Anti-overload non-silicon MEMS thick metal suspended micro inductor

A thick metal, anti-overload technology, applied in the field of MEMS technology, can solve the problems of poor reliability of suspended metal spiral coils, achieve the effect of high process reliability and yield, simple and easy process, and reduce loss factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

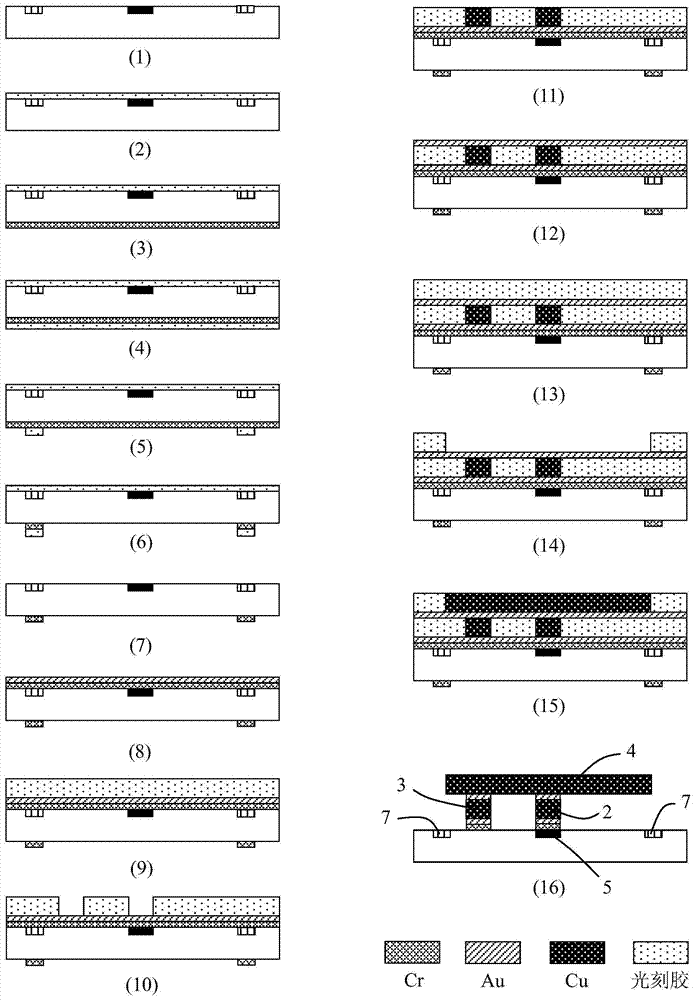

[0037] Below in conjunction with accompanying drawing, the embodiment of the present invention is described in detail, present embodiment implements under the premise of technical solution of the present invention, has provided detailed implementation scheme and specific operation process, but protection scope of the present invention is not limited to the following the described embodiment.

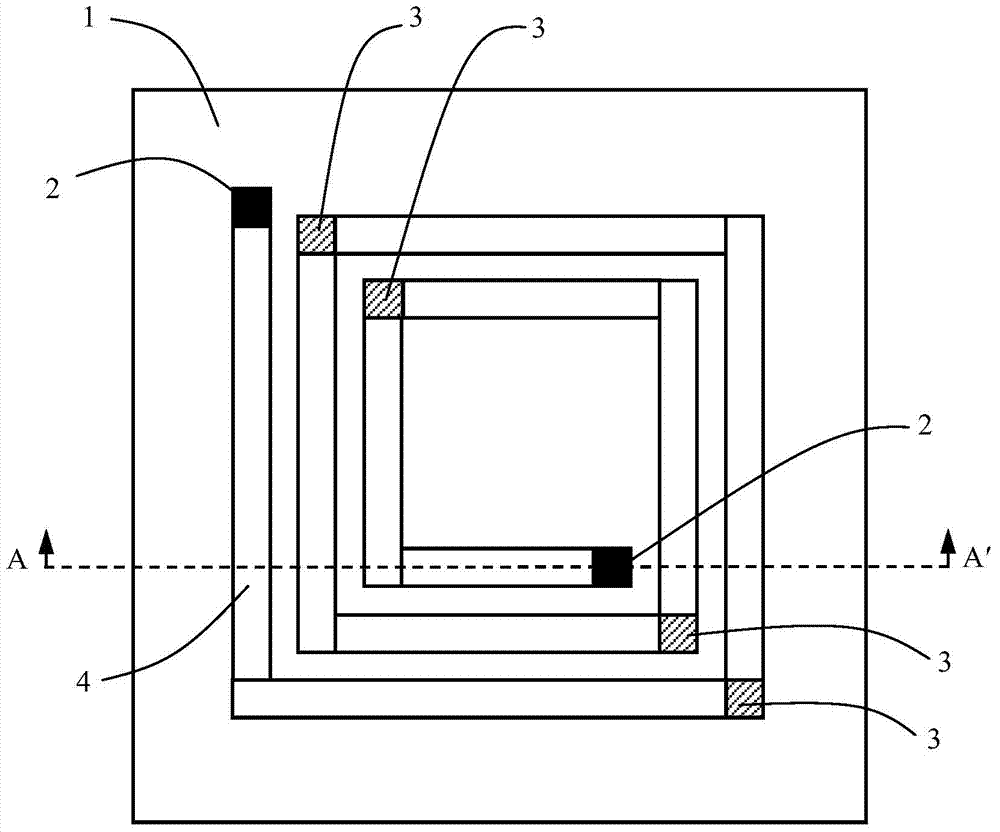

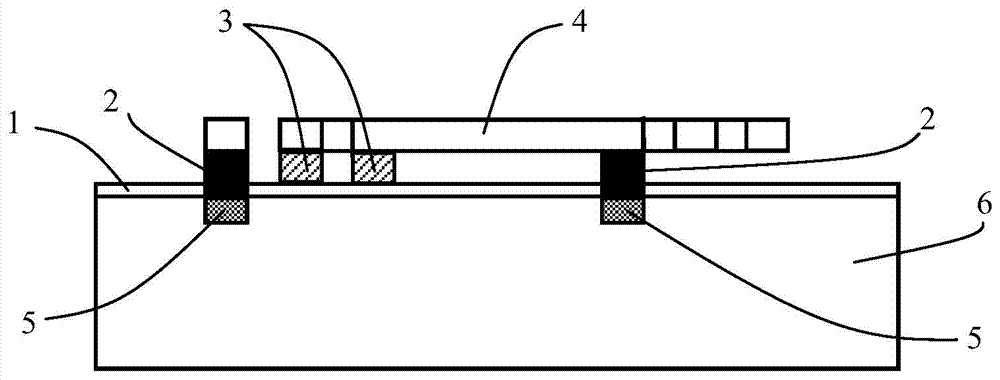

[0038] Such as figure 1 and figure 2 As shown, this embodiment is composed of a substrate, an electrical connection column 2 , a support body column 3 and a suspended metal helical coil 4 . The electrical connection column 2 is made on the electrical connection port 5 of the substrate, and the other end is connected with the suspended metal helical coil 4 . One end of the supporting column 3 is connected with the suspended metal spiral coil 4, and the other end is connected with the passivation layer 1 of the substrate.

[0039] The substrate includes a substrate 6 with circuits and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com