Preparation method of flame-retardant copolyester film of phosphorus, silicon and fluorine

A technology of copolyester and phosphorus-silicon, which is applied in the field of preparation of organic polymer compounds, can solve the problems of no phosphorus-silicon-fluorine flame-retardant copolyester resin, affecting the inherent properties of polyester materials, and poor flame-retardant effect. Achieve the effects of shortening production time and cycle, easy control of process conditions, and increasing char formation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

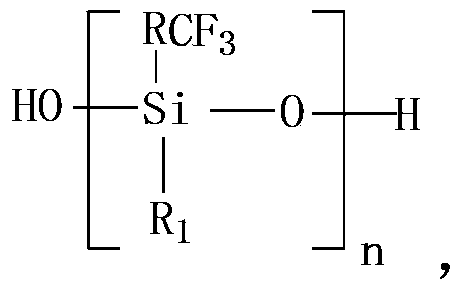

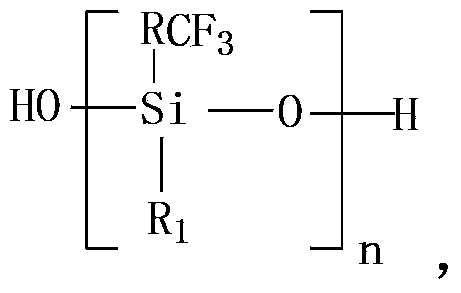

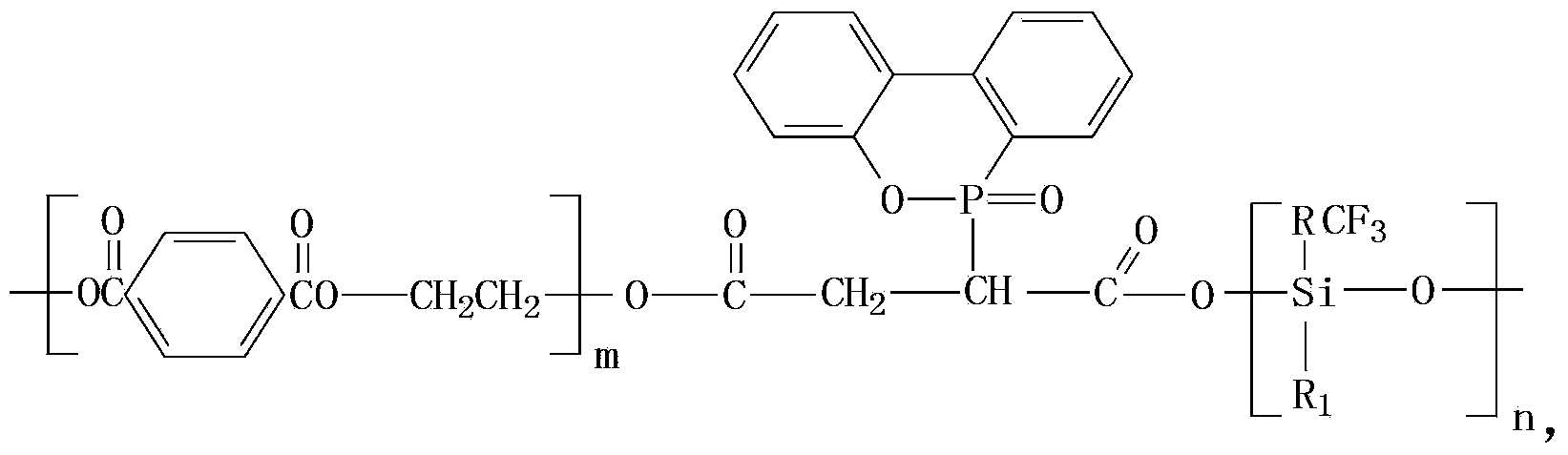

Method used

Image

Examples

Embodiment 1

[0035] The first step: under stirring at a speed of 60-120 rpm, 2000mol maleic anhydride, 3200mol of dihydroxy fluorosiloxane containing 3200mol of hydroxyl (hydroxyl mass content of 5%), 2020mol of DOPO, 10000mol of Phthalic acid, 18000mol ethylene glycol, 0.3kg esterification catalyst antimony acetate, 1.6kg polycondensation catalyst tetrabutyl titanate and 0.6kg stabilizer (bisphenol A phosphite: triphenyl phosphite: triethyl phosphate =1: 2: 1 mass ratio) One-time addition to the reactor with fractional distillation condenser, beating and mixing for 10-20 minutes, heating to 105±5℃ for simultaneous addition and esterification for 0.5-1 hour, The temperature is increased to 250±5°C to accelerate the completion of the esterification reaction, and the reaction is terminated when the effluent volume reaches more than 96% of the theoretical effluent volume.

[0036] The second step: Put the reaction material of the first step into the polycondensation reactor, stir at a speed of 1...

Embodiment 2

[0038] The first step: under stirring at a speed of 60-120 rpm, 2000mol of maleic anhydride, 3600mol of dihydroxy fluorosiloxane (hydroxyl mass content of 7%), 2020mol of DOPO, 10500mol of Phthalic acid, 22000mol ethylene glycol, 0.8kg esterification catalyst (cobalt acetate: sodium acetate = 2:1 mass ratio), 0.6kg polycondensation catalyst ethylene glycol antimony and 0.9kg stabilizer (bisphenol A phosphite: Catechol phosphate: triethyl phosphate = 2:1:4 mass ratio) One-time addition to the reactor with fractionating condenser, beating and mixing for 10-20 minutes, heating to 125 ± 5 ℃ for simultaneous addition The reaction between the formation and the esterification is 0.5 to 1 hour, and then the temperature is increased to 255±5°C to accelerate the completion of the esterification reaction. The reaction is terminated when the effluent volume reaches more than 96% of the theoretical effluent volume.

[0039] The second step: Put the reaction materials of the first step into th...

Embodiment 3

[0041] Step 1: Mix 2000mol of maleic anhydride, 4000mol of dihydroxy fluorosiloxane (hydroxyl mass content 8%), 2020mol of DOPO, and 11000mol of A mixture of phthalic acid and 2,6-naphthalenedicarboxylic acid (terephthalic acid: 2,6-naphthalenedicarboxylic acid = 6:1 molar ratio), 25000mol ethylene glycol, 1.0kg esterification catalyst (cobalt acetate: acetic acid Sodium: manganese acetate = 1:1:1 mass ratio), 0.9kg polycondensation catalyst antimony trioxide and 0.1kg stabilizer trimethyl phosphate, triphenyl phosphate = 1:1 mass ratio) one-time addition with fractionation In the reactor of the condenser, beating and mixing for 10-20 minutes, heating to 145±5℃ for simultaneous addition and esterification for 0.5-1 hour, and then heating to 250±5℃ to accelerate the completion of the esterification reaction. The reaction ends when the effluent volume reaches more than 96% of the theoretical effluent volume.

[0042] The second step: Put the reaction materials of the first step in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com