Electric valve

A technology for electric valves and valve housings, applied in valve details, valve devices, valve housing structures, etc., which can solve the problems of filter pressure loss, large minimum diameter, poor movement, etc., to reduce pressure loss and loss coefficient , The effect of preventing the intrusion of foreign matter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

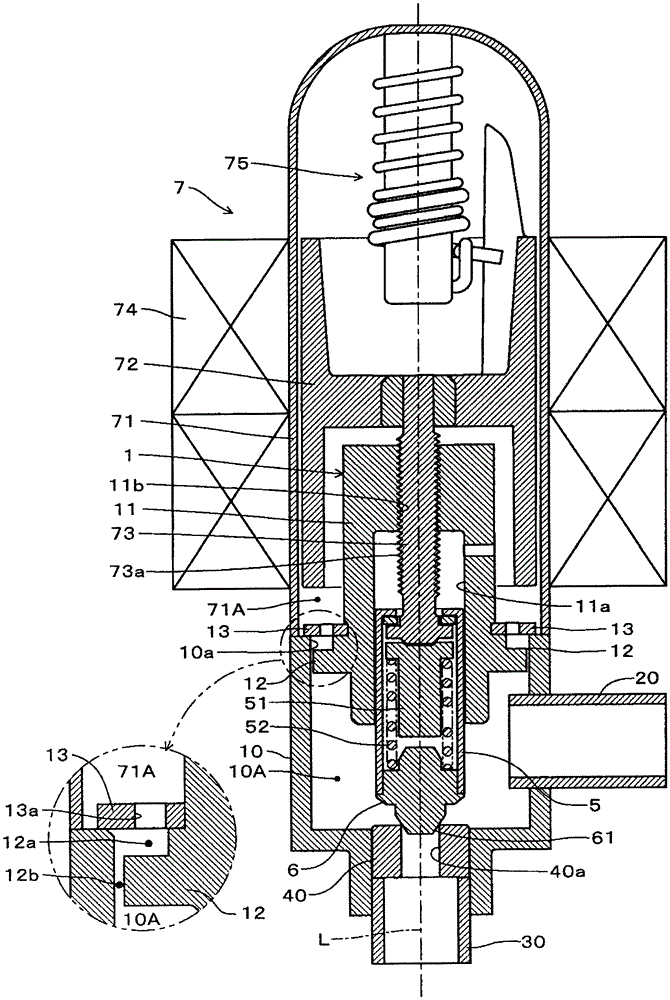

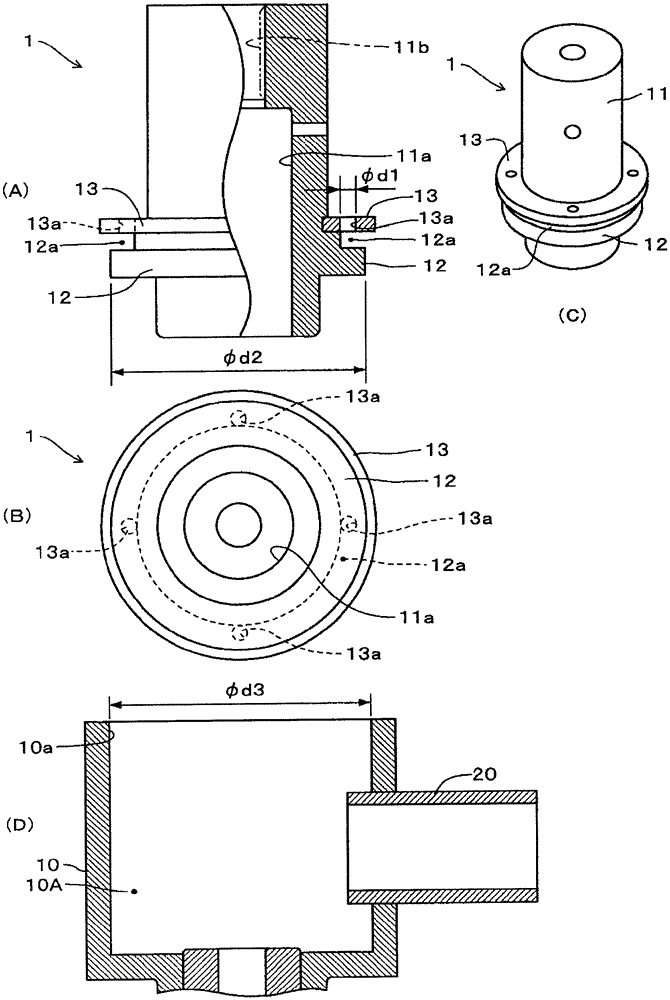

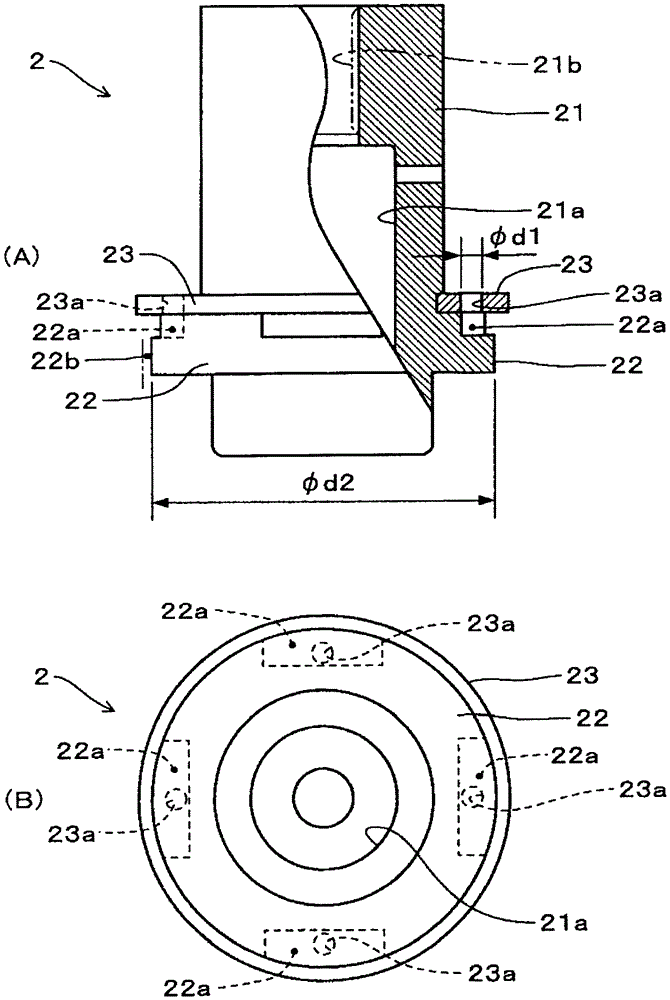

[0042] Next, an embodiment of an electric valve according to the present invention will be described with reference to the drawings. figure 1 It is a longitudinal sectional view and an enlarged sectional view of main parts of the electric valve according to the first embodiment, figure 2 It is a partially broken side view of the supporting member of the electric valve of the first embodiment ( figure 2 (A)), bottom view ( figure 2 (B)), perspective view ( figure 2 (C)) and the sectional view of the valve housing ( figure 2 (D)). image 3 It is a partially broken side view of the support member of the electric valve of the second embodiment ( image 3 (A)) and bottom view ( image 3 (B)). Figure 4 It is a partially cutaway side view of a supporting member of an electric valve according to a third embodiment ( Figure 4 (A)) and bottom view ( Figure 4 (B)). The following embodiments are the same as those described above Figure 5 and Figure 6 The difference of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com