A kind of wide frequency wide temperature high power density low loss manganese zinc soft magnetic ferrite material and preparation method thereof

A high-power density, manganese-zinc soft magnet technology, applied in the direction of inorganic material magnetism, etc., can solve the problems of inability to achieve low loss, no public power loss, etc., and achieve excellent working performance, low-temperature startup response, and low-frequency loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

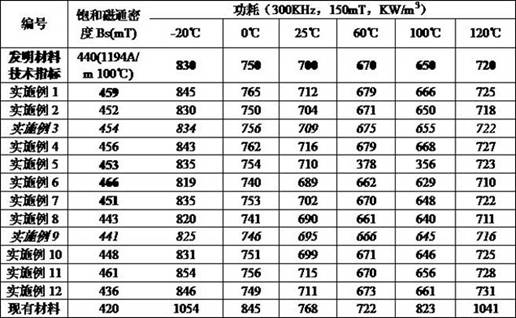

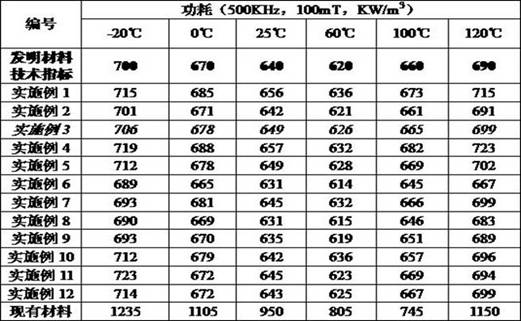

Examples

Embodiment 1

[0043] A manganese-zinc soft magnetic ferrite material with wide frequency, wide temperature, high power density and low loss, including main component, auxiliary component A and auxiliary component B, calculated by weight percentage, the main component includes 70.05% Fe 2 o 3 , 24.15% MnO and 5.80% ZnO;

[0044] Based on the weight of the main component, the auxiliary component A is CaCO 3 0.02%, Nb 2 o 5 0.05%, NiO 0.20%, Co 3 o 4 0.32%;

[0045] Based on the weight of the main component, the auxiliary component B is SiO 2 0.01%, CuO 0.05%, MoO 0.01%, Bi 2 o 3 0.05%.

[0046] A method for preparing a manganese-zinc soft ferrite material with wide frequency, wide temperature, high power density and low loss, comprising the following steps:

[0047] (1) Primary ingredients: In this embodiment, it is Fe by weight percentage 2 o 3 :MnO:ZnO= 70.05: 24.15:5.80 for batching; based on the weight of the main component, the auxiliary component A is: CaCO 3 0.02%, Nb 2 ...

Embodiment 2

[0067] In the same situation as in Example 1, the auxiliary component A added in step (1) is: CaCO 3 0.03%, Nb 2 o 5 0.03%, SnO 2 0.15%, Co 3 o 4 0.25%; In step (4), auxiliary component B is added as Y in the second batch 2 o 3 0.01%, K 2 CO 3 0.01%, MoO 0.03%.

Embodiment 3

[0069] In the same situation as in Example 1, the auxiliary component A added in step (1) is: CaCO 3 0.10%, NiO0.50%, SnO 2 0.01%, Co 3 o 4 0.2%; in step (4), the auxiliary component B is added to the secondary ingredients: SiO 2 0.01%, Al 2 o 3 0.01%, MoO 0.07%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com