Nitrogen protected tea leaf enzyme deactivating and drying integrated machine

A technology of nitrogen protection and integrated machine, which is applied in the field of machinery and can solve the problems of affecting the quality of finished products and the decline of tea quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

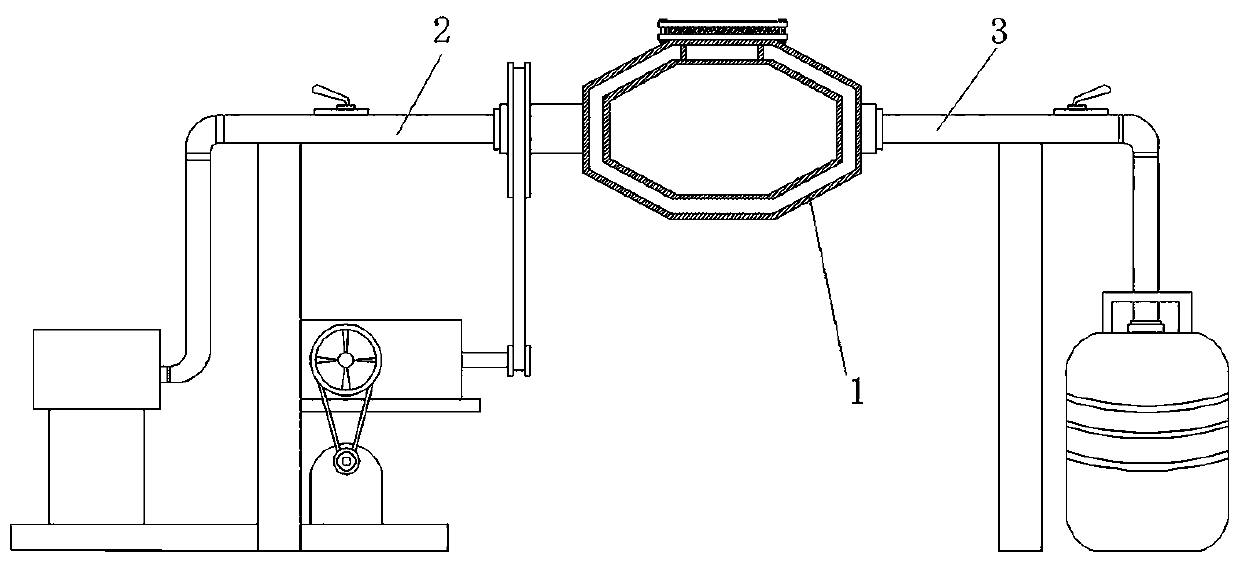

Image

Examples

specific Embodiment 1

[0031] The housing adopts a double-layer structure, which includes an outer layer and an inner layer, the outer layer is arranged outside the inner layer, and a hollow cavity is formed between the outer layer and the inner layer; the heating device includes a steam generator, and the first fixed The shaft includes a nitrogen pipeline and a steam pipeline. One end of the nitrogen pipeline communicates with the space in the casing, the other end of the nitrogen pipeline communicates with the gas storage tank, one end of the steam pipeline communicates with the hollow cavity, and the other end of the steam pipeline communicates with the steam from the steam generator. Oral communication occurs. Using steam heating, the steam temperature is 100 degrees, when the steam enters, the nitrogen is preheated, which can achieve a better green removal effect. At this time, the second fixed shaft includes a nitrogen discharge pipe and a steam discharge pipe, one end of the nitrogen discharg...

specific Embodiment 2

[0034] The heating device includes an electric heating device, the electric heating device includes at least three electric heating wires, and at least three electric heating wires are evenly embedded in the housing in a spiral shape, and the electric heating device also includes a temperature controller, and the temperature controller controls the connection of the at least three electric heating wires Power input. Alternatively, the electric heating device includes at least three electric heating tubes, and the at least three electric heating tubes are arranged in a ring shape in the casing. The electric heating device also includes a temperature controller, and the temperature controller controls the electric energy input terminals connected to the at least three electric heating tubes. It is more convenient to use electric heating to heat the shell.

[0035] A temperature sensor is arranged in the casing, the temperature sensor is connected to a signal processing module, t...

specific Embodiment 3

[0036] The heating device includes a natural gas burner. The natural gas burner is provided with at least one burner, and at least one burner is arranged under the casing. The natural gas burner is provided with a gas regulating switch. The heat generated by natural gas combustion is used to directly heat the casing to ensure the effect of greening. The equipment has a simple structure and is easy to manufacture.

[0037] A temperature sensor is arranged in the casing, the temperature sensor is connected to a signal processing module, the signal processing module is connected to a display device, and the display device is arranged on the bracket. It is convenient for the user to understand the temperature inside the shell, and then the user can control the heated temperature of the shell through the gas regulating switch to achieve a better heating effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com