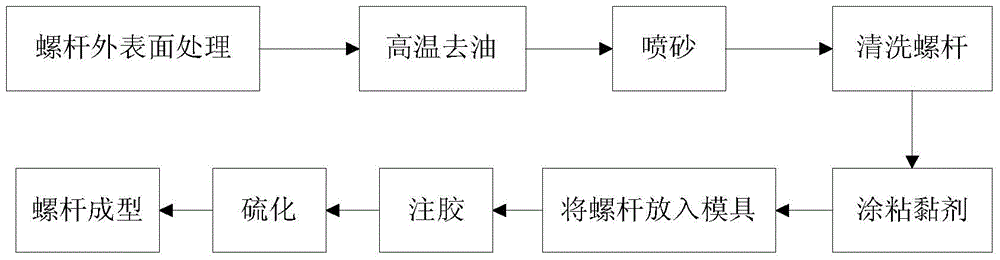

Two-screw pump and preparation method of corresponding rubber lined screw rods of two-screw pump

A twin-screw pump and screw technology, used in pumps, pump components, mechanical equipment, etc., can solve the problems of increasing leakage flow, reducing work efficiency, screw stuck, etc., to reduce leakage flow, improve work efficiency, and ensure quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

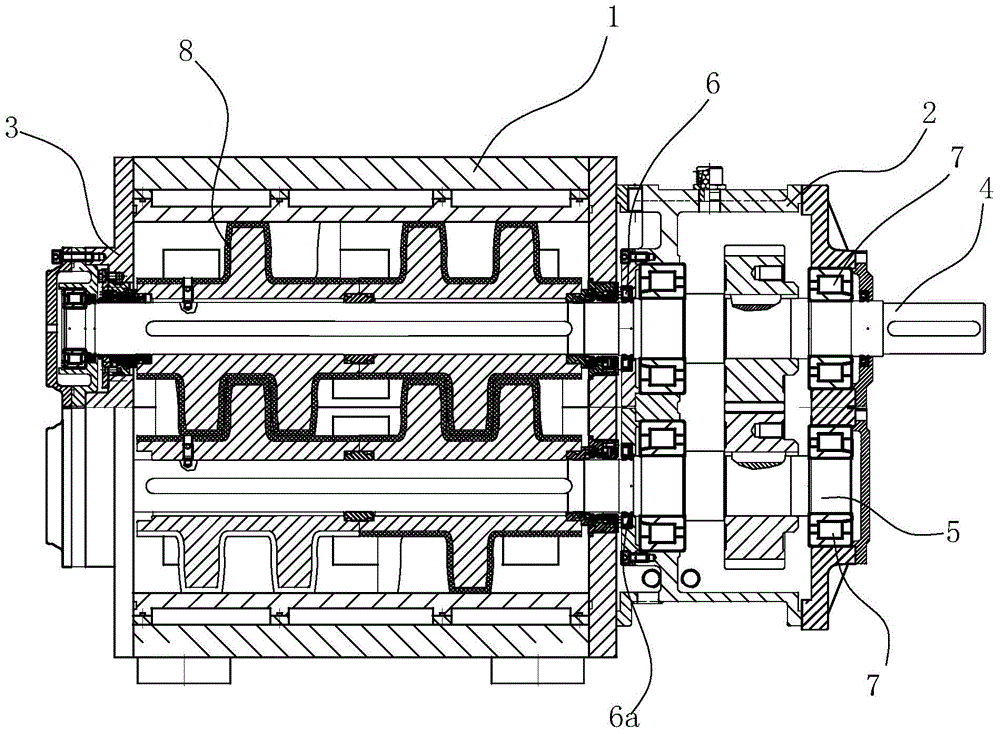

[0027] The present invention will be described in further detail below in conjunction with the embodiments of the drawings.

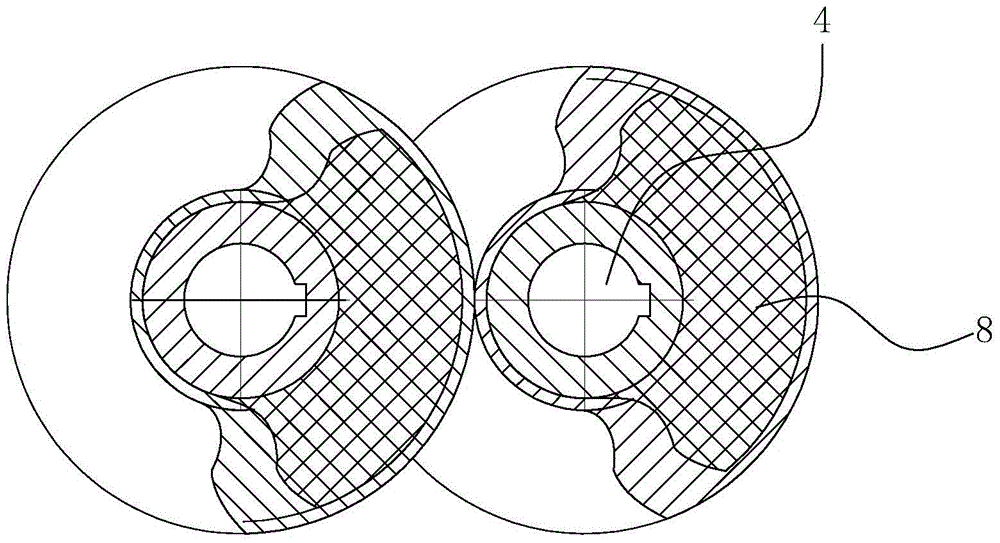

[0028] Such as figure 2 , 3 As shown, the twin screw pump of this embodiment includes a pump body 1, a pump front cover 2, a pump rear cover 3, and a driving screw 4 and a driven screw 5 arranged in the pump body 1 to mesh with each other. The pump body 1 adopts two ends In the transportation structure with liquid inlet and middle discharge, the front end of the active screw 4 protrudes outside the front cover 2 of the pump, and a sealing seat 6 is provided on the inner end plate of the front cover 2 to make the twin-screw pump have good sealing performance and not easy Liquid leakage, corresponding to the driven screw 5. The inner end plate of the pump front cover 2 is also provided with a sealing seat 6a. The sealing seats 6, 6a are provided with installation channels for the driving screw 4 and the driven screw 5 to penetrate. The outer end plate of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com