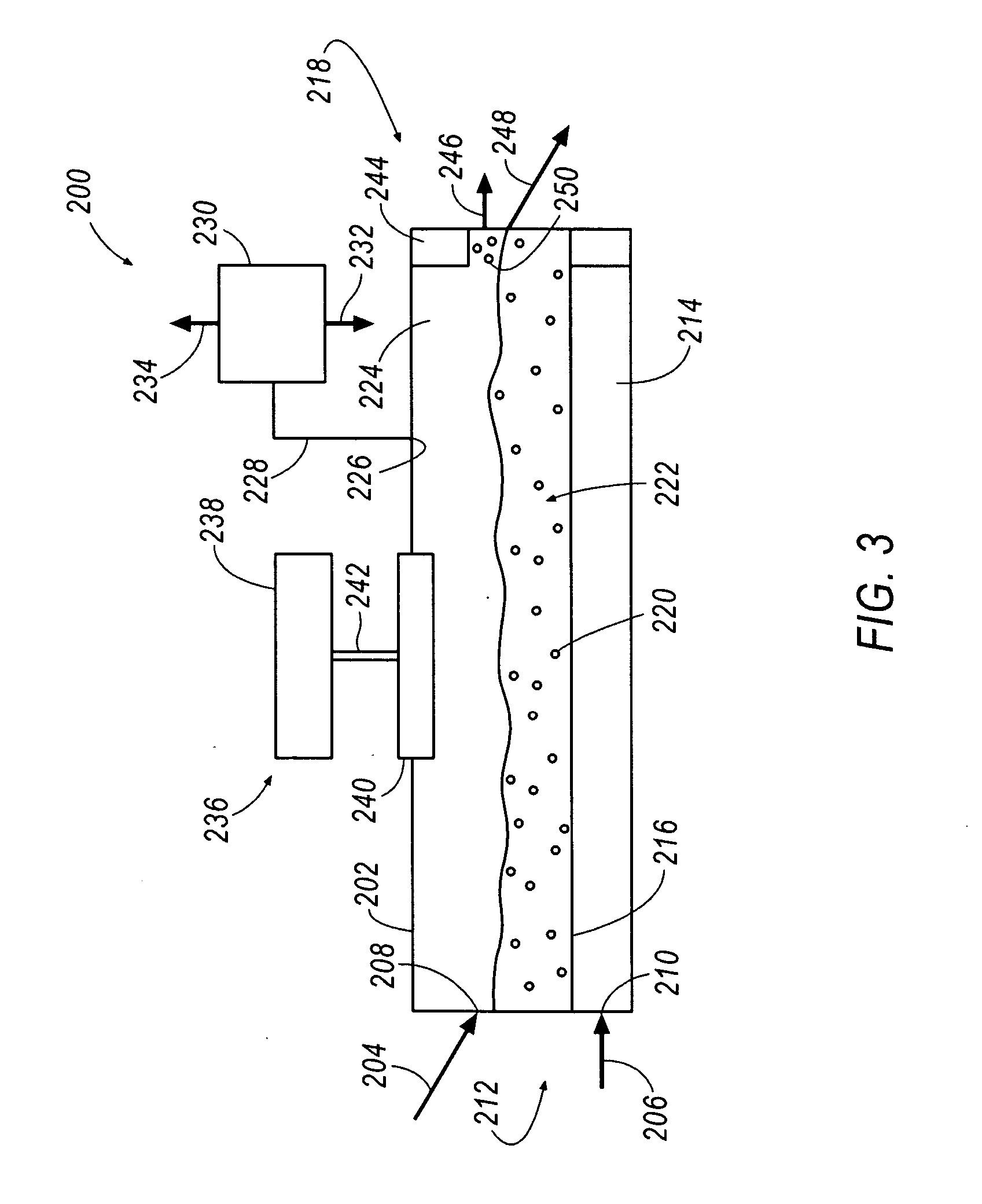

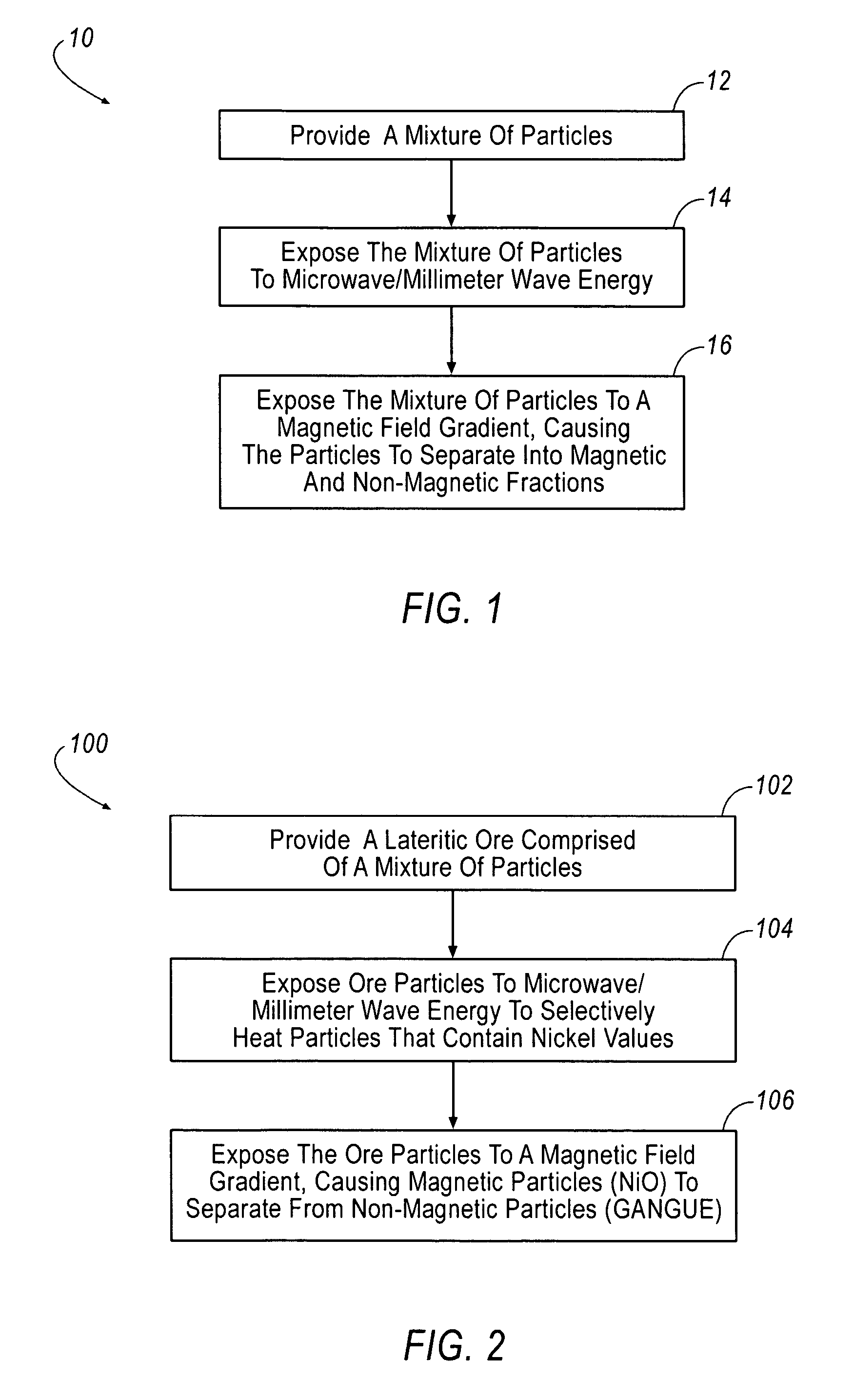

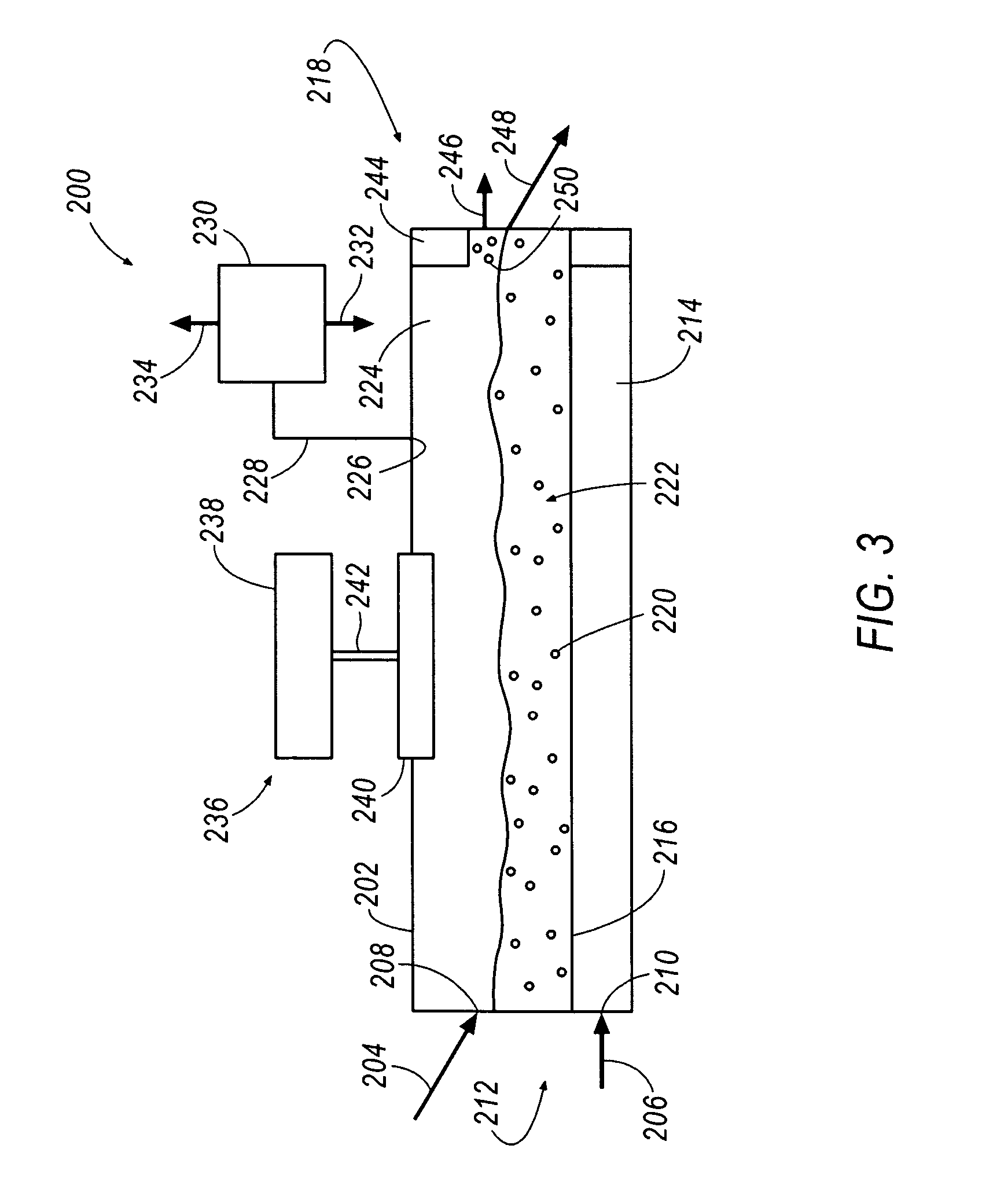

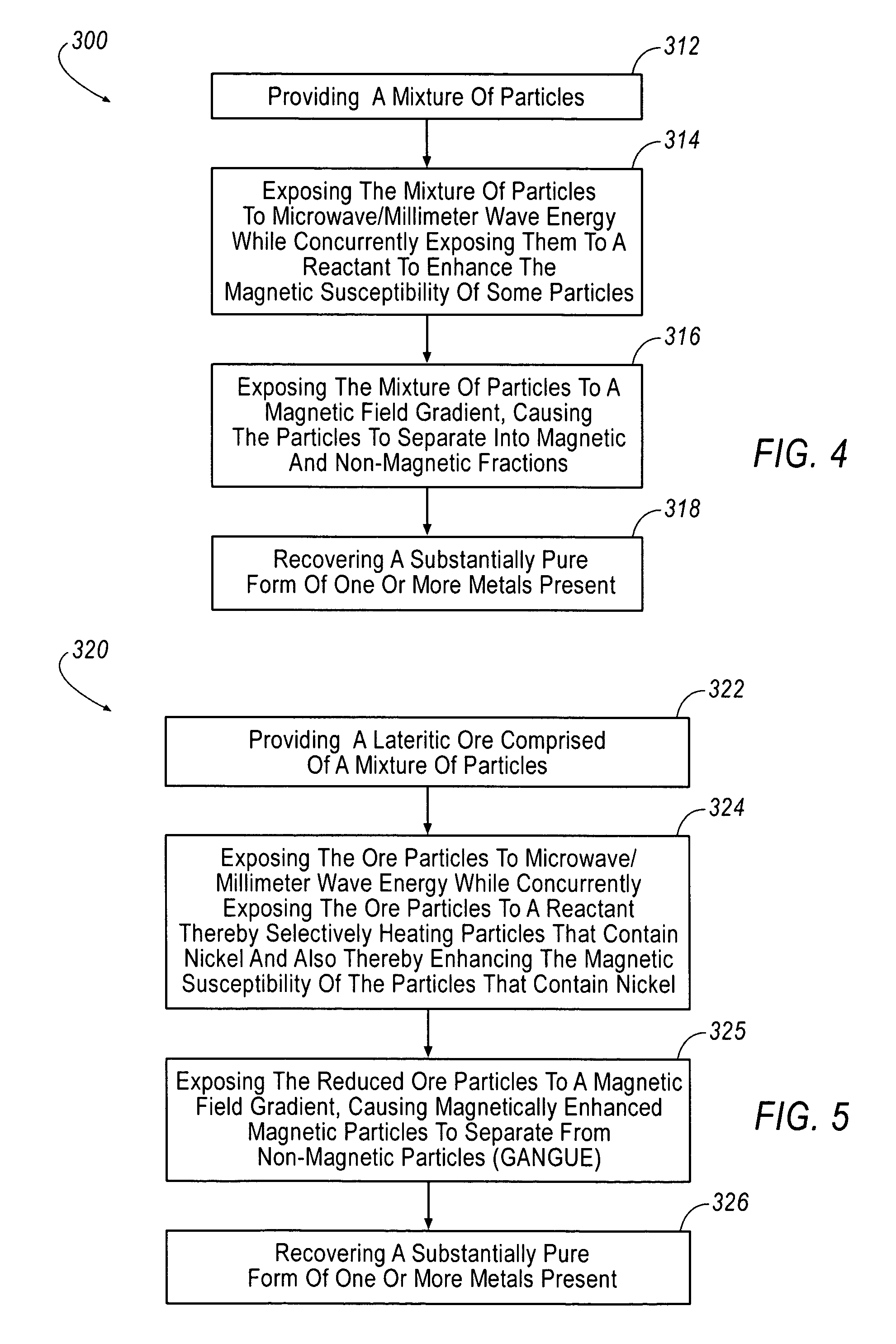

Method & apparatus for separating metal values

InactiveUS20050092657A1Capital outlaySave energy resourcesDrying solid materials with heatSolvent extractionHalogenMagnetic susceptibility

Methods and apparatuses for separating metal values, such as nickel and nickel compounds, from mineral ores, including lateritic ores are disclosed. The method includes providing a mixture of particles (e.g., crushed and sized ore) that is composed of at least a first group of particles and a second group of particles. Group members have similar chemical composition, while particles belonging to different groups have dissimilar chemical compositions. The mixture of particles is concurrently, or generally concurrently, heated (using microwave / millimeter wave energy) and exposed to a reactant. The wave energy and the reactant act to increase the difference in either the magnetic susceptibility or other separation properties between the first and second group of particles. The mixture of particles is then passed through an appropriate separator to separate the particles of interest. Optional steps are disclosed for purifying selected particles. The reactant includes sulfur, sulfur compounds, halogens, or halogen compounds.

Owner:WAVE SEPARATION TECH

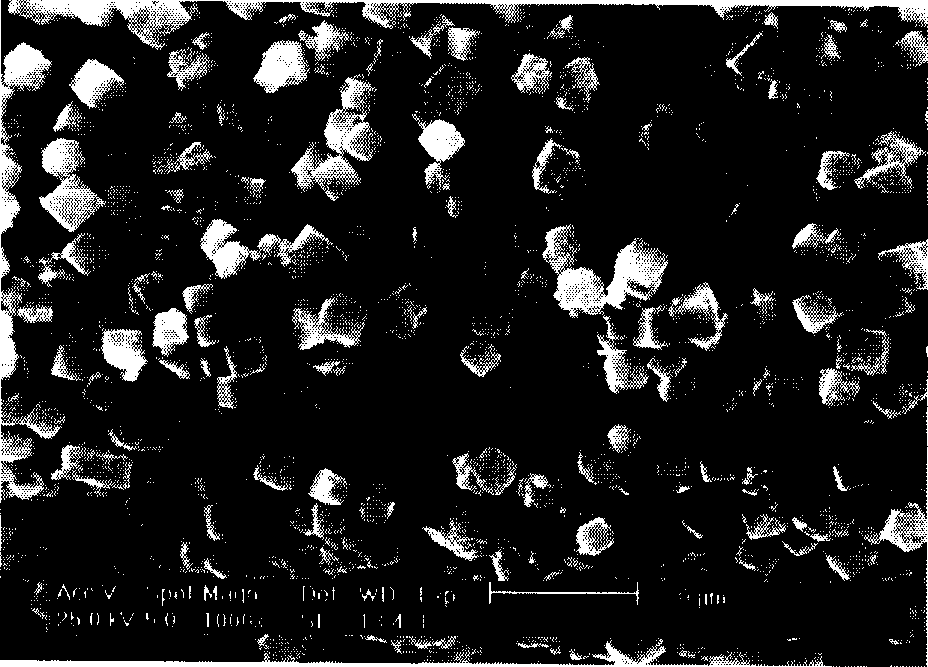

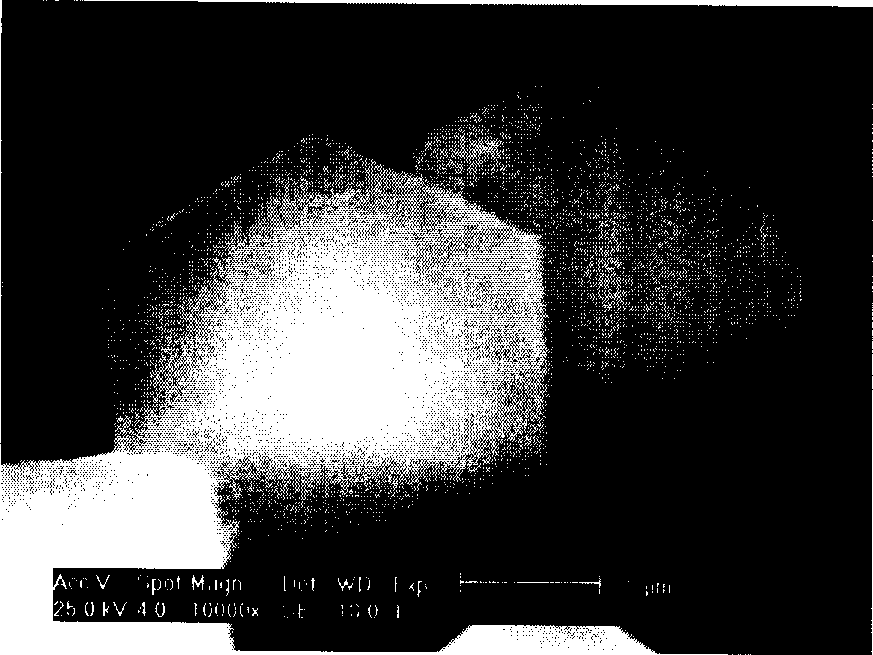

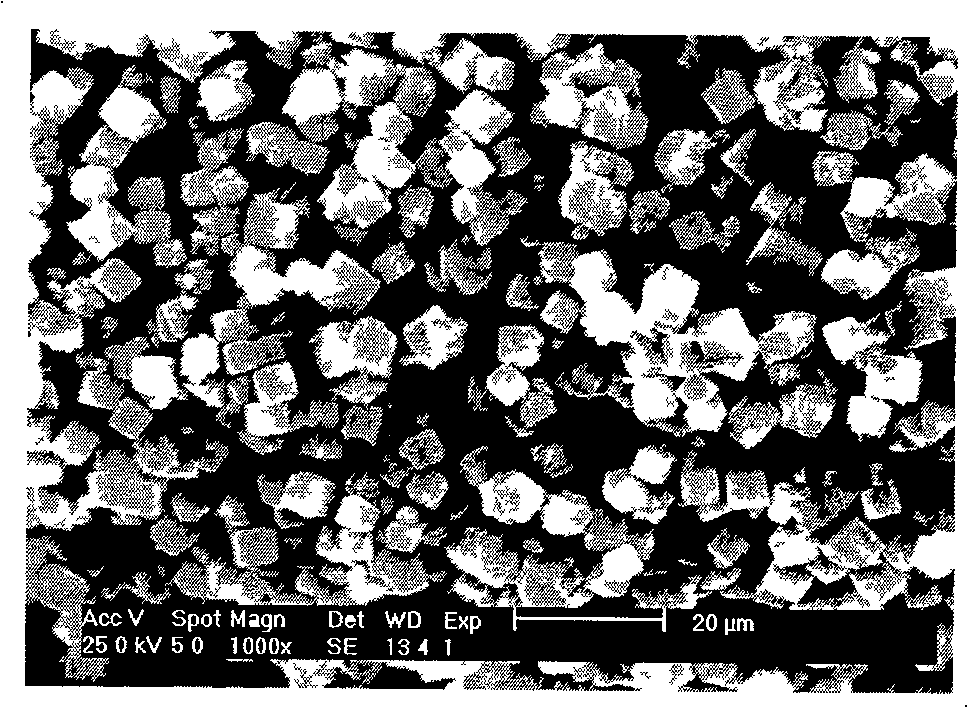

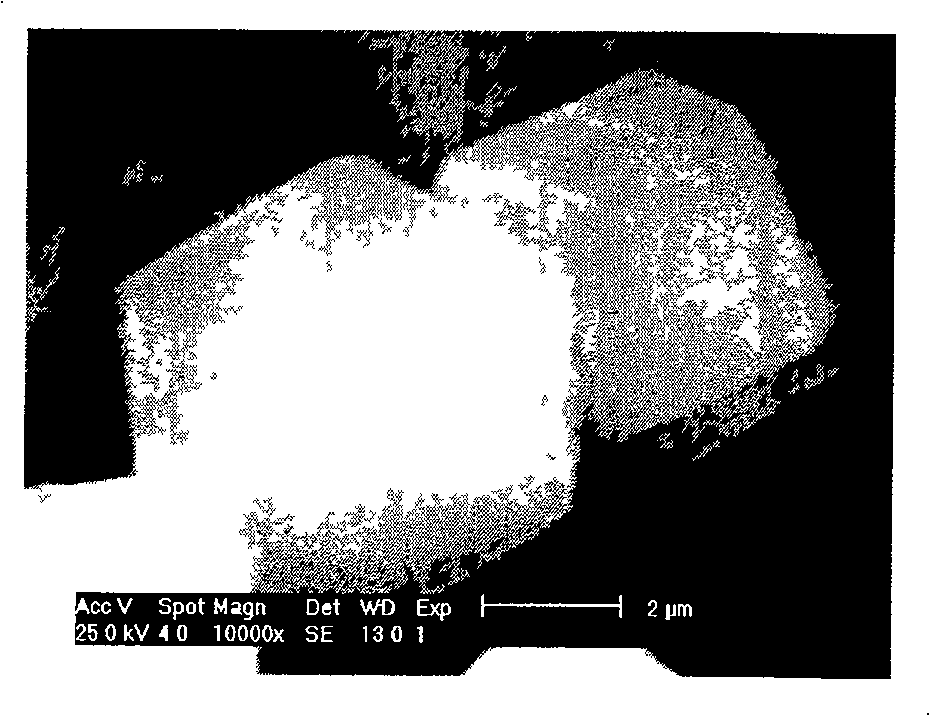

4A type zeolite molecular sieve and its preparation method

InactiveCN1868876AIncrease magnetic susceptibilityUniform particlesCrystalline aluminosilicate zeolitesSal ammoniacMolecular sieve

A 4A zeolite molecular sieve with a certain magnetism and carrying Fe contained compound on its surface is a granular one containing Fe (3.55-9.70 mass%). Its preparing process includes such steps as synthesizing 4A zeolite molecular sieve, preparing Fe ion solution and aqueous solution of NH4, and magnetically modifying the 4A zeolite molecular sieve by chemical deposition method.

Owner:HEBEI UNIV OF TECH

Application of umbilical cord mesenchymal stem cell medicine in promoting skin wound healing

InactiveCN107875171AImprove efficacyImprove self-healing abilityPeptide/protein ingredientsHydroxy compound active ingredientsSelf-healingMagnetic susceptibility

The invention discloses an application of an umbilical cord mesenchymal stem cell medicine in promoting skin wound healing and belongs to the technical field of biological medicines. Umbilical cord mesenchymal stem cells and human fibroblasts induced and differentiated by the umbilical cord mesenchymal stem cells are taken as medicine bodies, the target ability of the medicine is improved throughbonding of small molecular active peptides and medicine-carrying liposome and addition of magnetic particles to the liposome, besides, cells can be supplemented with magnetism, cell activity can be improved, aging can be delayed, and epidermal cell growth is facilitated. An injection is magnetized before injection, the magnetic susceptibility of the injection is increased through a compound electrolyte, the magnetized injection can activate cells in the medicine and cells in the human body, and the medicine effect and the self-healing capacity can be improved. In short, the medicine is applicable to chronic wounds which cannot heal easily and free of toxicity and risks.

Owner:深圳市莱利赛生物科技有限公司

Electromagnetic ultrasonic probe

ActiveCN105628786AStable lift-off distanceEasy to moveUsing electrical meansElectrical/magnetic thickness measurementsEngineeringMagnet

The invention discloses an electromagnetic ultrasonic probe. The electromagnetic ultrasonic probe comprises a shell, a signal processing module, a magnet and a coil below the magnet, wherein a ball bearing mechanism is arranged inside a central space of the coil; the ball bearing mechanism comprises a ball, a restraining ring and fixing posts; the ball is limited inside the restraining ring for rolling; the restraining ring is limited by the fixing posts inside the central space of the coil. The lift-off distance between the electromagnetic ultrasonic probe and a workpiece can be regulated according to the length of a part, protruding out of the bottom of the probe, of the ball, and during detection, the lift-off distance can keep constant no matter the surface of the workpiece is a curved surface or a plane; point contact between the electromagnetic ultrasonic probe and the surface of the workpiece is achieved, so that influence of a magnetic attractive force of the electromagnetic ultrasonic probe on movement becomes smaller and the probe moves more smoothly.

Owner:HUZHOU CITY SPECIAL EQUIP INSPECTION INST

Magnetizing and roasting method of iron oxide ore

InactiveCN104593587AIncrease magnetic susceptibilityPromote grain merging and growthMagnetic separationThermal insulationCrystallite

The invention discloses a magnetizing and roasting method of an iron oxide ore. The method comprises the following steps: adding a mixed material of which the fineness is -7mm to -10mm to a sealed reaction container, wherein the material comprises the following raw materials: 94.3%-97.1% of iron oxide ore, 1.8%-3.7% of a reducing agent bituminous coal and 1%-2.2% of a catalyst Na2CO3; 1 heating a container to 500 DEG C in a temperature rise zone, reacting C and O2 to generate CO2 and CO, and forming a weak reducing atmosphere by a reaction container; 2 heating a high-temperature zone to 820-850 DEG C, rapidly reacting CO and F2O3 under catalysis of Na2CO3 to generate CO2 and Fe3O4, dissociating Na<+> from Na2CO3, and prompting Fe3O4 crystalline grains to mix and grow; and 3 maintaining the temperature of a thermal insulation zone at 780-820 DEG C, finishing subsequent reducing reaction on CO and unreduced Fe2O3 in the step 2, and mixing the Fe3O4 in the step 3 with the Fe3O4 in the step 2 to grow. According to the method disclosed by the invention, the temperature of reducing reaction is divided into three zones, namely the temperature rise zone, the high-temperature zone and the thermal insulation zone, and full reducing reduction of the Fe2O3 is achieved, so that the magnetic susceptibility of the iron oxide ore is improved; and in addition, a catalyst Na2CO3 is capable of prompting the Fe3O4 crystalline grains to mix and grow; and the magnetic susceptibility is further improved.

Owner:陕西大山机械有限公司

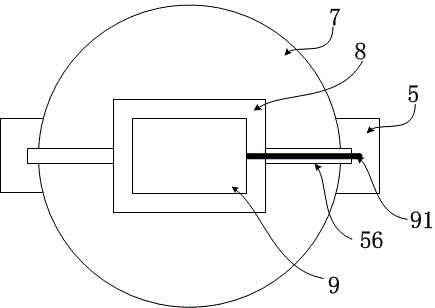

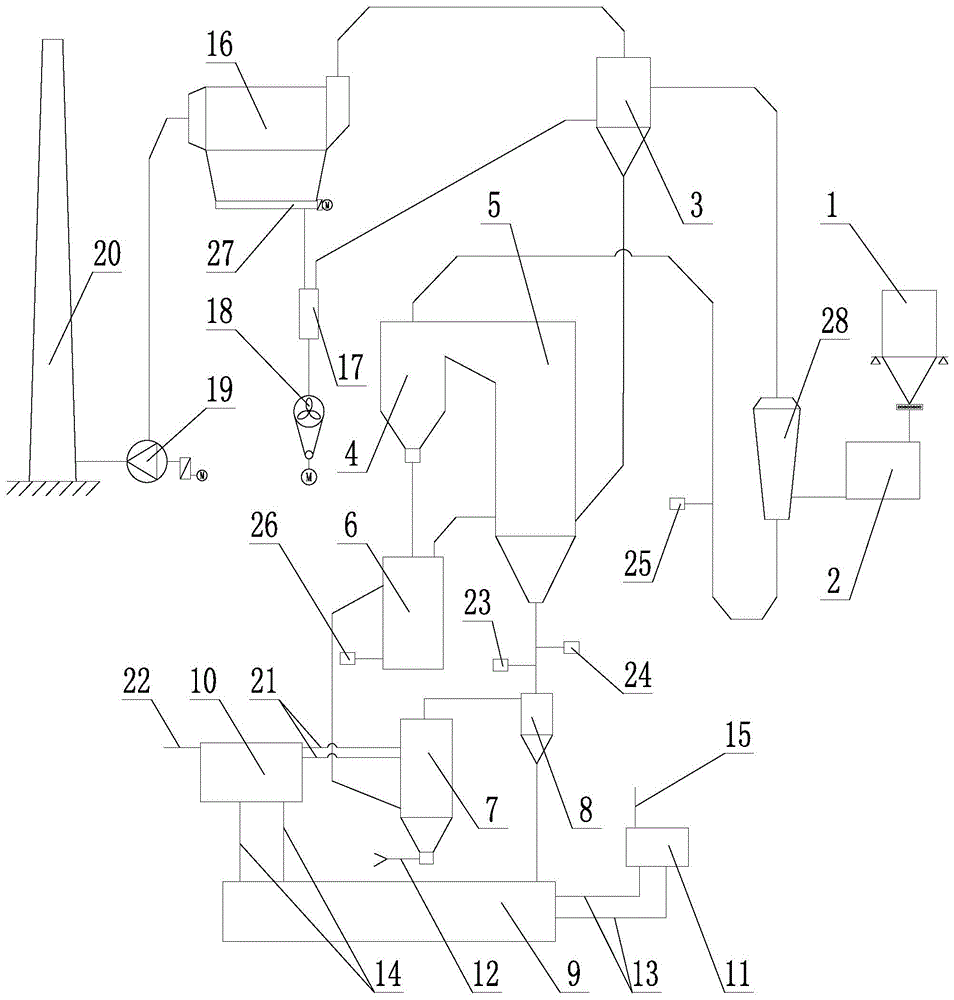

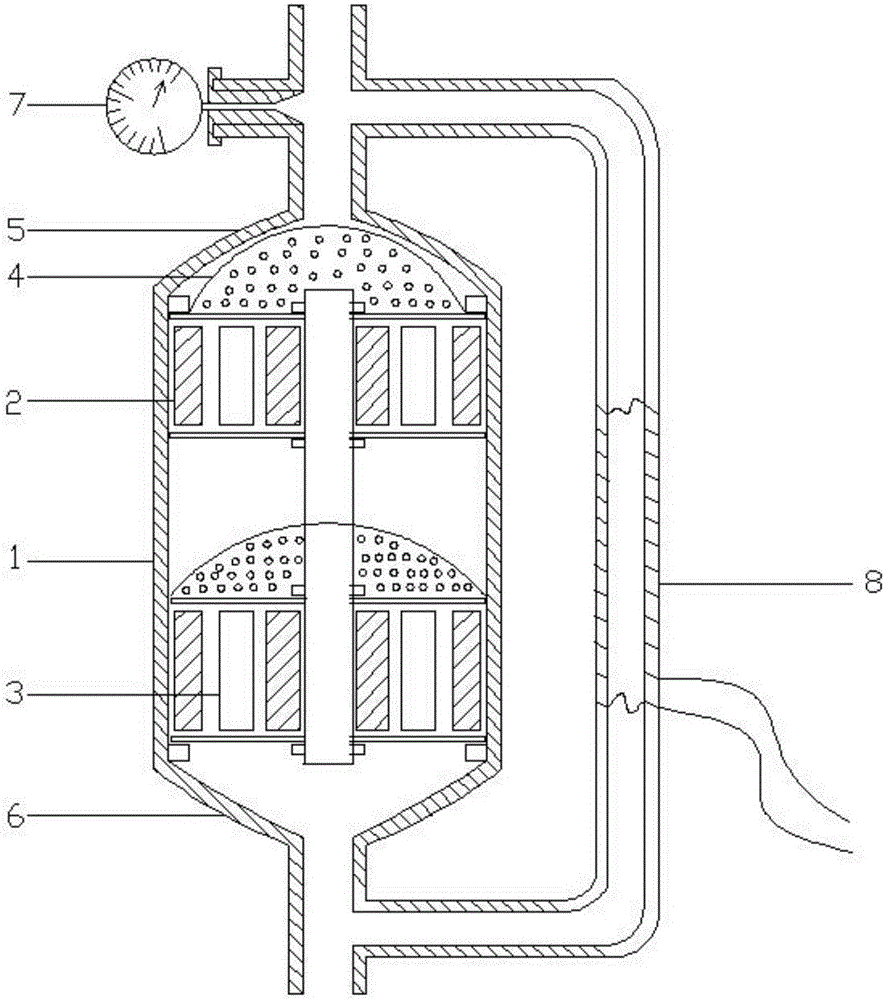

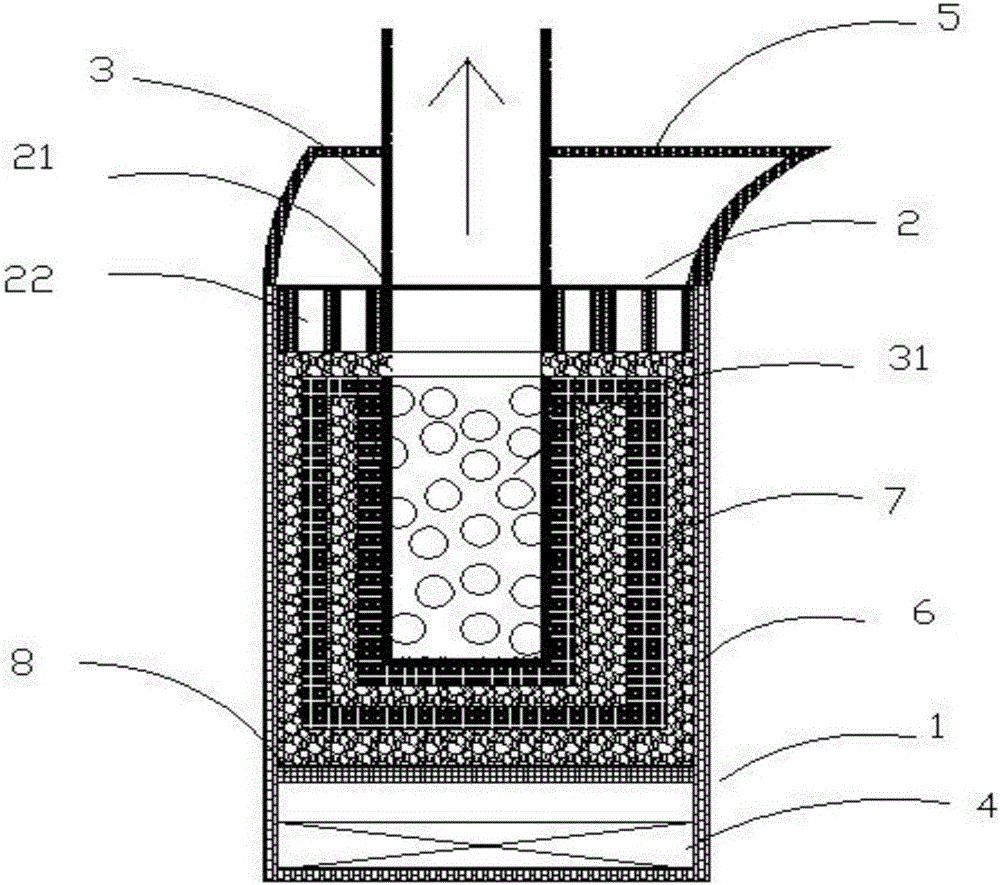

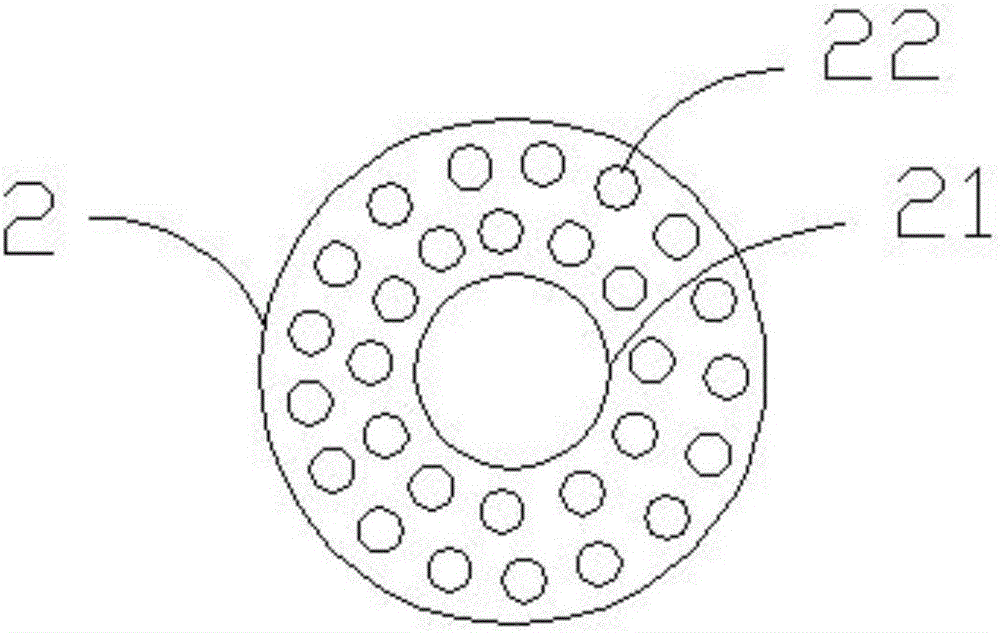

Device and method used for realizing powdery iron mineral magnetization treatment and generating steam

InactiveCN104831055AWide adaptabilityMeet the magnetization treatmentCombustion processIncreasing energy efficiencyMagnetic susceptibilityResource utilization

The invention discloses a device and a method used for realizing powdery iron mineral magnetization treatment and generating steam, and belongs to the technical field of refractory iron mineral magnetization treatment. The device is composed of a feeding system, a roasting system, a magnetizing separation system, a cyclone dust removing system, and a steam generation system; compared with conventional shaft kiln and rotary kiln technology, adaptability on iron mineral raw material is higher; powdery iron mineral magnetization treatment requirements can be satisfied; magnetisability, recovery rate, resource utilization rate, and thermal efficiency are high; energy can be saved by almost 70% compared with that of rotary kiln technology, and construction investment is reduced by almost 50%. According to the method, fluidization technology is adopted for recovery of high temperature flue gas and material waste heat, and saturated steam or middle pressure steam used for electricity generation can be produced based on actual demands; and the method is high in automatic degree, is convenient for operation, and is high in single production yield.

Owner:SHENYANG XINBO IND TECH

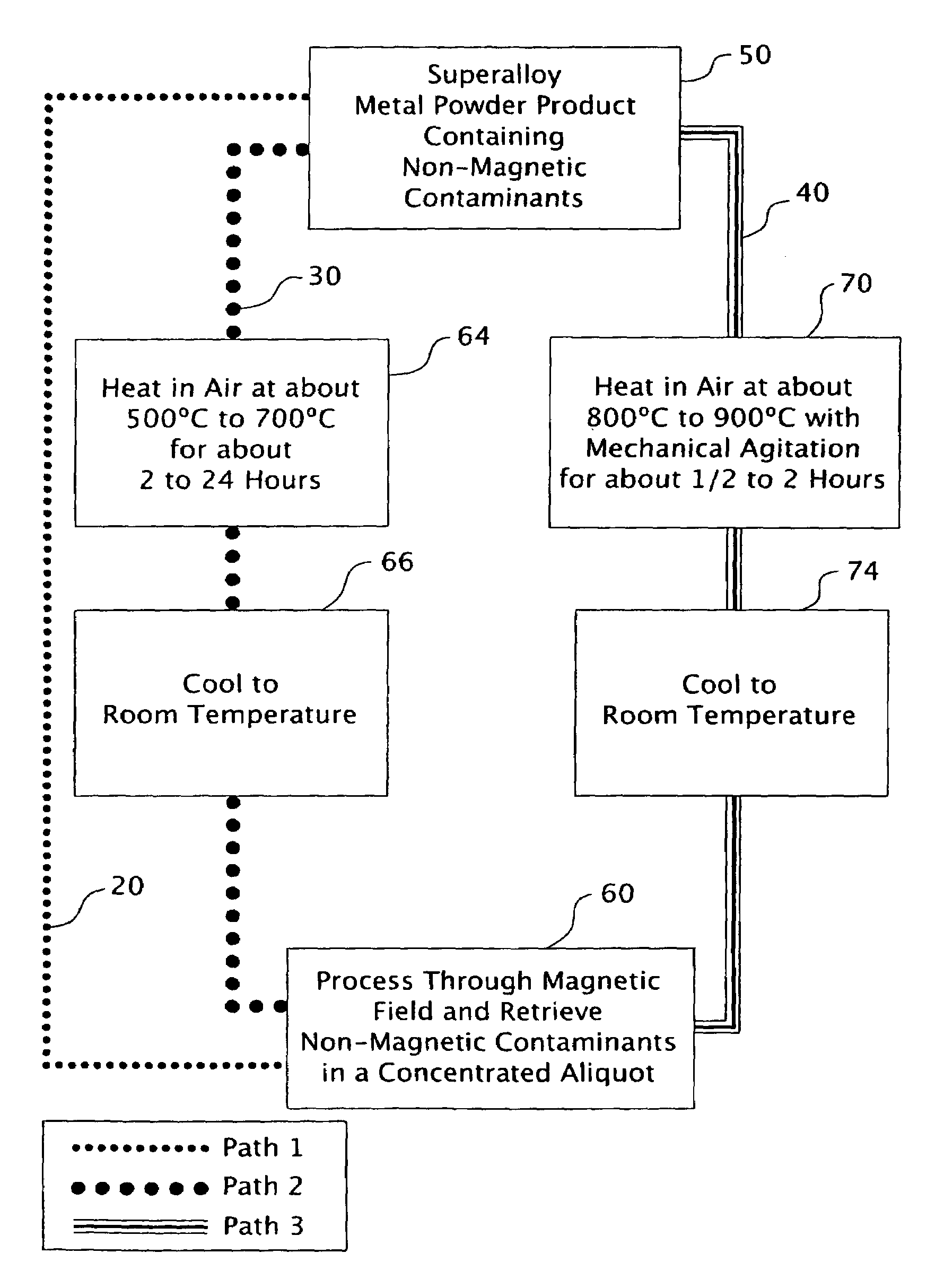

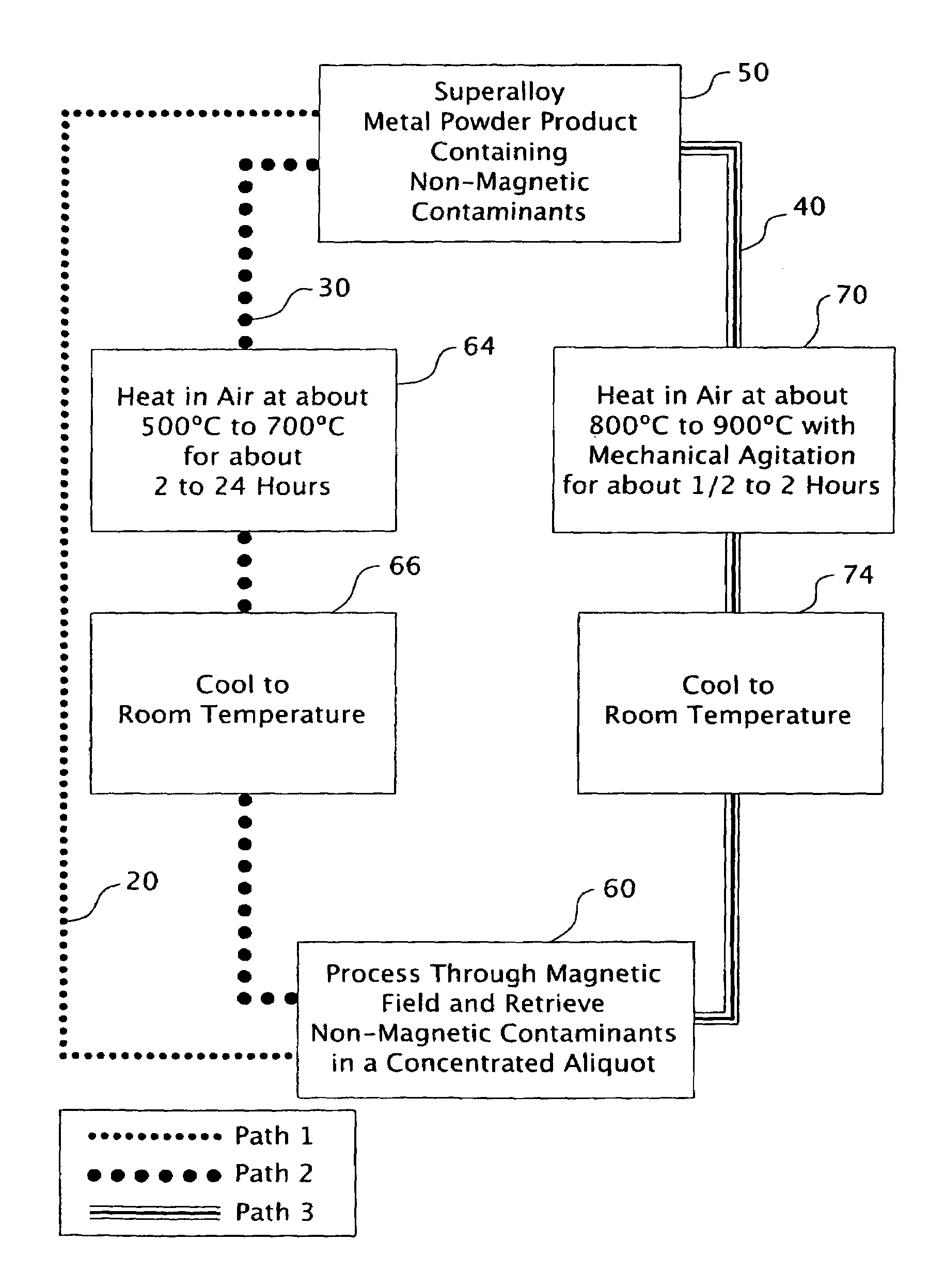

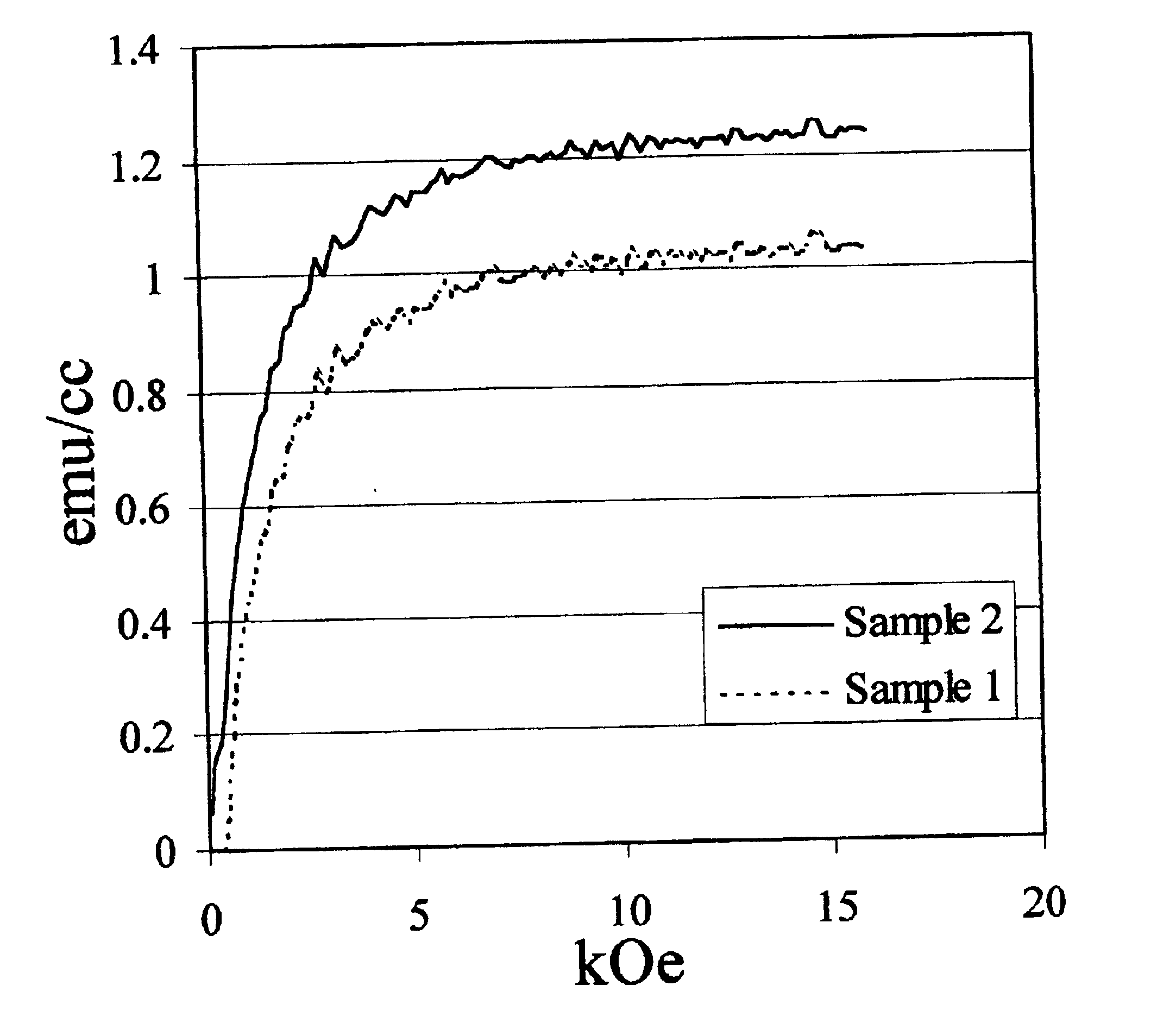

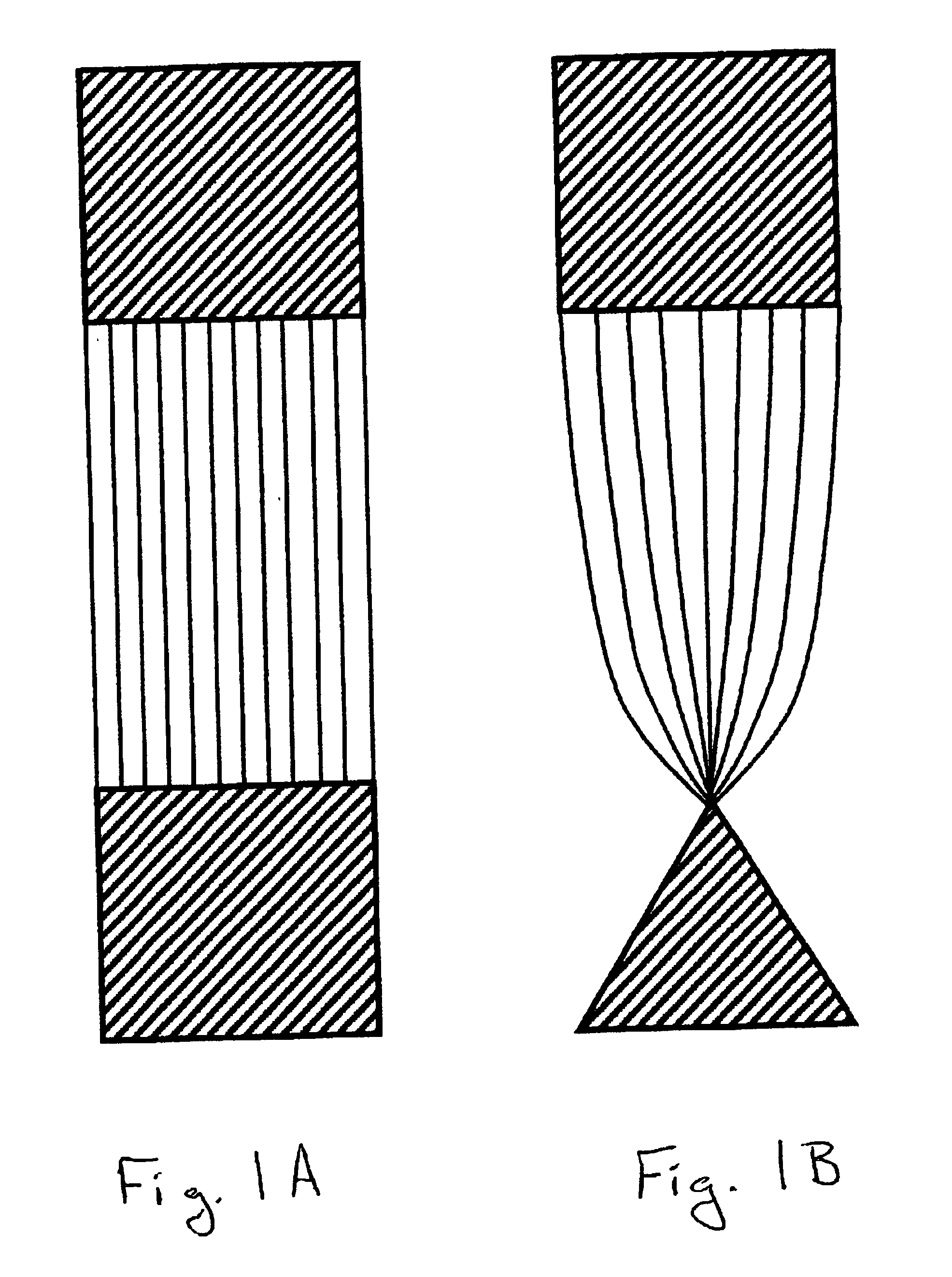

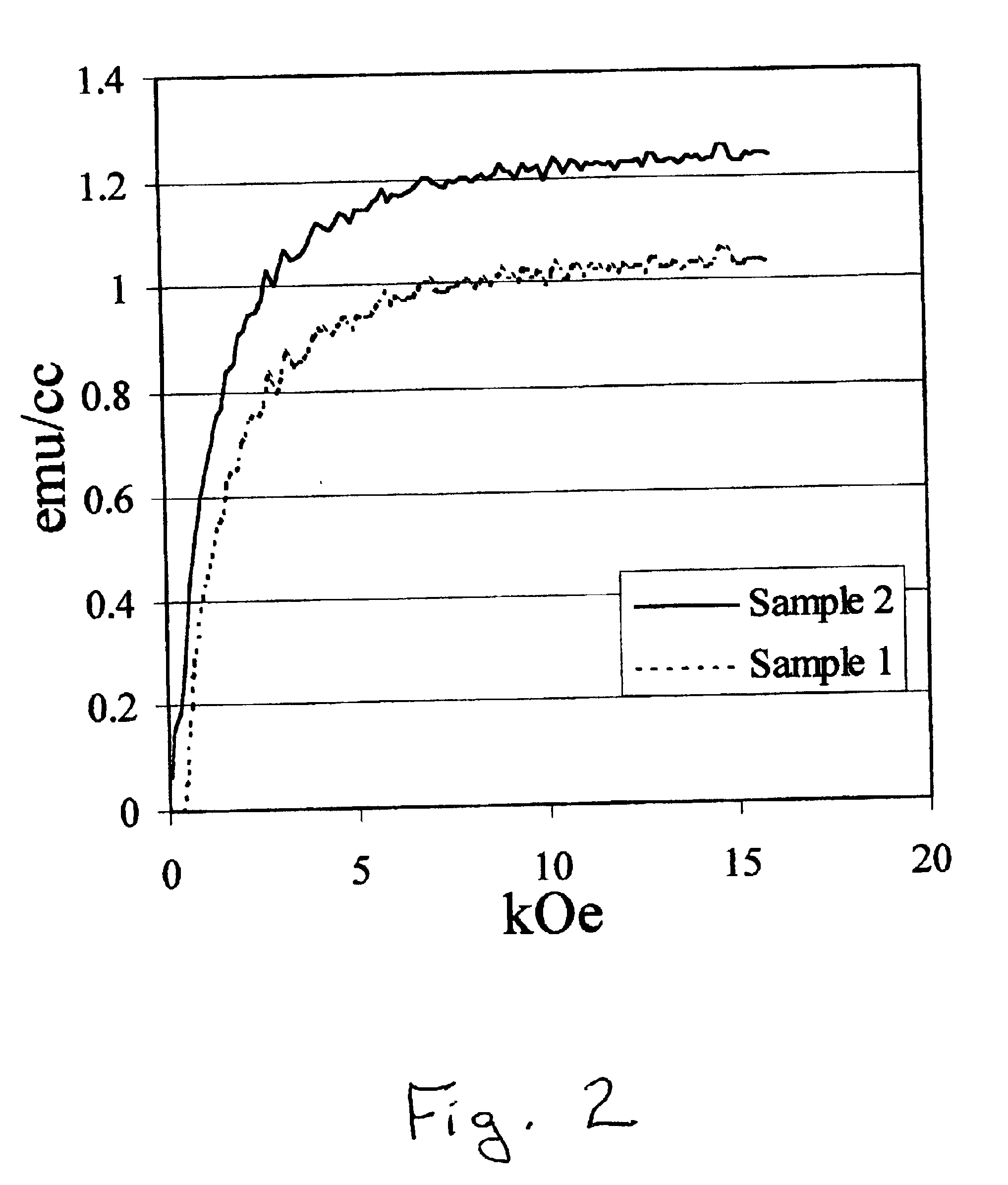

Method of separating superalloy metal powder from admixed contaminants

ActiveUS7056400B1Facilitate productionEnhance magnetic propertyWater/sewage treatment by magnetic/electric fieldsMagnetic separationPollutantChromium

A method is provided for separating superalloy metal powder from contaminants, such as process-produced contaminants, by enhancing the magnetic properties thereof, such as by oxidizing or leaching of chromium, for example, followed by magnetic separation of the contaminants from the superalloy metal powder to thereby enhance the concentration of the contaminants. Heating conditions or mechanical agitation or both are employed to resist agglomeration of the metal powder before magnetic separation thereof from the contaminants. Certain preferred times and temperatures are disclosed.

Owner:RJ LEE GRP INC

Method of separating admixed contaminants from superalloy metal powder

ActiveUS20050167003A1Easy to separateIncrease magnetic susceptibilityElectrostatic separationWater/sewage treatment by magnetic/electric fieldsPollutantMagnetic separation

A method is provided for separating superalloy metal powder from contaminants, such as process-produced contaminants, by enhancing the magnetic properties thereof in a carburizing atmosphere followed by magnetic separation of the contaminants from the superalloy metal powder to thereby enhance the concentration of the contaminants. Heating or mechanical agitation or both are employed to resist agglomeration of the metal powder before magnetic separation thereof from the contaminants. Certain preferred times and temperatures are disclosed.

Owner:RJ LEE GRP INC

Plastic material having enhanced magnetic susceptibility, method of making and method of separating

ActiveUS6920982B2Increase magnetic susceptibilityIncreased susceptibilityButtonsRecord carriersMagnetic susceptibilityWaste stream

The magnetic susceptibility of one or more plastic articles is enhanced to enable their separation from a waste stream using magnetic separators. An amount of paramagnetic material is added to the plastic formulation to influence magnetic susceptibility without affecting the properties associated with the function of the plastic article. The material is preferably selected from a group consisting of magnetite, ferro-silicon and ferromagnetic particles (e.g., iron filings). The amount or material can be varied in the range of between 0.05% and 5% by weight of the plastic formulation. The plastic with altered magnetic susceptibility and a method separating that plastic from a waste stream are also disclosed.

Owner:ERIEZ MAGNETICS

Method for separating metal values by exposing to microwave/millimeter wave energy

InactiveUS7571814B2Lower capital outlaysSave energy resourcesDrying solid materials with heatSolvent extractionMagnetic susceptibilityHalogen

Methods and apparatuses for separating metal values, such as nickel and nickel compounds, from mineral ores, including lateritic ores are disclosed. The method includes providing a mixture of particles (e.g., crushed and sized ore) that is composed of at least a first group of particles and a second group of particles. Group members have similar chemical composition, while particles belonging to different groups have dissimilar chemical compositions. The mixture of particles is concurrently, or generally concurrently, heated (using microwave / millimeter wave energy) and exposed to a reactant. The wave energy and the reactant act to increase the difference in either the magnetic susceptibility or other separation properties between the first and second group of particles. The mixture of particles is then passed through an appropriate separator to separate the particles of interest. Optional steps are disclosed for purifying selected particles. The reactant includes sulfur, sulfur compounds, halogens, or halogen compounds.

Owner:WAVE SEPARATION TECH

Oxygen-free cooling and residual heat recovering method for magnetizing-roasted iron ore product

InactiveCN103789536AChange the water cooling processReduce pollutionIncreasing energy efficiencyMagnetic separationIronstoneGranularity

The invention relates to the technical field of metallurgy, in particular to an oxygen-free cooling and residual heat recovering method for a magnetizing-roasted iron ore product. The method comprises the following steps: feeding a magnetizing-roasted high-temperature material being 800-850 DEG C and 8-25 millimeters in granularity from the upper part of a vertical cooler; introducing blast furnace gas of which the CO or H2 volume content is not greater than 30 percent from the lower part of the vertical cooler, and controlling the flow rate of the high blast coal gas at 0.8-1.5 m / s; performing heat exchange between the high-temperature material and the blast coal gas in the vertical cooler during inverse flow, wherein the temperature of the high-temperature material is lowered below 200 DEG C, and the temperature of the blast coal gas is raised to 700-750 DEG C. The magnetizing-roasted high-temperature material undergoes secondary oxidation in a cooling process, and can undergo secondary micro-reduction in the cooling process in the cooler, so that the quality of the magnetizing-roasted iron ore product is improved. Meanwhile, the over-reduction of the material is prevented, and cyclic utilization of residual heat is realized.

Owner:JIUQUAN IRON & STEEL GRP

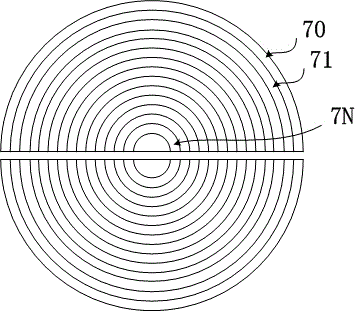

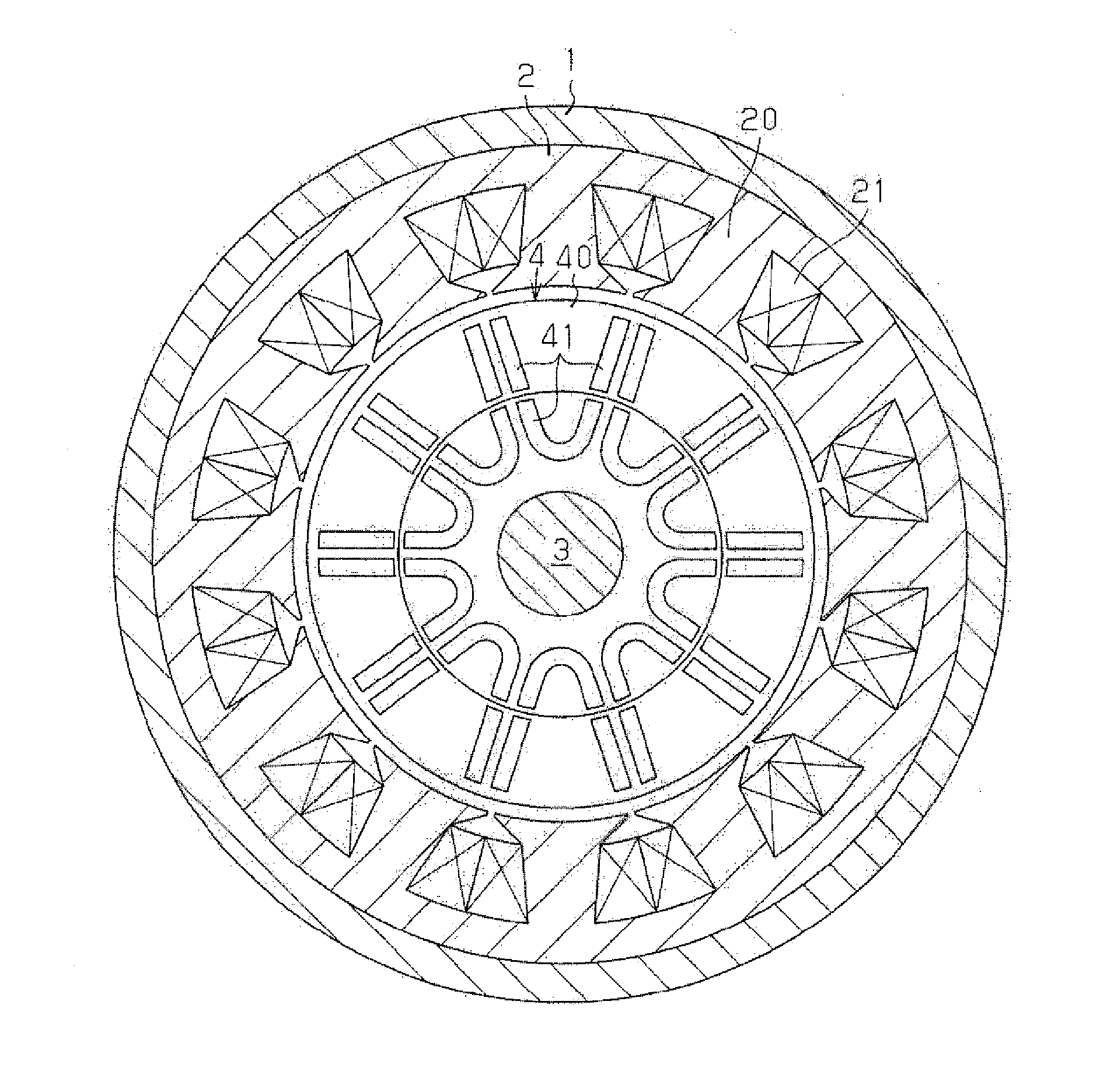

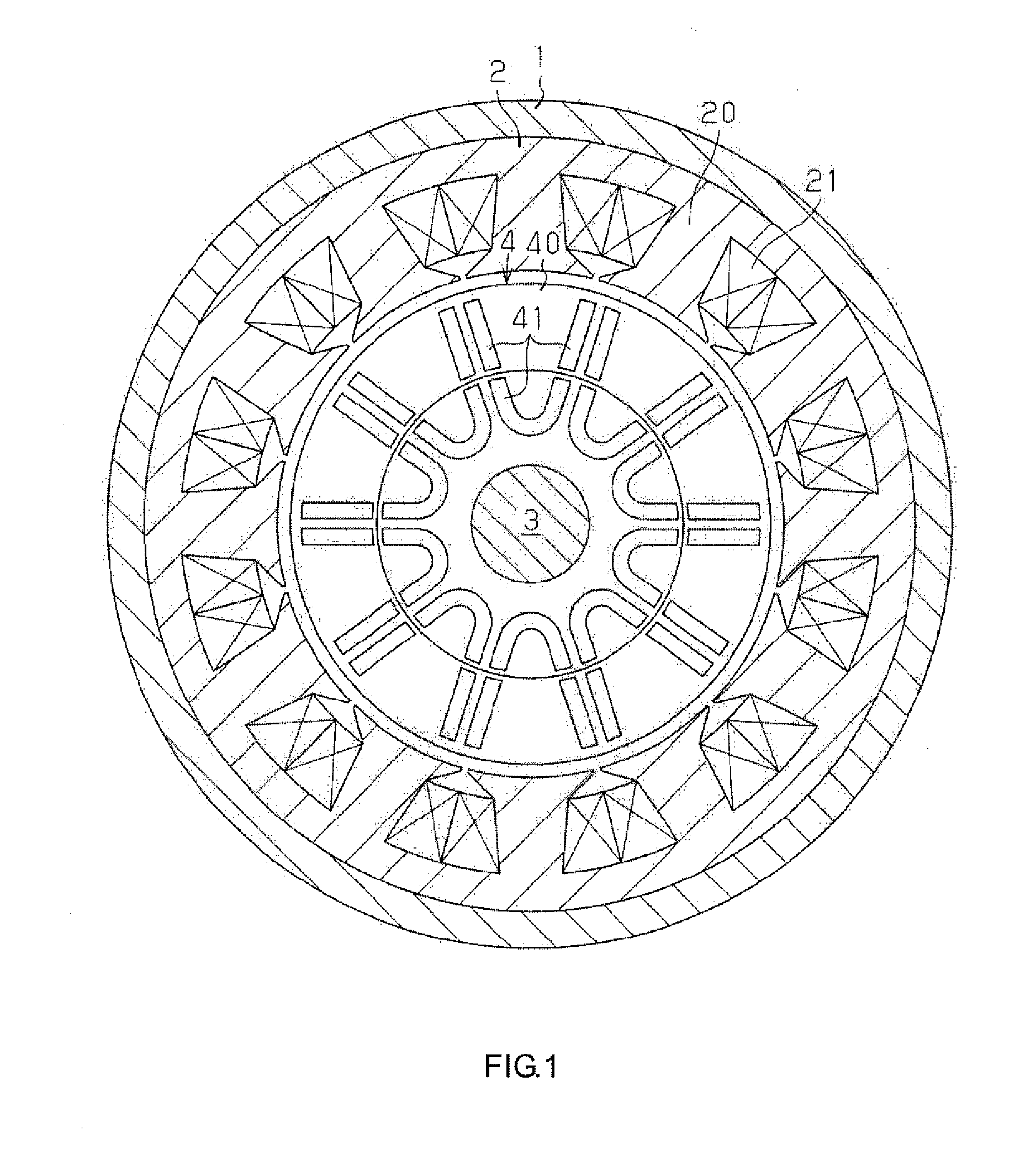

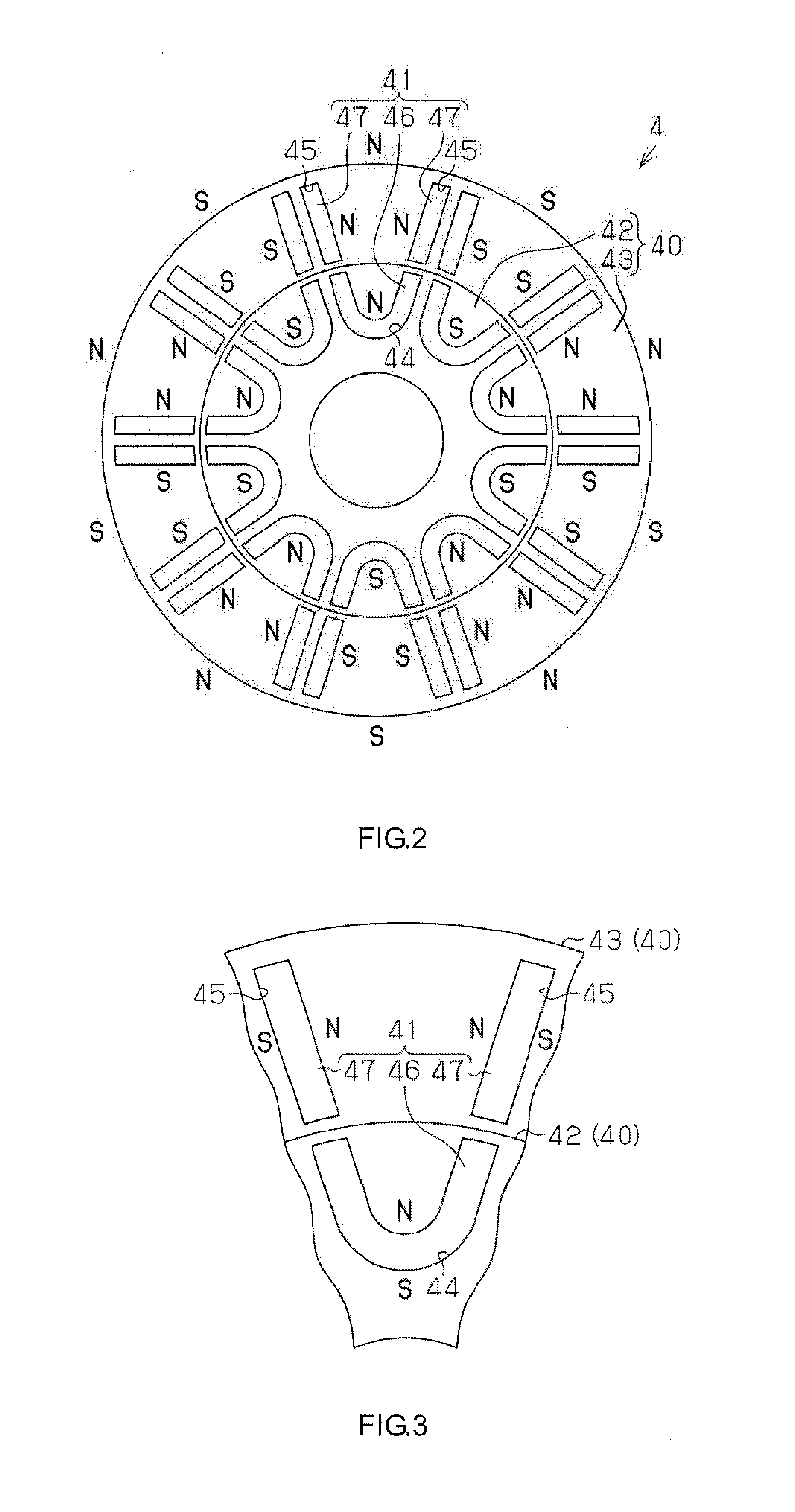

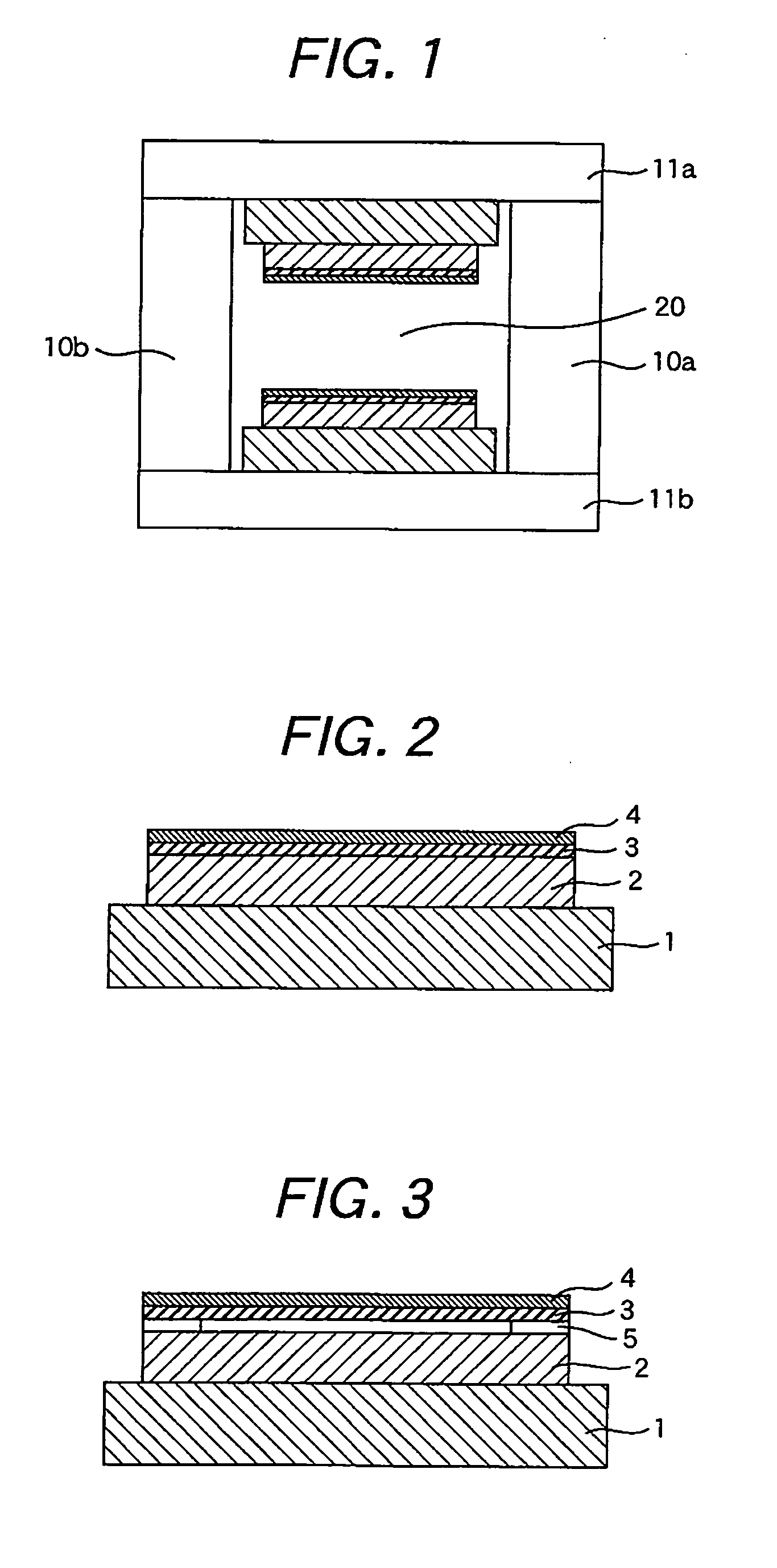

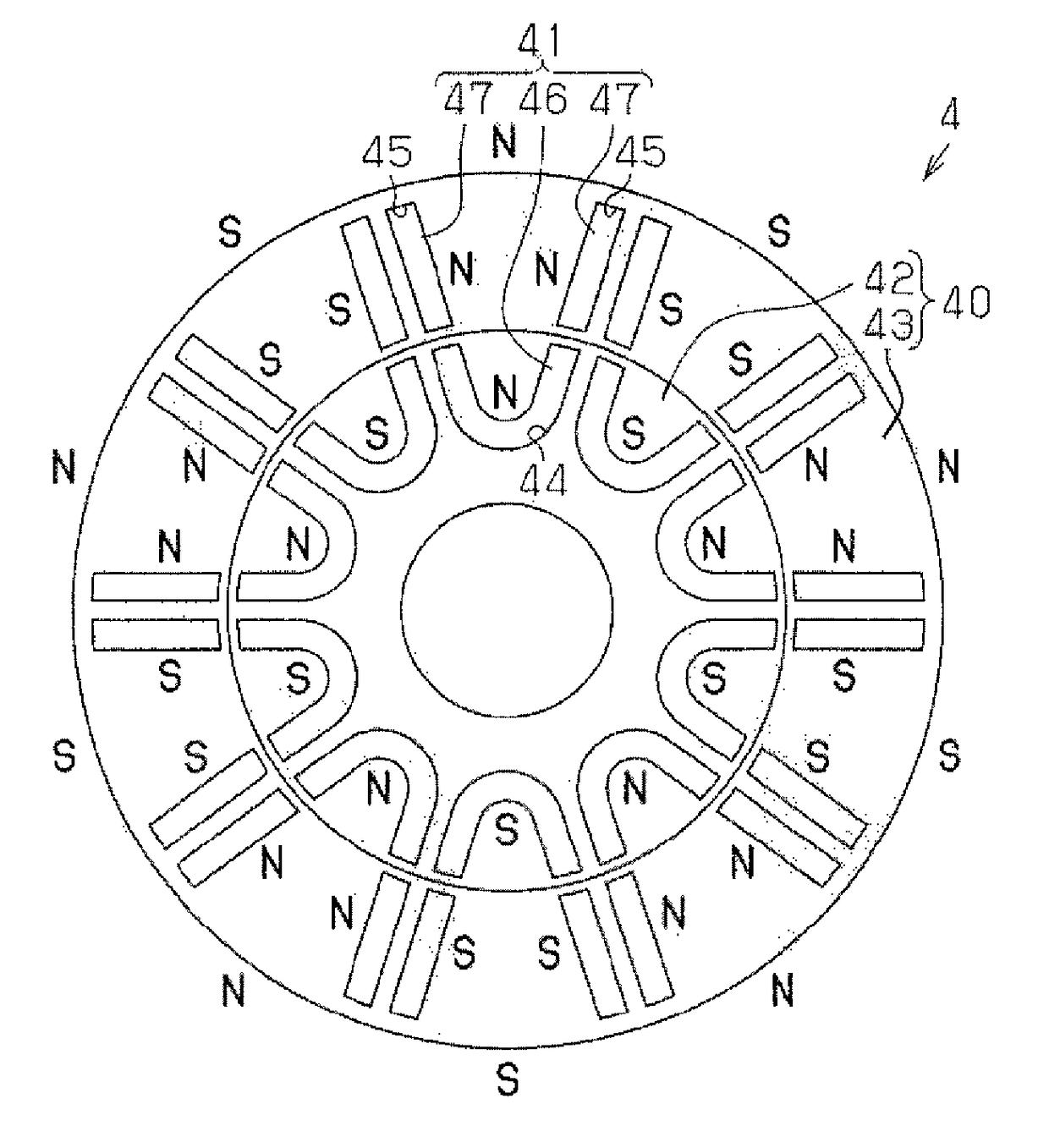

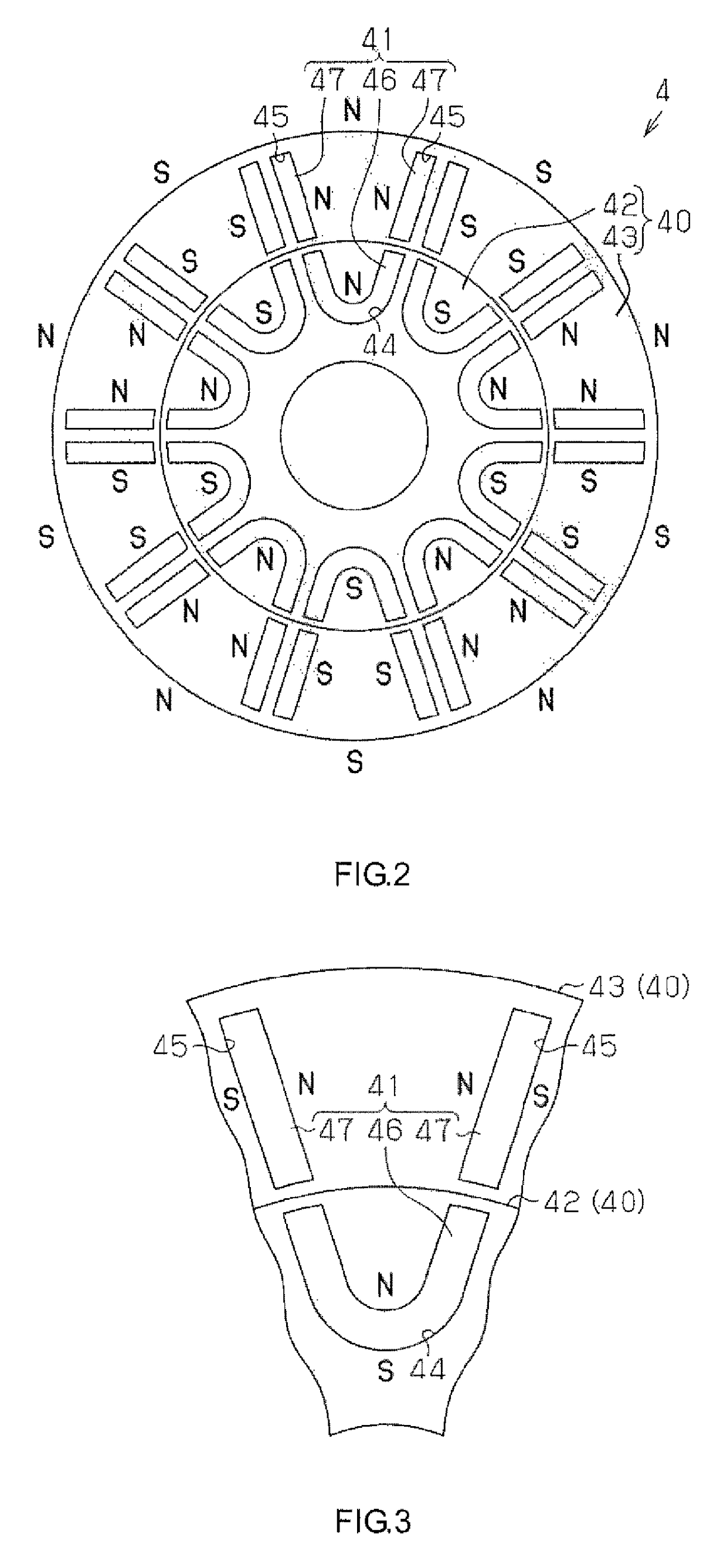

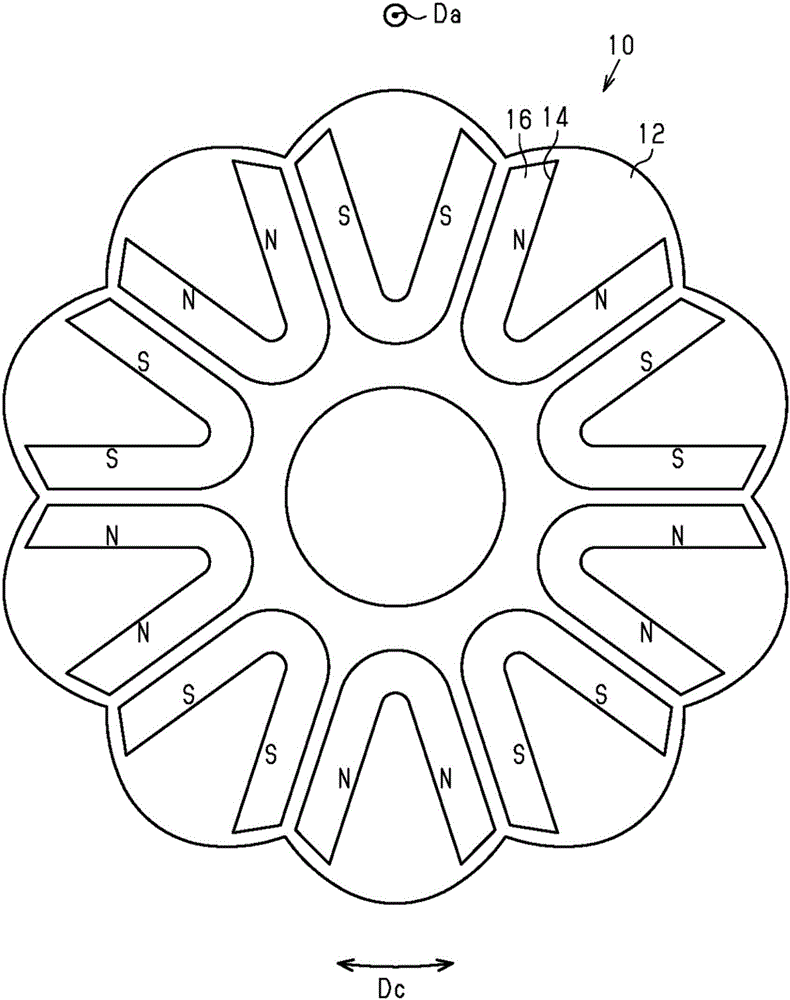

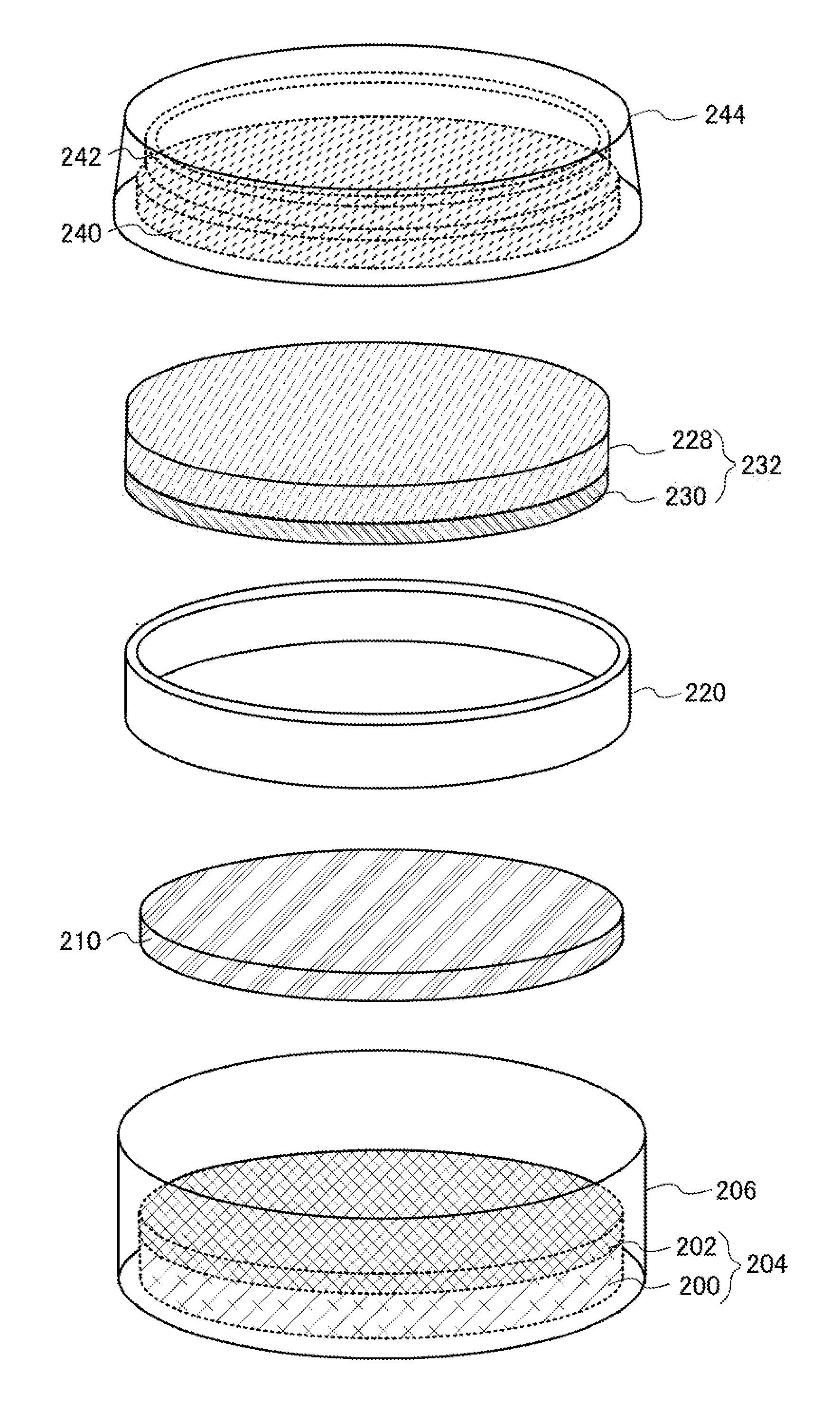

Magnet embedded rotor and method of manufacturing the magnet embedded rotor

InactiveUS20140225469A1Magnetization ratio is improvedEnhanced magnetizationMagnetic circuit rotating partsMagnetic bodiesMagnetic susceptibilityMagnetization

A magnet embedded rotor configured such that the magnetization ratio of field permanent magnets is improved is provided. The magnet embedded rotor includes a first annular core in which first permanent magnets are embedded, and a second annular core in which second permanent magnets, which are independent from the first permanent magnets, are embedded. The magnet embedded rotor has a structure in which the second annular core is fitted onto the outer periphery of the first annular core. The first permanent magnets and the second permanent magnets constitute field permanent magnets.

Owner:JTEKT CORP

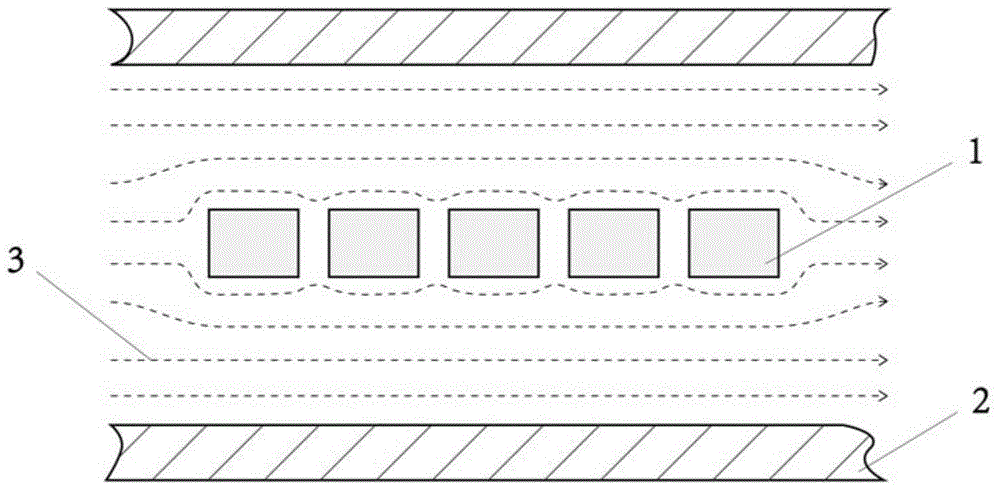

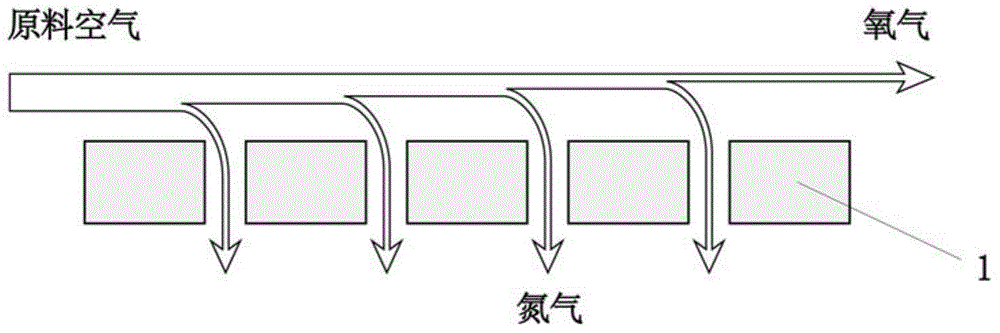

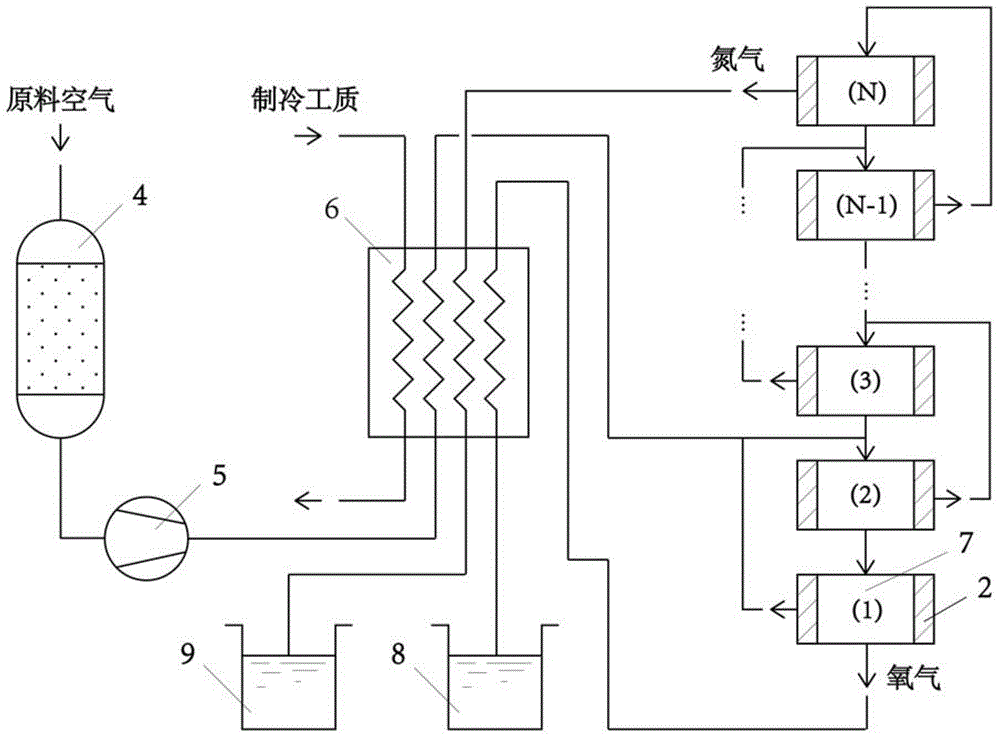

Cryogenic air-separation superconducting magnetic separator, separating device and separating method

InactiveCN105561728AImprove qualityIncrease magnetic susceptibilitySolidificationLiquefactionMagnetic tension forceMagnetic susceptibility

The invention discloses a cryogenic air-separation superconducting magnetic separator, a separating device and a separating method. The superconducting magnetic separator comprises a shell and a separating core arranged inside the shell, wherein the separating core comprises an outer magnet and a separating element of which at least one part is a porous superconducting thin film; the separating element is arranged inside the magnetic field of the outer magnet; one side of the porous superconducting thin film is in contact with an air raw material entering from an air raw material inlet, and is used for collecting oxygen and exhausting the oxygen via an oxygen outlet; the other side of the superconductor is used for collecting nitrogen passing through a pore structure and exhausting the nitrogen via a nitrogen outlet. Compared with the conventional magnetic air separation, the invention has the following advantages: the strength and the gradient of the magnetic field are higher, the magnetic susceptibility of oxygen molecules in the cryogenic air raw material is doubled, and cool needed for maintaining the superconducting state of the magnet and the thin film can be provided, so that the separating efficiency and the product purity are higher, the cryogenic air-separation superconducting magnetic separator, the separating device and the separating method have a broad application space in the fields, such as chemical, metallurgy, medical treatment and the like, in which high-purity oxygen is needed.

Owner:ZHEJIANG UNIV

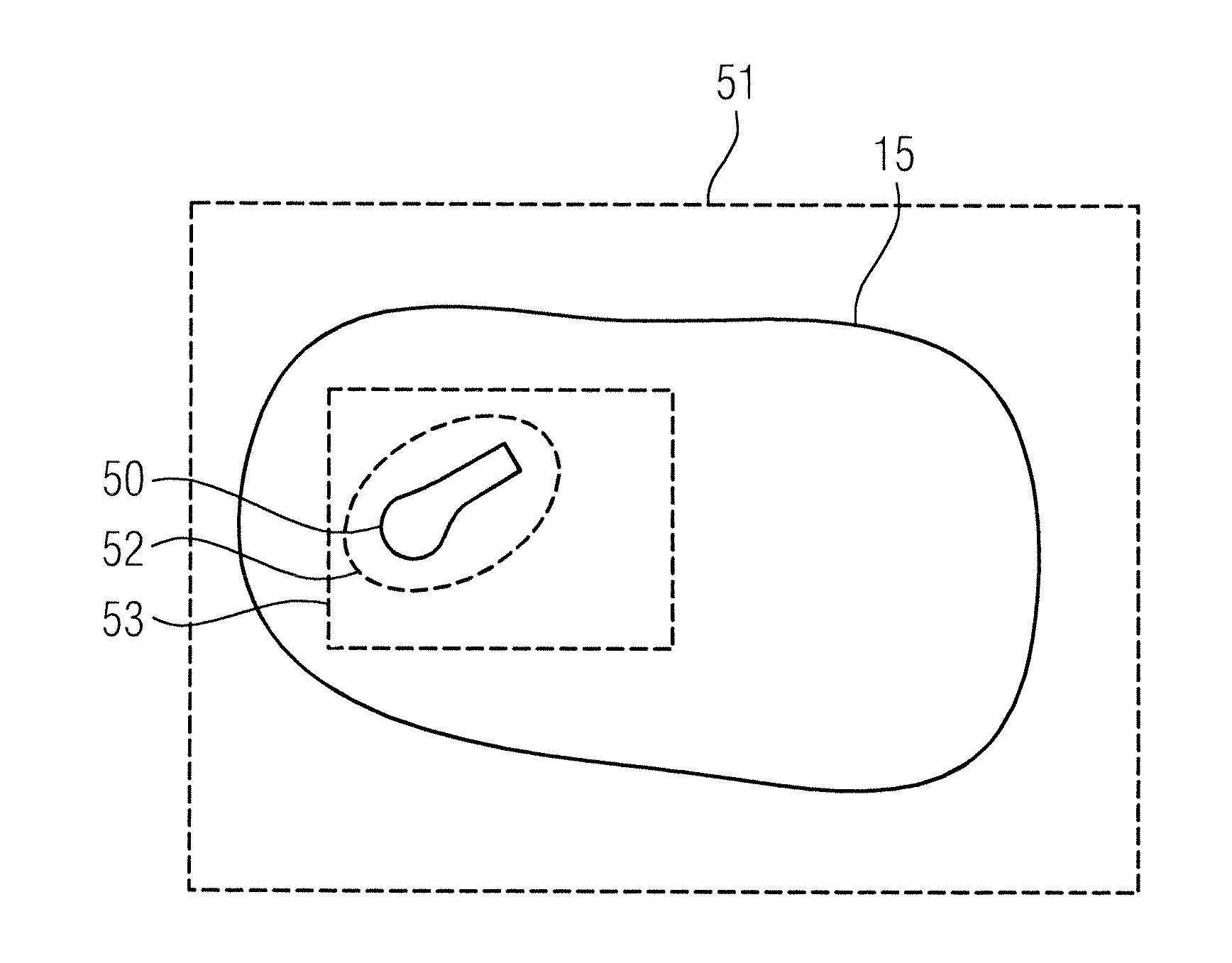

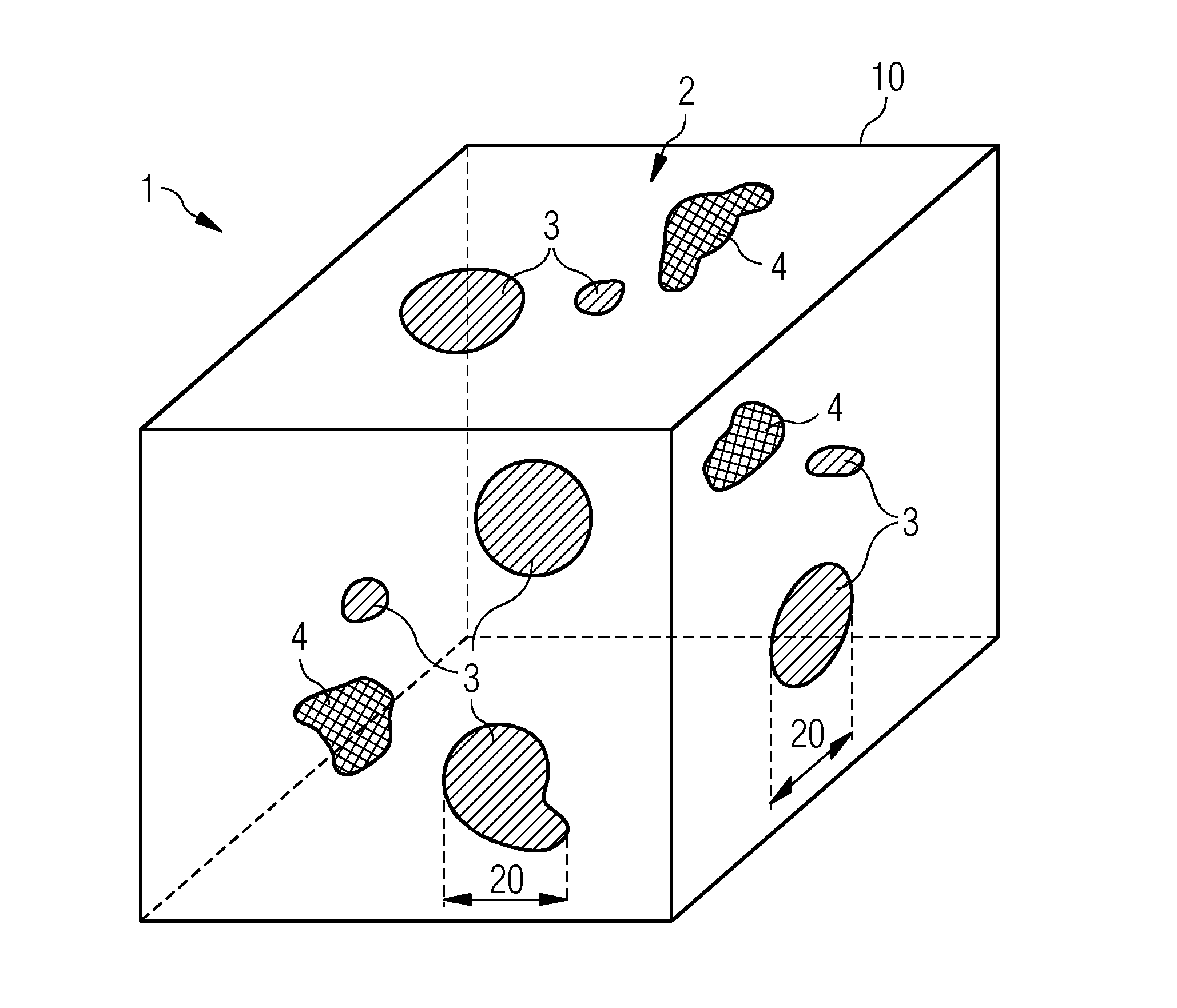

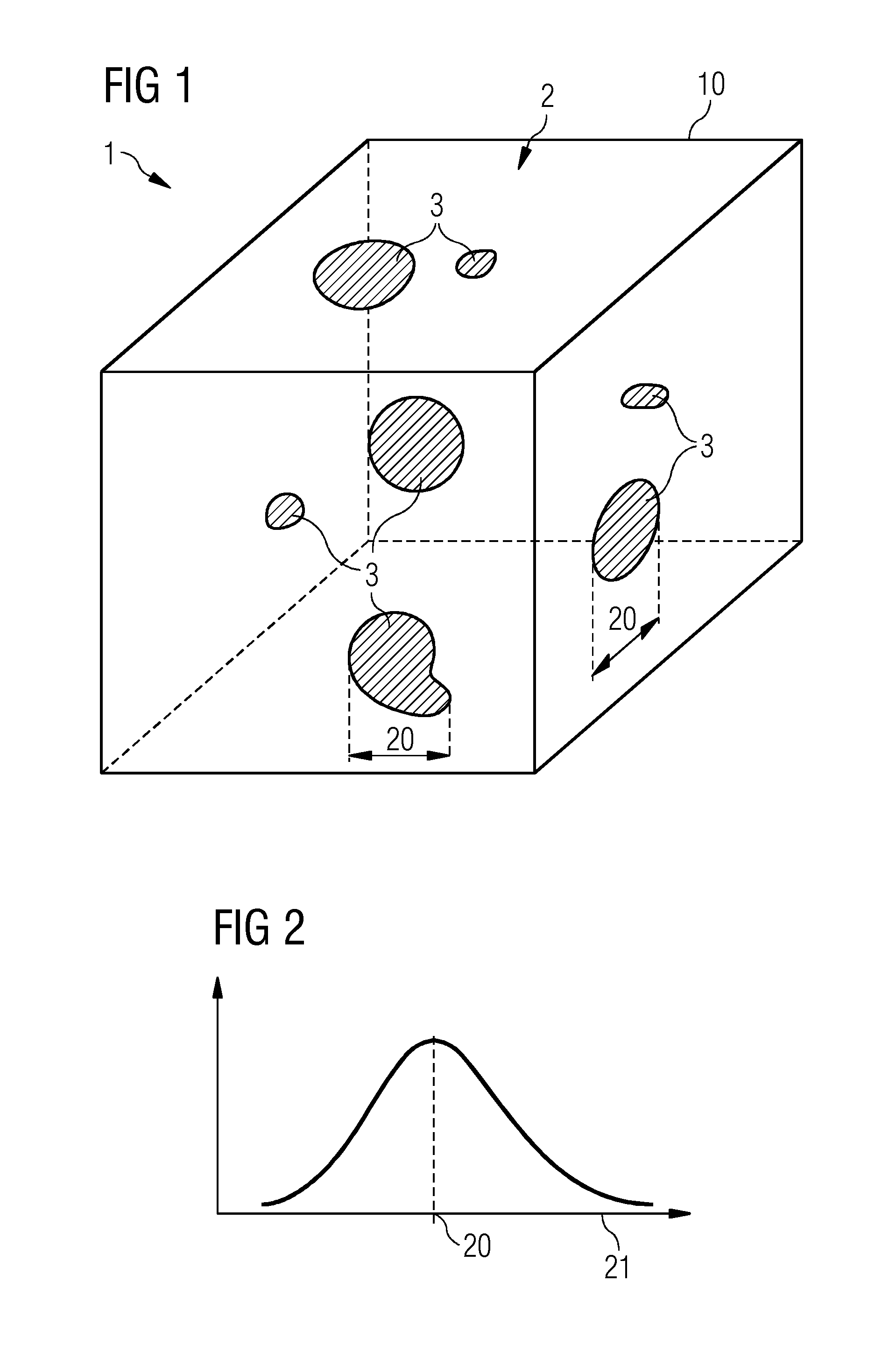

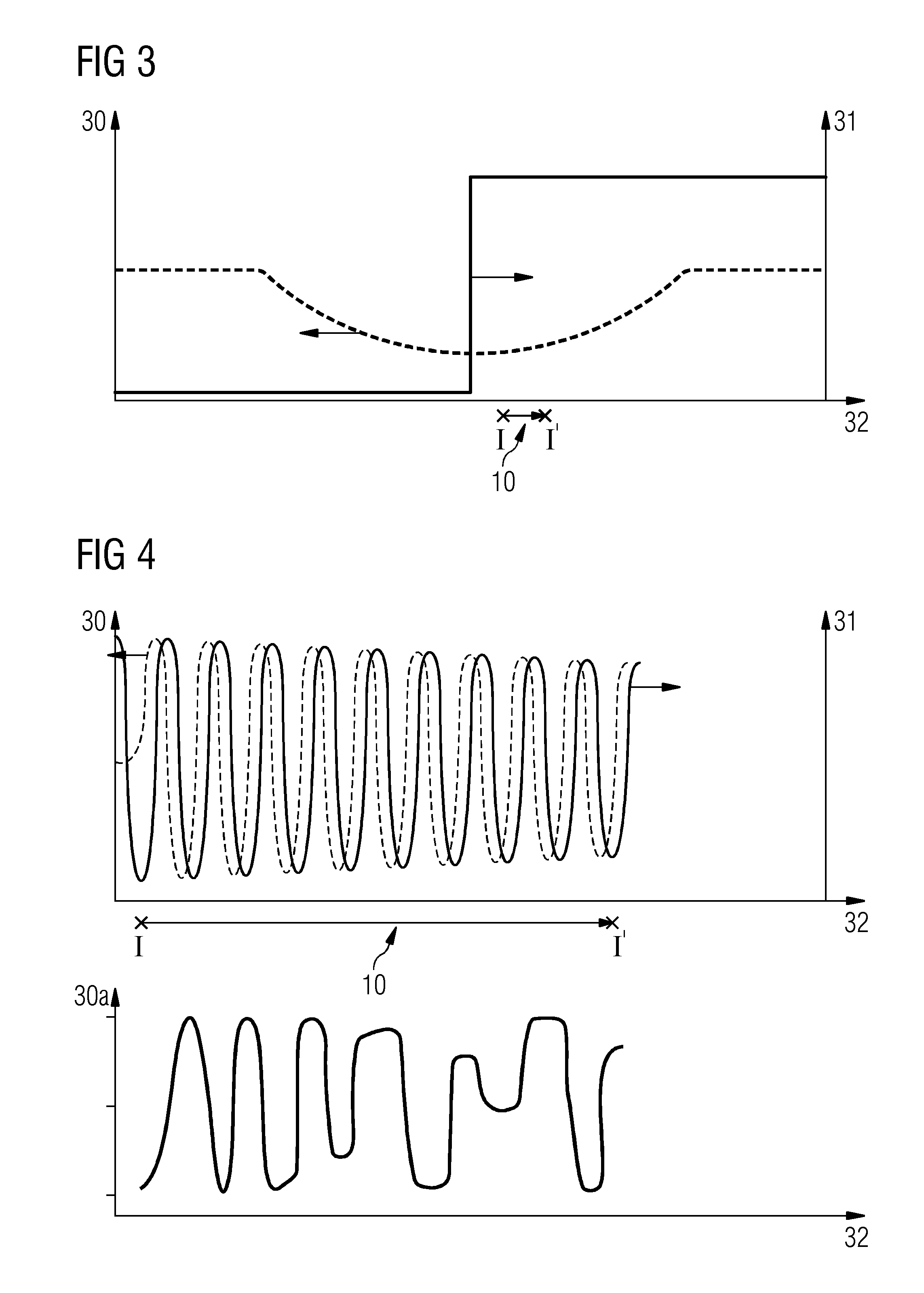

Method and apparatus for attenuation correction of emission tomography scan data

ActiveUS20160259024A1High resolutionAccurate informationMeasurements using NMR imaging systemsX/gamma/cosmic radiation measurmentAttenuation coefficientUltrasound attenuation

In a method for attenuation correction of emission tomography scan data acquired from an examination object in a combined magnetic resonance emission tomography apparatus, wherein an interference object is situated in the examination region, which causes a magnetic interference field during combined magnetic resonance emission tomography imaging, magnetic resonance scan data of the examination object are acquired by executing a magnetic resonance sequence designed to at least partially compensate inference due to the magnetic interference field. Emission tomography scan data are acquired and an attenuation map is generated using the acquired magnetic resonance scan data. Attenuation correction of the emission tomography scan data is implemented using the generated attenuation map.

Owner:SIEMENS HEALTHCARE GMBH

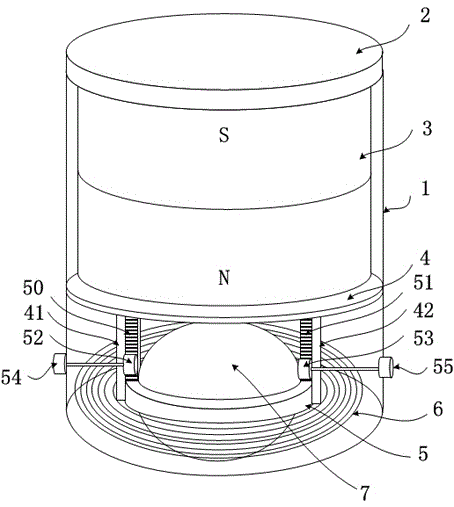

High strength and high efficiency fluid magnetizing tube, magnetizing device and system

InactiveCN1821109AImprove technical indicatorsImprove magnetization efficiencyWater/sewage treatment by magnetic/electric fieldsEnergy based chemical/physical/physico-chemical processesEngineeringHigh intensity

The present invention provides high strength and high efficiency fluid magnetizing tube, magnetizing device and magnetizing system, and belongs to the field of fluid magnetizing technology. The fluid magnetizing tube includes a magnetic tube, a magnetic conducting tube, and a locating and guiding element to form one or several fluid channels and has straight or curved axis. The magnetic tube includes a magnetic ring, an isolating ring of non-ferromagnetic material and a duct; the magnetic conducting tube is high permeability duct or one other magnetic tube; and the end plates possess fluid channel. The magnetizing device includes a casing and several magnetizing tubes connected serially and / or in parallel. The magnetizing system has magnetizing device, conventional pump and power device to perform circular fluid magnetizing. The present invention has high strength axial and radial magnetic field and high fluid magnetizing efficiency.

Owner:朱澄清

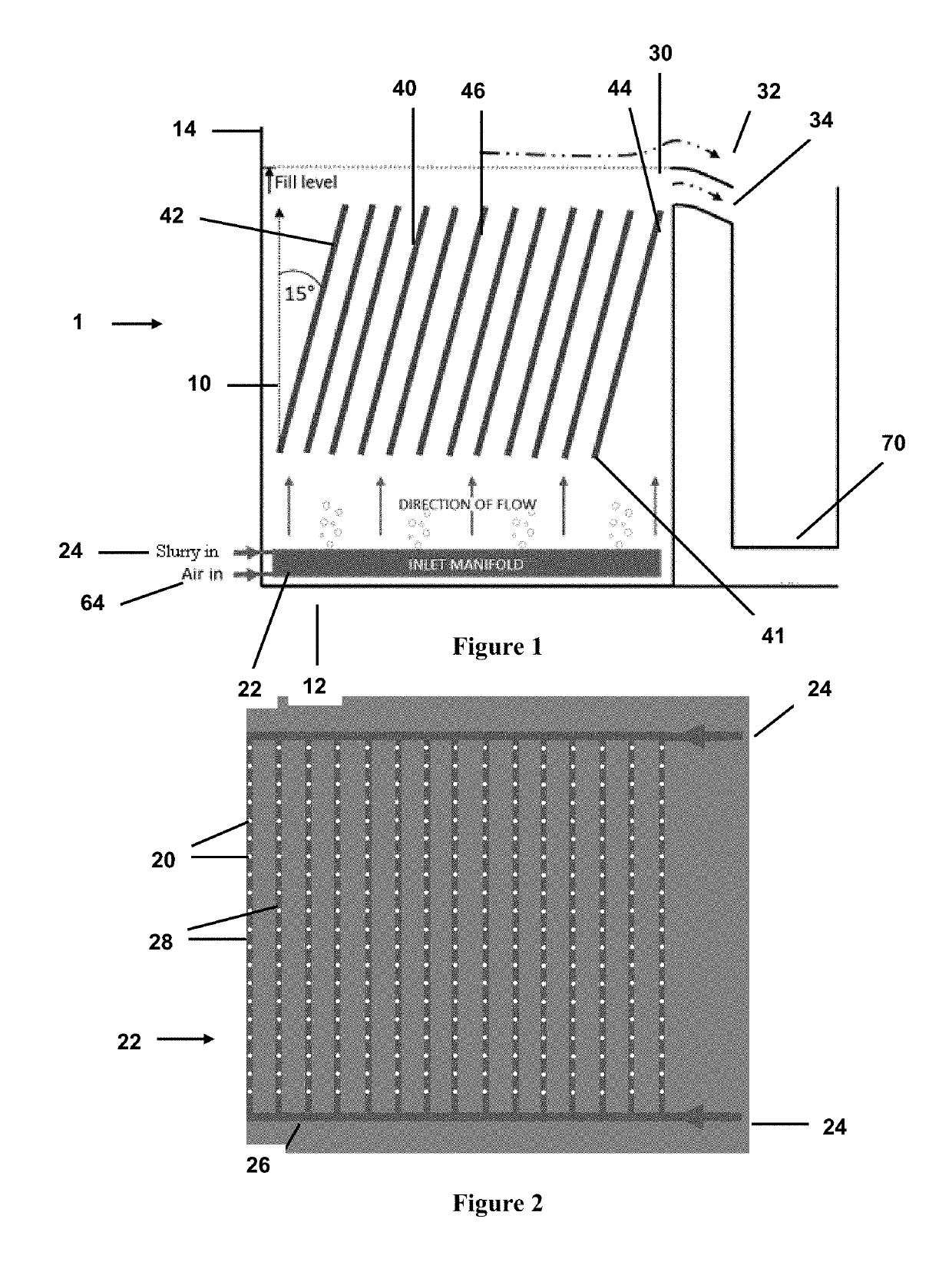

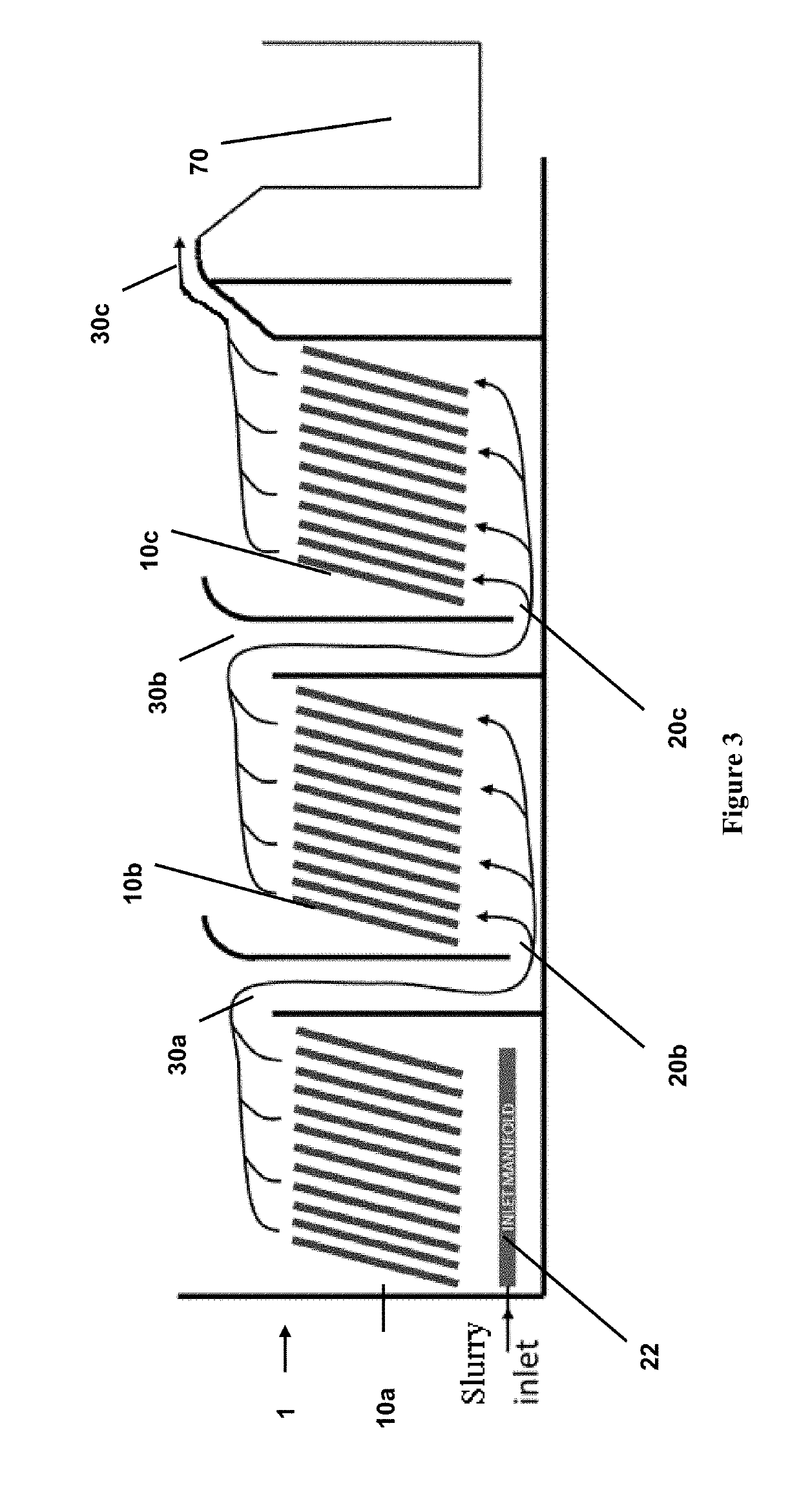

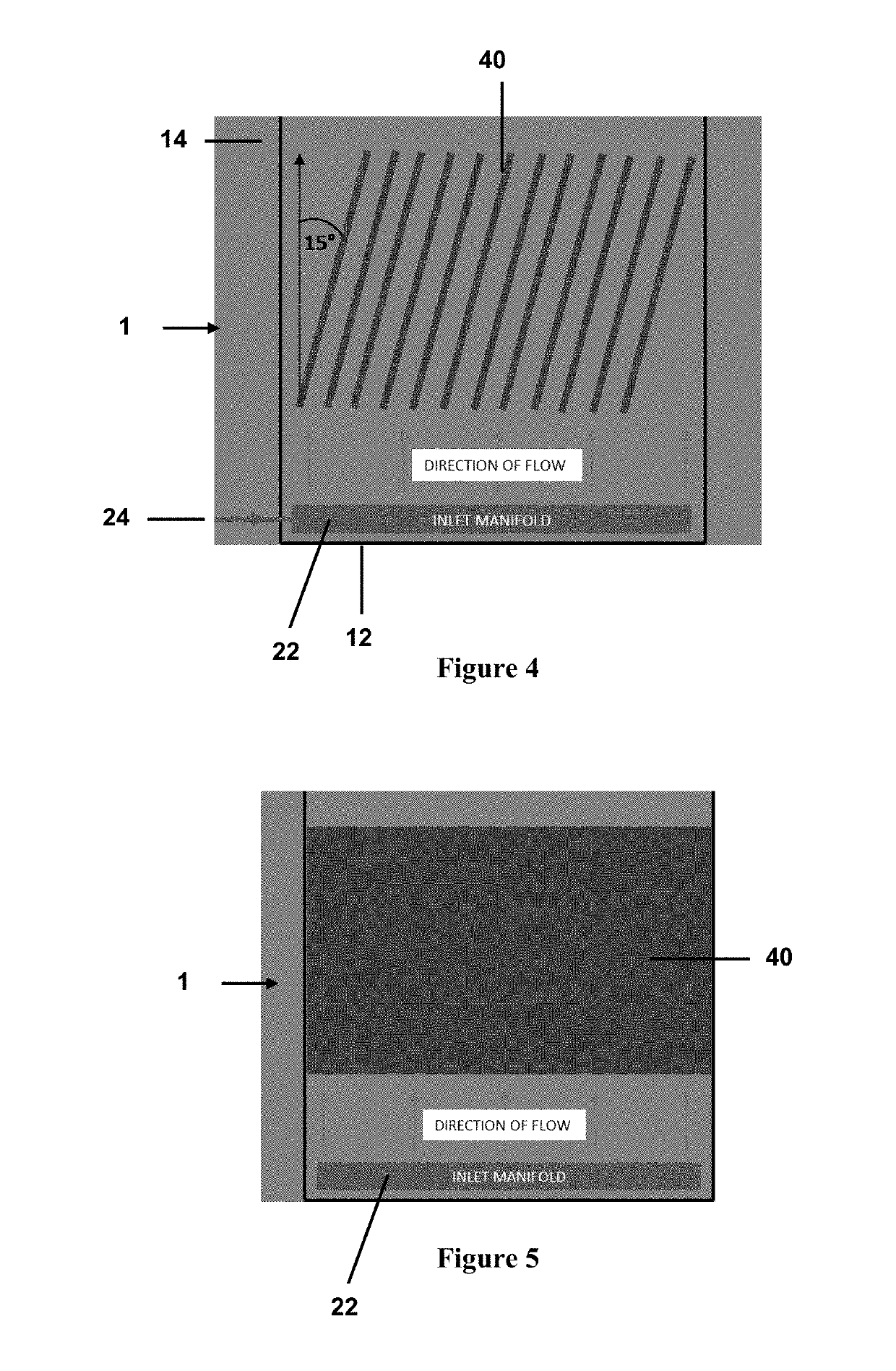

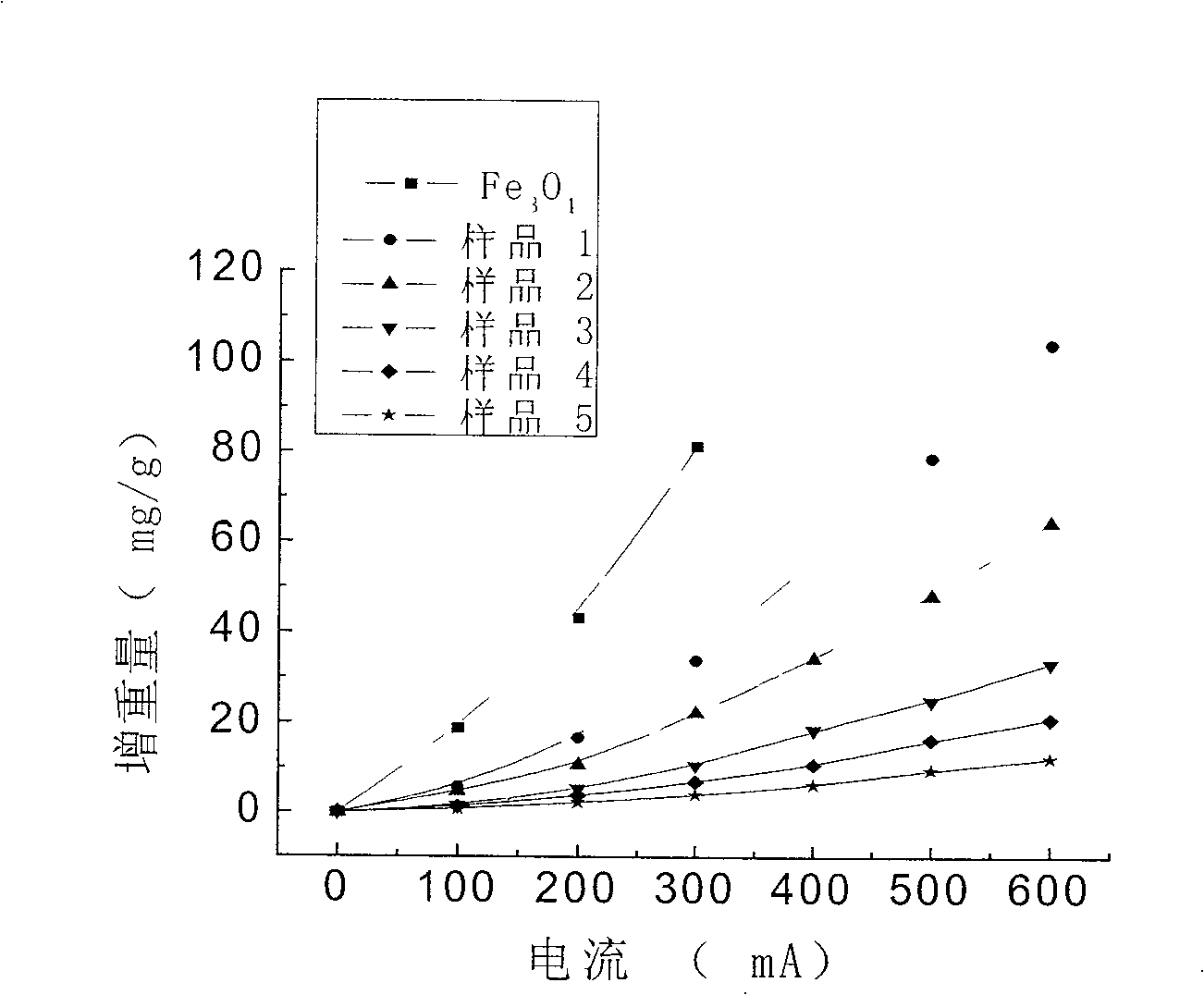

Process

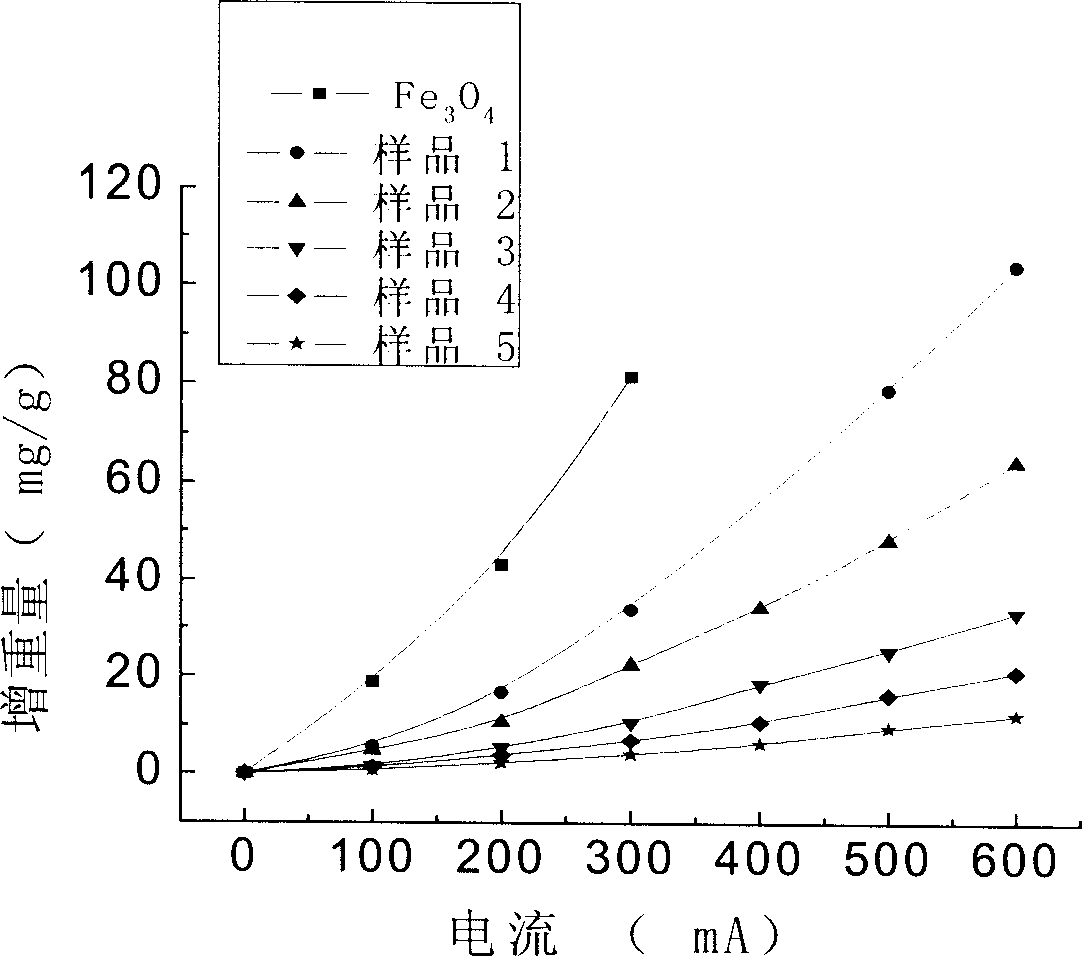

ActiveUS20190203368A1Increase the proportionIncrease magnetic susceptibilityCellsSludge treatment by de-watering/drying/thickeningIron oxideMaterials science

The present invention relates to processes including the step of electrochemically treating an iron mineral. The processes are for improving the grade of iron, producing a magnetic iron mineral, or producing an iron oxide. In one aspect, the process for improving the grade of iron includes electrochemically treating a slurry including at least one iron mineral to thereby improve the grade of the iron in the slurry.

Owner:ENVIROGOLD GLOBAL PTY LTD

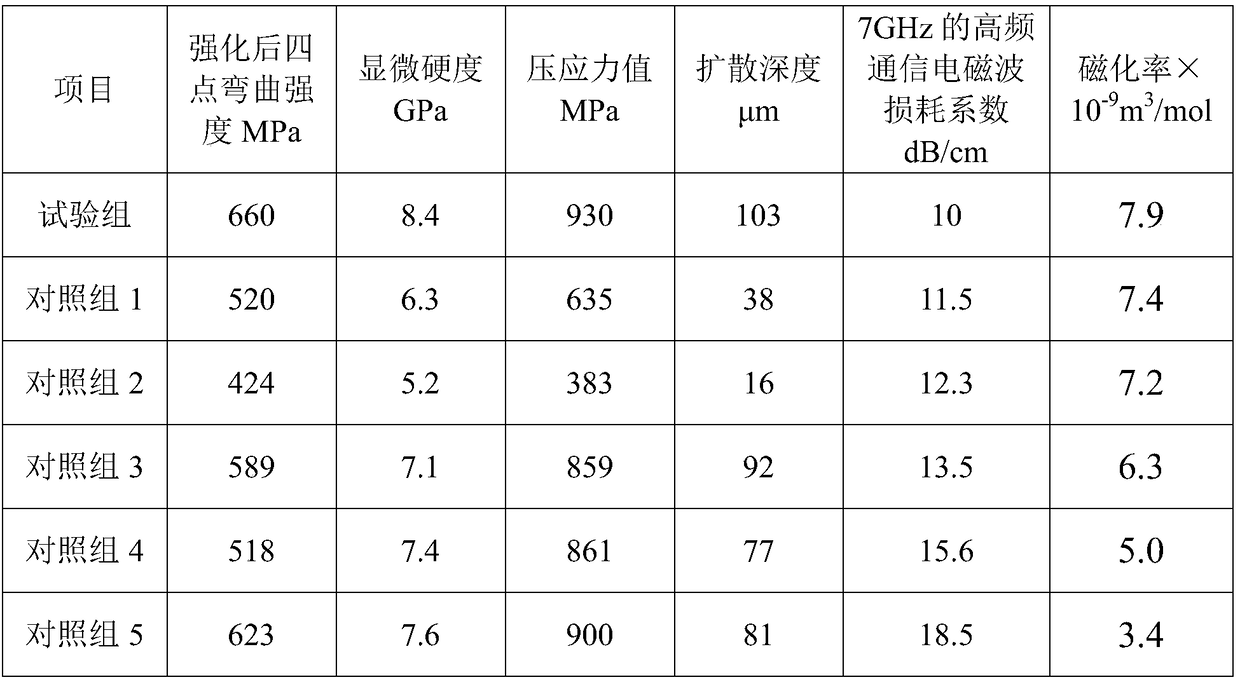

Preparation method of microcrystalline glass applied to 5G communication mobile terminal

The invention provides a preparation method of a microcrystalline glass applied to a 5G communication mobile terminal, and belongs to the technical field of microcrystalline glass. The preparation method comprises following steps: step A, preparing following raw materials in parts by weight: 45 to 75 parts of quartz sand, 10 to 25 parts of aluminum oxide, 14.5 to 39.6 parts of sodium carbonate, 2.3 to 9.2 parts of potassium nitrate, 0 to 12.5 parts of lithium carbonate, 0 to 41 parts of magnesium carbonate, 0 to 8 parts of titanium oxide, 0 to 20 parts of zirconium oxide, 0 to 10 parts of zincoxide, 0 to 3 parts of rubidium oxide, 0 to 5 parts of gallium oxide, 0 to 3 parts of europium oxide, 0 to 9 parts of ammonium dihydrogen phosphate, 0 to 3 parts of antimony oxide, 0 to 3 parts of yttrium oxide, 0 to 3 parts of cerium oxide, 0 to 5 parts of iron oxide, 0 to 2 parts of manganese oxide, 0 to 3 parts of nickel oxide, and mixing all raw materials to obtain a mixture; step B, meltingthe mixture; step C, moulding the melt; and step D, carrying out annealing, nucleation, and crystallization to obtain the microcrystalline glass. By controlling the raw materials and technology, the obtained front cover microcrystalline glass has high transmittance of visible light, high strength, and high hardness, and the obtained rear cover microcrystalline glass has high strength and low magnetic loss.

Owner:GLASS TECH RES INST OF SHAHE CITY OF HEBEI PROVINCE

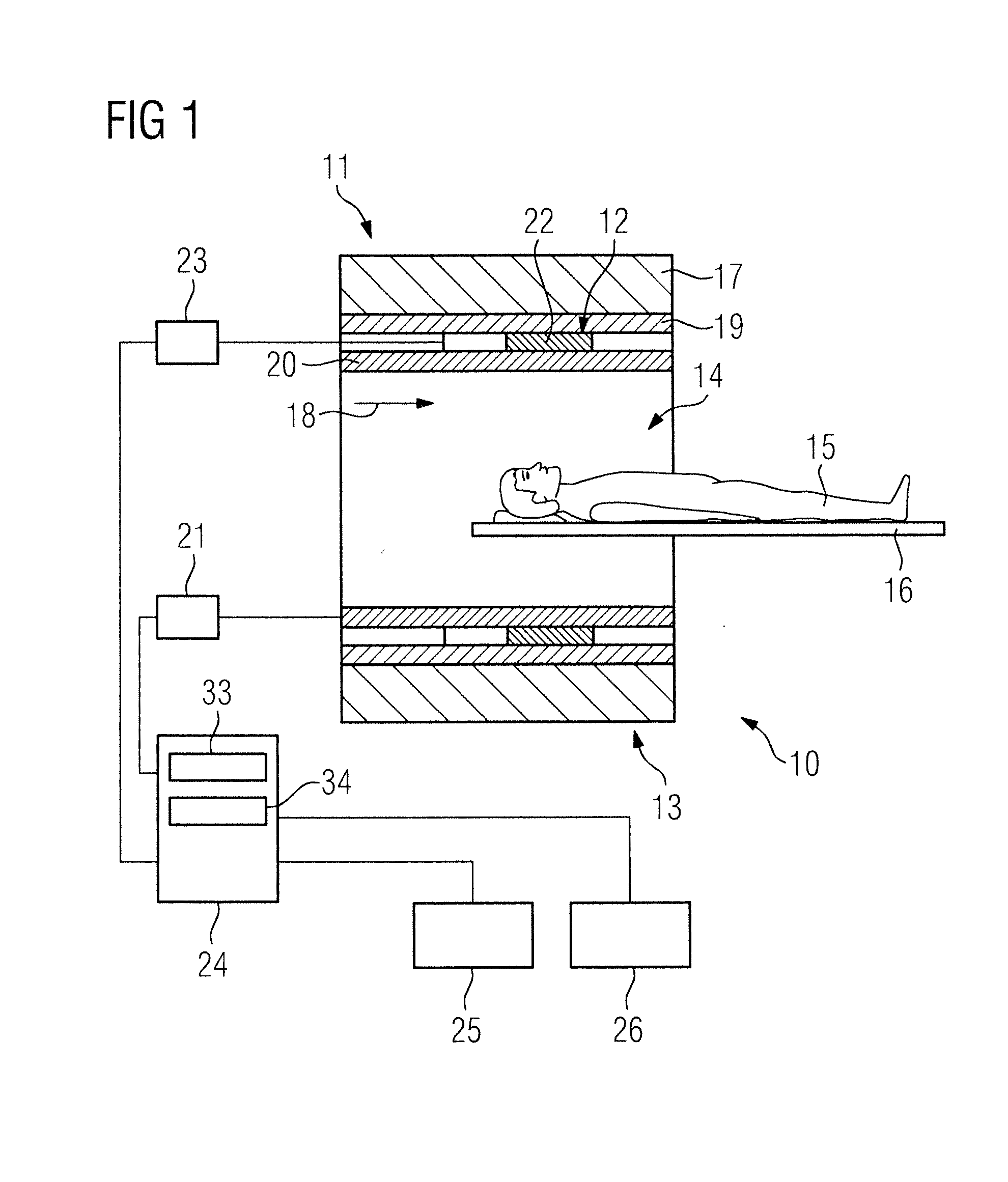

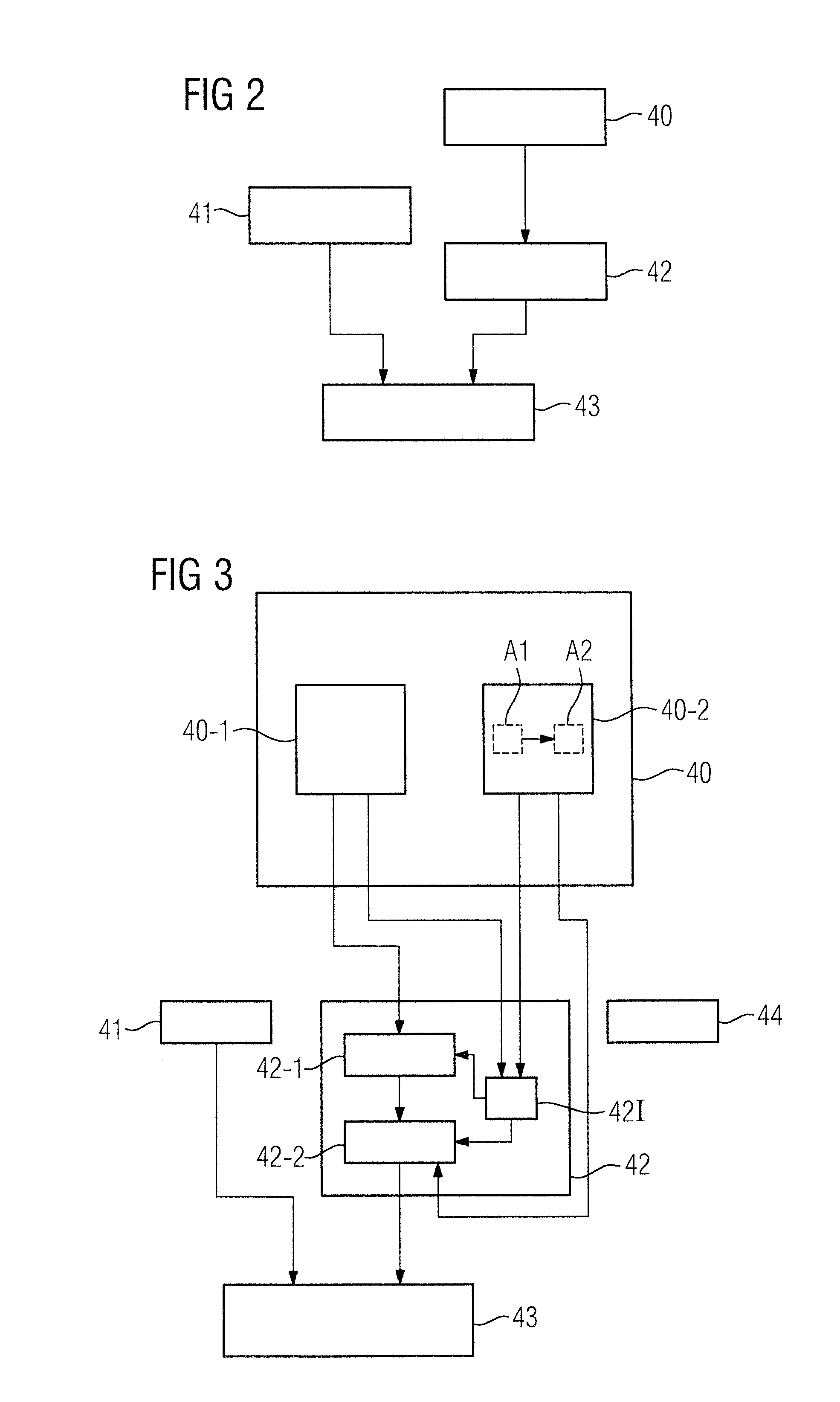

MRI apparatus with high-resistance magnet

InactiveUS20070159171A1Improve the immunityEasy to demagnetizeMagnetic measurementsThin material handlingHigh resistanceMagnetic field gradient

Eddy current generated around a magnetic circuit in an MRI apparatus is one of the causes of deviation from an ideal magnetic field gradient waveform and causes image distortion, loss of strength, ghost generation, loss of signal, and spectral distortion. An object of the present invention is to suppress the generation of the eddy current. In an MRI apparatus, a ferromagnetic material formed from powder is used in a part of a magnetic circuit: the powder mainly comprising a mother phase containing iron or cobalt and showing ferromagnetism; and a high-resistance layer having a resistance not less than ten times as high as the mother phase and a Vickers hardness lower than that of the mother phase being formed in layers along parts of the surface of the powder on parts or the entire of the surface.

Owner:HITACHI LTD

Method of separating admixed contaminants from superalloy metal powder

ActiveUS7153377B2Easy to separateIncrease magnetic susceptibilityElectrostatic separationWater/sewage treatment by magnetic/electric fieldsSuperalloyMetal powder

Owner:RJ LEE GRP INC

Four-dimensional magnetic suspension auto-modulation recycled oil/gas reformer

InactiveCN105771839AFully magnetizedLow magnetic susceptibilityEnergy based chemical/physical/physico-chemical processesElectrical polarityMagnetization

The invention relates to the field of fuel magnetization energy conservation, in particular to a four-dimensional magnetic suspension auto-modulation recycled oil / gas reformer which comprises a suspension magnetization device main body, permanent magnet porous suspension bodies, plunger type mesoporous suspension auto-modulation magnetic pillars, a plurality of reverse magnetic positioning sealing pads, an upper magnetization cabin sealing cover and a lower magnetization cabin sealing cover, wherein the suspension magnetization device main body is sealed by the upper magnetization cabin sealing cover and the lower magnetization cabin sealing cover; the reverse magnetic positioning sealing pads are arranged inside the sealed suspension magnetization device main body; a four-dimensional magnetic suspension channel is formed between two adjacent reverse magnetic positioning sealing pads; the four-dimensional magnetic suspension channels are formed by the plunger type mesoporous suspension auto-modulation magnetic pillars which are embedded into two permanent magnet porous suspension bodies. The four-dimensional magnetic suspension auto-modulation recycled oil / gas reformer provided by the invention is simple in structure, moreover, the magnetization rate of fuel can be effectively increased, furthermore, the fuel can be more sufficiently combusted, the energy can be relatively well saved, and the environment can be protected.

Owner:YANTAI JIUZHOU FUEL OIL & FUEL GAS ENERGY SAVING TECH

Material for use in a magnetic resonance system, method for producing the material and magnetic resonance system

InactiveUS20130249557A1Improve visibilityShort relaxation timeMagnetic paintsInorganic material magnetismResonanceMaterials science

A material for use in a magnetic resonance system includes a carrier material and a doping material. The carrier material and the doping material are admixed in a specific proportion. A volume of the material smaller than 1 mm2 contains a substantially homogeneous intermixing of the carrier material and the doping material.

Owner:SIEMENS HEALTHCARE GMBH

4A type zeolite molecular sieve and its preparation method

InactiveCN100413783CIncrease magnetic susceptibilityUniform particlesCrystalline aluminosilicate zeolitesSal ammoniacMolecular sieve

A 4A zeolite molecular sieve with a certain magnetism and carrying Fe contained compound on its surface is a granular one containing Fe (3.55-9.70 mass%). Its preparing process includes such steps as synthesizing 4A zeolite molecular sieve, preparing Fe ion solution and aqueous solution of NH4, and magnetically modifying the 4A zeolite molecular sieve by chemical deposition method.

Owner:HEBEI UNIV OF TECH

Oxygen-enriched device applied to energy conservation and emission reduction of motor vehicle engine

InactiveCN105781807AIncrease magnetic susceptibilityImprove the efficiency of oxygen enrichmentNon-fuel substance addition to fuelInternal combustion piston enginesAir filterPositive pressure

The invention discloses an oxygen-enriched device applied to energy conservation and emission reduction of a motor vehicle engine. The oxygen-enriched device is easy to manufacture and convenient to operate and comprises a positive pressure source, a gas separator and a negative pressure source. The gas separator comprises a sleeve, an oxygen-enriched pipe and an oxygen suction film. The oxygen-enriched pipe is a pipe of which one end is closed and the other end is opened. The part, extending into an inner cavity of the sleeve, of the closed end of the oxygen-enriched pipe is the oxygen suction part of the oxygen-enriched pipe. A magnetic part is embedded into the oxygen suction part of the oxygen-enriched pipe. The pipe wall of the oxygen suction part of the oxygen-enriched pipe is provided with at least one through hole. All the through holes are coated with the oxygen suction film completely. The positive pressure source is arranged at the air supply end of the sleeve. The negative pressure source is arranged at the opened end of the oxygen-enriched pipe. The gas separator further comprises a gas division disk fixedly installed at an exhaust outlet of the sleeve. The air supply end of the sleeve is further provided with an air filtering net.

Owner:GUANGZHOU YUNENG AMPEREX TECH CO LTD

Magnet embedded rotor and method of manufacturing the magnet embedded rotor

InactiveUS9601952B2Enhanced magnetizationIncrease magnetic susceptibilityMagnetic circuit rotating partsMagnetic bodiesMagnetizationMagnet

A magnet embedded rotor configured to provide an improved magnetization ratio of the field permanent magnets is provided. The magnet embedded rotor includes a first annular core in which first permanent magnets are embedded, and a second annular core in which second permanent magnets, which are independent from the first permanent magnets, are embedded. The magnet embedded rotor has a structure in which the second annular core is fitted onto the outer periphery of the first annular core. The first permanent magnets and the second permanent magnets constitute field permanent magnets.

Owner:JTEKT CORP

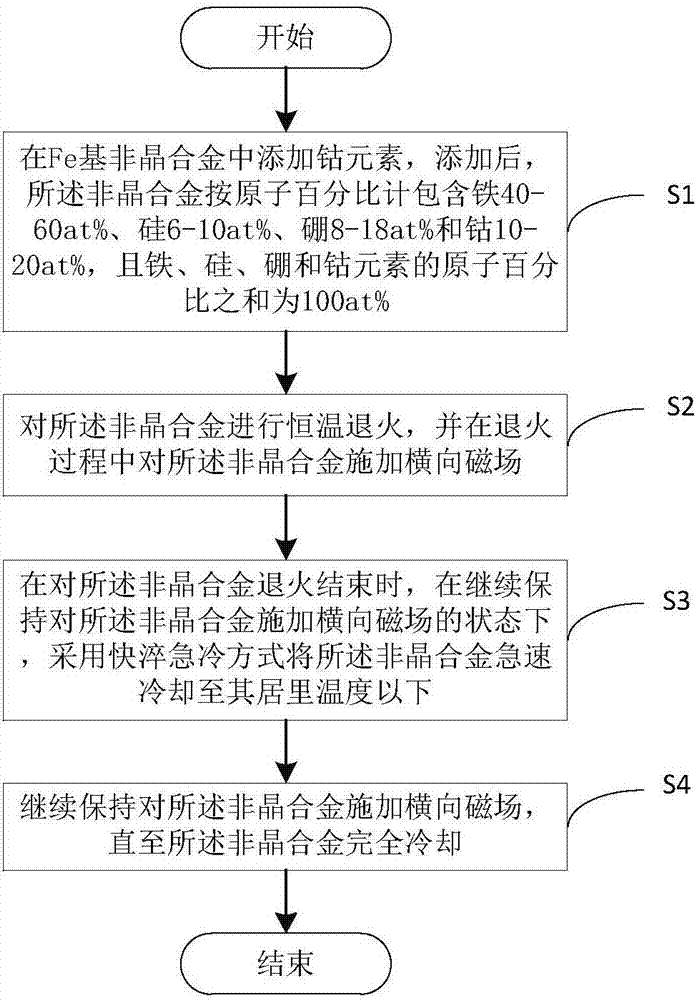

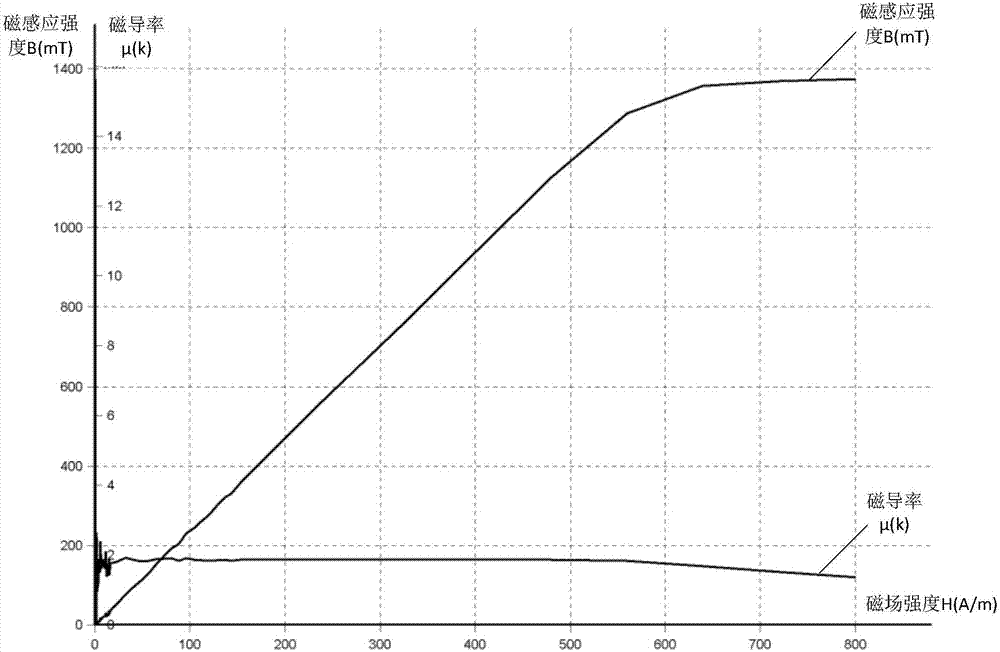

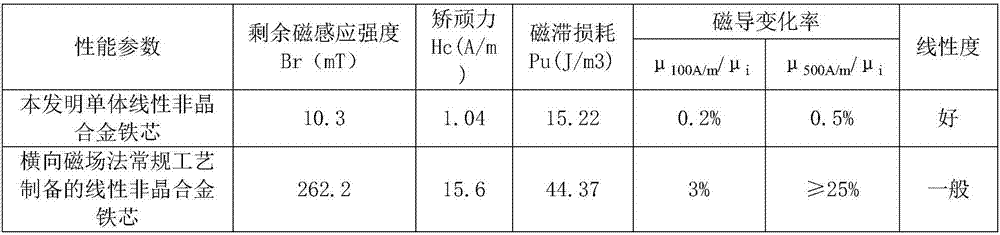

Preparation method of monomer linear amorphous alloy iron core

InactiveCN106920672AIncrease magnetic susceptibilityIncrease hysteresis anisotropyMagnetic materialsMagnetic core manufactureMagnetic susceptibilityTransverse magnetic field

The invention relates to the technical field of metallurgy, and discloses a preparation method of a monomer linear amorphous alloy iron core. According to the method, an appropriate amount of cobalt element with high ferromagnetic property and high magnetic susceptibility is added on the basis of Fe-based amorphous alloy, so that the magnetic-lag anisotropy of the amorphous alloy is increased, and the sensitivity of the alloy for a magnetic field is improved; meanwhile, when the amorphous alloy is annealed at a constant temperature, a transverse magnetic field is applied to the amorphous alloy, and the direction of the magnetic-lag anisotropy is controlled, so that the magnetic-lag loop of the material is adjusted; after annealing is finished, the amorphous alloy is quickly cooled to below the Curie temperature of the amorphous alloy in a rapid quenching manner in the state that the application of the transverse magnetic field is continued to be maintained, atomic magnetic moments arranged along the same direction of the action of the magnetic field in the magnetic domain of the amorphous alloy are quickly cured, and alloy atoms are prevented from causing the influence of alloy to be influenced by metal inherent microstructure crystal and atom arrangement change due to thermal motion broken magnetic moment orientation and too slow alloy cooling. The finally prepared amorphous alloy iron core is high in linearity, low in iron core loss and high in magnetic conductivity.

Owner:深圳晶弘新能源科技有限公司

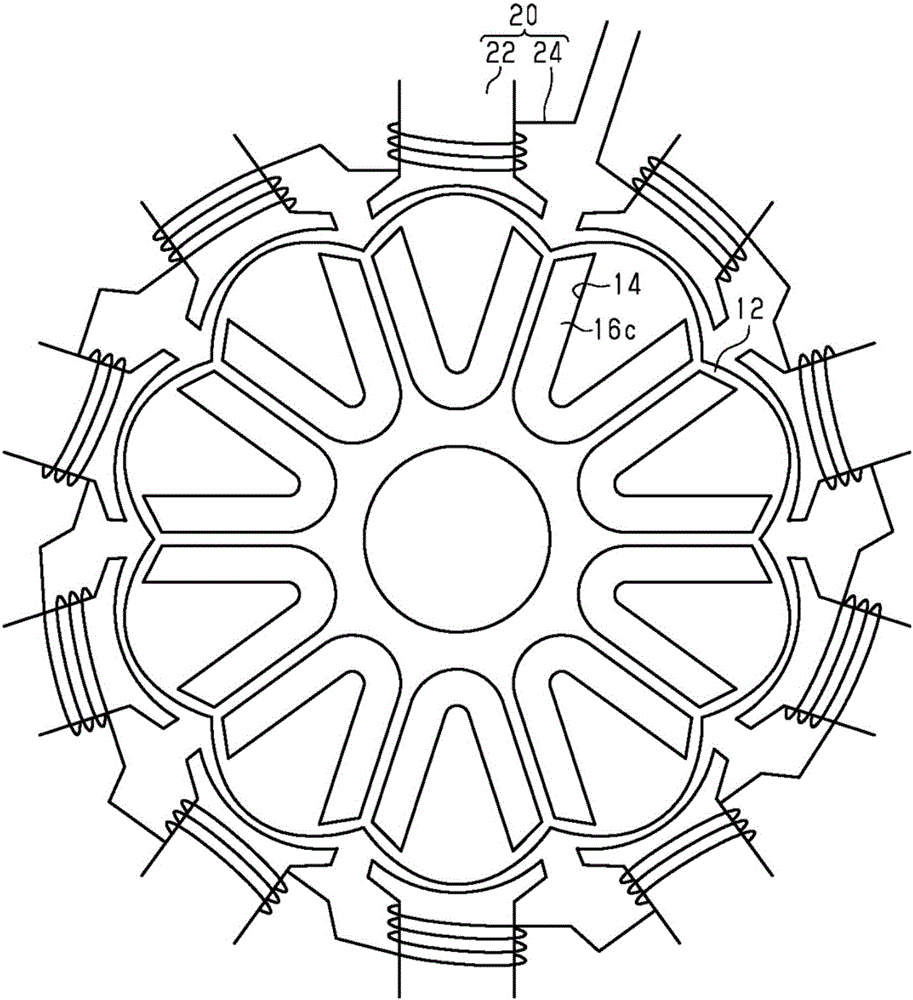

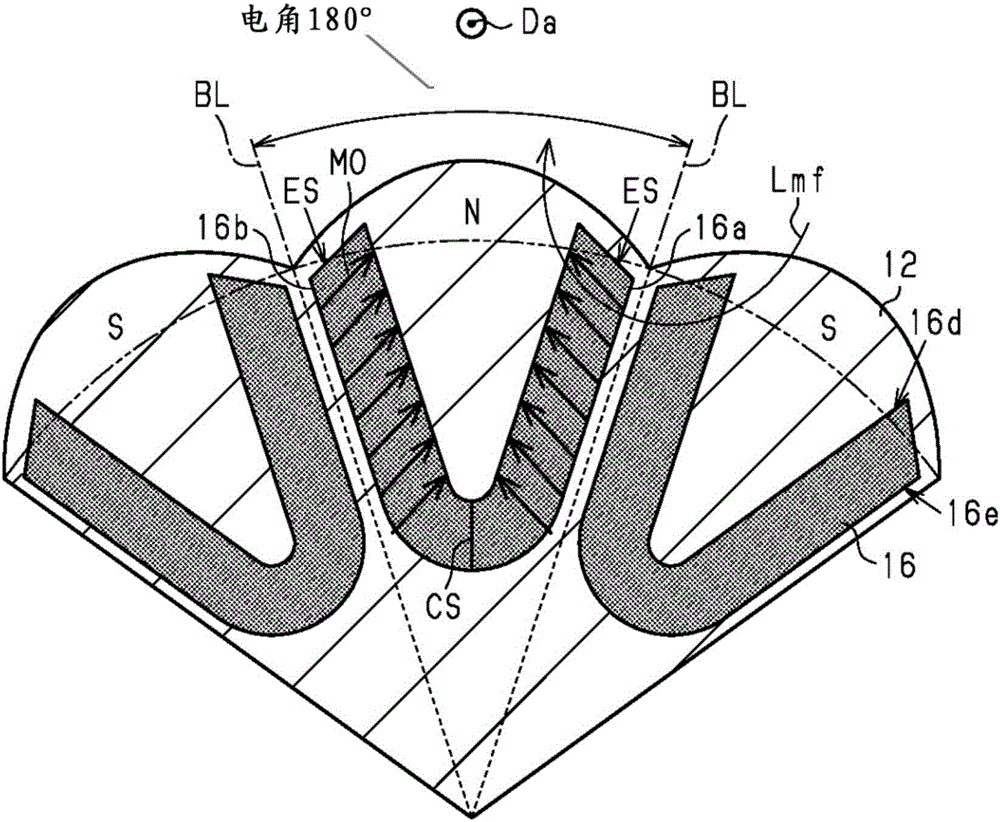

Interior permanent magnet rotor and method for manufacturing the same

InactiveCN106505761AInhibition of magnetic flux reductionImprove efficiencyMagnetic circuit rotating partsManufacturing stator/rotor bodiesPermanent magnet rotorMagnetic poles

The invention provides an interior permanent magnet rotor and a method for manufacturing the same. The interior permanent magnet rotor restrains demagnetization of permanent magnets embedded in a core 12. Each permanent magnet is formed by joining a first portion 16a and a second portion 16b at a connection CS. The first and second portions 16a, 16b extend from the outer side toward the inner side in the radial direction of the core 12. The outer end faces ES of the first and second portions 16a, 16b in the radial direction of the core 12 extend in an orientation direction MO as viewed in section perpendicular to the axial direction Da. The outside diameter of the core 12 gradually increases from the boundaries BL between a single magnetic pole and magnetic poles adjoining the single magnetic pole toward the middle of the single magnetic pole in the circumferential direction of the core 12.

Owner:JTEKT CORP

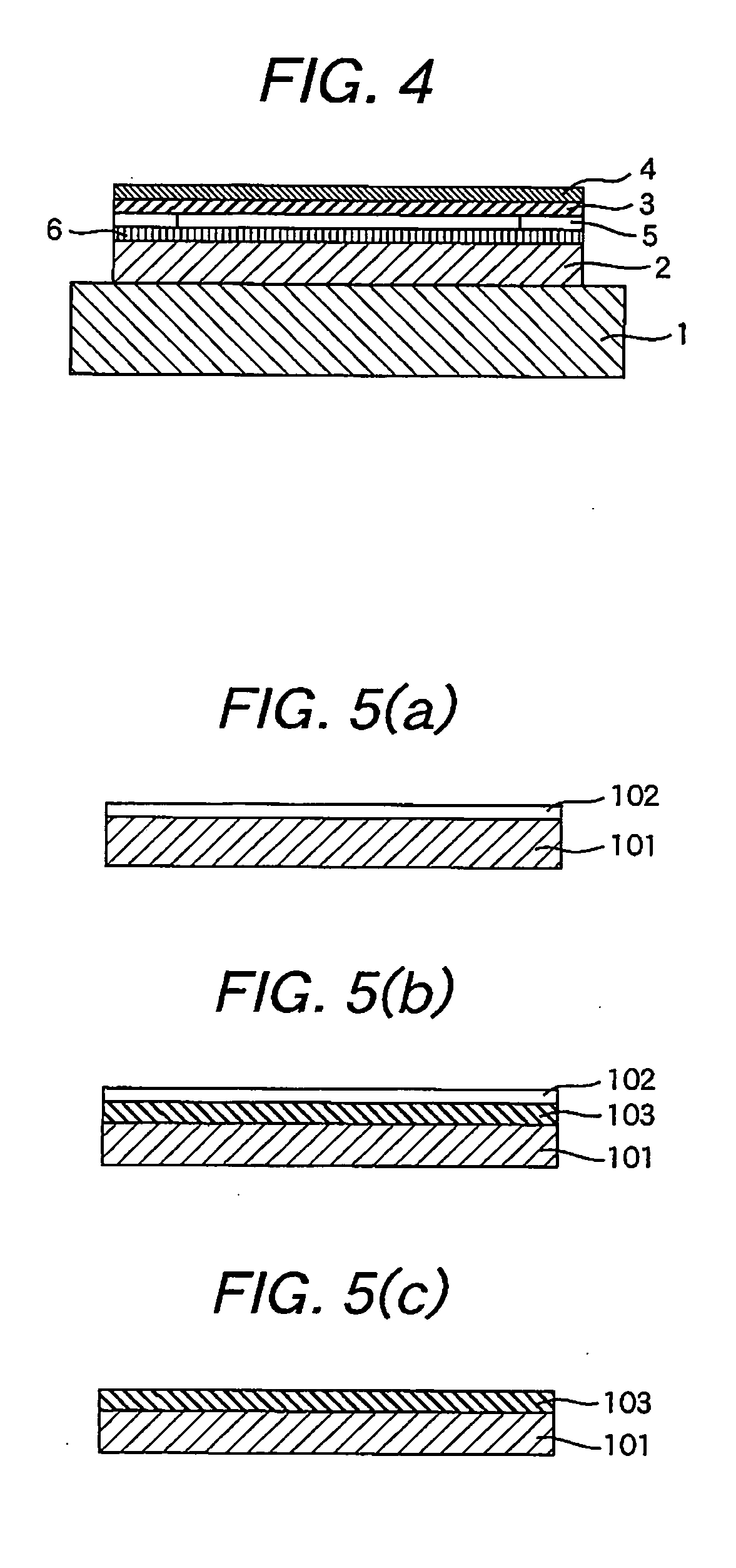

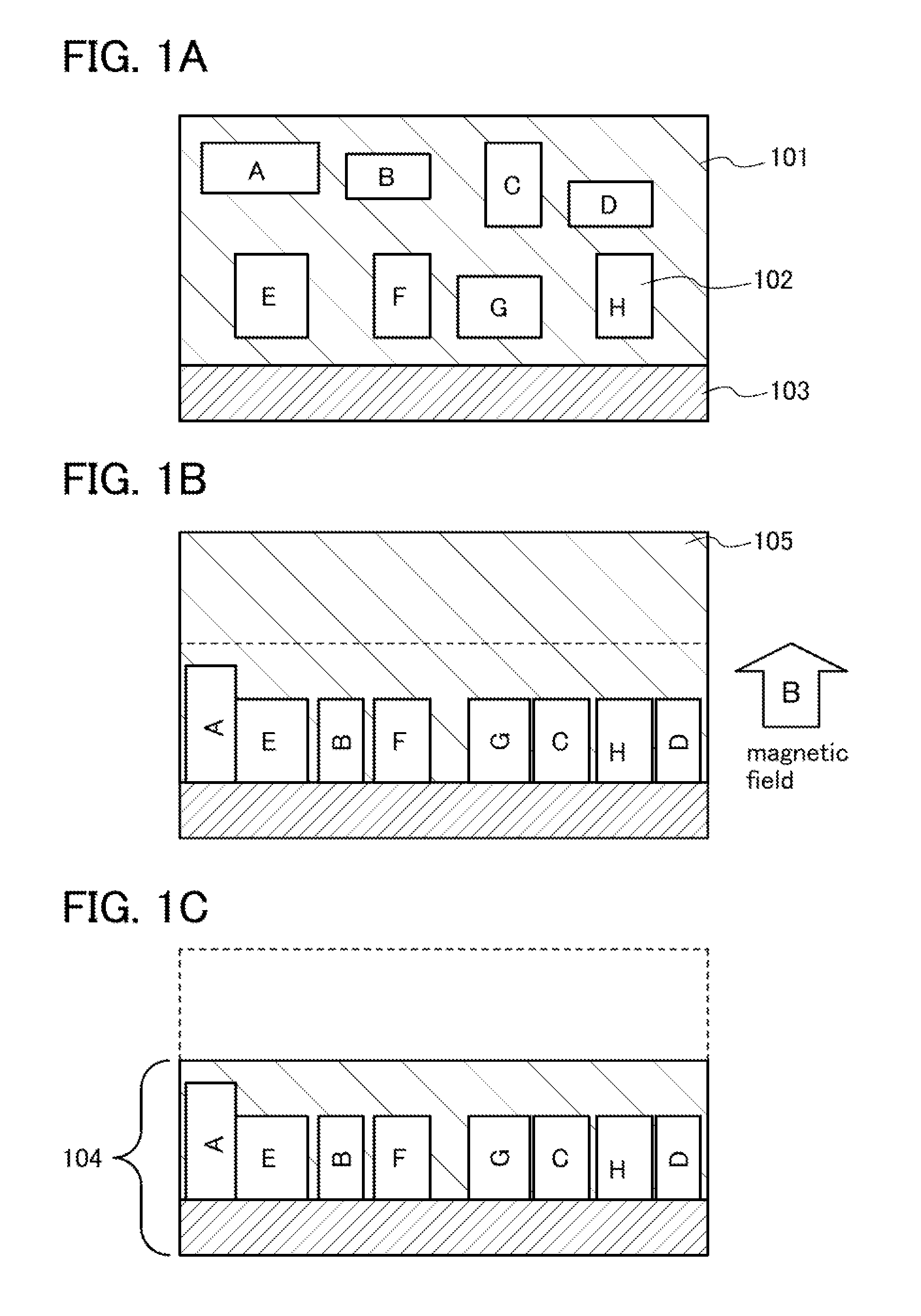

Method for manufacturing nonaqueous electrolyte secondary battery

ActiveUS20120177843A1Increase magnetic susceptibilityPromote aggregationFinal product manufactureElectrode collector coatingSlurryLithium-ion battery

When an active material with low ionic conductivity and low electric conductivity is used in a nonaqueous electrolyte secondary battery such as a lithium ion battery, it is necessary to reduce the sizes of particles; however, reduction in sizes of particles leads to a decrease in electrode density. Active material particles of an oxide, which include a transition metal and have an average size of 5 nm to 50 nm, are mixed with an electrolyte, a binder, and the like to form a slurry, and the slurry is applied to a collector. Then, the collector coated with the slurry is exposed to a magnetic field. Accordingly, the active material particles aggregate so that the density thereof increases. Alternatively, the active material particles may be applied to the collector in a magnetic field. The use of the aggregating active material particles makes it possible to increase the electrode density.

Owner:SEMICON ENERGY LAB CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com