Patents

Literature

40results about How to "Reduce loss factor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

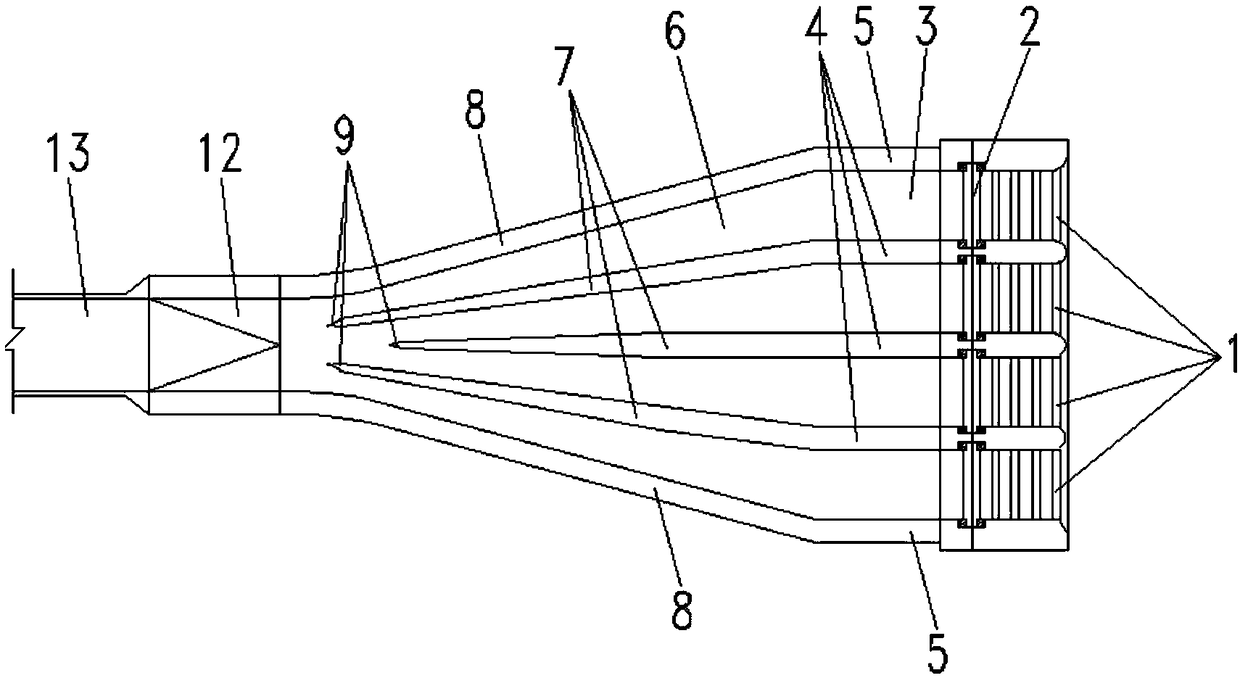

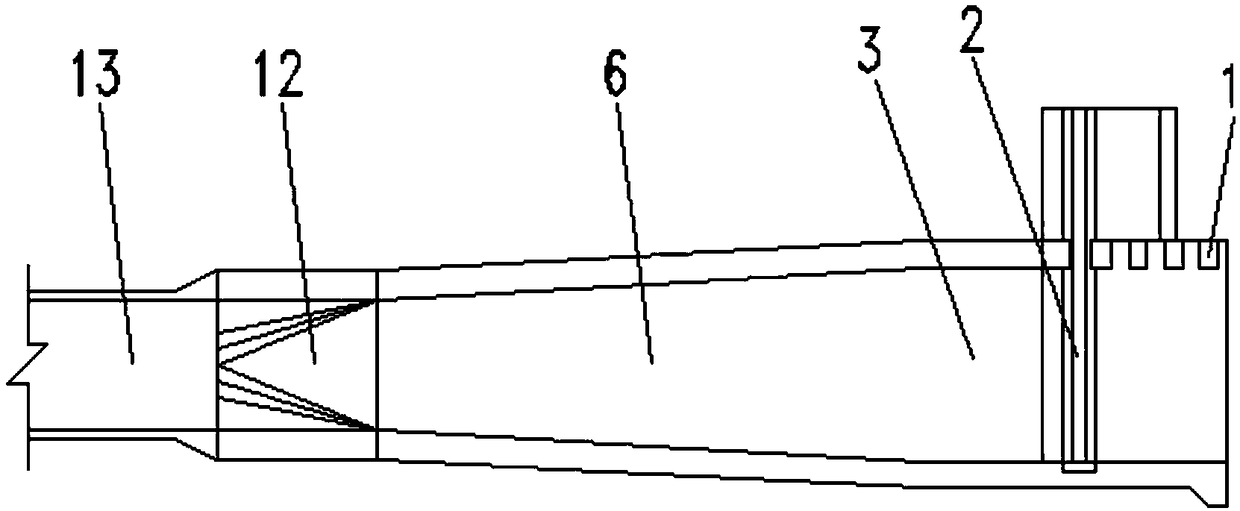

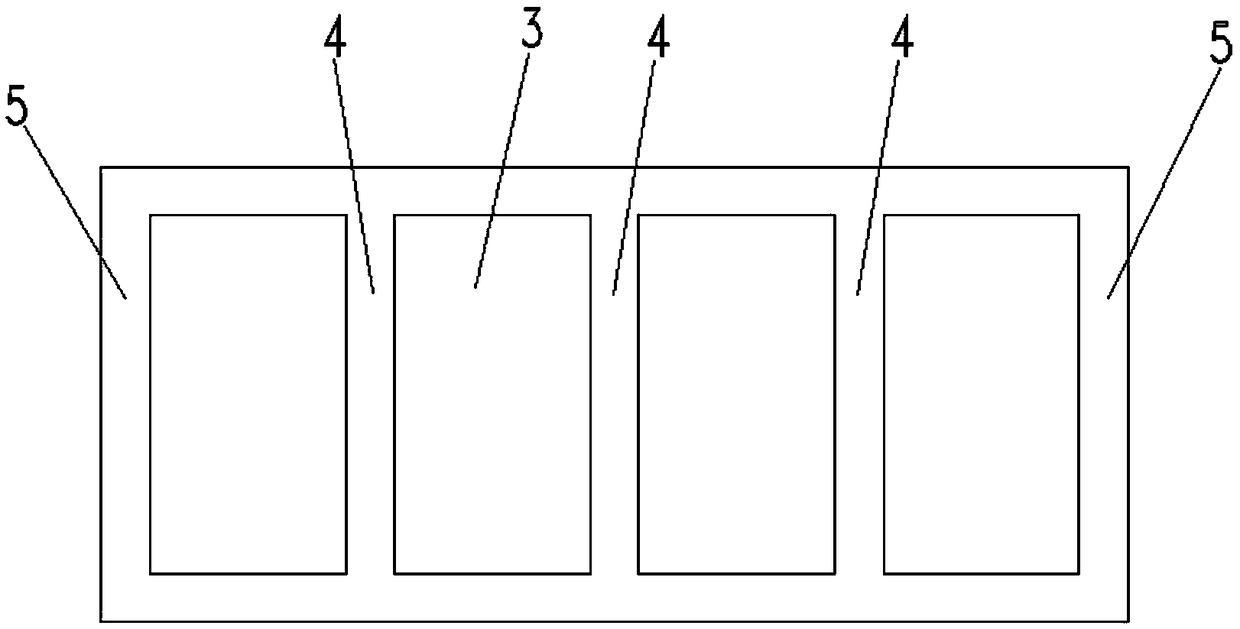

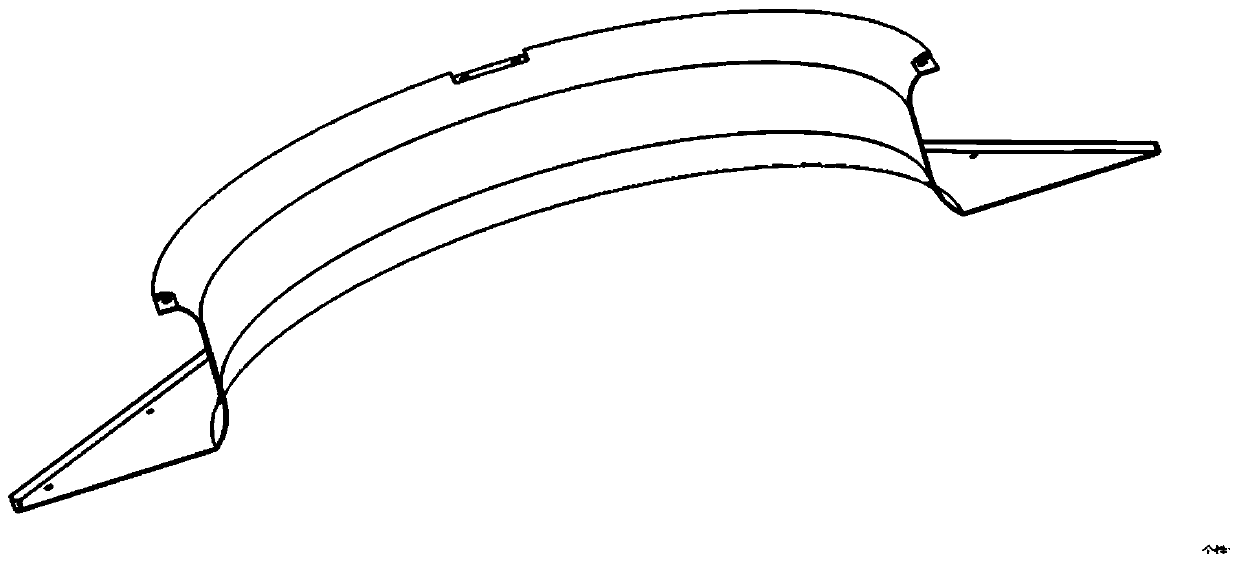

Turbine rotor blade of gas turbine

ActiveCN102102544AReduce loss factorExpected Cooling Distribution EffectBlade accessoriesMachines/enginesEdge regionGas turbines

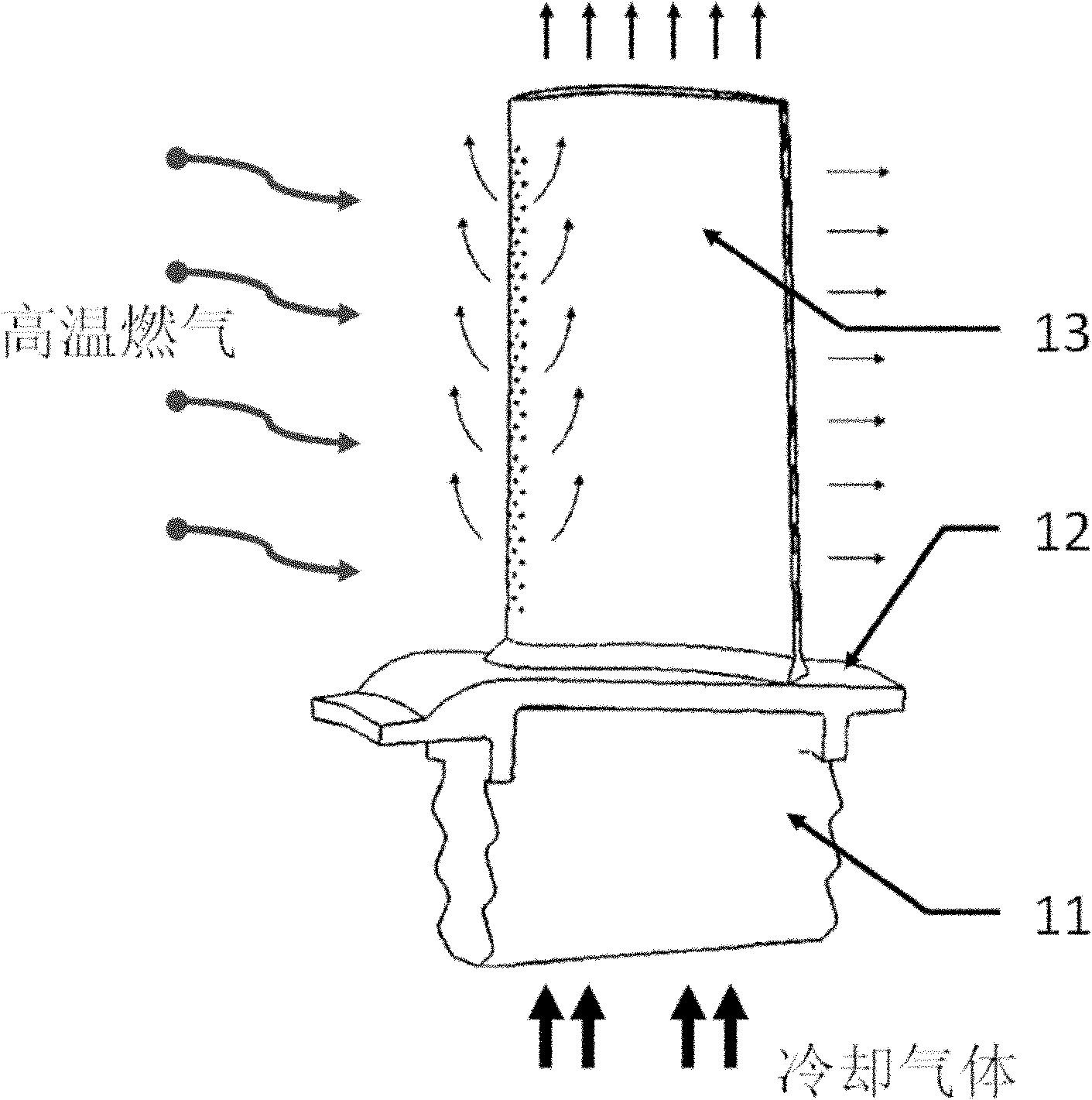

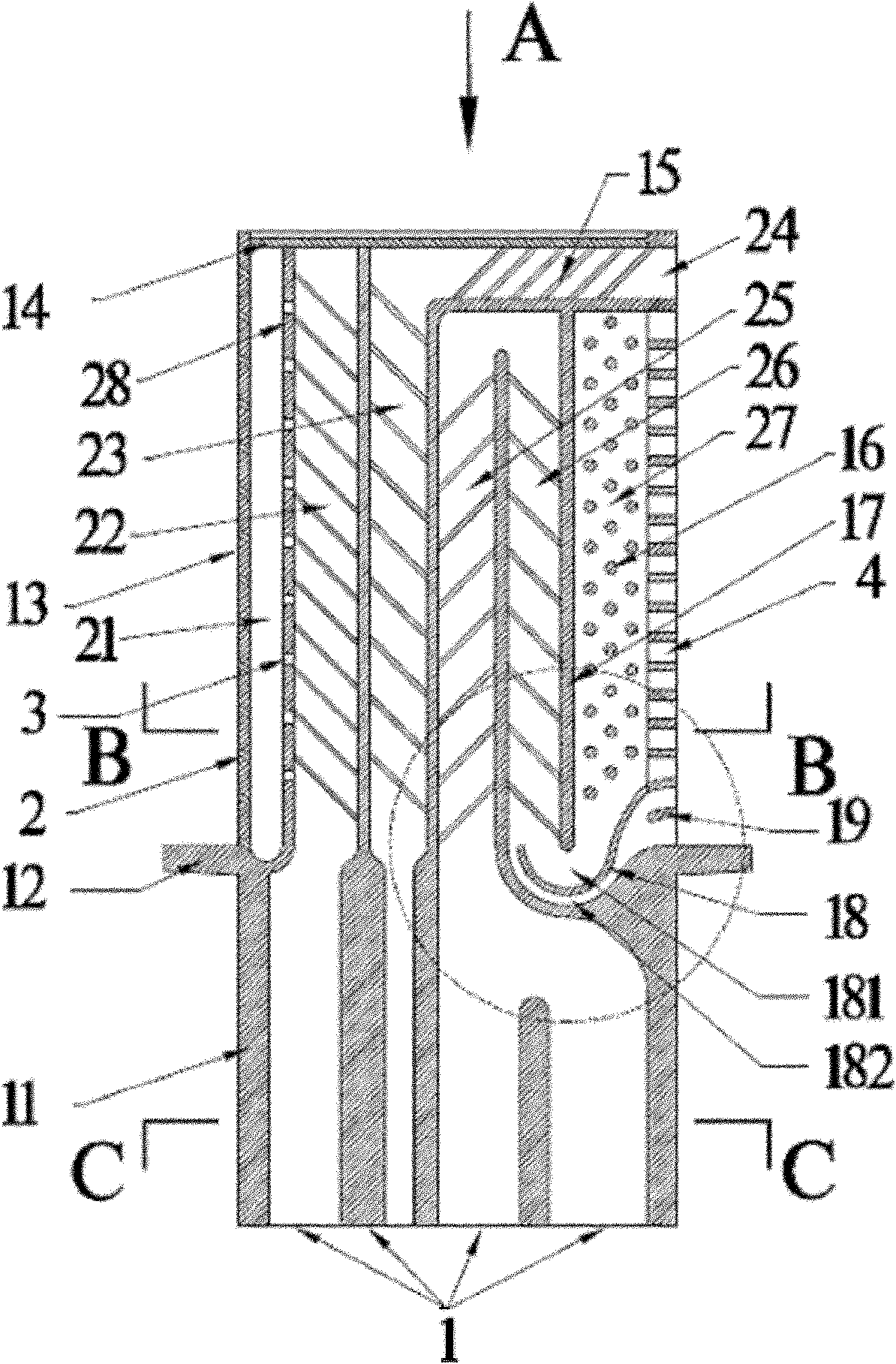

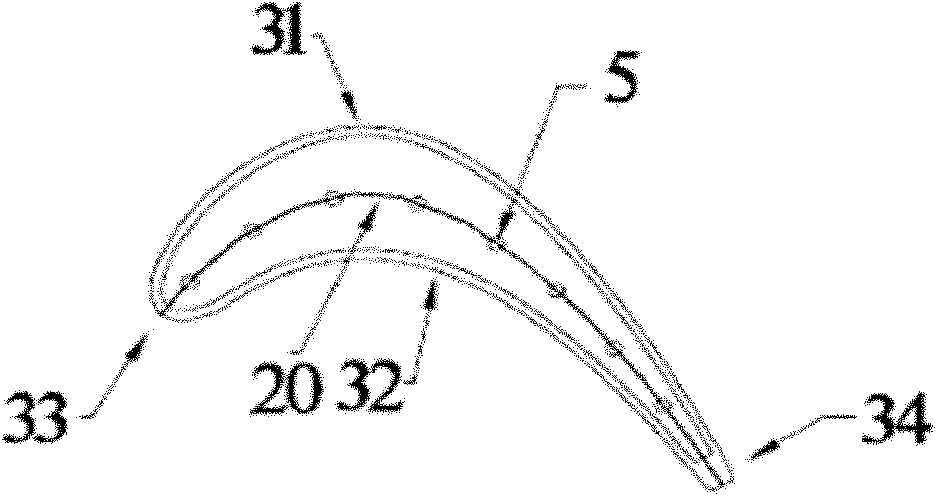

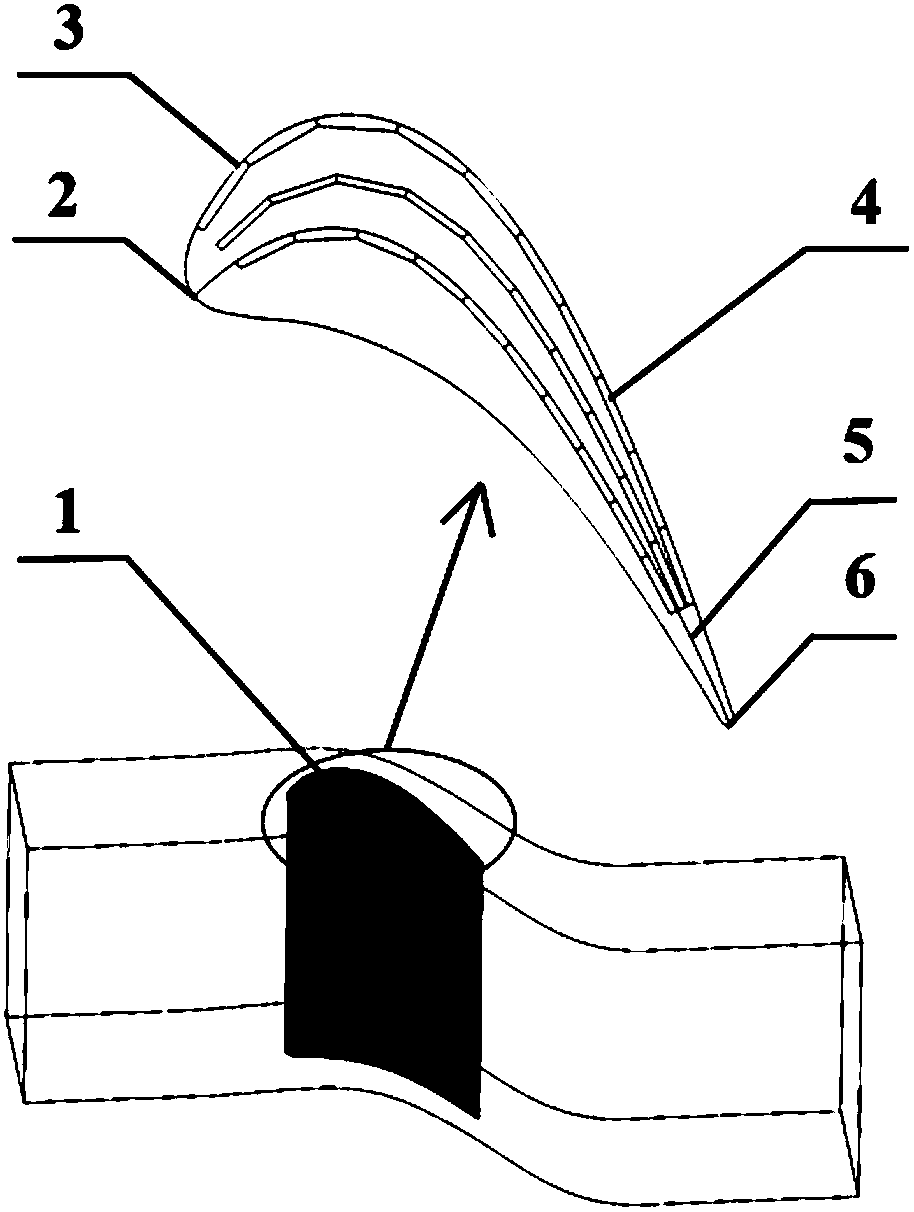

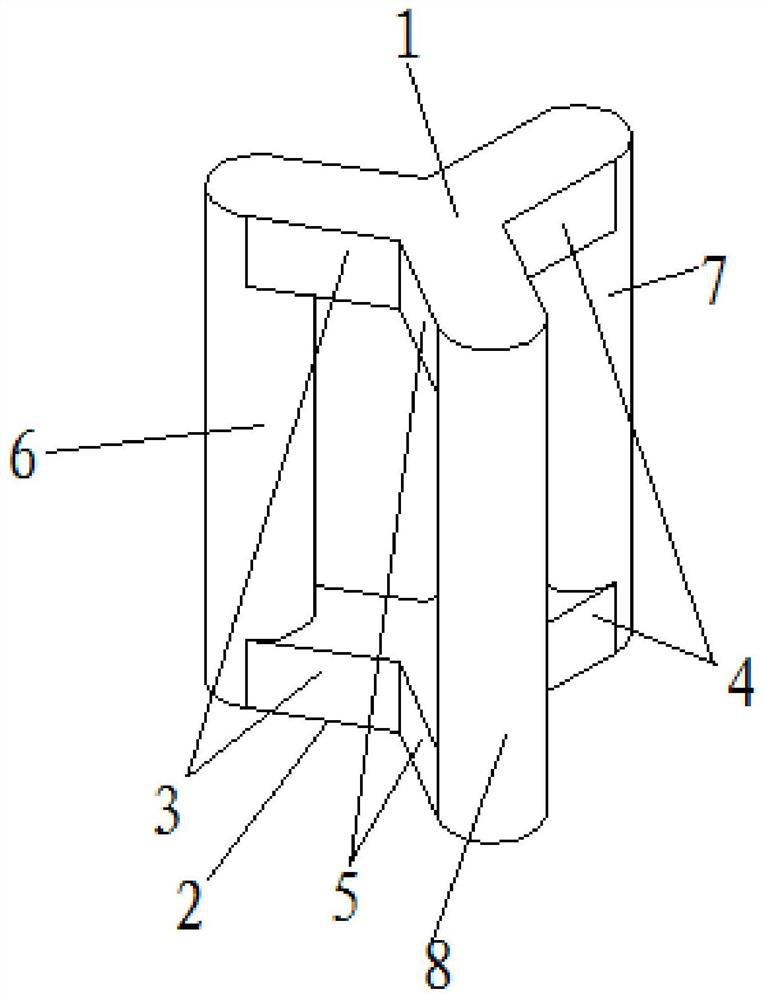

The invention discloses a turbine rotor blade of a gas turbine. The turbine rotor blade comprises a blade root, a blade platform and a blade profile, wherein a cooling structure of a snakelike passage is adopted in the blade, and comprises three cooling loops for circulating cooling gas, namely an impingement cooling loop for cooling a front edge region of the blade, a strengthening convection cooling loop for cooling a top region of the blade and a column rib and jet cooling loop for cooling a tailing edge region of the blade. For the cooling gas flowing to the tailing edge of the blade, at least one flow guide sheet structure is added at an elbow region close to the tailing edge of the blade and the blade root, so that sufficient cooling gas is distributed for cooling the root of the tailing edge of the blade. Thus, the temperature of the root of the tailing edge of the blade is reduced.

Owner:BEIJING HUAQING GAS TURBINE & INTEGRATED GASIFICATION COMBINED CYCLE ENG TECH

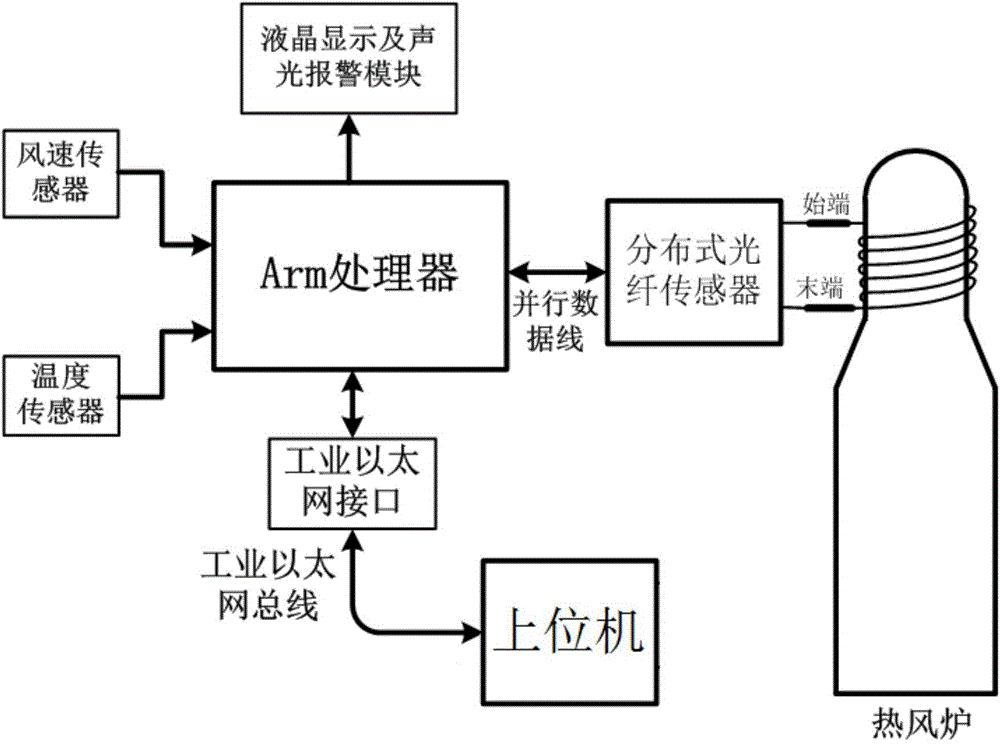

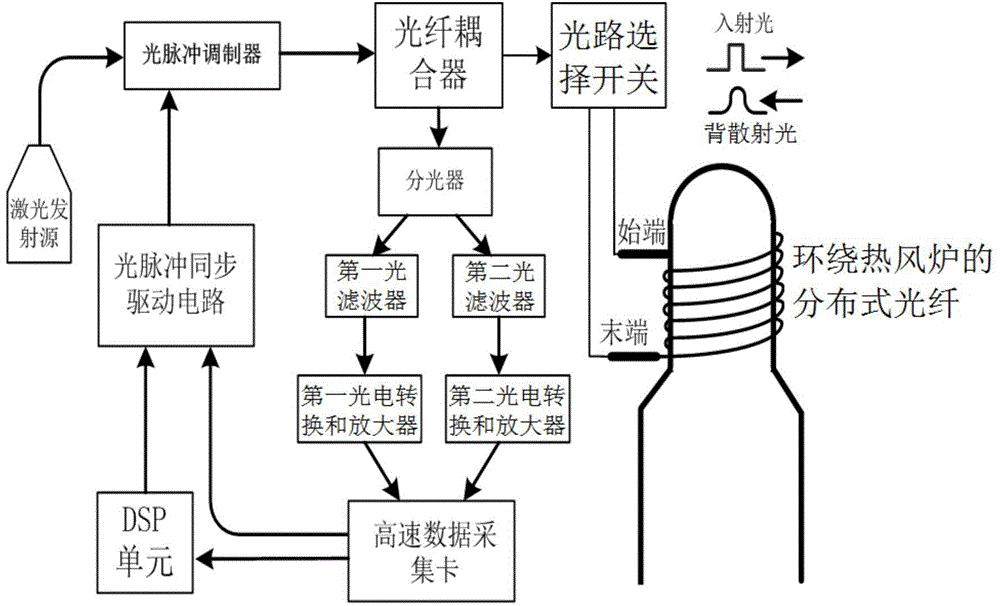

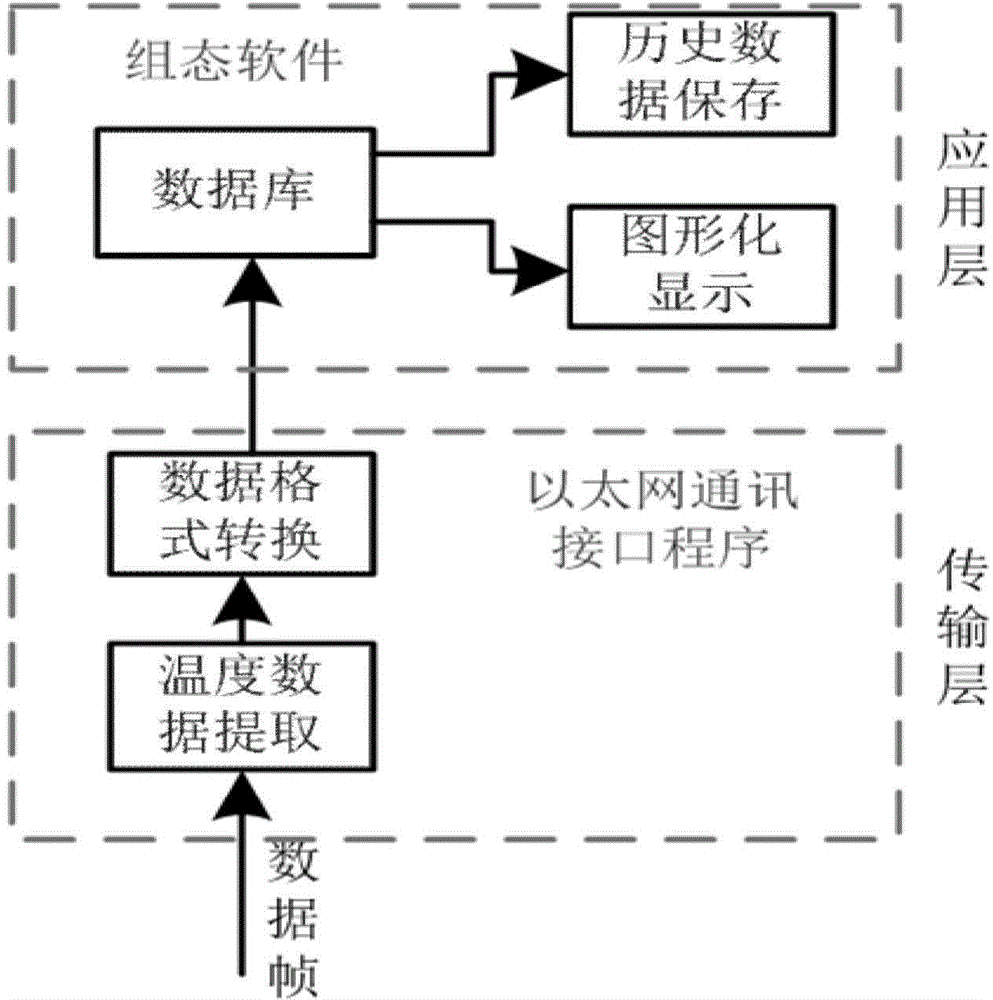

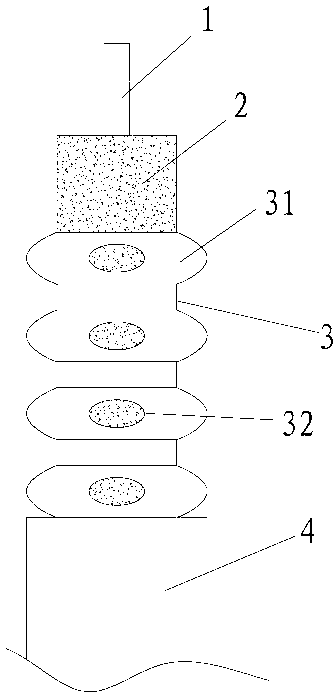

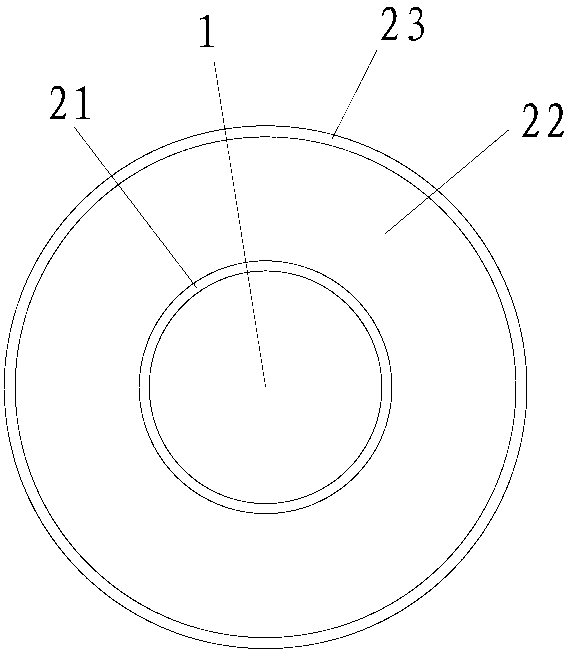

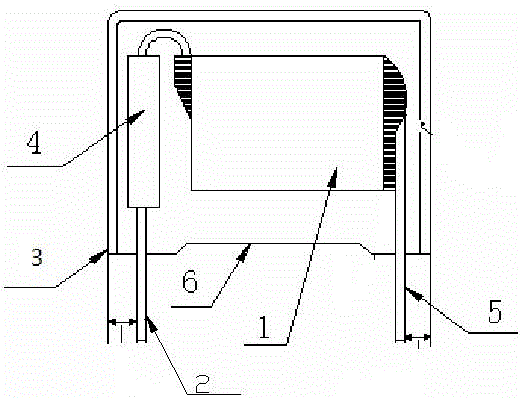

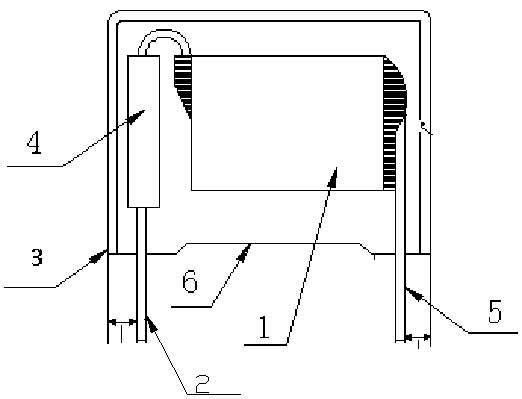

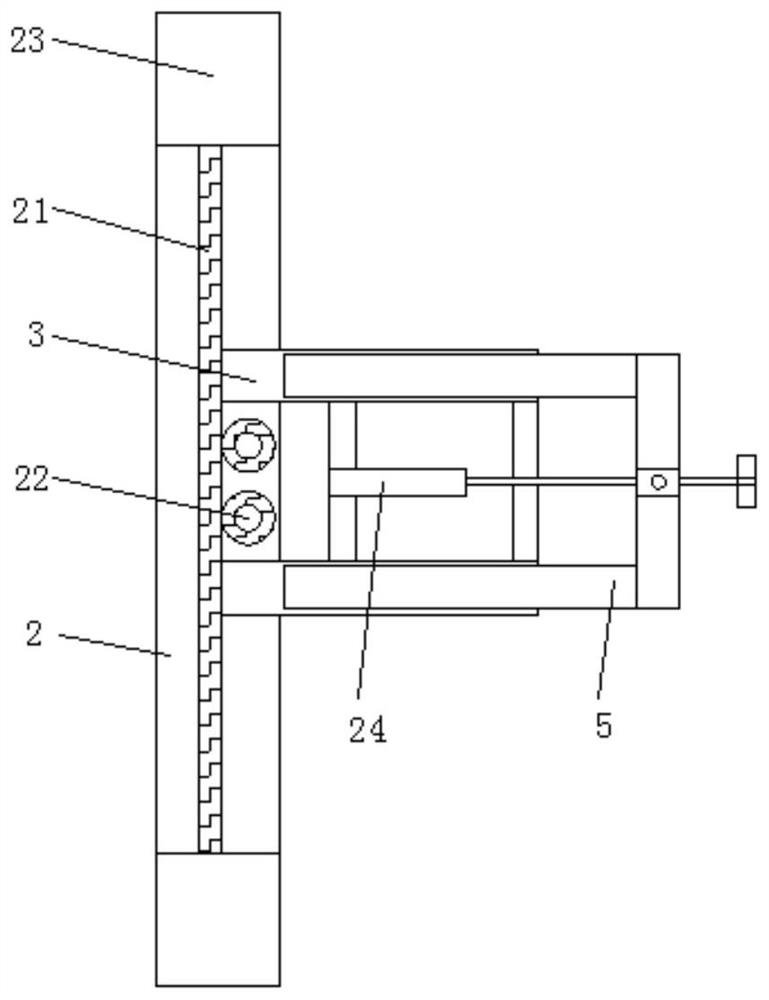

Distributed optical fiber-based blast furnace hot blast stove temperature monitoring system and method

ActiveCN104697665AImprove insulation performancePrecise positioningThermometers using physical/chemical changesProduction rateIndustrial Ethernet

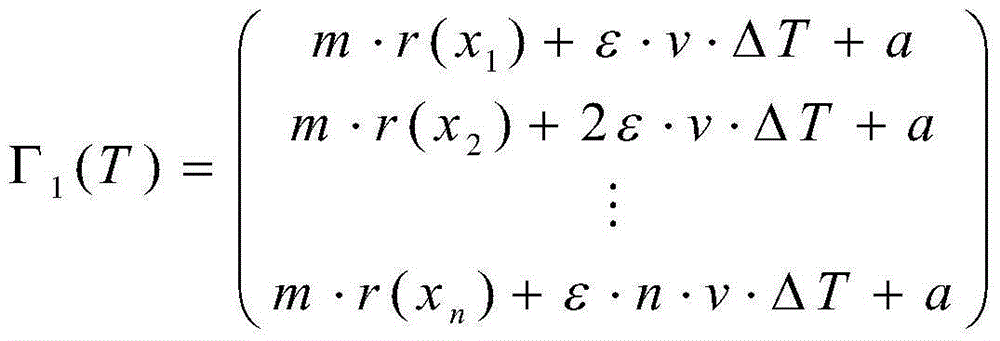

The invention discloses a distributed optical fiber-based blast furnace hot blast stove temperature monitoring system and method and belongs to the technical field of hot blast stove temperature detection. According to the distributed optical fiber-based blast furnace hot blast stove temperature monitoring system and method, a distributed optical fiber transversely winds the top part of a hot blast stove, both the starting end and end of the distributed optical fiber are connected with a distributed optical fiber sensor, the distributed optical fiber sensor is connected with an ARM processor, the distributed optical fiber sensor receives back scattering signals generated by the optical fiber, a novel temperature signal demodulation method is used, the temperature value of each measuring point on the optical fiber is extracted through a double-end single-way demodulation method, and the temperature value of each measuring point is sent to the ARM processor; the ARM processor is connected with an upper computer through an industrial Ethernet interface. According to the distributed optical fiber-based blast furnace hot blast stove temperature monitoring system and method, the surface temperature of the hot blast stove is performed with multi-point measurement through the distributed optical fiber, because the optical fiber directly and firmly contacts with a hot blast stove shell, the temperature measurement result is capable of reflecting the real temperature of the hot blast stove body; the distributed optical fiber-based blast furnace hot blast stove temperature monitoring system and method are convenient for early forecasting the stove shell damage situation and good for improving the service life of the hot blast stove, lowering the coke ratio and improving the blast furnace production rate.

Owner:马鞍山博新高科产业服务有限公司

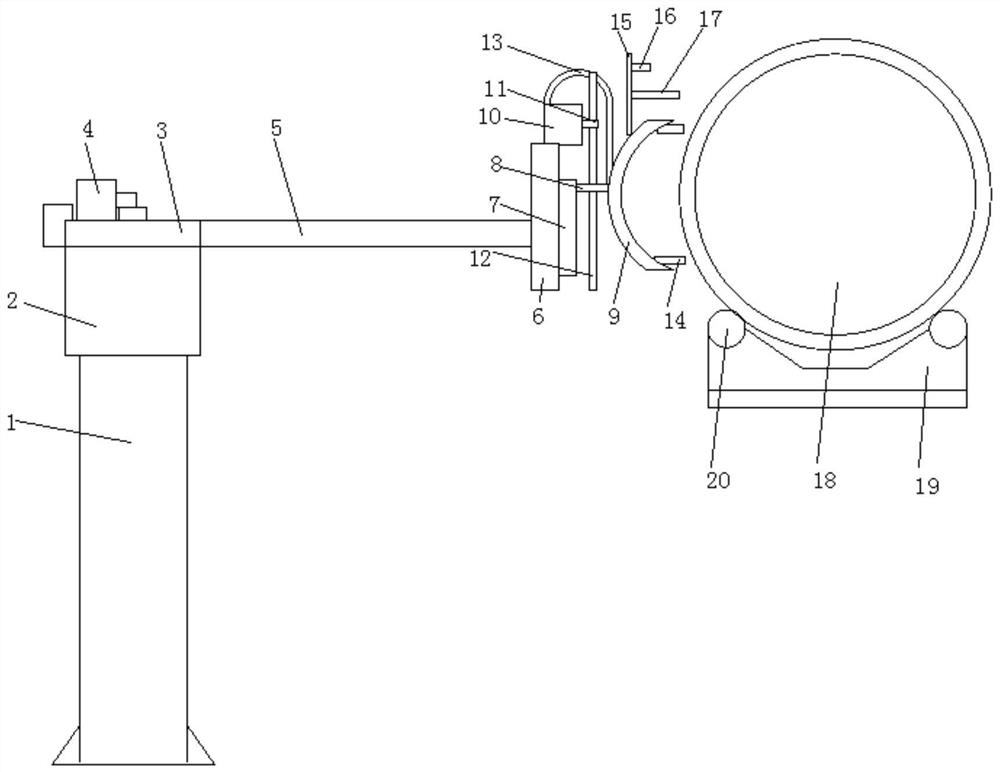

Special spraying device for wind-power tower

InactiveCN101637753AReduce wasteReduce loss factorLiquid surface applicatorsCoatingsFillet weldElectricity

The invention relates to a special spraying device for a wind-power tower, belonging to special spraying devices. The invention avoids the defects of nonuniform thickness, missing spraying, sagging, pinhole formation, wrinkle, serious paint waste, and the like of a tower spraying paint film, and is characterized in that according to pattern requests, a positioning fixed disk is arranged on a platform to be leveled and then is fixedly welded by the welding mode of manual butt joint, a central point is found out so as to line out positioning lines of a roller and a positioning fixed hole and todrill out the positioning fixed hole, the roller is coiled, longitudinal seams of the roller are welded by the mode of automatic welding, and circle checking is carried out until meeting the qualification; according to the pattern requests, the roller and a rib plate are positioned and are fixed by spot welding on the positioning fixed disk, and meanwhile, symmetrical manual fillet welds are welded on the positioning fixed disk so as to prevent welding deformation; and according to patterns, a positioning retainer ring is welded, and finally the integral production of the spraying device is accomplished. The invention used for spraying has the advantages of smooth surface of paint and no defects of sagging, pinhole formation, wrinkle, and the like, and greatly improves the spraying quality.

Owner:山东安得利斯风电技术装备有限公司

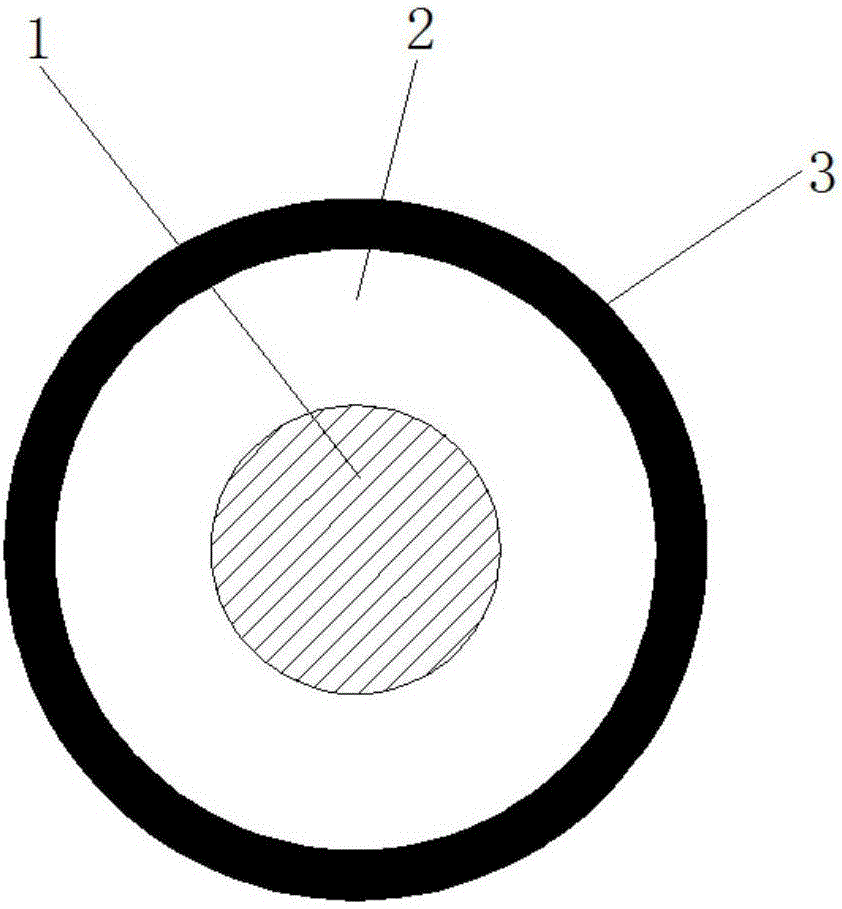

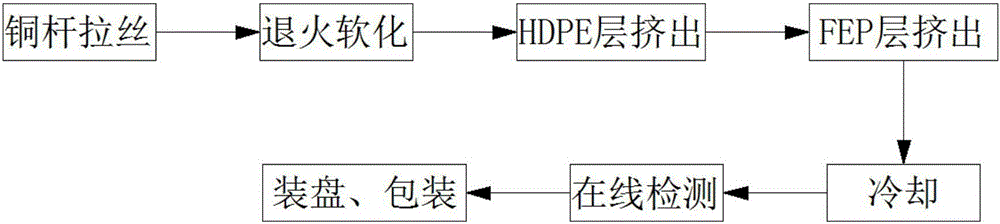

Insulated core wire, high-fire-retardant data cable and processing craft thereof

InactiveCN106782860AHigh temperature resistanceCan stop the spreadPlastic/resin/waxes insulatorsClimate change adaptationElectrical conductorInsulation layer

The invention provides an insulated core wire, a high-fire-retardant data cable and the processing craft thereof, particularly relates to the technical field of the cables and cords. The insulated core wire comprises a conductor wherein the periphery of the conductor covers an inner insulation layer and an outer insulation layer in turn along the radial direction. The inner insulation layer is the HDPE insulation layer and the outer insulation layer is the FEP insulation layer, which solves the technical problem of the low of the insulated core wire temperature grade and flame retardant grade in the prior art and is capable of greatly improving the temperature grade and flame retardant grade of the cables. And the data cable owns the technical effects of higher security transfer property and fireproof performance.

Owner:JIANGSU HENGTONG WIRE & CABLE TECH

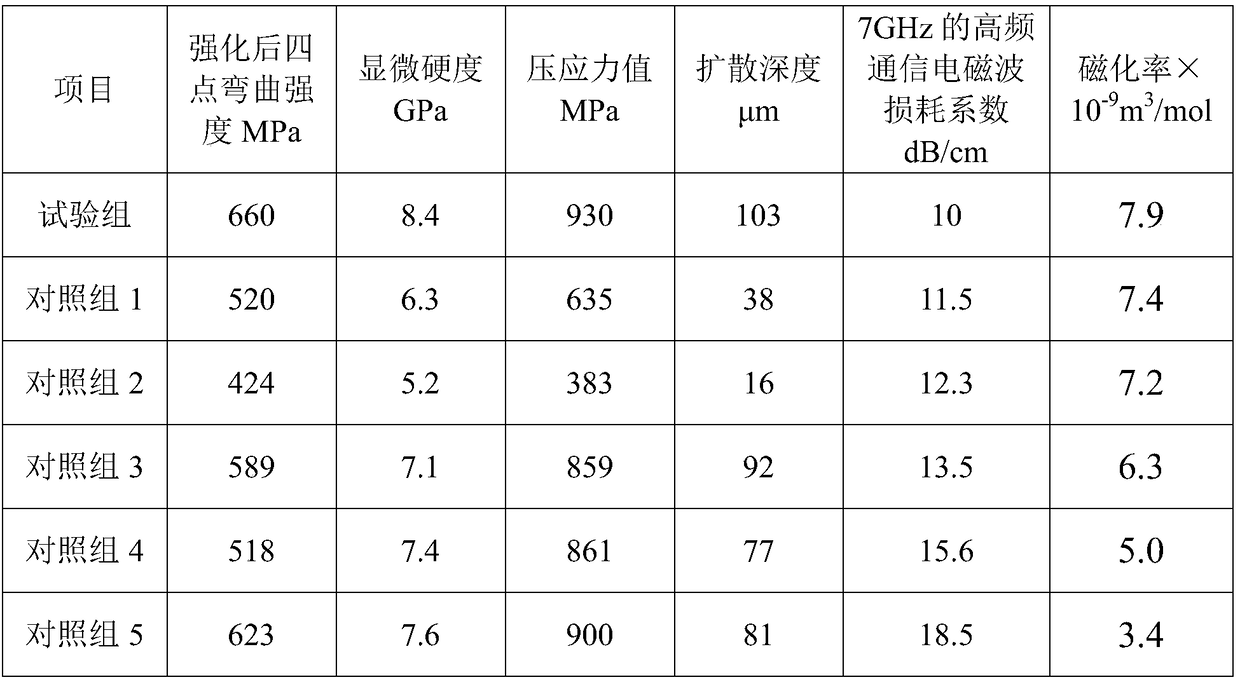

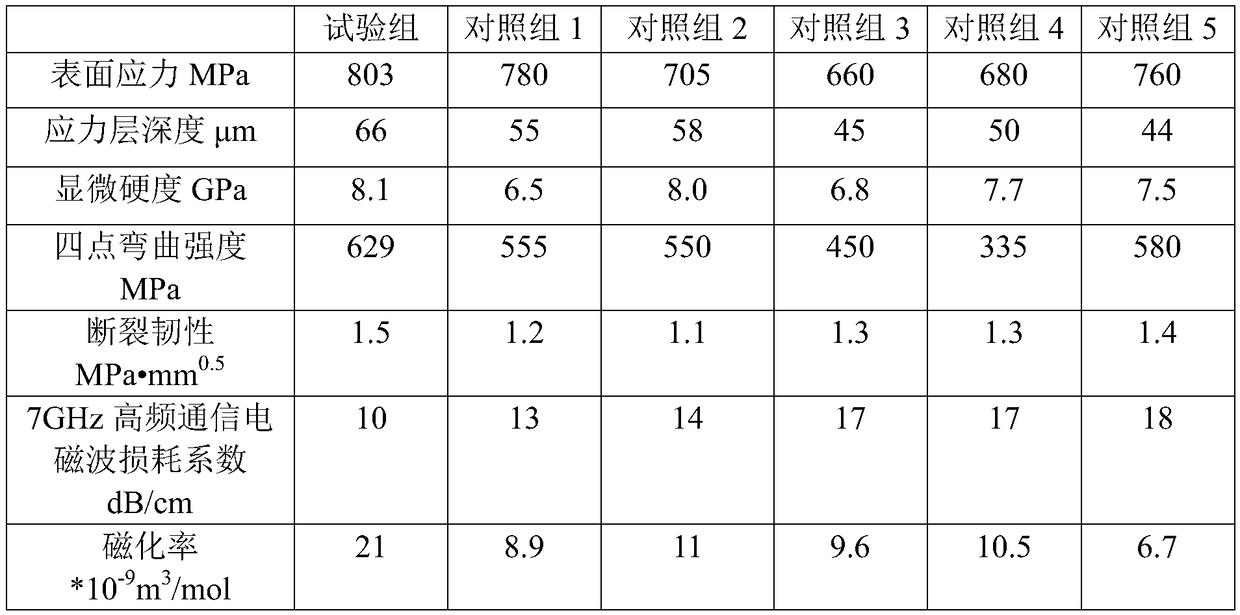

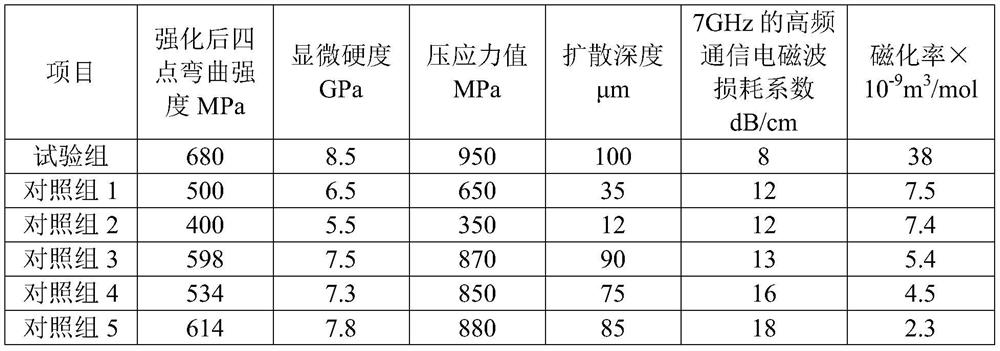

Preparation method of microcrystalline glass applied to 5G communication mobile terminal

The invention provides a preparation method of a microcrystalline glass applied to a 5G communication mobile terminal, and belongs to the technical field of microcrystalline glass. The preparation method comprises following steps: step A, preparing following raw materials in parts by weight: 45 to 75 parts of quartz sand, 10 to 25 parts of aluminum oxide, 14.5 to 39.6 parts of sodium carbonate, 2.3 to 9.2 parts of potassium nitrate, 0 to 12.5 parts of lithium carbonate, 0 to 41 parts of magnesium carbonate, 0 to 8 parts of titanium oxide, 0 to 20 parts of zirconium oxide, 0 to 10 parts of zincoxide, 0 to 3 parts of rubidium oxide, 0 to 5 parts of gallium oxide, 0 to 3 parts of europium oxide, 0 to 9 parts of ammonium dihydrogen phosphate, 0 to 3 parts of antimony oxide, 0 to 3 parts of yttrium oxide, 0 to 3 parts of cerium oxide, 0 to 5 parts of iron oxide, 0 to 2 parts of manganese oxide, 0 to 3 parts of nickel oxide, and mixing all raw materials to obtain a mixture; step B, meltingthe mixture; step C, moulding the melt; and step D, carrying out annealing, nucleation, and crystallization to obtain the microcrystalline glass. By controlling the raw materials and technology, the obtained front cover microcrystalline glass has high transmittance of visible light, high strength, and high hardness, and the obtained rear cover microcrystalline glass has high strength and low magnetic loss.

Owner:GLASS TECH RES INST OF SHAHE CITY OF HEBEI PROVINCE

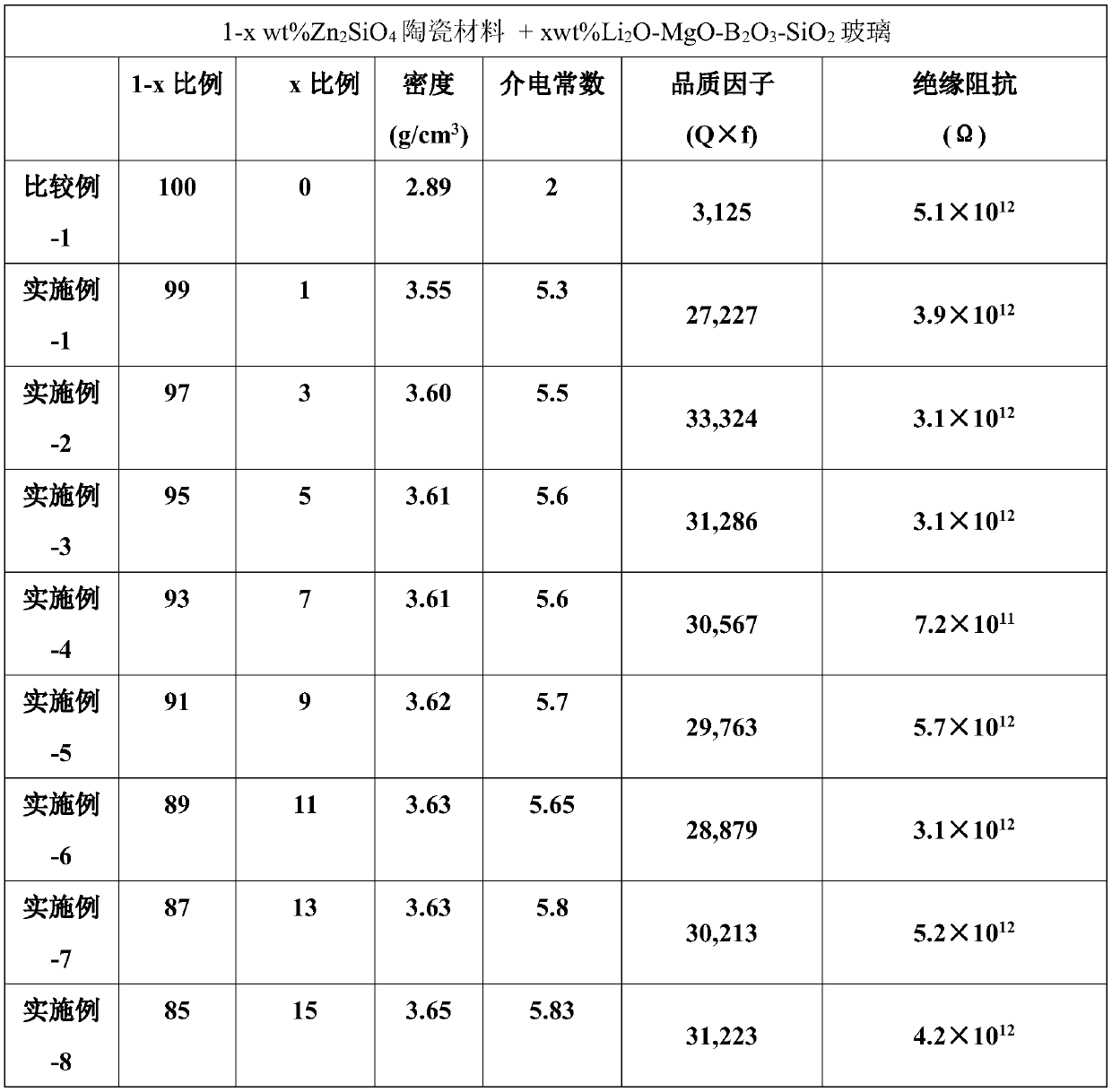

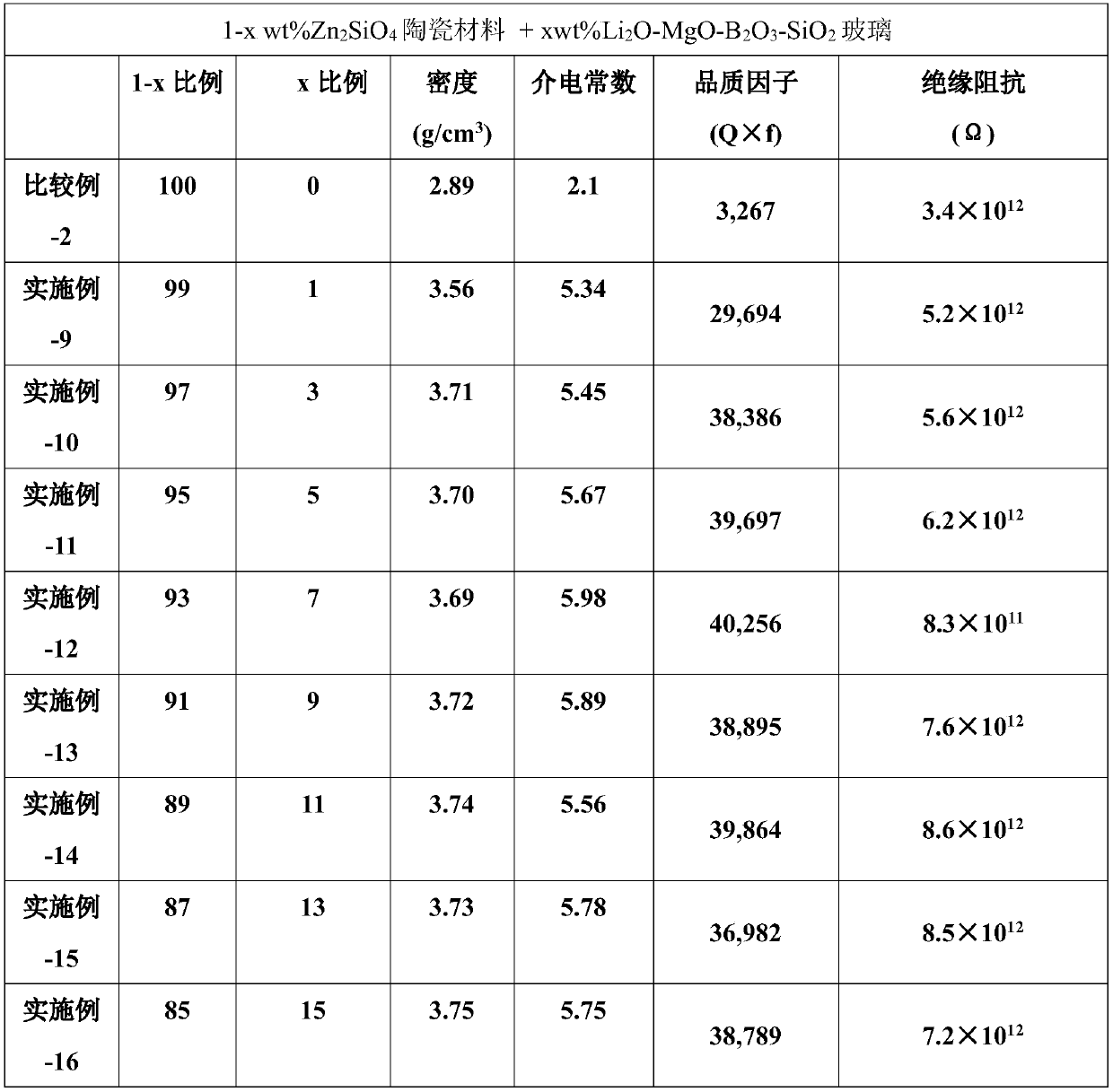

Low-temperature co-sintered ceramic microwave and millimeter wave material

The invention discloses a low-temperature co-sintered ceramic microwave and millimeter wave material. Mainly, a Zn2SiO4 ceramic material is mixed with Li2O-MgO-B2O3-SiO2 glass; mainly, by adding the glass to the ceramic, the glass additional amount is smaller than or equal to 15 wt% after the glass is added to the ceramic; if the glass additional amount is too high, the glass can absorb microwaveenergy, loss is increased, and quality factors are reduced; thus, the content of the glass in the material is smaller than or equal to 15 wt%, a low content of glass is added, and therefore the material still can have the characteristics of low dielectric constant and high quality factor after being sintered at the low temperature of 900 DEG C.

Owner:SYNERGY TECH

Preparation of nematic liquid crystal film and recording method of high resolved transient grating thereof

InactiveCN101299104AReduce loss factorAdjustable lifeStatic indicating devicesNon-linear opticsOptical radiationInformation transmission

The present invention provides a preparation of a nematic liquid crystal device and a recording method of the high-resolution transient raster thereof. The nematic liquid crystal device is a nematic liquid crystal box which is prepared while uses the poly(N-vinylcarbazole) photoconduction polymer film as an oriented layer. The space-modulated optical radiation can form a high-resolution space charge field in the photoconduction polymer film. The field can traverse to the nematic liquid crystal film for driving the liquid crystal module for reorient and establish a high-resolution refraction ratio raster. The liquid crystal film can record the transient raster which has a peak value of efficiency of single order diffraction for -20% and a lifetime attenuating according to the e exponential relationship along with the increasing of the impressed voltage. The nematic liquid crystal device which can record the transient rater which has characteristics of adjustable lifetime and same intensity of peak value has latent application value in the fields of optical information procession, optical information transmission and the like.

Owner:HARBIN INST OF TECH

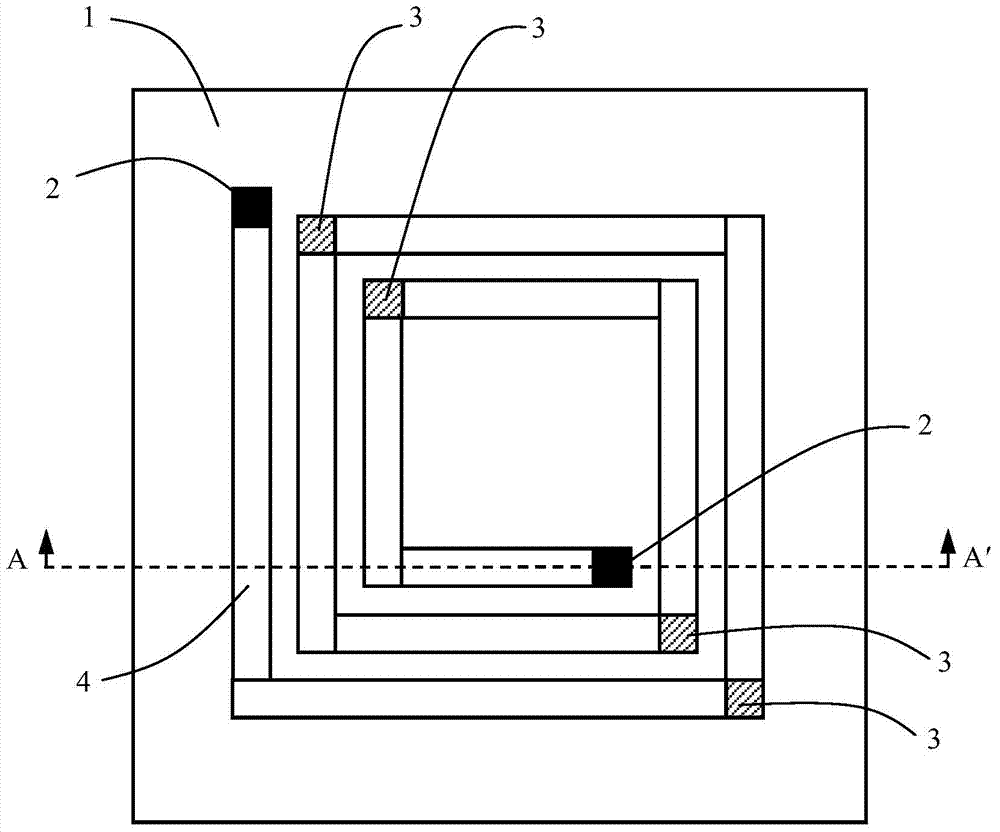

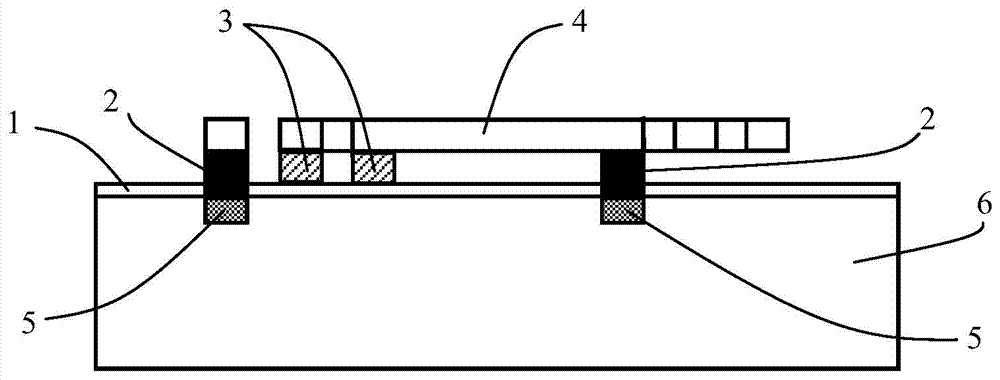

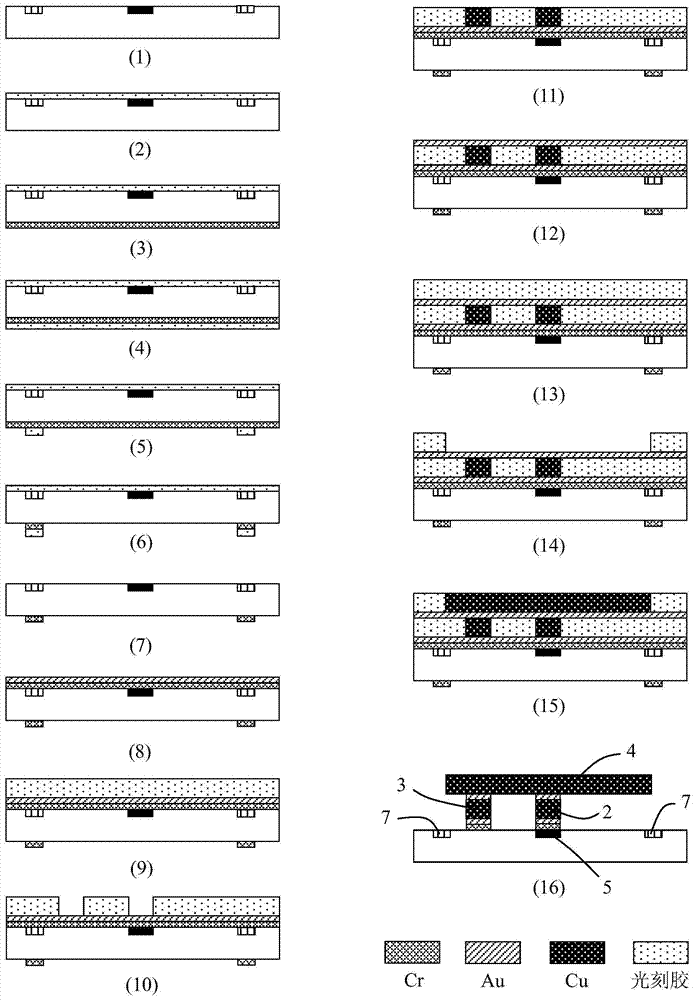

Anti-overload non-silicon MEMS thick metal suspended micro inductor

InactiveCN103928439AReduce loss factorGood RF performanceSemiconductor/solid-state device detailsSolid-state devicesRadio frequencySpiral coil

The invention discloses an anti-overload non-silicon MEMS thick metal suspended micro inductor. The suspension height of the MEMS suspended micro inductor is 20 microns, the thickness of a metal layer of a suspended metal spiral coil is 20 microns, and a supporting column arranged on the diagonal portion of the coil is additionally arranged between the suspended metal spiral coil and a substrate to improve the anti-overload capacity of the coil. The manufacturing process includes the steps that the substrate is cleaned and processed; the front side of the substrate is glued, Cr is applied to the back side of the substrate in a sputtering mode, the back side of the substrate is subjected to gluing, exposure, developing and corrosion, and an overlay alignment mark is manufactured; glue removing, sputtering, gluing, exposure, developing and Cu electroforming are carried out; sputtering, gluing, photoetching, developing and Cu electroforming are carried out; photoresists and seed layers are removed. The MEMS suspended micro inductor has excellent radio frequency performance and strong anti-overload capacity, polishing is not needed in the technical process, the technical process is simple, and the rate of finished products is high.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

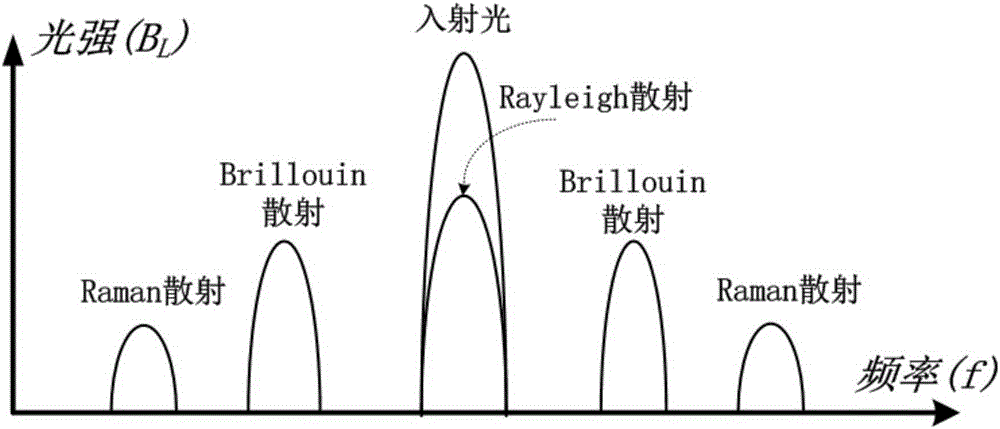

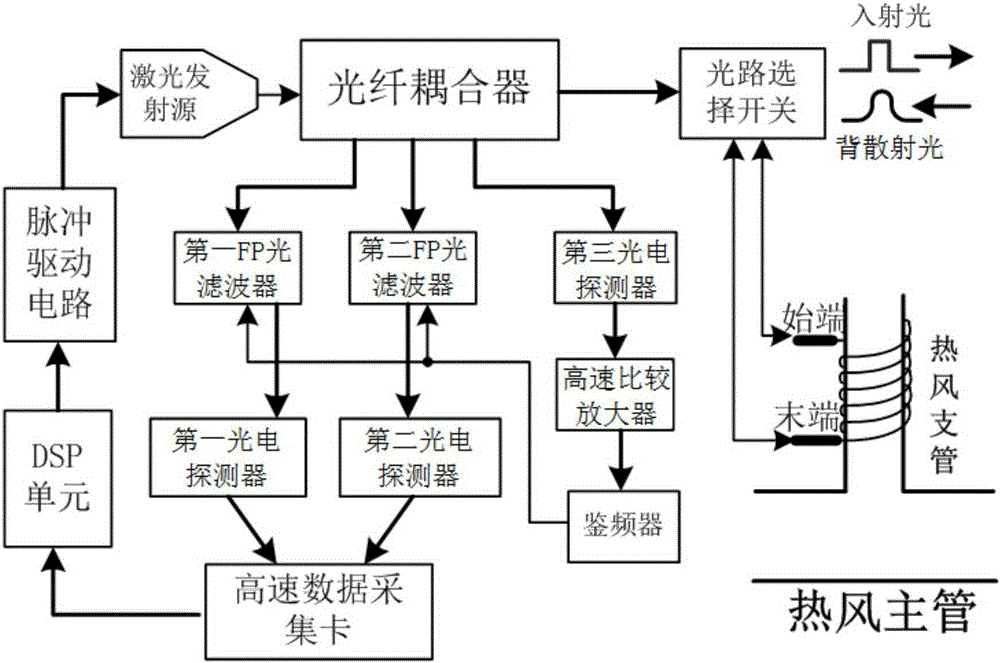

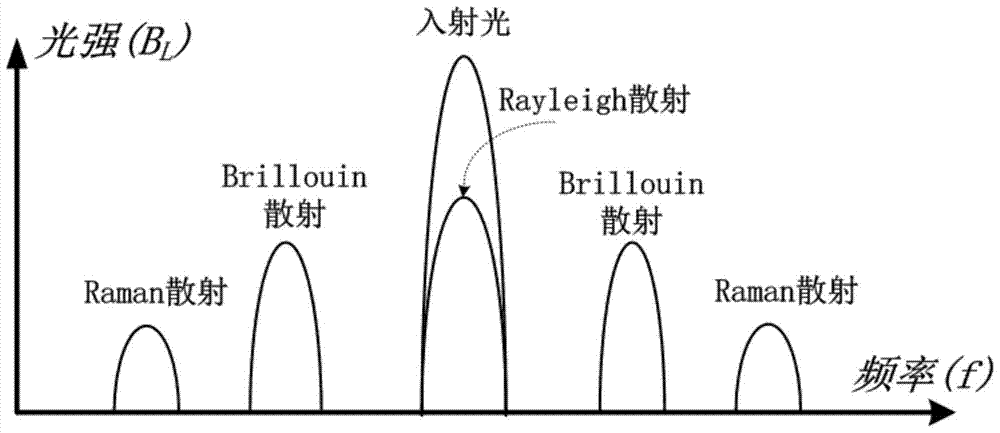

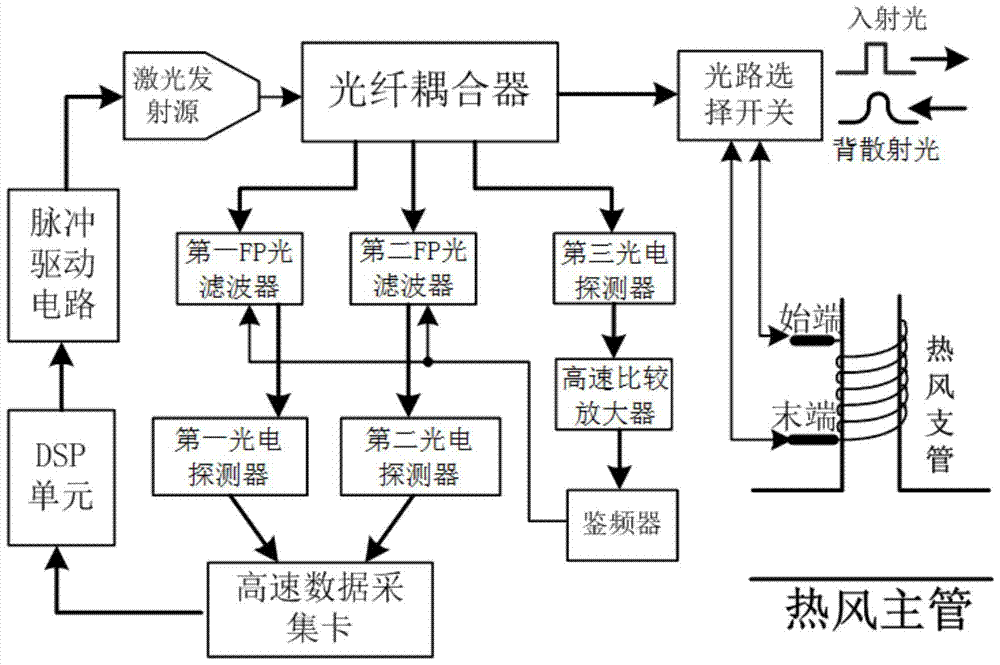

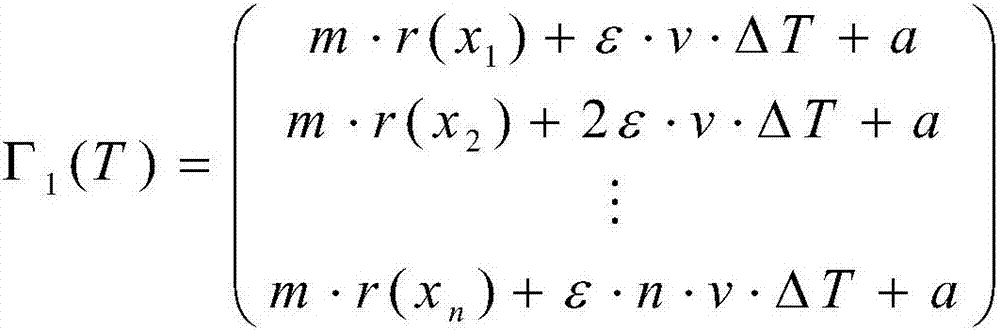

System and method for detecting temperature of hot air pipe based on distributed optical fiber

ActiveCN105181171AReduce maintenance costsReduce the number of wind breaksThermometers using physical/chemical changesChecking devicesProduction rateMeasurement point

The invention discloses a system and a method for detecting the temperature of a hot air pipe based on a distributed optical fiber, and belongs to the technical field of blast furnace hot air pipe temperature detection. The system comprises a distributed optical fiber sensor and a distributed optical fiber, and is characterized in that the distributed optical fiber is wound on the hot air pipe; the distributed optical fiber sensor receives backscattering signals generated by the distributed optical fiber, and center frequency compensation is carried out on a light source given out by a laser emission source through a Rayleigh frequency tracking method; and meanwhile, demodulation is carried out on the received signals through a double-end single-way demodulation method, a temperature value of each measurement point on the distributed optical fiber is extracted, and the extracted temperature values are transmitted to a processor so as to carry out compensation and correction on temperature data. According to the invention, multi-point measurement is carried out on the surface temperature of the hot air pipe through the distributed optical fiber wound at the surface of the hot air pipe, center frequency drift of the light source is compensated by adopting the Rayleigh frequency tracking method, and a temperature measurement result can truly reflect the surface temperature of the hot air pipe, thereby being conducive to prolonging the service life of the hot air pipe, improving the productivity of the blast furnace, and preventing the hot air pipe of the blast furnace from being burnt through.

Owner:马鞍山市安工大智能装备技术研究院有限公司

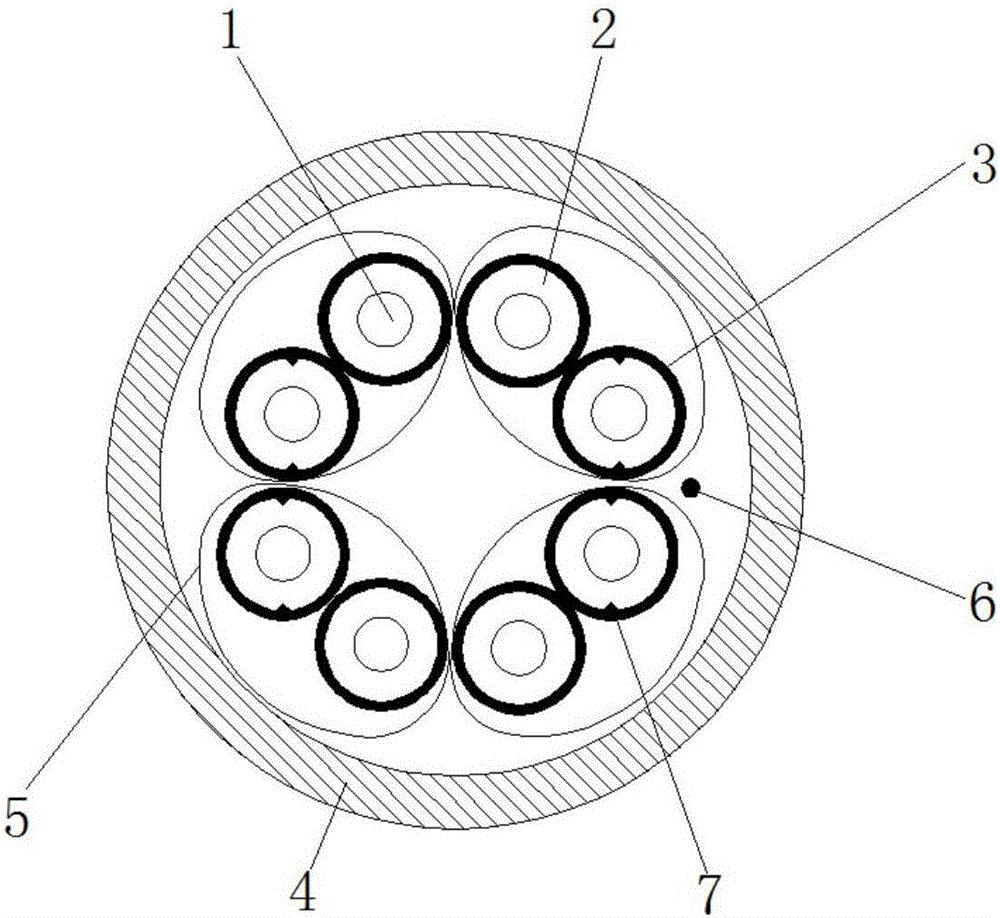

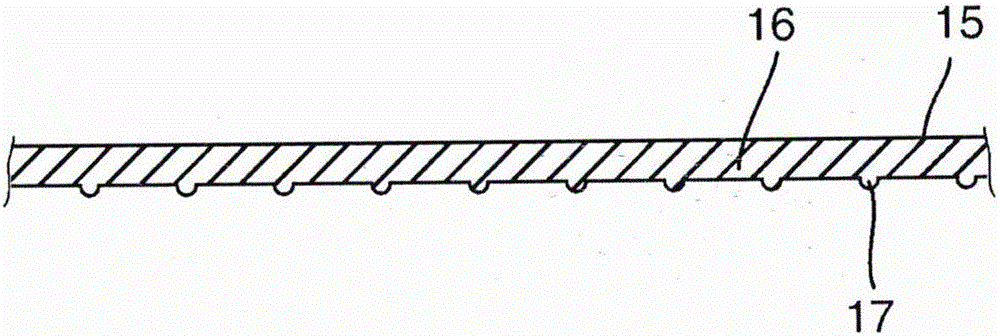

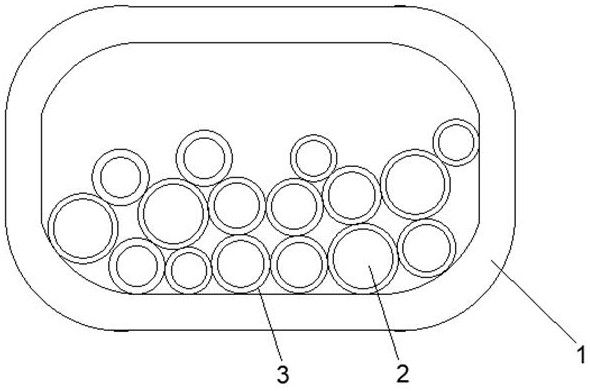

Coupled leakage cable

InactiveCN103022610AReduce loss factorGood electrical performanceWaveguidesLeaky-waveguide antennasElectrical conductor

The invention relates to the cable technology, in particular to a coupled leakage cable. The technical scheme includes that the coupled leakage cable comprises an inner conductor, an insulating layer coated outside the inner conductor, an outer conductor coated outside the insulating layer and a sheath coated outside the outer conductor, the outer conductor is provided with multiple smooth and parallel-distributed annular protrusions which enable the outer conductor to be winkled, each annular protrusion is provided with a smooth hole, and the insulating layer comprises an inner thin layer coated on the inner conductor, a foaming layer coated on the inner thin layer and an outer thin layer coated on the foaming layer. The coupled leakage cable has good electric performance.

Owner:ZHEJIANG DETONG TECH

Long-life polyester material for capacitor film

InactiveCN106496965AGood stretch resistanceImprove high temperature resistancePolyesterGlycidyl methacrylate

Owner:ANHUI FEIDA ELECTRICAL TECH CO LTD

Glass ceramic applied to rear cover of mobile terminal for 5G communication and reinforced glass ceramic

The invention discloses glass ceramic applied to a rear cover of a mobile terminal for 5G communication and reinforced glass ceramic and belongs to the technical field of glass ceramics. The glass ceramic is prepared from components in percentage by mass of oxides as follows: 45%-75% of SiO2, 10%-25% of Al2O3, 8%-20% of Na2O, 1%-4% of K2O, 0-5% of Li2O, 0-20% of MgO, 0-10% of ZnO, 1%-8% of TiO2, 0-20% of ZrO2, 0-3% of Eu2O3, 0-5% of P2O5, 0-3% of Sb2O3 and 0-5% of Fe2O3. The glass ceramic has the properties of high strength and low magnetic loss, and the performance of the reinforced glass ceramic is further improved.

Owner:GLASS TECH RES INST OF SHAHE CITY OF HEBEI PROVINCE

Method for improving hydraulic properties of water inlet/outlet of lower storage reservoir of pumped storage power station

PendingCN109056672AImprove water flowImprove running stabilityWater-power plantsHydro energy generationPower stationSurface pressure

The invention relates to a method for improving the hydraulic properties of a water inlet / outlet of a lower storage reservoir of a pumped storage power station. According to the method, by taking a series of engineering measures such as arranging a vortex prevention beam section, an adjustment section, a diffusion section and a round-to-square transition section, the distribution conditions of flow fields of the water inlet / outlet are improved, the hydraulic parameters such as the flow rate nonuniform coefficient, the flow distribution coefficient, head loss and the head loss coefficient are controlled within the reasonable range, and harmful backflow and ring current and fracture surface negative pressure are eliminated, so that the fracture surface pressure changes stably along the river, and the hydraulic conditions of the water inlet / outlet are improved.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

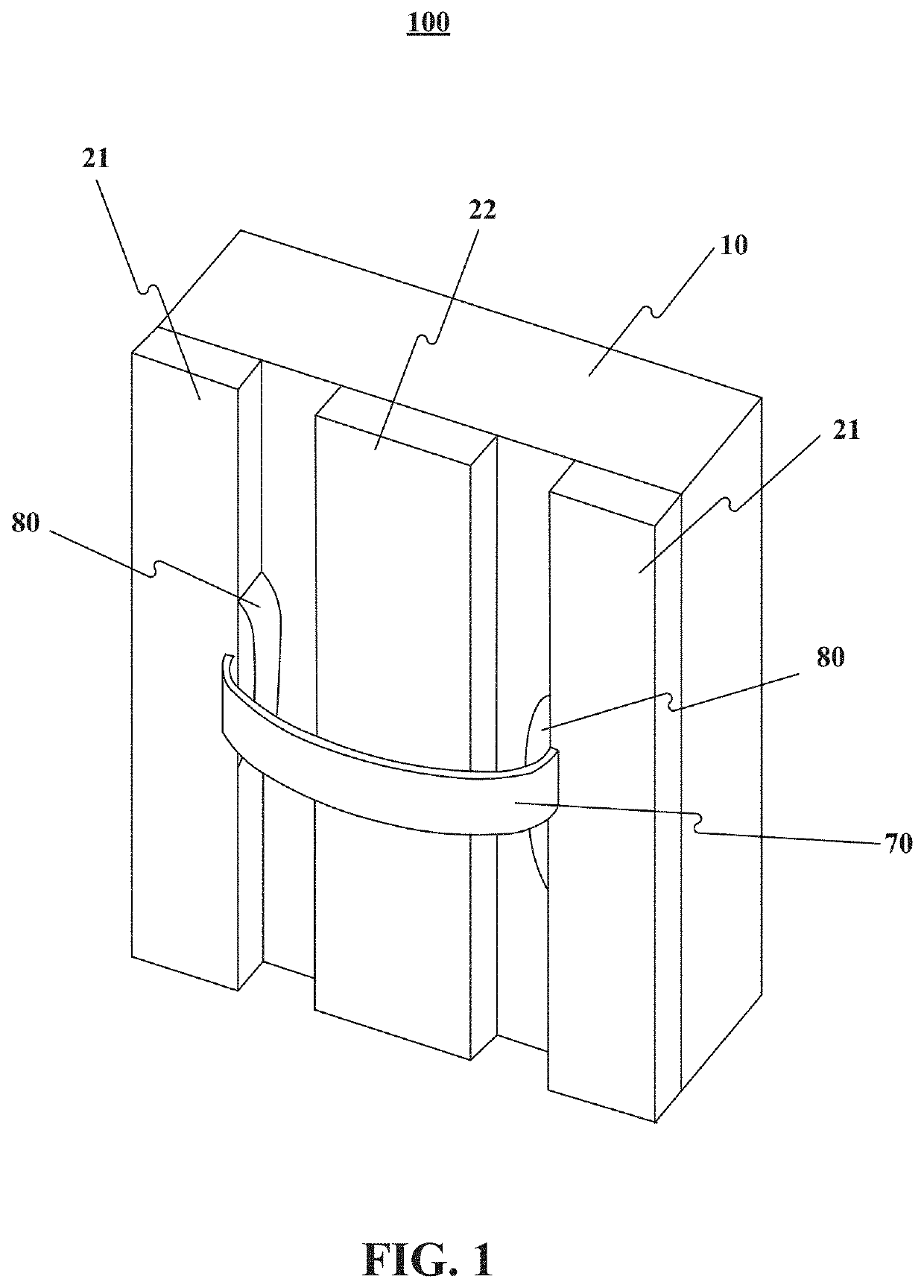

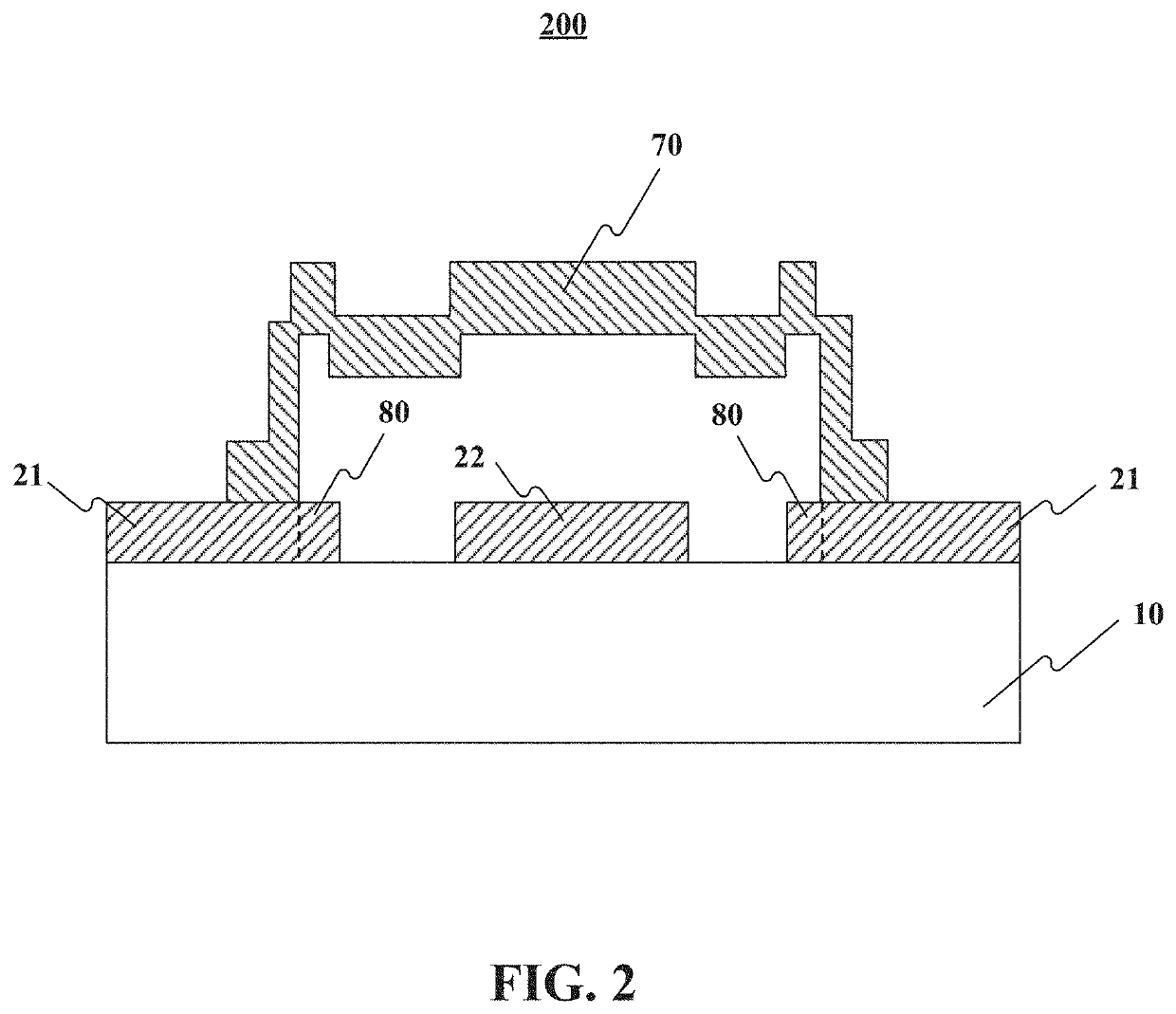

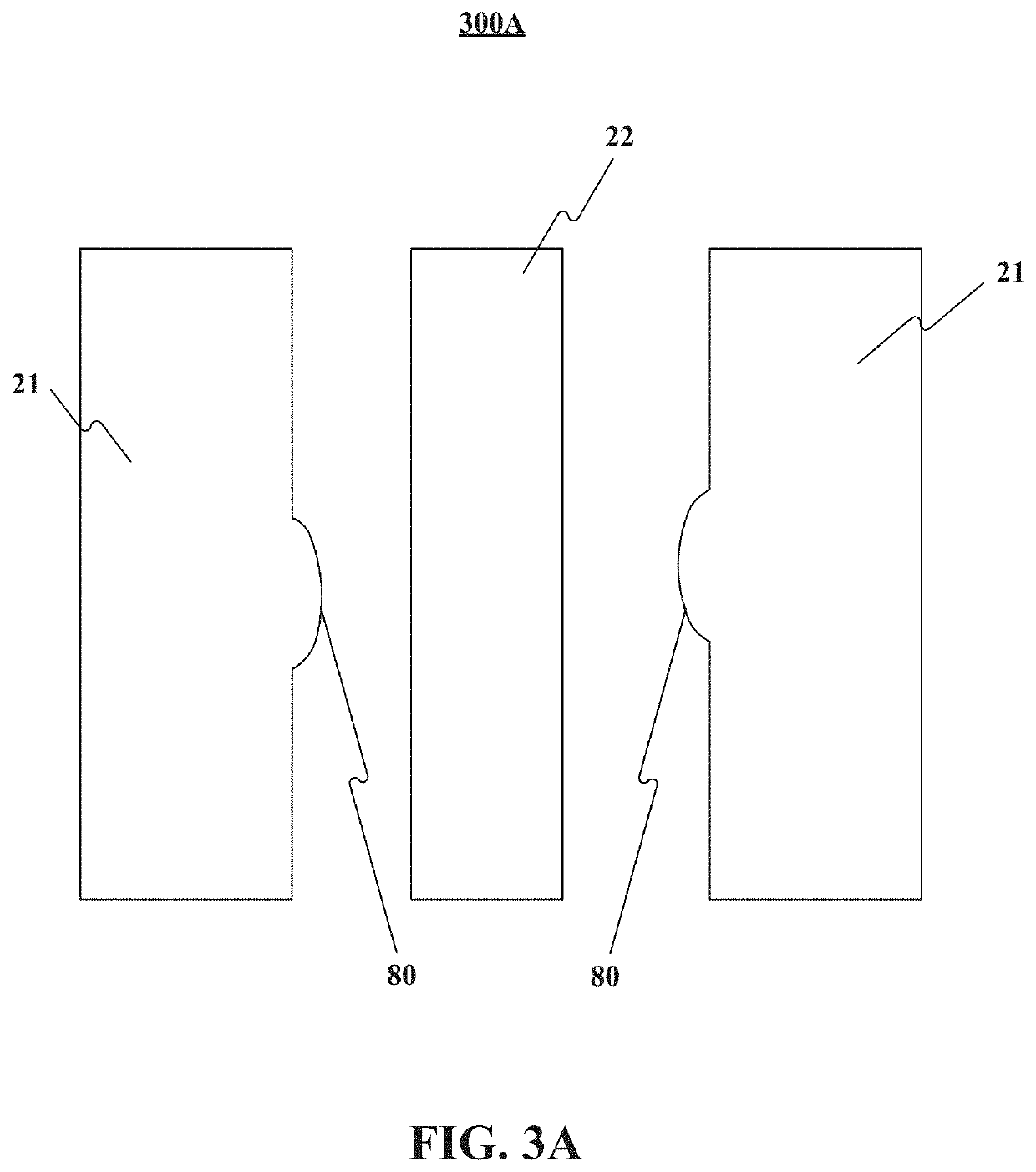

Packaging structure, manufacturing method of packaging structure, and quantum processor

ActiveUS20210359384A1Reduce loss factorReduce intensityQuantum computersSemiconductor/solid-state device detailsAir bridgeCoplanar waveguide

A packaging structure, a method of manufacturing a packaging structure, and a quantum processor include a substrate; a coplanar waveguide including a first ground wire, a second ground wire, and a signal wire, wherein the first ground wire, the second ground wire, and the signal wire are disposed on a surface of the substrate at intervals, and the signal wire is located between the first ground wire and the second ground wire; an air bridge including a first end connected with the first ground wire and a second end connected with the second ground wire, wherein a gap exists between the air bridge and a surface of the signal wire away from the substrate; and a compensation structure located on the surface of the substrate.

Owner:ALIBABA GRP HLDG LTD

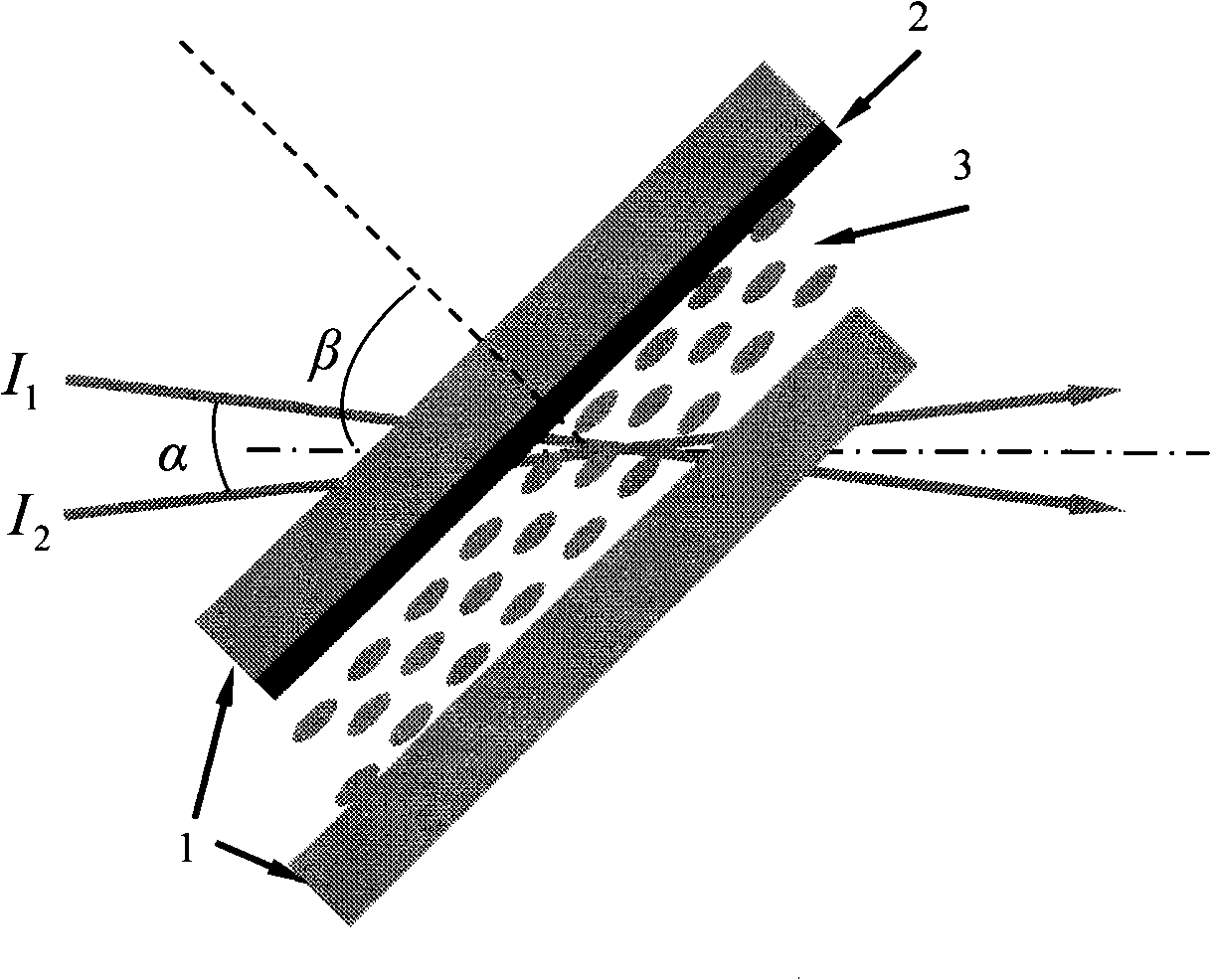

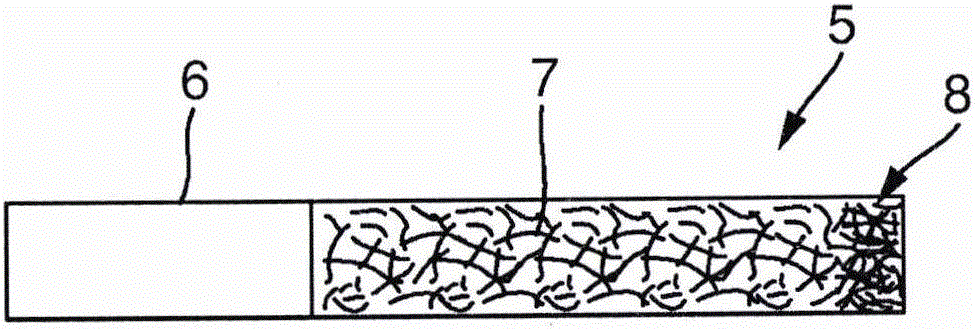

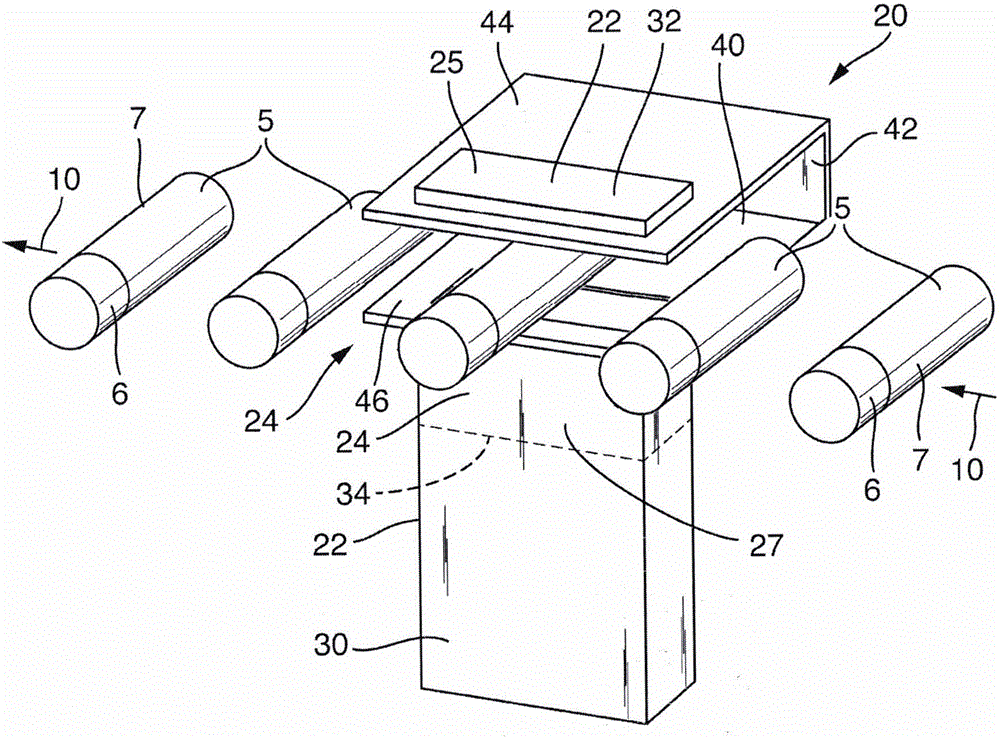

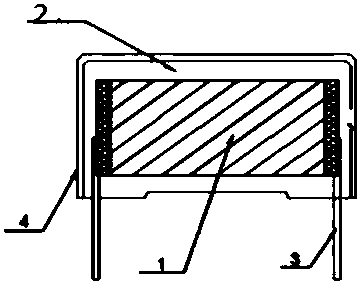

Apparatus, machine, method and use for checking cigarette head quality

InactiveCN106690407AReduce contributionImprove qualityCigarette manufactureMoisture content investigation using microwavesCouplingMicrowave resonators

The invention relates to an apparatus, a machine, a method and a use for checking the cigarette head quality on transversely conveyed cigarettes with at least one conveying device for transversely conveying cigarettes (5) along a conveying path (10). The apparatus according to the invention comprises at least one microwave measuring device (20) which comprises at least one microwave resonator, which is designed as a reflection resonator (21) with a resonator cavity (24) which extends longitudinally and in particular provided with a rectangular cross section, a passage channel (40) passes through the resonator cavity in a manner that the resonator cavity is transverse to the longitudinal extending part, the conveying path (10) passes through the passage channel (40), on opposite sides relative to the passage channel (40), the reflection resonator (21) has a microwave coupling input mechanism on one side, and the other side is defined by a reflection surface (32) which is arranged in parallel to the passage channel (40).

Owner:HAUNI MASCHINENBAU AG

A metallized polypropylene film fixed capacitor for suppressing electromagnetic power interference

ActiveCN106653361BEasy to useExtended storage timeThin/thick film capacitorFixed capacitor dielectricCapacitanceOvervoltage

The invention discloses a metalized polypropylene film fixed capacitor for suppressing electromagnetic power interference, comprising a capacitor, a shell, pins, and resin. The capacitor is arranged inside the shell. The resin fills the gap between the shell and the capacitor. One pin is welded to each of the two ends of the capacitor, and the pins extend to the outside of the shell. The capacitor is formed by taking a polypropylene film as a medium, depositing zinc and aluminum on the film by means of vacuum evaporation as electrodes, and winding the film. The resin is prepared from epoxy resin, poly-1-butene resin, modified sericite powder, and starch. The metalized polypropylene film fixed capacitor for suppressing electromagnetic power interference of the invention can withstand overvoltage shock, has excellent flame-retardant property, and is widely applied to cross-line power supplies and other anti-jamming occasions.

Owner:ANHUI FEIDA ELECTRICAL TECH CO LTD

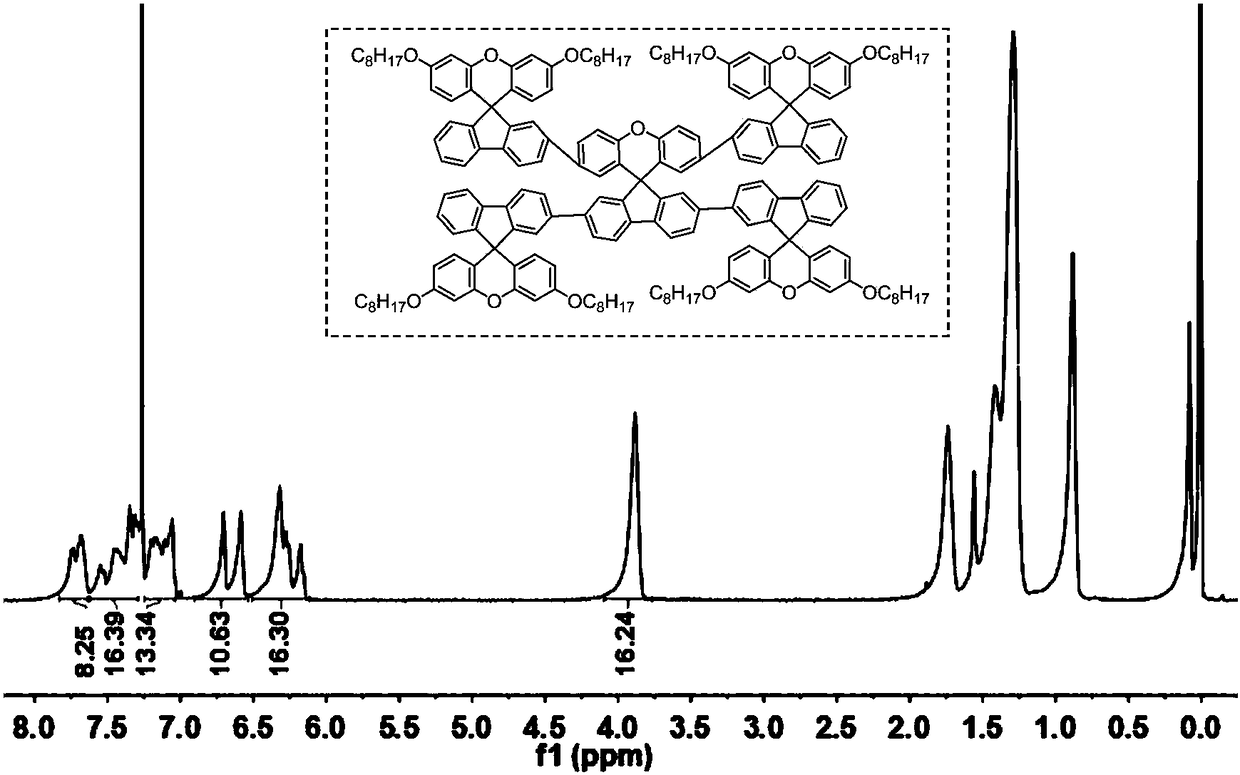

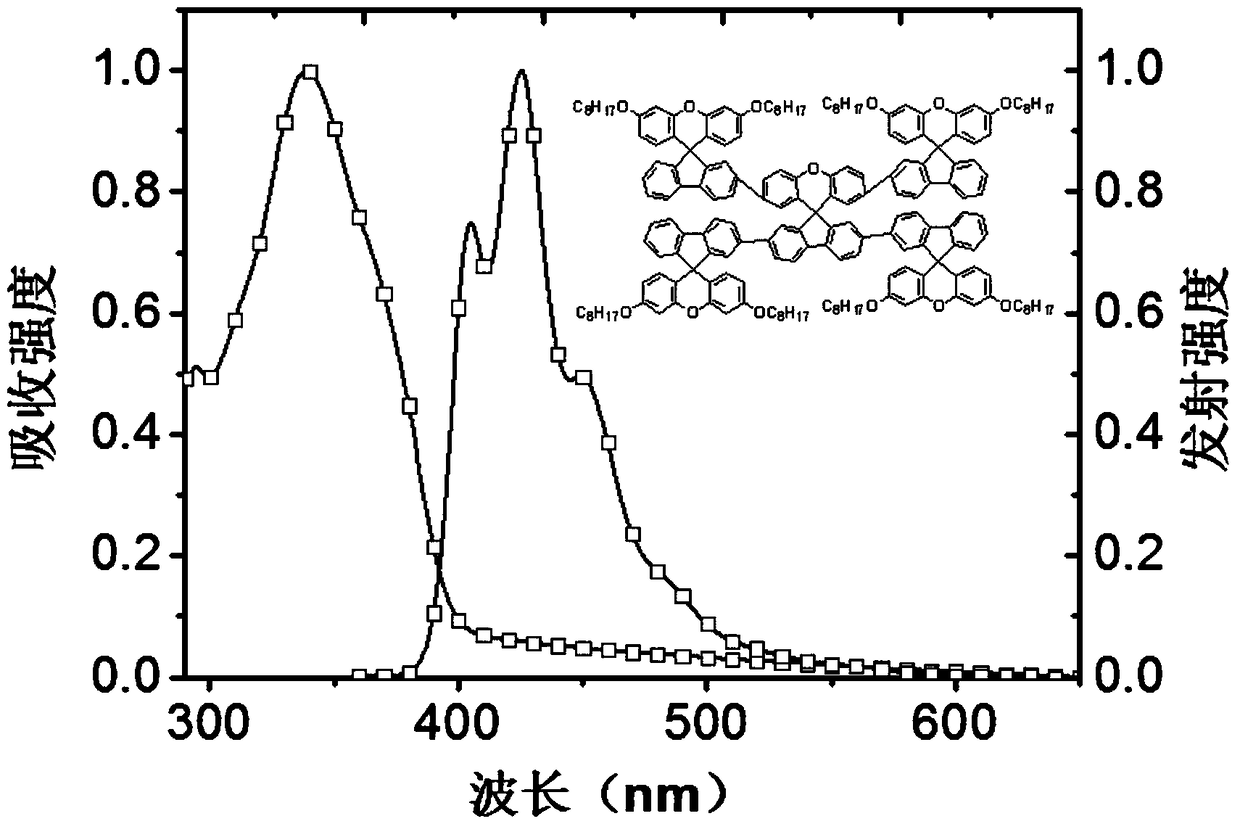

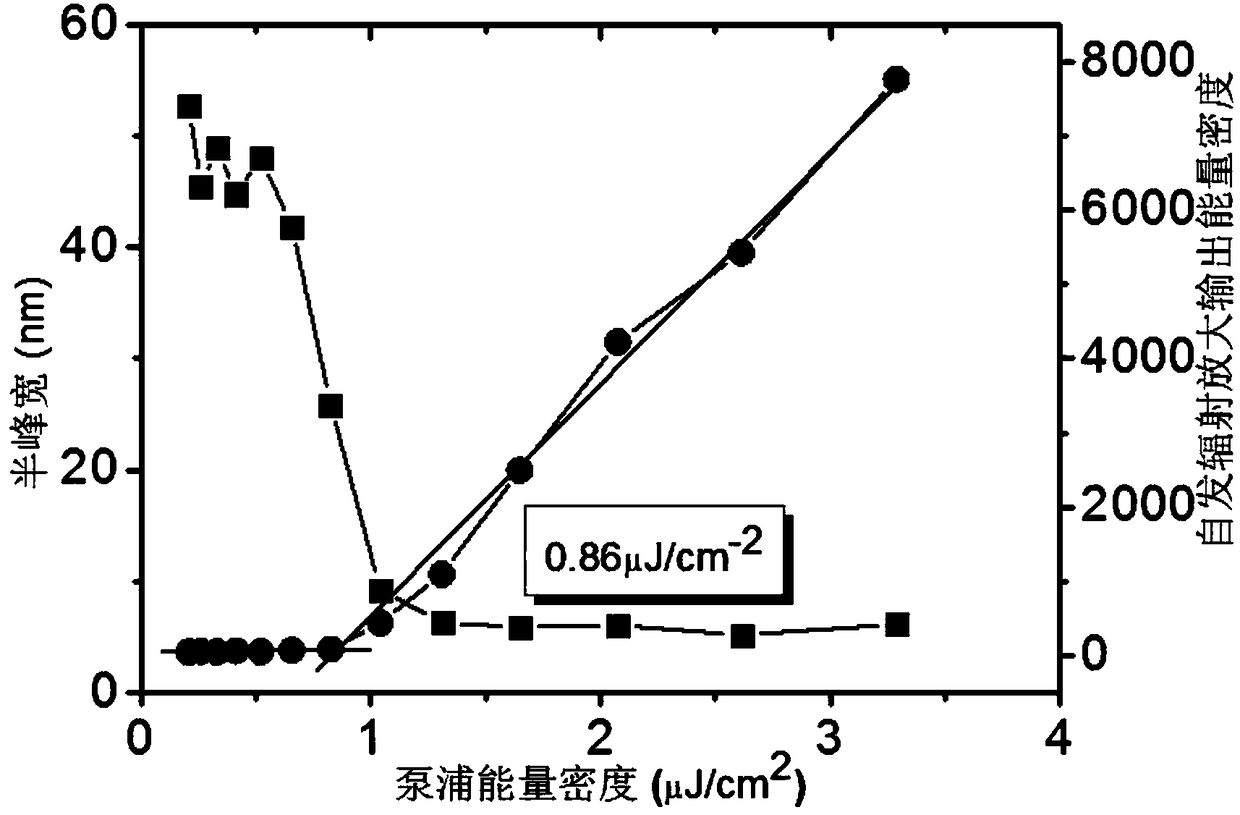

Sterically hindered multi-arm oligomeric fluorene organic laser materials and preparation method thereof

InactiveCN108129441AEasy to separateEasy to achieve industrial mass productionOrganic chemistryLuminescent compositionsOrganic laserGain coefficient

The invention discloses sterically hindered multi-arm oligomeric fluorene organic laser materials and a preparation method thereof. The preparation method comprises that tetrabromo-containing multi-arm oligomeric fluorene as a starting material and multi-arm oligomeric fluorene borate undergo a reaction under conditions: 1, a volume ratio of toluene to tetrahydrofuran of 1: 1, 2, tetra(triphenylphosphine)palladium (II) catalysis and 3, an anhydrous oxygen-free environment to produce a series of sterically hindered multi-arm oligomeric fluorene organic laser materials through Suzuki reaction coupling. The sterically hindered multi-arm oligomeric fluorene organic laser material can be easily dissolved in organic solvents such as toluene, tetrahydrofuran and chloroform and has good solvability, high quantum efficiency, a high laser gain coefficient, a low loss coefficient and a low ASE threshold value. The preparation method has the advantages of easy control of reactions, simple processes, good repeatability and high yield. Therefore, the study of the materials has great advantages and has a good reference for screening high-laser performance materials.

Owner:NANJING UNIV OF POSTS & TELECOMM

Metalized polypropylene film anti-interference resistance-capacitance module

ActiveCN106504896AEasy to useImprove anti-aging propertiesThin/thick film capacitorFixed capacitor dielectricCapacitanceInterference resistance

The invention discloses a metalized polypropylene film anti-interference resistance-capacitance module comprising a capacitor, a resistor, a first pin, a second pin, resin and a shell. The capacitor is connected in series with the resistor. The capacitor and the resistor are arranged in the shell. The resin fills between the shell and the capacitor and the resistor. One end of the capacitor is welded to the second pin. One end of the resistor is connected with the first pin. The first pin and the second pin extend to the outside of the shell. According to the metalized polypropylene film anti-interference resistance-capacitance module, the occasion of electric impact in case of failure of the capacitor does not occur.

Owner:ANHUI FEIDA ELECTRICAL TECH CO LTD

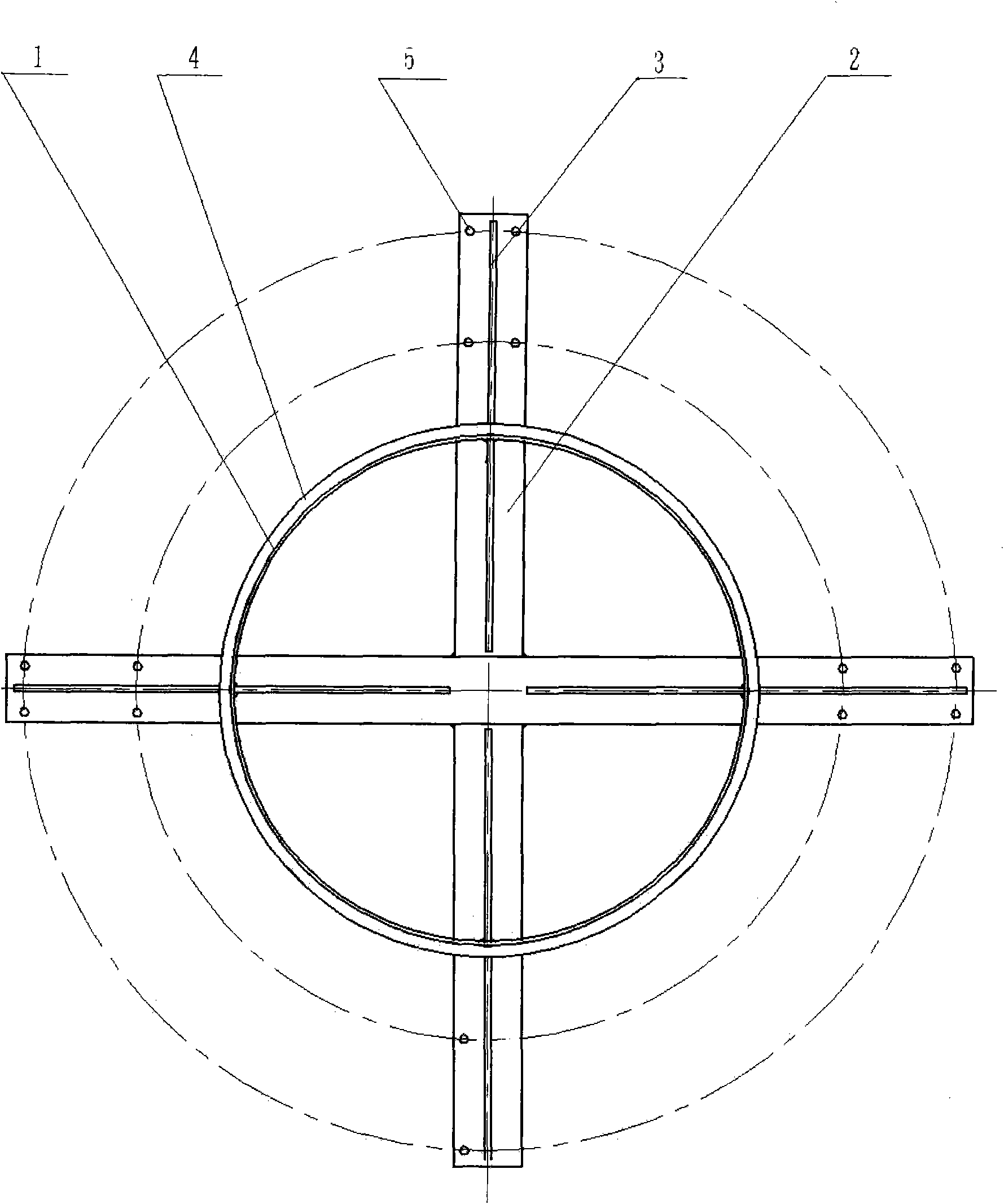

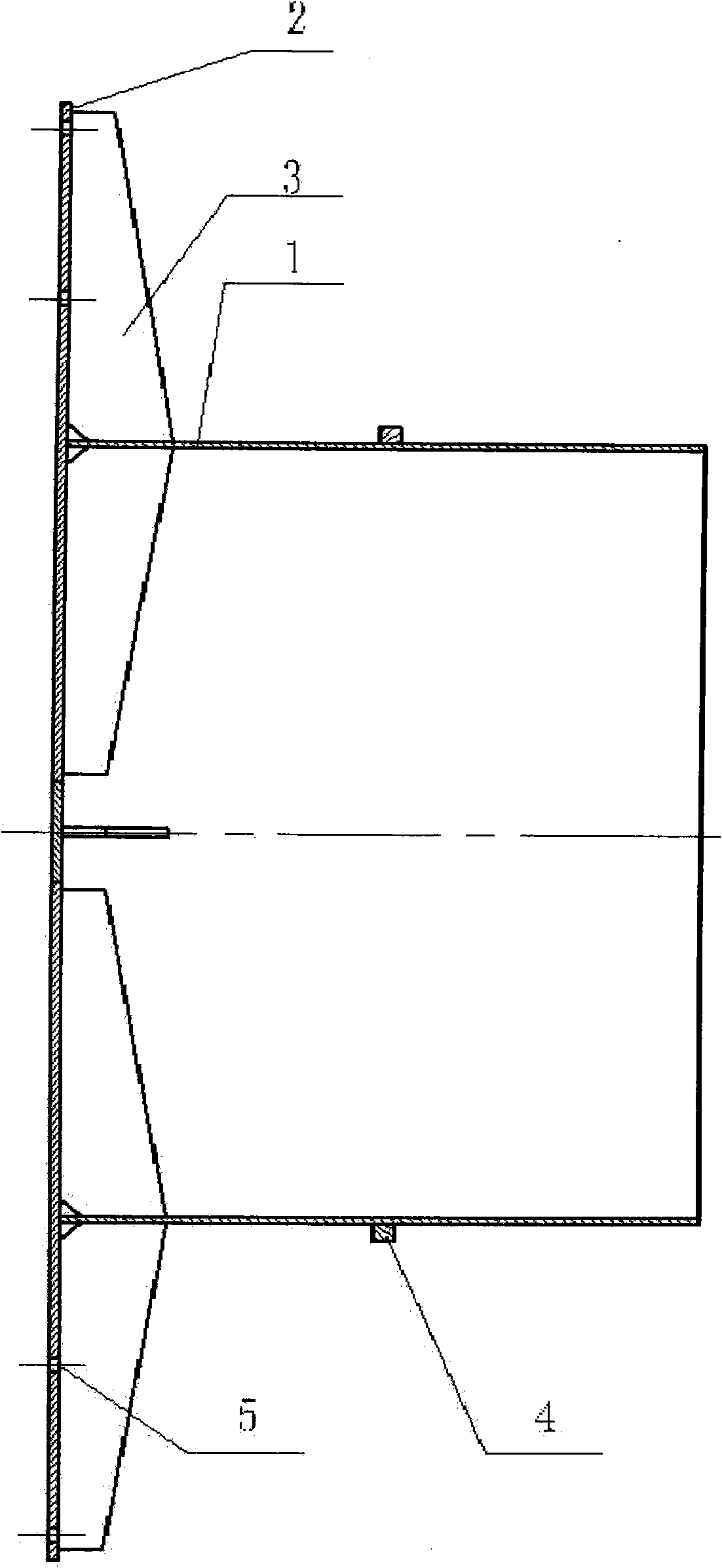

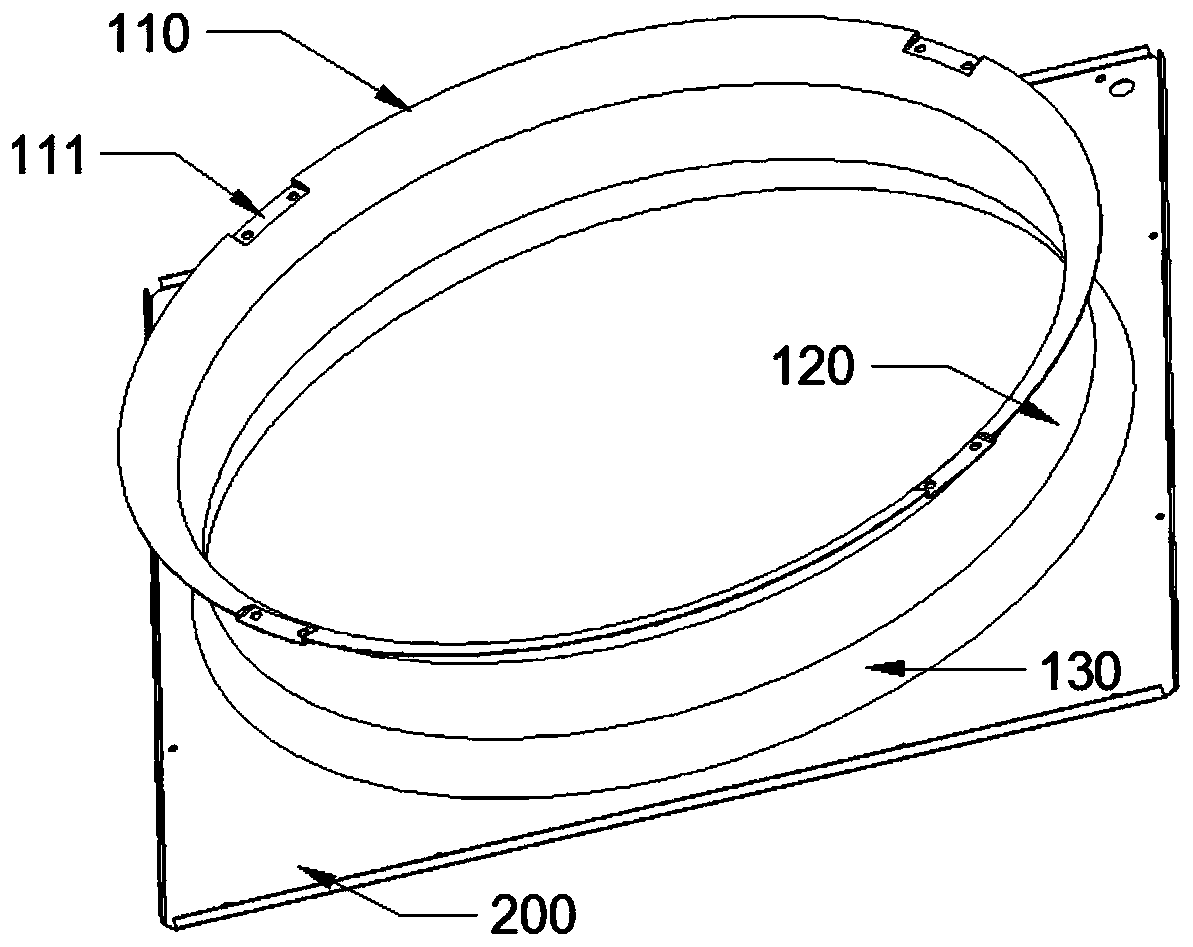

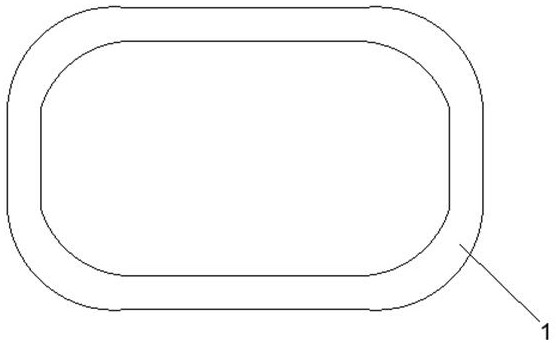

Guide ring device and axial flow fan

PendingCN111350698AAvoid damageImprove performancePump componentsLighting and heating apparatusImpellerRing device

The invention relates to a guide ring device which is arranged on a mounting top plate of an axial flow fan. The guide ring device comprises an air outlet arc section, a throat section and an air inlet arc section, wherein the upper edge of the air outlet arc section is externally expanded; the lower edge of the air inlet arc section is externally expanded and the air inlet arc section is fixedlyconnected with the mounting top plate; and the throat section is located between the air outlet arc section and the air inlet arc section, the upper end of the throat section is in tangent connectionwith the air outlet arc section, and the lower end of the throat section is in tangent connection with the air inlet arc section. The invention further provides the axial flow fan. The axial flow fancomprises an air impeller, the mounting top plate and the guide ring device, and the position of the maximum section of the air impeller is aligned to the upper end point of the throat section of theguide ring device. The guide ring structure can play an effect similar to a current collector very well, loss coefficient of the structure is reduced, and an intake air flow field is improved.

Owner:浙江科贸实业有限公司

A temperature detection method of hot air pipe based on distributed optical fiber

ActiveCN105181171BReduce maintenance costsReduce the number of wind breaksThermometers using physical/chemical changesChecking devicesMeasurement pointLaser light

Owner:马鞍山市安工大智能装备技术研究院有限公司

Turbine cascade blade top structure with array type DBD plasma excitation layout

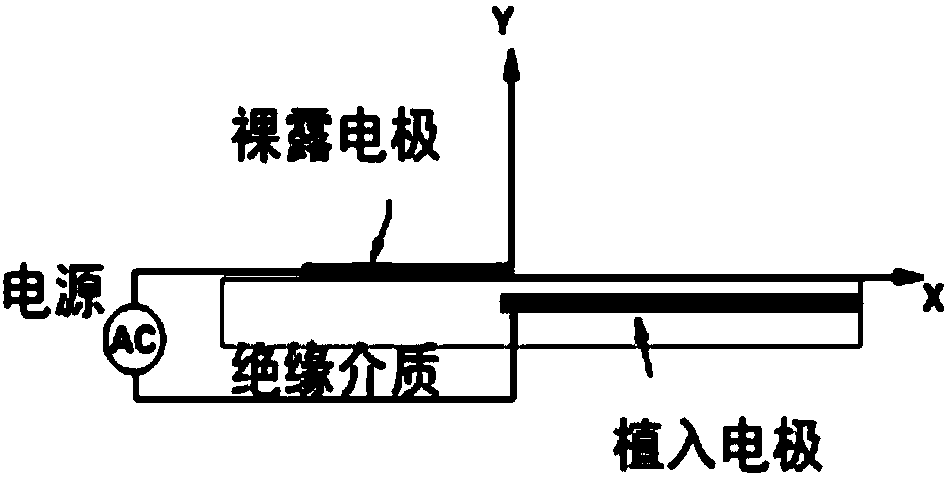

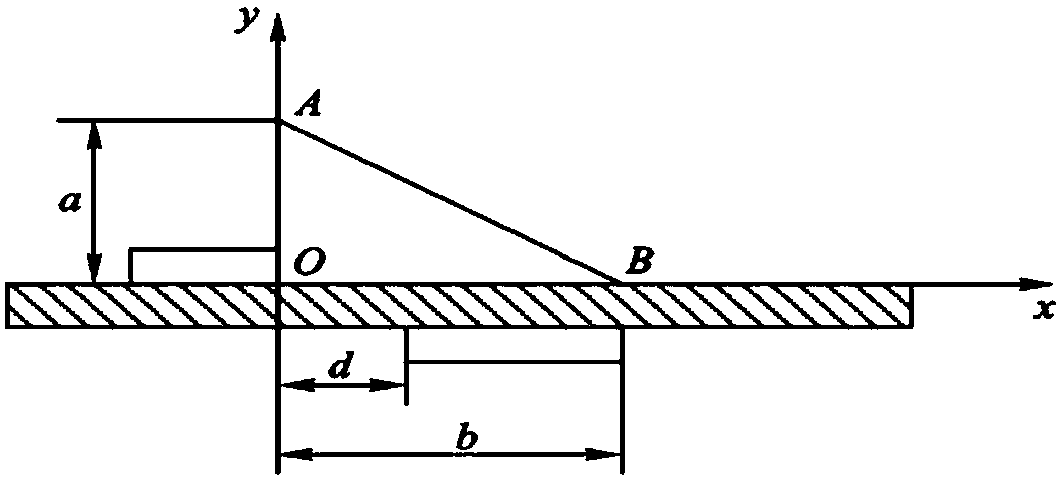

InactiveCN108487935AReduce leakage flowReduce lossesBlade accessoriesMachines/enginesFront edgePressure difference

The invention discloses a turbine cascade blade top structure with an array type DBD plasma excitation layout and belongs to the technical field of turbine active control. The problem that due to theeffects of the two side pressure differential of the pressure face and the suction face of a blade, energy loss is caused by leakage flowing formed at the blade top can be solved. The turbine cascadeblade top structure comprises a blade top and a plurality of plasma exciters. The multiple plasma exciters are arranged on a plurality of contour lines on the upper surface of the blade top in an array mode. The contour lines are lines formed from the front edge point of the blade top to the tail edge point. The length direction of a bare electrode of the plasma exciter on each contour line is parallel to the corresponding contour line, and the length of the bare electrode on each contour line is smaller than or equal to the length of the corresponding contour line. The turbine cascade blade top structure is an active flowing control blade top structure.

Owner:HARBIN INST OF TECH

A metallized polypropylene film anti-interference resistance-capacitance module

ActiveCN106504896BEasy to useImprove anti-aging propertiesThin/thick film capacitorFixed capacitor dielectricCapacitanceInterference resistance

The invention discloses a metalized polypropylene film anti-interference resistance-capacitance module comprising a capacitor, a resistor, a first pin, a second pin, resin and a shell. The capacitor is connected in series with the resistor. The capacitor and the resistor are arranged in the shell. The resin fills between the shell and the capacitor and the resistor. One end of the capacitor is welded to the second pin. One end of the resistor is connected with the first pin. The first pin and the second pin extend to the outside of the shell. According to the metalized polypropylene film anti-interference resistance-capacitance module, the occasion of electric impact in case of failure of the capacitor does not occur.

Owner:ANHUI FEIDA ELECTRICAL TECH CO LTD

A sum-frequency sodium beacon laser

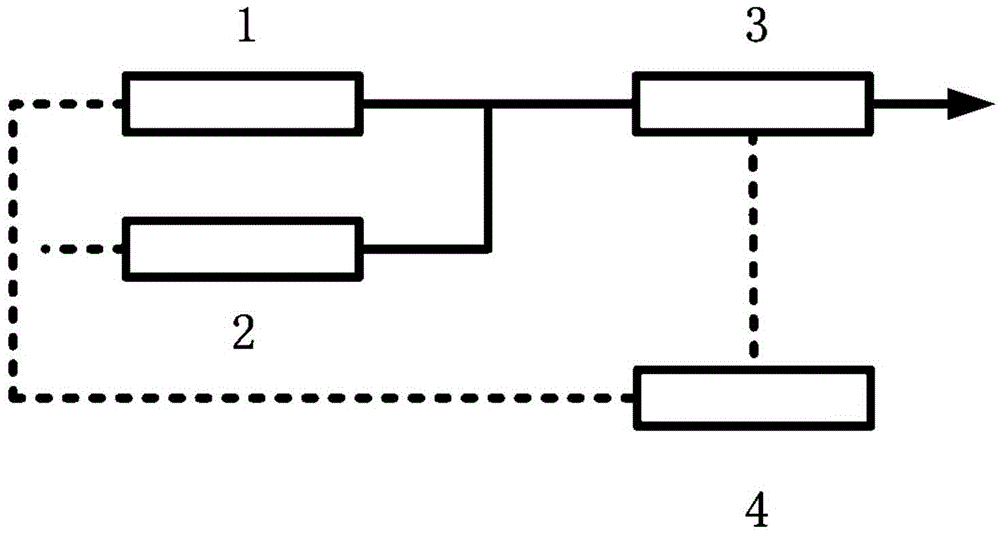

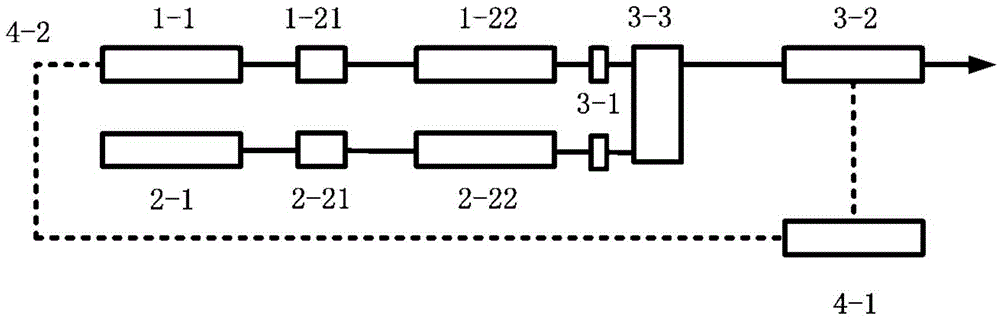

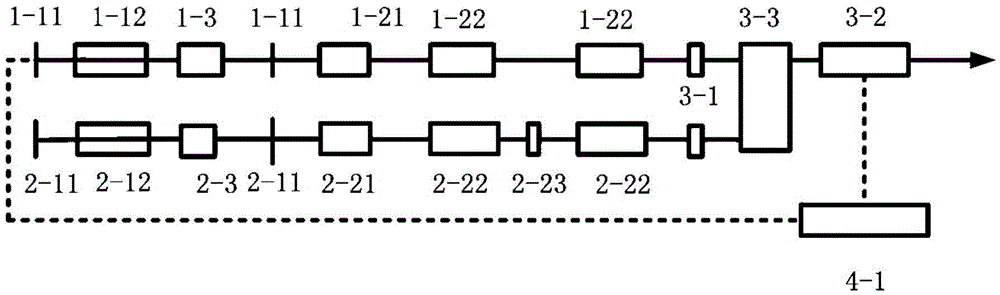

ActiveCN104269731BReduce heat productionReduce loss factorLaser detailsFrequency spectrumType frequency

The invention relates to a sum-frequency sodium beacon laser. The sum-frequency sodium beacon laser comprises a 1064nm fundamental frequency laser sub-system, a 1319nm fundamental frequency laser sub-system, a sum-frequency sub-system and a frequency control sub-system, wherein the 1064nm fundamental frequency laser sub-system emits 1064nm fundamental frequency laser beams and carries out power amplification, the 1319nm fundamental frequency laser sub-system emits 1319nm fundamental frequency laser beams and carries out power amplification; the amplified 1064nm fundamental frequency laser and the amplified 1319nm fundamental frequency laser are subjected to non-linear frequency conversion in the sum-frequency sub-system to generate sodium beacon laser beams with the wave length of 589nm; the frequency control sub-system monitors the central frequency and the frequency spectrum of the sodium beacon laser beams with the wave length of 589nm in real time and carries out feedback type frequency control over the 1064nm fundamental frequency laser sub-system or the 1319nm fundamental frequency laser sub-system so that the 589nm sodium beacon laser beams obtained after sum frequency can be aligned at a sodium atom D2a and D2b bimodal spectrum.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

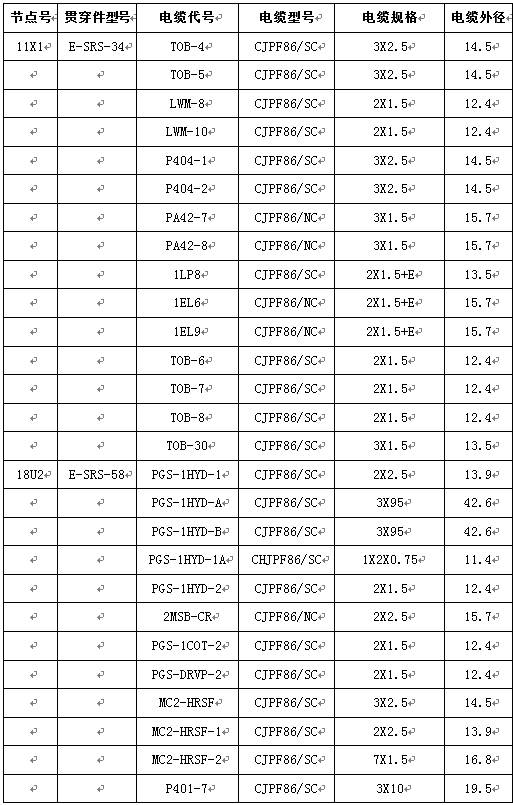

Method for controlling use amount of fireproof sealing material of sleeve type cable

PendingCN114201880AReduce wasteReduce the use effectGeometric CADDesign optimisation/simulationElement analysisEngineering

The invention discloses a method for controlling the use amount of a fireproof sealing material of a sleeve type cable, and relates to the technical field of ship construction. The method specifically comprises the following steps: S1, determining the theoretical dosage of the fireproof sealing material of the sleeve type cable: carrying out element analysis on a cable penetrating through a node; determining a cable penetration rate, and carrying out model selection matching on a penetration piece and a sleeve; theoretical dosage calculation and checking are carried out on the sealing material sleeve and the sealant through software; s2, construction is carried out according to the following plugging technological process: the cables are arranged to penetrate through the penetration piece, and each cable is wrapped with a sleeve; the remaining space of the penetration piece is filled with a sleeve, and the sleeve is fixed in a cross wrapping mode; fireproof sealants are smeared at the two ends of the penetration piece in a sealed mode; finishing the surface of the sealant with a wet towel; and after construction is completed, a flashlight is used for irradiation for final detection. The method has the advantages that accurate theoretical dosage can be provided through auxiliary calculation of software; the construction process is optimized, waste of plugging materials is reduced, and the purposes of reducing cost and increasing efficiency are achieved.

Owner:SHANGHAI ZHENHUA HEAVY IND QIDONG MARINE ENG

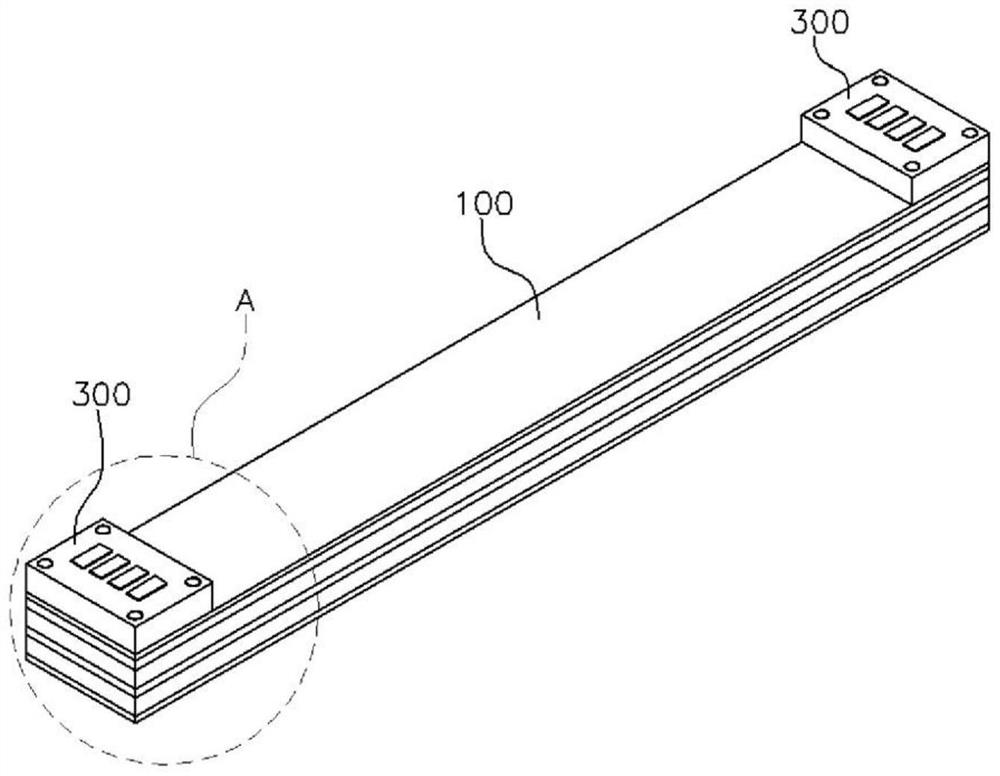

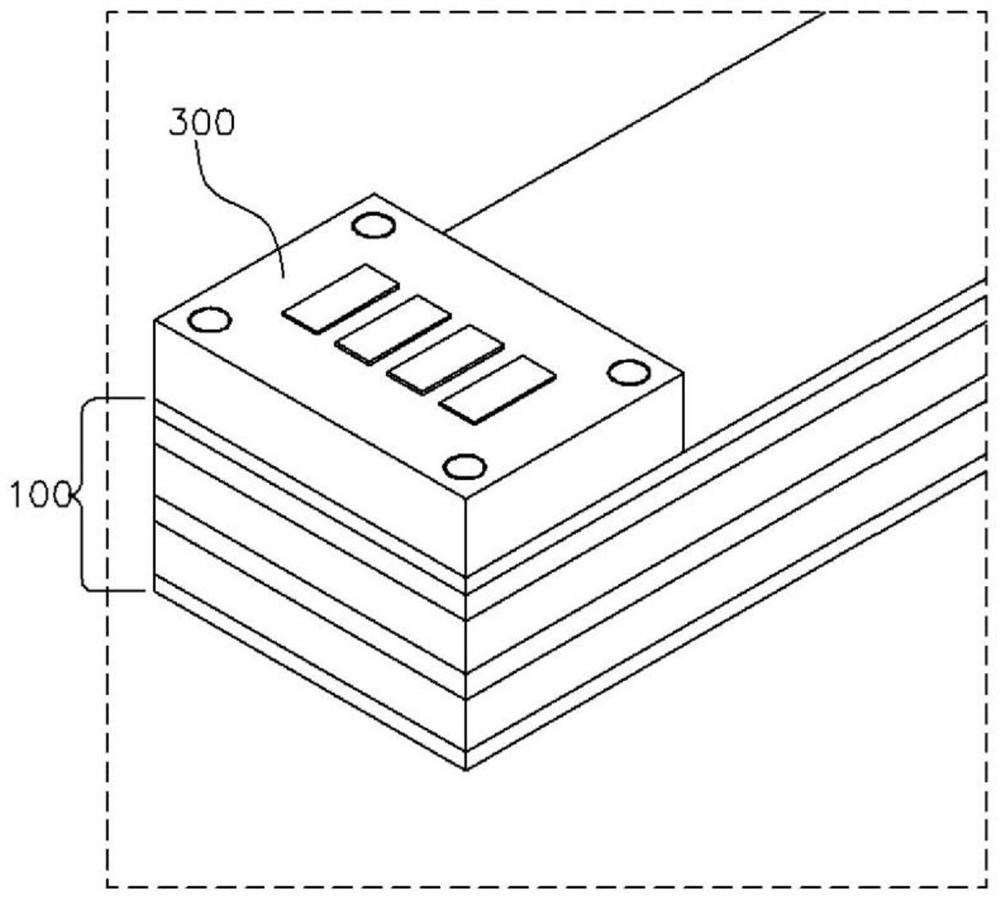

Flexible cable jumper device and method for manufacturing same

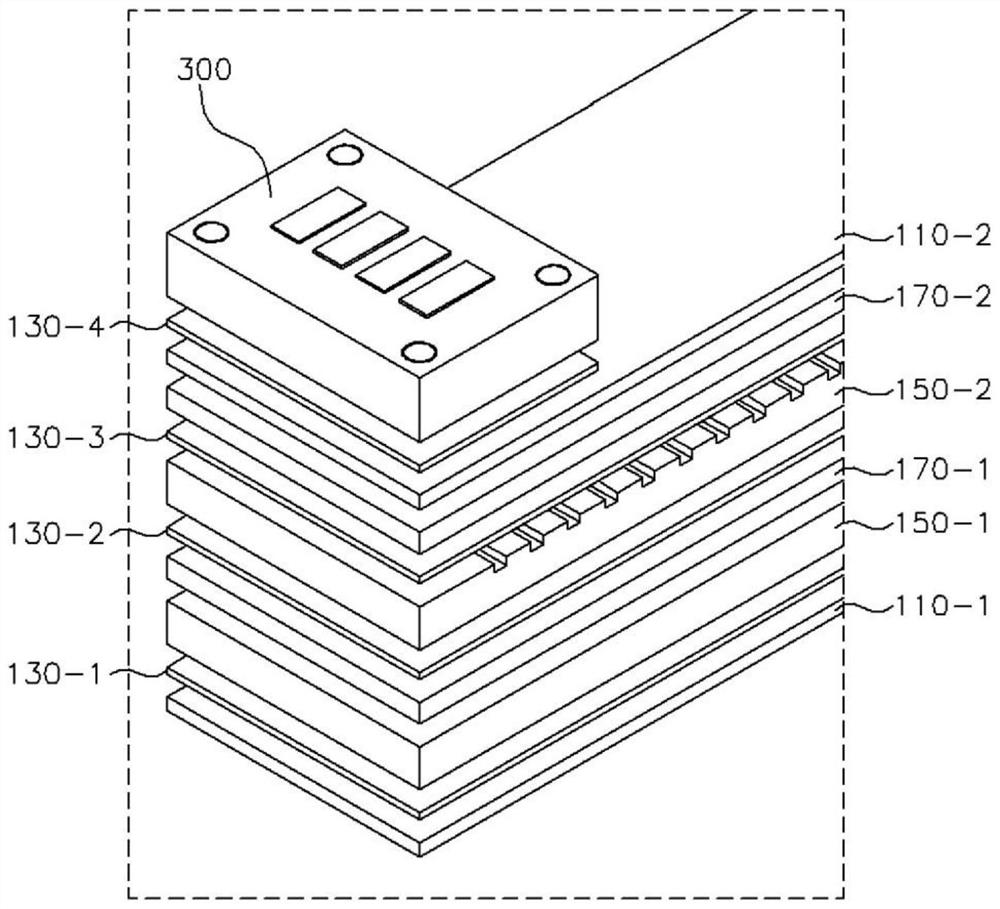

PendingCN113811959AReduce lossImprove heat resistanceStrip/foil conductorsPlastic/resin/waxes insulatorsHeat resistanceElectrical connection

The present invention relates to a flexible cable jumper device comprising a flexible cable jumper structure and an RF connector, wherein the flexible cable jumper structure comprises: a cover layer; a first metal layer laminated on the cover layer and having a circuit pattern formed thereon; a first dielectric layer laminated on the first metal layer; a first adhesive layer coated on the first dielectric layer; a second metal layer which is laminated on the first dielectric layer coated with the first adhesive layer and has a circuit pattern formed thereon; a heat-resistant layer laminated on the second metal layer; and a terminal layer formed in an area of the heat-resistant layer and electrically connected to the first metal layer and the second metal layer, and the RF connector is coupled on one side of the flexible cable jumper structure and comprises a plug having an electrode formed therein electrically connected to the terminal layer. The flexible cable jumper device of the present invention has heat resistance and low-loss characteristics by using heat-resistant material and a low dielectric constant material in a hybrid structure.

Owner:AMOSENSE

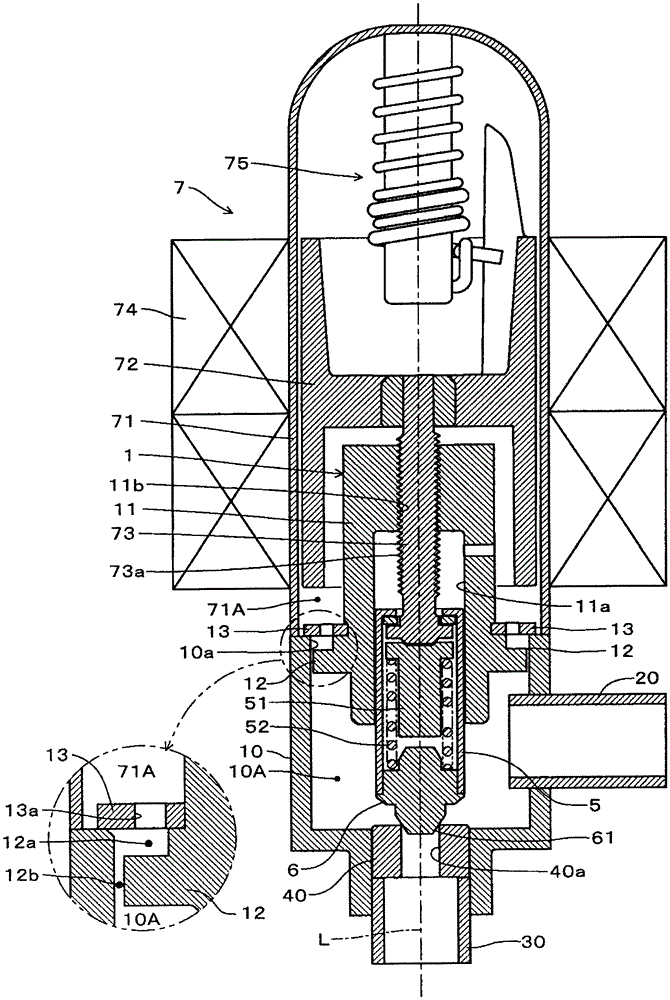

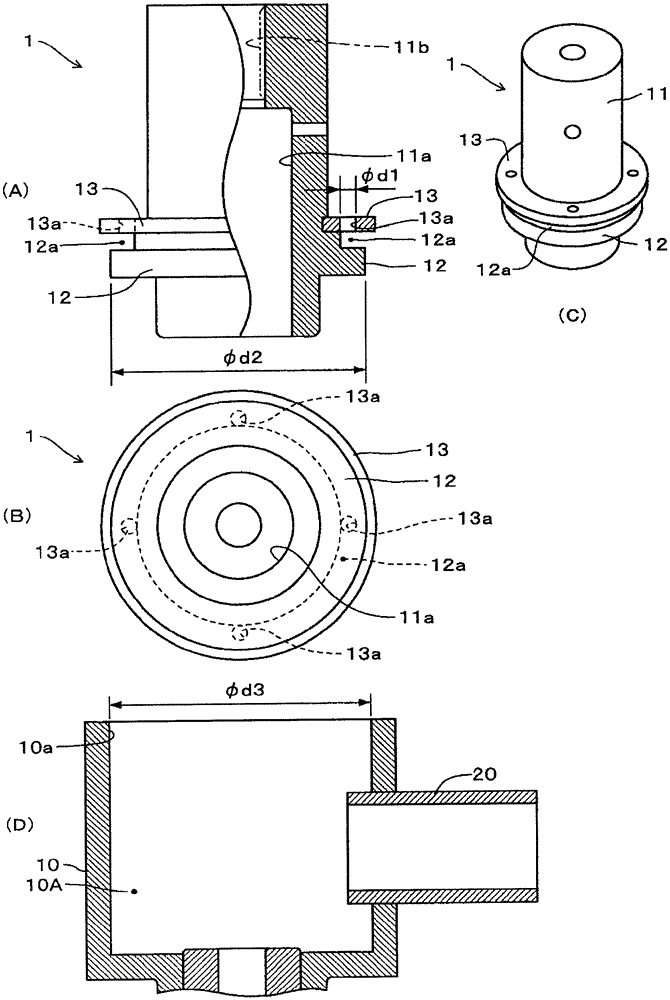

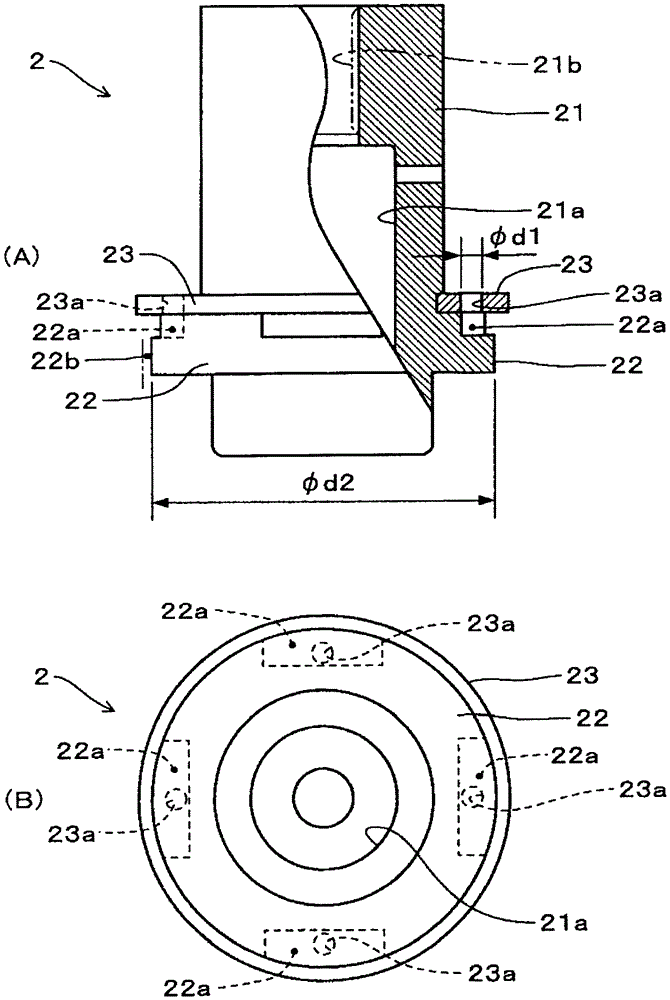

Electric valve

ActiveCN102444740BReduce widthPrevent intrusionOperating means/releasing devices for valvesEfficient regulation technologiesForeign matterEngineering

PROBLEM TO BE SOLVED: To provide an electrically-driven valve having a foreign matter collecting mechanism, in the electrically-driven valve in which a rotor chamber and valve chamber are uniformly pressurized with a support member for supporting a rotor shaft.SOLUTION: The support member 1 is mounted on an opening 10a of a valve housing 10. A case 71 is firmly fixed on an end of the opening 10a by welding. A magnet rotor 72 is stored in the case 71. A female screw section 73a of the rotor shaft 73 is screwed with a male screw section 11b of a holder section 11 of the support member 1, and the rotor shaft 73 is supported by the support member 1. A gap 12b is formed by lessening a diameter of a circumference of a fitting section 12 of the support member 1 rather than an inner diameter of the valve housing 10. A diameter-reduced section 12a (recessed section) is formed at a flange 13 side of the fitting section 12. A communication hole 13a communicating with the diameter-reduced section 12a is formed on the flange 13.

Owner:SAGINOMIYA SEISAKUSHO INC

Transformer and iron core structure thereof

PendingCN112582152ACompact structureStructural Space SymmetryTransformers/inductances magnetic coresUnwanted magnetic/electric effect reduction/preventionTransformerEngineering

The invention discloses a transformer and an iron core structure thereof. The iron core structure comprises an upper iron yoke, a lower iron yoke and three iron core columns arranged between the upperiron yoke and the lower iron yoke, the upper iron yoke and the lower iron yoke are both Y-shaped structures, and each Y-shaped structure comprises three connecting parts connected with the three ironcore columns in a one-to-one correspondence manner. Any iron core column is connected between the telecentric end of the connecting part of the upper iron yoke and the corresponding telecentric end of the connecting part of the lower iron yoke. According to the iron core structure, three-phase iron core magnetic circuits can be symmetrical and consistent in length, and the magnetic circuit is shortest; and meanwhile, the non-independence of the three magnetic circuits can be ensured, so that the loss coefficient is lower.

Owner:CSR ZHUZHOU ELECTRIC CO LTD

Turbine rotor blade of gas turbine

ActiveCN102102544BReduce loss factorExpected Cooling Distribution EffectBlade accessoriesMachines/enginesTurbine bladeFront edge

The invention discloses a turbine rotor blade of a gas turbine. The turbine rotor blade comprises a blade root, a blade platform and a blade profile, wherein a cooling structure of a snakelike passage is adopted in the blade, and comprises three cooling loops for circulating cooling gas, namely an impingement cooling loop for cooling a front edge region of the blade, a strengthening convection cooling loop for cooling a top region of the blade and a column rib and jet cooling loop for cooling a tailing edge region of the blade. For the cooling gas flowing to the tailing edge of the blade, at least one flow guide sheet structure is added at an elbow region close to the tailing edge of the blade and the blade root, so that sufficient cooling gas is distributed for cooling the root of the tailing edge of the blade. Thus, the temperature of the root of the tailing edge of the blade is reduced.

Owner:BEIJING HUAQING GAS TURBINE & INTEGRATED GASIFICATION COMBINED CYCLE ENG TECH

A kind of glass-ceramic and chemically strengthened glass-ceramic and application thereof

ActiveCN108558216BHigh Visible Light TransmissionHigh strengthTransmittanceUltimate tensile strength

Owner:GLASS TECH RES INST OF SHAHE CITY OF HEBEI PROVINCE

A new type of painting equipment for the outer wall of the tower

The invention discloses a new type of painting equipment for the outer wall of a tower tube, which includes a bracket. The outer surface of the upper end of the bracket is provided with a track, and the middle position of the outer surface of the upper end of the track is movable. A walking servo motor is installed, and the inside of the walking frame is equipped with gears. The middle position of the outer surface of the upper end of the track is provided with a rack. The outer surface of one side of the walking frame is movably equipped with a telescopic frame, and the telescopic frame is far away from the A fixed seat is fixedly installed on one side of the walking frame, and a slideway is provided in the middle of the outer surface of the side far away from the telescopic frame. The present invention can carry out three-dimensional and all-round spraying on various parts of the outer wall of the tower tube, so that the surface of the tower tube can obtain a certain smoothness and uniformity, reduce the fatigue of workers, enhance work efficiency, improve the quality of paint, and reduce the The loss coefficient of the paint is improved, and the corrosion and service life of the wind turbine tower are prolonged.

Owner:陈鹤存

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com