Floating oxygen carbonation technology for grass wood high temperature decomposition

A high-temperature decomposition and vegetation technology, applied in the petroleum industry, special forms of dry distillation, biofuels, etc., can solve the problems of secondary environmental pollution, cumbersome carbonization technology, etc., and achieve the effect of high carbonization rate, novel technology and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

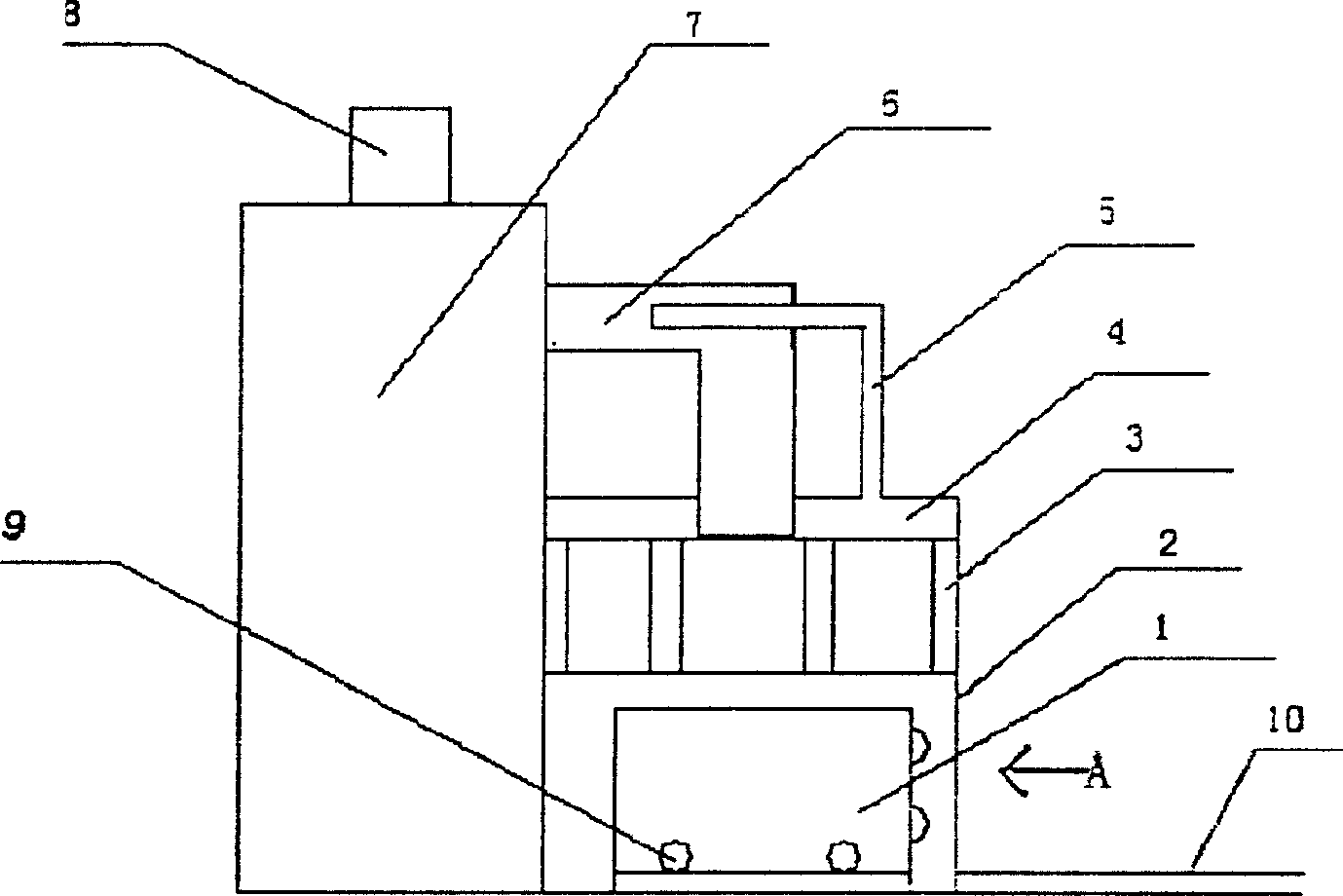

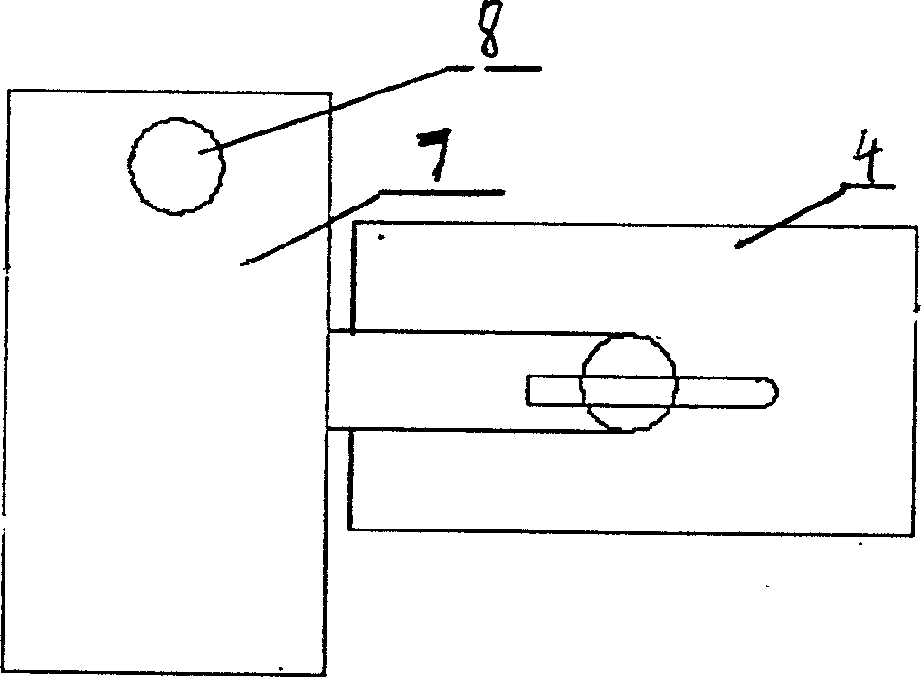

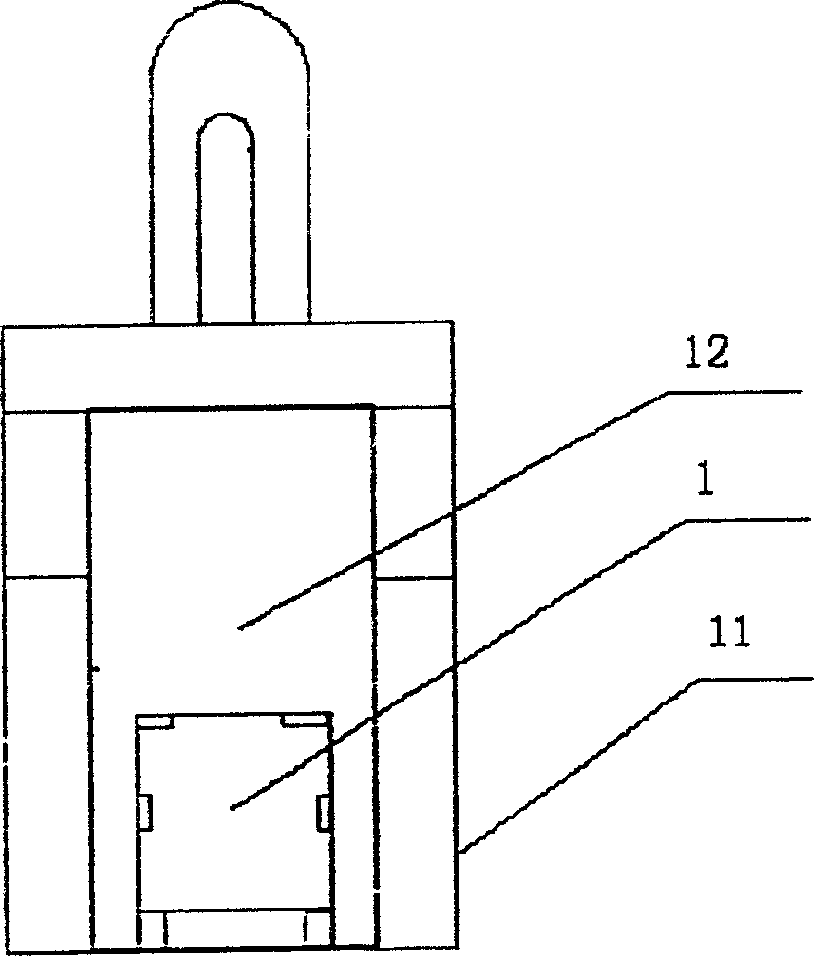

[0014] Such as figure 1 , figure 2 , as shown in Figure 3, this vegetation pyrolysis floating oxygen carbonization process is realized in this way: the vegetation is sent into the inner furnace 1 through the furnace door 11 at the beginning of carbonization, and after ignition, the vegetation is decomposed and decomposed to produce high-temperature gas rising and floating oxidation in the air. The flame seals the furnace mouth 12, and the grass and trees are continuously sent into the furnace for continuous carbonization. Carbon dioxide rises into the chimney 6, and the steam pipe 5 ejects high-speed steam flow, blowing carbon dioxide and other waste gas into the flue 7, the flow speed slows down, the smoke carried by carbon dioxide absorbs water vapor and sinks into the flue, and the dust-free carbon dioxide and water vapor are discharged from the chimney 8 into the atmosphere. After the inner furnace 12 is full of charcoal, the temperature is quickly lowered to below the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com