Patents

Literature

49results about How to "No oxidation reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

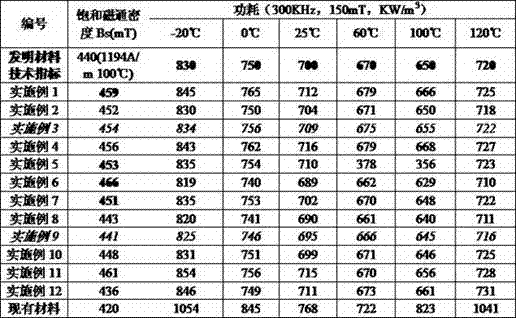

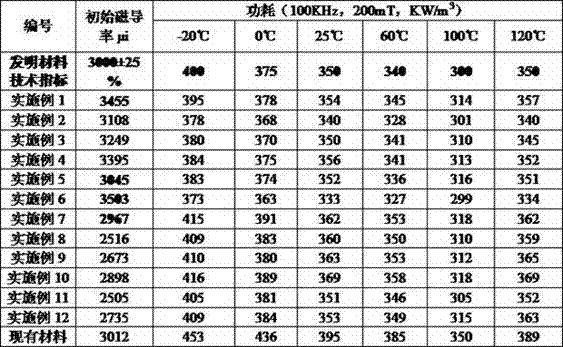

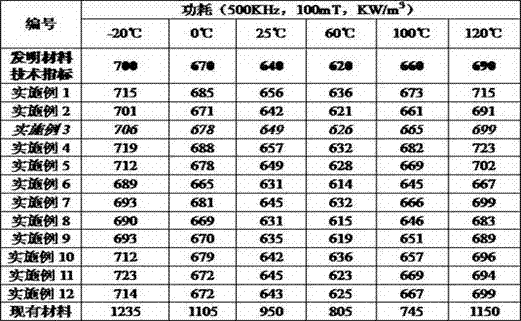

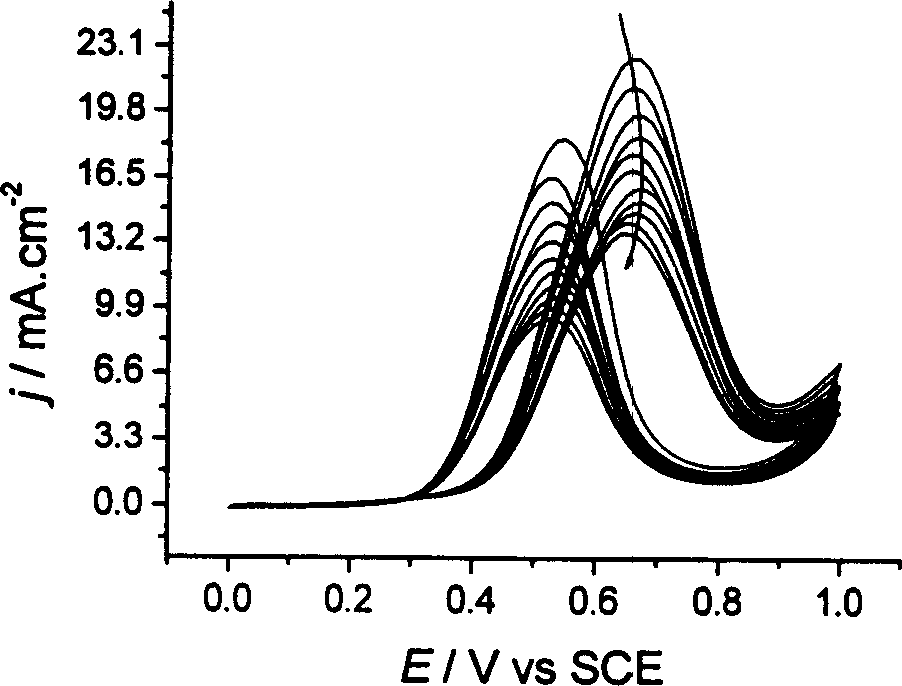

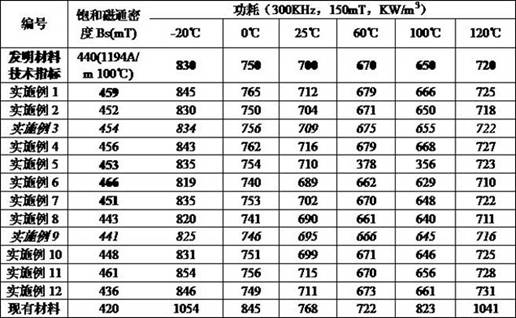

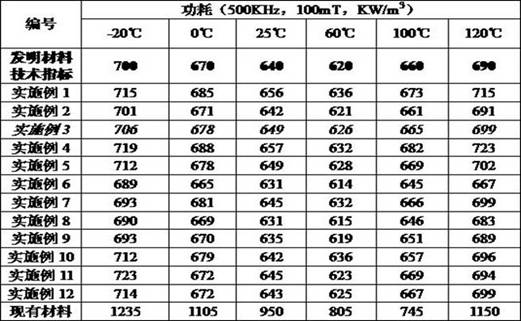

Broadband wide temperature range high-power density low-loss manganese-zinc soft magnetic ferrite material and preparation method thereof

ActiveCN107473727AImprove workabilityLow high frequency lossInorganic material magnetismSpray GranulationManganese

The invention discloses a broadband wide temperature range high-power density low-loss manganese-zinc soft magnetic ferrite material. The material comprises main ingredients, an auxiliary ingredient A and an auxiliary ingredient B, wherein the main ingredients comprise the following components in percentage by weight: Fe2O3, MnO and ZnO; based on the weight of the main ingredients, the auxiliary ingredient A comprises at least three of CaCO3, Nb2O5, NiO, SnO2 and Co3O4; and the auxiliary ingredient B comprises at least three of SiO2, Y2O3, K2CO3, Al2O3, CuO, MoO and Bi2O3. The preparation method of the material sequentially comprises the following steps: primary batching, primary sanding, pre-sintering, secondary batching, secondary sanding, performing component analysis, performing spray granulation, molding and sintering. The material disclosed by the invention has low loss in a temperature range from 20 DEG C below zero to 120 DEG C under the conditions of 100-500KHz and 100-200mT, and has high magnetic conductivity and high high-temperature saturation flux density. Compared with the conventional material, the material disclosed by the invention is energy-saving and can enable a switching power module to be miniature and efficient.

Owner:郴州市久隆旺高科电子有限公司

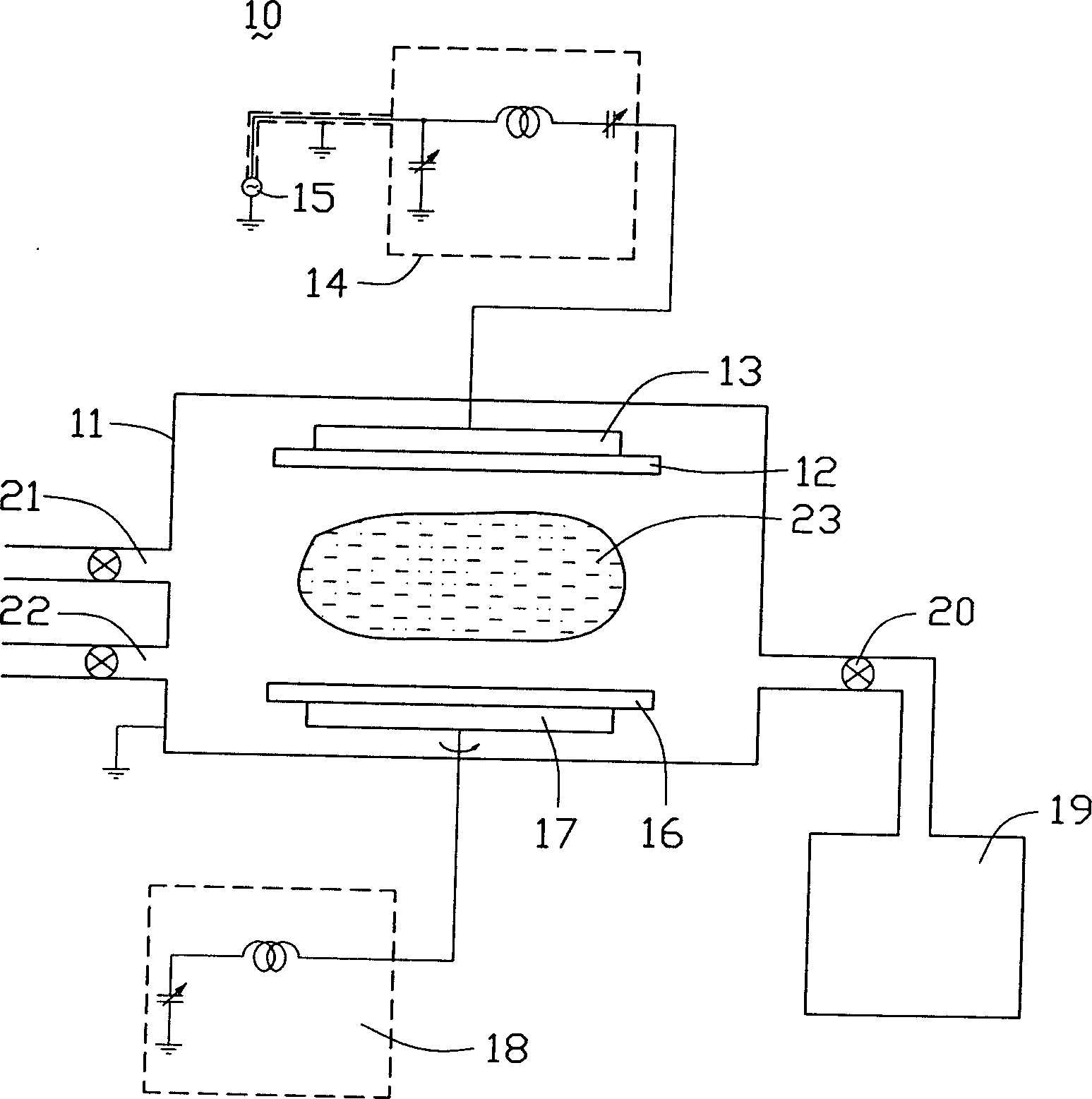

DBC (Direct Bonded Copper) substrate surface treatment process based on nano-silver soldering paste connecting chip

ActiveCN102560488ANo oxidation reactionWon't seepVacuum evaporation coatingSputtering coatingPre treatmentSurface finishing

The invention discloses a DBC (Direct Bonded Copper) substrate surface treatment process based on a nano-silver soldering paste connecting chip. The process solves the technology that not only the copper on the DBC substrate surface is prevented from bleeding out of a silver plating surface, but also the combination strength between the nano-silver soldering paste connecting chip and the DBC substrate is ensured. The DBC substrate surface treatment process comprises the following steps of: firstly carrying out cleaning pretreatment on the surface of a DBC substrate; then carrying out electronickelling treatment on the pretreated DBC substrate; and finally, after thorough cleaning, carrying out silverplating treatment on the surface of the electronickelled DBC substrate by using a magnetron sputtering method. The DBC substrate surface treatment process based on the nano-silver soldering paste connecting chip has the following beneficial effects: when the electronickelled DBC substrate subjected to magnetron sputtering silver is sintered at high temperature by using a nano-silver soldering paste, the metal copper on the surface of the DBC substrate does not oxidize, i.e. the metal copper does not permeate the surface of a silvering layer; after being sintered, the nano-silver soldering paste has good bonding strength with the electronickelled DBC substrate subjected to magnetron sputtering silver; and the DBC substrate surface treatment process is green and environment-friendly and has no adverse effect on the environment.

Owner:TIANJIN UNIV

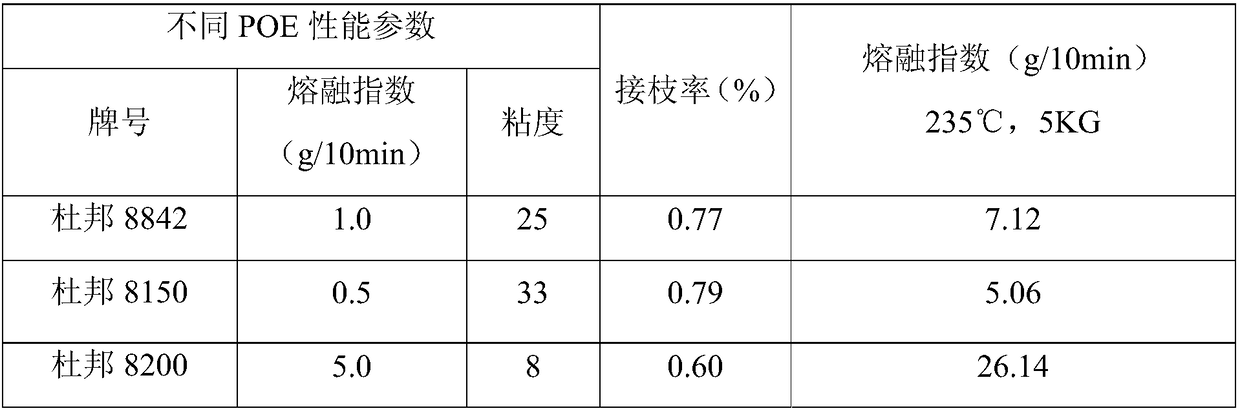

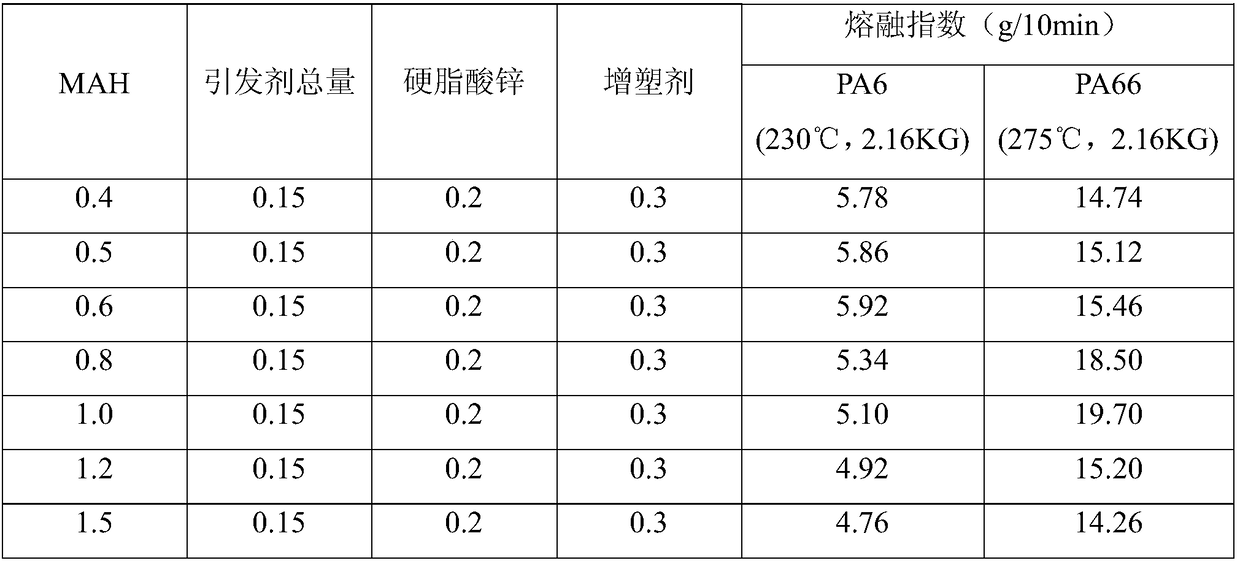

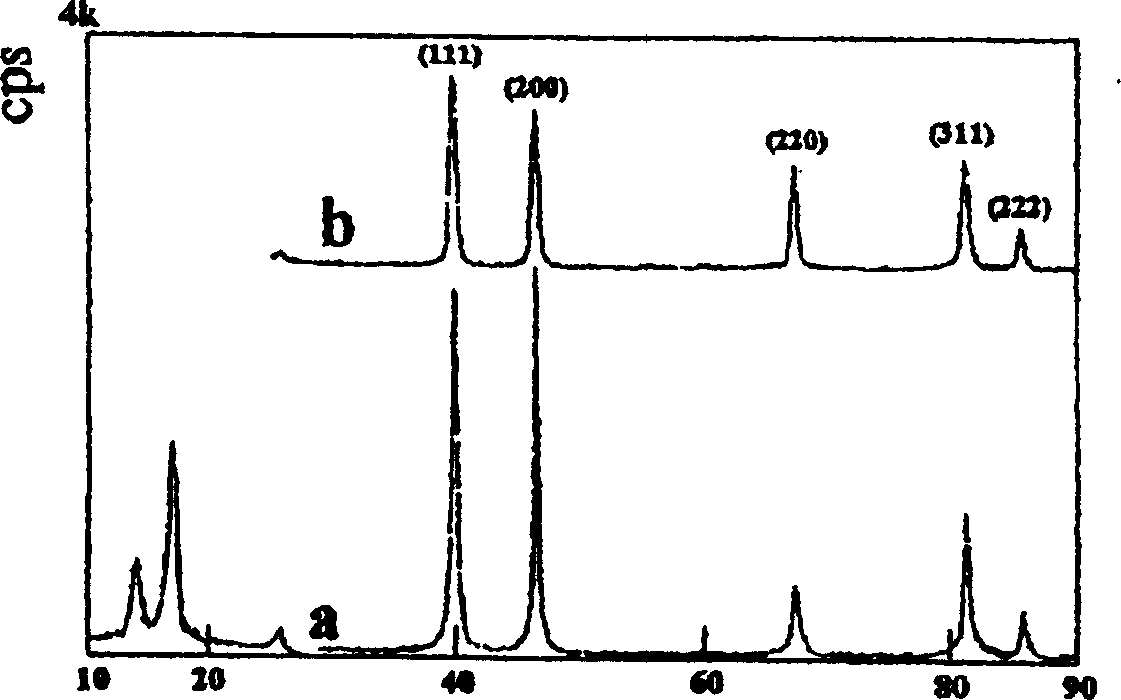

Low-temperature-resistant polyolefin grafted maleic anhydride flexibilizer used for nylon and preparation method of flexibilizer

ActiveCN108129833AImprove low temperature impact performanceGood compatibilityElastomerNylon material

The invention belongs to the field of polymer materials, and in particular relates to a low-temperature-resistant polyolefin grafted maleic anhydride flexibilizer used for nylon and a preparation method of the flexibilizer. The flexibilizer comprises the following raw materials in parts by weight: 100 parts of a polyolefin elastomer, 0.3-1.5 parts of maleic anhydride, 2-6 parts of an ionic polymer, 1.0-2.0 parts of polypropylene powder, 0.05-0.15 part of graft polypropylene, 0.05-0.25 part of a lubricant, 0.1-0.3 part of a plasticizer, 0.05-0.2 part of an initiator, and 0.1-0.3 part of an antioxidant. According to the flexibilizer provided by the invention, the maleic anhydride is grafted through the polyolefin elastomer, the polarity of the polyolefin elastomer is enhanced, and the grafted polyolefin elastomer can be used as a flexibilizer, an interfacial modifier and a compatibilizer of the nylon; and the flexibilizer can obviously improve the compatibility of the polyolefin elastomer and a strong-polarity nylon material, and can effectively improve the low-temperature impact performance.

Owner:SHENYANG KETONG PLASTIC

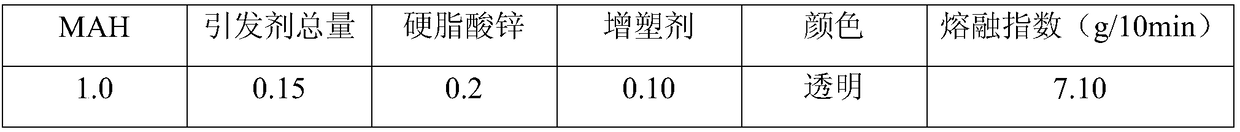

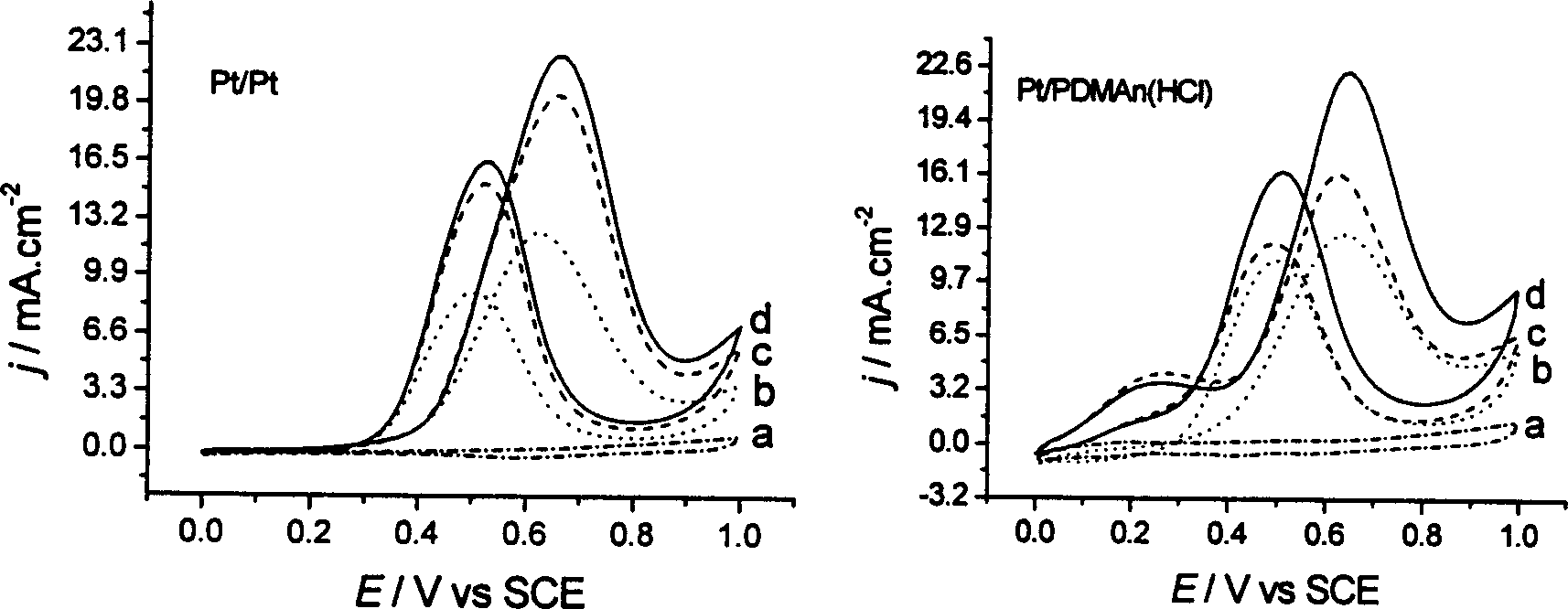

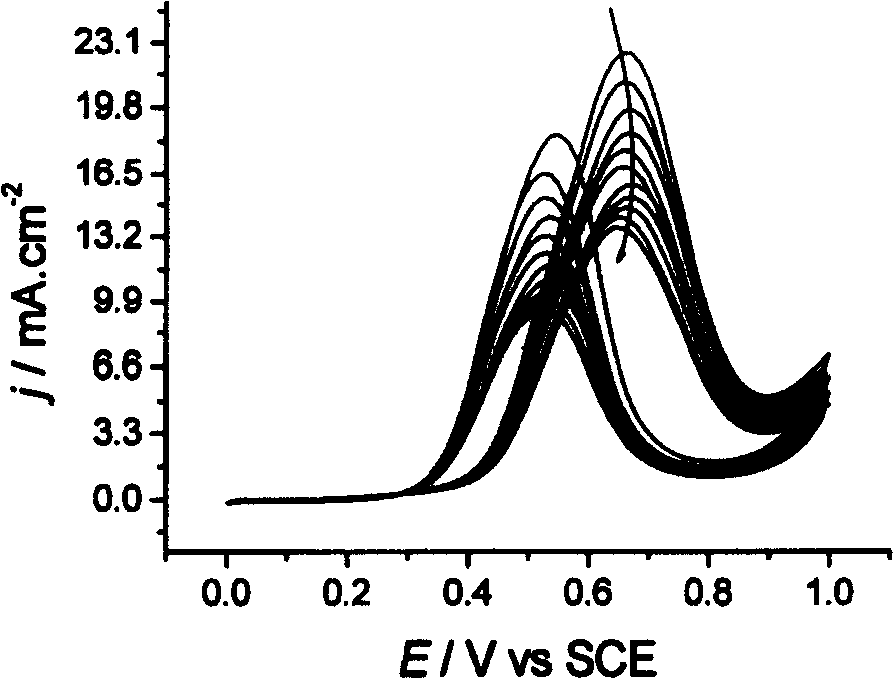

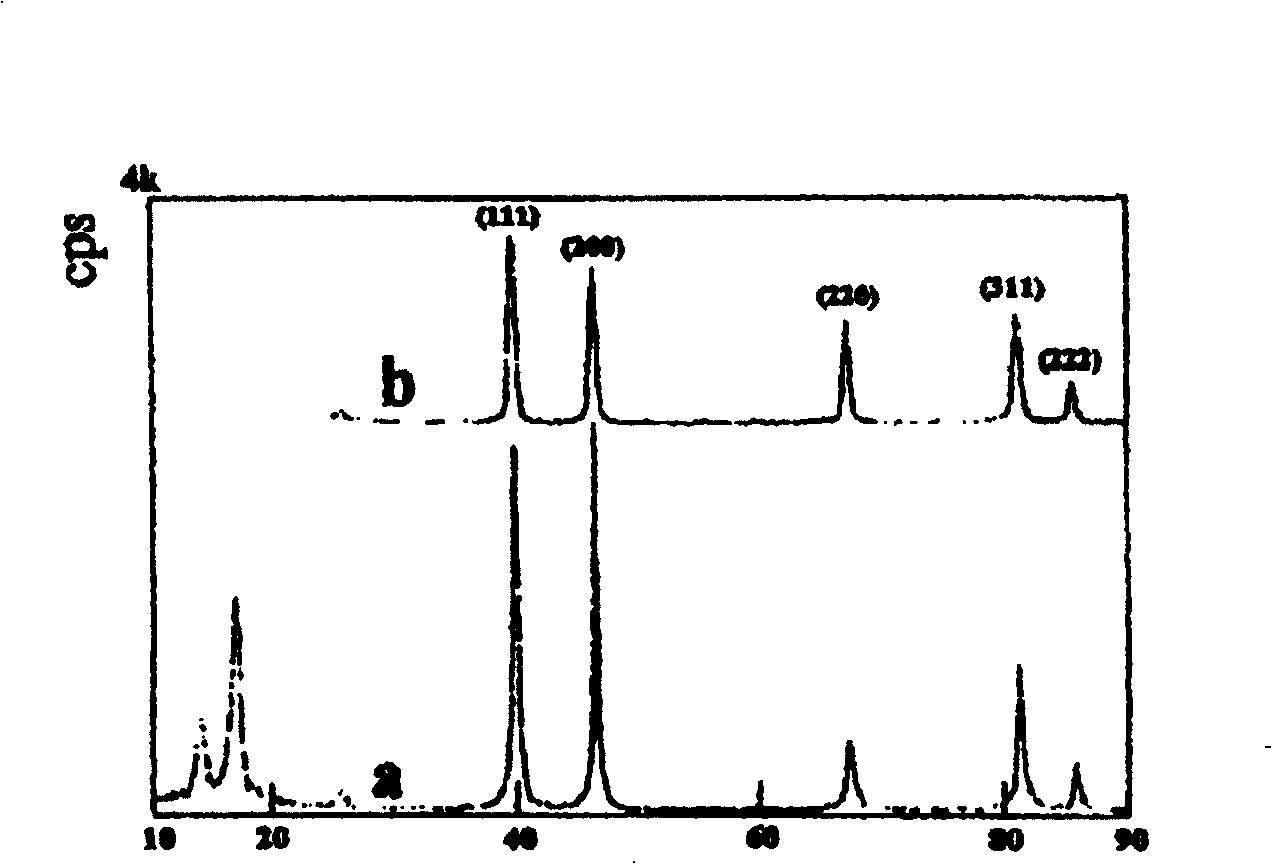

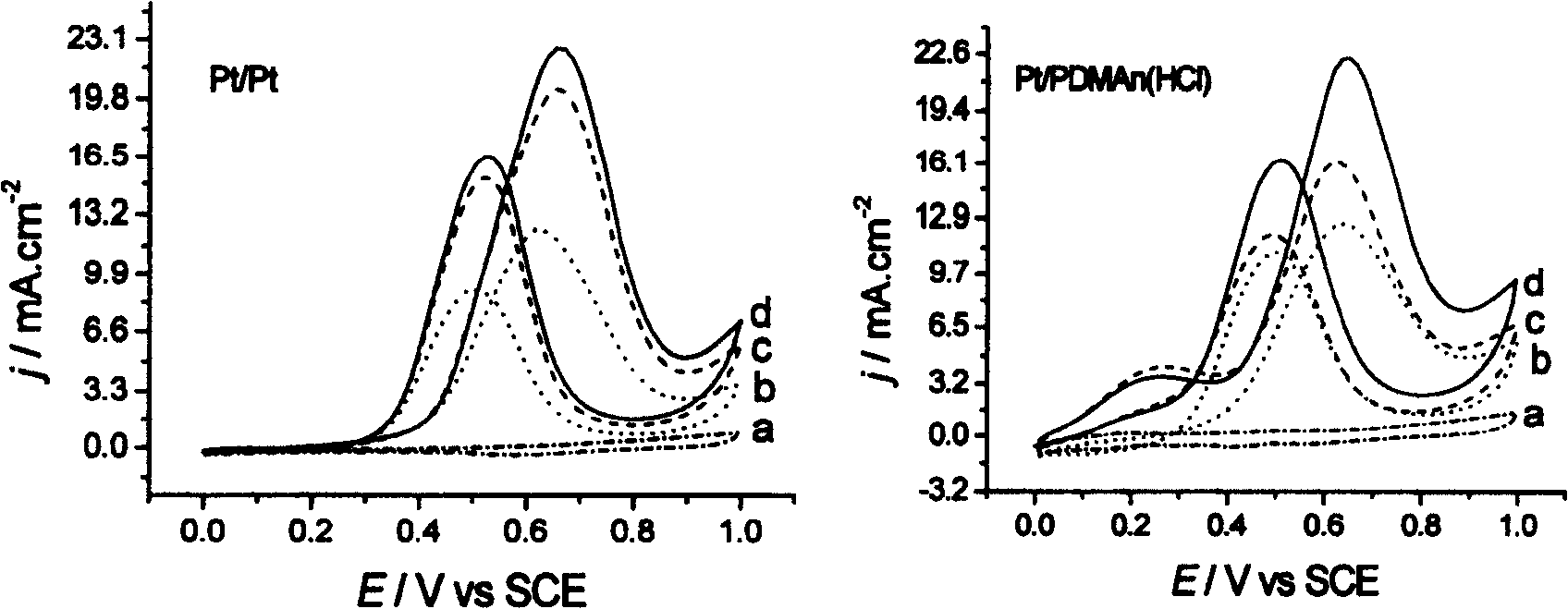

Methanol electro-oxidizing-catalyzing electrode, preparing process and application thereof

InactiveCN1667405AImprove solution processabilityLittle effect on conductivityMaterial electrochemical variablesPolyaniline derivativesElectricity

The invention discloses a menthol electro oxidation catalyst electrode, its process method and application, wherein the electrode relates to a metallization membrane modification electrode and is used as an electrochemical sensor for catalyzing menthol electro oxidation.A charged strong electron donating group polyaniline derivant poly-2,5-dimethoxybenzamine metallization membrane modification electrode comprises inert electrode base, conductive polymer membrane and catalyzer, wherein, polymer adhesion amount on the surface of base electrode is 0.3-1.0mgíñcm-2.The method comprises following steps: mixing PDMAn mixed with alcaine in N,N-dimethyl formamide or tetrahydrofuran to get 1.0í½10.0mg / mL liquor; coating liquor on electrode surface and drying it; changing coating times to adjust polymer adhesive materials; placing electrode in HCI liquor; conducting periodic scan or directional scan and changing times to get modification electrode with different platinum deposit rate.

Owner:XIAMEN UNIV

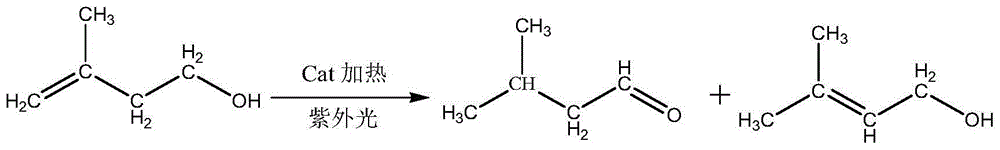

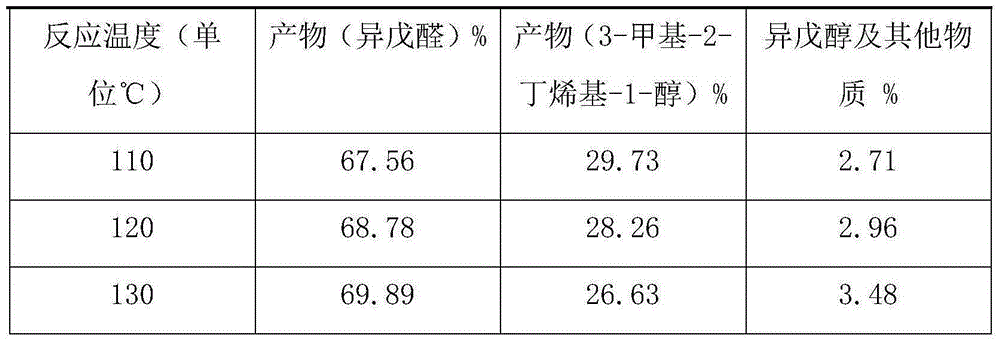

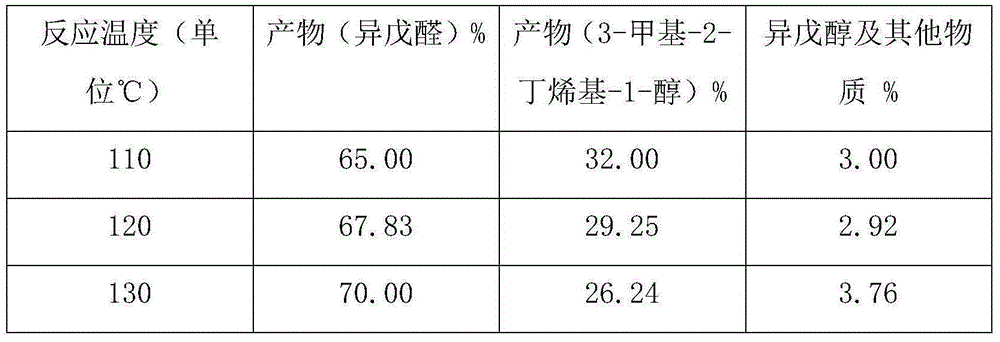

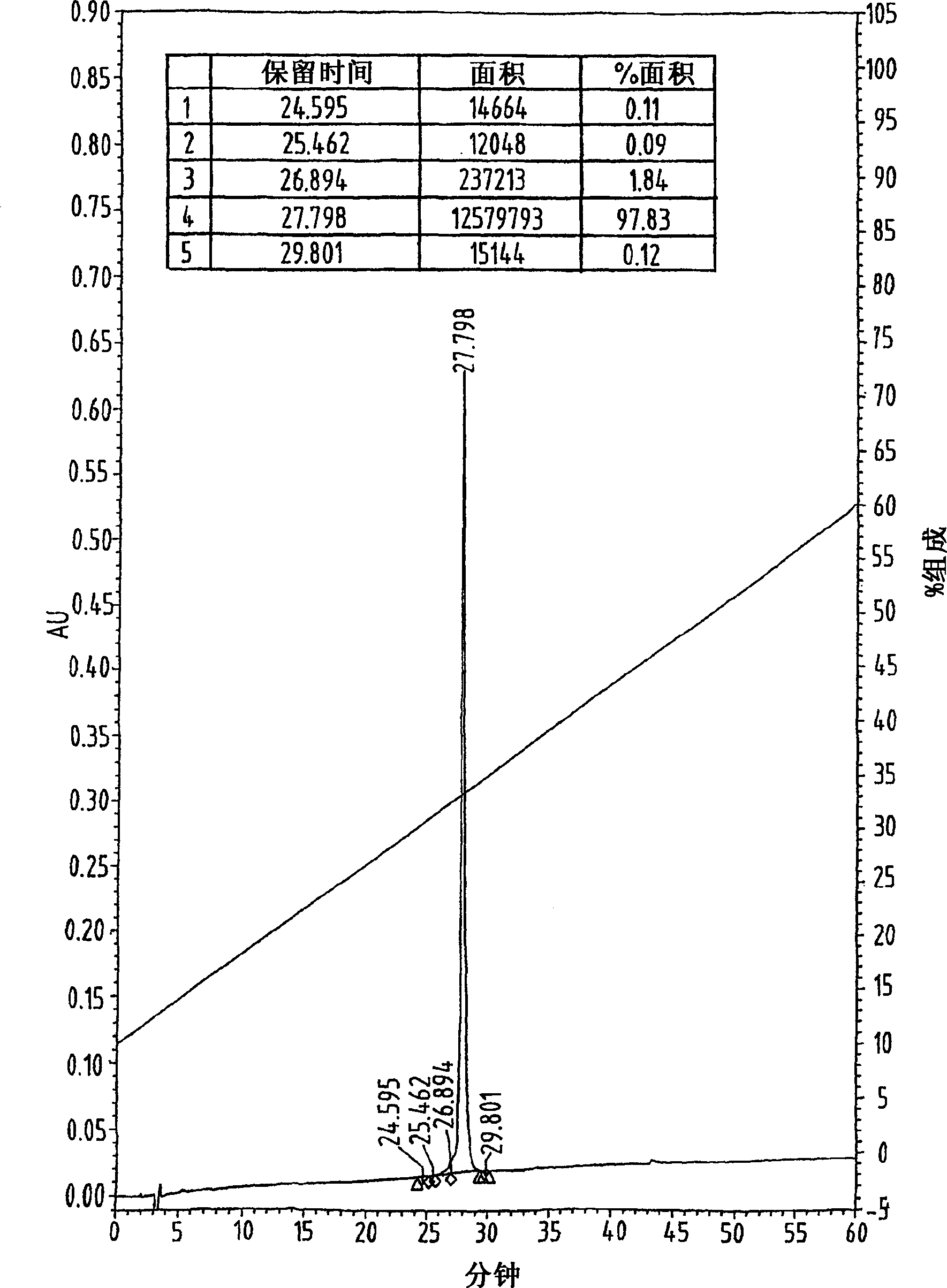

Method for preparing isoamyl aldehyde from 3-methyl-3-butenyl-1 alcohol

InactiveCN104926631ASufficient sourceImprove conversion ratePreparation by isomerisationOrganic compound preparationPhotocatalytic reactionReaction temperature

The invention discloses a method for preparing isoamyl aldehyde from 3-methyl-3-butenyl-1 alcohol. The method is characterized by comprising the following steps: putting raw materials comprising 98-98.5 percent (in percentage by mass) of 3-methyl-3-butenyl-1 alcohol and 1.5-2 percent of an organic metal compound catalyst into a reactor; putting the reactor into an oil bath pan of 140 DEG C under normal pressure to carry out heating reaction at a temperature of 110-130 DEG C; under a N2 atmosphere anoxic condition, continuously separating part of isoamyl aldehyde generated in a photo-catalytic reaction process by distilling, promoting reaction for generating isoamyl aldehyde to further positively carry out, wherein the total reaction time is 3-4 hours; finally, obtaining high-purity isoamyl aldehyde, 3-methyl-3-butenyl-1 alcohol and a little isoamyl alcohol by carrying out separation, rectification and purification on all crude product. The method is scientific and reasonable, low in reaction temperature and pressure, high in effective product conversion rate, energy-saving and low in production cost.

Owner:吉林众鑫化工集团有限公司

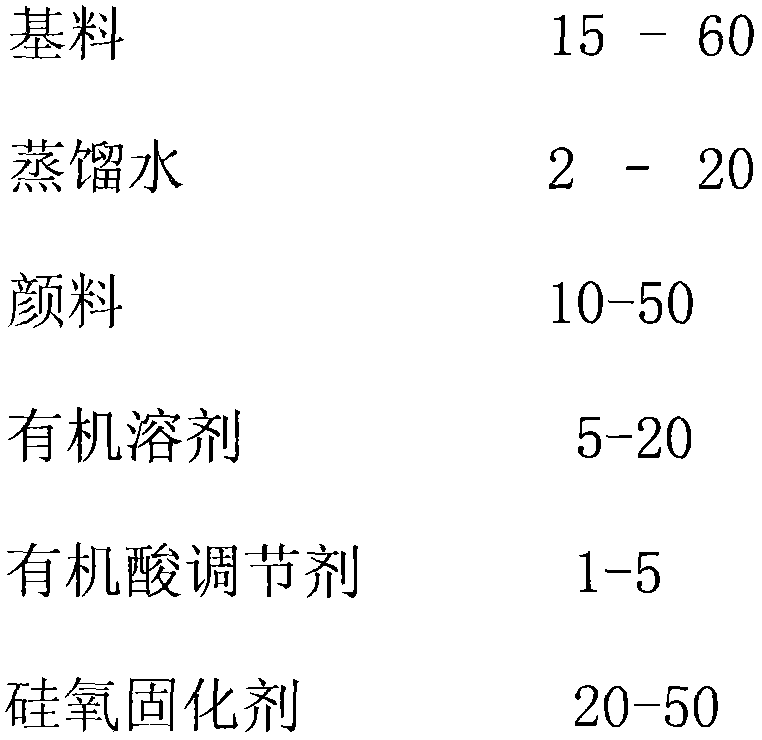

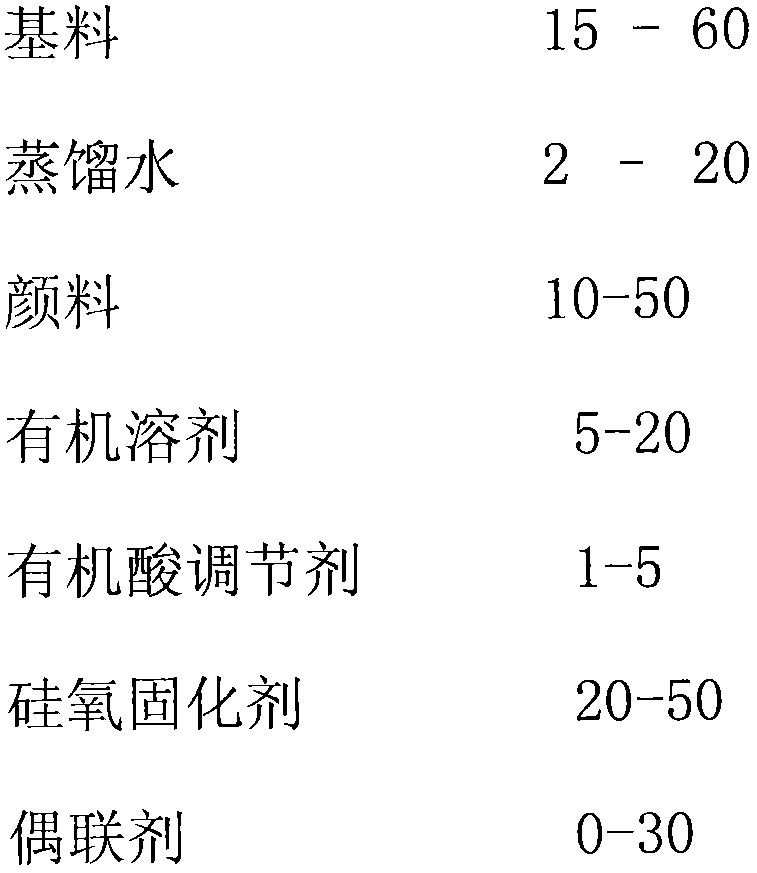

Tough inorganic baked-porcelain paint

ActiveCN102924982APrevent excessive gelationPrevent loss of lightPretreated surfacesCoatingsUltravioletLow temperature curing

The invention provides a tough inorganic baked-porcelain paint. The paint is characterized in comprising the components of: a base material, distilled water, a pigment, an organic solvent, an organic acid adjusting agent, a silica curing agent, and a coupling agent. The pH value of the pigment is regulated to 8-10H by using sodium hydroxide, and preferably 8-9H. The base material is a nano-grade oxide. The organic solvent includes alcohols, ethers, and ketones. The silica curing agent includes ethylsilane substituted derivatives. After the paint is cured, a formed coating has high hardness, and the coating is not subjected to any oxidation reaction under high temperature. With an ultraviolet resistance, the coating has ultrahigh weatherability in the respects of color and gloss maintenances. The coating also has certain toughness, such that a coating cracking phenomenon is prevented when the coating is impacted by a hard object. The paint can cure under 0-185 DEG C, such that low-temperature curing can be carried out, such that energy consumption is low. Also, if a surface reparation problem occurs, curing reparation can be carried out with the assistance of a high-temperature incandescent lamp.

Owner:乐思龙金属科技有限公司

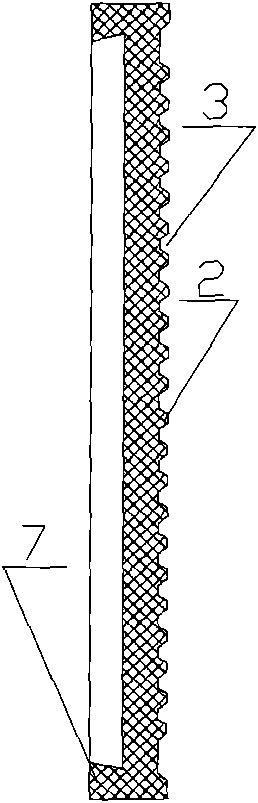

Method for producing dyed hollow filaments by recycled polyester

InactiveCN107447271AUniform average molecular weight distributionHigh strengthHollow filament manufactureFilament/thread formingMasterbatchPolyester

The invention discloses a method for producing dyed hollow filaments by recycled polyester in the field of polyester fiber production methods. The method includes: preparing a recycled material, and making the recycled material into recycled masterbatch; subjecting the recycled masterbatch to solid-phase tackifying under a vacuum state; mixing the tackified material and masterbatch, sending into a screw extruder to realize mixing and extruding, and spinning through a hollow spinneret plate to obtain hollow filaments; cooling and blowing the filaments under the protection of nitrogen; oiling, and subjecting multiple strands of filaments to interlacing treatment through an interlacing jet; winding and storing. The method can be used for recycling of various waste beverage bottles and textile offcut materials, and environmental friendliness and low energy consumption are realized.

Owner:JIANGSU FEILIN FIBER TECH

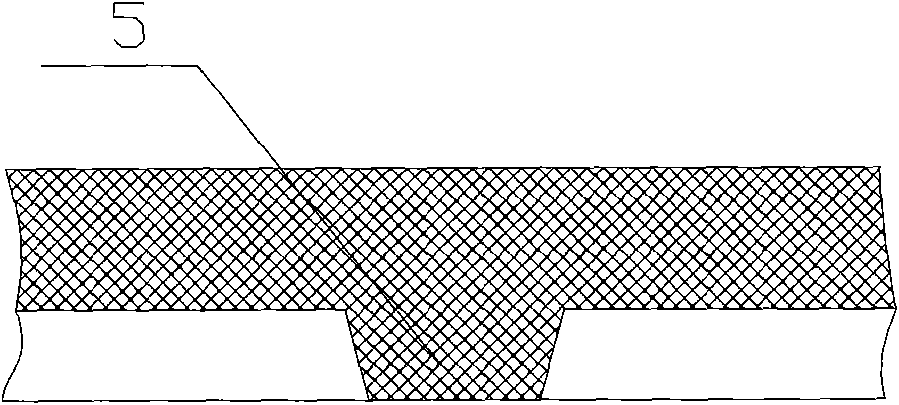

Treatment method for copper twisted wire

InactiveCN101054655AStrong diffusion effectUniform antioxidant capacityAtmospheric temperatureOxidation resistant

A technical handling method of cuprum wires cross relates to the annealing process of cuprum wires cross and comprises the following steps: putting cuprum wires cross into a annealing furnace, pumping air in the furnace to form negative-pressure in the furnace, filling the furnace with carbon dioxide protective gas; performing a heating treatment of two stages under pressure, performing a gas releasing decompression processing between stages, then cooling-down slowly in the furnace for 0.3-1 hour, and opening the furnace to cool-down naturally to atmospheric temperature. Therefore, electrical soft wires cross through such annealing treatment has brightening surfaces and excellent finish, without greasy dirt or other soils; exhibits uniform flexibility and strong antioxidant ability, and can be stored for a long time.

Owner:曹惠忠

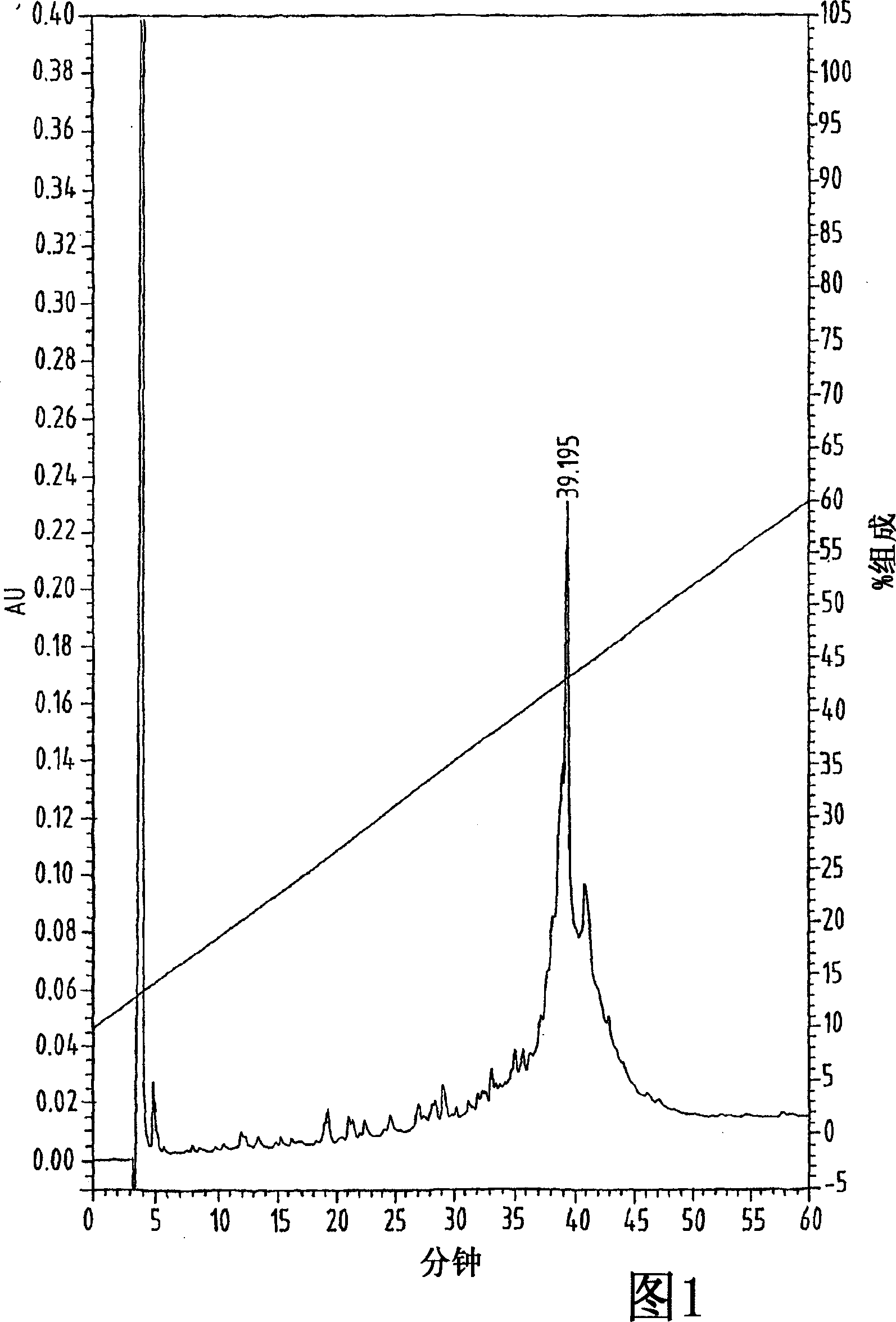

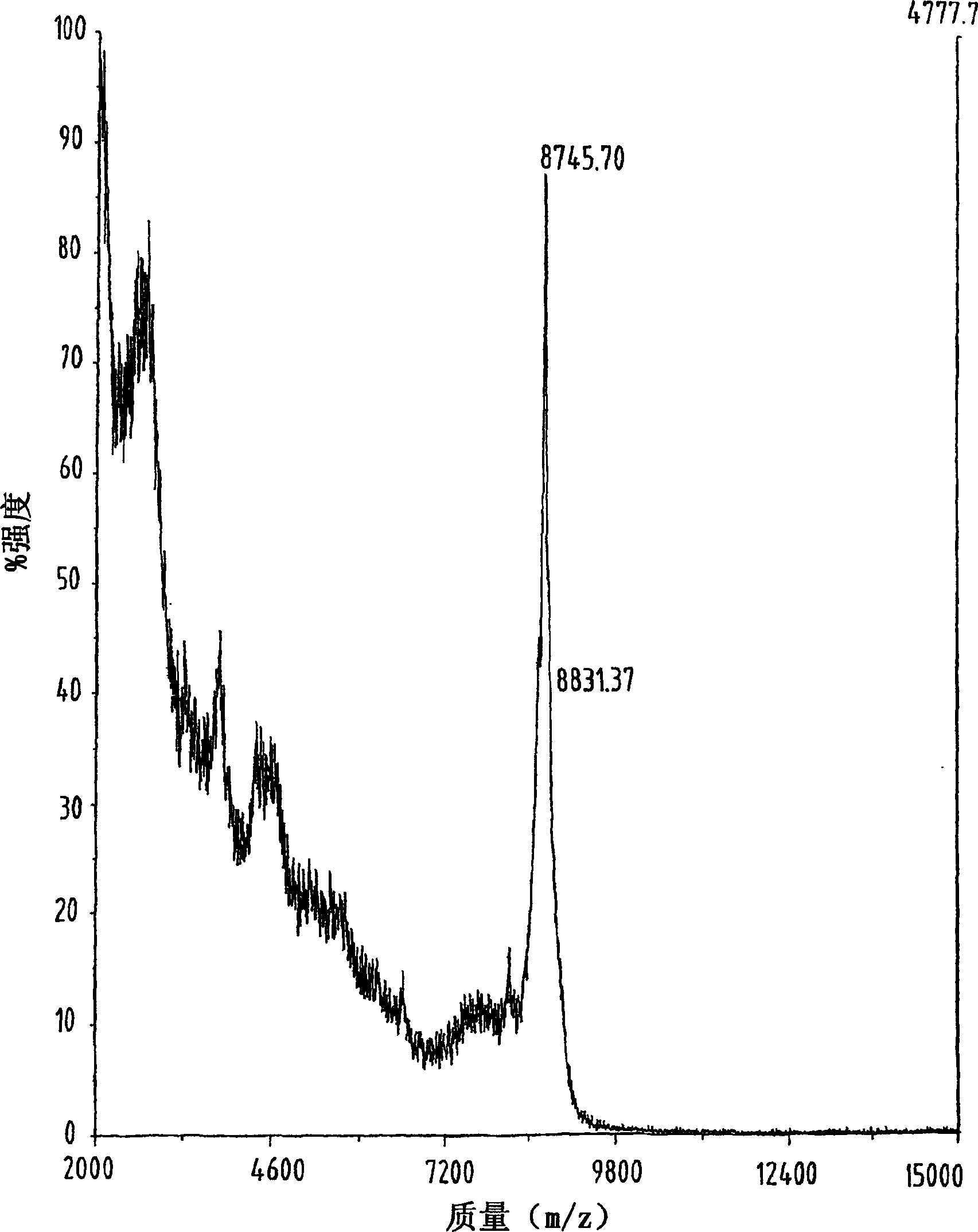

Process for folding chemically synthesized polypeptides

InactiveCN1449406ANo peroxidation reactionNo oxidation reactionPeptide preparation methodsChemical synthesisThio-

The present invention relates to a process for folding chemically synthesized polypeptides, comprising treating a polypeptide and / or protein that comprises two or more derivatized cysteine residues with a reducing agent in a folding buffer having a predetermined pH and temperature, wherein the derivatized cysteine residue corresponds to S-butyl-thio-cysteine residue and wherein the reducing agent is cysteine.

Owner:RMF DICTAGENE

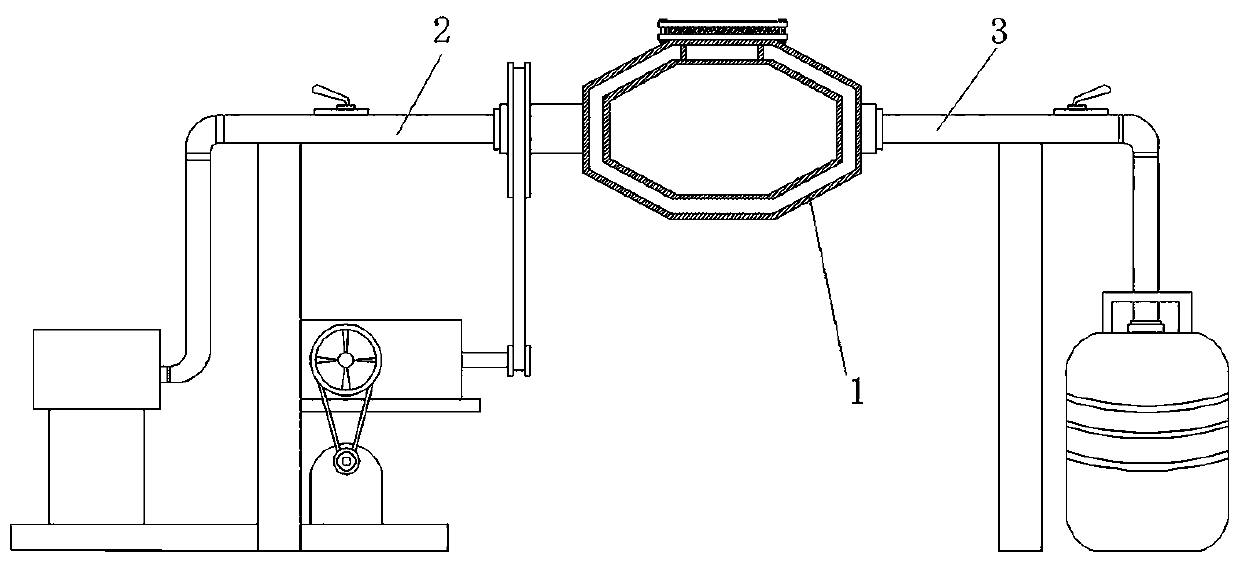

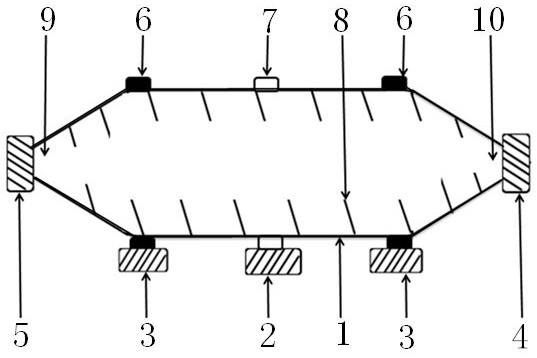

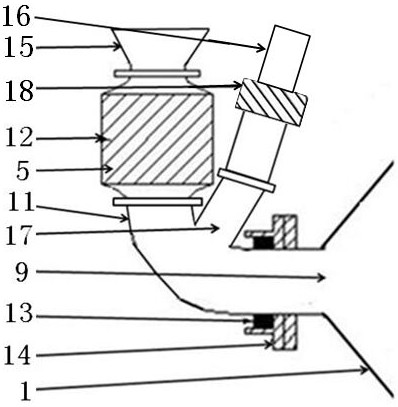

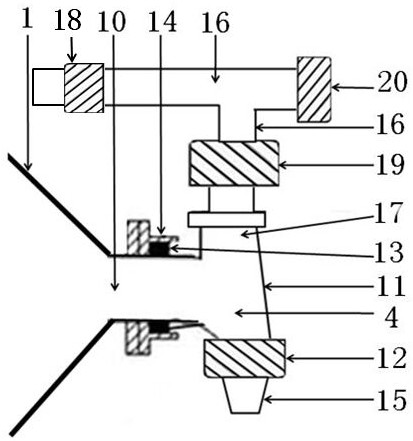

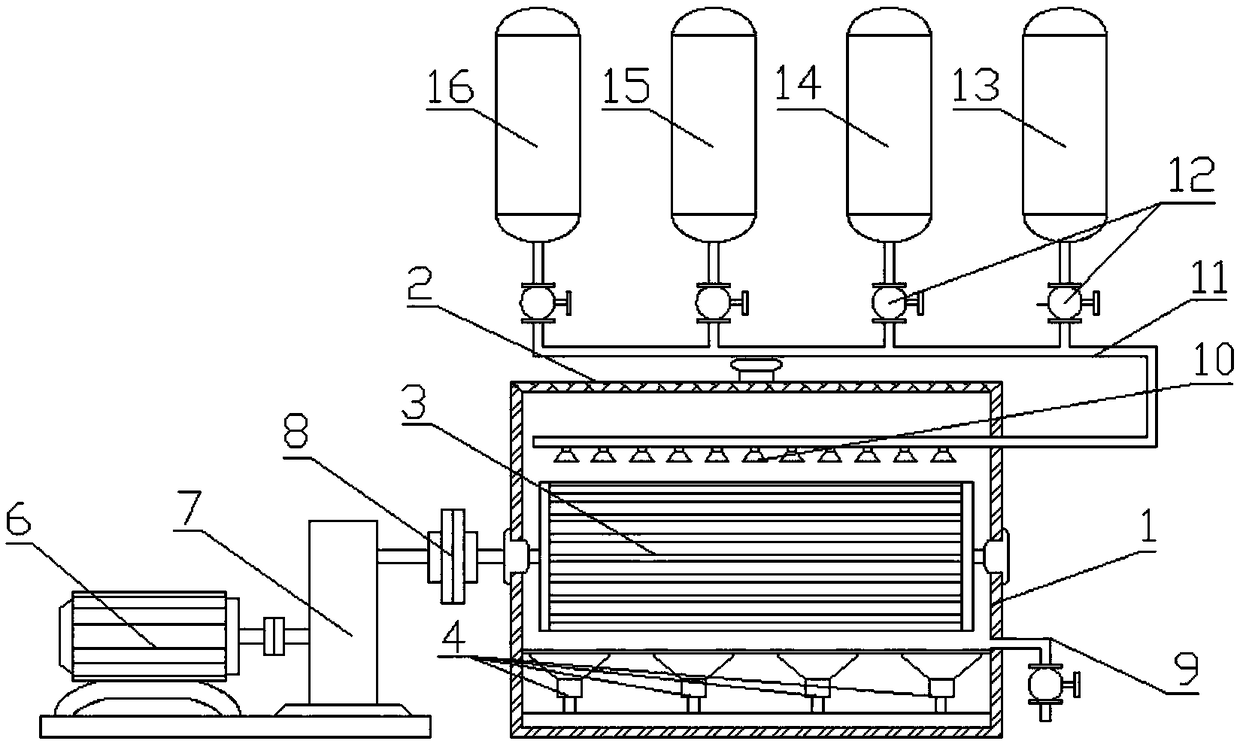

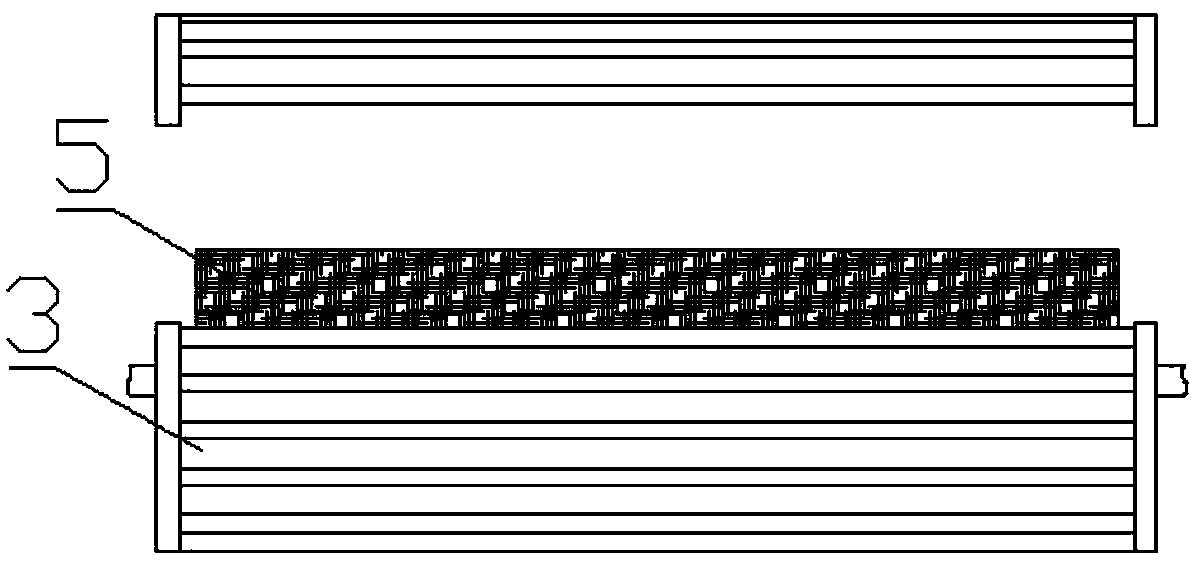

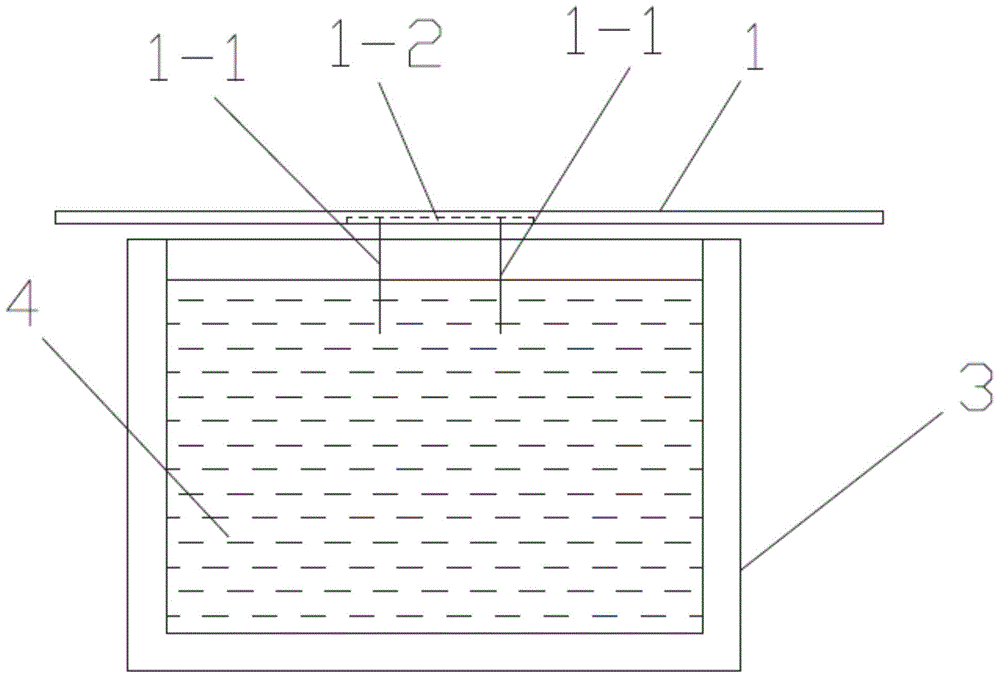

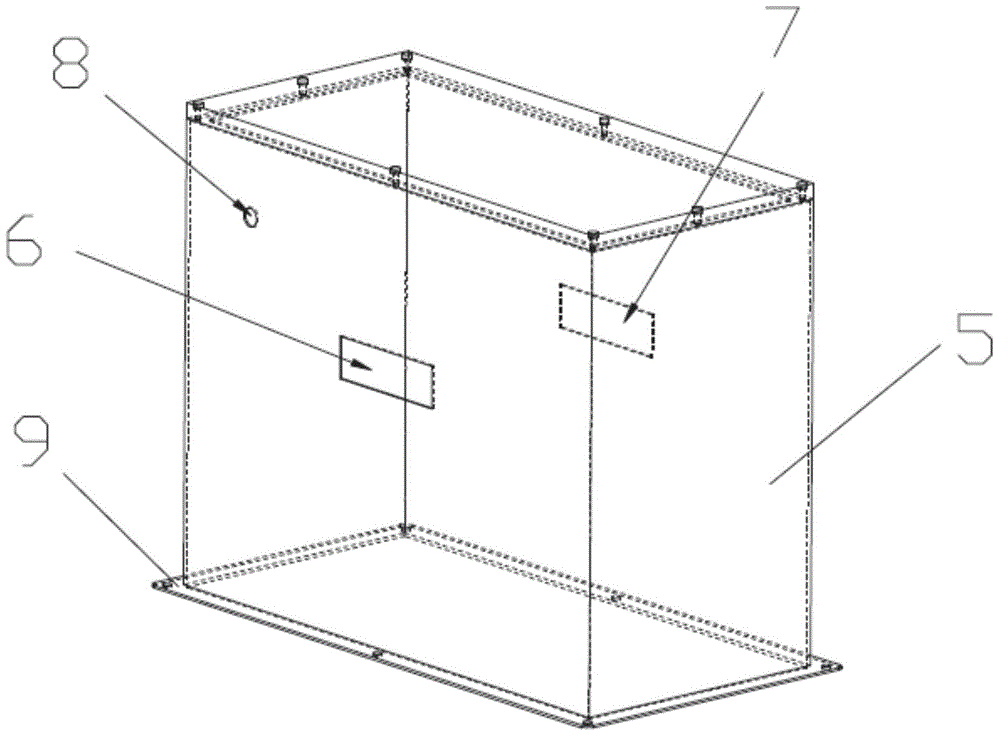

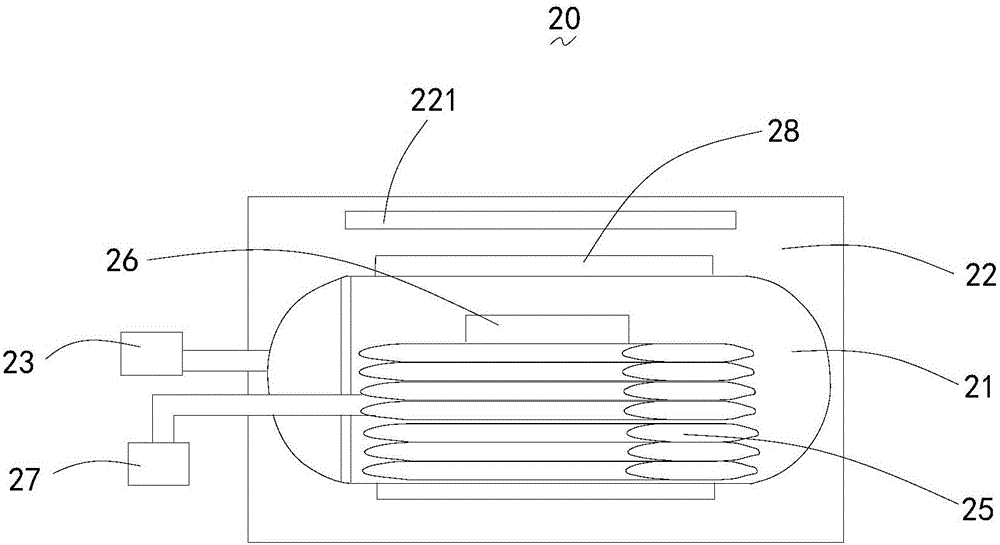

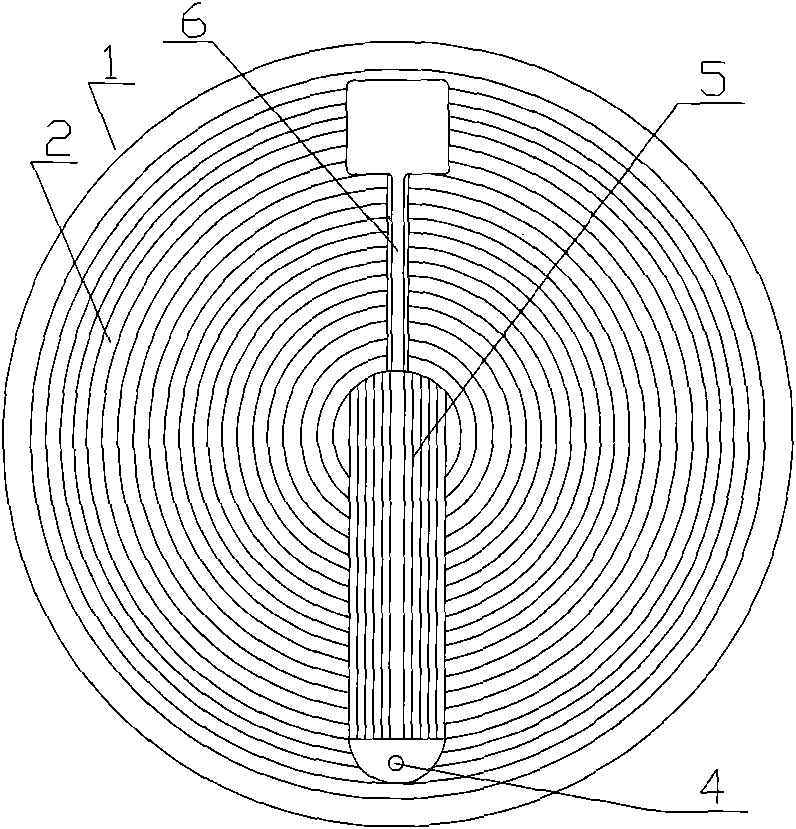

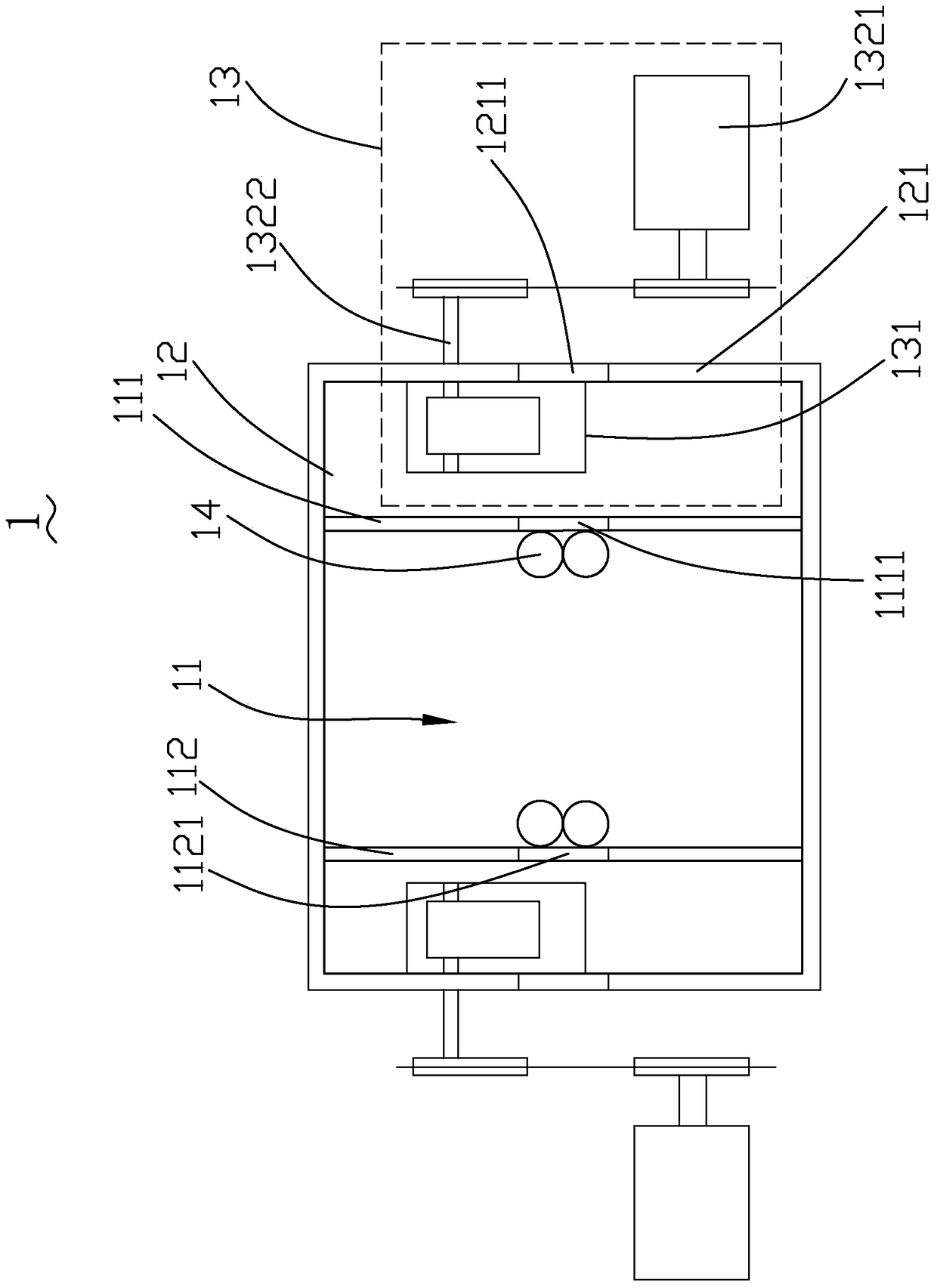

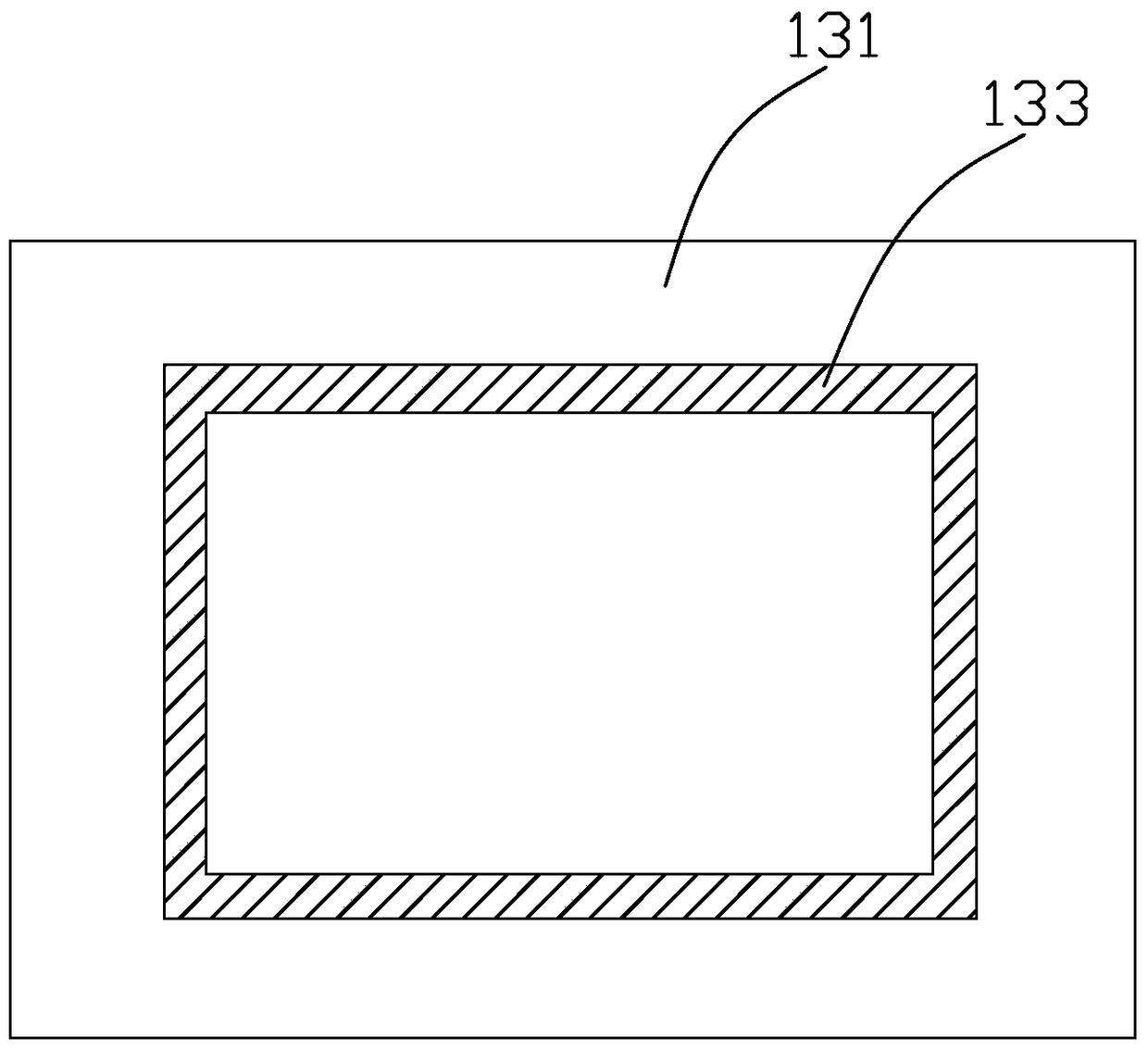

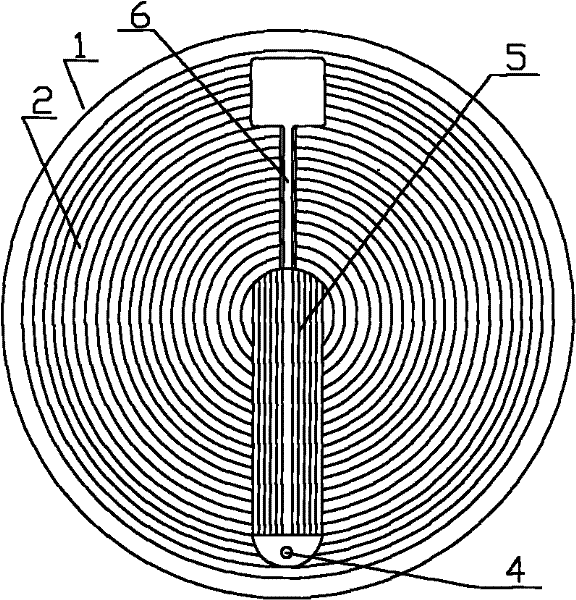

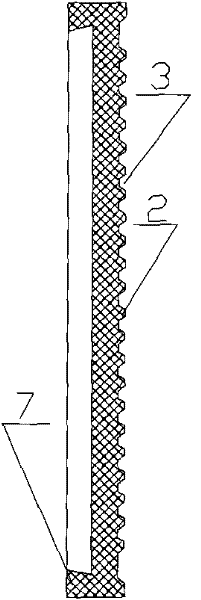

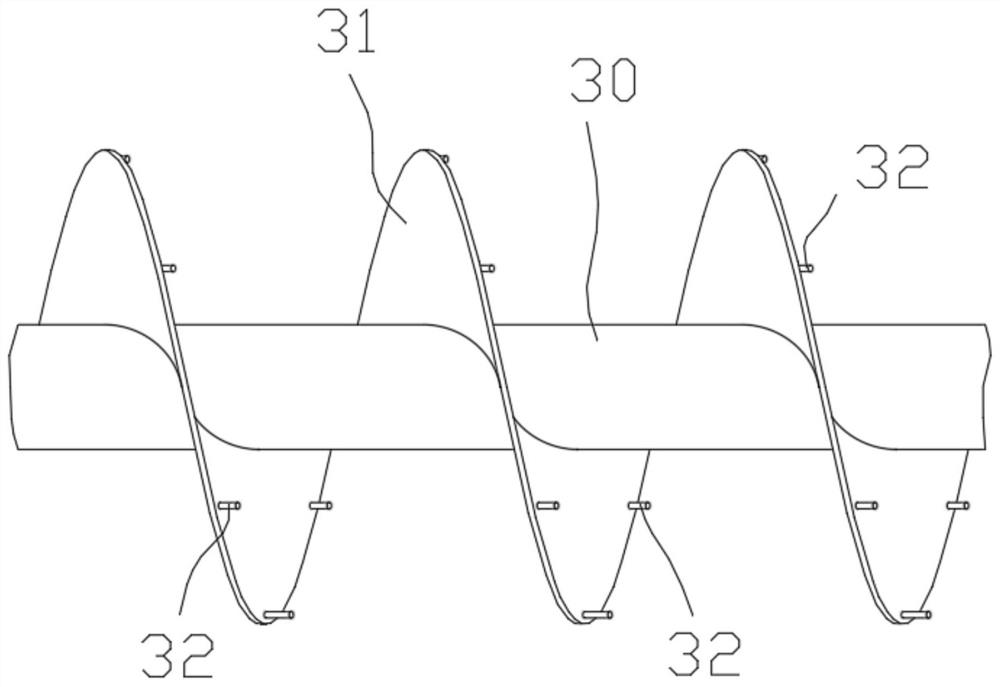

Nitrogen protected tea leaf enzyme deactivating and drying integrated machine

PendingCN107788146AGuarantee the quality of finished productsNo oxidation reactionPre-extraction tea treatmentAgricultural engineeringNitrogen

The present invention relates to the field of machinery and particularly relates to a tea leaf enzyme deactivating and drying integrated machine. The nitrogen protected tea leaf enzyme deactivating and drying integrated machine comprises a shell body and a bracket; the bracket comprises a first column and a second column, a first fixing shaft is arranged on an upper part of the first column, a second fixing shaft is arranged on an upper part of the second column, the shell body is connected with the first fixing shaft through a first bearing, and the shell body is connected with the second fixing shaft through a second bearing; the first fixing shaft is a hollow tube, one end of the first fixing shaft communicates with an inside of the shell body, and the other end of a first fixing shaftcommunicates with a gas storage tank; and a heating device for heating the shell body is also arranged on one side of the shell body. Through a design, tea leaves are placed in the sealed shell body and during rotating and heating processes of the shell body, nitrogen continuously enters into the shell body, so that the tea leaves are protected by the nitrogen during processes of high temperature,enzyme deactivating and drying, organic substances of chlorophyll, tea polyphenols, etc. in the tea leaves do not oxidize, and quality of finished products of the tea leaves are ensured.

Owner:北京旋光普利生物医药科技开发有限公司

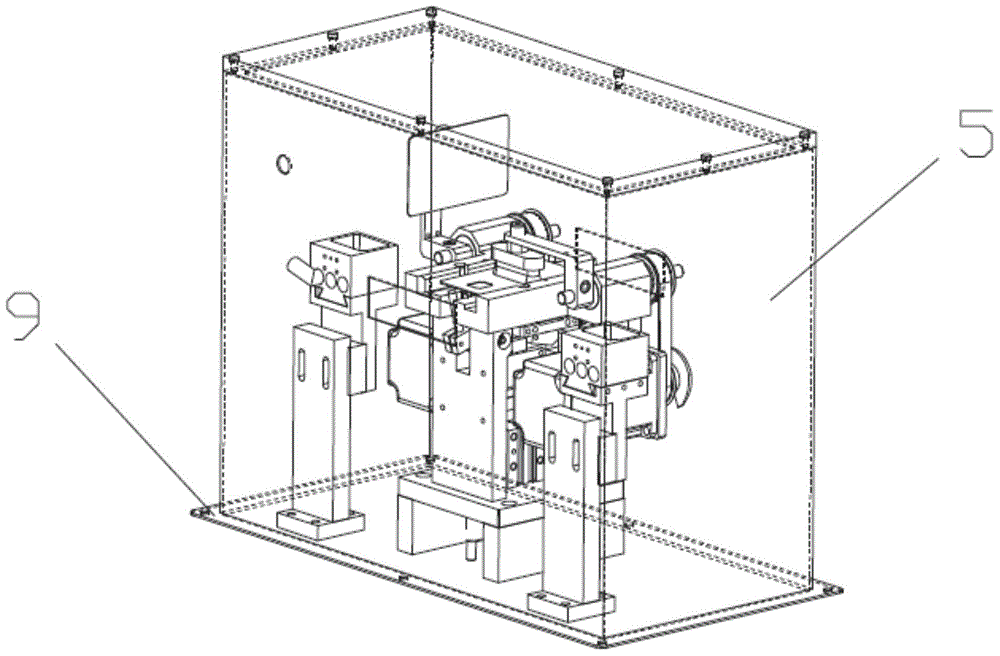

Silicon material cleaning device

InactiveCN108284101AAvoid pollutionQuality improvementCleaning using toolsCleaning using liquidsHydrofluoric acidDrive motor

The invention discloses a silicon material cleaning device. A main body structure of the silicon material cleaning device is designed as a cleaning tank, a cleaning tank cover is placed at the top ofthe cleaning tank, a cleaning roller is installed in the cleaning tank, and a cleaning brush is installed in the cleaning roller. The cleaning roller is powered by a driving motor, a speed adjusting device is installed on the right side of the driving motor, a connecting bearing is installed between the speed adjusting device and the cleaning tank, and an ultrasonic generator is installed at the bottom of the cleaning tank. According to the silicon material cleaning device, impurities on the surface of silicon materials can be cleaned effectively, the reaction is stable, and almost no heat isproduced, the oxidation reaction is not produced, so that contamination to silicon materials caused by oxidation is avoided to improve the quality of the silicon materials; dilute hydrofluoric acid does not react with silicon, so that the loss rate of the silicon materials is reduced; and the acid consumption is low so as to greatly reduce the cost of cleaning the silicon materials, energy is saved effectively, broad market potentials are achieved, and market demands can be met.

Owner:广德盛源电器有限公司

A kind of wide frequency wide temperature high power density low loss manganese zinc soft magnetic ferrite material and preparation method thereof

ActiveCN107473727BKeep aliveGrowth homogenization and refinementInorganic material magnetismSpray GranulationManganese

Owner:郴州市久隆旺高科电子有限公司

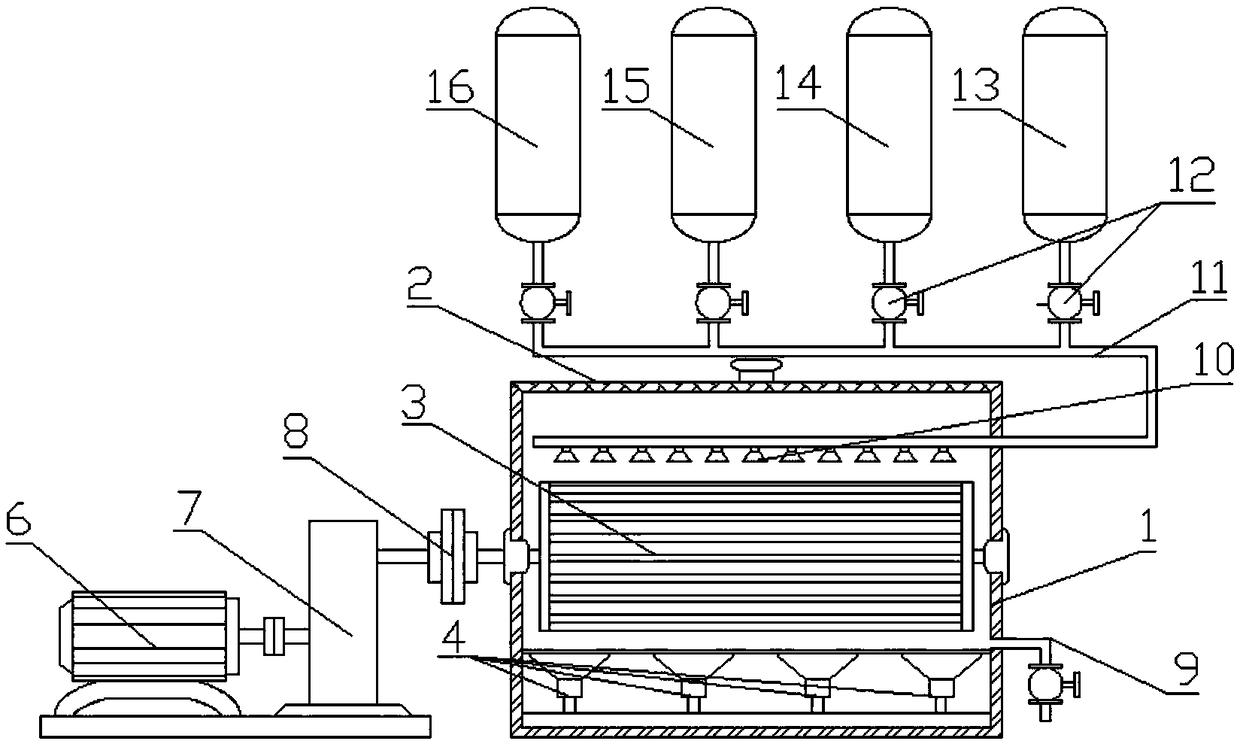

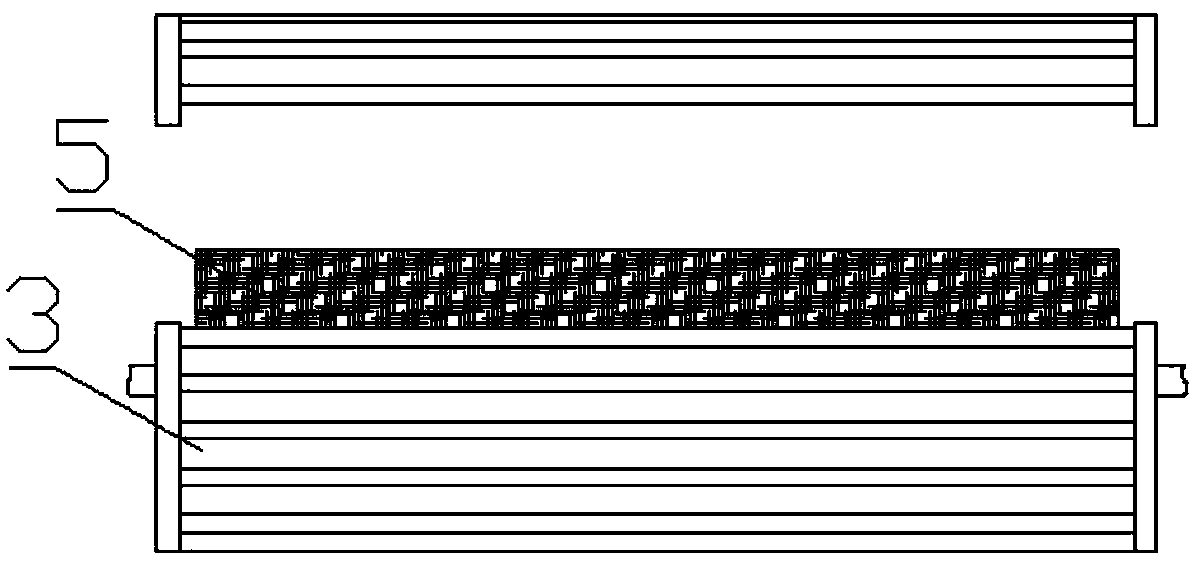

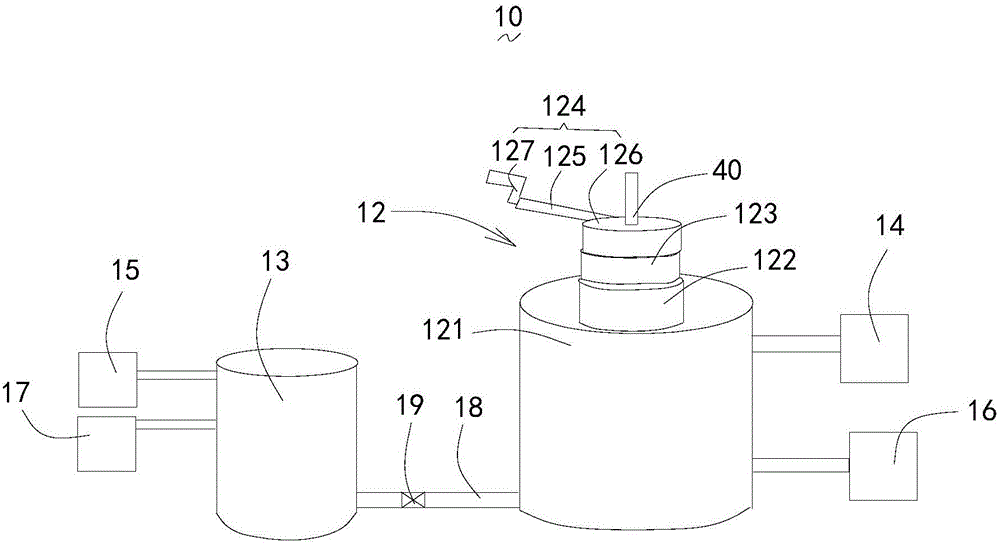

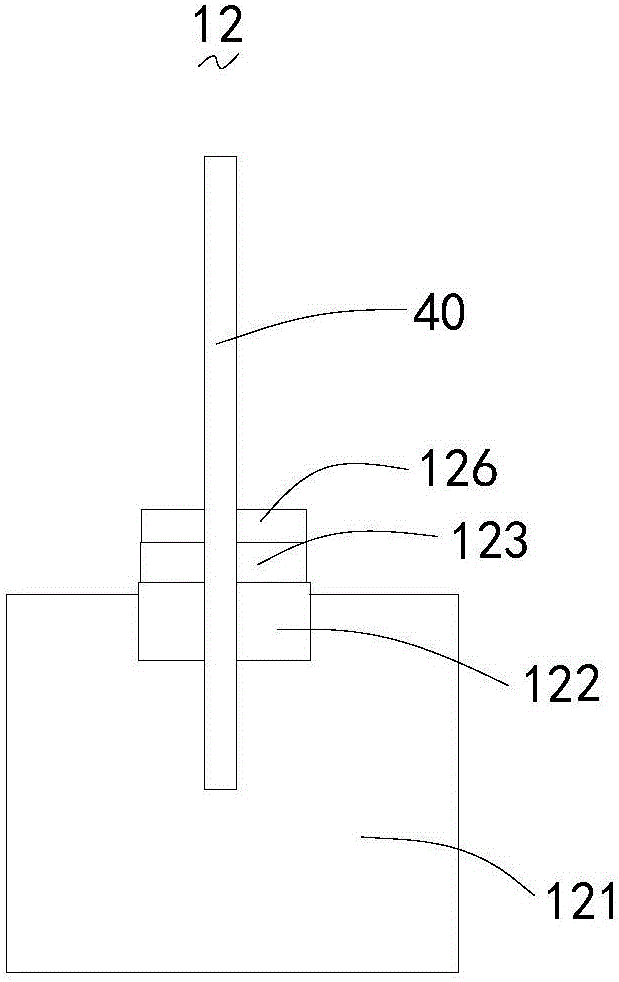

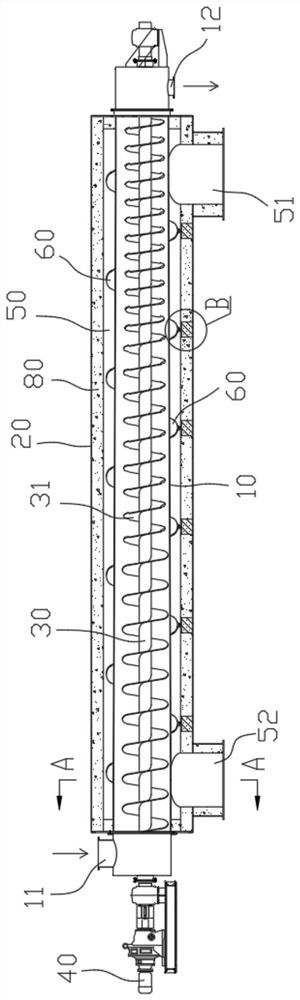

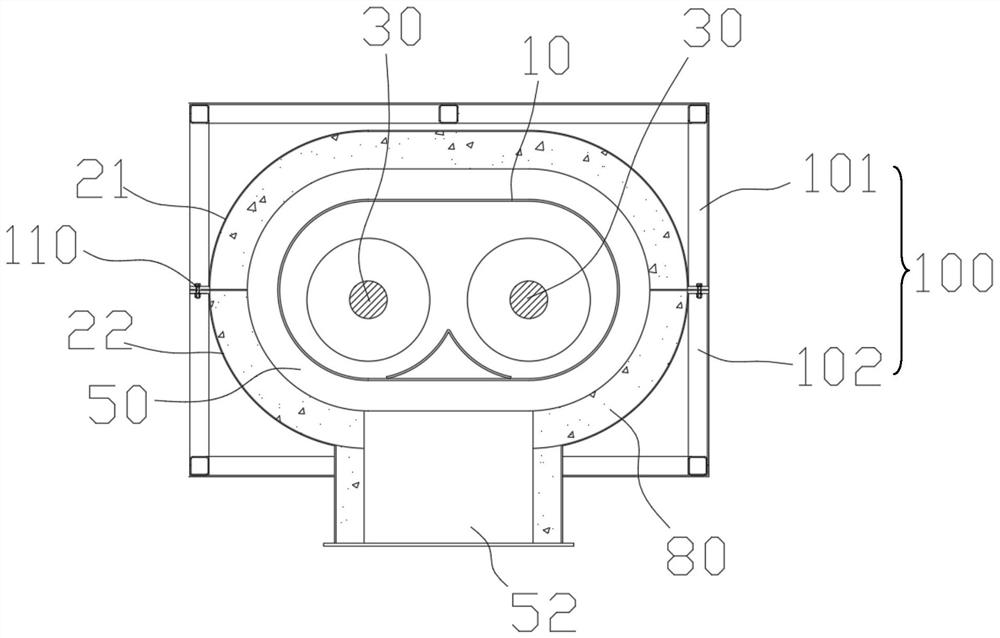

Superheated steam fixation device and method

InactiveCN112082343AIncrease contact surfaceDecreased heat transfer ratePre-extraction tea treatmentDrying gas arrangementsThermodynamicsEngineering

The invention discloses superheated steam fixation device. The superheated steam fixation device comprises a fixation drying bin, a driving device, a supporting wheel, a discharging device, a feedingdevice, a gas guide pipe, a steam device, an exhaust device and a pipeline fan. Tea leaves continuously enter and exit from the fixation drying bin through the feeding device and the discharging device, so that continuous superheated steam fixation drying is realized. Moisture generated during fixation drying of the tea leaves is heated by the steam device to become superheated steam, the superheated steam at 60-380 DEG C is used for carrying out heat transfer fixation and heat and mass transfer drying on the tea leaves in the fixation drying bin, the heat transfer efficiency of the superheated steam and the tea leaves is enhanced, the tea leaves are free of oxidation reaction in the superheated steam fixation drying process in the fixation drying bin, the fixation and color fixation effects of the tea leaves are good, and the tea leaves are uniformly fixed and dried. During fixation of the superheated steam, the surfaces of the tea leaves are wet, the drying stress is small, and the drying defects of burnt leaves, burnt edges, broken tea, water stuffy taste and the like are avoided. The tea leaves after fixation and drying of the superheated steam are soft and tough, and the subsequent rolling process is facilitated.

Owner:MENGZHOU YUANHONG DRYING EQUIP RES & DEV CO LTD

Methanol electro-oxidizing-catalyzing electrode, preparing process and application thereof

InactiveCN100447562CImprove solution processabilityLittle effect on conductivityMaterial electrochemical variablesPolyaniline derivativesPolymer science

A methanol electro-oxidation catalytic electrode, its preparation method and application thereof, relates to a metallized film modified electrode, provides a methanol electro-oxidation catalytic electrode and a preparation method, and uses it as an electrochemical sensor for catalyzing methanol electro-oxidation. It is a polyaniline derivative poly2,5-dimethoxyaniline metallized film modified electrode with a strong electron-donating group, including an inert electrode substrate, a conductive polymer film and a catalyst, and the adhesion amount of the polymer on the surface of the substrate electrode is 0.3~ 1.0 mg·cm -2 . The steps are as follows: dissolving hydrochloric acid-doped PDMAn in N, N-dimethylformamide or tetrahydrofuran to prepare a solution of 1.0-10.0 mg / ml, taking the polymer solution and coating the electrode surface, and drying. Adjust the amount of polymer attached to the electrode surface by changing the number of coatings; place the electrode in H 2 PtCl 6 or K 2 PtCl 6 In the HCl solution, the modified electrode with different platinum deposition amount was obtained by using controlled potential cyclic scanning or unidirectional scanning, and changing the number of times.

Owner:XIAMEN UNIV

Silicon material cleaning method

ActiveCN108212831AAvoid pollutionQuality improvementDrying solid materials without heatCleaning using toolsEngineeringDrive motor

The invention discloses a silicon material cleaning method. A body structure of a silicon material cleaning device is designed into a cleaning tank. A cleaning tank cover is placed on the top of the cleaning tank. A cleaning roller is arranged in the cleaning tank and internally provided with a cleaning brush. Power is provided for the cleaning roller through a drive motor. A speed adjusting device is arranged on the right side of the drive motor. A connecting bearing is arranged between the speed adjusting device and the cleaning tank. An ultrasonic generator is arranged at the bottom of thecleaning tank. The cleaning method comprises the steps that a silicon material is subjected to ultrasonic ethanol-water flushing and then is immersed through dilute alkali liquid, then, spraying is conducted through dilute acid liquid, finally, high-pressure washing is conducted, and then drying is conducted after water spinning-dry. By means of the silicon material cleaning method, impurities onthe surface of the silicon material can be effectively cleaned away, the reaction is stable, heat is basically not generated, and the oxidization reaction is not generated; and pollution to the silicon material due to oxidization is avoided, and the silicon material quality is improved; and the silicon material loss rate is reduced, and cost is saved.

Owner:广德盛源电器有限公司

Small-block-shaped nickel-copper alloy preparation method based on water washing technology

InactiveCN107321939AShorten the production cycleReduce segregation coefficientElectricityIntermediate frequency

The invention discloses a method for preparing a small block nickel-copper alloy based on a water washing process, which specifically includes the following steps: calculating the nickel-copper ratio according to the requirements for producing the nickel-copper alloy, then weighing the raw materials, putting them into an intermediate frequency furnace in batches, and energizing the melt , after all the materials are melted, inject the alloy solution into the ladle; move the ladle to the side of the cooling water pool, pour the alloy solution into the cooling water pool, the pouring speed is 100kg / min, and the temperature of the water in the cooling water pool is 70 ‑100℃; After all the alloy solution in the ladle is poured into the cooling water pool, it will be a small piece of nickel-copper alloy finished product when picked up. The invention is used to prepare the nickel-copper alloy of small block, the size of the block is uniform, no mold is needed in the production process, the cost is low, the production cycle of the nickel-copper alloy is shortened, and the production efficiency and product quality are improved.

Owner:HEBEI CHENGDA METAL GROUP

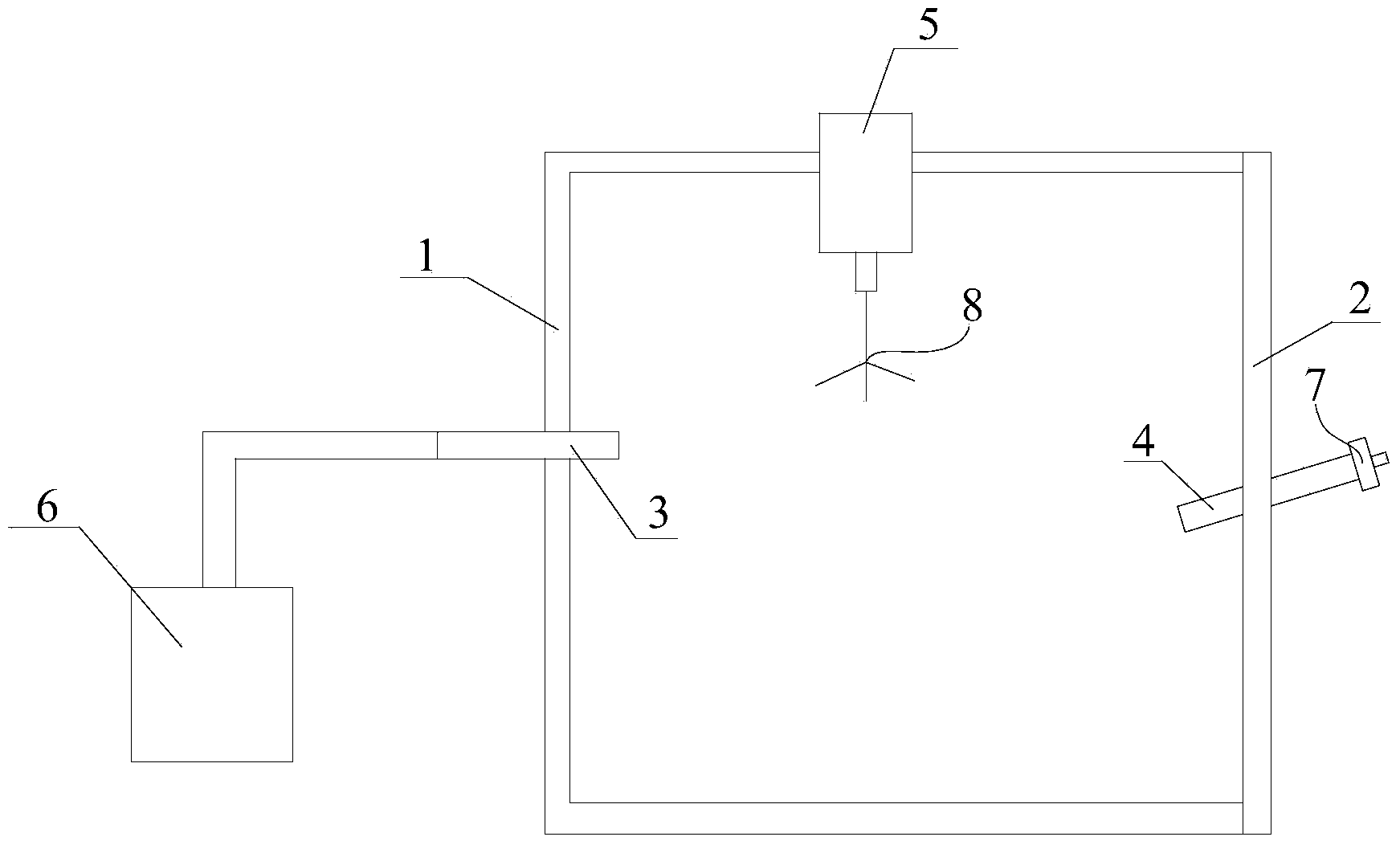

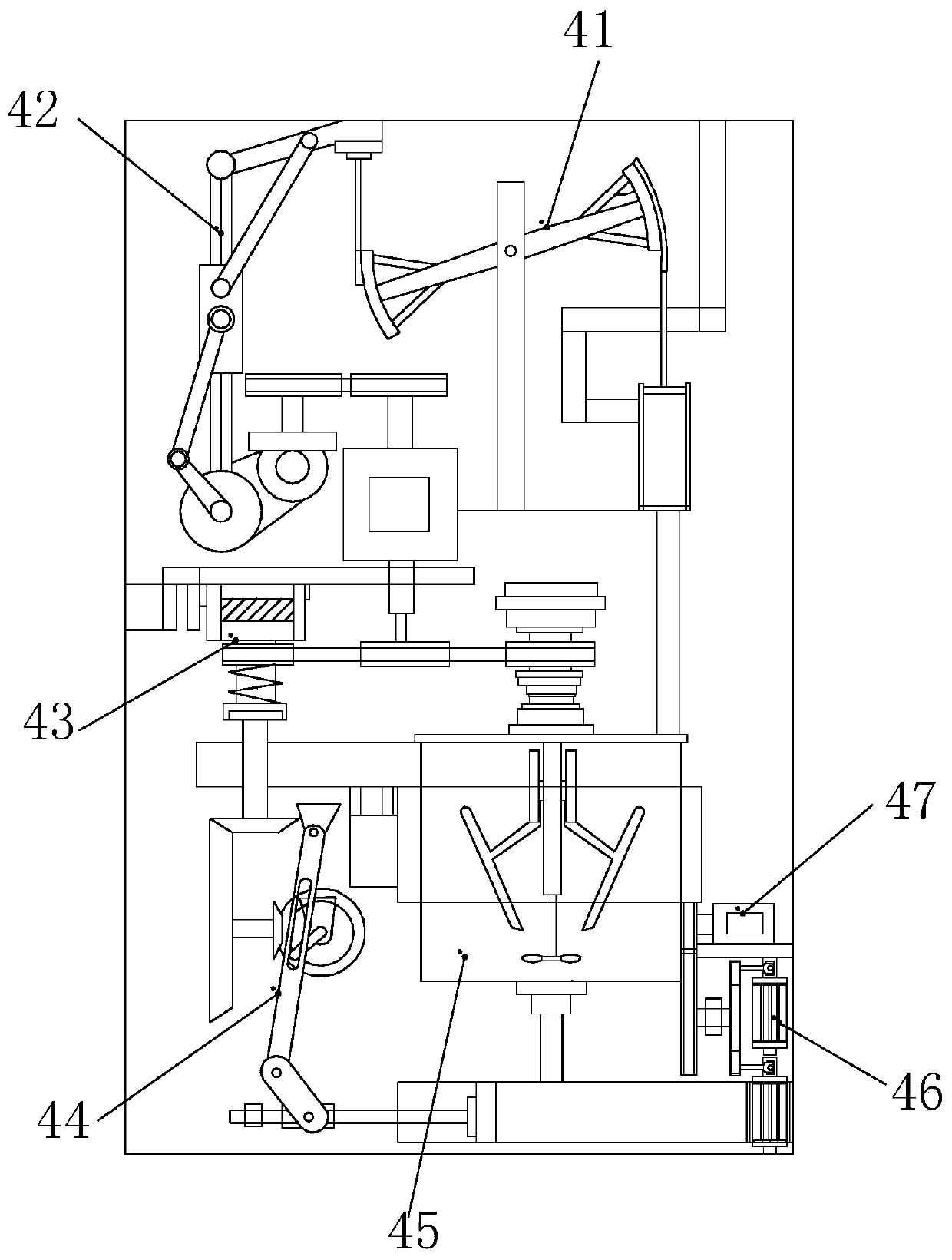

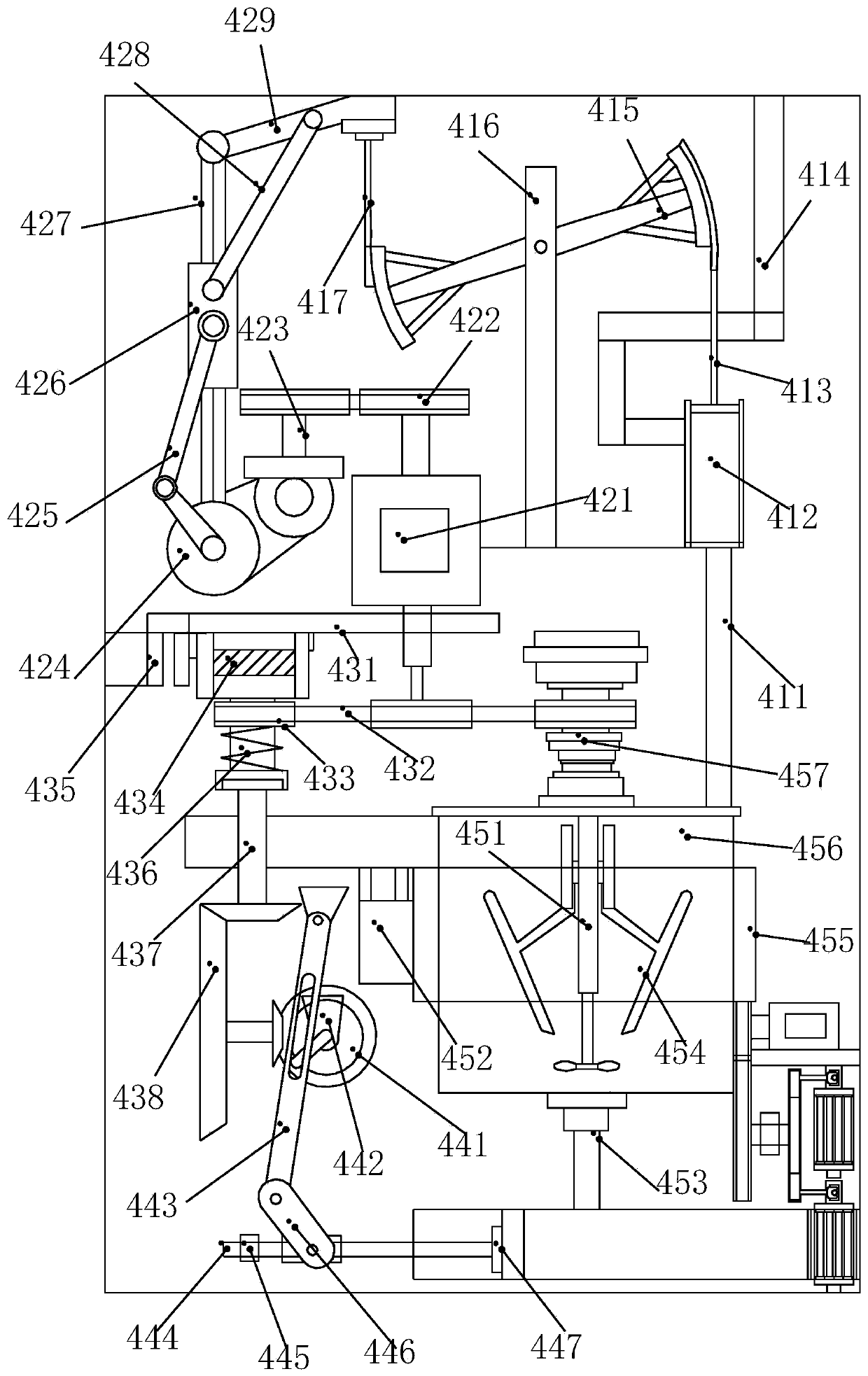

Intelligent card tin dipping equipment with soldering tin protection function

InactiveCN105127539AWill not oxidizeNo oxidation reactionSolder feeding devicesSmart cardEngineering

The invention discloses intelligent card tin dipping equipment with a soldering tin protection function. The intelligent card tin dipping equipment comprises a tin dipping device and a card conveying mechanism, and further comprises a sealing cover, wherein the tin dipping device is arranged in the sealing cover; the card conveying mechanism penetrates through the sealing cover; and the sealing cover is filled with inert gas. The intelligent card tin dipping equipment can ensure that melted soldering tin is not oxidized in a production process; and the chip welding quality of an intelligent card is improved and the production cost is saved.

Owner:GUANGZHOU MINGSEN TECH CO LTD

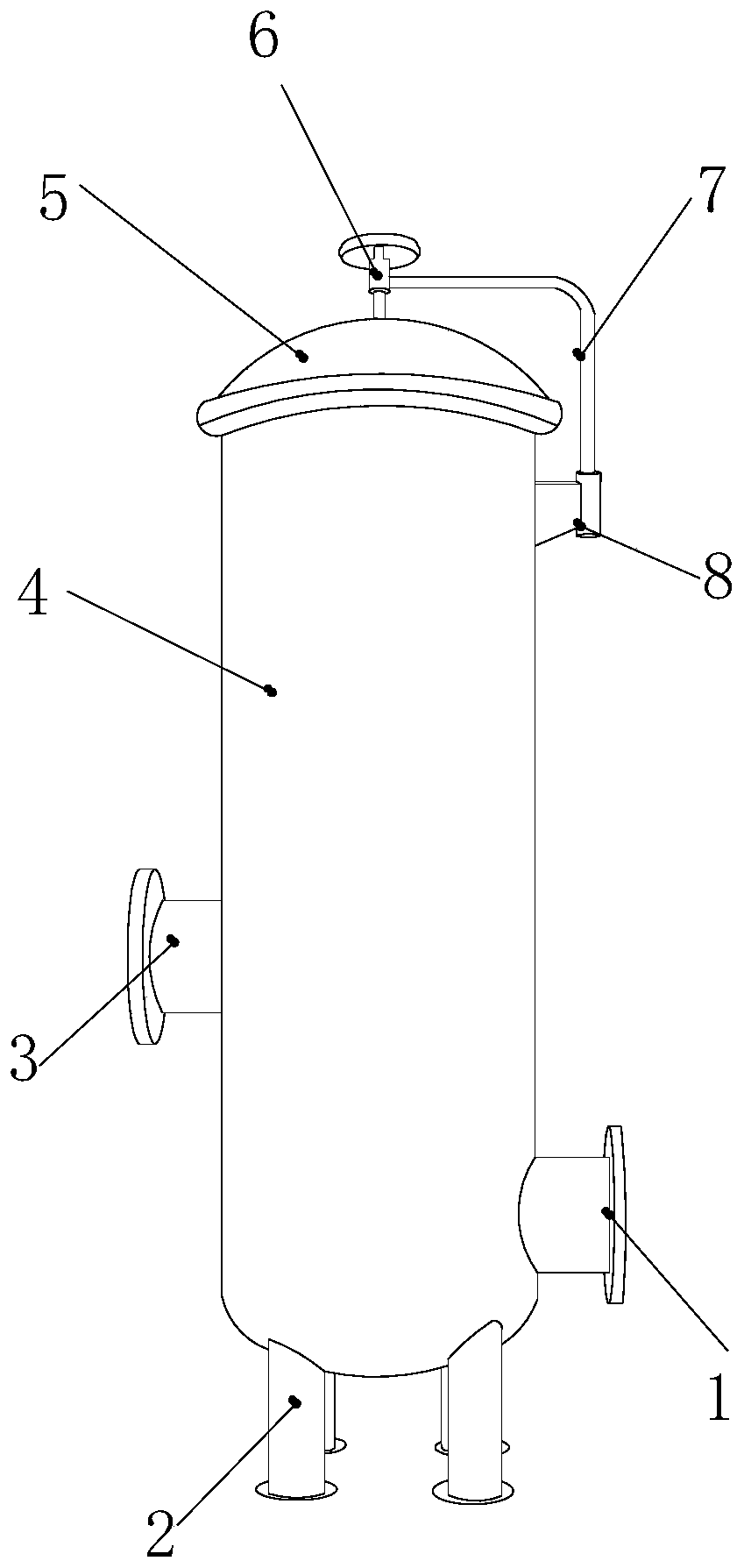

Gas protection non-oxidation quenching carburizing integrated furnace and quenching and carburizing method

InactiveCN103643004ANo oxidation reactionSave oxygenSolid state diffusion coatingFurnace typesProduct gasOxygen

Provided are a gas protection non-oxidation quenching carburizing integrated furnace and a method. The integrated furnace comprises a heating chamber. The heating chamber is composed of an enclosed space formed through enclosure of a furnace body and a furnace door. A gas outlet pipe is arranged on the furnace body or the furnace door. The gas outlet pipe is communicated with the heating chamber. A lighting up tuyere is arranged on the gas outlet pipe. A silicon carbon rod is arranged in the heating chamber. A gas inlet pipe is arranged on the furnace body or the furnace door. The gas inlet of the gas inlet pipe is communicated with a gas outlet of an ammonia cracking device, or the gas inlet of the gas inlet pipe is communicated with a gas supply inlet of a liquefied gas supply device. The heating chamber is an enclosed space. When the furnace door is closed, external air cannot go into the heating chamber, and the air in the heating chamber is brought to the gas outlet pipe by the ammonia cracking gases or liquefied gases, and burnt at the lighting up tuyere, and therefore oxygen in the heating chamber is less and less, so when a metal workpiece is heated to a high temperature, no oxidation reaction is generated on the surface of the metal workpiece.

Owner:朱明耀

Production method of quantum dot light bar

The invention discloses a production method of a quantum dot light bar. The method comprises the following steps that a quantum dot adhesive and a glass tube are provided, the opening end of the glass tube faces downwards, the quantum dot adhesive is loaded into the glass tube via the opening end, then the glass tube is filled with protective gas, and a gas embolism is formed in the glass tube; the glass tube containing the quantum dot adhesive is placed in a vacuum tank, the vacuum tank is placed in an infrared heating furnace, vacuumized and then filled with protective gas, and the infrared heating furnace is heated; the glass tube is taken out of the vacuum tank, the opening end of the glass tube is placed on a first heating source to be heated, and the opening end of the glass tube is heated, melted and sintered; and the glass tube is arranged in an annealing cavity with a second heating source, the annealing cavity is vacuumized and then filled with protective gas, and the quantum dot light bar can be obtained by heating the second heating source. By means of the production method of the quantum dot light bar, quantum dots can be poured into the glass tube in a packed mode, no air enters the glass tube, and oxidation is avoided.

Owner:DONGGUAN XUANLANG IND

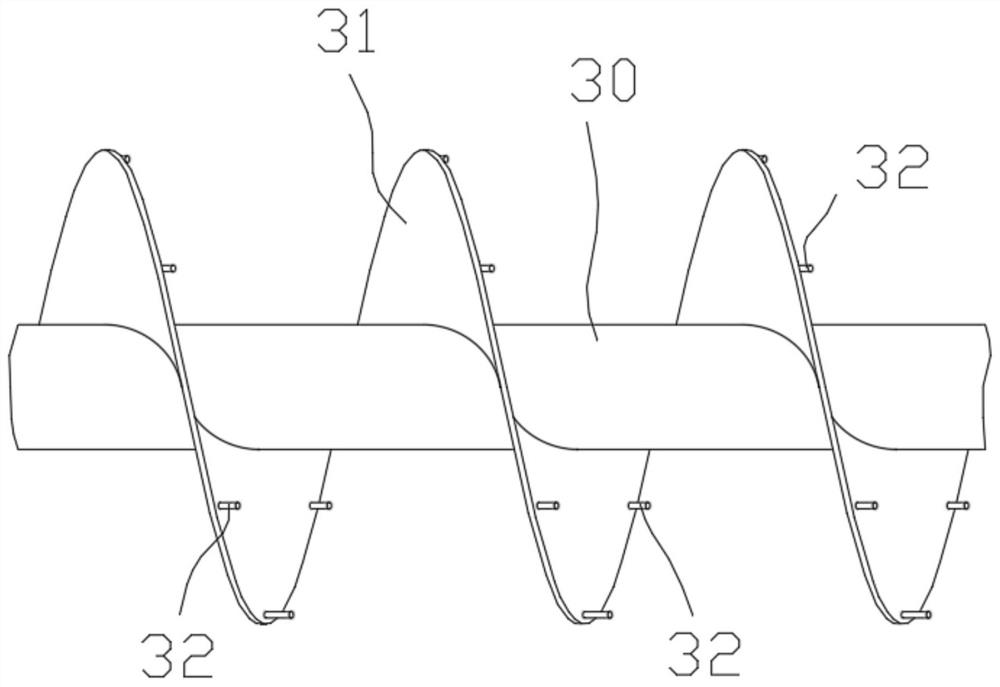

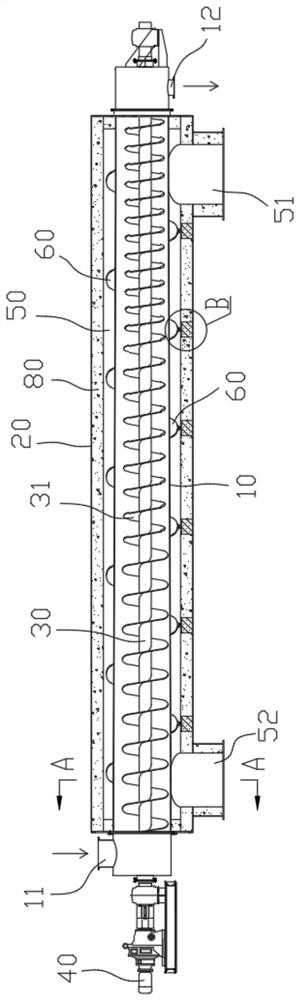

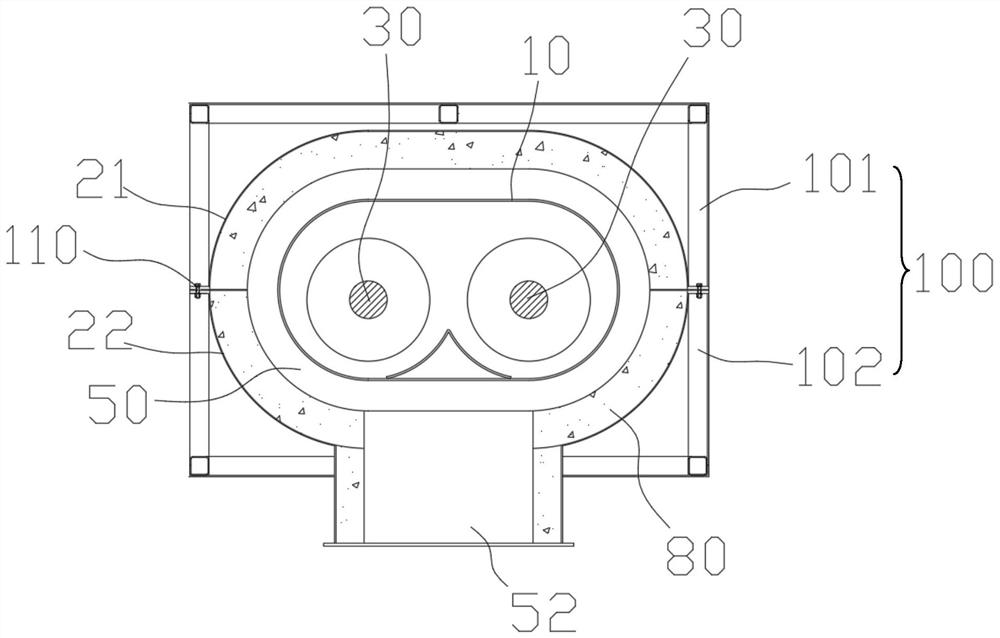

Biomass horizontal rotary core carbonization furnace

ActiveCN113072964AHigh char formation rateFull reaction timeStationary retortsElectric machineSpiral blade

The invention relates to the technical field of carbonization furnaces, and especially relates to a biomass horizontal type rotary core carbonization furnace. A rotary core pushing and twisting shaft is arranged in an inner cylinder, spiral blades are arranged on the peripheral wall of the rotary core pushing and twisting shaft, the front end of the rotary core pushing and twisting shaft extends out of the inner cylinder in a suspended mode and is driven by a motor to rotate, and the front end and the rear end of the inner cylinder extend out of an outer cylinder in a suspended mode; a raw material inlet is formed in the front end of the inner cylinder, a first outlet is formed in the rear end of the inner cylinder, a heating cavity is defined between the inner cylinder and the outer cylinder, a heating medium inlet is formed in the rear end of the outer cylinder, a heating medium outlet is formed in the front end of the outer cylinder, a plurality of stirring columns are vertically arranged on the spiral blade, and a spiral flow deflector is arranged on the peripheral wall of the inner cylinder; and a plurality of rolling supporting units are arranged at the bottom end of the spiral flow deflector, and the bottom end of the spiral flow deflector and the inner wall of the outer cylinder form rolling type supporting fit in the cylinder length direction through the rolling supporting units. The carbonization furnace has the advantages of high raw material carbon yield, improved production efficiency, ensured carbon quality, long service life and the like.

Owner:无锡光核新能源建设有限公司

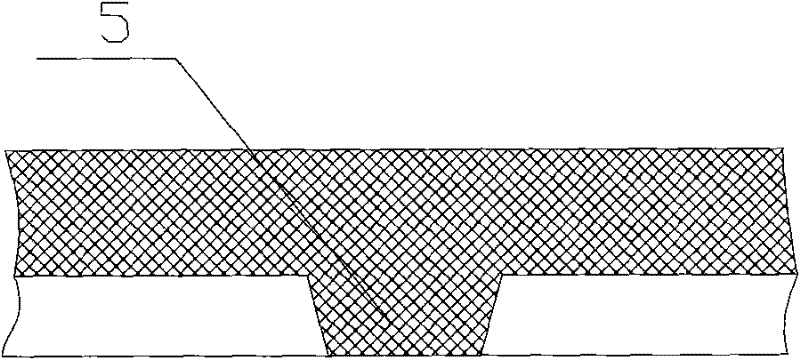

Large grid plate for air pressure filter

InactiveCN101601941ASolution to short lifeTaste effectAlcoholic beverage preparationFiltration separationFood safetyEngineering

The invention relates to a large grid plate for an air pressure filter, which can improve the safety class of food and rice wine taste fundamentally. The surface of a large silicone rubber grid plate forms a concavo-convex liquid-flow surface through multiple cycles of element rests; and the concavo-convex liquid-flow surface is provided with a deflector hole. The large silicone rubber grid plate has the advantages of innocuity, no odor, acid resistance, alkali resistance, high and low temperature resistance, insusceptibility to oxidation and photochemical action and long service life. In addition, the large silicone rubber grid plate not only does not exert any influence on the rice wine taste, but also really retains the original taste and flavor in a rice wine-making process and improves the safety class of the food. The large silicone rubber grid plate improves the squeezing efficiency of squeezed materials effectively to improve the discharging rate of the materials by more than 10 percent and reduces the discharging cost of the squeezed materials effectively. After being discarding as worthless material, the large silicone rubber grid plate can be recycled so as to protect environment.

Owner:杭州余杭新兴过滤机厂

Method for reducing peroxide value and acid value of ganoderma lucidum spore oil

The invention discloses a method for reducing peroxide value and acid value of ganoderma lucidum spore oil. The method comprises the following steps: 1) sequentially adding liquid nitrogen, purified water and liquid nitrogen into ganoderma lucidum spore powder, starch, wall-breaking enzyme, amylase and vitamin E powder, and carrying out heating in a water bath for an enzymolysis reaction for 3 hours; 2) adding NaHCO3 to adjust a pH value to 7.2, adding cultivation powder of bacillus subtilis, and carrying out stirring at a constant temperature of 38 DEG C for 1 hour; 3) carrying out low-temperature filter pressing, adding liquid nitrogen into an obtained filter cake, freezing the filter cake into blocks, carrying out vacuum drying, adsorbing oily substances on the upper layer of the filtrate, freezing the oily substances into blocks by liquid nitrogen, and carrying out vacuum drying; and 4) grinding a cake formed in the step 3) into powder, carrying out supercritical CO2 extraction to obtain spore oil, and then preparing a spore oil capsule. According to the method in the invention, wall breaking via lyase and supercritical extraction are combined, free oxygen in an enzymolysis system is removed through liquid nitrogen twice, then bacillus subtilis capable of consuming dissolved oxygen is added, and supercritical extraction is performed finally, so the spore oil in the whole production process is free of oxidation reaction and not prone to acidification and decay.

Owner:安徽金寨仙芝灵生物科技有限公司

Nano-powder/polyether-ether-ketone composite material and preparation method thereof

The invention provides a nano-powder / polyether-ether-ketone composite material and a preparation method thereof, and the nano-powder / polyether-ether-ketone composite material comprises the following components: polyether-ether-ketone and magnetic nano-powder, and the magnetic nano powder is one or two or more of nano ferroferric oxide, nano Fe powder, nano Ni powder, nano Co powder, and alloy nano powder (such as FeNi, FeCo and the like) or oxides. According to the preparation method, firstly, a magnetic nano-powder / diphenyl sulfone composite material is prepared, and when PEEK powder is generated through a condensation polymerization reaction, the PEEK powder grows by taking nano-powder as a crystal nucleus, so that the nano-powder can be prevented from being agglomerated; diphenyl sulfone is different from PEEK, can be dissolved in an organic solvent, is low in melting temperature and viscosity, and is easy for preparing a nano composite material with uniformly dispersed nano particles; and in the PEEK synthesis reaction process, the nano powder is always in diphenyl sulfone, agglomeration of the powder can be reduced as much as possible, and due to nitrogen protection, oxidation reaction cannot occur.

Owner:NANCHANG UNIV

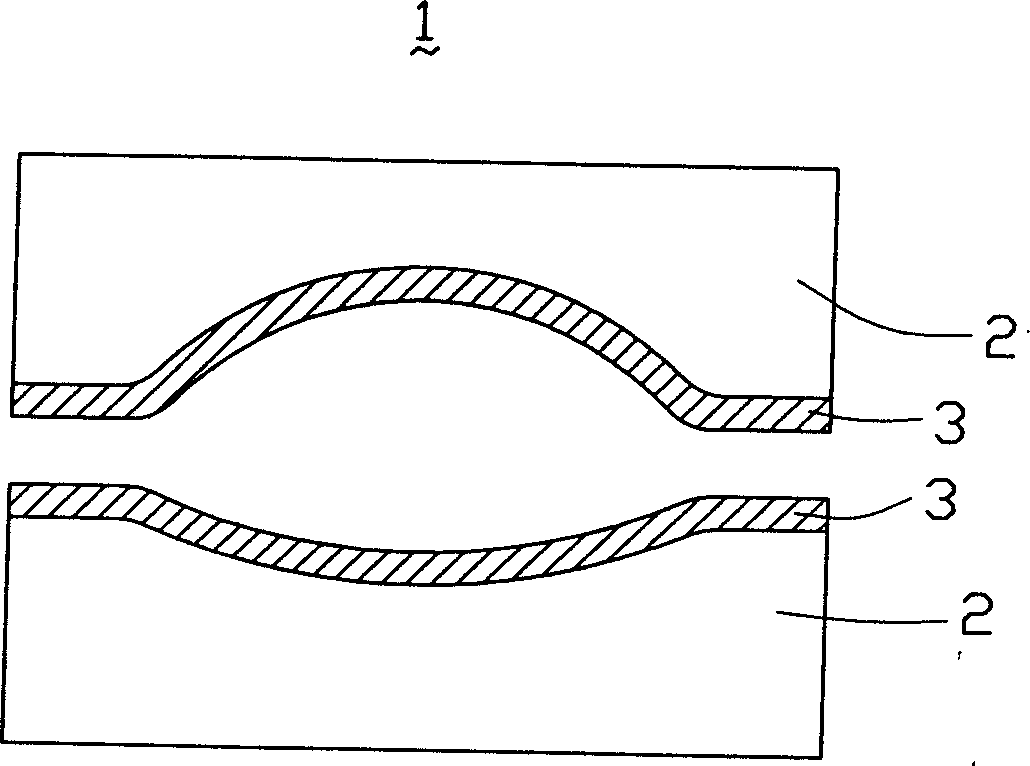

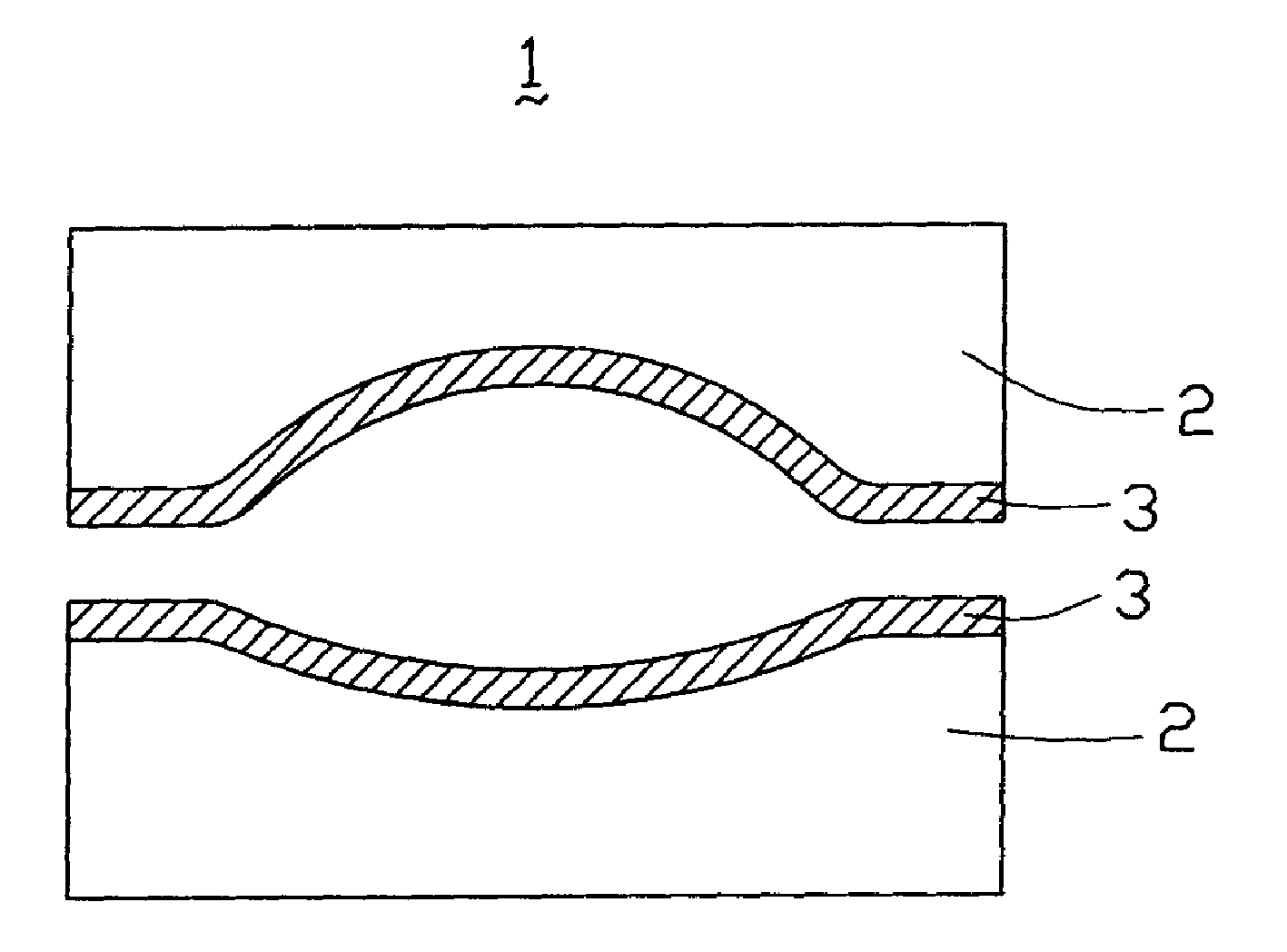

Die assembly for producing optical glass products and manufacturing method thereof

InactiveCN1239417CExtended service lifeSo as not to damageGlass pressing apparatusChemical vapor deposition coatingCarbon filmDiamond-like carbon

The present invention reveals one kind of mold for making optical glass product and its making process. The mold includes mold base and film attached to the mold base surface. The film is 50-200 angstrom thick and of diamond-like carbon. The mold making process includes the following steps: providing one mold base, and depositing carbon film on the surface of the mold in the rate of 3.3-8.3 angstrom each sec for 6-60 sec to form the film of 50-200 angstrom thickness.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Electroplating copper tank device

The invention discloses a copper tank electroplating device. The device comprises a main tank, two auxiliary tanks and two liquid blocking mechanisms. The main tank comprises a feeding side wall and a discharging side wall which are oppositely arranged, and the feeding side wall comprises a feeding channel; the discharging side wall comprises a discharging channel; the two auxiliary tanks extend from the feeding side wall and the discharging side wall respectively, and each auxiliary tank comprises a gateway right opposite to the feeding channel and the discharging channel; the two auxiliary tanks are each provided with one liquid blocking mechanism in a matched manner, and each liquid blocking mechanism comprises a liquid blocking plate and a driving device; the liquid blocking plates are arranged in the auxiliary tanks respectively, and each driving device drives the corresponding liquid blocking plate to do back-and-forth movement in the width direction of the copper tank electroplating device; and electroplating liquid in the electroplated copper tank enables the liquid blocking plates to cover the gateway to achieve liquid blocking. The copper tank electroplating device is simple in structure and good in liquid blocking effect, and the height and the width of the whole device are not increased.

Owner:DONGGUAN WERY DOOD CIRCUIT BOARD EQUIP

Large grid plate for air pressure filter

InactiveCN101601941BGood oxygen and aging resistanceGood anti-mildew effectAlcoholic beverage preparationFiltration separationFood safetyEngineering

The invention relates to a large grid plate for an air pressure filter, which can improve the safety class of food and rice wine taste fundamentally. The surface of a large silicone rubber grid plate forms a concavo-convex liquid-flow surface through multiple cycles of element rests; and the concavo-convex liquid-flow surface is provided with a deflector hole. The large silicone rubber grid platehas the advantages of innocuity, no odor, acid resistance, alkali resistance, high and low temperature resistance, insusceptibility to oxidation and photochemical action and long service life. In addition, the large silicone rubber grid plate not only does not exert any influence on the rice wine taste, but also really retains the original taste and flavor in a rice wine-making process and improves the safety class of the food. The large silicone rubber grid plate improves the squeezing efficiency of squeezed materials effectively to improve the discharging rate of the materials by more than 10 percent and reduces the discharging cost of the squeezed materials effectively. After being discarding as worthless material, the large silicone rubber grid plate can be recycled so as to protect environment.

Owner:杭州余杭新兴过滤机厂

Filters for the production of porous moldings

The invention discloses a filter for manufacturing porous molded pieces. The filter structurally comprises a discharging pipe, a supporting base, a feeding pipe, an intelligent movable adjusting filtering device, a movable cover plate, an exhausting pipe, a conveying pipe and a fixing base, wherein the supporting base is perpendicular to the lower side surface of the intelligent movable adjustingfiltering device and is fixedly connected with the intelligent movable adjusting filtering device, the discharging pipe is connected to the right side surface of the intelligent movable adjusting filtering device in a penetrating mode, the feeding pipe is arranged on the left side end surface of the intelligent movable adjusting filtering device, the movable cover plate is located on the upper side surface of the intelligent movable adjusting filtering device, and the movable cover plate and the intelligent movable adjusting filtering device are connected into an integrated structure in a matched mode. When the filter works, a filter screen device inside the device can be effectively and automatically adjusted, so that shutdown replacement is not needed, plastic can be fused, so that filtering is more delicate, and therefore the purpose of enabling the device to be more perfect is achieved.

Owner:中山市创汇环保包装材料有限公司

Polymer ceramic material for pouring mold and manufacturing method thereof

The invention discloses a polymer ceramic material for a pouring mold and a manufacturing method thereof. The polymer ceramic material comprises the following components in percentage by weight: 60-70% of a plastic material, 10-15% of ceramic powder, 5-10% of glass fiber, 1-3% of metal fiber and 1-2% of a plasticizer. A mold prepared from the polymer ceramic material is low in price, convenient toprocess, beneficial to molding, high in surface smoothness, long in service life, not prone to deformation, beneficial to accurate casting and capable of manufacturing large pressed parts. Compared with a metal material, the weight and the specific gravity are low, the material price and the overall weight are greatly reduced, water absorption is avoided, deformation of the mold is reduced, the surface is subjected to crystal plating treatment, the smoothness is greatly superior to that of the metal material, an oxidation reaction is avoided after the surface is made of a non-metal material,and the service life of the surface smoothness is prolonged.

Owner:自贡诚鑫阀门有限公司

Biomass Horizontal Rotary Core Carbonization Furnace

ActiveCN113072964BHigh char formation rateFull reaction timeStationary retortsElectric machineSpiral blade

The invention relates to the technical field of carbonization furnaces, in particular to a biomass horizontal rotary core carbonization furnace, wherein the inner cylinder is provided with a rotary core push twist shaft, and the outer peripheral wall of the rotary core push twist shaft has spiral blades, and the rotary core push twist shaft The front end of the twisted shaft hangs outside the inner cylinder and is driven by a motor to rotate. The front end and rear end of the inner cylinder respectively hang outside the outer cylinder. The front end of the inner cylinder is provided with a raw material inlet, and the rear end of the inner cylinder is provided with a first outlet. A heating chamber is enclosed between the inner cylinder and the outer cylinder. The rear end of the outer cylinder is provided with a heating medium inlet, and the front end of the outer cylinder is provided with a heating medium outlet. A plurality of stirring columns are vertically arranged on the spiral blades. There is a spiral deflector, the bottom of the spiral deflector is provided with a plurality of rolling support units, and the bottom of the spiral deflector forms a rollable support fit in the direction of the cylinder length through the rolling support units and the inner wall of the outer cylinder. The invention has the advantages of high raw material char formation rate, improved production efficiency, guaranteed charcoal product quality and long service life.

Owner:无锡光核新能源建设有限公司

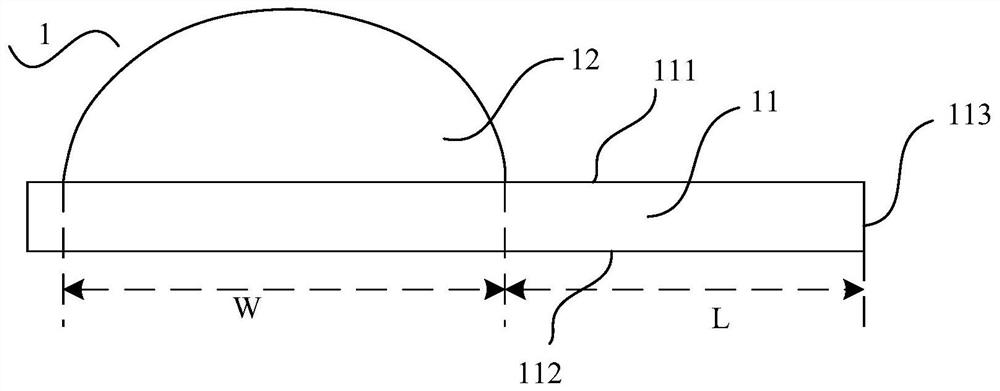

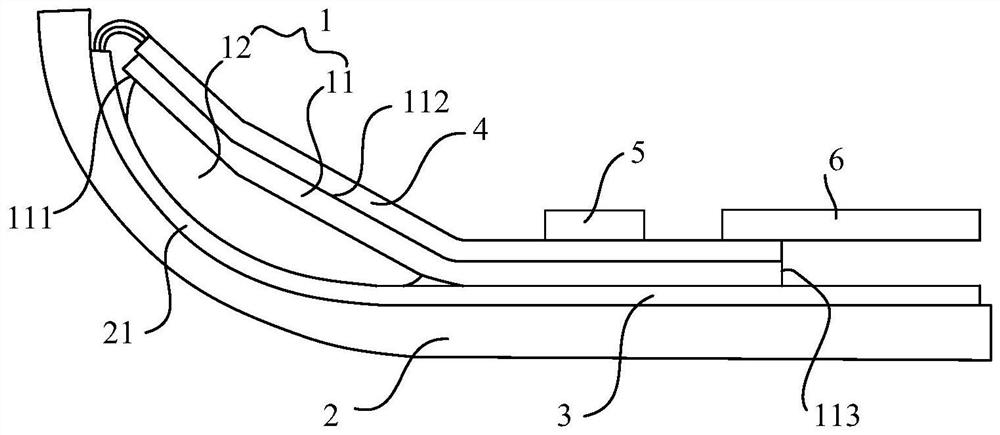

Composite foam, flexible OLED display panel and display device

ActiveCN111179756BQuality assuranceNo interferenceSolid-state devicesIdentification meansDisplay deviceEngineering

Owner:BOE TECH GRP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com