Sterically hindered multi-arm oligomeric fluorene organic laser materials and preparation method thereof

A technology of laser materials and oligofluorene, which is applied in the direction of luminescent materials, organic chemistry, chemical instruments and methods, etc., can solve the problems that the laser technology industry has not formed a scale, and achieve the effect of reaction atom economy and simple separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

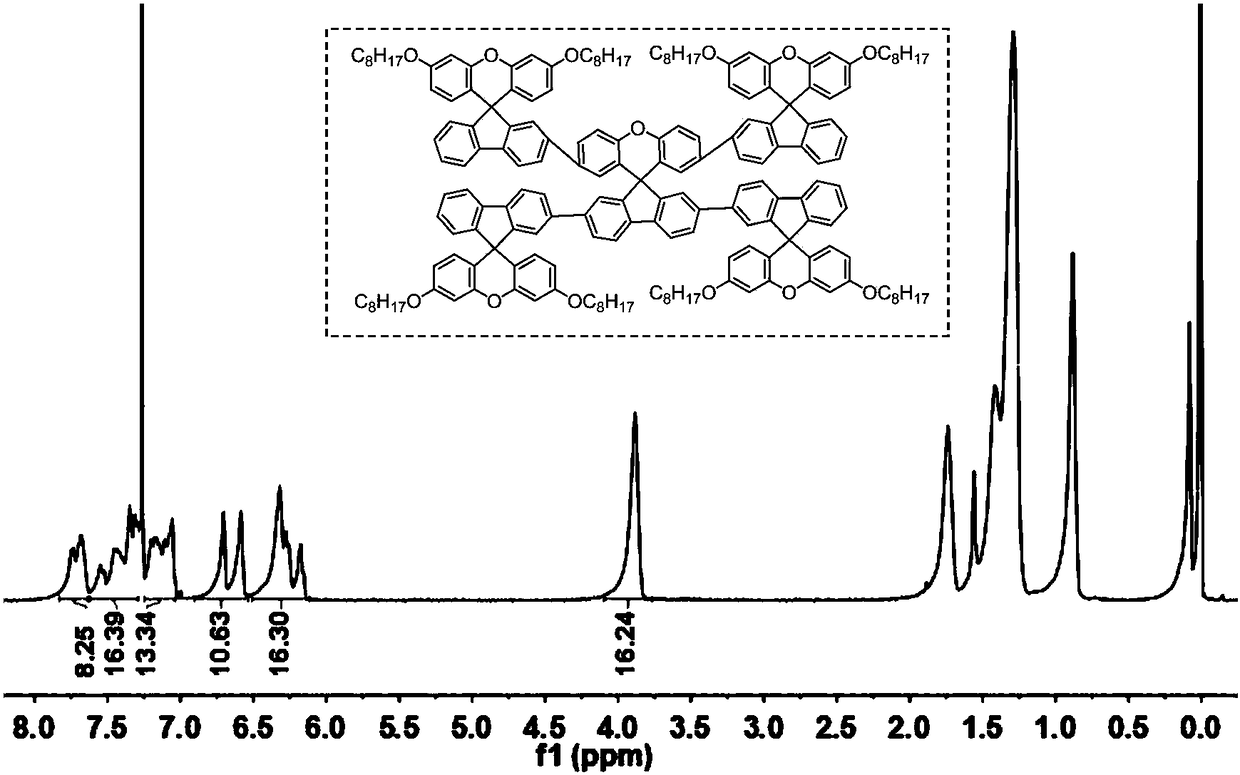

[0041] Example 1: Prepared by ① ③

[0042]

[0043] Example implementation 1: preparation of KF (A) and K 2 CO 3 (B) 20-30 mL of each 2-3 mol / L mixed solution is used as lye, the organic phase is toluene and tetrahydrofuran solution, and 10 ml of toluene and tetrahydrofuran are prepared, and the A and B solutions are bubbled for 2-3 hours. Assemble the dried three-neck flask, magnet, and condenser, leaving only the sampling port in the sealed system. Accurately weigh compounds ① (1g, 1.54mmol, 1eq), ② (5.50g, 7.70mmol, 5eq) in the reaction bottle, and ensure that the system is sealed, evacuated 2-3 times, and filled with nitrogen balloon, and then use tin foil Wrapped in paper, protected from light, quickly weighed tetrakistriphenylphosphine palladium (0.36g, 0.31mmol, 0.2eq) in a nitrogen environment, quickly added to the reaction bottle, and repeated the above operations. Inject organic phase A into the reaction vial. 90-100 ℃ oil bath stirring heating reaction, after...

example 2

[0044] Example 2: Prepared by ④ ⑤

[0045]

[0046] Preparation of KF(A) and K 2 CO 3 (B) 20-30 mL of each 2-3 mol / L mixed solution is used as lye, the organic phase is toluene and tetrahydrofuran solution, and 10 ml of toluene and tetrahydrofuran are prepared, and the A and B solutions are bubbled for 2-3 hours. Assemble the dried three-neck flask, magnet, and condenser, leaving only the sampling port in the sealed system. Accurately weigh compound ④ (1g, 1.58mmol, 1eq), ② (5.65g, 7.90mmol, 5eq) in the reaction bottle, and ensure that the system is sealed, vacuumize 2-3 times, and fill with nitrogen balloon, and then use tin foil Wrapped in paper, protected from light, quickly weighed tetrakistriphenylphosphine palladium (0.37g, 0.32mmol, 0.2eq) into the reaction bottle under nitrogen atmosphere, and repeated the above operation. Inject organic phase A into the reaction vial. 90-100 ℃ oil bath stirring heating reaction, after 10min, add 6.2mL of lye. Stir the reaction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gain coefficient | aaaaa | aaaaa |

| absorption coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com