A metallized polypropylene film fixed capacitor for suppressing electromagnetic power interference

A technology for fixing capacitors and polypropylene films, which is applied in the field of capacitors, can solve the problems of weak anti-interference performance of electromagnetic power supply, affect capacitor performance, and reduce work performance, and achieve strong oxidation resistance, low high-frequency loss, and excellent vibration The effect of the characteristic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

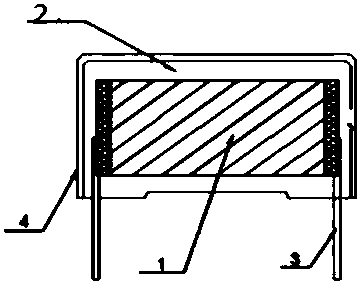

[0015] A metallized polypropylene film fixed capacitor for suppressing electromagnetic power interference, comprising a capacitor 1, a casing 4, pins 3, and a resin 2, the capacitor 1 is arranged inside the casing 4, and resin 2 is filled between the casing 4 and the capacitor 1, The two ends of the capacitor 1 are respectively welded with a pin 3, and the pins 3 extend to the outside of the shell 4; the capacitor uses a polypropylene film as a medium, and zinc and aluminum are deposited on the film by vacuum evaporation as a medium. The electrode is rolled, and the resin is made of the following components in parts by weight: epoxy resin 32, poly-1-butene resin 5, modified sericite powder 1, starch 0.5.

[0016] Further, a gold layer is sprayed on the joint between the capacitor and the pin.

[0017] Further, the polypropylene film is made of the following components in parts by weight: polypropylene resin 28, olivine powder 1, rosin 3, dicumyl peroxide 0.4. % citric acid so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com