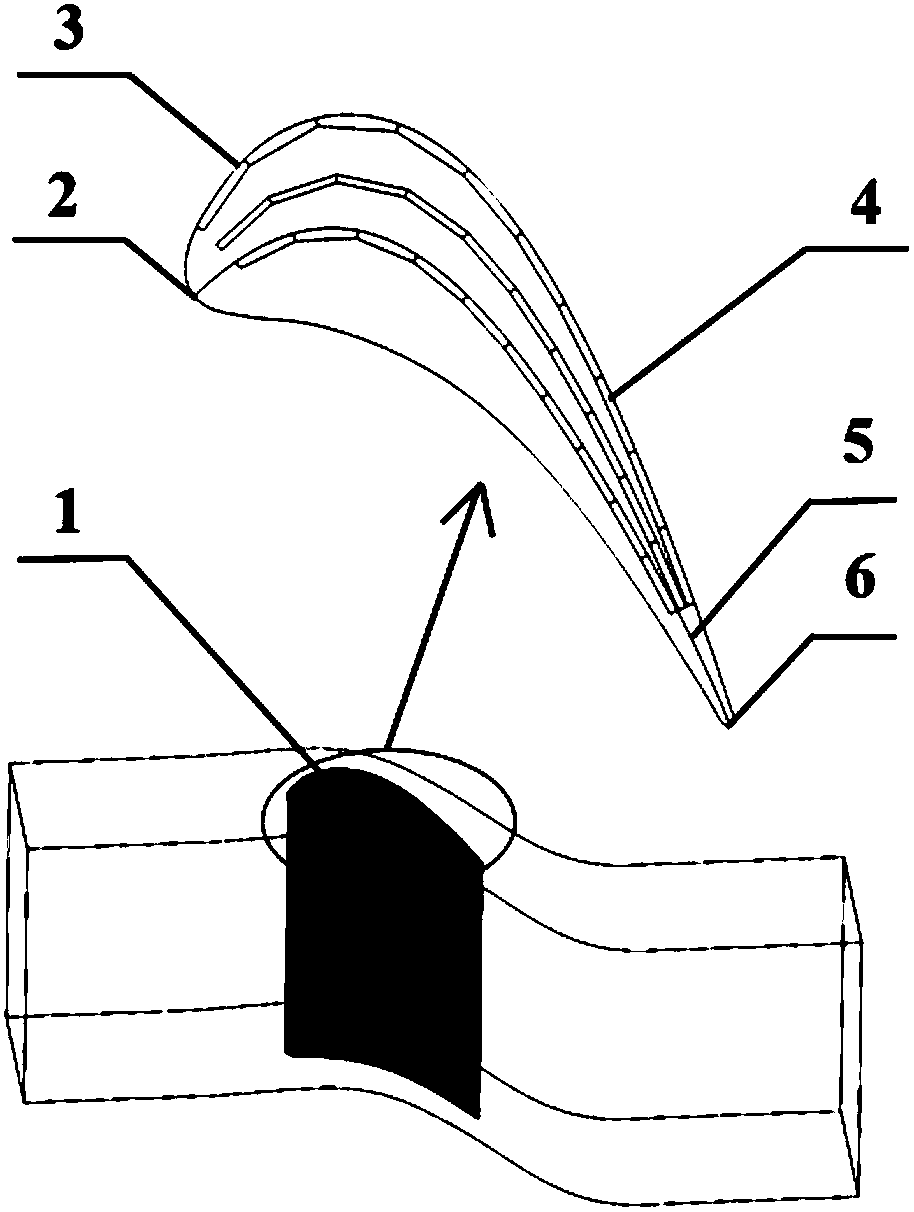

Turbine cascade blade top structure with array type DBD plasma excitation layout

An array type, plasma technology, applied in the direction of blade support components, engine components, machines/engines, etc., can solve the problems of energy leakage and loss at the top of the blade, and achieve the goal of suppressing leakage flow, reducing leakage flow and energy loss coefficient Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

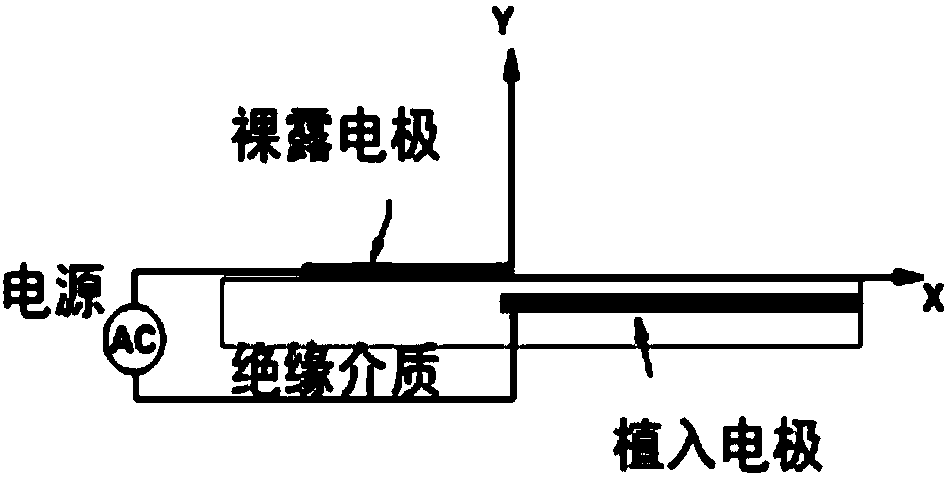

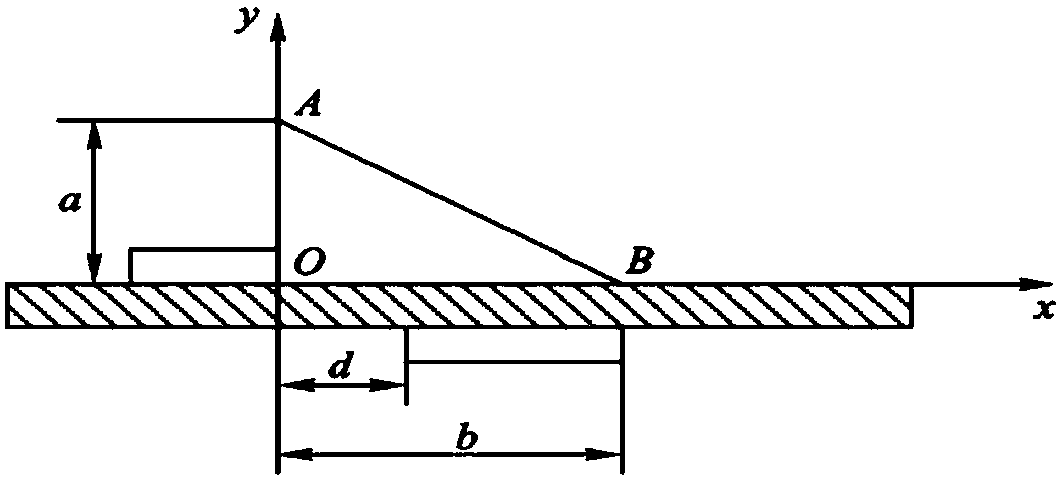

Method used

Image

Examples

specific Embodiment

[0030] In order to verify the effect of the present invention, carry out following numerical simulation, concrete simulation parameter and result are as follows:

[0031] The main parameters of the simulated turbine cascade profile are shown in Table 1:

[0032] Table 1

[0033]

[0034] Such as Figure 5 As shown, the size of the leakage vortex is significantly reduced when the array plasma excitation scheme is applied compared with the non-array plasma excitation scheme. Therefore, it shows that the scheme of the present invention can effectively control the flow in the tip clearance and reduce the leakage flow.

[0035] Such as Figure 6 It can be seen from the results of the leakage flow and energy loss coefficient of the numerical simulation that the leakage flow is reduced by 45.2% when the array plasma excitation scheme is applied compared with the non-array plasma excitation scheme. The energy loss coefficient decreased by 21.6%.

[0036] It can be seen that, b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com