Die assembly for producing optical glass products and manufacturing method thereof

A technology of optical glass and manufacturing method, applied in glass pressing, manufacturing tools, glass molding and other directions, can solve the problem of optical glass products not easy to demould, and achieve the effects of small deformation, good thermal conductivity and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings.

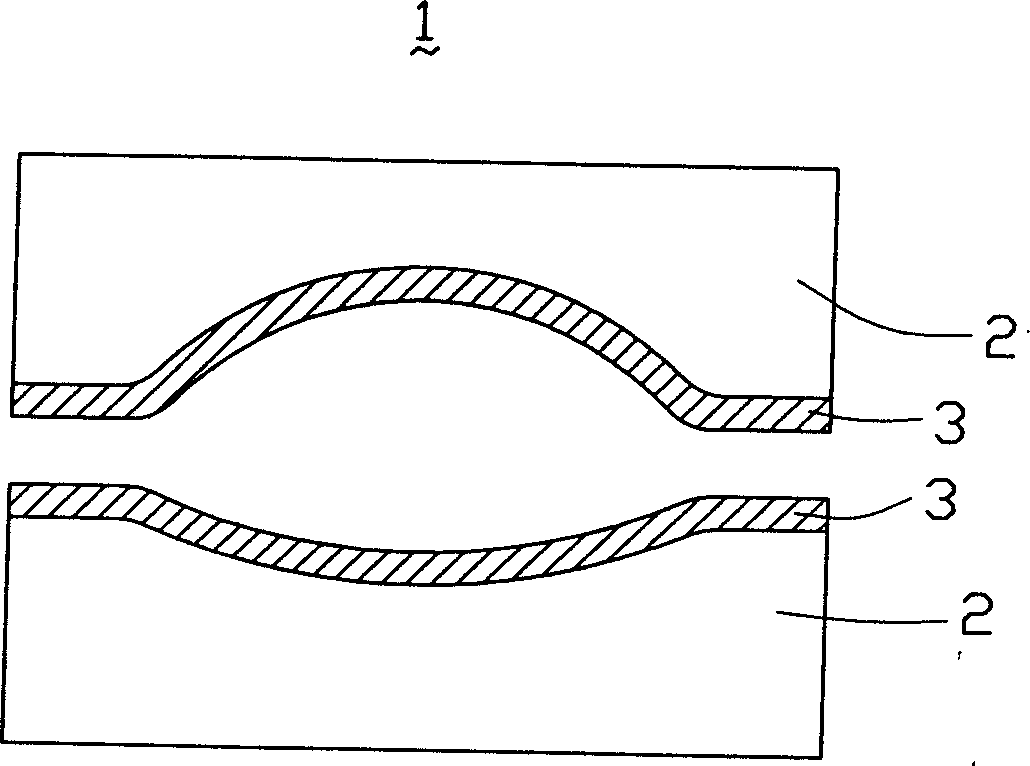

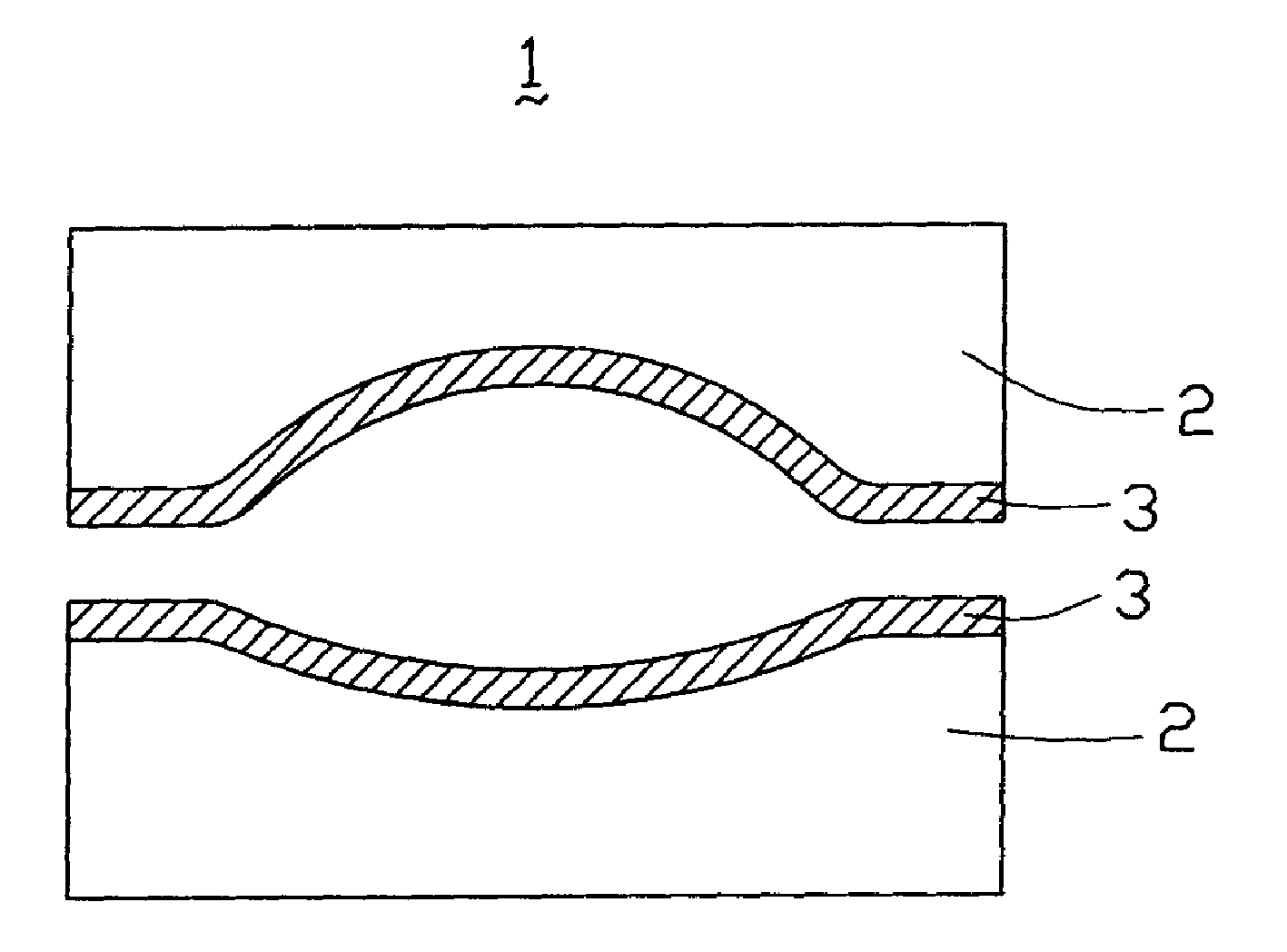

[0024] see figure 1 , the present invention provides a mold 1 for molding an aspheric glass lens, which includes a mold base 2 with an aspheric molding surface and a film layer 3 located on the molding surface of the mold base 2 . Among them, the mold base 2 can choose the following materials: SiC, Si, Si 3 N 4 , ZrO 2 , TiN, TiO 2 , TiC, B 4 C, WC, W or WC-Co alloy. The film layer 3 is a diamond-like carbon film (Diamond Like Carbon, DLC) with a thickness of 50-200 angstroms. This kind of diamond carbon film has good chemical inertness and can resist the erosion of various acids, alkalis and harmful gases; it is transparent, has high dielectric strength, good thermal conductivity, high hardness, and low coefficient of friction. It will not stick to aspherical glass lenses during high-temperature molding. It can ensure the aspherical glass lens to be d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com