Biomass horizontal rotary core carbonization furnace

A carbonization furnace and biomass technology, which is applied to stationary carbonization furnaces and other directions, can solve the problems of reduced carbon production rate, reduced utilization value and process reliability, and low single-machine capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

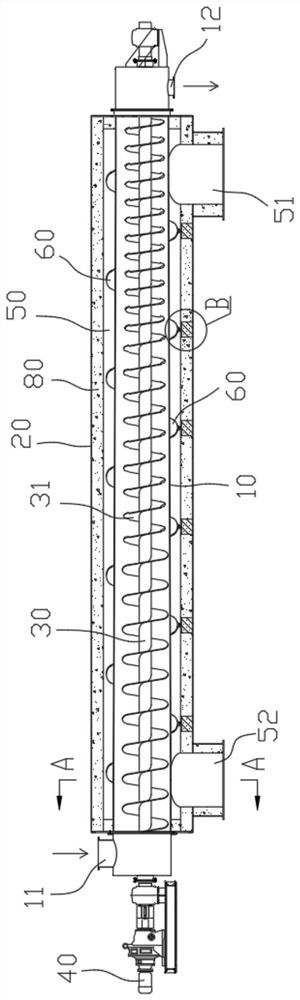

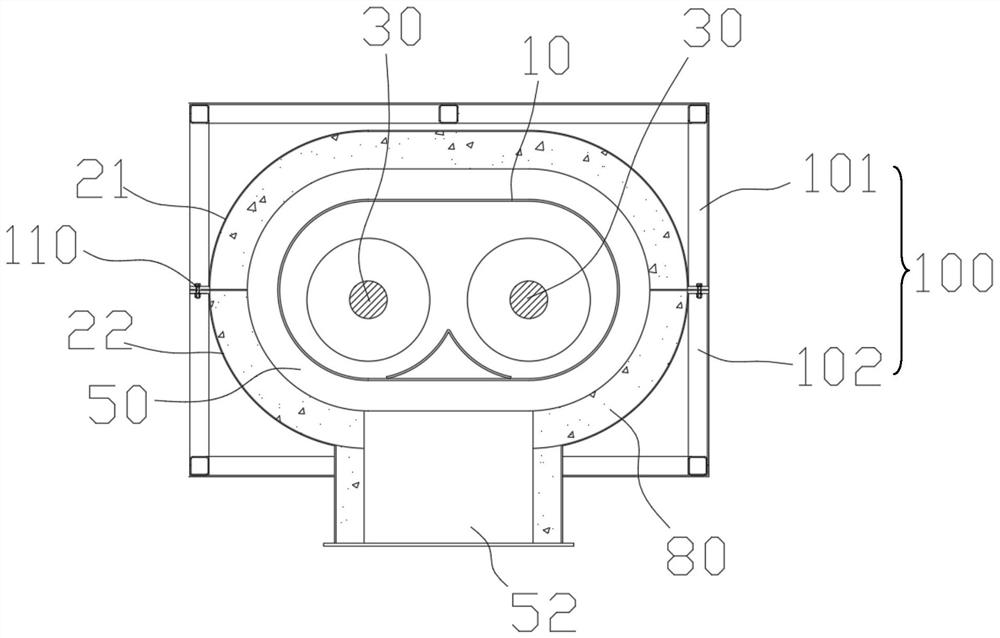

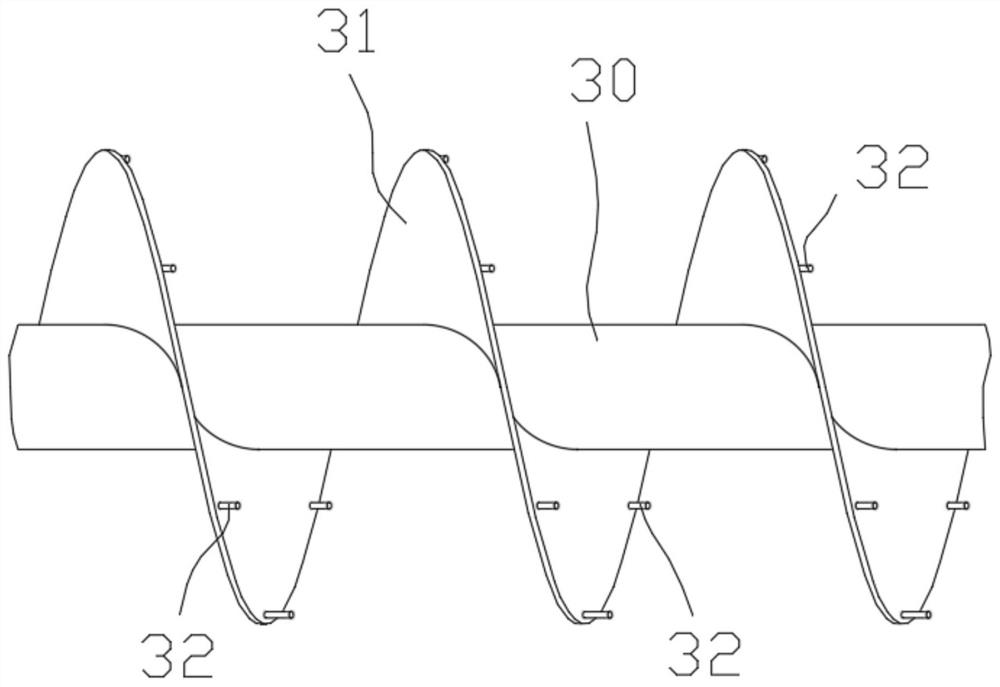

[0019] Such as Figure 1-4 As shown, the biomass horizontal rotary core carbonization furnace of this embodiment includes an inner cylinder 10 and an outer cylinder 20 sleeved outside the inner cylinder 10. The inner cylinder 10 is provided with a rotary core push twisting shaft 30, and the rotary core push twist There are helical blades 31 on the peripheral wall of the shaft 30. The front end of the rotary core push-twist shaft 30 hangs outside the inner cylinder 10 and is driven by the motor 40 to realize the rotation of the rotary core push-twist shaft 30. The front end and the rear of the inner cylinder 10 The ends are respectively suspended outside the outer cylinder 20, the front end of the inner cylinder 10 is provided with a raw material inlet 11, the rear end of the inner cylinder 10 is provided with a first outlet 12, and the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com