Preparation method of microcrystalline glass applied to 5G communication mobile terminal

A technology for glass-ceramics and mobile terminals, which is applied in the field of glass-ceramics used in 5G communication mobile terminals, can solve problems such as use, poor color balance, and easy breakage, and achieves simple preparation of raw materials, improved mechanical properties, and stable processes. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A preparation of transparent glass-ceramics applied to 5G communication mobile terminals, comprising the following steps:

[0043] A. Preparation of raw materials

[0044] In parts by weight, prepare 50 parts of quartz sand, 20 parts of alumina, 15 parts of sodium carbonate, 5 parts of potassium nitrate, 6 parts of lithium carbonate, 15 parts of magnesium carbonate, 5 parts of zirconia, 6 parts of zinc oxide, and 4 parts of titanium oxide. 6 parts, 6 parts of ammonium dihydrogen phosphate, 1 part of antimony oxide, 1 part of yttrium oxide, mixed to obtain batching material;

[0045] B. Glass melting

[0046] Put the above batch materials into the melting furnace, melt at 1500°C, homogenize and clarify at high temperature, and melt the batch materials into a uniform and defect-free glass melt;

[0047] C. Glass forming

[0048] The above-mentioned glass melt goes through the forming process, flows into the tin bath through the runner, starts forming at 1250 ° C, and b...

Embodiment 2

[0057] A dark brown glass-ceramic applied to the back cover of a 5G communication mobile terminal, the preparation process is as follows:

[0058] A. Batch preparation

[0059] In parts by weight, take 50 parts of quartz sand, 20 parts of aluminum oxide, 18 parts of sodium carbonate, 5 parts of potassium nitrate, 6 parts of lithium carbonate, 15 parts of magnesium carbonate, 4 parts of titanium oxide, 1 part of antimony oxide, and 3 parts of iron oxide. Parts, accurately weigh the batch material, place it in the mixer, and enter the next process after mixing evenly;

[0060] B. Glass melting

[0061] Put the above-mentioned batch materials into the electric melting furnace, melt at 1650°C, homogenize and clarify at high temperature, and melt the batch materials into a uniform and defect-free melt;

[0062] C. Glass forming

[0063] The melted glass flows into the tin bath through the flow channel, and begins to form at 1250°C, and becomes a 1.2mm thick glass original sheet ...

Embodiment 3

[0072] A method for preparing a transparent glass-ceramic for a front cover applied to a 5G communication mobile terminal, comprising the following steps:

[0073] A. Preparation of raw materials: by weight, prepare 48.2 parts of quartz sand, 20.6 parts of alumina, 26.7 parts of sodium carbonate, 2.3 parts of potassium nitrate, 7.4 parts of lithium carbonate, 15 parts of magnesium carbonate, 2 parts of zirconia, rubidium oxide 1 part, 3 parts of ammonium dihydrogen phosphate, 1 part of antimony oxide, mixed to obtain batch materials;

[0074] B. Glass melting: Put the above batch materials into the melting furnace, melt them at 1600°C, homogenize and clarify at high temperature, and melt the batch materials into glass melt;

[0075] C. Glass forming: the above-mentioned glass melt is passed through the float forming process, and the above-mentioned glass melt is cooled to 1250°C-1200°C and flowed into a tin bath for forming, and it is flattened and polished at 1193-1127°C. Ul...

PUM

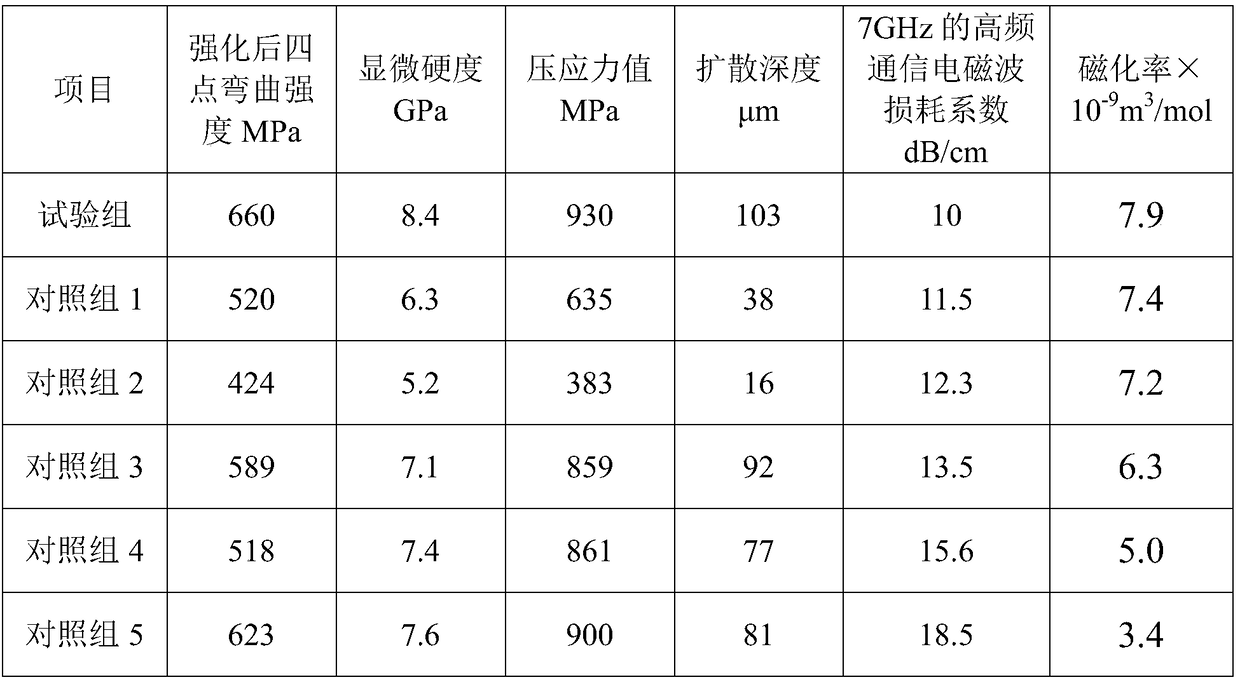

| Property | Measurement | Unit |

|---|---|---|

| magnetic susceptibility | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com