A metallized polypropylene film anti-interference resistance-capacitance module

A polypropylene film and metallization technology, applied in the field of capacitors, can solve the problems of reduced withstand voltage, easy aging, and shortened lifespan, and achieve the effects of improved anti-aging performance and molding processing performance, excellent high temperature resistance, and guaranteed normal use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

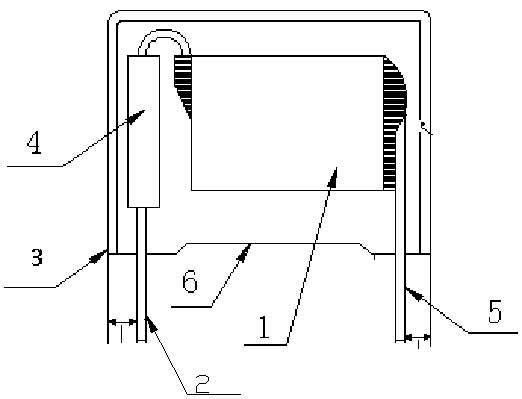

[0016] A metallized polypropylene film anti-interference resistance-capacitance module, including a capacitor 1, a resistor 4, a first pin 2, a second pin 5, a resin 6, and a casing 3, the capacitor 1 is connected in series with the resistor 4, and the capacitor 1 and the resistor 4 are arranged inside the casing 3, resin 6 is filled between the casing 3 and the capacitor 1 and the resistor 4, one end of the capacitor 1 is welded to the second pin 5, one end of the resistor 4 is connected to the first pin 2, Both the first pin 2 and the second pin 5 extend to the outside of the shell 4 .

[0017] Further, the capacitor is formed by using polypropylene film as the medium, and depositing zinc and aluminum on the film as electrodes by vacuum evaporation.

[0018] Further, the polypropylene film is made of the following components in parts by weight: polypropylene resin 25, halloysite powder 2, rosin 4, dicumyl peroxide 0.8, and its preparation method is: mix rosin at a mass conce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com