Patents

Literature

131results about How to "Low high frequency loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

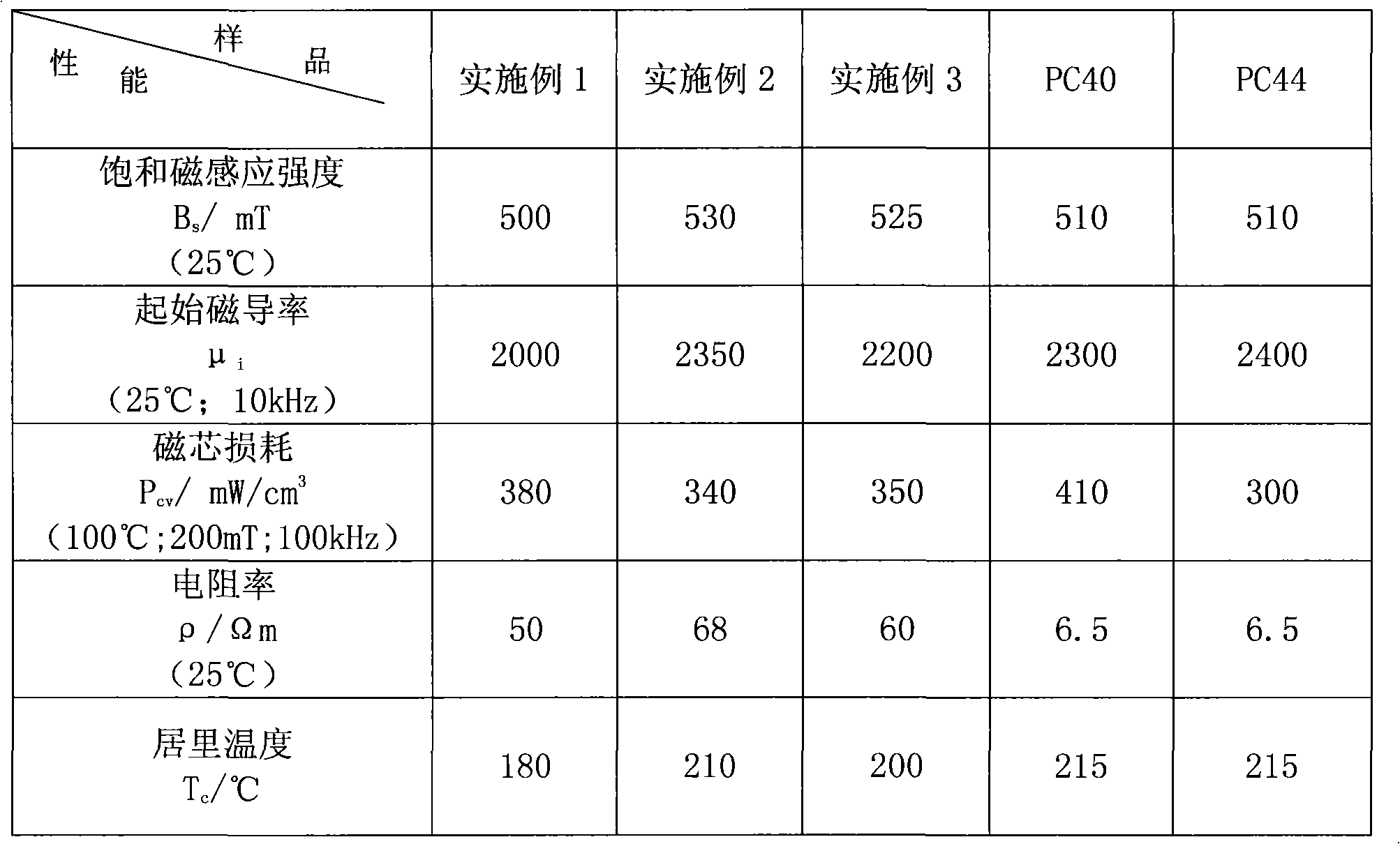

Broadband wide temperature range high-power density low-loss manganese-zinc soft magnetic ferrite material and preparation method thereof

ActiveCN107473727AImprove workabilityLow high frequency lossInorganic material magnetismSpray GranulationManganese

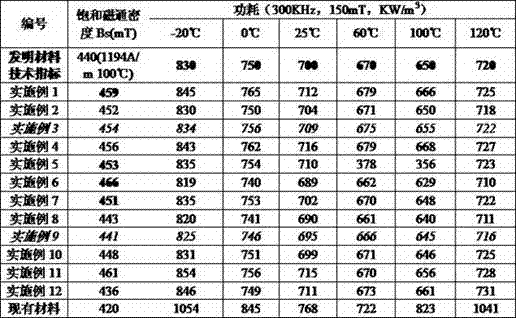

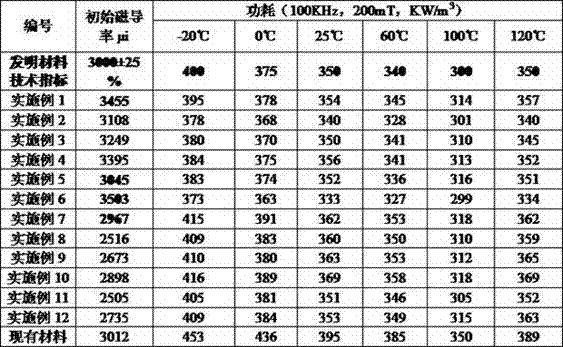

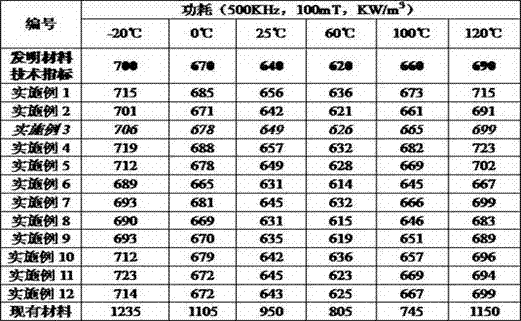

The invention discloses a broadband wide temperature range high-power density low-loss manganese-zinc soft magnetic ferrite material. The material comprises main ingredients, an auxiliary ingredient A and an auxiliary ingredient B, wherein the main ingredients comprise the following components in percentage by weight: Fe2O3, MnO and ZnO; based on the weight of the main ingredients, the auxiliary ingredient A comprises at least three of CaCO3, Nb2O5, NiO, SnO2 and Co3O4; and the auxiliary ingredient B comprises at least three of SiO2, Y2O3, K2CO3, Al2O3, CuO, MoO and Bi2O3. The preparation method of the material sequentially comprises the following steps: primary batching, primary sanding, pre-sintering, secondary batching, secondary sanding, performing component analysis, performing spray granulation, molding and sintering. The material disclosed by the invention has low loss in a temperature range from 20 DEG C below zero to 120 DEG C under the conditions of 100-500KHz and 100-200mT, and has high magnetic conductivity and high high-temperature saturation flux density. Compared with the conventional material, the material disclosed by the invention is energy-saving and can enable a switching power module to be miniature and efficient.

Owner:郴州市久隆旺高科电子有限公司

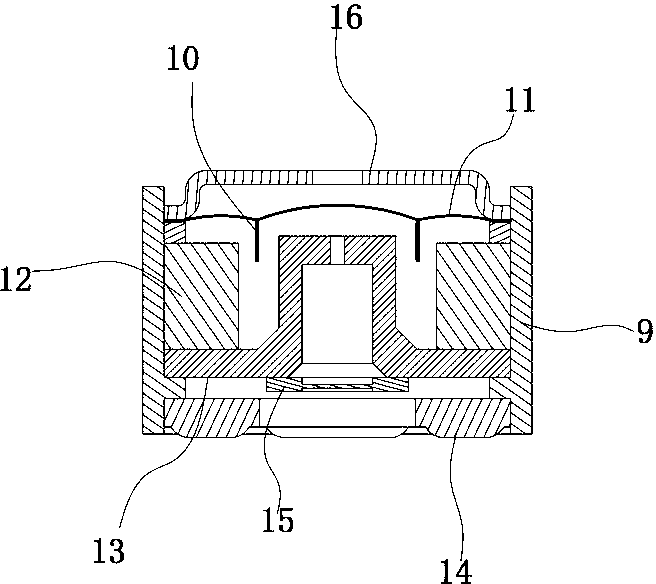

In-ear headset with multiple dynamic drive units

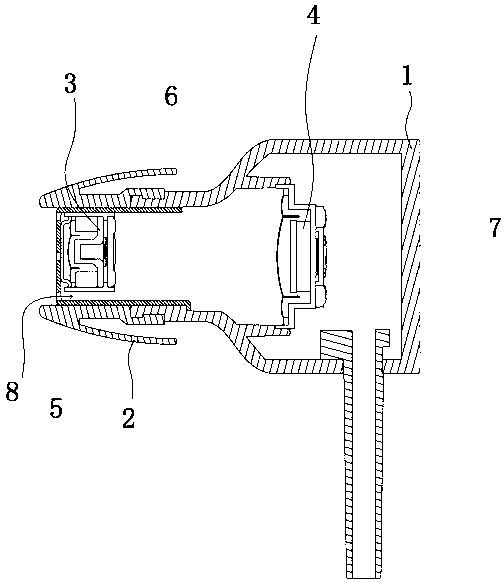

InactiveCN103179483AWith treble and bassExcellent high-frequency extension characteristicsEarpiece/earphone attachmentsEngineeringAudio frequency

The invention discloses an in-ear headset with multiple dynamic drive units in the field of headsets. The in-ear headset comprises a headset shell with an accommodating space and an audio component mounted in the headset shell, the audio component is a multichannel system structure composed of the multiple dynamic drive units, each dynamic drive unit is composed of a high-frequency dynamic drive and a low-frequency and medium-frequency drive, the accommodating space in the headset shell contains voice tubes, each high-frequency dynamic drive is arranged at the front end of each voice tube, and each low-frequency and medium-frequency drive is arranged at the rear end of the voice tube. The multichannel headset formed by the dynamic drive units has treble, bass and distinguished high-frequency extension characteristic as the high-frequency dynamic drives and the low-frequency and medium-frequency drives are designed, larger bandwidth is provided for audio play, and audio tracks are more stable and have larger bandwidth. In addition, the in-ear headset is simple in structure, low in production cost and convenient for wide popularization.

Owner:ZHONGMING DONGGUAN ELECTRONICS

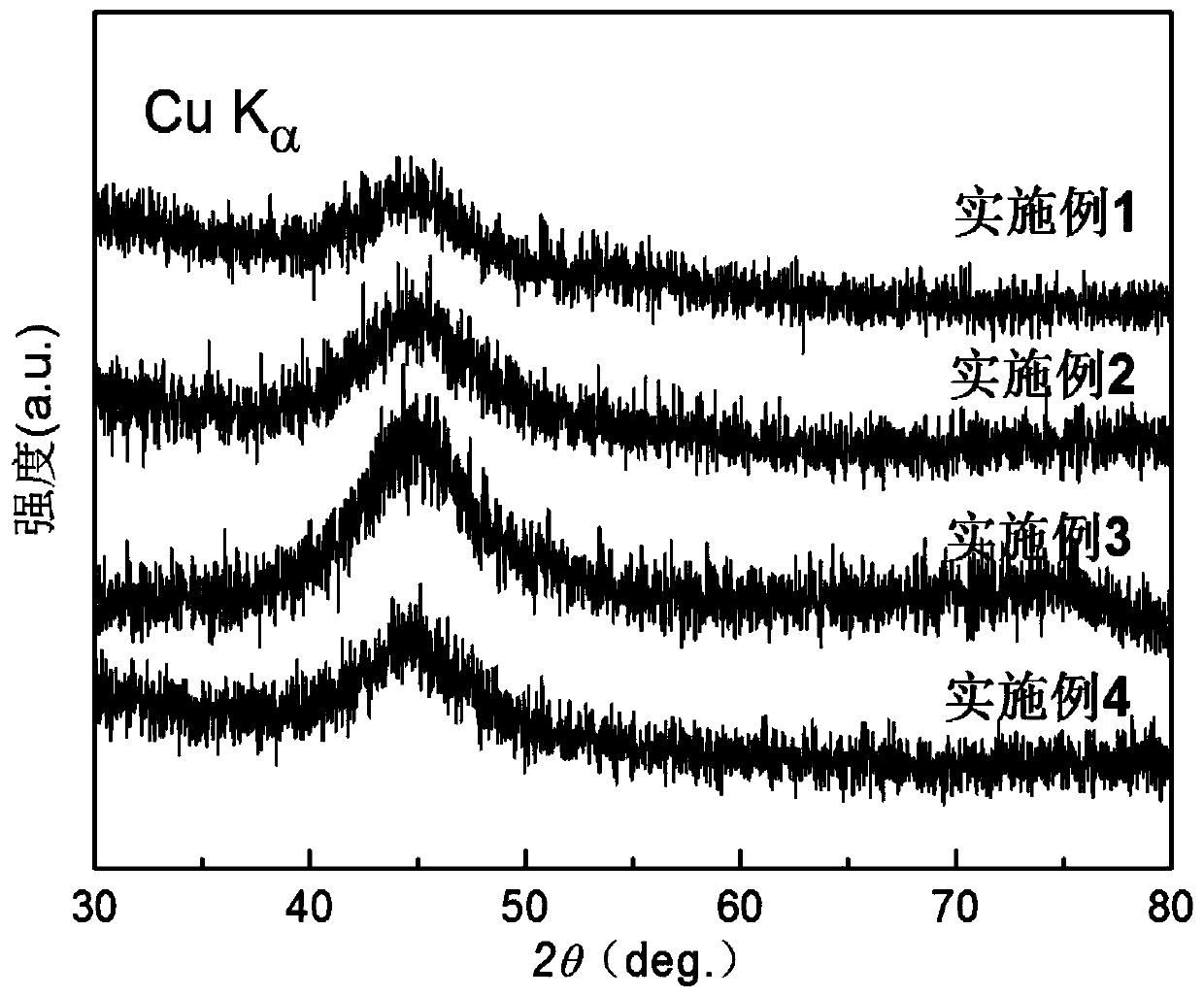

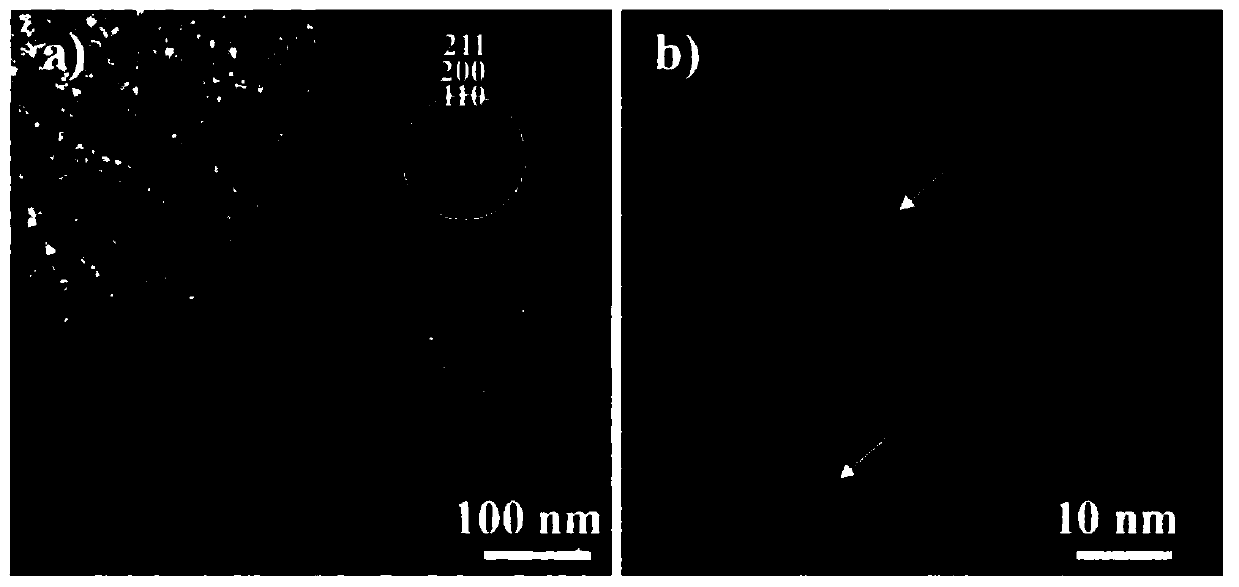

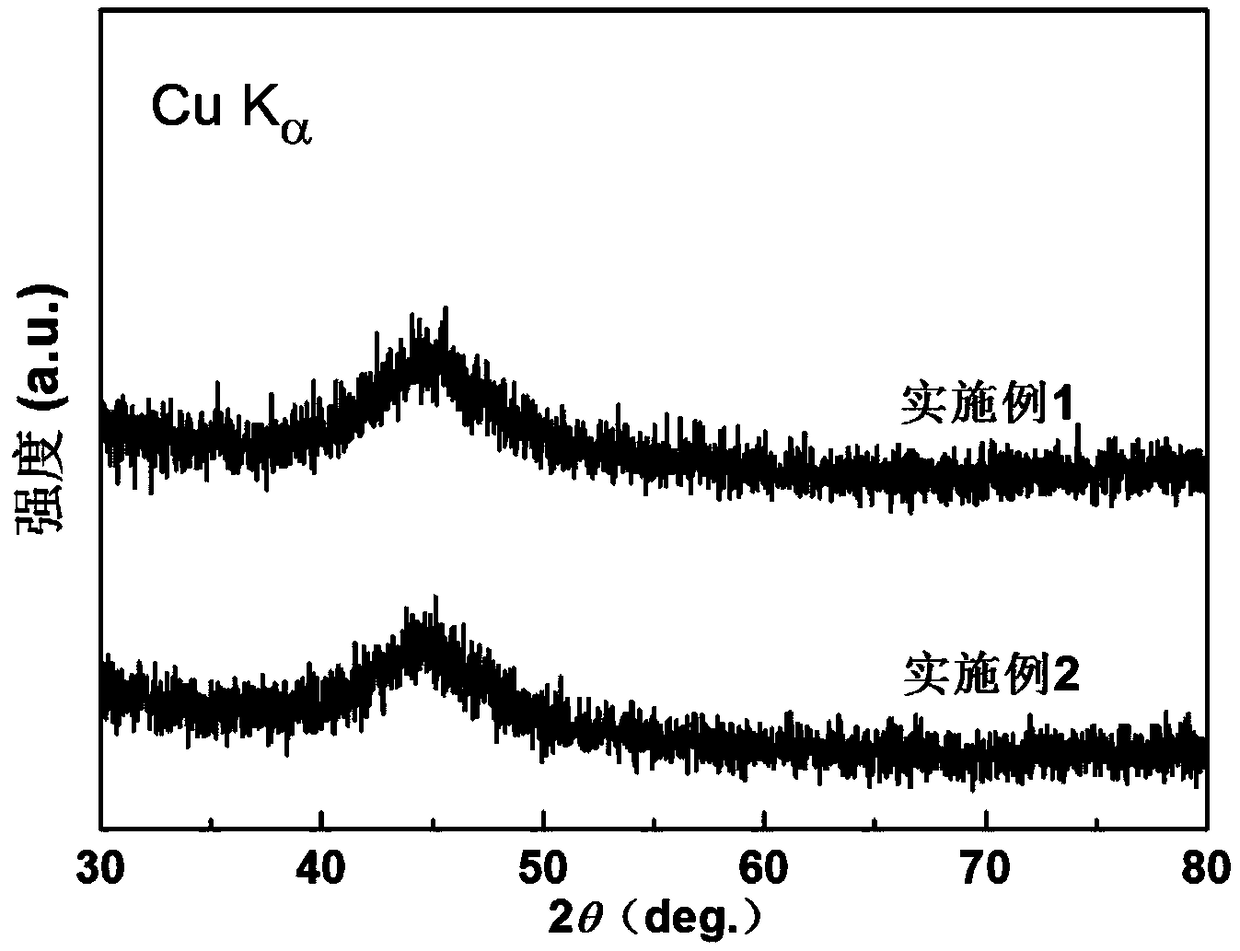

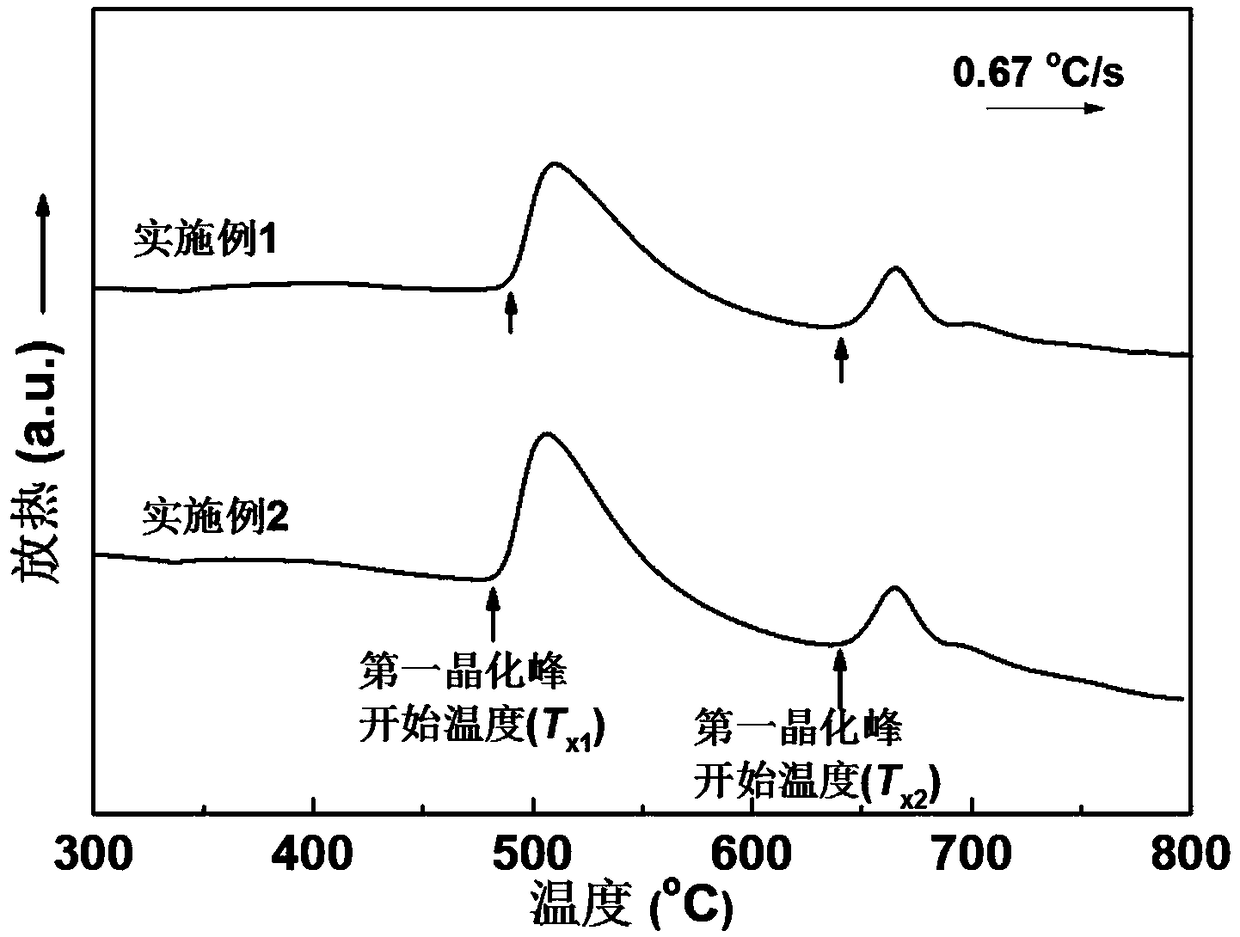

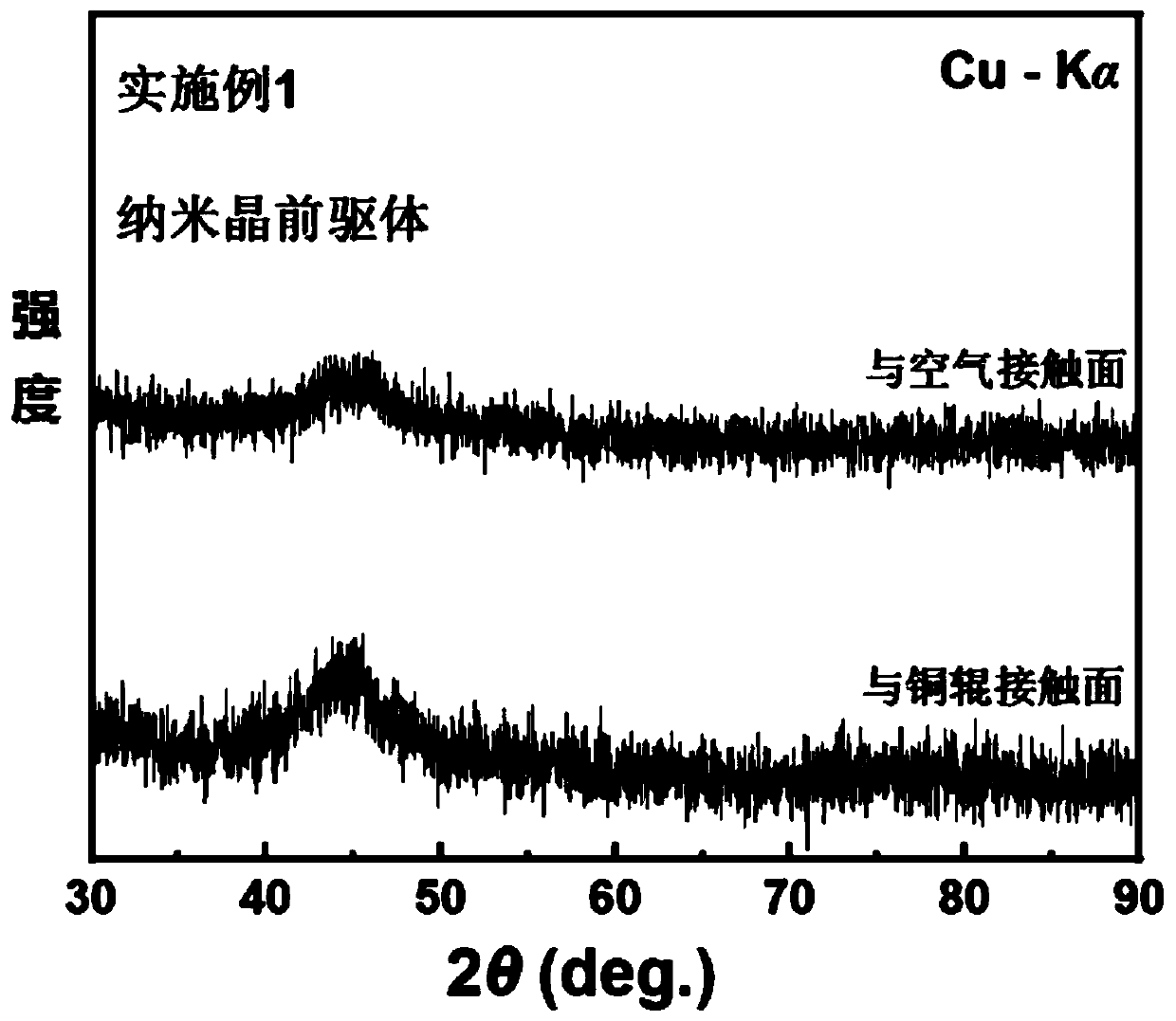

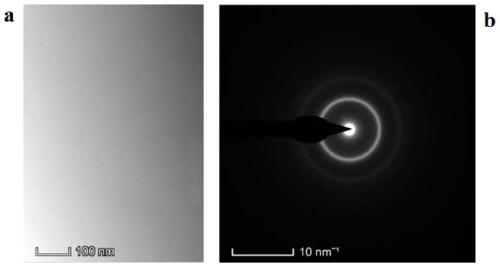

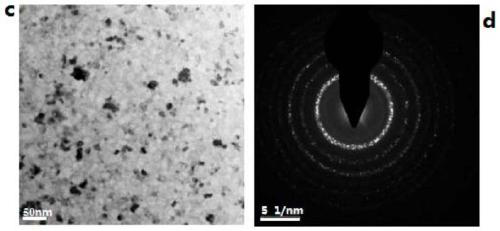

Nanocrystalline magnetically soft alloy, amorphous magnetically soft alloy and preparation methods of nanocrystalline magnetically soft alloy and amorphous magnetically soft alloy

ActiveCN110670000AImprove high frequency permeabilityImproving the high and high frequency permeability of soft magnetic alloysInorganic material magnetismCrystallization temperatureFerromagnetism

The invention provides a nanocrystalline magnetically soft alloy, an amorphous magnetically soft alloy and preparation methods of the nanocrystalline magnetically soft alloy and the amorphous magnetically soft alloy. The nanocrystalline magnetically soft alloy comprises the compositions of Fe, Cu, Si, B, and Nb, and further comprises at least one element between Mn and Cr, wherein the atomic percentage content of each element at the at least one between the Mn and the Cr is not more than 3.5 at%. The antiferromagnetism of the Mn element and / or the Cr element is utilized, and a heat treatment mode of multi-stage rate annealing is combined, so that the high-frequency magnetic permeability of the magnetically soft alloy is improved, the high-frequency loss of the magnetically soft alloy is reduced, and the high-frequency magnetic performance of the magnetically soft alloy is improved; meanwhile, the crystallization temperature interval is narrower, and the heat treatment temperature interval is wider, so that the high-quality nanocrystalline magnetically soft alloy or the high-quality amorphous magnetically soft alloy are obtained favorably and the preparation cost is reduced; and inaddition, the oxidation resistance of the Mn element and / or the Cr element is further utilized, so that the tolerance of impurities is improved, the surface of an amorphous strip is prevented from being crystallized, the amorphous forming capacity is improved, and the high-quality magnetically soft alloy can be prepared through low-purity commercial raw materials.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +3

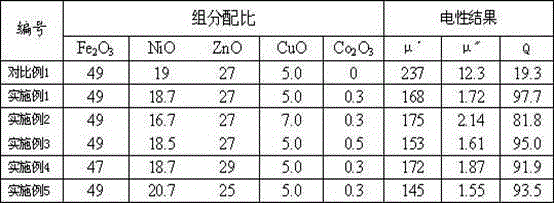

NiCuZn ferrite material and manufacturing method thereof

The invention discloses a NiCuZn ferrite material and a preparation method thereof. The ferrite material comprises a main component and an additive. The main component is composed of 47-49 mol% of Fe2O3, 15-22 mol% of NiO, 25-30 mol% of ZnO, 4-7 mol% of CuO and 0.1-0.5 mol% of Co2O3. The additive is composed of A and B, wherein A accounts for 0.1-0.5 wt% of the whole material, and B accounts for 0.1-0.5 wt% of the whole material. A is BBSZ glass; and B is one or two of Ta2O5, SiO2 and SnO2. The nickel-zinc ferrite soft magnetic material disclosed by the invention has the characteristics of high initial permeability and low loss; under the frequency of 13.56 MHz, mu' is greater than 150, and mu' is less than 2; and the nickel-zinc ferrite soft magnetic material is very suitable for producing NFC (near field communication) ferrite magnetic sheets by an LTCC (low temperature co-fired ceramic) running technique.

Owner:东莞成电创新电子科技有限公司

Processing method of electromagnetic shielding magnetic material

ActiveCN108122669AImprove magnetic permeabilityConstant magnetic permeabilityInductances/transformers/magnets manufactureElectromagnetic transmissionPulse current

The invention discloses a processing method of an electromagnetic shielding magnetic material. A soft magnetic alloy magnetic material strip is wound into a soft magnetic alloy magnetic material ring,and the ring is installed a thermal processing furnace; protection gas is injected into the thermal processing furnace and the furnace is heated after the furnace is vacuumized, the furnace temperature is kept, a longitudinal magnetic field and a transverse magnetic field are exerted on the magnetic material through an alternating pulse current A and an alternating pulse current B, and cooling isconducted; after the thermally-processed soft magnetic alloy magnetic material ring is attached to double-sided adhesive tape with a PET base material to form a tape-covered magnetic material strip belt, ultrasonic vibrating, roller pressing and smashing are conducted on the tape-covered magnetic material strip belt to form soft magnetic alloy roller pressing strip belts, and the soft magnetic alloy roller pressing strip belts and multiple pieces of double-sided adhesive tape are overlapped alternately and pressed into a soft magnetic alloy composite overlapped strip belt of a sandwich structure. The magnetic material processed through the method has the advantages of being high and constant in magnetic conductivity, high in frequency and temperature stability, low in high-frequency vortex loss and high in electromagnetic transmission and conversion efficiency.

Owner:SHANGHAI LIANGZI HUIJING ELECTRONICS CO LTD

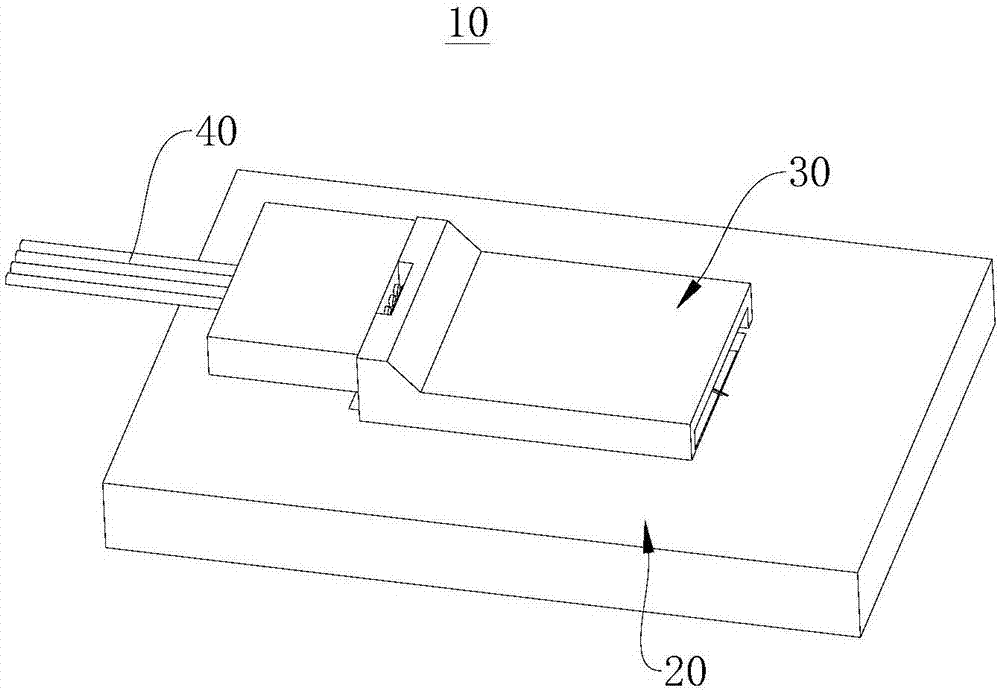

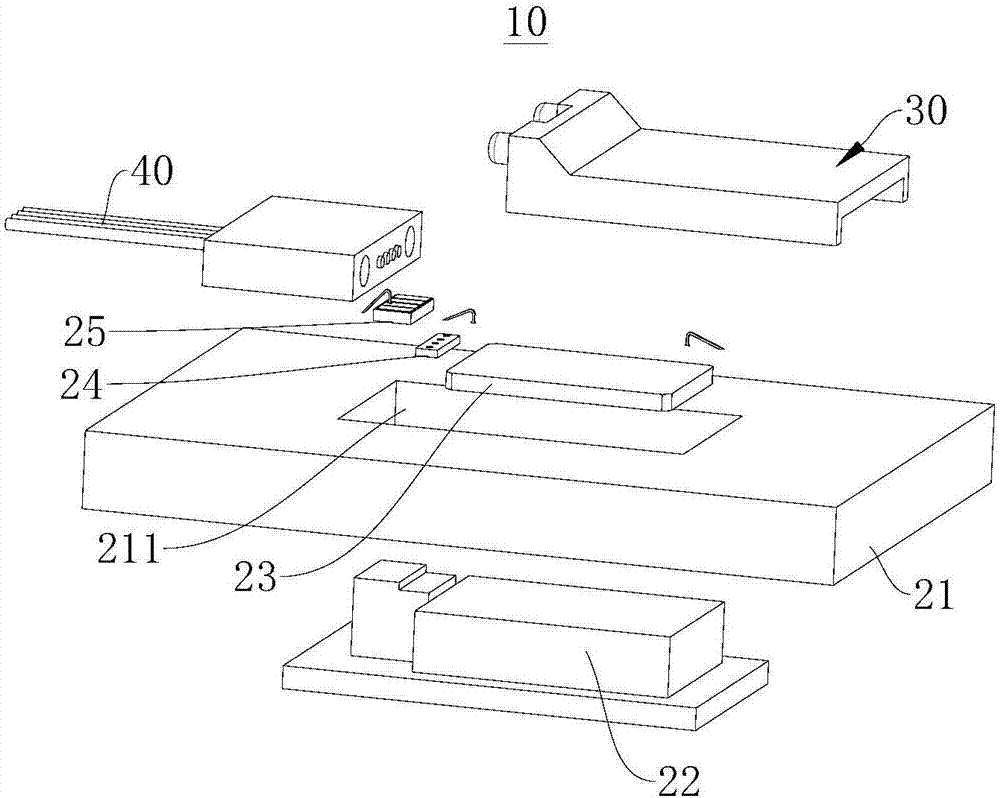

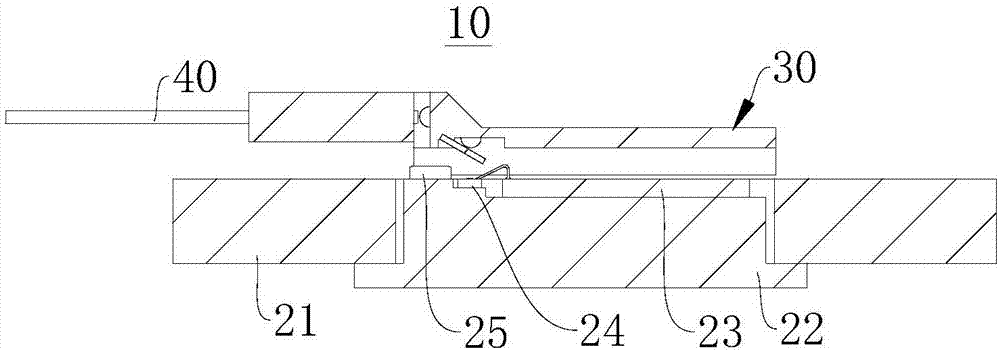

PCB (Printed Circuit Board) component and light emitting component

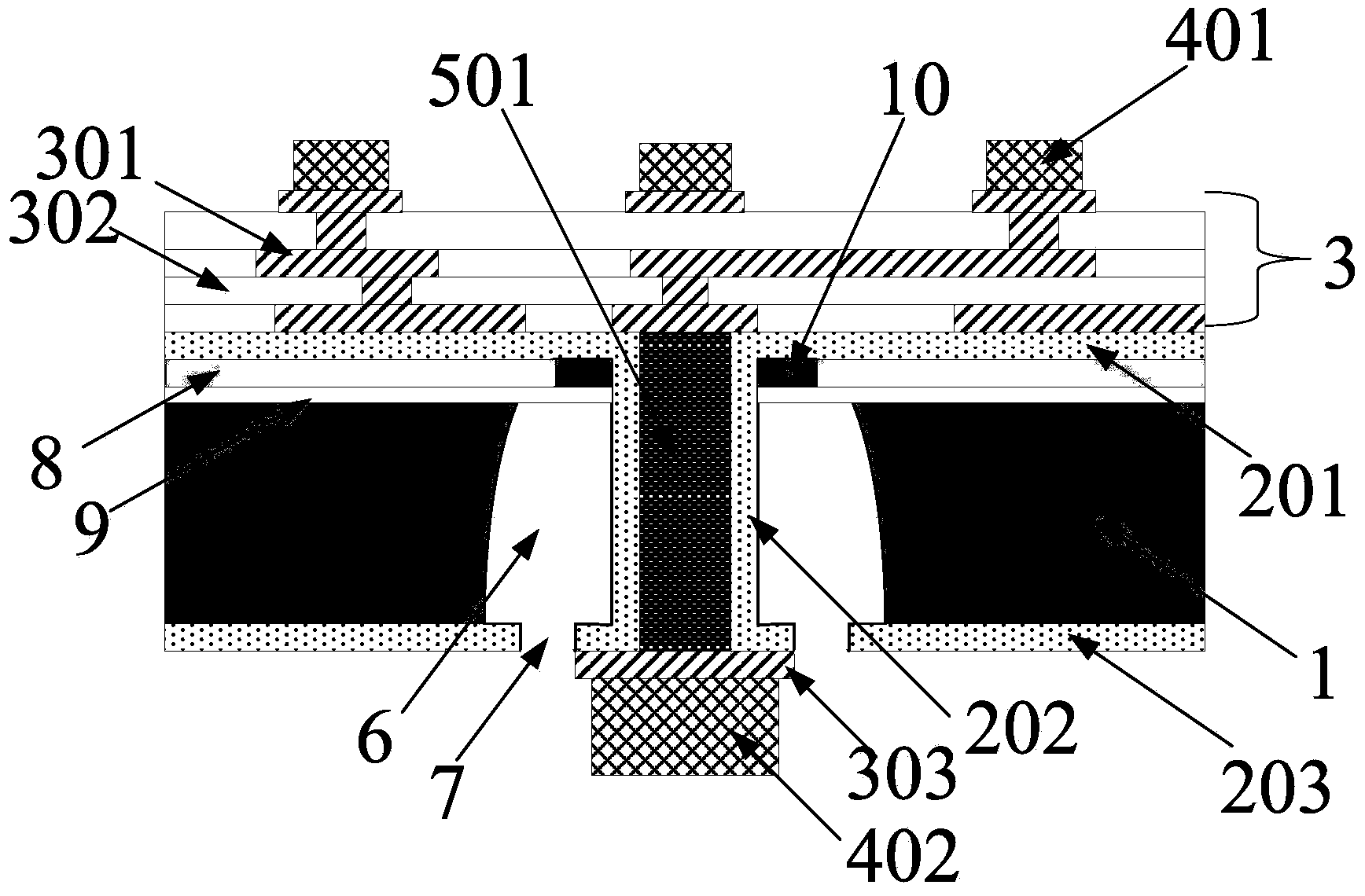

InactiveCN107546568ALow high frequency lossImprove transmission characteristicsLaser constructional detailsSemiconductor lasersEngineeringArch height

The invention provides a PCB (Printed Circuit Board) component and a light emitting component, and relates to the technical field of communication. The PCB component comprises a PCB substrate and a driving chip, wherein a mounting hole is formed in the PCB substrate; a mounting surface is arranged at the bottom of the mounting hole; the driving chip is arranged on the mounting surface; and a height difference between the top surface of the driving chip and the top surface of the PCB substrate is less than the thickness of the driving chip. Therefore, the height difference between the top surface of the driving chip and the top surface of the PCB substrate is smaller; the arch height formed by gold wire bonding connection between the top surface of the driving chip and the top surface of the PCB substrate is lower; the high-frequency loss of the PCB component is lower; and the transmission characteristic is good.

Owner:NEW H3C TECH CO LTD

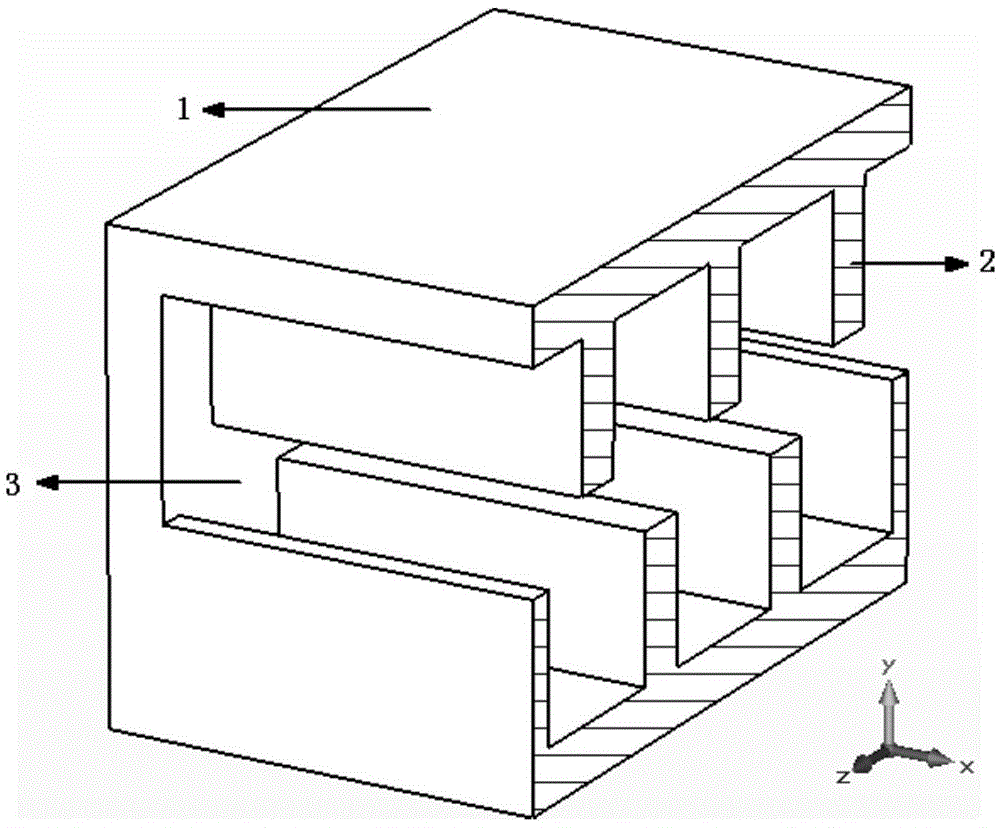

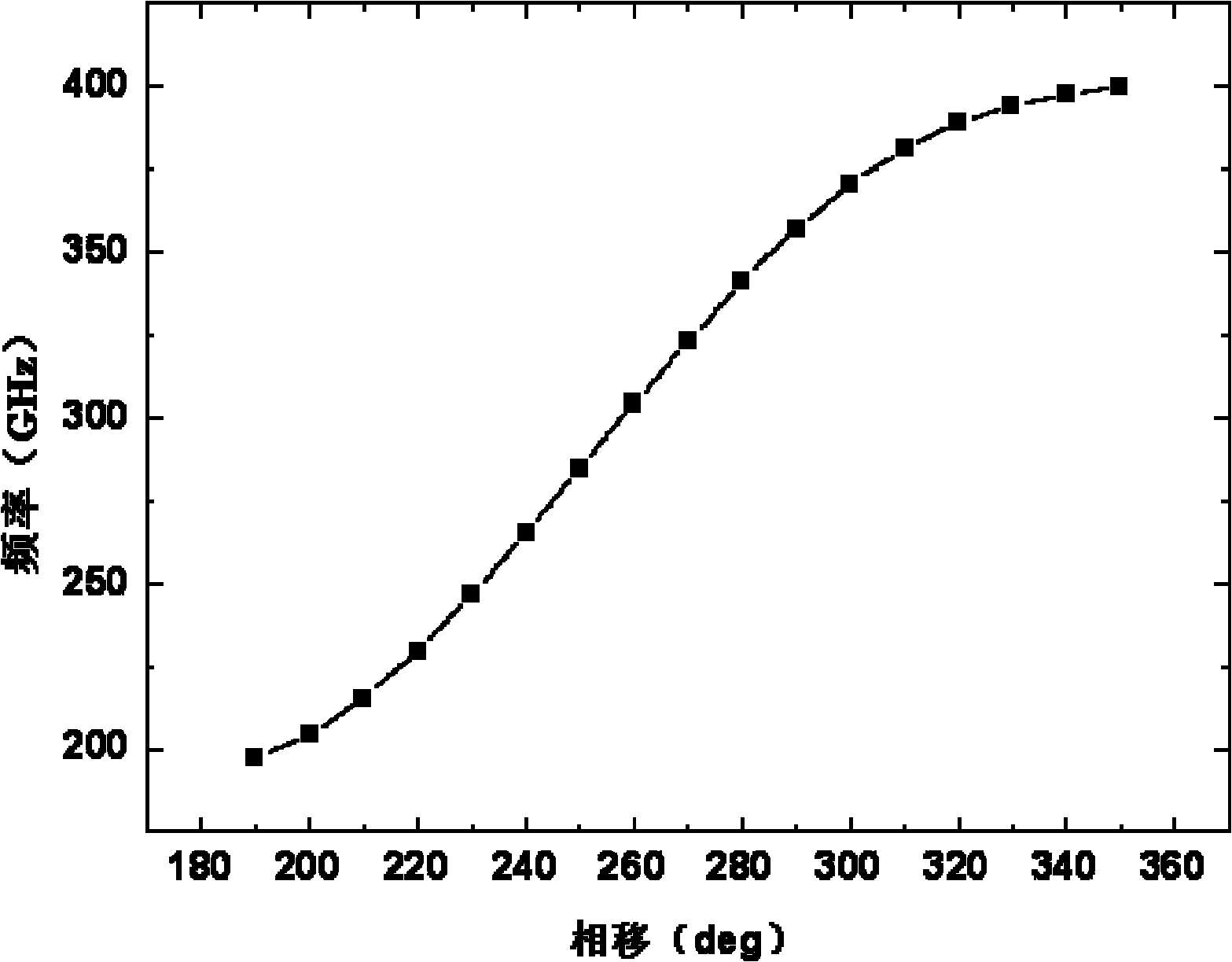

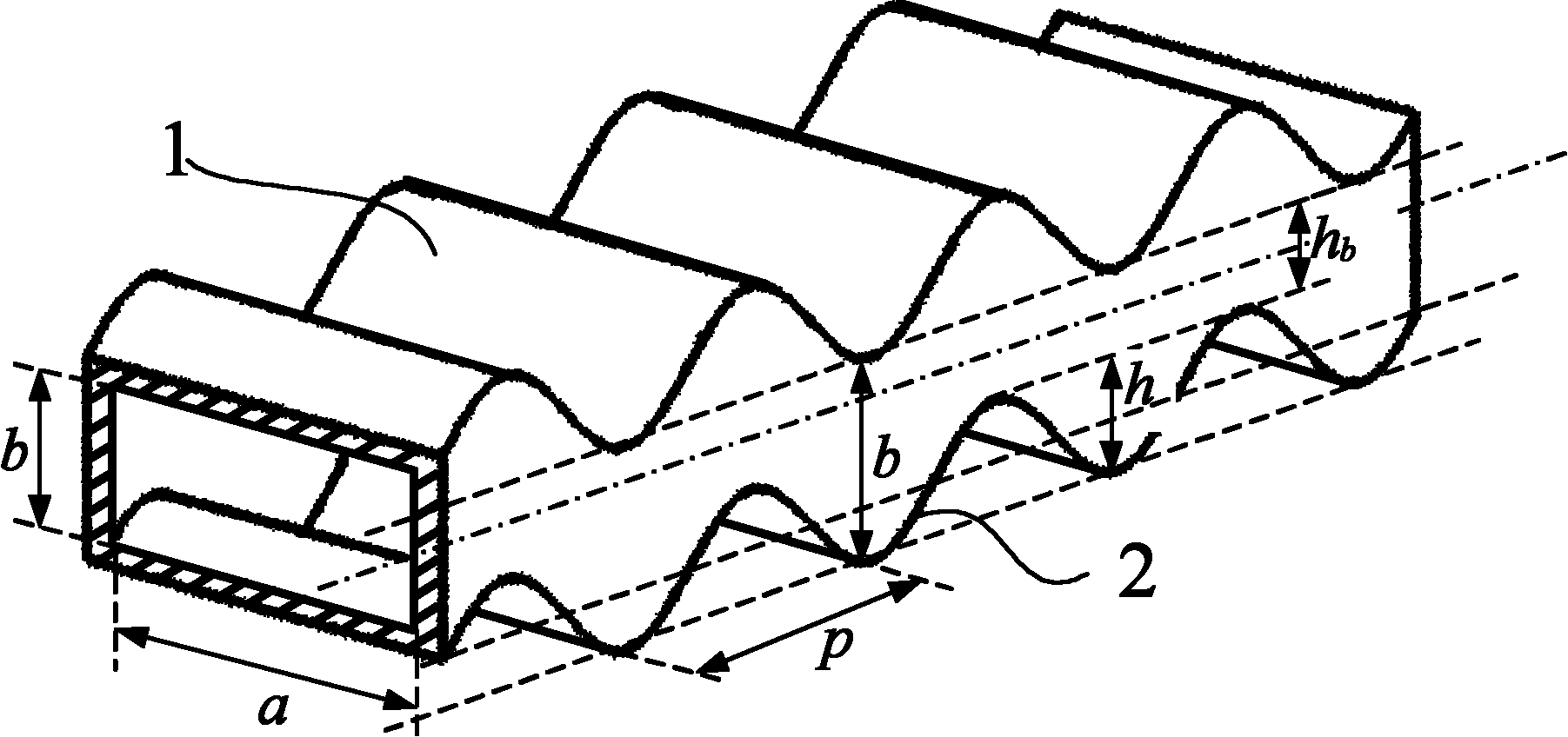

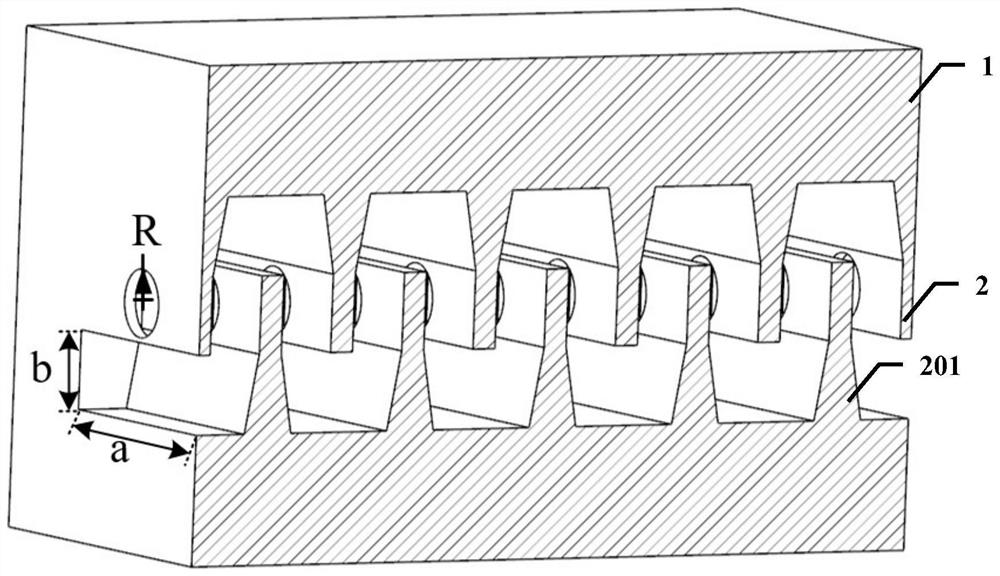

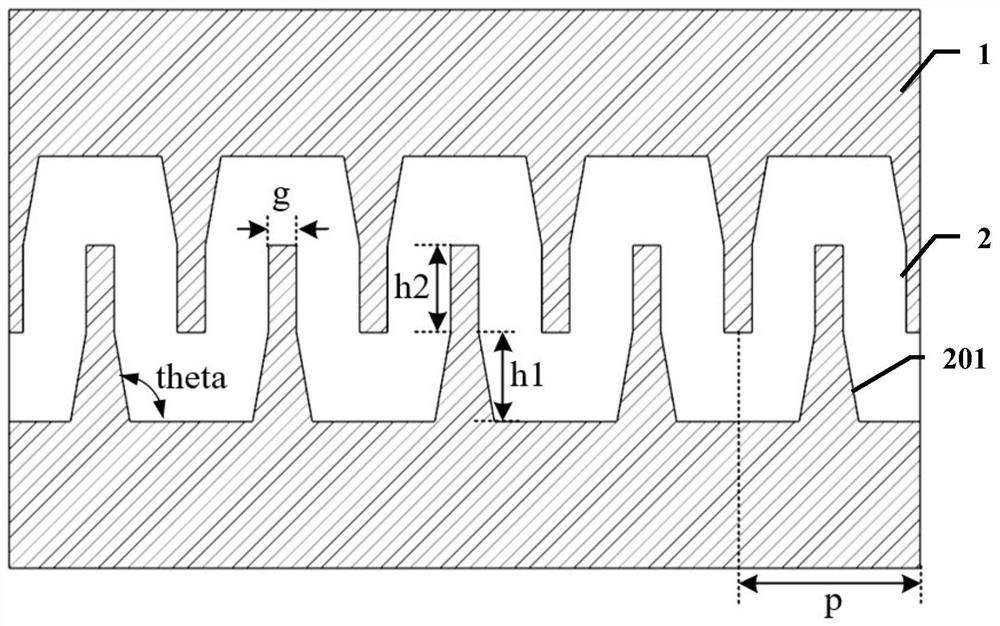

Half-cycle staggered cosine end plane gate slow wave structure

ActiveCN105575745ALow high frequency lossIncrease cold bandwidthTransit-tube circuit elementsWave structureElectron

The invention provides a half-cycle staggered cosine end plane gate slow wave structure. The slow wave structure comprises a shell, multiple first gate bodies formed on the first edge of an inner cavity and multiple second gate bodies formed on the second edge, opposite to the first edge, of the inner cavity; the first gate bodies and the second gate bodies are arranged in a staggered manner along an axial line of the slow wave structure; electron beam channels are formed between the first gate bodies and the second gate bodies; and the slow wave structure is characterized in that the end planes, perpendicular to the axial line, of each first gate body and each second gate body are provided with cosine outlines on the sides of the electron beam channels. According to the slow wave structure, the high frequency loss of the low wave structure is lowered, and cold bandwidth is increased, so that the slow wave structure is suitable for improvement of terahertz efficiency and bandwidth.

Owner:NO 12 RES INST OF CETC

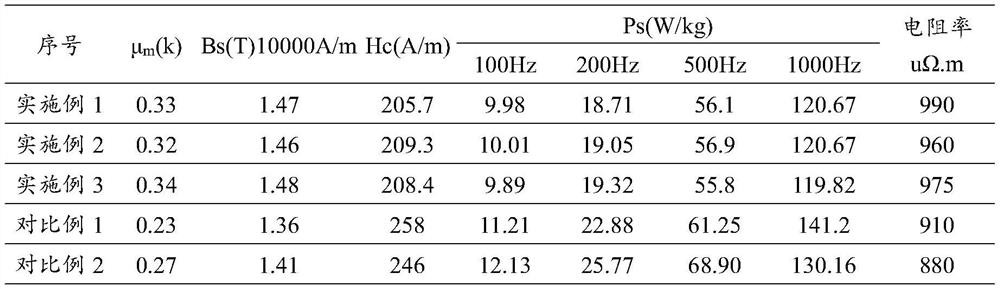

MnZn ferrite material in lean iron formula and preparation method thereof

The invention discloses an MnZn ferrite material in a lean iron formula; the material is prepared from main components and auxiliary components, wherein the main components and the molar percentage are as follows by oxide: Fe2O3: 45 to 49mol percent; MnO: 31.7 to 34.5 mol percent; and the balance ZnO; the auxiliary components and the weight percentage are as follows by oxide: SnO2: 0.1 to 0.5 weight percent; ZrO2: 0.1 to 0.5 weight percent; the invention also relates to a preparation method of the MnZn ferrite material in the lean iron formula, which comprises the following steps: (1) material preparation; (2) primary ball milling; (3) pre-burning; (4) secondary ball milling and doping; (5) adhesive adding and granulation; (6) forming; (7) sintering; the invention controls the content of the main components, particuarlly adopts lean iron, adds special auxiliary components into the main components, so as to prepare iron material which has higher resistivity, lower high-frequency loss, and simultaneously has higher saturation magnetic induction, higher curie temperature and other excellent integrated performance; and the preparation method of the invention not only has low cost and simple process, but also strictly controls the temperature curve, and carries out atmosphere protection.

Owner:苏州天铭磁业有限公司

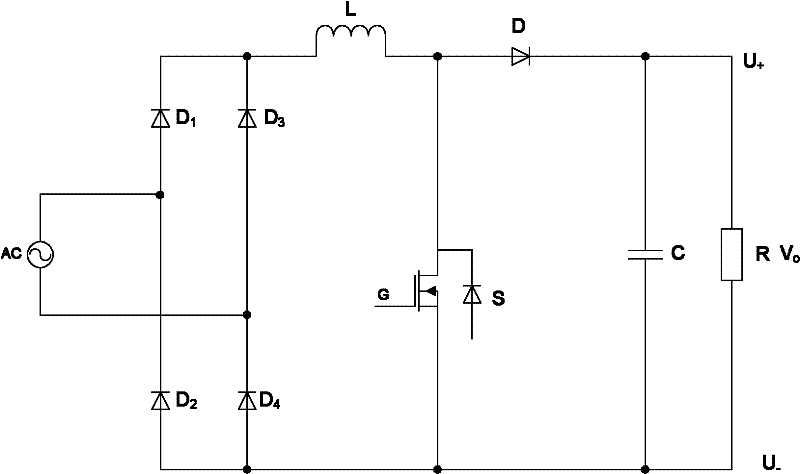

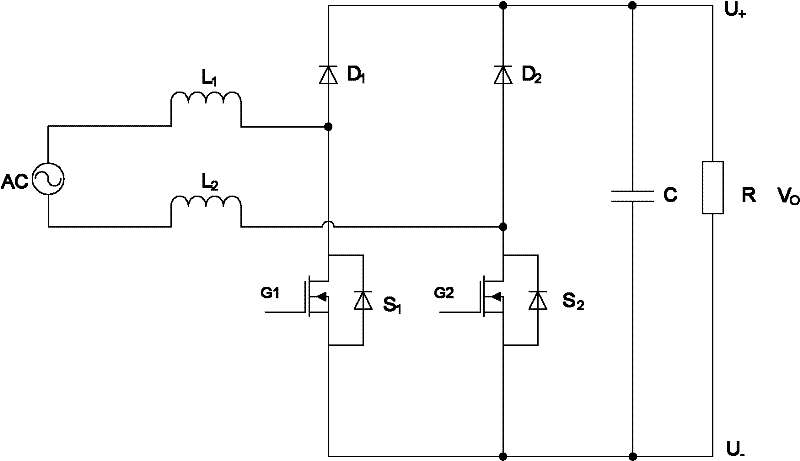

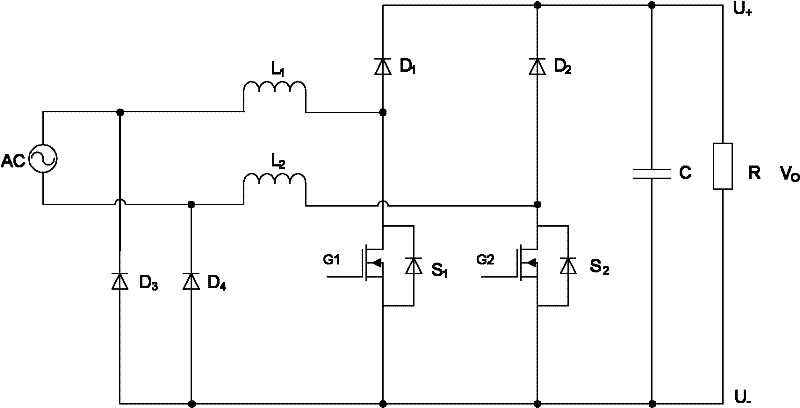

Power factor correction (PFC) circuit and control method

InactiveCN102457174AEliminate high frequency reverse currentLow high frequency lossEfficient power electronics conversionEnergy industryReverse currentCapacitance

The invention discloses a power factor correction (PFC) circuit and a control method. According to a power frequency cycle, a first controllable switching device (S1) or a second controllable switching device (S2) is controlled to be turned on or off; in a power frequency positive half-cycle, the first controllable switching device (S1) is turned off while the second controllable switching device (S2) is turned on; and in a power frequency negative half-cycle, the second controllable switching device (S2) is turned off while the first controllable switching device (S1) is turned on. A main power current loop which is continuously switched on is provided through a low-impedance path of the first controllable switching device (S1) or the second controllable switching device (S2). By replacing a slow recovery diode with the controllable switching devices, the influence of a junction capacitance effect is eliminated, a reverse current of each switching cycle is remarkably reduced, the high-frequency loss of a line is reduced, and the efficiency of the PFC circuit is improved. By the invention, an electromagnetic interference (EMI) effect can be improved, the quantity of components is decreased, and efficiency and power density are improved.

Owner:ZTE CORP

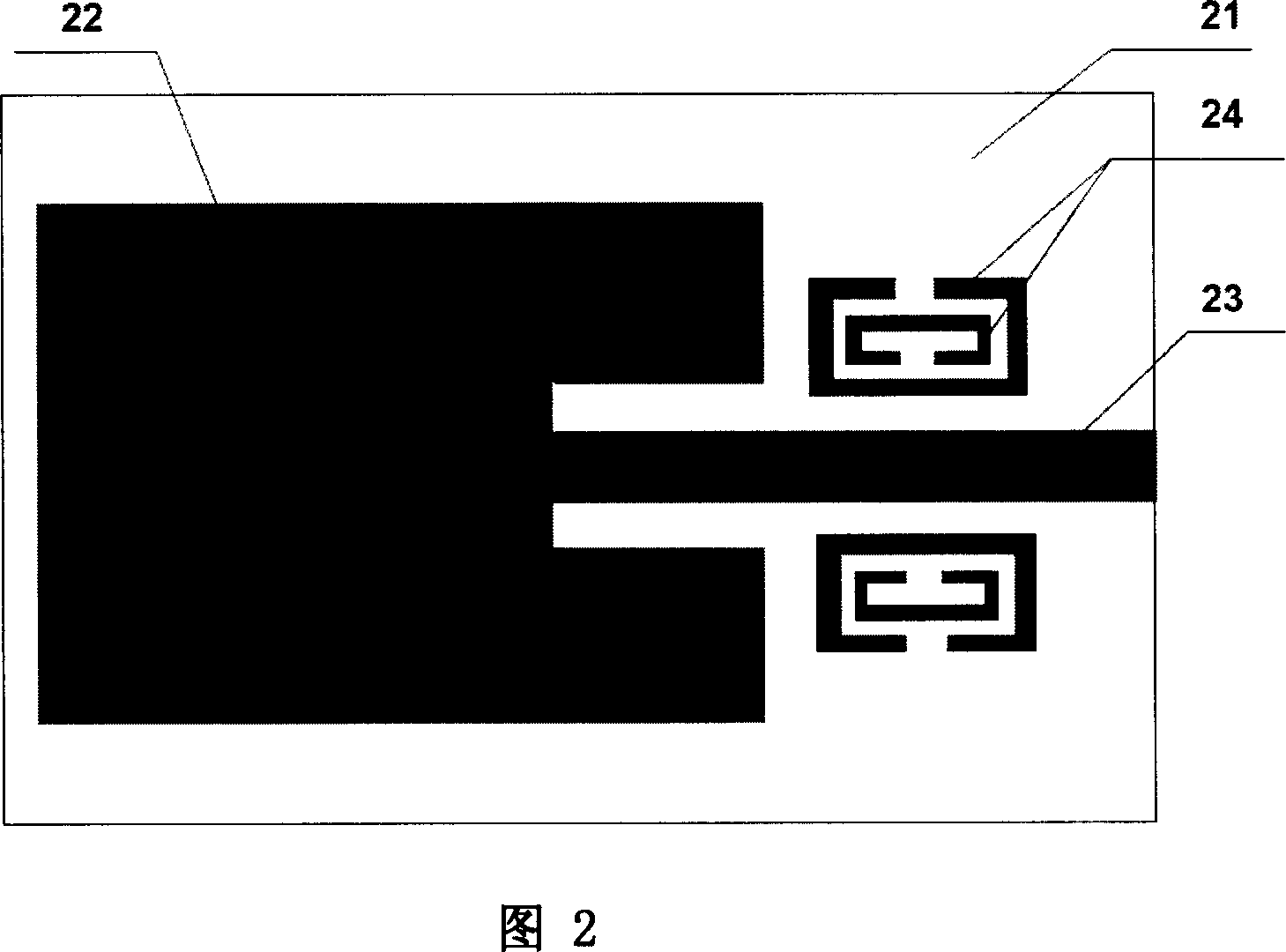

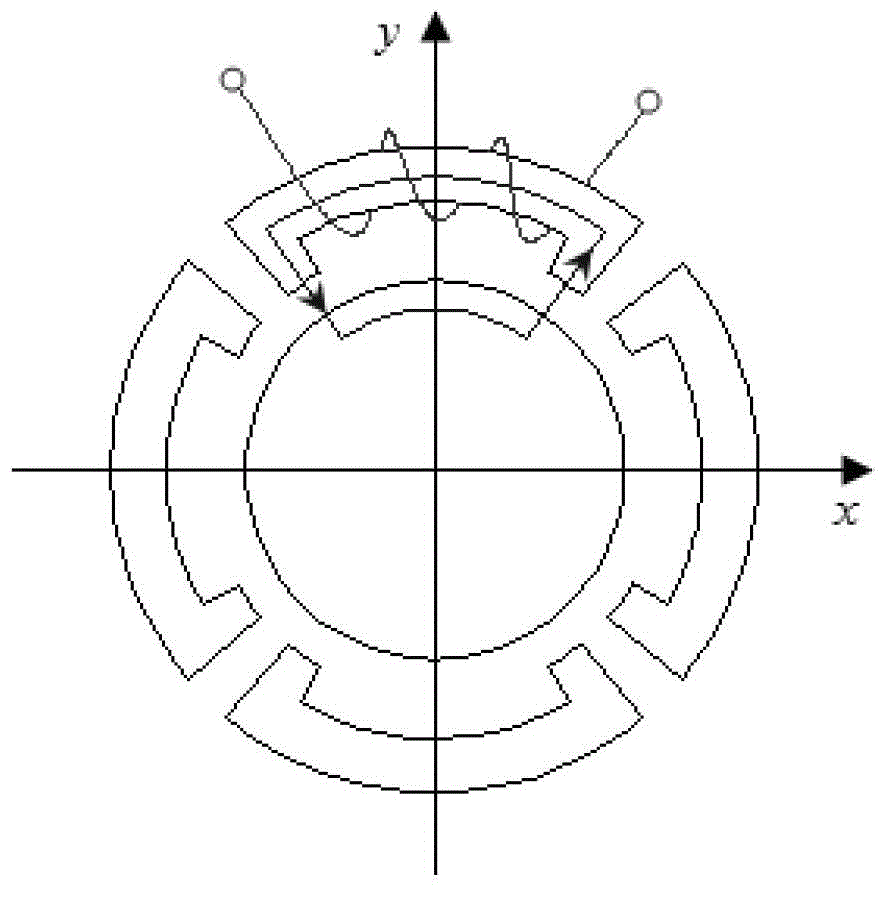

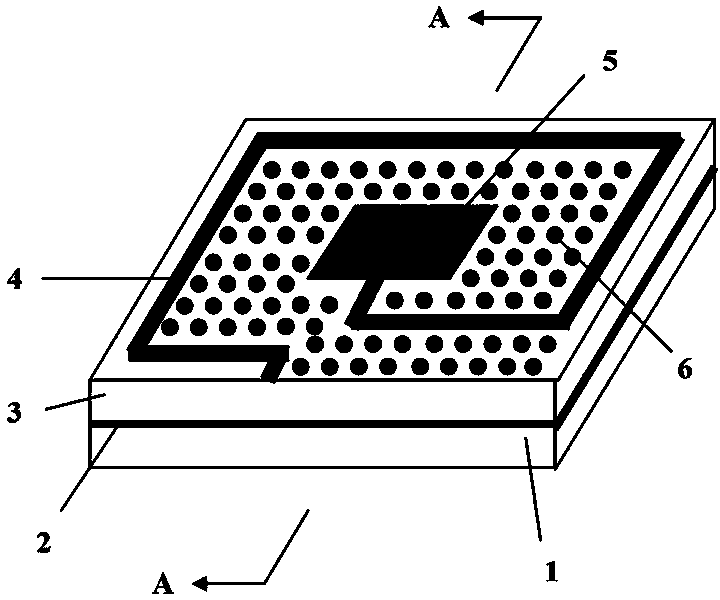

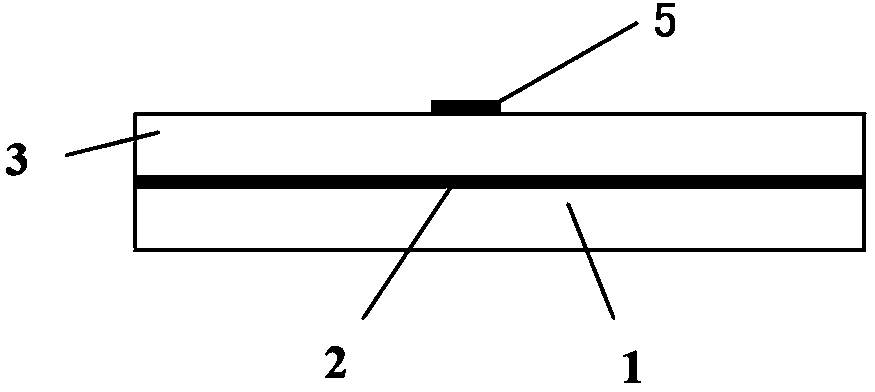

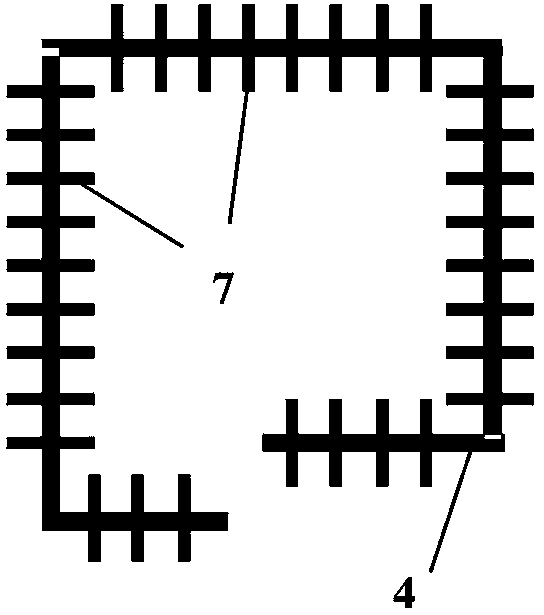

Micro strip antenna

InactiveCN1945899AOverall small sizeLow high frequency lossRadiating elements structural formsHigher order harmonicsMagnetic media

This invention relates to an antenna working at the microwave band including a medium substrate, one side of which is adhered with a metal layer as the ground, the other side is adhered with a concave metal plate as a plate stick antenna unit and a micro-strip line as the feeding line connecting to the concave of the metal plate, and an artificial magnetic medium material is set symmetrically at both sides of the micro-strip line and adhered on the substrate. This invention can realize forbidden band at a certain working frequency sphere so as to suppress high order harmonics.

Owner:ZHEJIANG UNIV

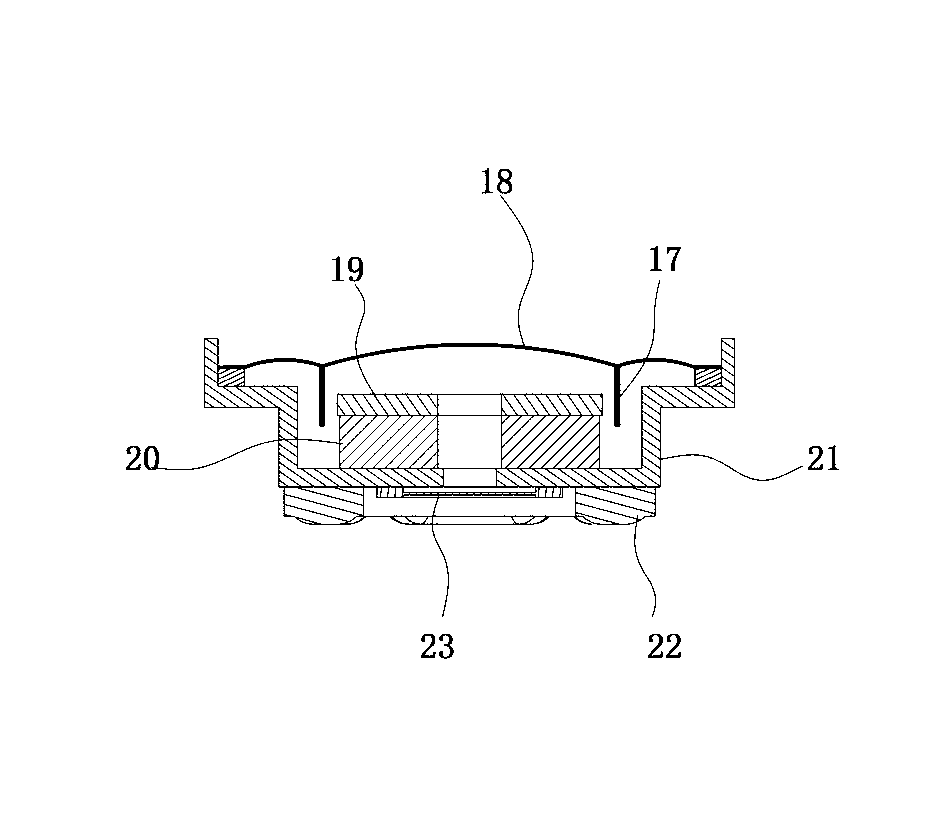

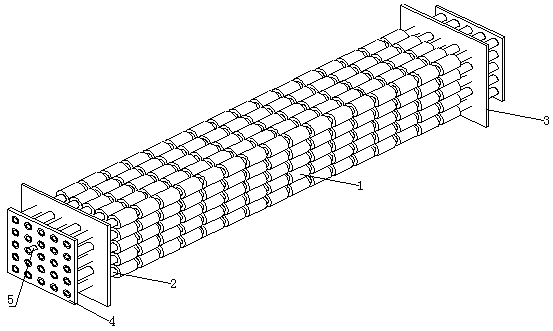

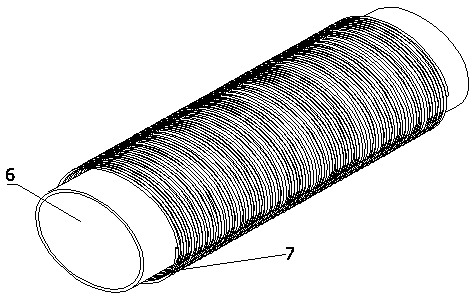

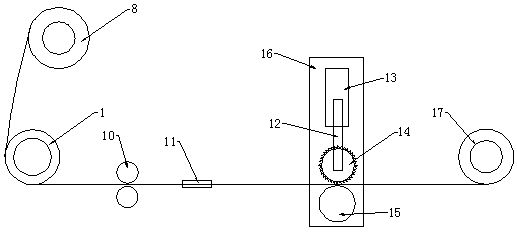

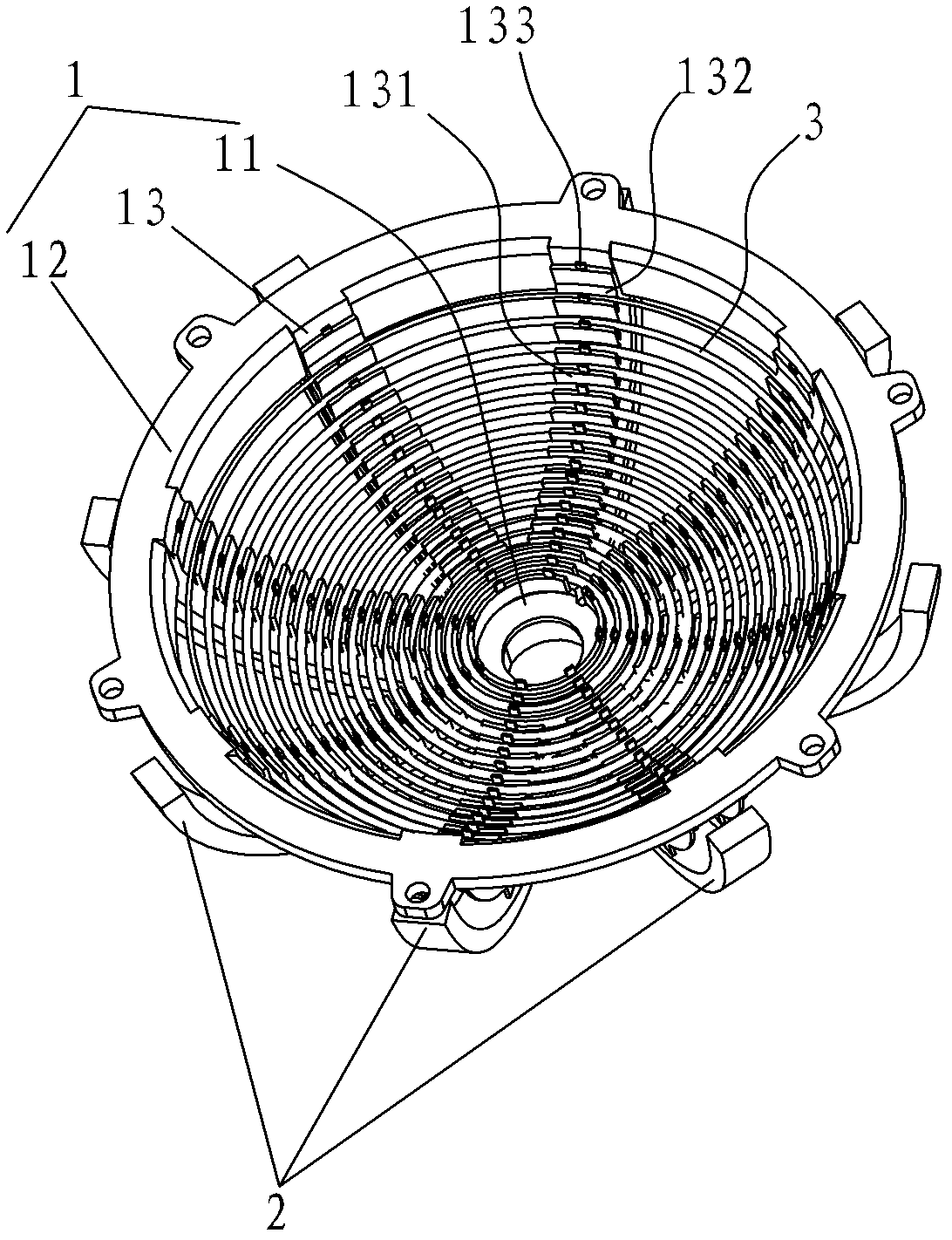

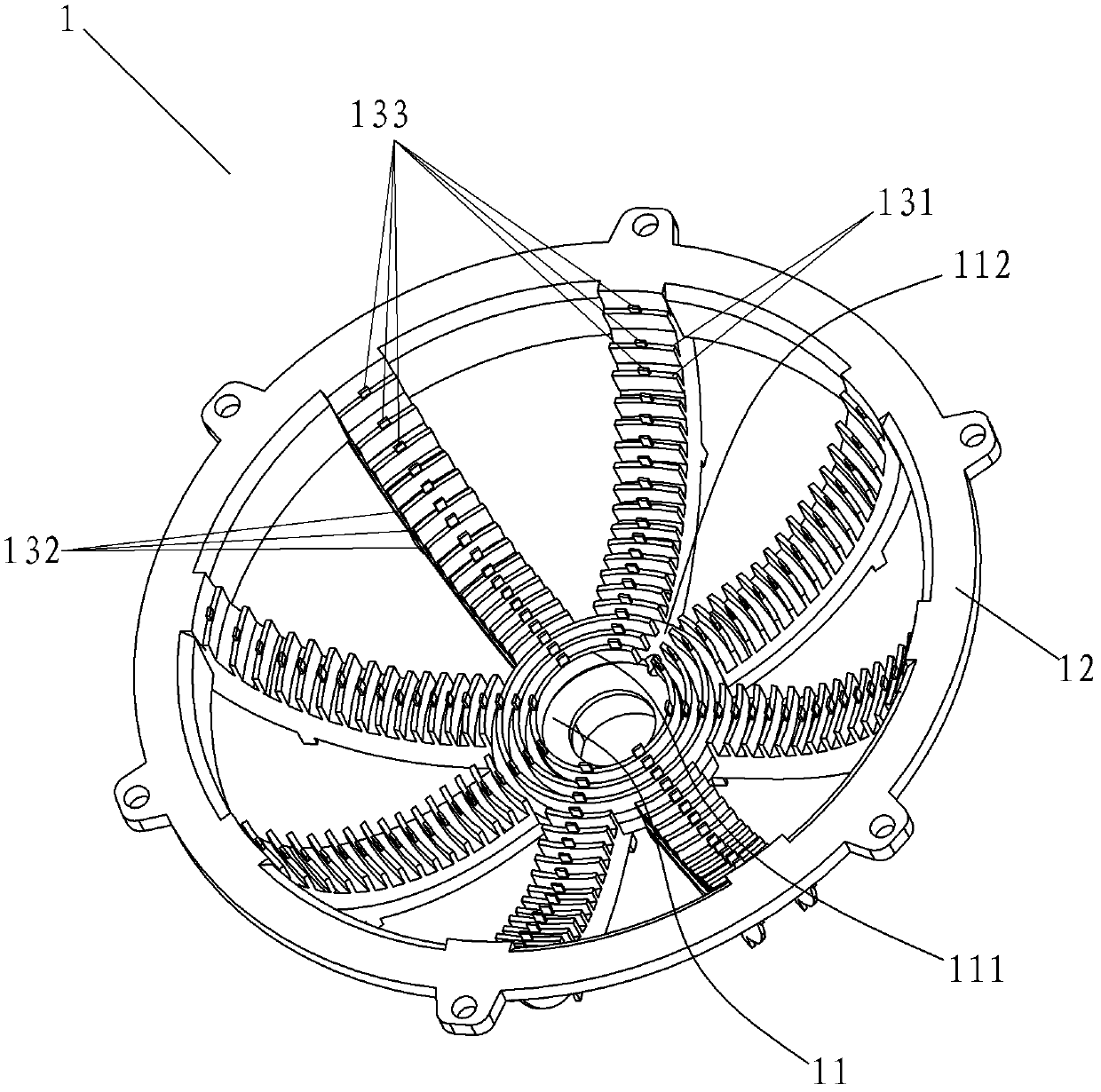

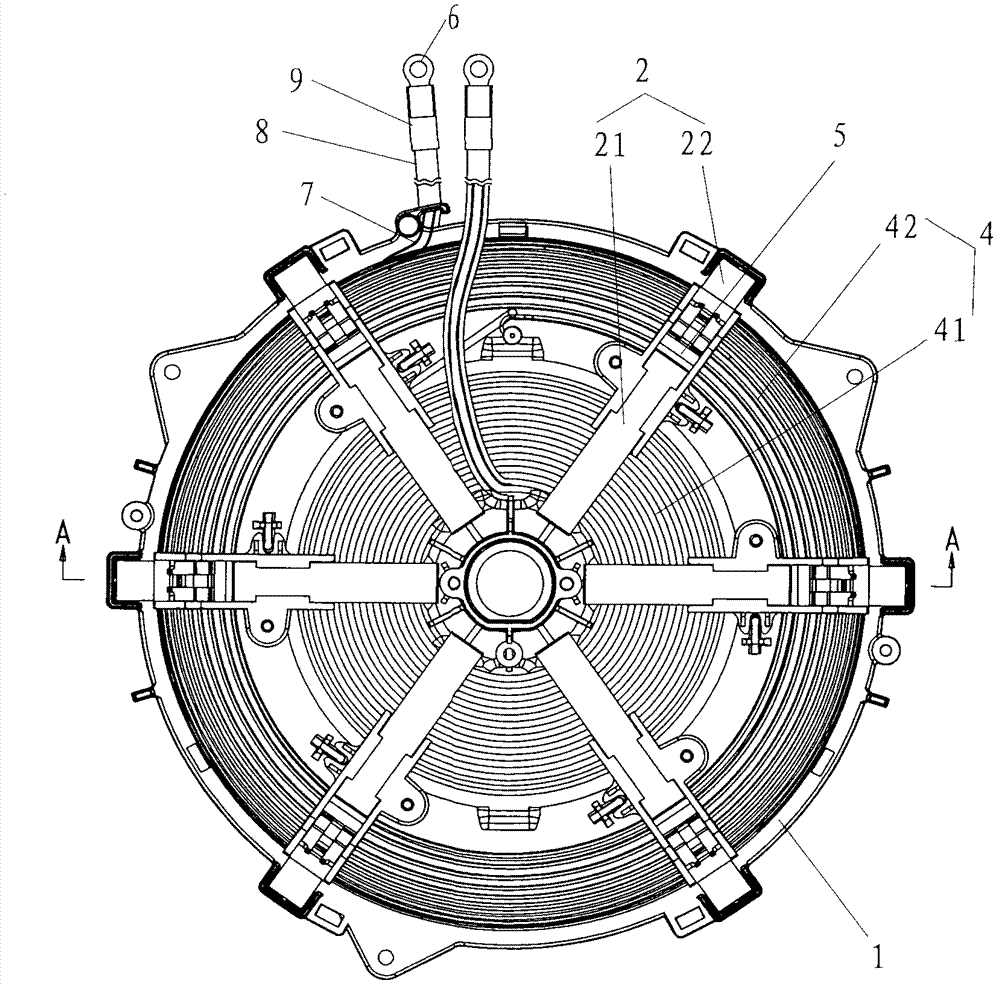

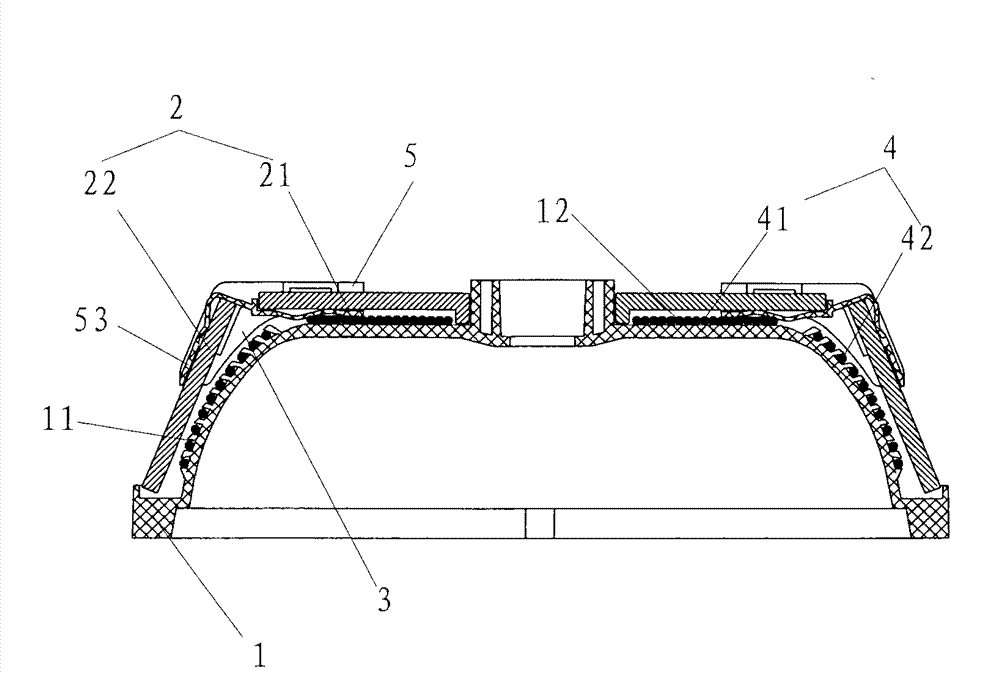

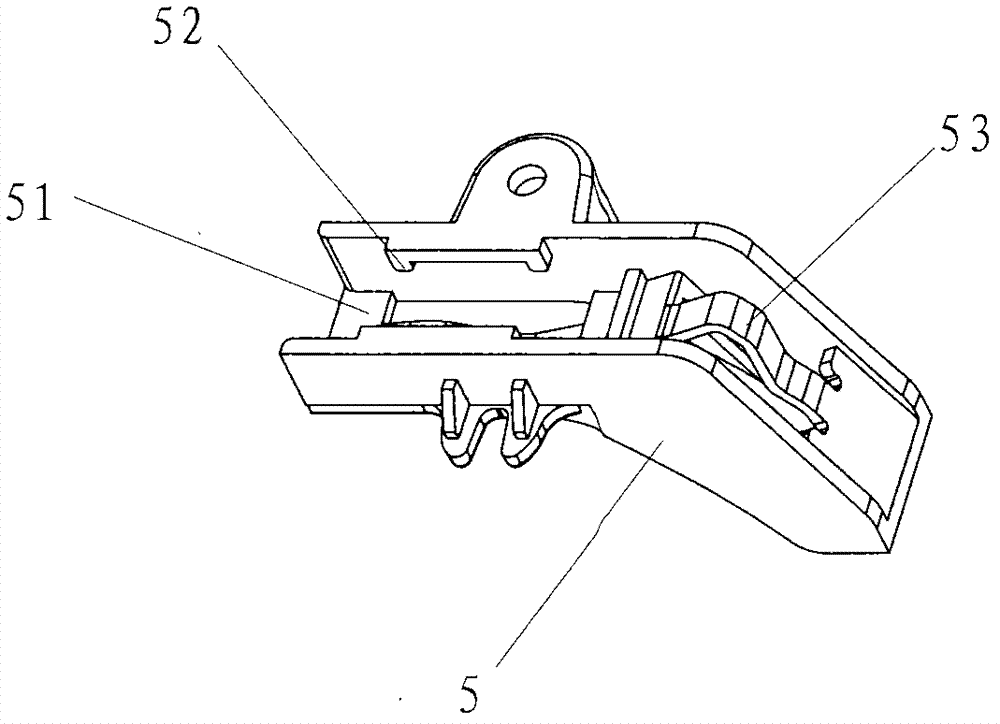

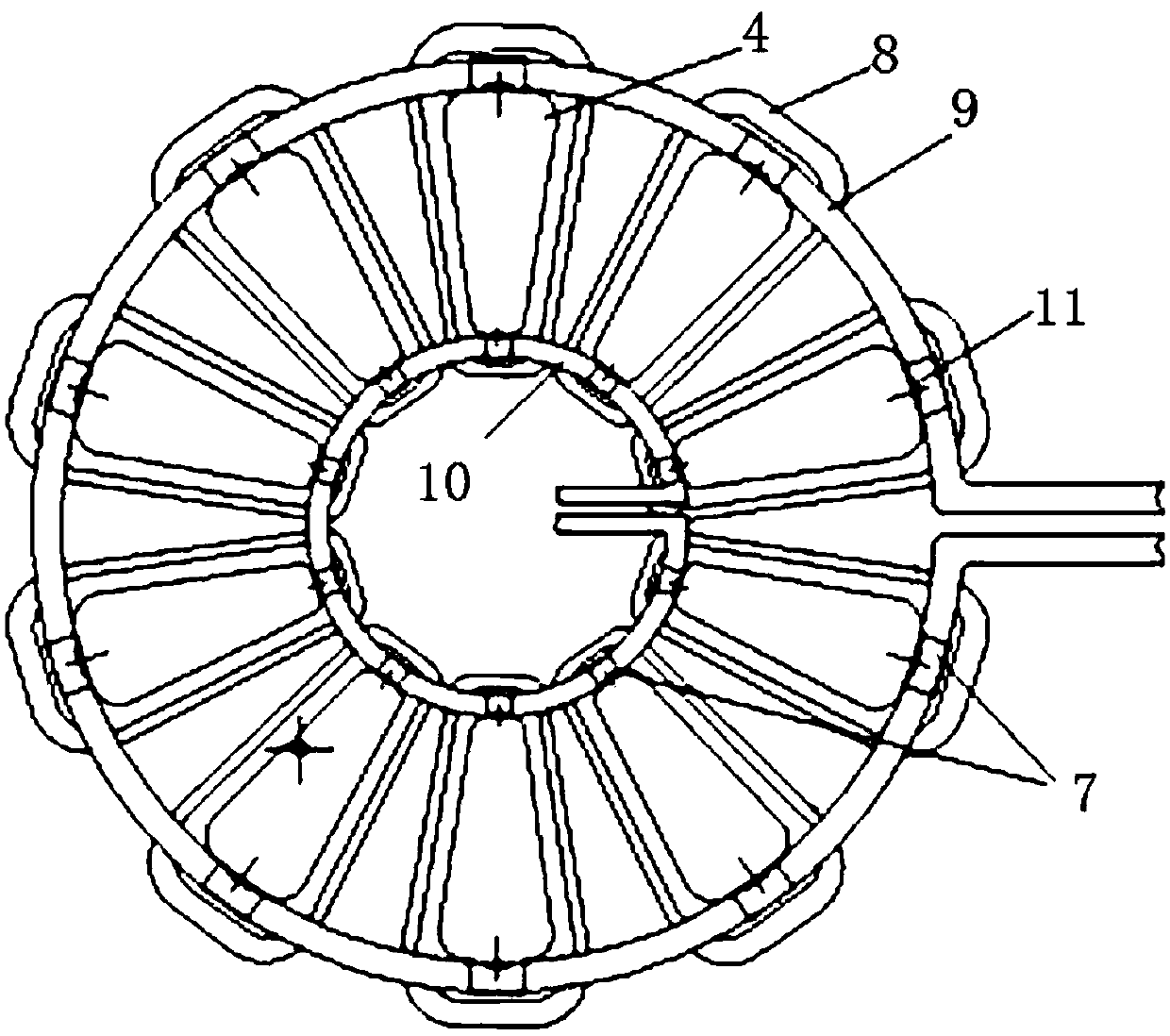

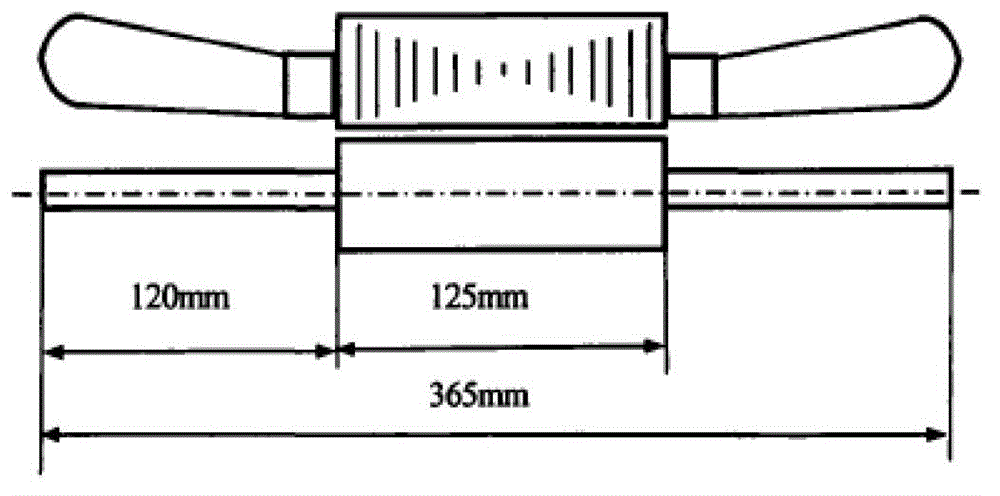

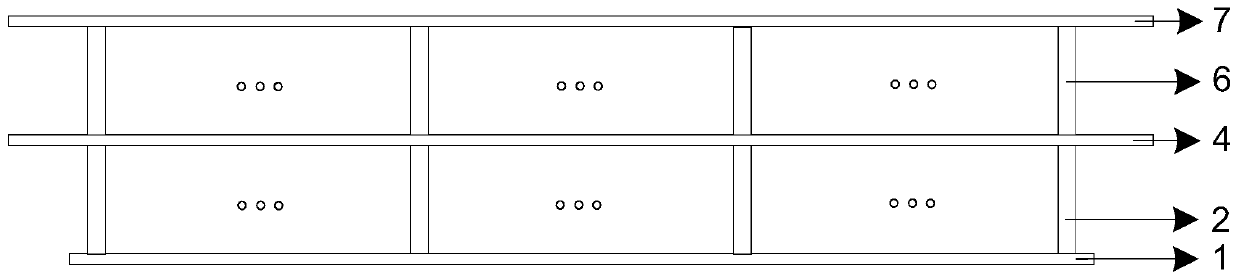

Wire coil for electromagnetism electric rice cooker and coiling method thereof

InactiveCN103298175ALow high frequency lossEfficient use ofCoil arrangementsHome appliance efficiency improvementWire wrapCooker

The invention discloses a wire coil for an electromagnetism electric rice cooker and a coiling method thereof. The wire coil comprises a coil disk support, a magnetic strip and an enamel-cover stranded wire. Coiling grooves are formed on the curved surface of the concave surface of the coil disk support. The enamel-cover stranded wire is sequentially coiled into the coiling grooves. The magnetic strip is arranged on the convex surface of the coil disk support. An inner hole for insertion of one end of the enamel-cover stranded wire is formed in the center of the inner side of the coil disk support. At utilization time, one end of the enamel-cover stranded wire passes through the inner hole of the coil disk support, and then is coiled from inside to outside in the anticlockwise direction along the coiling grooves, when coiled through a wire jumper slot, the enamel-cover stranded wire is coiled outward for one circle, and after wire coiling is finished, a boss is heated and compressed so as to block the enamel-cover stranded wire. The wire coil is quick in heat dissipating, dense and even in generated excitation wire, economic and environment-friendly, and realizes three-dimensional heating.

Owner:江西德源欣茂铜业有限公司

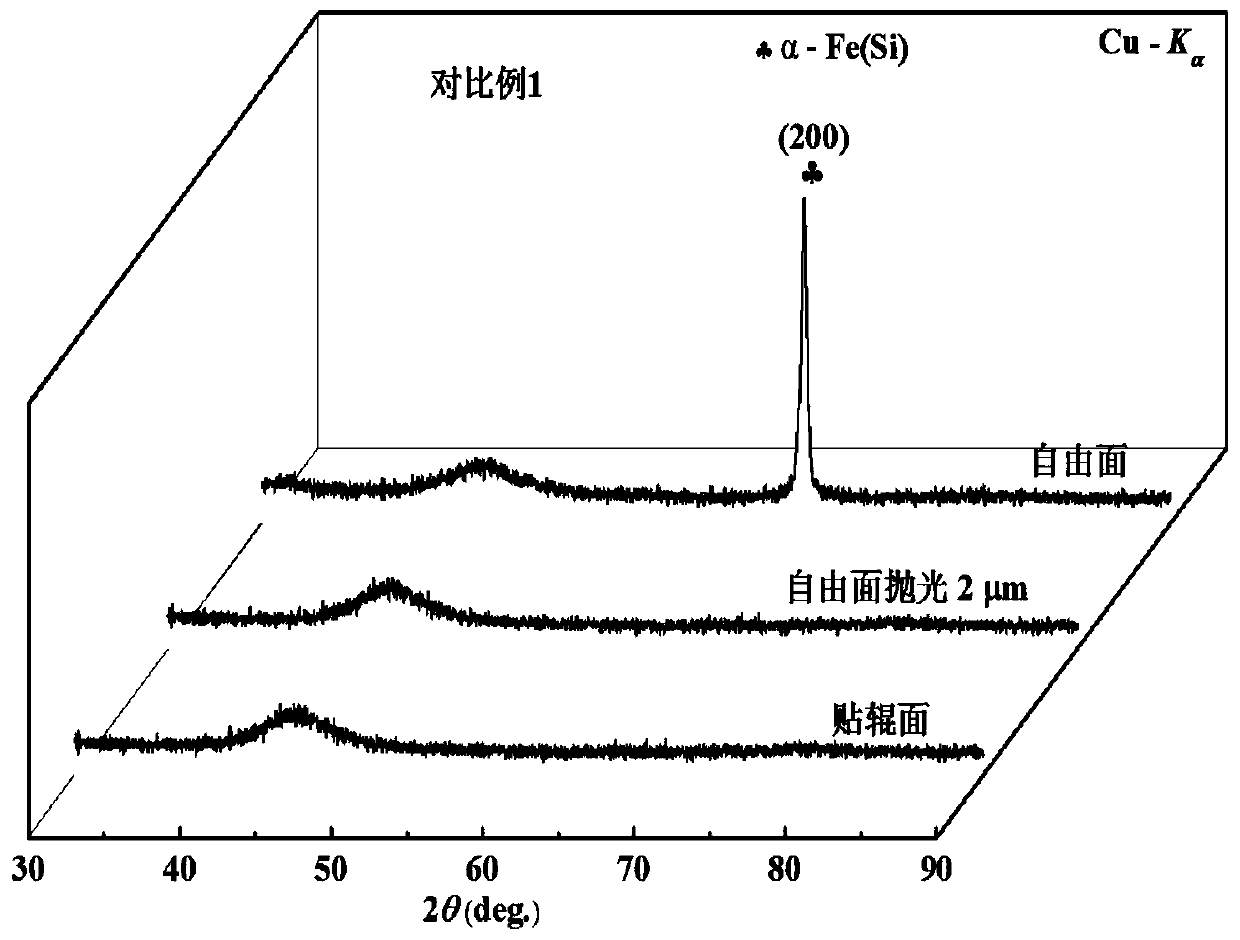

Preparation method of low-loss nano crystal soft magnetic alloy

ActiveCN109234628AIncrease nucleation rateRefine grain sizeFurnace typesInductances/transformers/magnets manufactureThermal insulationCopper

The invention provides a preparation method of low-loss nano crystal soft magnetic alloy. In the method of the invention, when crystallization heat treatment is performed on a strip obtained in a quenching technology, a heat treatment process is divided into four steps: step I, applying a magnetic field for thermal insulation in a copper cluster precipitation temperature zone along a length direction of an alloy strip; step II, performing thermal insulation in an optimum potential heat release temperature zone under a magnetic-field-free condition; step III, applying the magnetic field for thermal insulation in an optimum crystallization and growth temperature zone of alpha-Fe-phase nano crystal grains; and finally, applying the magnetic field for thermal insulation at a temperature less than the copper cluster precipitation temperature along a width direction of the strip. Compared with an existing heat treatment method, the method can reduce the high-frequency loss of the nano crystal soft magnetic alloy and can improve the comprehensive performance of the nano crystal soft magnetic alloy.

Owner:NINGBO INNOVATION CENT FOR APPLIED MAGNETICS CO LTD +2

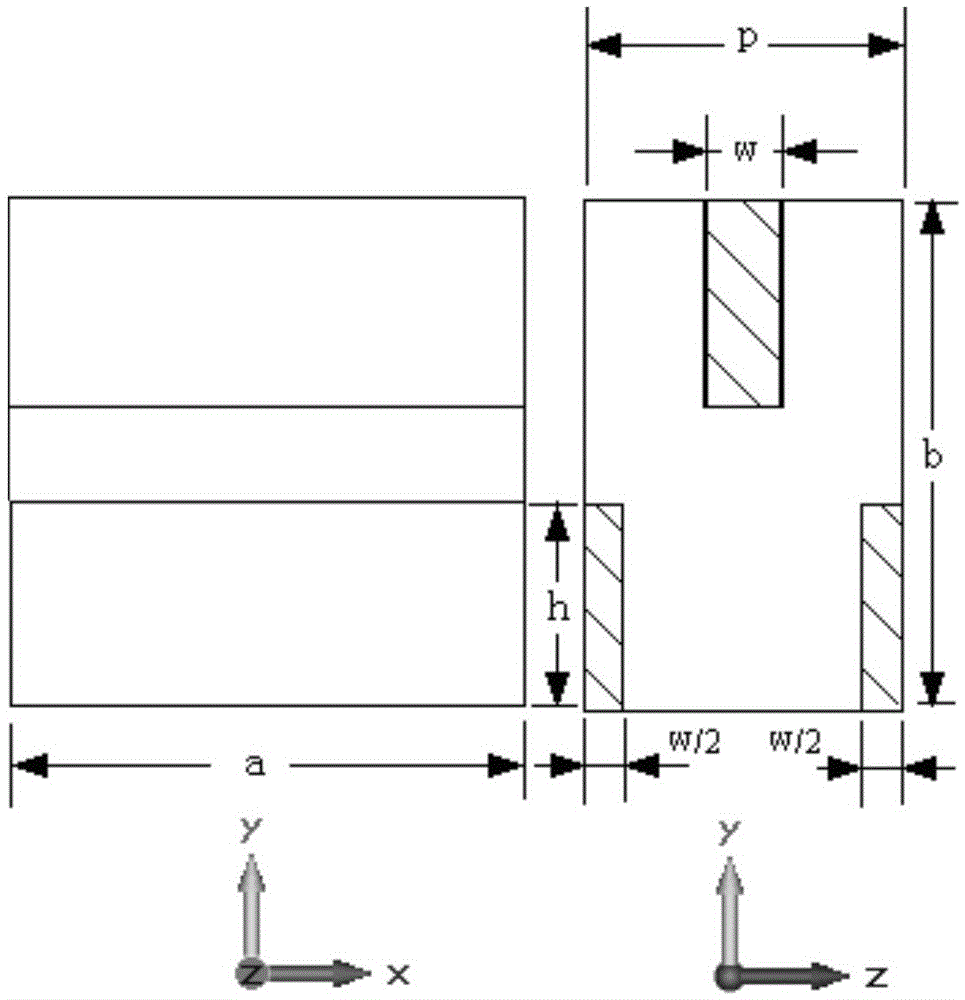

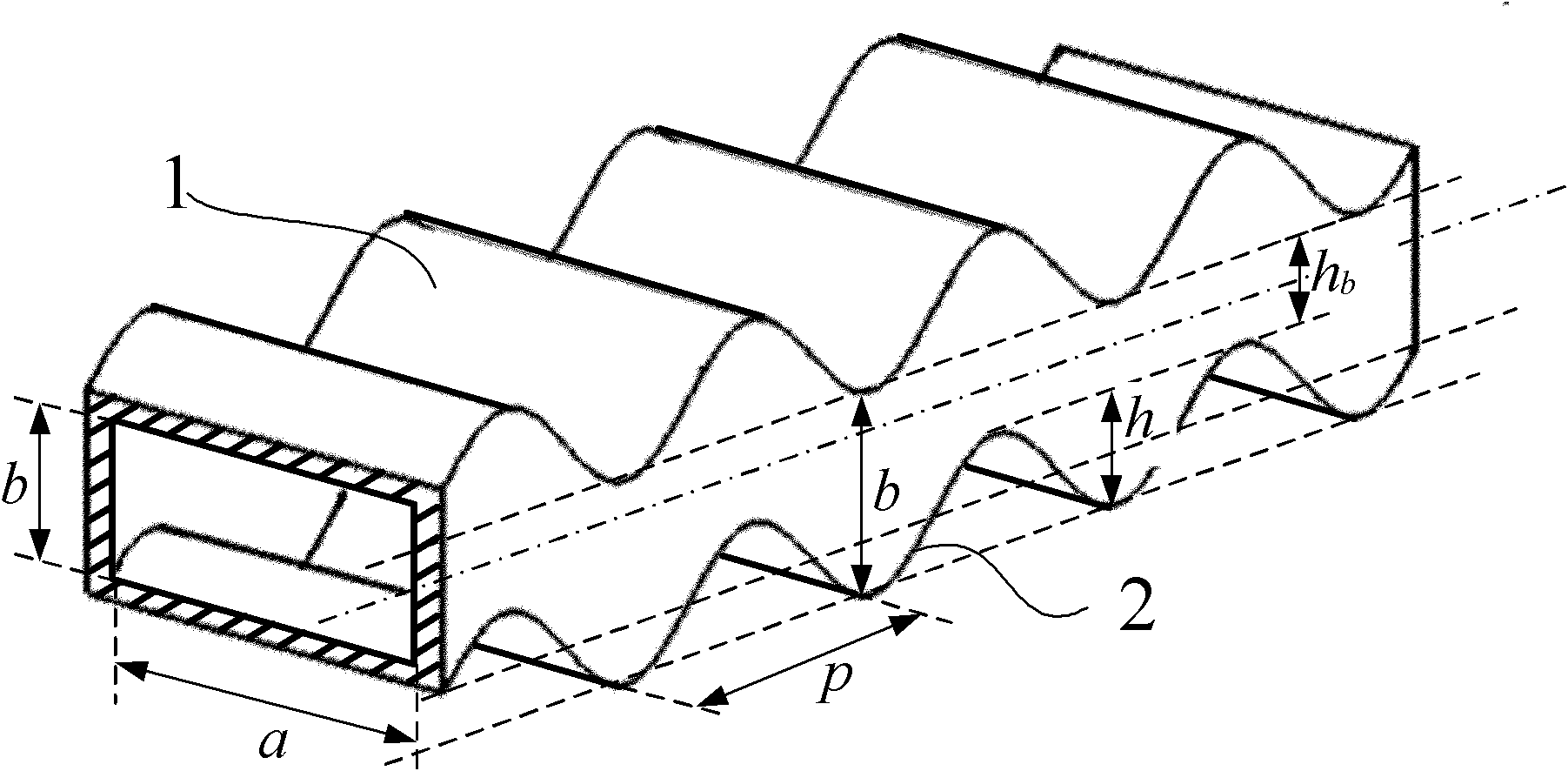

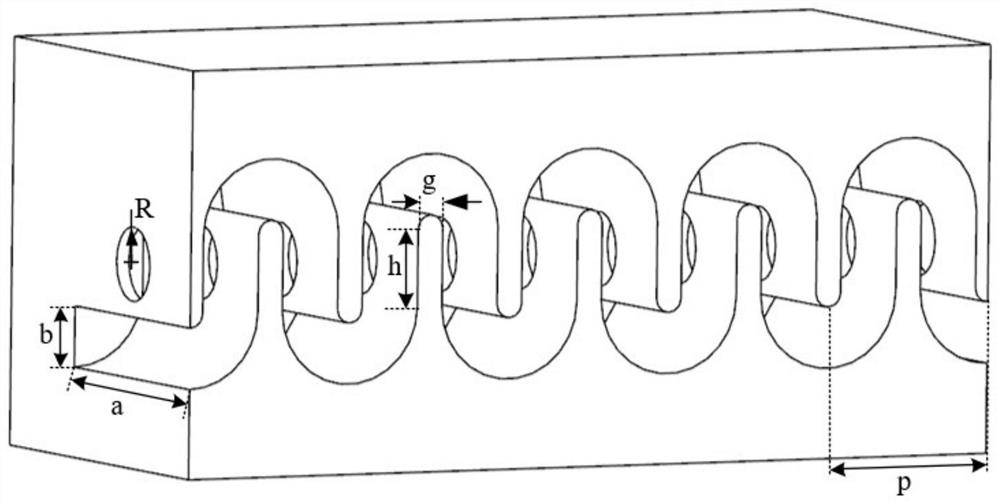

Fluctuant waveguide slow wave structure

InactiveCN102054644AThe main structure is simpleReduce processing difficultyTravelling-wave tubesTransit-tube circuit elementsWave structureBand shape

The invention provides a fluctuant waveguide slow wave structure, belonging to the technical field of vacuum electronics. The structure is formed by deforming a conventional rectangular waveguide of which the size of wide edges is a, and the size of narrow edges is b; the E face of the fluctuant waveguide slow wave structure is regularly fluctuant; the H face of the fluctuant waveguide slow wave structure is a plane; crossed contour lines of the E face and the H face are regularly-changed wavy lines; the period length of the regularly-changed wavy lines is p; and the fluctuant height h of the regularly-changed wavy lines is a difference of the size b of the narrow edges for the rectangular waveguide and the height hb of an electron beam channel. The fluctuant waveguide slow wave structure is simple in main structure and easy to process, has the characteristics of low high-frequency loss, small reflection and wide frequency band, is suitable for using banded electron beam to operate, and the like. The fluctuant waveguide slow wave structure is completely applied to travelling wave tubes (TWT) which work in a terahertz wave band, and is a novel slow wave structure with great application potential.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

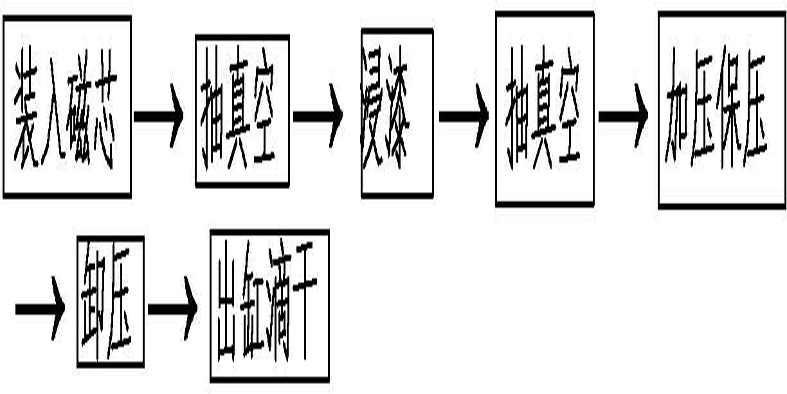

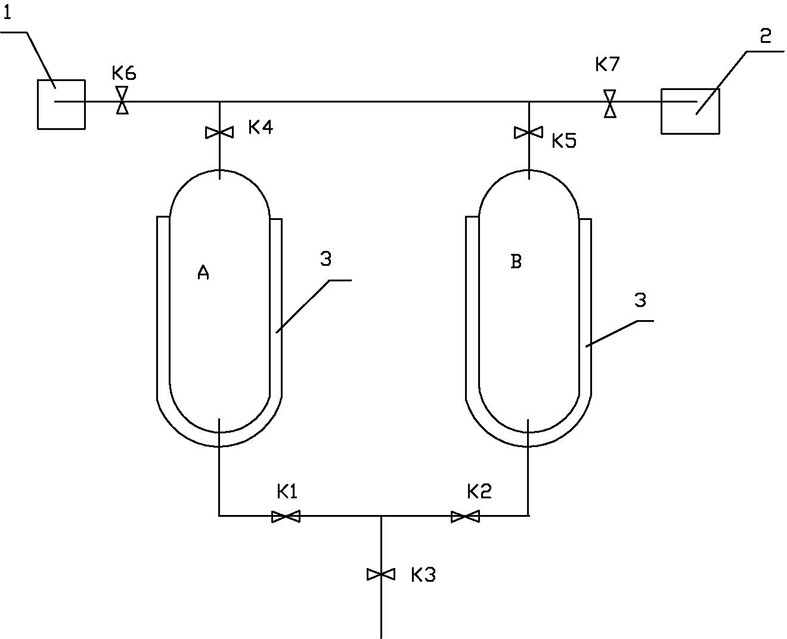

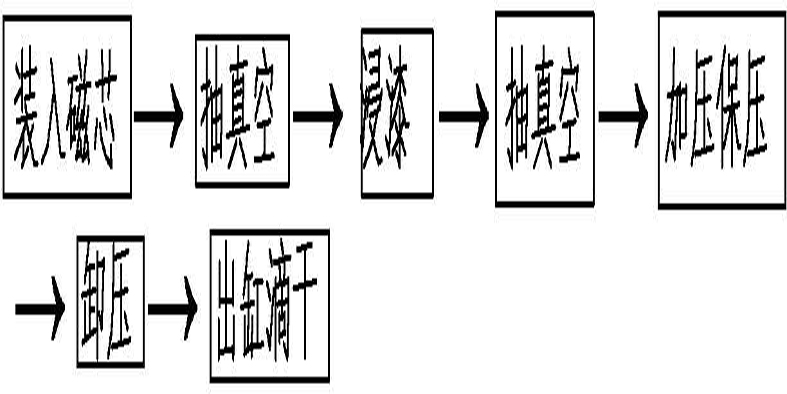

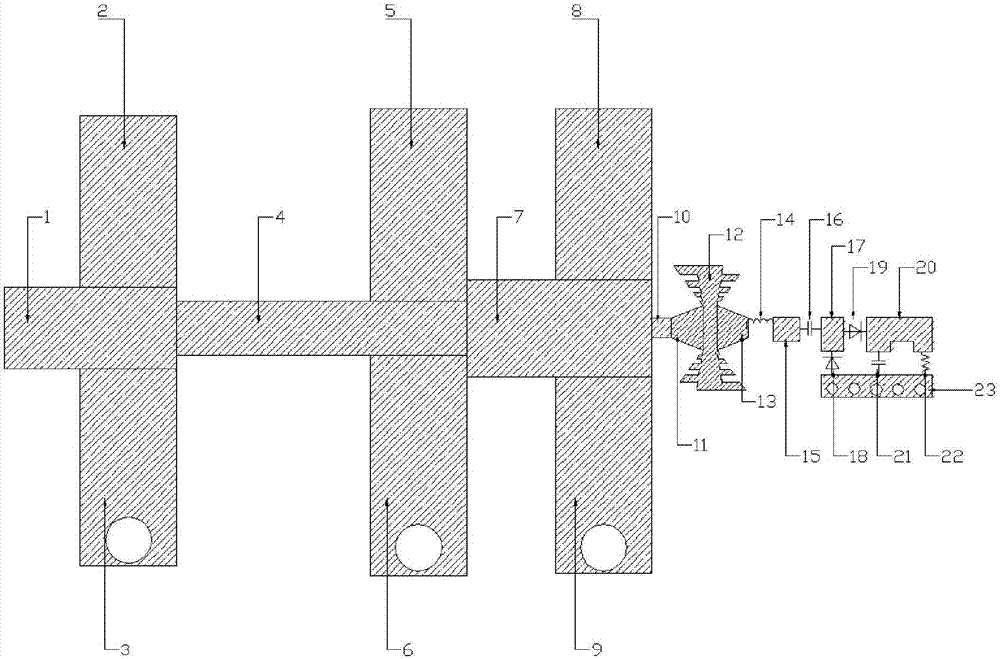

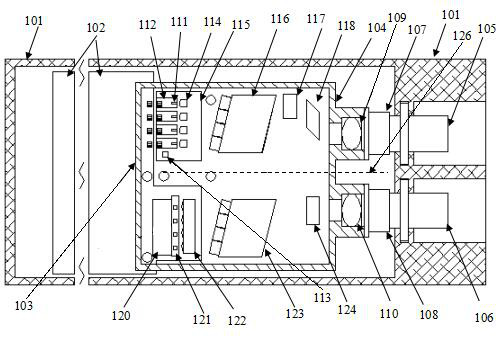

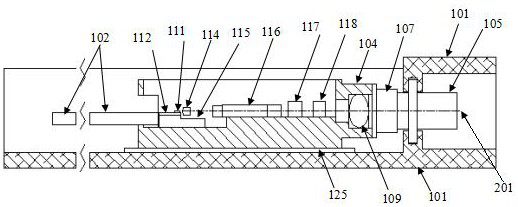

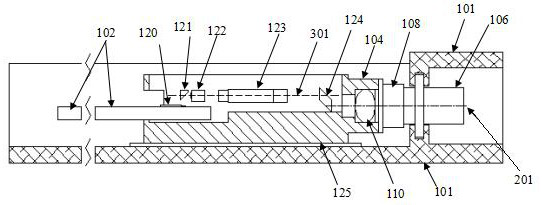

Paint dipping method for bonding amorphous C type magnetic core by pure resin and special equipment

InactiveCN101840777ANothing producedRealize safe productionLiquid surface applicatorsInductances/transformers/magnets manufactureEpoxyVacuum pumping

The invention discloses a paint dipping method for bonding an amorphous C type magnetic core by pure resin, which is characterized in that the method comprises the following steps of: (a) putting the magnetic core into sealable containers; (b) carrying out vacuum pumping on the containers; (c) pumping pure epoxy resin paint into the containers and immersing the magnetic core; (d) carrying out vacuum pumping on the containers, pressurizing and keeping the pressure to 0.4 to 0.6MPa for 40 to 80 minutes; (e) decompressing and discharging the epoxy resin paint; and (f) taking the dipped magnetic core out of a vat and draining. The heating temperature of the pure epoxy resin paint added in the step (c) needs to be kept to be 60+ / -5 DEG C. The invention also discloses special equipment adopting the method, which comprises two sealable containers with covers, wherein a heating device is also arranged on the two sealable containers with the covers, the two sealable containers with the covers are communicated with a pipeline and are also connected with vacuum pumping and pressurizing pipelines, and a valve is arranged on the pipeline. The process method has the advantages of good paint dipping effect and convenient operation.

Owner:FOSHAN CITY ZHONGYAN AMORPHOUS TECH

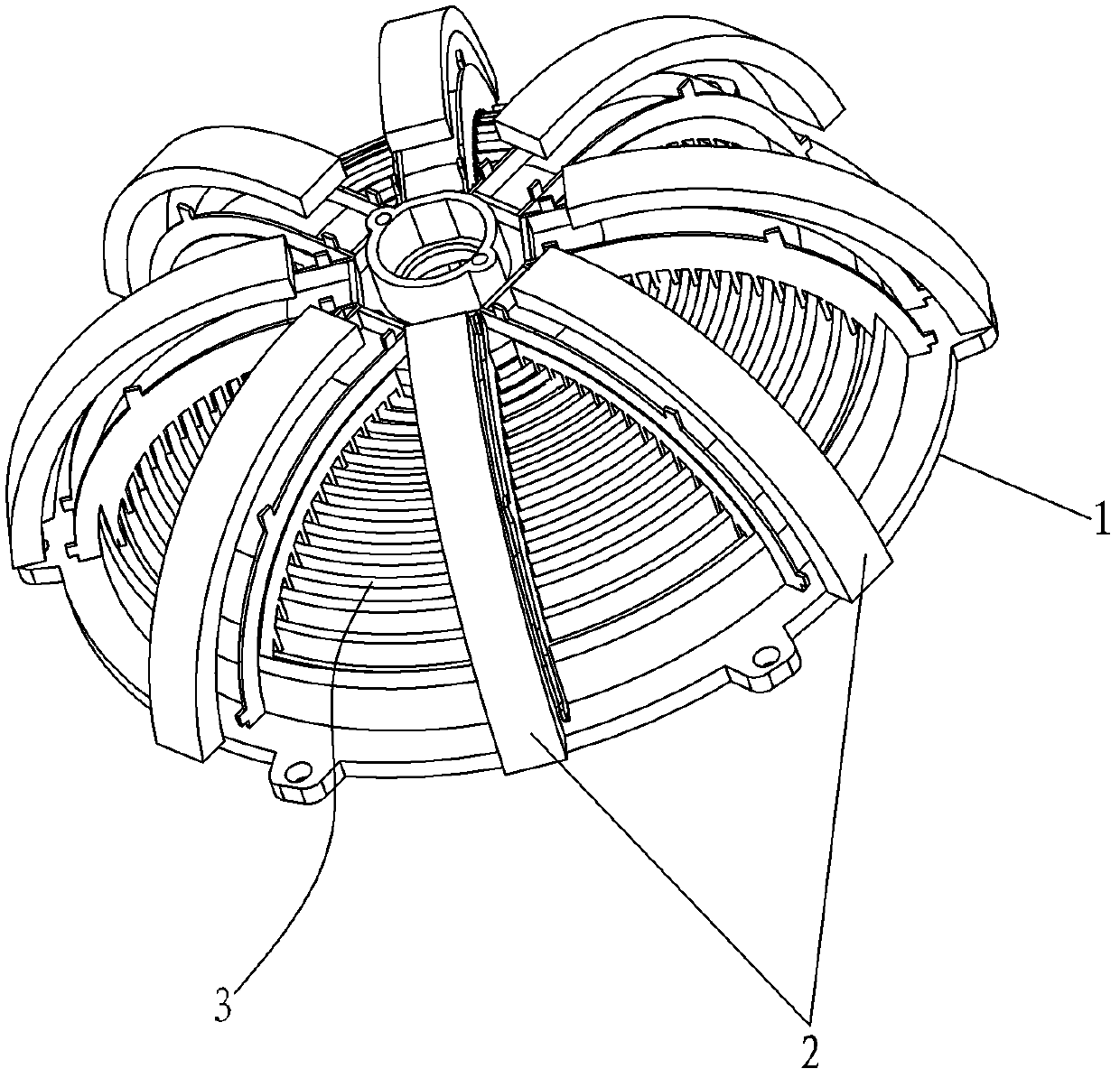

Wire coil for electromagnetic rice cooker and coiling method

InactiveCN102769950AIncrease insulation distanceReduce the chance of short circuitsCoil arrangementsCooking vesselsCookerEngineering

The invention discloses a wire coil for an electromagnetic rice cooker and a coiling method. The wire coil for the electromagnetic rice cooker comprises a support, a magnetic stripe and a stranded wire. The coiling method includes the following steps of firstly, dividing the stranded wire into two parts; secondly, separately coiling one part of the stranded wire on the outer surface of the support; thirdly, coiling the other part of the stranded wire on the bottom surface of the support; and fourthly, mounting the magnetic stripe on the support. During use, different parts of the stranded wire are coiled separately and gaps are reserved among turns of the stranded wire. Therefore, the wire coil compared with the prior art has the advantages that insulation distance between each two adjacent turns is increased, probability of short circuit among the turns in case of transient overvoltage and overcurrent is reduced, probability of direct short circuit among the turns as a result of failure of insulation caused by thermal ageing of insulation materials of wires is reduced, high-frequency coil loss caused by high-frequency proximity effect generated by compact arrangement of the turns is reduced, and heat of the wire coil is easy to radiate, so that uniform heating in large area of the rice cooker is facilitated.

Owner:江西德源欣茂铜业有限公司

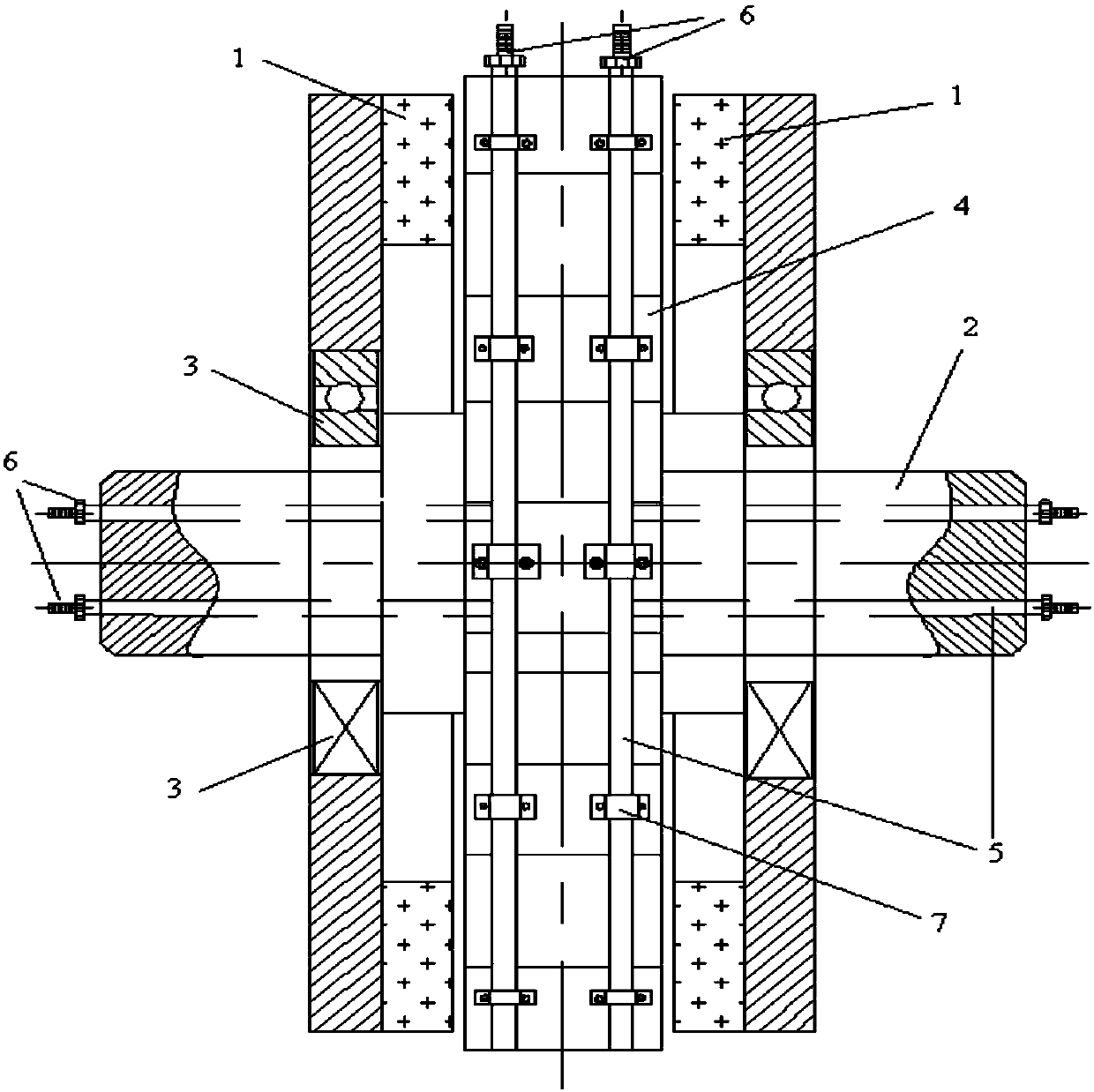

Water cooling soft magnet composite material disk type motor

ActiveCN107800245AGood magnetic conductivityLow high frequency lossMagnetic circuit stationary partsCooling/ventillation arrangementHigh volume manufacturingSoft magnet

The invention discloses a disk type motor taking a soft magnet composite material as a stator, and relates to the technical field of a motor. The motor comprises rotors, a fixed shaft, bearings and astator; the motor adopts the fixed shaft; the motor stator is positioned between a pair of rotor plates; the rotor plates can rotate around the motor fixed shaft; the rotors and the fixed shaft are connected through the bearings; the stator comprises stator iron core modules, coil windings, fixed rings and fixed clamps; each stator iron core module is a columnar module prepared from the soft magnet composite material and having a trapezoidal section; the coil windings are directly wound around the stator iron core modules; the multiple stator iron core modules are arranged into a circular ringshape based on a circumference, and the outer ring and the inner ring of the circular ring are fixed by the fixed rings; and the fixed rings are buckled on the stator iron core modules through the fixed clamps and bolts, so as to enable the circular ring formed by the stator iron core modules to form a stable and firm integrated body. The motor disclosed in the invention adopts water cooling, andis simple in structure, light in weight, high in efficiency, good in cooling effect and suitable for mechanical batch production.

Owner:蚂蚁新能源(天津)有限公司

Novel wire insulating material

InactiveCN106084513AImprove insulation performanceHigh strengthPlastic/resin/waxes insulatorsInsulated cablesPolyesterTemperature resistance

The invention discloses a novel wire insulating material and relates to the technical field of electric engineering. The insulating material contains, by weight, 40-50 parts of nano-ceramics, 10-19 parts of polyurethane, 20-40 parts of chlorinated polyethylene rubber, 15-22 parts of silicon carbide, 2-8 parts of barium sulfate powder, 1.8-4.2 parts of sodium silicate, 2-5 parts of rubber, 8-11 parts of xylenol, 2-6 parts of iron oxide powder, 1.5-1.9 parts of sulphur, 9-17 parts of oxalic polyester, 12-16 parts of diglycidyl cyclohexanedicarboxylate, 4-12 parts of meerschaum, 2-7 parts of asphalt, 4-8 parts of an adhesive and 6-10 parts of a plasticizer. According to the novel wire insulating material, nano-ceramics is used as the main raw materials, and the other raw materials function together and cooperate with each other. Thus, the insulating material has good insulating properties, high strength, high temperature resistance, low high-frequecny loss, good humidity resistance, excellent flame retardancy and ageing resistance and long service life, and is appropriate to be used as a wire.

Owner:HEFEI PULFI WIRE TECH CO LTD

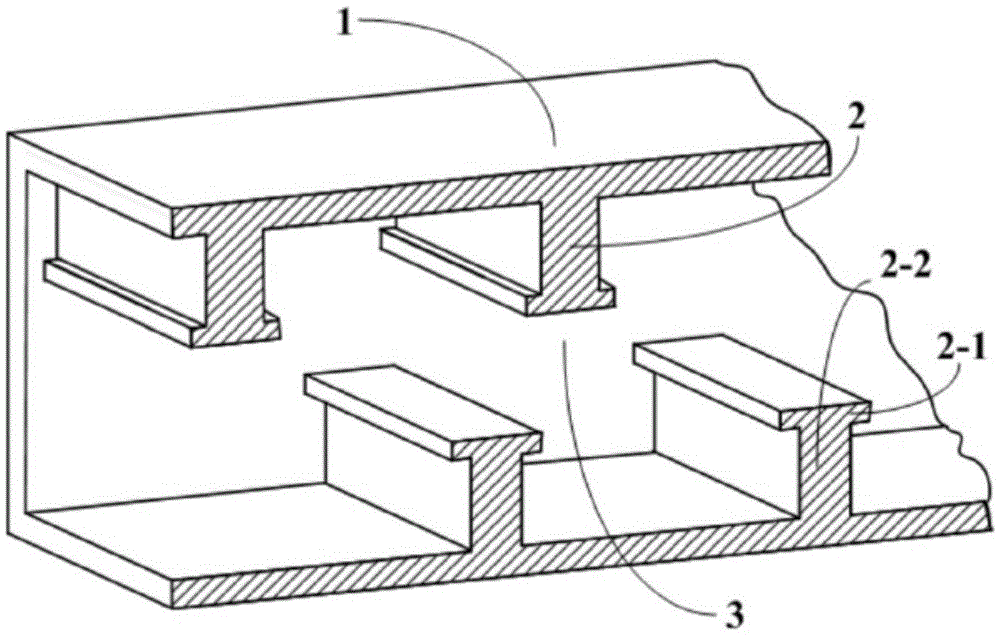

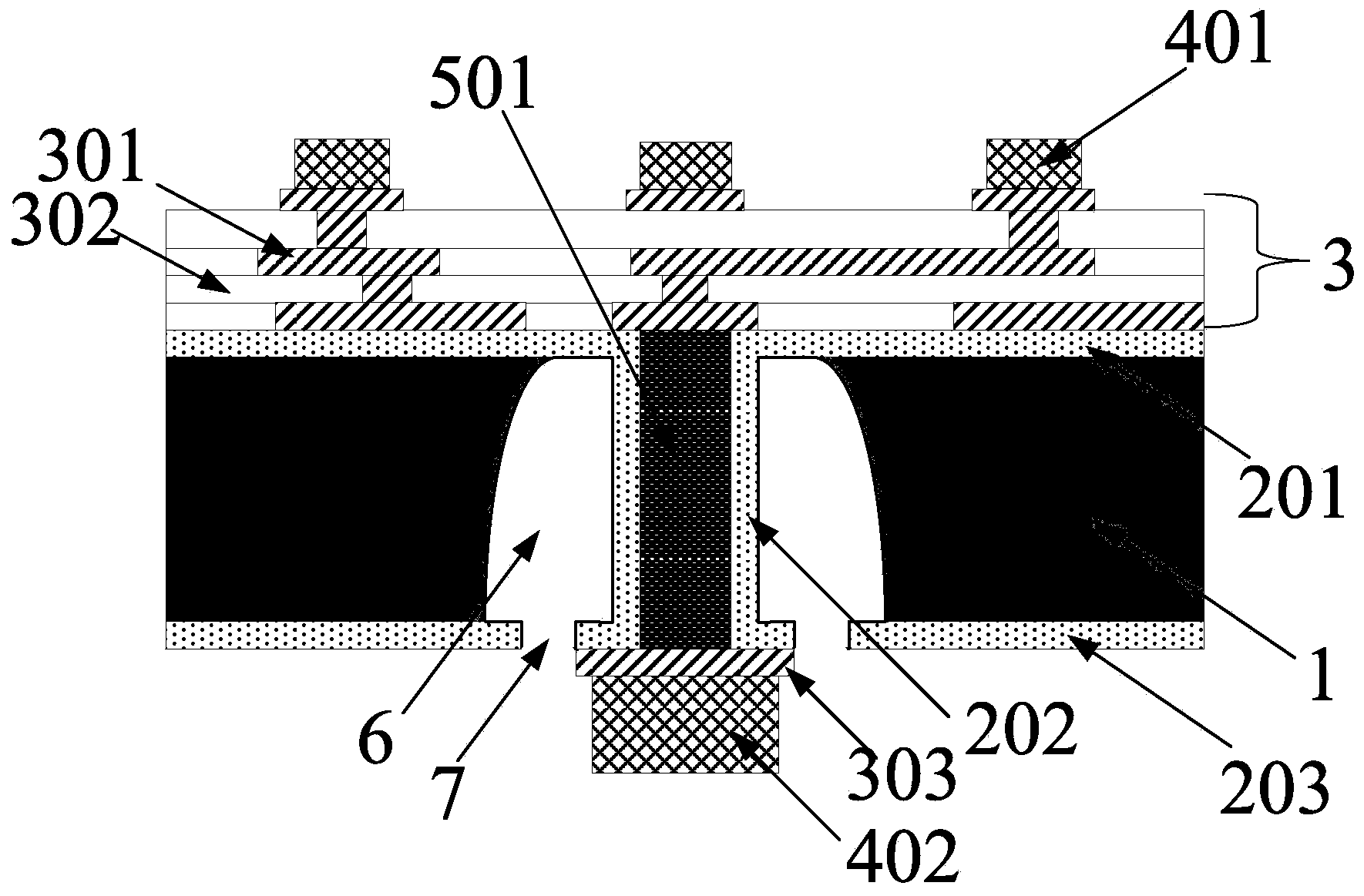

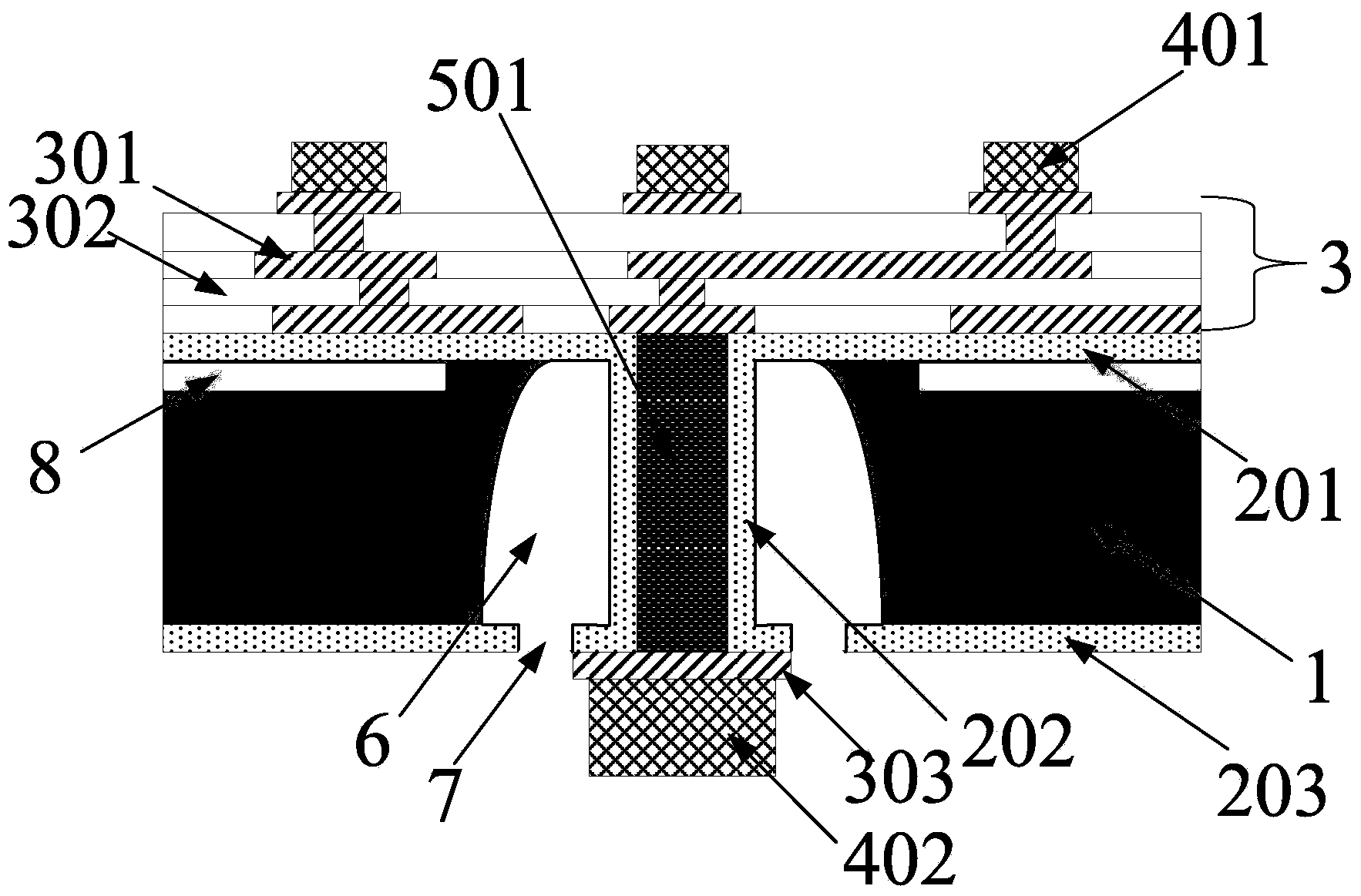

Trapezoid-like staggered double-gate slow wave structure

ActiveCN113113278AImprove interaction abilityIncrease output powerTransit-tube circuit elementsBroadbandEngineering

The present invention discloses a trapezoid-like staggered double-gate slow wave structure. On the basis of the staggered double-gate slow-wave structure, a trapezoidal gate is adopted at the bottom, a rectangular gate is adopted in the middle, and a circular electron beam channel is formed in the rectangular gate; the trapezoidal gate and the rectangular gate form trapezoidal-like gates, and the trapezoidal-like gates are sequentially arranged in a staggered mode in a longitudinal direction, namely a transmission direction. Tests show that the dispersion characteristic of the trapezoid-like staggered double-gate slow wave structure is improved, the broadband is wider, the high-frequency loss is greatly reduced; and meanwhile, the coupling impedance value is higher because the axial field components of the electron beam channel are more concentrated, which means that the interaction capability of an electron beam and an electromagnetic wave is increased, and further the output power, the gain and the interaction efficiency of a traveling wave tube are improved.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

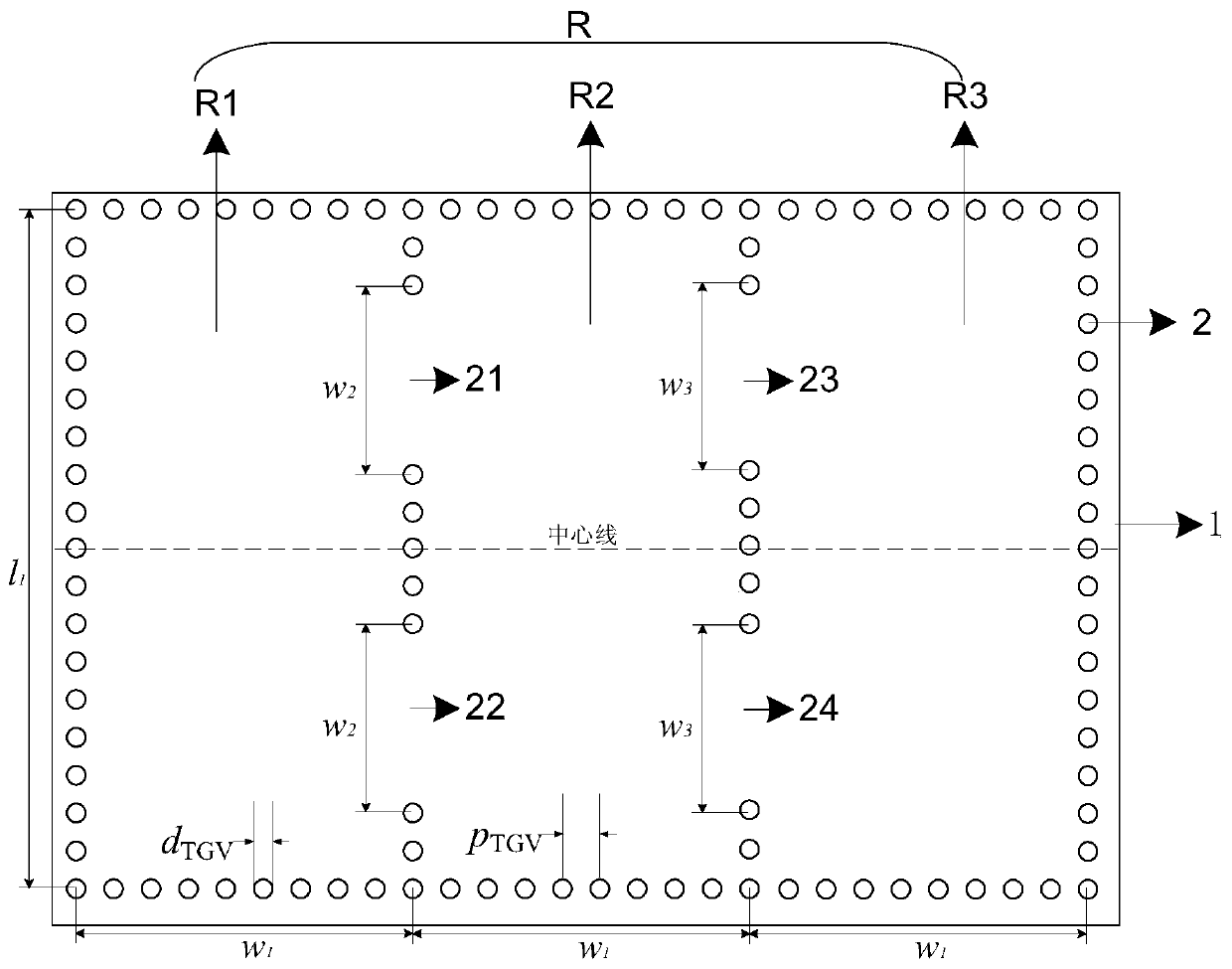

Wafer silicon through hole structure and preparation method thereof

ActiveCN104143544AReduce the electric field densityReduce thermal stress effectsSemiconductor/solid-state device detailsSolid-state devicesThermal expansionStress effects

The invention belongs to the field of micro electronic techniques and discloses a wafer silicon through hole structure. The wafer silicon through hole structure comprises a through hole, a front passivation layer, a through hole passivation layer, a back passivation layer and a cavity in the periphery of the through hole passivation layer. The through hole is formed in a silicon substrate of a wafer, the through hole passivation layer is arranged on the lateral wall in the through hole, the front passivation layer and the back passivation layer are arranged on the front face and the back face of the silicon substrate and are respectively connected with the through hole passivation layer, and the cavity is formed in the periphery of the through hole passivation layer and in the silicon substrate. The thermal stress effect caused by large difference between coefficients of thermal expansion of through hole metal and silicon materials is reduced by forming the cavity outside the through hole in the wafer silicon substrate. Meanwhile, electric field density of the periphery of the through hole is greatly reduced so as to reduce high frequency loss of the through hole.

Owner:NAT CENT FOR ADVANCED PACKAGING

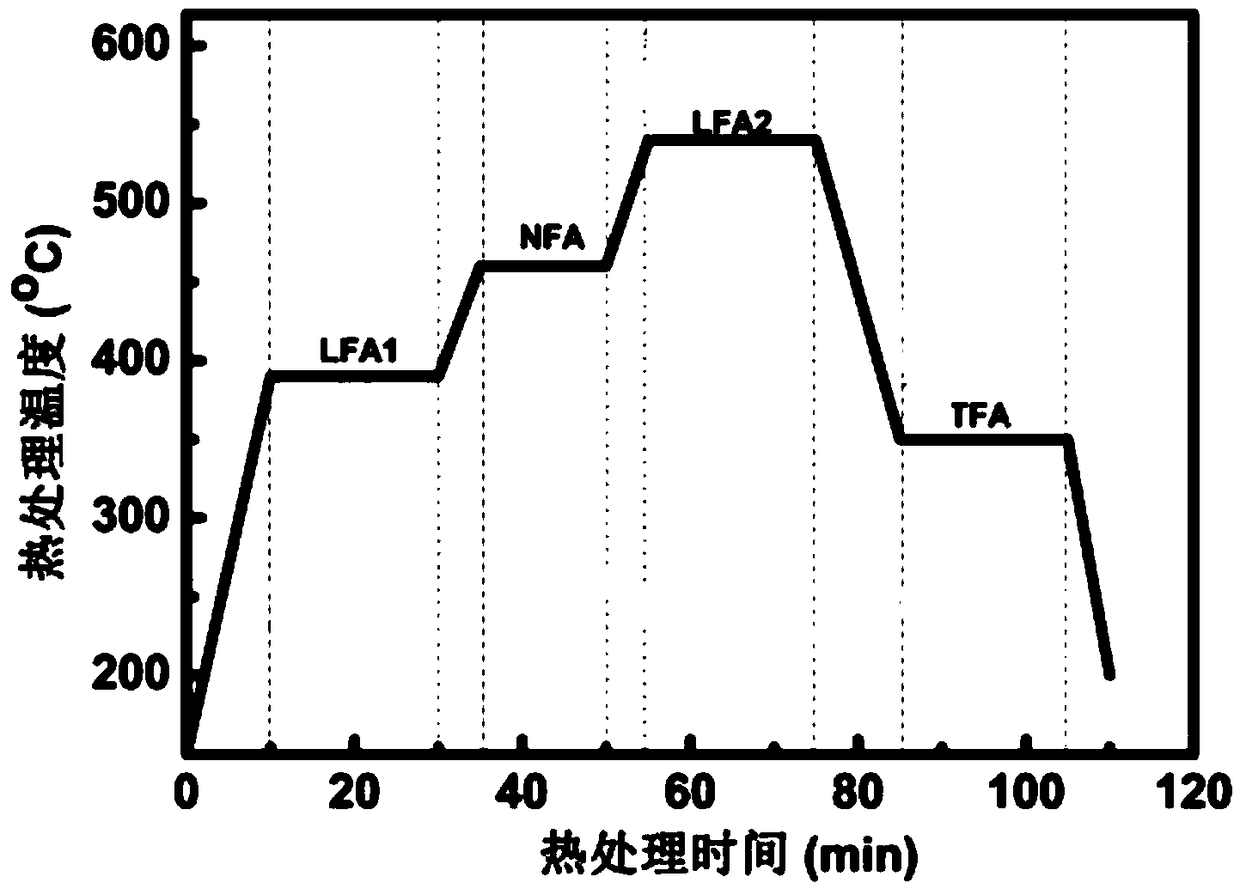

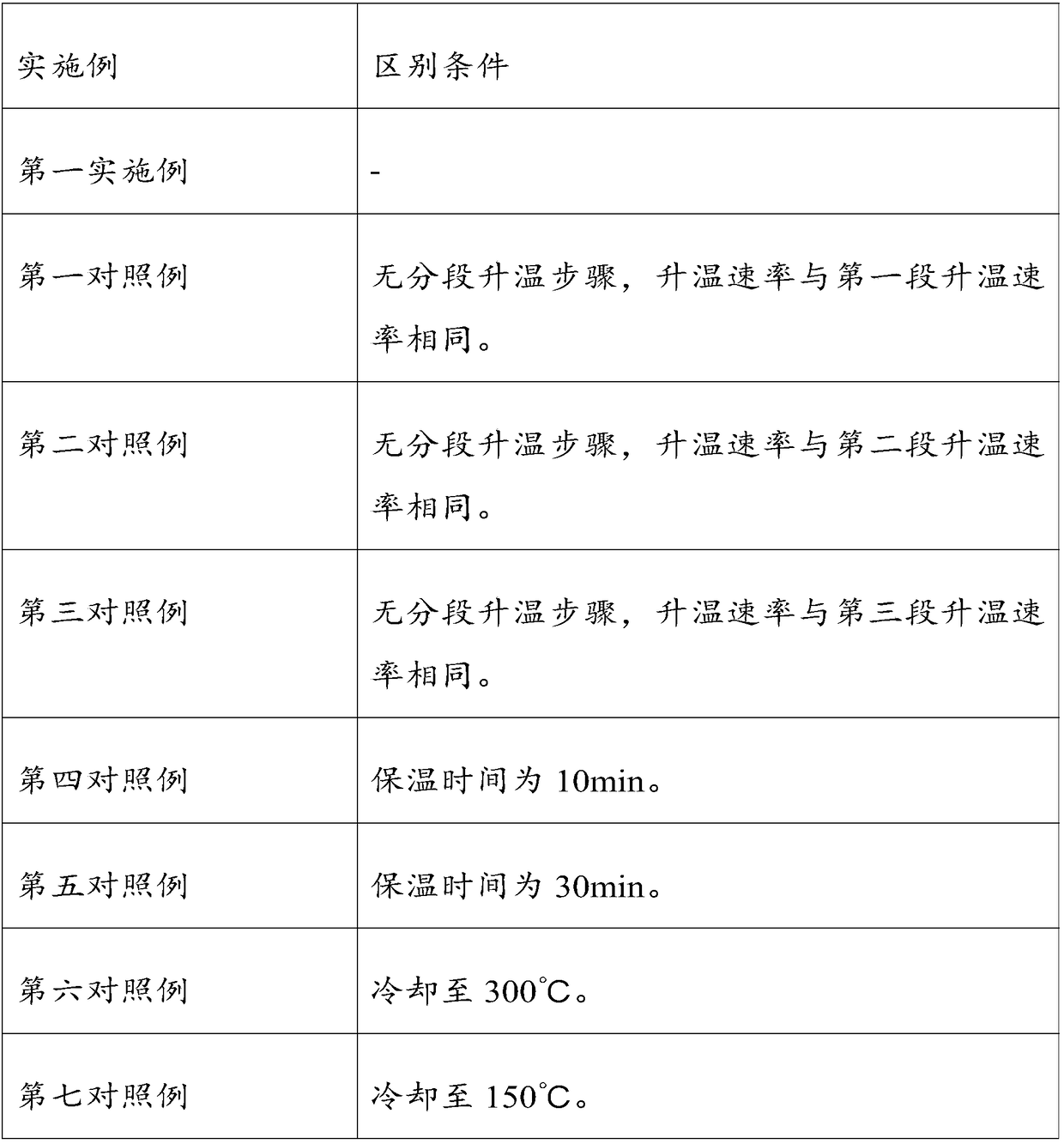

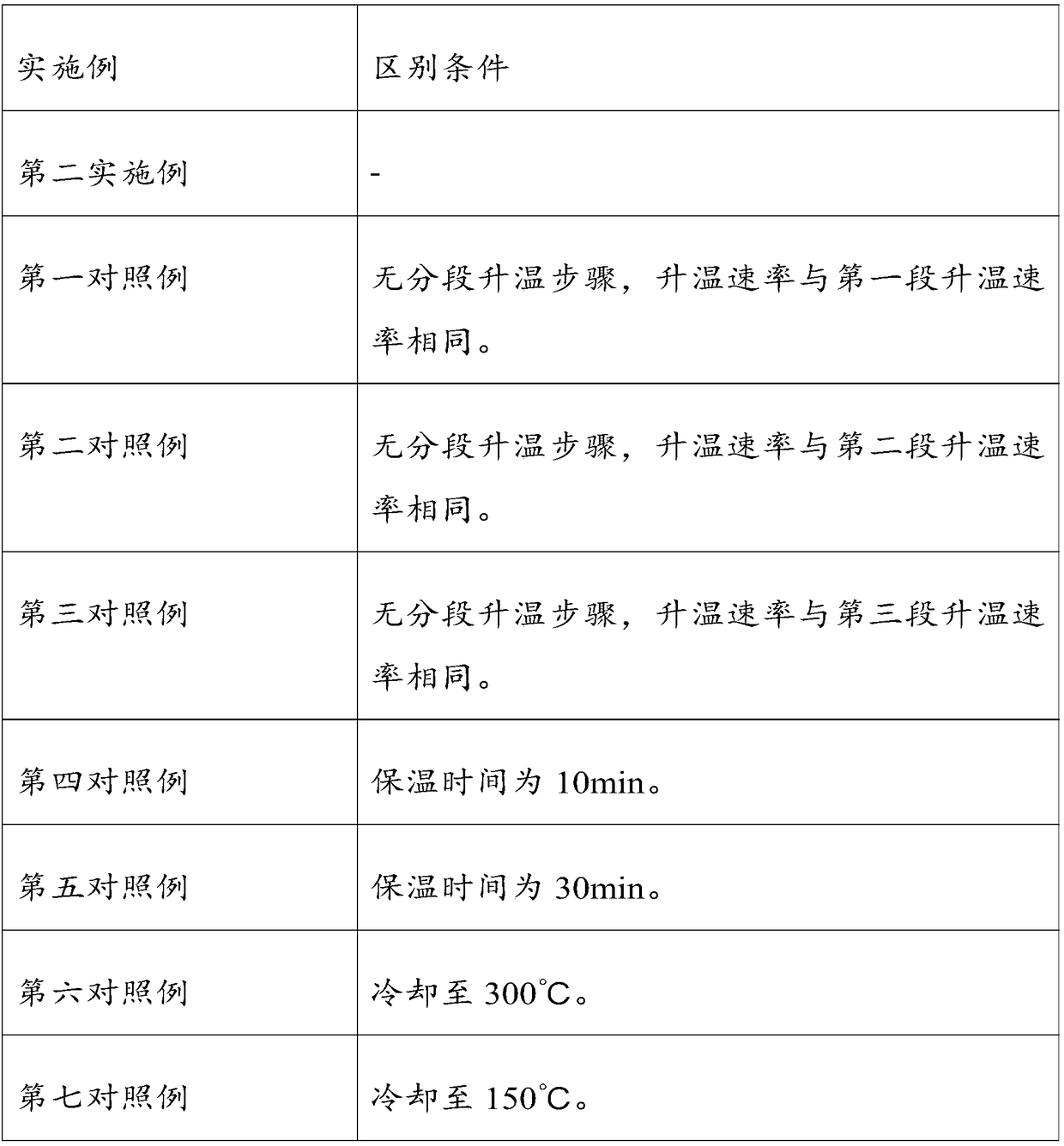

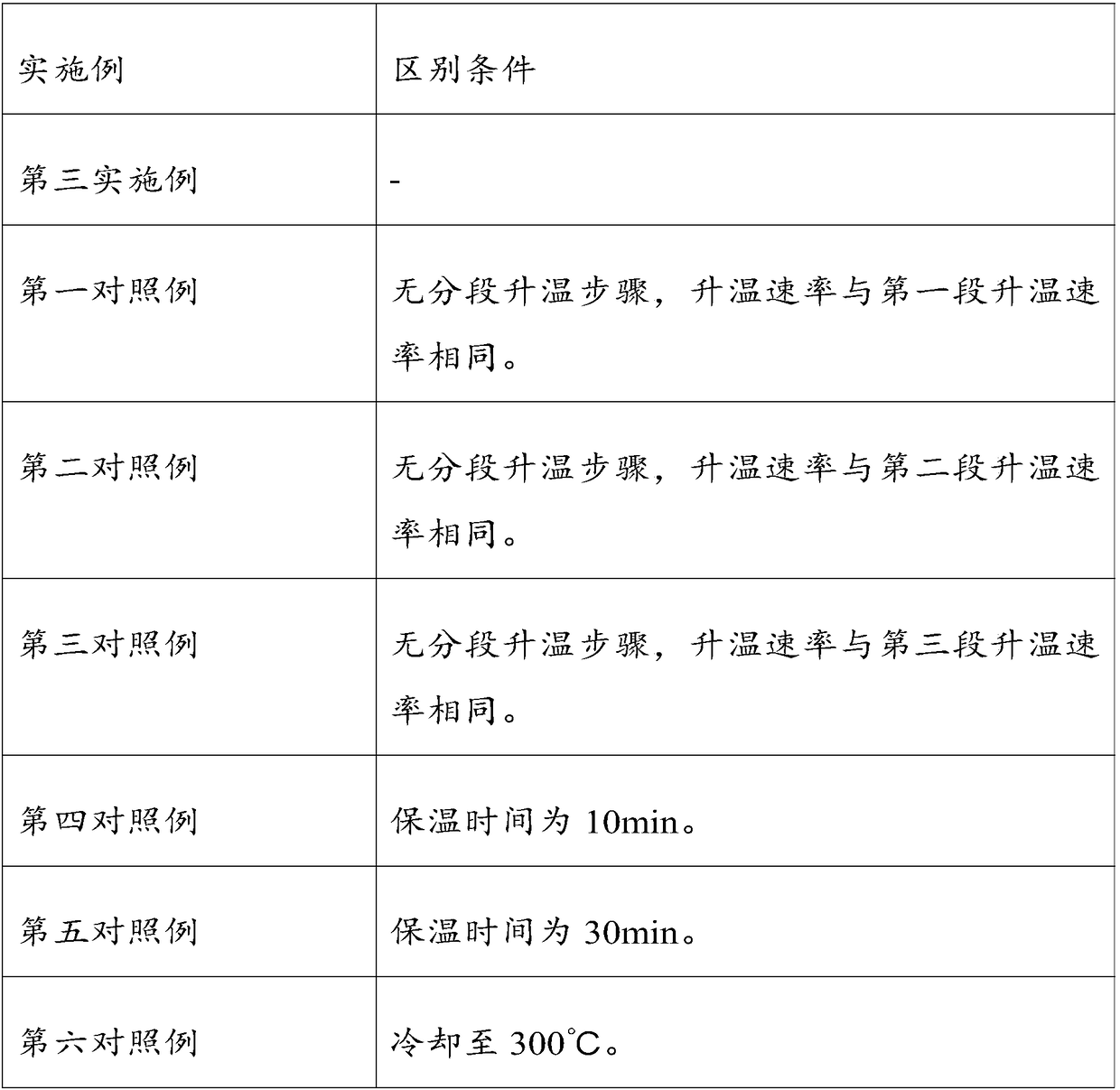

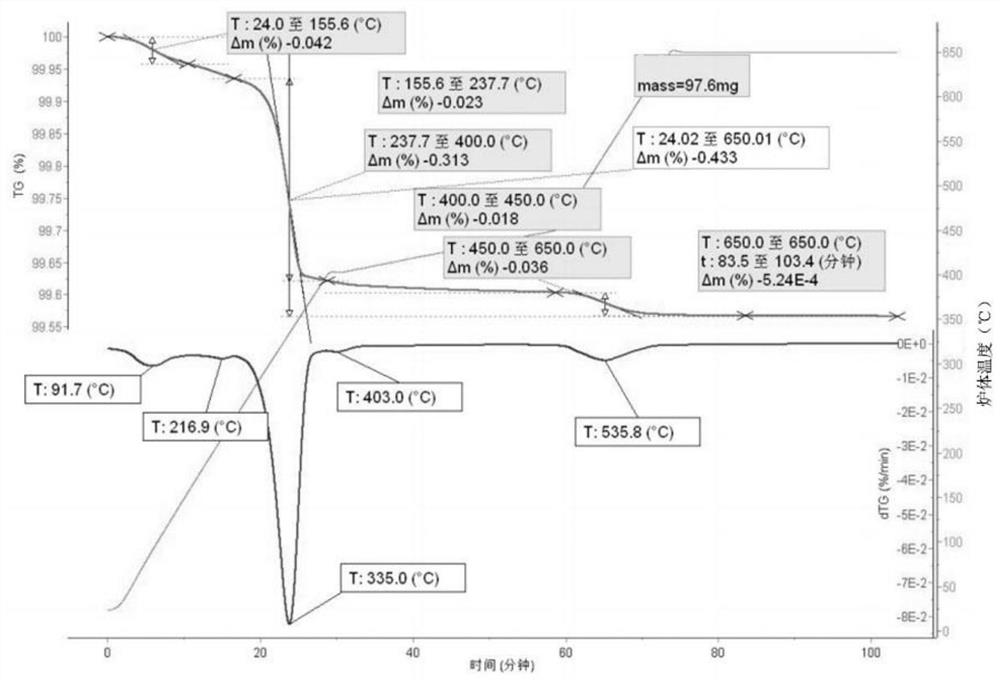

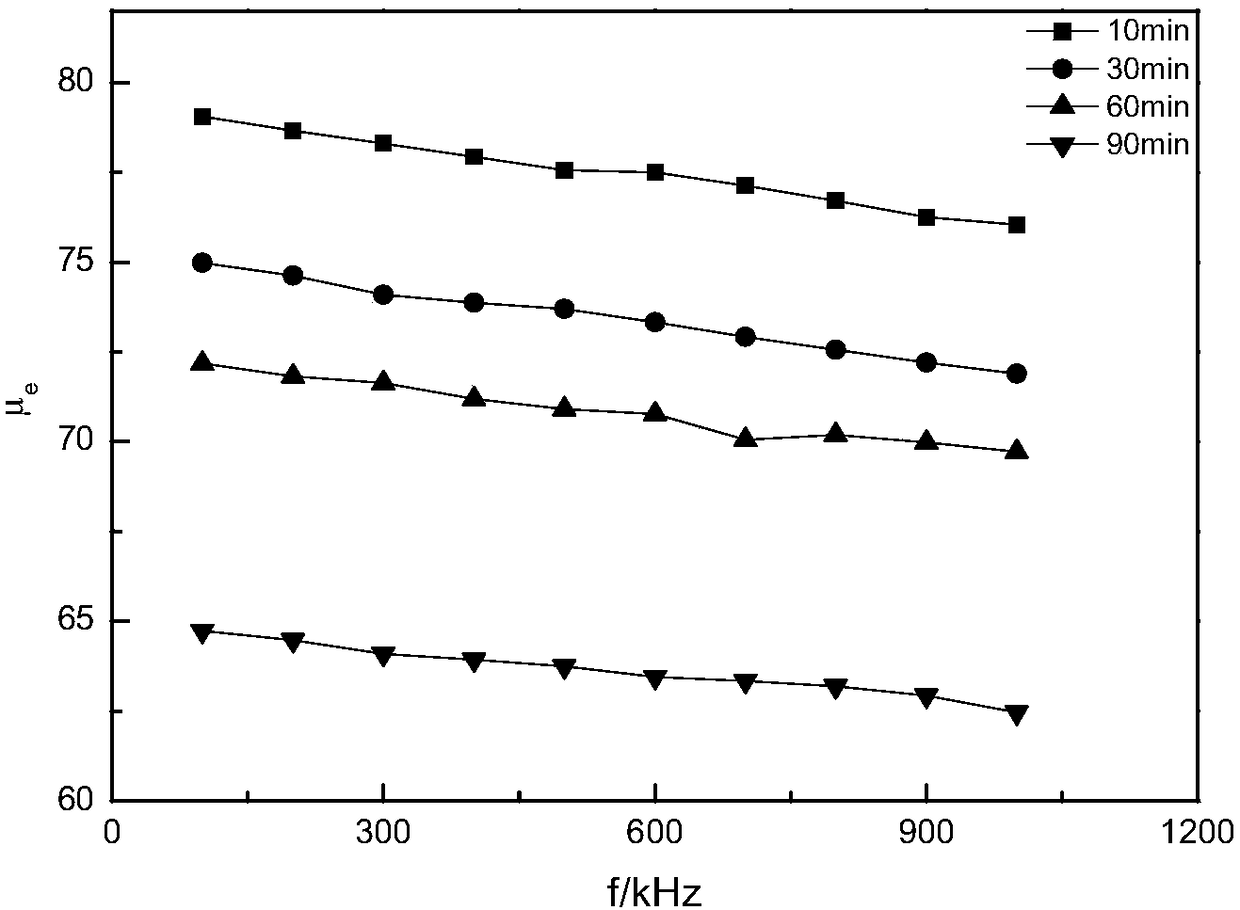

Heat treatment process of an amorphous soft magnetic material

PendingCN108806914ALow coercivityGood soft magneticMagnetic materialsMagnetic inductanceMaterials science

The embodiment of the invention relates to the field of wireless charging, and provides a heat treatment process of an amorphous soft magnetic material, which comprises the following steps: in a magnetic field furnace containing an amorphous soft magnetic material, a sectional temperature rise is carried out, and the sectional temperature rise includes a first stage temperature rise, a second stage temperature rise and a third stage temperature rise. Wherein the first annealing temperature of the first heating step is 445 DEG C to 455 DEG C; the second annealing temperature of the second heating step is 465-475 DEG C; the third annealing temperature of the third heating step is 535 - 545 DEG C. In the heat treatment process, the heat treatment process of segmented heating makes the soft magnetic materials have excellent soft magnetic properties, high permeability, high magnetic inductance, low high frequency loss, reduce coercivity and other excellent properties. In addition, the invention also provides an amorphous soft magnetic material, which has excellent soft magnetic properties after the heat treatment process.

Owner:江苏墨泰新材料有限公司

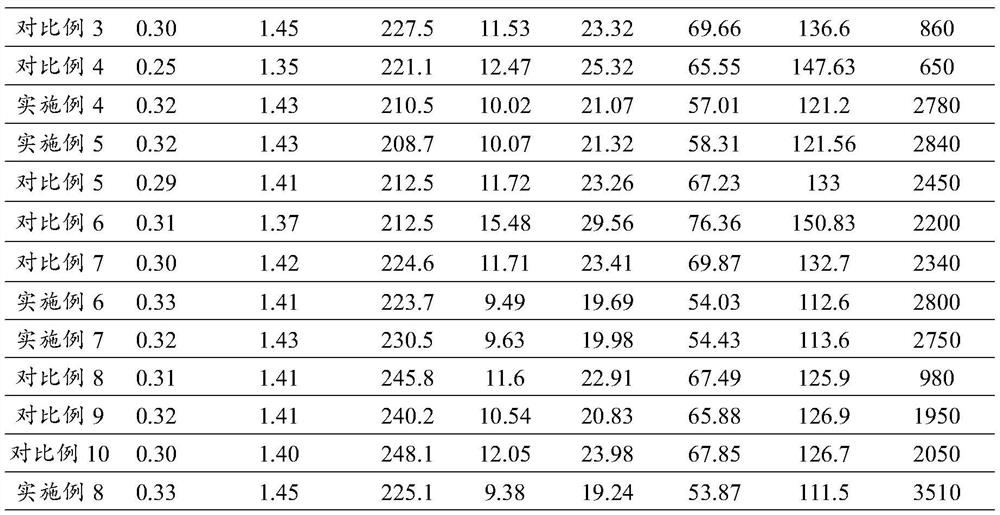

Iron-based soft magnetic composite material and preparation method thereof

ActiveCN113451027AReduce porosity and non-magnetic impurities residueGuaranteed magnet chemical purityInductances/transformers/magnets manufactureMagnetic materialsNitrogen gasPowder

The invention relates to an iron-based soft magnetic composite material and a preparation method thereof, and belongs to the technical field of soft magnetic composite material preparation. The preparation method comprises the following steps: carrying out ball milling treatment on pure iron powder; coating the pure iron powder with an insulating layer; performing normal-temperature compression molding; placing the pressed sample in an annealing furnace, filling with nitrogen, stabilizing the pressure to 0.02-0.04 MPa, and heating the sample to 250-270 DEG C, wherein the heating rate is 15-18 DEG C / min; then reducing the heating rate to 3-5 DEG C / min, performing heating to 400-450 DEG C, and keeping the temperature; performing heating to 550-600 DEG C at a heating rate of 15-18 DEG C / min, preserving heat for 5-20 minutes, cooling the sample to 200 DEG C or below along with the furnace, and performing discharging. Through a multi-stage heat treatment method, organic matters such as a lubricant in the material are discharged to the greatest extent in the heat treatment process, and the defects such as pores and non-magnetic impurities are reduced; and the uniformity and integrity of an insulating coating layer on the surface of the powder are kept.

Owner:山东精创磁电产业技术研究院有限公司

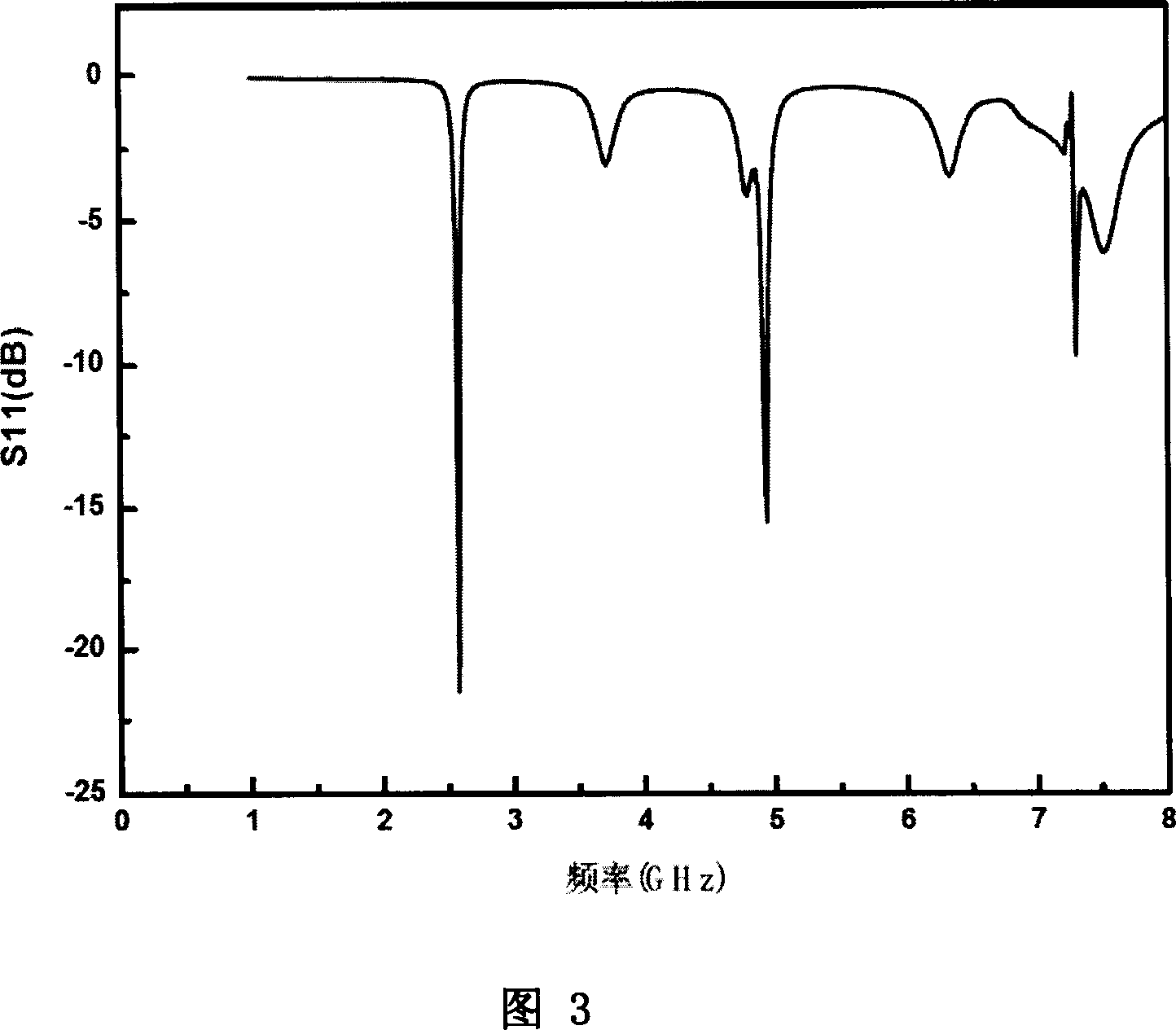

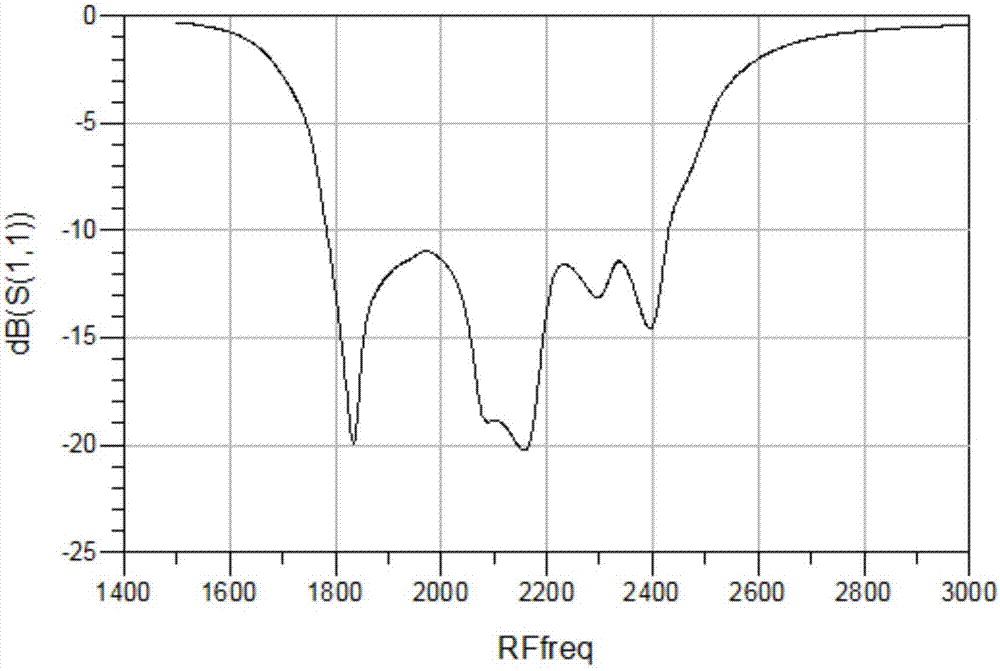

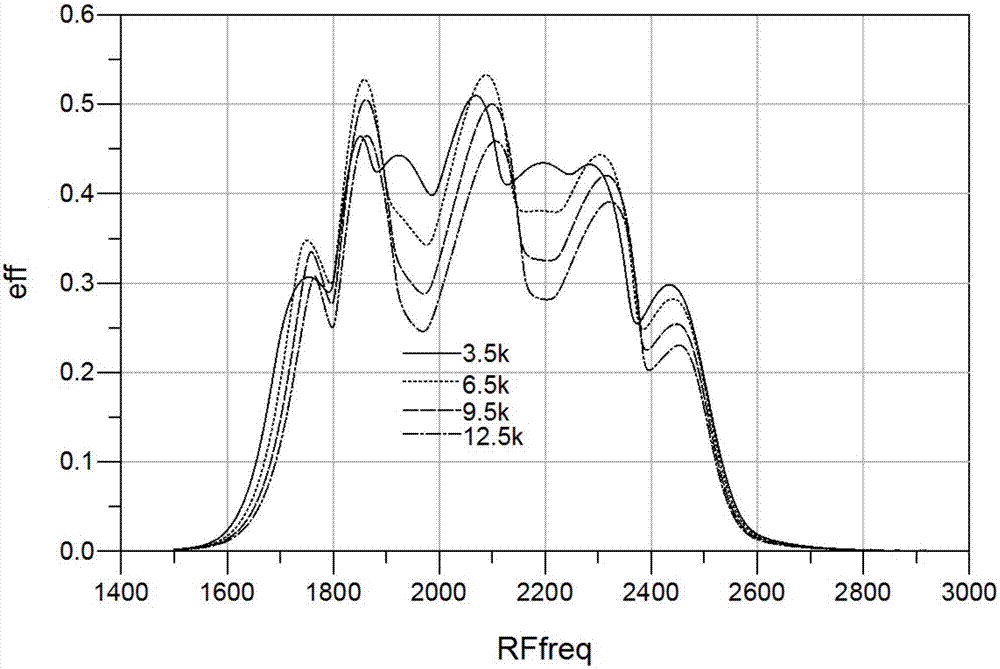

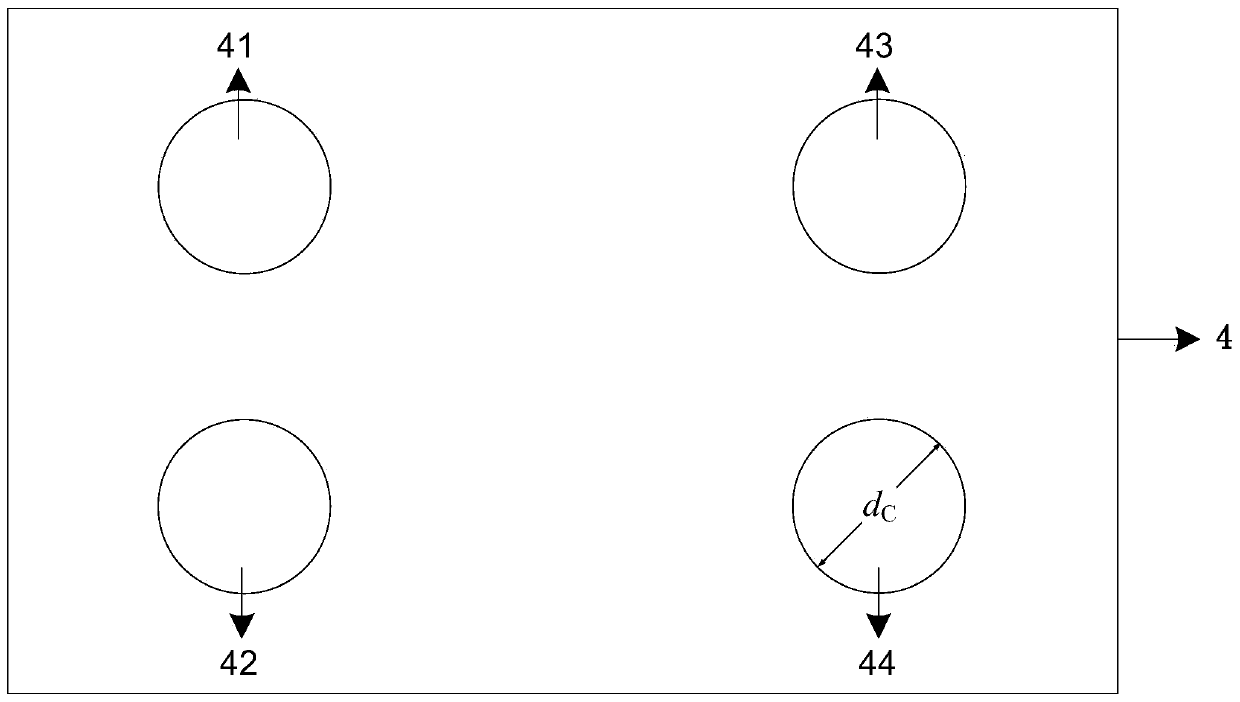

Small-signal broadband voltage doubler rectifier with load adaptability

ActiveCN107332447AReduce parasitic effectsLow high frequency lossAc-dc conversion without reversalEfficient power electronics conversionDielectric substrateImpedance matching

The invention belongs to the technical field of microwave rectification, and provides a small-signal broadband voltage doubler rectifier with load adaptability. The rectifier mainly comprises an upper microstrip structure, an intermediate dielectric substrate and an underlying metal floor. The upper microstrip structure includes an input impedance matching network, a load adaptive regulation network and a first order voltage doubler rectification network, wherein the input impedance matching network consists of a 50 ohm microstrip line input, three pairs of open short circuit branches, three sections of impedance transformation branches, and a matching inductor; the load adaptive adjustment network consists of two sections of width tapered branches and a centrosymmetric fishbone-shaped branch; and the first order voltage doubler rectification network consists of an energy storage blocking capacitor, an energy storage filter capacitor, a rectifier diode, a load resistor, a metal pad and a ground hole. By adjusting the size of the input impedance matching network and the load adaptive regulation network, the small-signal broadband voltage doubler rectifier achieves good conversion efficiency of the rectifier over a broadband wide load range.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

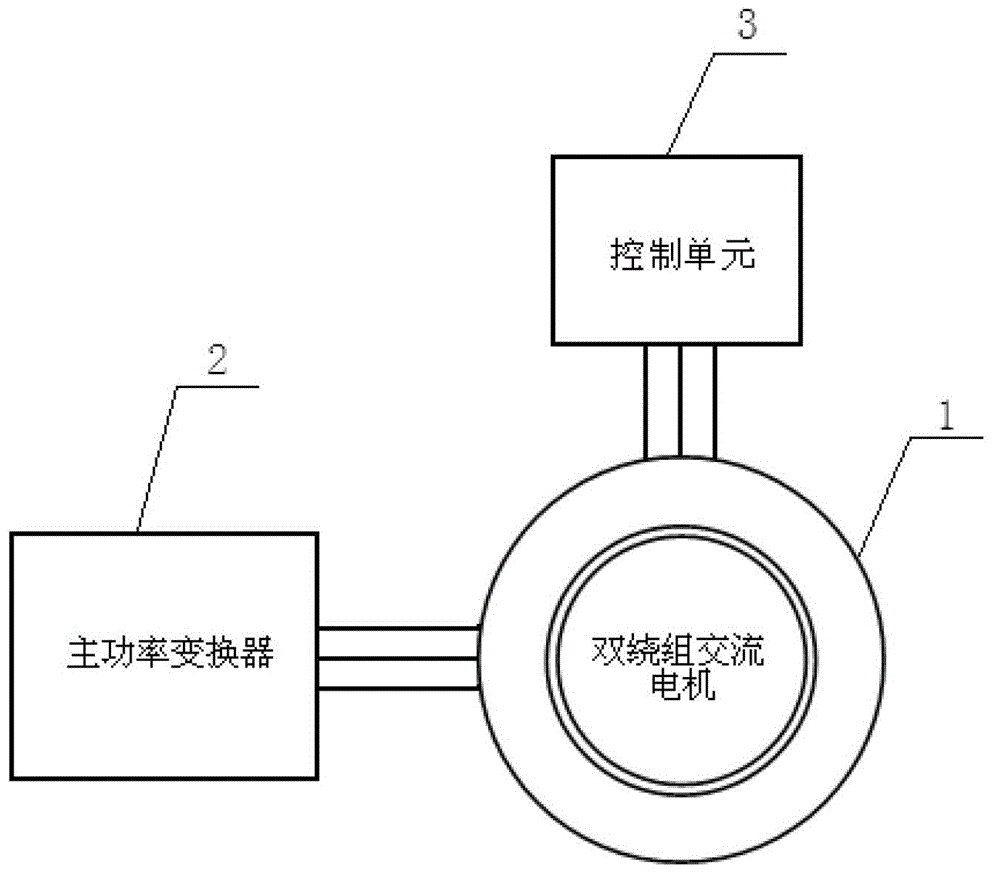

High-speed motor system

ActiveCN103337918AReduce vibrationSuppress noiseMagnetic circuit stationary partsWindings conductor shape/form/constructionVibration amplitudeElectric machine

A high-speed motor system belongs to the field of motors. The invention solves the problems that two electromagnetic dampers are needed to be respectively mounted at two ends of a rotor to reduce the system vibration through producing damping force by adopting the electromagnetic dampers, if so, the size and the loss of the system are increased; in addition, the damping force is applied to the two ends of the rotor, but generally, the vibration amplitude of an axial intermediate point of the rotor is maximum, so that the damping effect is difficult to reach the best. The high-speed motor system comprises a duplex winding alternating current motor, a main power converter and a control unit, wherein the duplex winding alternating current motor comprises a stator and a rotor, the stator comprises a stator core and a stator winding, the stator core is cylindrical, the stator winding adopts a duplex winding structure formed by a main winding and an auxiliary winding, an outgoing line of the main winding is connected with the main power converter, and an outgoing line of the auxiliary winding is connected with the control unit.

Owner:HARBIN INST OF TECH

Nanocrystalline soft magnetic alloy and preparation method and application thereof

ActiveCN111554465AIncrease ferromagnetic coupling exchange interactionImprove high magnetic inductionMagnetic materialsMischmetalUltimate tensile strength

The invention belongs to the technical field of preparation of magnetic functional materials, and particularly relates to nanocrystalline soft magnetic alloy and a preparation method and application thereof. The nanocrystalline soft magnetic alloy comprises the following components: Fe, Cu, Si, B, Nb, V and rare earth metal. By adding the rare earth metal, the ferromagnetic coupling exchange effect between ordered phases of the nanocrystalline soft magnetic alloy can be improved, and the high magnetic induction intensity and high-frequency high magnetic conductivity of the nanocrystalline softmagnetic alloy are improved. Other raw materials in the nanocrystalline soft magnetic alloy can be purified by adding the rare earth metal, and impurities in the nanocrystalline soft magnetic alloy are reduced.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +3

Microstrip antenna with phase shifting function

ActiveCN103956579AChanging the dielectric constantChange speed of propagationResonant antennasGround planeDielectric layer

The invention discloses a microstrip antenna with the phase shifting function. The microstrip antenna comprises a substrate, a metal ground plane, a signal transmission line and a radiation patch, wherein the metal ground plane is located on the upper surface of the substrate. The microstrip antenna further comprises a ferroelectric dielectric layer, the metal ground plane is located on the lower surface of the ferroelectric dielectric layer, the signal transmission line is attached to the upper surface of the ferroelectric dielectric layer, and a direct-current bias voltage and a high-frequency electromagnet wave signal are superimposed and are added between the signal transmission line and the metal ground plane. The microstrip antenna has the advantages of being simple in structure, small in high-frequency loss, low in noise, low in cost and the like.

Owner:NAT UNIV OF DEFENSE TECH

Alkalescent Chemical Silver Plating Solution

ActiveUS20100116168A1Excellent conductivity and anti-blushingLow high-frequency lossAnti-corrosive paintsLiquid/solution decomposition chemical coatingElectroless platingComplex ions

An alkalescent chemical silver electroless plating solution, which comprises: 0.01˜20 g / L silver ion or silver complex ion, 0.1˜150 g / L amine complexing agent, 0.1˜150 g / L amino acids complexing agent, and 0.1˜150 g / L polyhydroxy acids complexing agent. The alkalescent chemical silver plating solution provided by the present invention is able to overcome problems existing in acidic chemical silver plating processes commonly used at present. These problems include gnawing and corrosion of copper wires, lateral corrosion and difficulty of plating silver in blind holes, presence of solder ball voids and low strength of soldering. The silver layer plated by said silver plating solution possesses characteristics of high corrosion resistance, low contact resistance, no electromigration, high welding strength, and avoidance of bubbles produced in the solder when the plating pieces are being welded.

Owner:CHARTERMATE INT

Capacitor device structure, capacitor and manufacturing method thereof

PendingCN108336070ALow high frequency lossImprove featuresSemiconductor/solid-state device detailsSolid-state devicesCapacitanceElectrical resistance and conductance

The invention provides a capacitor device structure, a capacitor and a manufacturing method thereof, specific to the shortcomings of low capacitance density of the capacity, poor fatigue resistance ofthe device, easily damaged electrical performance and incapability of recovery after multiple times of continuous bending in the prior art. The capacitor device structure comprises a top electrode structure and a bottom electrode structure; the top electrode structure and the bottom electrode structure both adopt a composite electrode structure; the capacitor comprises the capacitor device structure; the top electrode is subjected to photoetching and wet corrosion to form a separated device array; by adoption of the capacitor device structure, the surface resistance of the bottom electrode and the top electrode is greatly lowered, thereby lowering high-frequency loss of the device, reducing cracks generated in the thin film bending process, and effectively improving the bending characteristic and the anti-fatigue characteristic of the device; and by adopting the transparent capacitor device structure, a totally transparent capacitor can be configured while the surface resistance and the anti-bending characteristic of the electrodes are greatly lowered.

Owner:无锡博硕精睿科技有限公司

Two-layer stacked differential microwave bandpass filter

ActiveCN109728390AAvoid transmissionImproved resonant frequency extractionWaveguide type devicesBandpass filteringResonant cavity

The present invention relates to a two-layer stacked differential microwave bandpass filter. The two-layer stacked differential microwave bandpass filter comprises: a first metal layer; a plurality offirst conductor pillars disposed on the first metal layer; a second metal layer arranged on the first conductor pillars and provided with an input radiation window and an output radiation window; a plurality of second conductor pillars arranged on the second metal layer; and a third metal layer arranged on the second conductor pillars and provided with a differential input port and a differentialoutput port, wherein the first metal layer, the first conductor pillars and the second metal layer form at least three coupled resonators, and a plurality of coupling windows are arranged between each two coupled resonators; the second metal layer, the second conductor pillars and the third metal layer form an input resonant cavity and an output resonant cavity. The filter provided by the embodiment obviously inhibits the transmission of the common mode signals, obviously improves the resonance frequency extraction and improves the performances.

Owner:XIDIAN UNIV

Hard connection implementation method of optical module and optical module

ActiveCN113589454AAvoid misalignmentAvoid taking up spaceCoupling light guidesOptical ModuleChannel coupling

The invention relates to a hard connection implementation method of an optical module and the optical module, and the method comprises the steps: carrying out the hard connection, carrying out the integrated assembly of a PCBA and an optical device, and then carrying out the surface mounting of internal key elements, thereby avoiding the obvious dislocation of an optical path or a circuit; carrying out key high-frequency interconnection, carrying out light path interconnection by utilizing the characteristic that parallel light paths are insensitive to axial deviation and transverse deviation, forming a non-positive-sequence implementation method, thus the advantage of large light spot coupling tolerance can be compatible, each channel can be kept to be coupled to the optimal tolerance curve position, and meanwhile, the device is simple in structure, the coupling method is easy to control, and has the advantages of small occupied space, easy assembly and the like.

Owner:LINKTEL TECH CO LTD

Metal composite magnetic powder and metal magnetic powder core

InactiveCN108597718AImprove permeabilityLow high frequency lossInorganic material magnetismInductances/transformers/magnets manufactureNitrogen plasmaRadar

The application belongs to the field of the metal soft magnetic material, and especially relates to metal composite magnetic powder and the metal magnetic powder core. The preparation of the metal composite magnetic powder provided by the invention comprises the step of enabling the flattened metal magnetic powder to react with nitrogen plasma to obtain metal composite magnetic powder formed witha nitride insulation cladding layer on the surface. A layer of continuous and stable nitride insulating layer is formed on the surface of the metal magnetic powder by using the chemical vapor deposition equipment and taking the nitrogen plasma as the reaction medium, the electric contact between the magnetic powder is effectively blocked, thereby reducing the high-frequency loss of the metal magnetic powder. The metal magnetic powder core prepared by using the above metal composite magnetic powder is high in magnetic conductivity and the low in high frequency loss; the metal composite magneticpowder is simple in preparation process, short in reaction time, low in cost, pollution-free, easy to popularize and use and can be extensively applied to the telecommunication, the radar, the water-absorbing and electromagnetic shielding and various fields.

Owner:GUANGDONG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com